maintenance MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 2 of 1839

00-1

GENERAL

CONTENTS

HOW TO USE THIS MANUAL 2..............

Scope of Maintenance, Repair and Servicing

Explanations 2.................................

Definition of Terms 2...........................

Indication of Tightening Torque 2................

Model Indications 3............................

Explanation of Manual Contents 4...............

HOW TO USE

TROUBLESHOOTING/INSPECTION SERVICE

POINTS 6....................................

Troubleshooting Contents 6.....................

Diagnosis Function 7...........................

How to Use the Inspection Procedures 10.......

Connector Measurement Service Points 11.......

Connector Inspection 12........................

Inspection Service Points for a Blown Fuse 13...

Points to Note for Intermittent Malfunctions 13....

TREATMENT BEFORE/AFTER THE FORDING

A STREAM 14..............................

Inspection and Service before Fording a Stream

14 ............................................

Inspection and Service after Fording a Stream

15 ............................................

VEHICLE IDENTIFICATION 16...............

Vehicle Information Code Plate 16...............

Models 16.....................................

Model Code 18................................

Chassis Number 19............................

Engine Model Number 20.......................

Theft Protection

MAJOR SPECIFICATIONS 23................

PRECAUTIONS BEFORE SERVICE 29.......

SUPPLEMENTAL RESTRAINT SYSTEM

(SRS) 33....................................

SUPPORT LOCATIONS FOR LIFTING AND

JACKING 37................................

Support Positions for a Garage Jack 37.........

Support Positions for axle stands and a

Single-Post Lift or Double-Post Lift 38...........

STANDARD PARTS-TIGHTENING-TORQUE

TABLE 39..................................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 3 of 1839

GENERAL -How to Use This Manual00-2

HOW TO USE THIS MANUAL

SCOPE OF MAINTENANCE, REPAIR

AND SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle

inspections, adjustments, and the removal and

installation procedures for major components.

For detailed information concerning the inspection,

checking, adjustment, disassembly and reassembly

of the engine, transmission and major components

after they have been removed from the vehicle,

please refer to separate manuals covering the

engine and the transmission.

ON-VEHICLE SERVICE

“On-vehicle Service” is procedures for performing

inspections and adjustments of particularly

important locations with regard to the construction

and for maintenance and servicing, but other

inspection (for looseness, play, cracking, damage,

etc.) must also be performed.

INSPECTION

Under this title are presented inspection and

checking procedures to be performed by using

special tools and measuring instruments and by

feeling, but, for actual maintenance and servicing

procedures, visual inspections should always be

performed as well.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is

corrected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assembly on inspection and means the

maximum or minimum value within which the part

or assembly must be kept functionally or in strength.

It is a value established outside the range of

standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be

completed in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker during the performance of

maintenance and servicing procedures in order to

avoid the possibility of injury to the worker, or

damage to component parts, or a reduction of

component or vehicle function or performance, etc.

INDICATION OF TIGHTENING TORQUE

Tightening torques (units: N×m) are set to take into

account the central value and the allowable

tolerance. The central value is the target value,

and the allowable tolerance provides the checking

range for tightening torques. If bolts and nuts are

not provided with tightening torques, refer to

P.00-39.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 590 of 1839

13E-1

MITSUBISHI STABILITY

CONTROL

(MITSUBISHI SC)

CONTENTS

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 4..............

SPECIAL TOOLS 4........................

TROUBLESHOOTING 5....................

ON-VEHICLE SERVICE 18.................

Operation Test of MITSUBISHI SC 18.........Wheel Speed Sensor (FR) Check 18..........

Vehicle Speed Sensor Check 18..............

SC-ECU* 19...............................

G SENSOR 20.............................

WHEEL SPEED SENSOR (FR) 20..........

VEHICLE SPEED SENSOR 20..............

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: front impact sensors, SRS-ECU, SRS warning lamp, air bag module, clock spring and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 902 of 1839

Page 1310 of 1839

37A-1

STEERING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 5.................

LUBRICANTS 5..............................

SEALANT AND ADHESIVE 5.................

SPECIAL TOOLS 6..........................

ON-VEHICLE SERVICE 8.....................

Steering Wheel Free Play Check 8..............

Steering Angle Check 8........................

Tie Rod End Ball Joint Starting Torque Check 8..

Stationary Steering Effort Check 9...............

Steering Wheel Returnability Check 9............

Oil Pump Belt Tension Check <6G7,4D5> 9......Power Steering Fluid Level Check 10............

Power Steering Fluid Replacement 10...........

Power Steering System Bleeding 10.............

Oil Pump Pressure Test 11.....................

Power Steering Oil Pressure Switch Check

<6G7,4M4> 12.................................

Ball Joint Dust Cover Check 12.................

STEERING WHEEL AND SHAFT* 13.........

POWER STEERING GEAR BOX AND

LINKAGE 16................................

POWER STEERING OIL PUMP 30...........

POWER STEERING OIL HOSES 35..........

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: SRS-ECU, SRS warning lamp, air bag module, clock spring and interconnecting

wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or maintenance) are

indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1457 of 1839

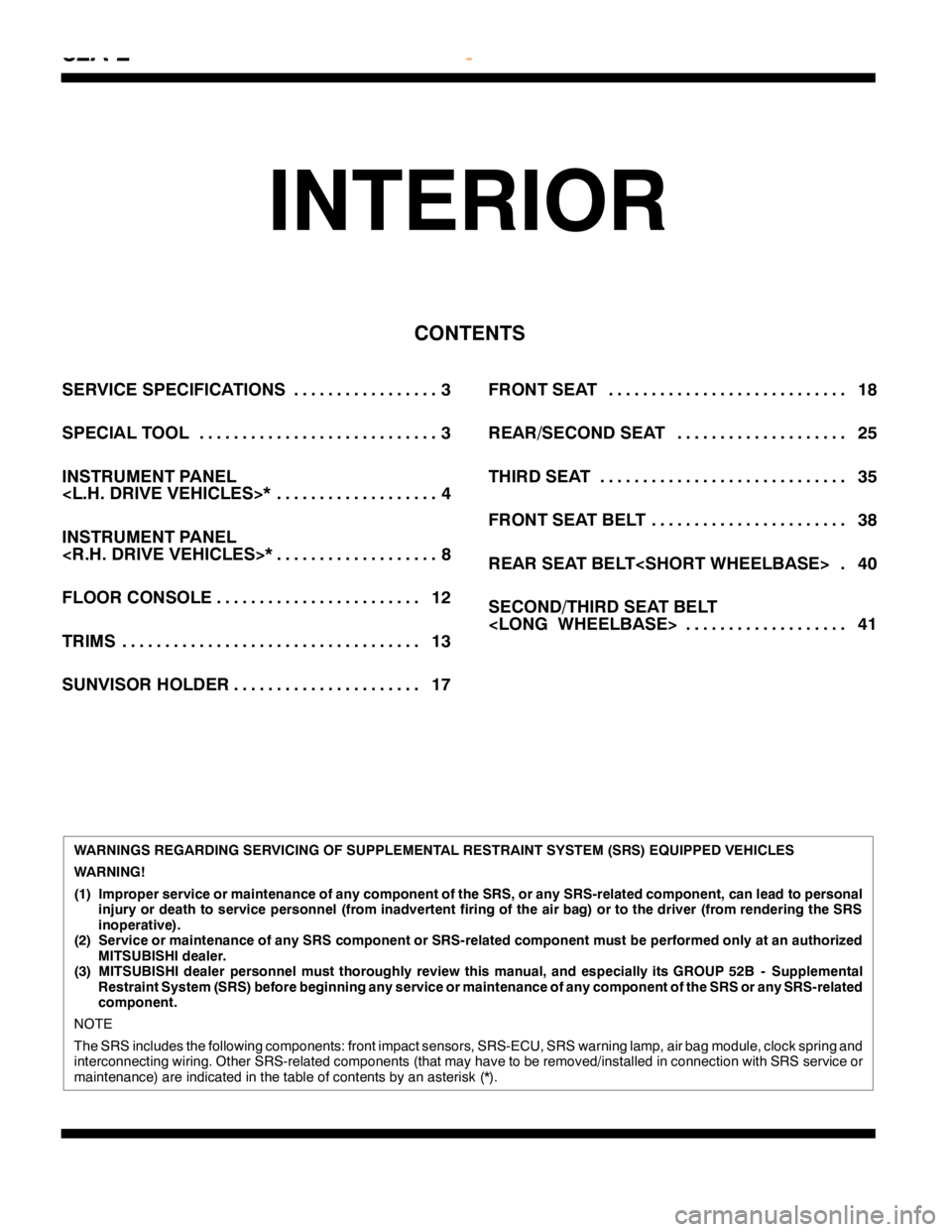

52A-2

INTERIOR

CONTENTS

SERVICE SPECIFICATIONS 3.................

SPECIAL TOOL 3............................

INSTRUMENT PANEL

INSTRUMENT PANEL

FLOOR CONSOLE 12........................

TRIMS 13...................................

SUNVISOR HOLDER 17......................FRONT SEAT 18............................

REAR/SECOND SEAT 25....................

THIRD SEAT 35.............................

FRONT SEAT BELT 38.......................

REAR SEAT BELT

SECOND/THIRD SEAT BELT

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver (from rendering the SRS

inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: front impact sensors, SRS-ECU, SRS warning lamp, air bag module, clock spring and

interconnecting wiring. Other SRS-related components (that mayhave to be removed/installed in connectionwith SRS service or

maintenance) are indicated in the table of contents by an asterisk(*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1501 of 1839

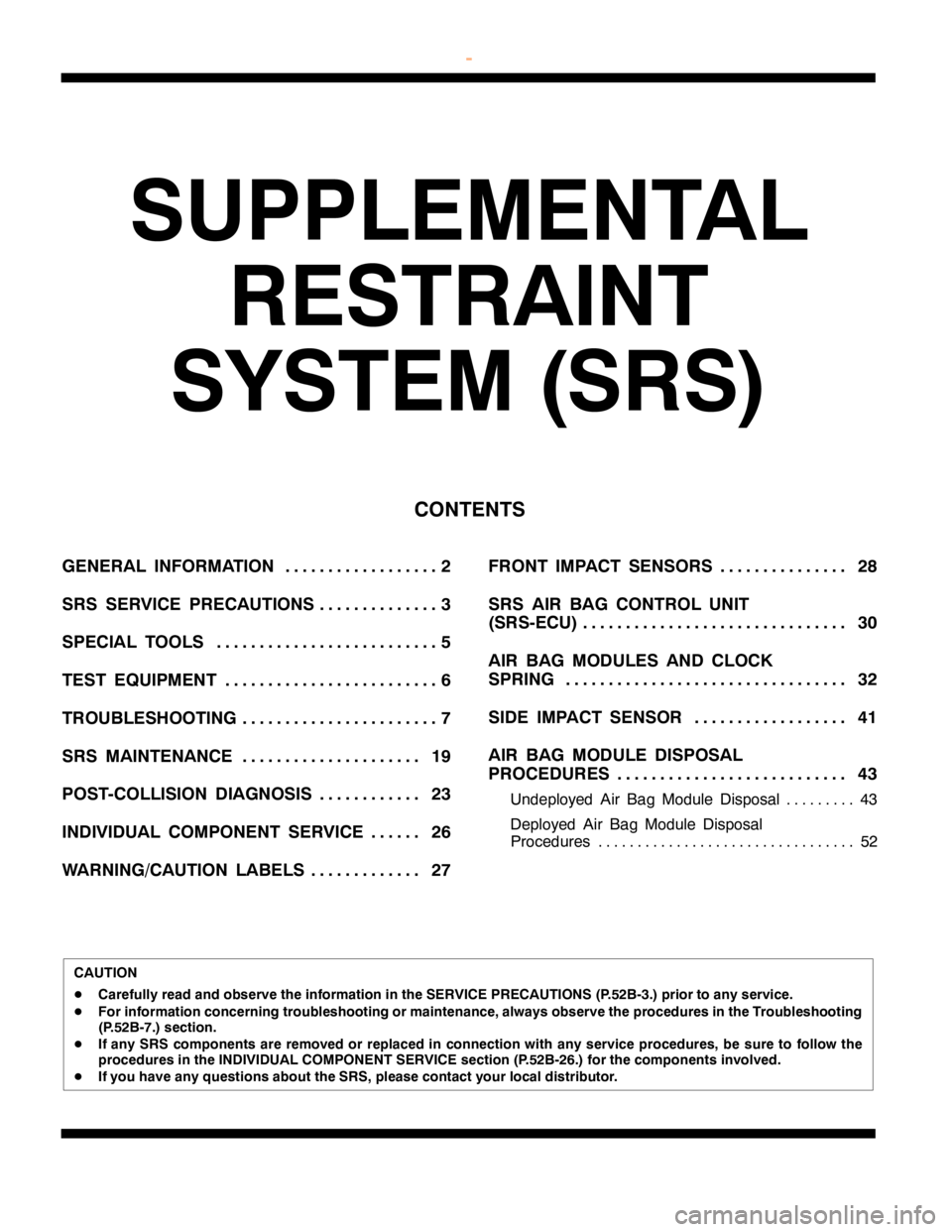

52B-1

SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)

CONTENTS

GENERAL INFORMATION 2..................

SRS SERVICE PRECAUTIONS 3..............

SPECIAL TOOLS 5..........................

TEST EQUIPMENT 6.........................

TROUBLESHOOTING 7.......................

SRS MAINTENANCE 19.....................

POST-COLLISION DIAGNOSIS 23............

INDIVIDUAL COMPONENT SERVICE 26......

WARNING/CAUTION LABELS 27.............FRONT IMPACT SENSORS 28...............

SRS AIR BAG CONTROL UNIT

(SRS-ECU) 30...............................

AIR BAG MODULES AND CLOCK

SPRING 32.................................

SIDE IMPACT SENSOR 41..................

AIR BAG MODULE DISPOSAL

PROCEDURES 43...........................

Undeployed Air Bag Module Disposal 43.........

Deployed Air Bag Module Disposal

Procedures 52.................................

CAUTION

DCarefully read and observe the information in the SERVICE PRECAUTIONS (P.52B-3.) prior to any service.

DFor information concerning troubleshooting or maintenance, always observe the procedures in the Troubleshooting

(P.52B-7.) section.

DIf any SRS components are removed or replaced in connection with any service procedures, be sure to follow the

procedures in the INDIVIDUAL COMPONENT SERVICE section (P.52B-26.) for the components involved.

DIf you have any questions about theSRS, please contact your local distributor.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1553 of 1839

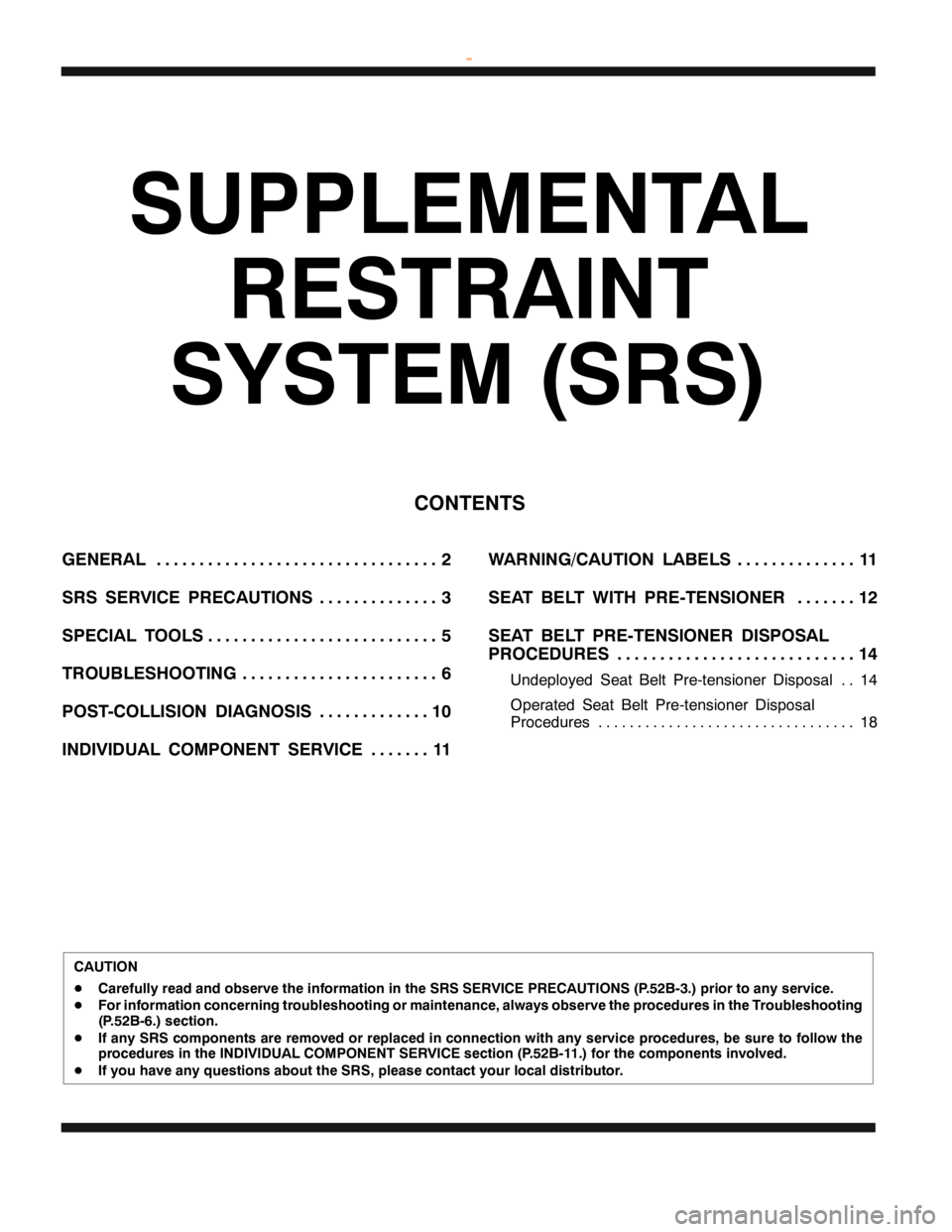

52B-1

SUPPLEMENTAL

RESTRAINT

SYSTEM (SRS)

CONTENTS

GENERAL 2.................................

SRS SERVICE PRECAUTIONS 3..............

SPECIAL TOOLS 5...........................

TROUBLESHOOTING 6.......................

POST-COLLISION DIAGNOSIS 10.............

INDIVIDUAL COMPONENT SERVICE 11.......WARNING/CAUTION LABELS 11..............

SEAT BELT WITH PRE-TENSIONER 12.......

SEAT BELT PRE-TENSIONER DISPOSAL

PROCEDURES 14............................

Undeployed Seat Belt Pre-tensioner Disposal 14..

Operated Seat Belt Pre-tensioner Disposal

Procedures 18.................................

CAUTION

DCarefully read and observe the information in the SRS SERVICE PRECAUTIONS (P.52B-3.) prior to any service.

DFor information concerning troubleshooting or maintenance, always observe the procedures in the Troubleshooting

(P.52B-6.) section.

DIf any SRS components are removed or replaced in connection with any service procedures, be sure to follow the

procedures in the INDIVIDUAL COMPONENT SERVICE section (P.52B-11.) for the components involved.

DIf you have any questions about the SRS, please contact your local distributor.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1678 of 1839

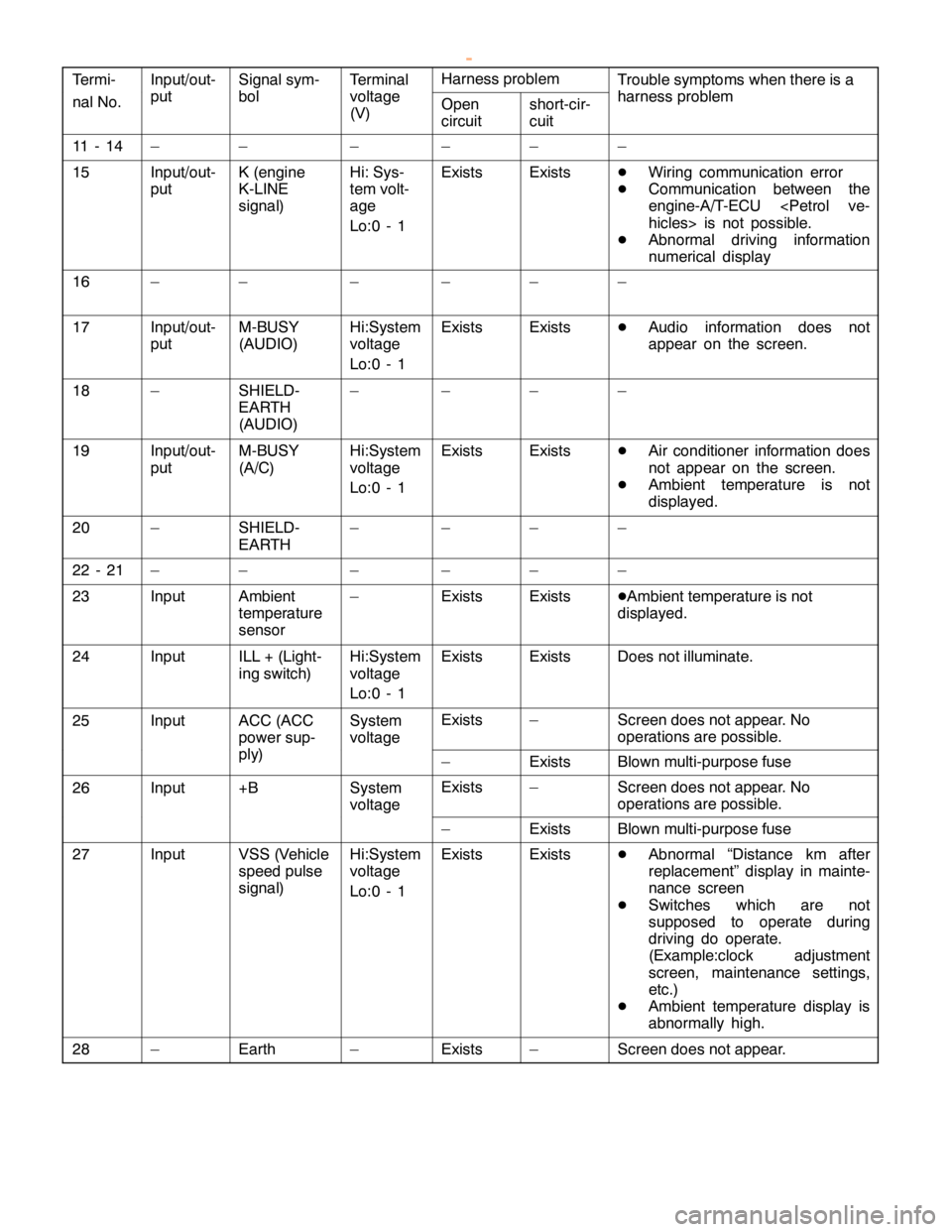

CHASSIS ELECTRICAL -RV Meter54A-17

Termi-Input/out-

t

Signal sym-

bl

Terminal

lt

Harness problemTrouble symptoms when there is a

hblnal No.

p

put

gy

bolvoltage

(V)Open

circuitshort-cir-

cuit

yp

harness problem

11 - 1 4––––––

15Input/out-

putK (engine

K-LINE

signal)Hi: Sys-

tem volt-

age

Lo:0 - 1ExistsExistsDWiring communication error

DCommunication between the

engine-A/T-ECU

DAbnormal driving information

numerical display

16––––––

17Input/out-

putM-BUSY

(AUDIO)Hi:System

voltage

Lo:0 - 1ExistsExistsDAudio information does not

appear on the screen.

18–SHIELD-

EARTH

(AUDIO)––––

19Input/out-

putM-BUSY

(A/C)Hi:System

voltage

Lo:0 - 1ExistsExistsDAir conditioner information does

not appear on the screen.

DAmbient temperature is not

displayed.

20–SHIELD-

EARTH––––

22 - 21––––––

23InputAmbient

temperature

sensor–ExistsExistsDAmbient temperature is not

displayed.

24InputILL + (Light-

ing switch)Hi:System

voltage

Lo:0 - 1ExistsExistsDoes not illuminate.

25InputACC (ACC

power sup-

l)

System

voltageExists–Screen does not appear. No

operations are possible.

pp

ply)

g

–ExistsBlown multi-purpose fuse

26Input+BSystem

voltageExists–Screen does not appear. No

operations are possible.

g

–ExistsBlown multi-purpose fuse

27InputVSS (Vehicle

speed pulse

signal)Hi:System

voltage

Lo:0 - 1ExistsExistsDAbnormal “Distance km after

replacement” display in mainte-

nance screen

DSwitches which are not

supposed to operate during

driving do operate.

(Example:clock adjustment

screen, maintenance settings,

etc.)

DAmbient temperature display is

abnormally high.

28–Earth–Exists–Screen does not appear.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk