ignition MITSUBISHI MONTERO 2000 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 314 of 1839

GDI -Troubleshooting

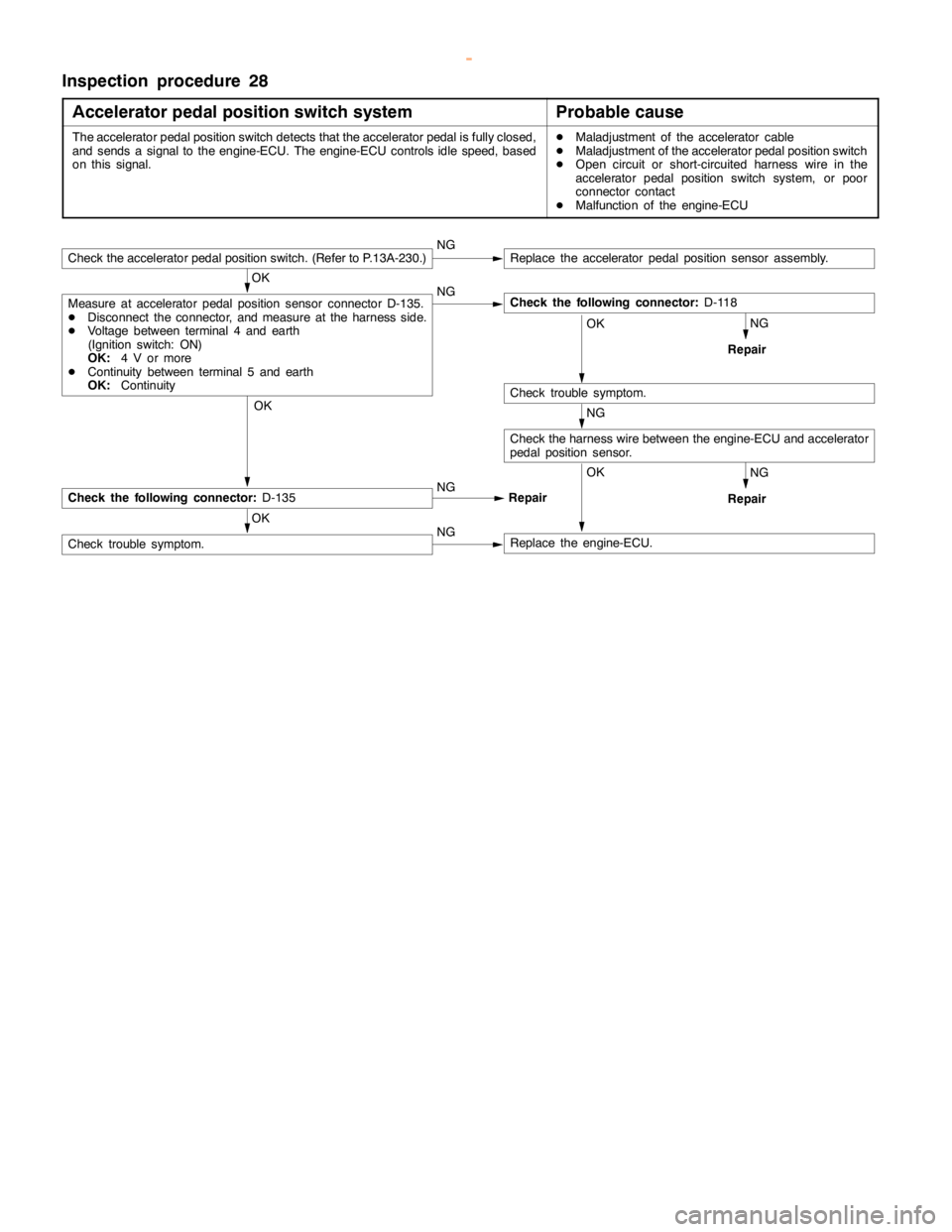

Inspection procedure 28

Accelerator pedal position switch system

Probable cause

The accelerator pedal positionswitch detects that the acceleratorpedal isfully closed,

and sends a signal to the engine-ECU. The engine-ECU controlsidle speed,based

on this signal.DMaladjustment of the accelerator cable

DMaladjustment of the accelerator pedal positionswitch

DOpen circuit or short-circuited harness wire in the

accelerator pedal positionswitch system, or poor

connector contact

DMalfunction of the engine-ECU

NG

Repair

NG

Repair

Check the acceleratorpedal positionswitch. (Refer to P.13A-230.)NGReplace the accelerator pedal positionsensor assembly.

OK

Measure at accelerator pedal positionsensor connector D-135.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 4 and earth

(Ignition switch: ON)

OK:

4 V or more

DContinuity between terminal 5 and earth

OK:

ContinuityNGCheck the following connector:

D-118

OK

Check trouble symptom.

NG

Check the harness wire between the engine-ECU and accelerator

pedal positionsensor.

OK

Check the following connector:

D-135NG

Repair

OK

Check trouble symptom.NGReplace the engine-ECU.

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 315 of 1839

GDI -Troubleshooting

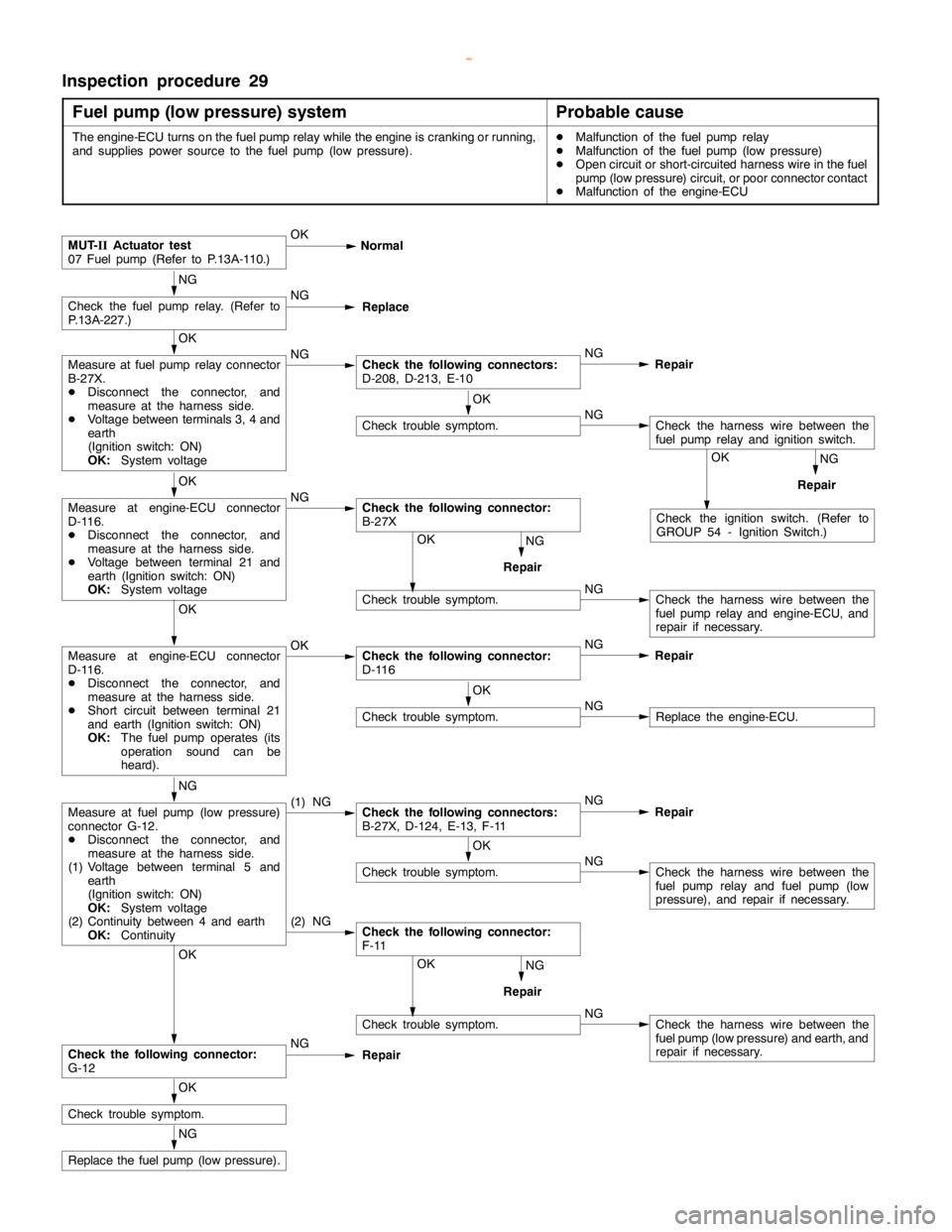

Inspection procedure 29

Fuel pump (low pressure) system

Probable cause

The engine-ECU turns on the fuelpumprelay while theengine iscranking or running,

and supplies power source to the fuelpump(low pressure).DMalfunction of the fuel pumprelay

DMalfunction of the fuel pump(low pressure)

DOpen circuit or short-circuited harness wire in the fuel

pump(low pressure) circuit, or poor connector contact

DMalfunction of the engine-ECU

Check trouble symptom.NGCheck the harness wire between the

fuel pump(low pressure) and earth, and

repair if necessary.

NG

RepairOK

Check trouble symptom.NGCheck the harness wire between the

fuel pumprelay and engine-ECU, and

repair if necessary.

NG

RepairOK

NG

RepairOK

Check the ignition switch. (Refer to

GROUP 54 - Ignition Switch.)

(2) NGCheck the following connector:

F-11

MUT-

IIActuator test

07 Fuel pump(Refer to P.13A-110.)OK

Normal

NG

Check the fuelpumprelay. (Refer to

P.13A-227.)NG

Replace

OK

Measure at fuel pumprelay connector

B-27X.

DDisconnect the connector, and

measure at the harness side.

DVoltage between terminals 3, 4 and

earth

(Ignition switch: ON)

OK:

System voltageNGCheck the following connectors:

D-208, D-213, E-10NG

Repair

OK

Check trouble symptom.NGCheck the harness wire between the

fuel pumprelay and ignition switch.

OK

Measure at engine-ECU connector

D-116.

DDisconnect the connector, and

measure at the harness side.

DVoltage between terminal 21 and

earth (Ignition switch: ON)

OK:

System voltageNGCheck the following connector:

B-27X

OK

Measure at engine-ECU connector

D-116.

DDisconnect the connector, and

measure at the harness side.

DShort circuit between terminal 21

and earth (Ignition switch: ON)

OK:

The fuel pump operates(its

operation sound can be

heard).OKCheck the following connector:

D-116NG

Repair

OK

Check trouble symptom.NGReplace the engine-ECU.

NG

Measure at fuel pump(low pressure)

connector G-12.

DDisconnect the connector, and

measure at the harness side.

(1) Voltage between terminal 5 and

earth

(Ignition switch: ON)

OK:

System voltage

(2) Continuity between 4 and earth

OK:

Continuity(1) NGCheck the following connectors:

B-27X, D-124, E-13, F-11NG

Repair

OK

Check trouble symptom.NGCheck the harness wire between the

fuel pumprelay and fuelpump(low

pressure), and repair if necessary.

OK

Check the following connector:

G-12NG

Repair

OK

Check trouble symptom.

NG

Replace the fuel pump(low pressure).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 316 of 1839

GDI -Troubleshooting

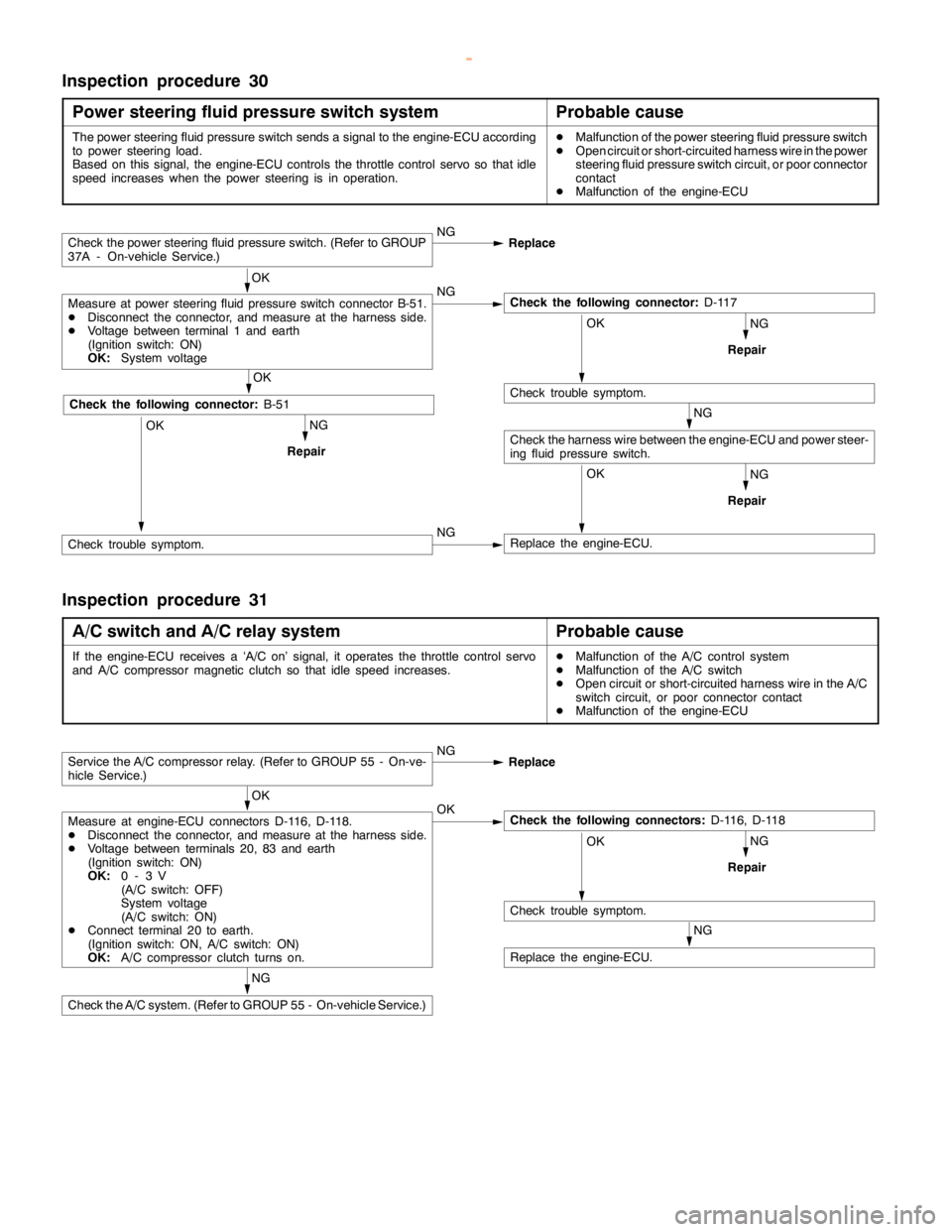

Inspection procedure 30

Power steering fluid pressure switch system

Probable cause

The power steering fluid pressure switch sends a signal to the engine-ECU according

to power steering load.

Based on this signal, the engine-ECU controls the throttle control servo so thatidle

speed increases when the power steering is in operation.DMalfunction of the power steering fluid pressure switch

DOpen circuit or short-circuited harness wire in the power

steering fluid pressure switch circuit, or poor connector

contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Replace the engine-ECU.

NG

Repair

Check the power steering fluid pressure switch. (Refer to GROUP

37A - On-vehicle Service.)NG

Replace

OK

Measure at power steering fluid pressure switch connector B-51.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 1 and earth

(Ignition switch: ON)

OK:

System voltageNGCheck the following connector:

D-117

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and power steer-

ing fluid pressure switch.NG

RepairOK

OK

Check the following connector:

B-51

Check trouble symptom.NG

Inspection procedure 31

A/C switch and A/C relay system

Probable cause

If the engine-ECU receives a ‘A/C on’ signal, it operates the throttle control servo

and A/C compressor magnetic clutch so thatidlespeed increases.DMalfunction of the A/C control system

DMalfunction of the A/C switch

DOpen circuit or short-circuited harness wire in the A/C

switch circuit, or poor connector contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Check trouble symptom.

NG

Replace the engine-ECU.

Service the A/C compressor relay. (Refer to GROUP 55 - On-ve-

hicle Service.)NG

Replace

OK

Measure at engine-ECU connectors D-116, D-118.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminals 20, 83 and earth

(Ignition switch: ON)

OK:

0-3V

(A/C switch: OFF)

System voltage

(A/C switch: ON)

DConnect terminal 20 to earth.

(Ignition switch: ON, A/C switch: ON)

OK:

A/C compressor clutch turns on.OKCheck the following connectors:

D-116, D-118

Check the A/C system. (Refer to GROUP 55 - On-vehicle Service.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 317 of 1839

GDI -Troubleshooting

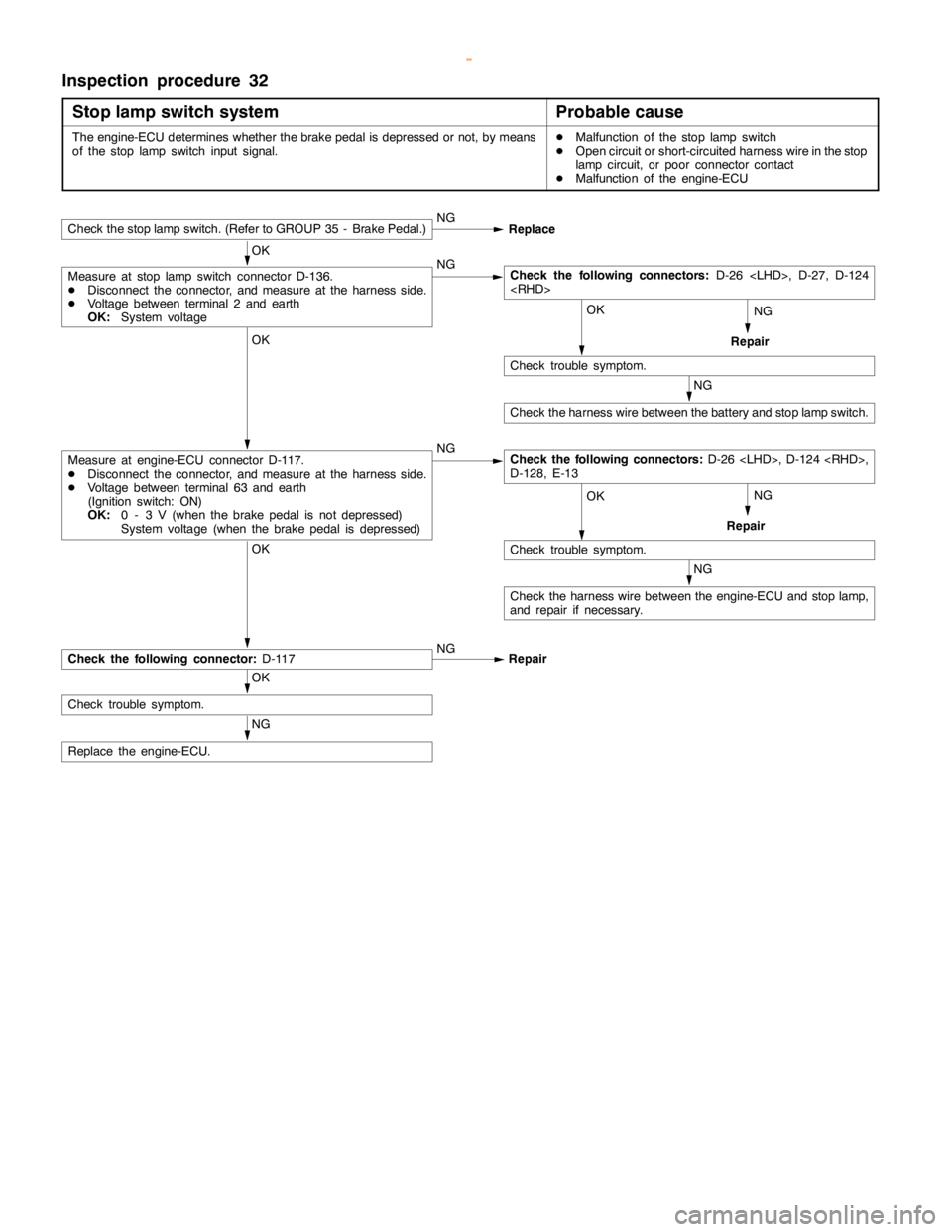

Inspection procedure 32

Stop lamp switch system

Probable cause

The engine-ECU determines whether the brakepedal is depressed or not, by means

of the stoplampswitch input signal.DMalfunction of the stoplampswitch

DOpen circuit or short-circuited harness wire in the stop

lampcircuit, or poor connector contact

DMalfunction of the engine-ECU

NG

NG

NG

Repair

Check the stoplampswitch. (Refer to GROUP 35 - Brake Pedal.)NG

Replace

OK

Measure at stoplampswitch connector D-136.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 2 and earth

OK:

System voltageNG

OK

Check trouble symptom.

Check the harness wire between the battery and stoplampswitch.

NG

Repair

OK

Measure at engine-ECU connector D-117.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 63 and earth

(Ignition switch: ON)

OK:

0 - 3 V (when the brakepedal is not depressed)

System voltage (when the brakepedal is depressed)NG

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and stoplamp,

and repair if necessary.

OK

Check the following connector:

D-117NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.

Check the following connectors:

D-26

Check the following connectors:

D-26

D-128, E-13

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 319 of 1839

GDI -Troubleshooting

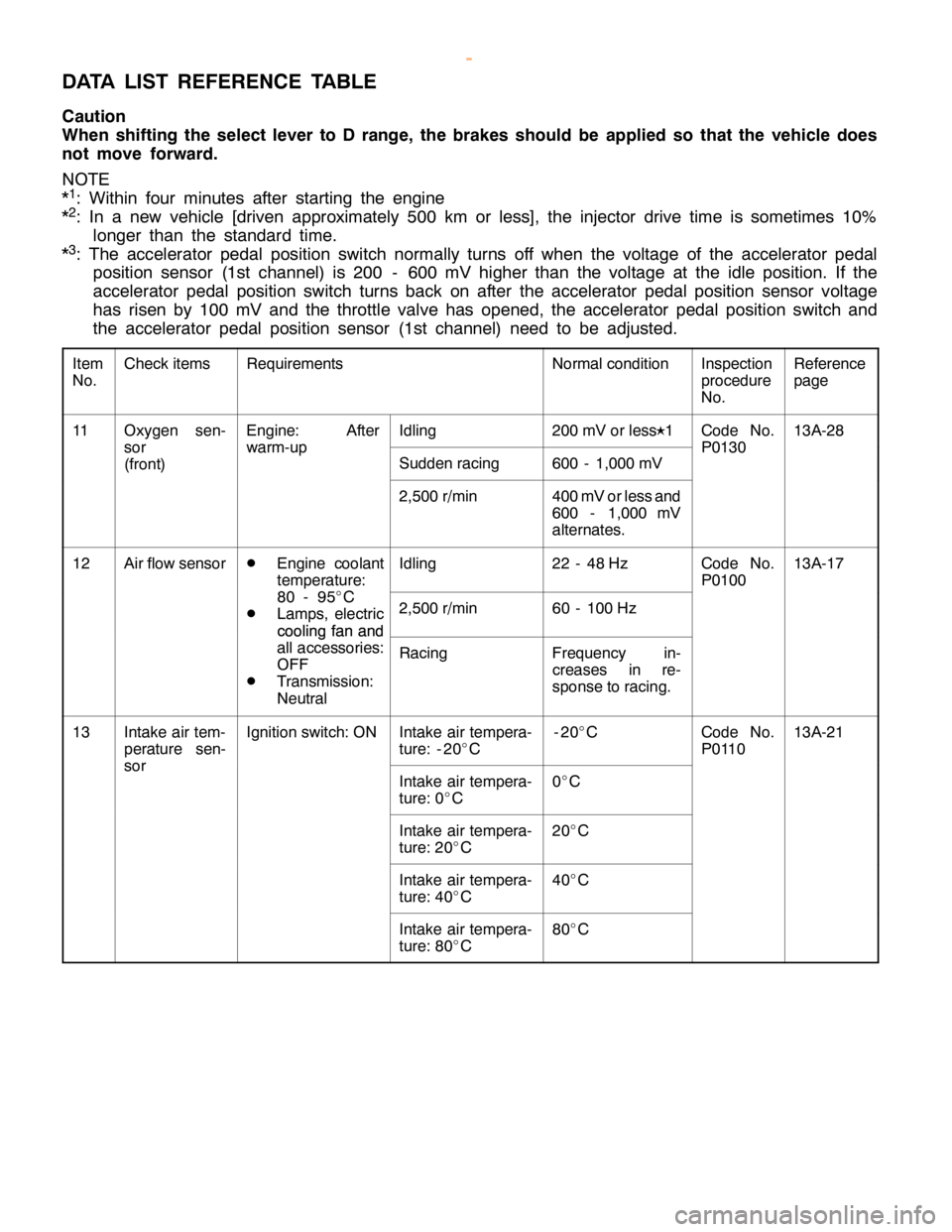

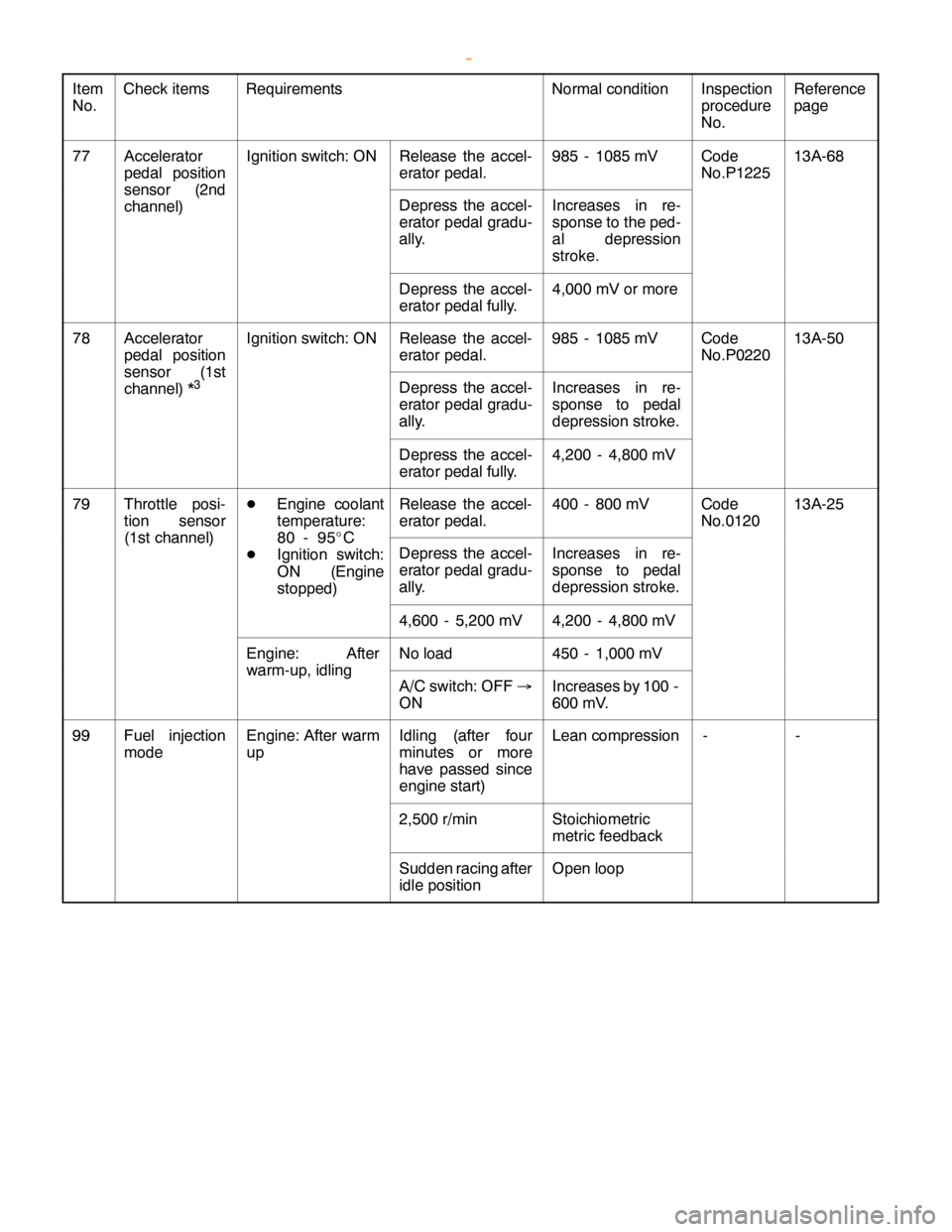

DATA LIST REFERENCE TABLE

Caution

When shifting the select lever to D range, the brakes should be applied so that the vehicle does

not move forward.

NOTE

*

1: Within four minutes after starting the engine

*2: In a new vehicle [driven approximately 500 km or less], the injector drive time is sometimes 10%

longer than the standard time.

*

3: The accelerator pedal position switch normally turns off when the voltage of the accelerator pedal

position sensor (1st channel) is 200 - 600 mV higher than the voltage at the idle position. If the

accelerator pedal position switch turns back on after the accelerator pedal position sensor voltage

has risen by 100 mV and the throttle valve has opened, the accelerator pedal position switch and

the accelerator pedal position sensor (1st channel) need to be adjusted.

Item

No.Check itemsRequirementsNormal conditionInspection

procedure

No.Reference

page

11Oxygen sen-Engine: AfterIdling200 mV or lessK

1Code No.13A-28

sor

(front)warm-up

Sudden racing600 - 1,000 mV

P0130

2,500 r/min400 mV or less and

600 - 1,000 mV

alternates.

12Air flow sensorD

Engine coolant

temperature:Idling22 - 48 HzCode No.

P010013A-17

80 - 95_

C

D

Lamps, electric

cooling fan and2,500 r/min60 - 100 Hz

cooling fan and

all accessories:

OFF

D

Transmission:

Neutral

RacingFrequency in-

creases in re-

sponse to racing.

13Intake air tem-

perature sen-Ignition switch: ONIntake air tempera-

ture: - 20_

C-20_

CCode No.

P011013A-21

sor

Intake air tempera-

ture: 0_

C0_

C

Intake air tempera-

ture: 20_

C20_

C

Intake air tempera-

ture: 40_

C40_

C

Intake air tempera-

ture: 80_

C80_

C

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 320 of 1839

GDI -Troubleshooting

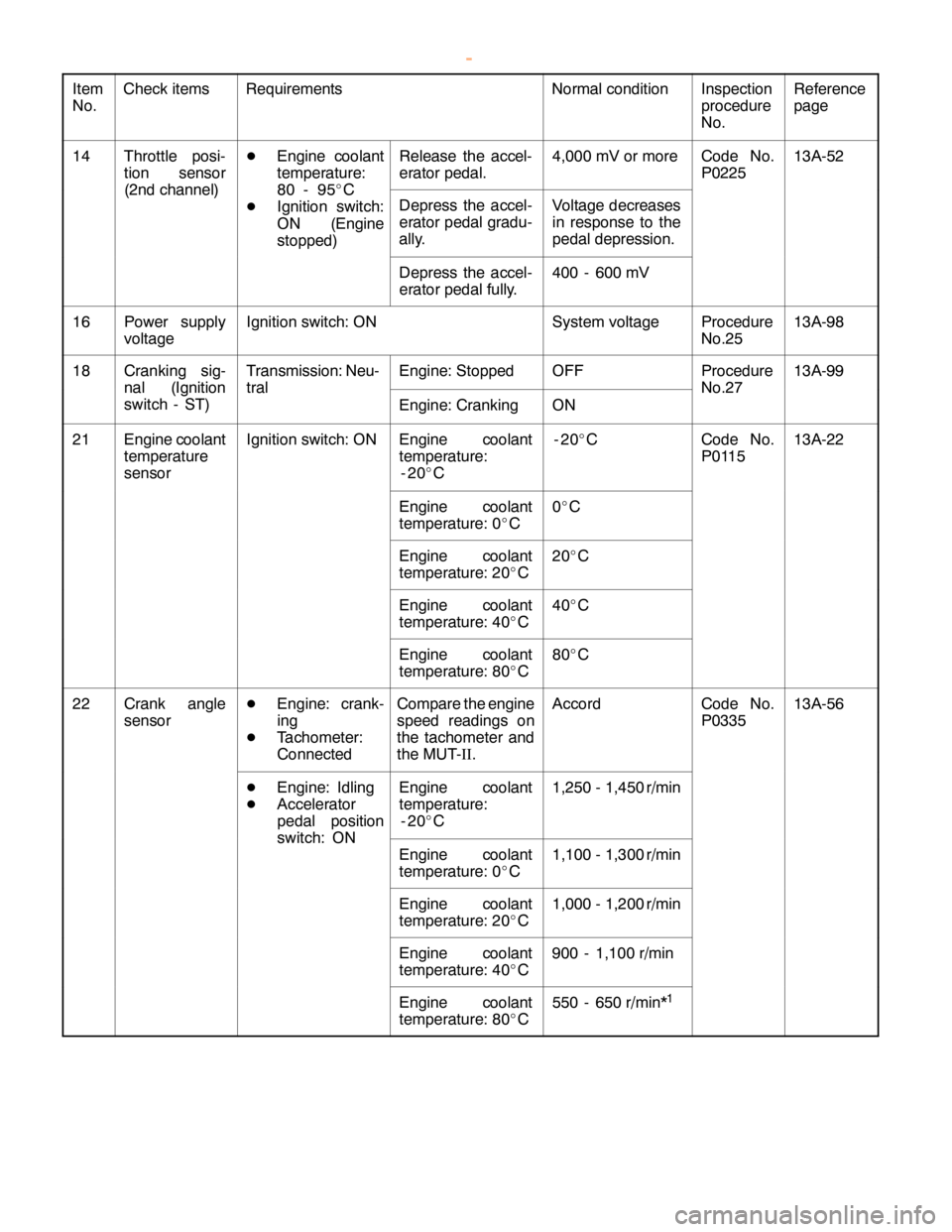

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

14Throttle posi-

tion sensorDEngine coolant

temperature:Release the accel-

erator pedal.4,000 mV or moreCode No.

P022513A-52

(2nd channel)80 - 95_C

DIgnition switch:

ON (Engine

stopped)

Depress the accel-

erator pedal gradu-

ally.Voltage decreases

in response to the

pedal depression.

Depress the accel-

erator pedal fully.400 - 600 mV

16Power supply

voltageIgnition switch: ONSystem voltageProcedure

No.2513A-98

18Cranking sig-Transmission: Neu-Engine: StoppedOFFProcedure13A-99

nal (Ignition

switch - ST)tral

Engine: CrankingON

No.27

21Engine coolant

temperature

sensorIgnition switch: ONEngine coolant

temperature:

-20_C-20_CCode No.

P011513A-22

Engine coolant

temperature: 0_C0_C

Engine coolant

temperature: 20_C20_C

Engine coolant

temperature: 40_C40_C

Engine coolant

temperature: 80_C80_C

22Crank angle

sensorDEngine: crank-

ing

DTachometer:

ConnectedCompare the engine

speed readings on

the tachometer and

the MUT-II.AccordCode No.

P033513A-56

DEngine: Idling

DAccelerator

pedal positionEngine coolant

temperature:

-20_C1,250 - 1,450 r/min

switch: ON

Engine coolant

temperature: 0_C1,100 - 1,300 r/min

Engine coolant

temperature: 20_C1,000 - 1,200 r/min

Engine coolant

temperature: 40_C900 - 1,100 r/min

Engine coolant

temperature: 80_C550 - 650 r/min*1

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

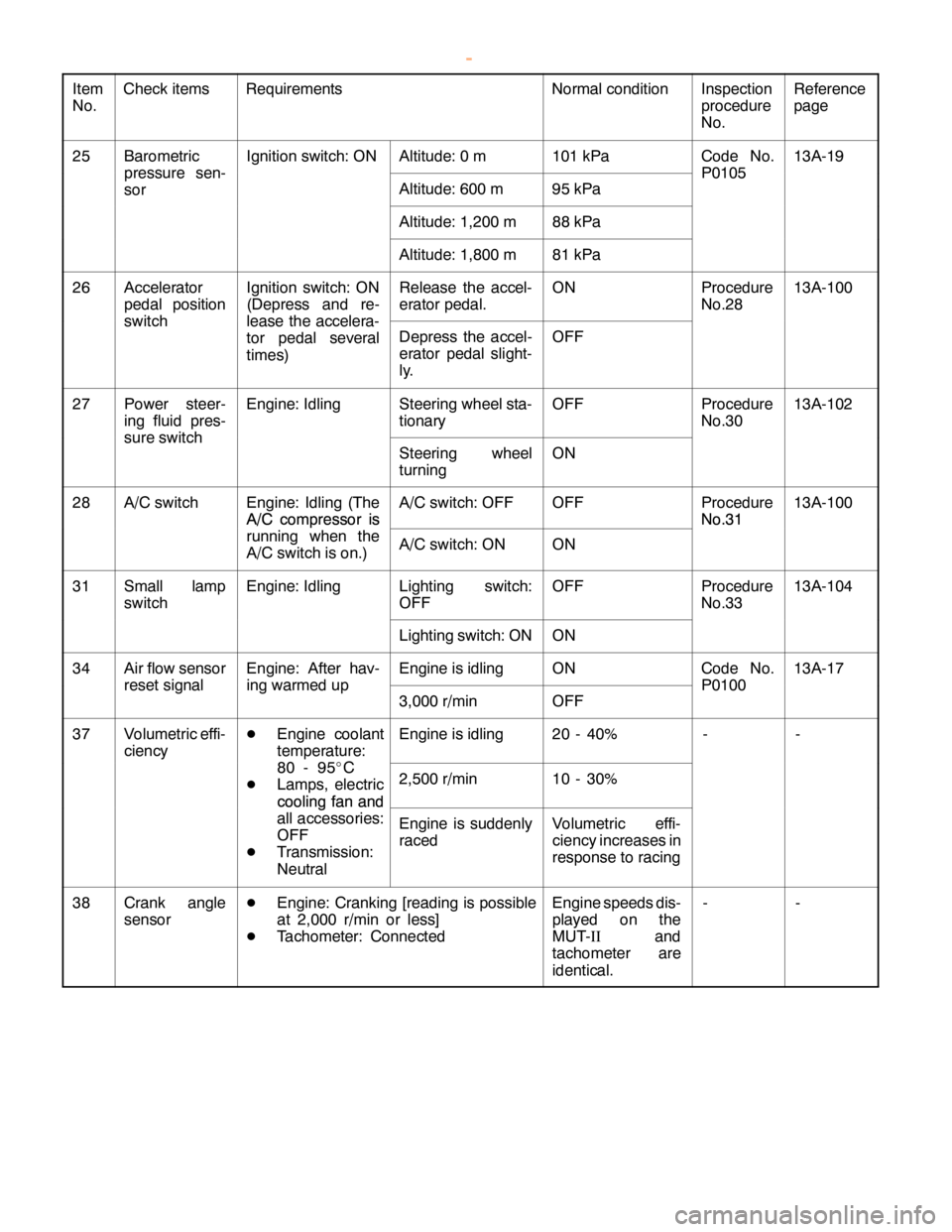

Page 321 of 1839

GDI -Troubleshooting

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

25BarometricIgnition switch: ONAltitude: 0 m101 kPaCode No.13A-19

pressure sen-

sor

Altitude: 600 m95 kPa

P0105

Altitude: 1,200 m88 kPa

Altitude: 1,800 m81 kPa

26Accelerator

pedal positionIgnition switch: ON

(Depress and re-Release the accel-

erator pedal.ONProcedure

No.2813A-100

switchlease the accelera-

tor pedal several

times)

Depress the accel-

erator pedal slight-

ly.OFF

27Power steer-

ing fluid pres-Engine: IdlingSteering wheel sta-

tionaryOFFProcedure

No.3013A-102

sure switch

Steering wheel

turningON

28A/C switchEngine: Idling (The

A/C compressor isA/C switch: OFFOFFProcedure

No.3113A-100

A/C compressor is

running when the

A/C switch is on.)

A/C switch: ONON

No.31

31Small lamp

switchEngine: IdlingLighting switch:

OFFOFFProcedure

No.3313A-104

Lighting switch: ONON

34Air flow sensorEngine: After hav-Engine is idlingONCode No.13A-17

reset signaling warmed up

3,000 r/minOFF

P0100

37Volumetric effi-

ciencyDEngine coolant

temperature:Engine is idling20 - 40%--

80 - 95_C

DLamps, electric

cooling fan and2,500 r/min10 - 30%

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

Engine is suddenly

racedVolumetric effi-

ciency increases in

response to racing

38Crank angle

sensorDEngine: Cranking [reading is possible

at 2,000 r/min or less]

DTachometer: ConnectedEngine speeds dis-

played on the

MUT-IIand

tachometer are

identical.--

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

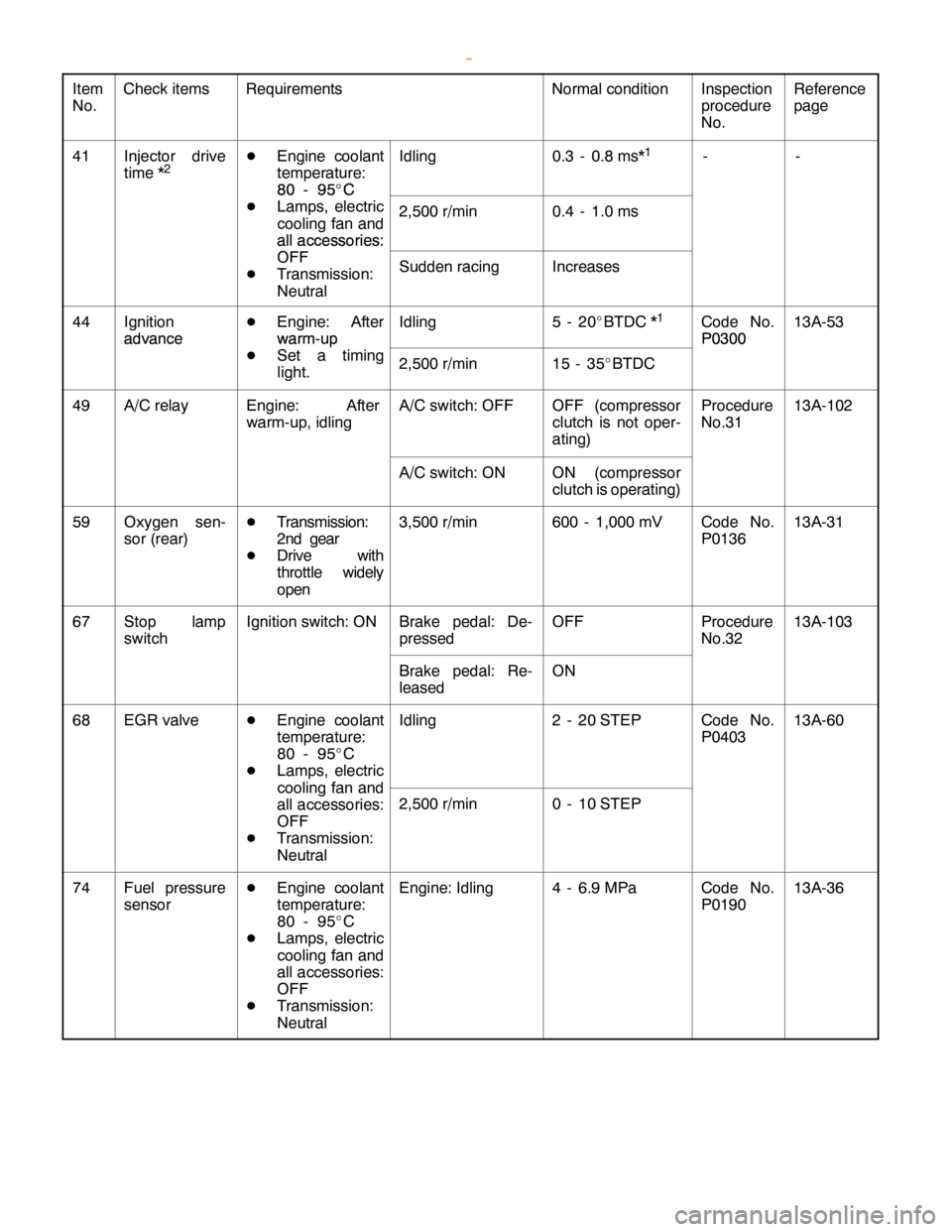

Page 322 of 1839

GDI -Troubleshooting

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

41Injector drive

time *2DEngine coolant

temperature:

80 - 95_CIdling0.3 - 0.8 ms*1--

80 - 95_C

DLamps, electric

cooling fan and

all accessories:

2,500 r/min0.4 - 1.0 ms

all accessories:

OFF

DTransmission:

Neutral

Sudden racingIncreases

44Ignition

advanceDEngine: After

warm-upIdling5-20_BTDC *1Code No.

P030013A-53

advancewarm-up

DSet a timing

light.

2,500 r/min15 - 35_BTDC

P0300

49A/C relayEngine: After

warm-up, idlingA/C switch: OFFOFF (compressor

clutch is not oper-

ating)Procedure

No.3113A-102

A/C switch: ONON (compressor

clutch is operating)

59Oxygen sen-

sor (rear)DTransmission:

2nd gear

DDrive with

throttle widely

open3,500 r/min600 - 1,000 mVCode No.

P013613A-31

67Stop lamp

switchIgnition switch: ONBrake pedal: De-

pressedOFFProcedure

No.3213A-103

Brake pedal: Re-

leasedON

68EGR valveDEngine coolant

temperature:

80 - 95_C

DLamps, electricIdling2 - 20 STEPCode No.

P040313A-60

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

2,500 r/min0 - 10 STEP

74Fuel pressure

sensorDEngine coolant

temperature:

80 - 95_C

DLamps, electric

cooling fan and

all accessories:

OFF

DTransmission:

NeutralEngine: Idling4 - 6.9 MPaCode No.

P019013A-36

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 323 of 1839

GDI -Troubleshooting

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

77Accelerator

pedal positionIgnition switch: ONRelease the accel-

erator pedal.985 - 1085 mVCode

No.P122513A-68

sensor (2nd

channel)

Depress the accel-

erator pedal gradu-

ally.Increases in re-

sponse to the ped-

al depression

stroke.

Depress the accel-

erator pedal fully.4,000 mV or more

78Accelerator

pedal positionIgnition switch: ONRelease the accel-

erator pedal.985 - 1085 mVCode

No.P022013A-50

sensor (1st

channel) *3Depress the accel-

erator pedal gradu-

ally.Increases in re-

sponse to pedal

depression stroke.

Depress the accel-

erator pedal fully.4,200 - 4,800 mV

79Throttle posi-

tion sensorDEngine coolant

temperature:Release the accel-

erator pedal.400 - 800 mVCode

No.012013A-25

(1st channel)80 - 95_C

DIgnition switch:

ON (Engine

stopped)

Depress the accel-

erator pedal gradu-

ally.Increases in re-

sponse to pedal

depression stroke.

4,600 - 5,200 mV4,200 - 4,800 mV

Engine: AfterNo load450 - 1,000 mV

warm-up, idling

A/C switch: OFF®

ONIncreases by 100 -

600 mV.

99Fuel injection

modeEngine: After warm

upIdling (after four

minutes or more

have passed since

engine start)Lean compression--

2,500 r/minStoichiometric

metric feedback

Sudden racing after

idle positionOpen loop

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 324 of 1839

GDI -Troubleshooting

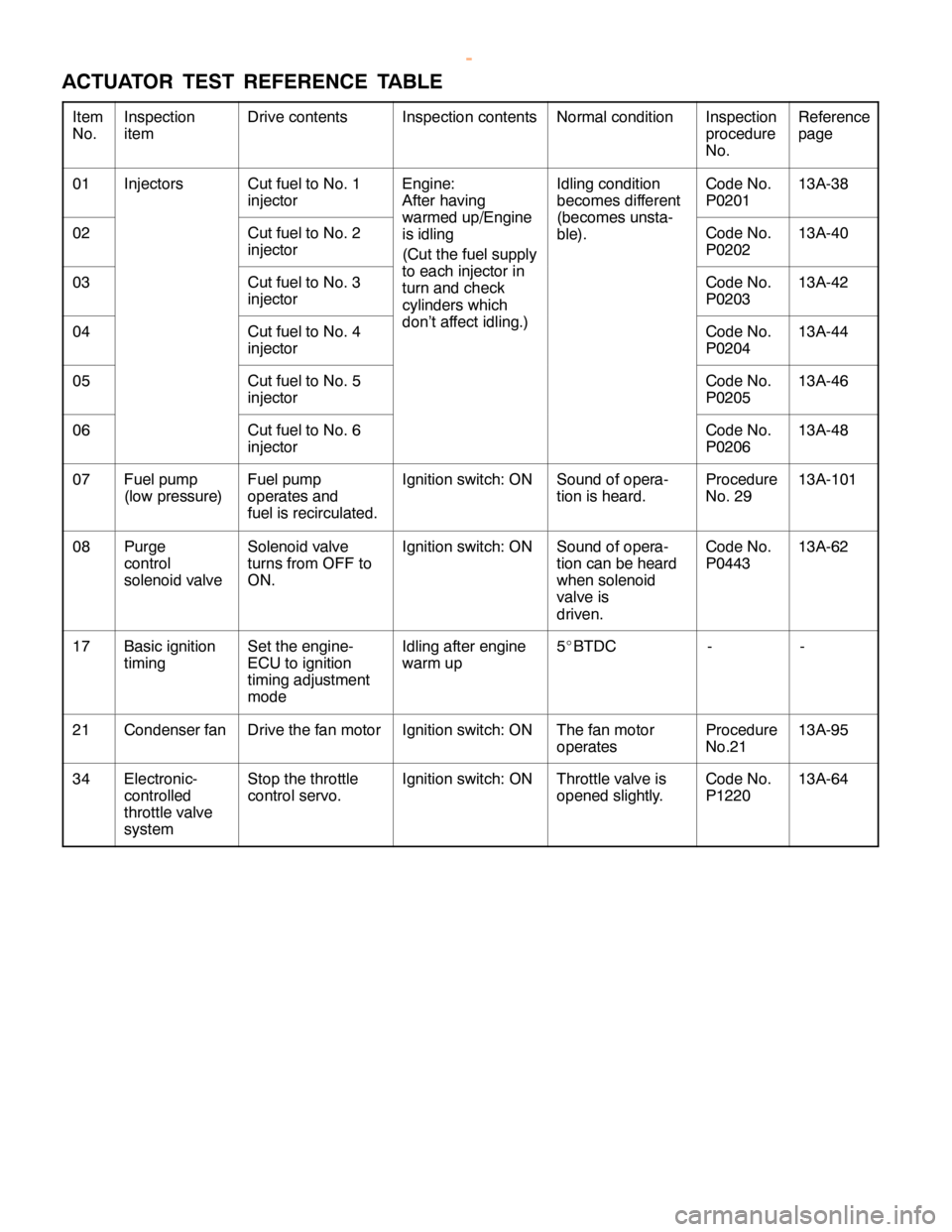

ACTUATOR TEST REFERENCE TABLE

Item

No.Inspection

itemDrive contentsInspection contentsNormal conditionInspection

procedure

No.Reference

page

01InjectorsCut fuel to No. 1

injectorEngine:

After havingIdling condition

becomes differentCode No.

P020113A-38

02Cut fuel to No. 2

injector

warmed up/Engine

is idling

(Cut the fuel supply(becomes unsta-

ble).

Code No.

P020213A-40

03Cut fuel to No. 3

injectorto each injector in

turn and check

cylinders whichCode No.

P020313A-42

04Cut fuel to No. 4

injectordon’t affect idling.)Code No.

P020413A-44

05Cut fuel to No. 5

injectorCode No.

P020513A-46

06Cut fuel to No. 6

injectorCode No.

P020613A-48

07Fuel pump

(low pressure)Fuel pump

operates and

fuel is recirculated.Ignition switch: ONSound of opera-

tion is heard.Procedure

No. 2913A-101

08Purge

control

solenoid valveSolenoid valve

turns from OFF to

ON.Ignition switch: ONSound of opera-

tion can be heard

when solenoid

valve is

driven.Code No.

P044313A-62

17Basic ignition

timingSet the engine-

ECU to ignition

timing adjustment

modeIdling after engine

warm up5_BTDC--

21Condenser fanDrive the fan motorIgnition switch: ONThe fan motor

operatesProcedure

No.2113A-95

34Electronic-

controlled

throttle valve

systemStop the throttle

control servo.Ignition switch: ONThrottle valve is

opened slightly.Code No.

P122013A-64

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk