weight MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 25 of 1839

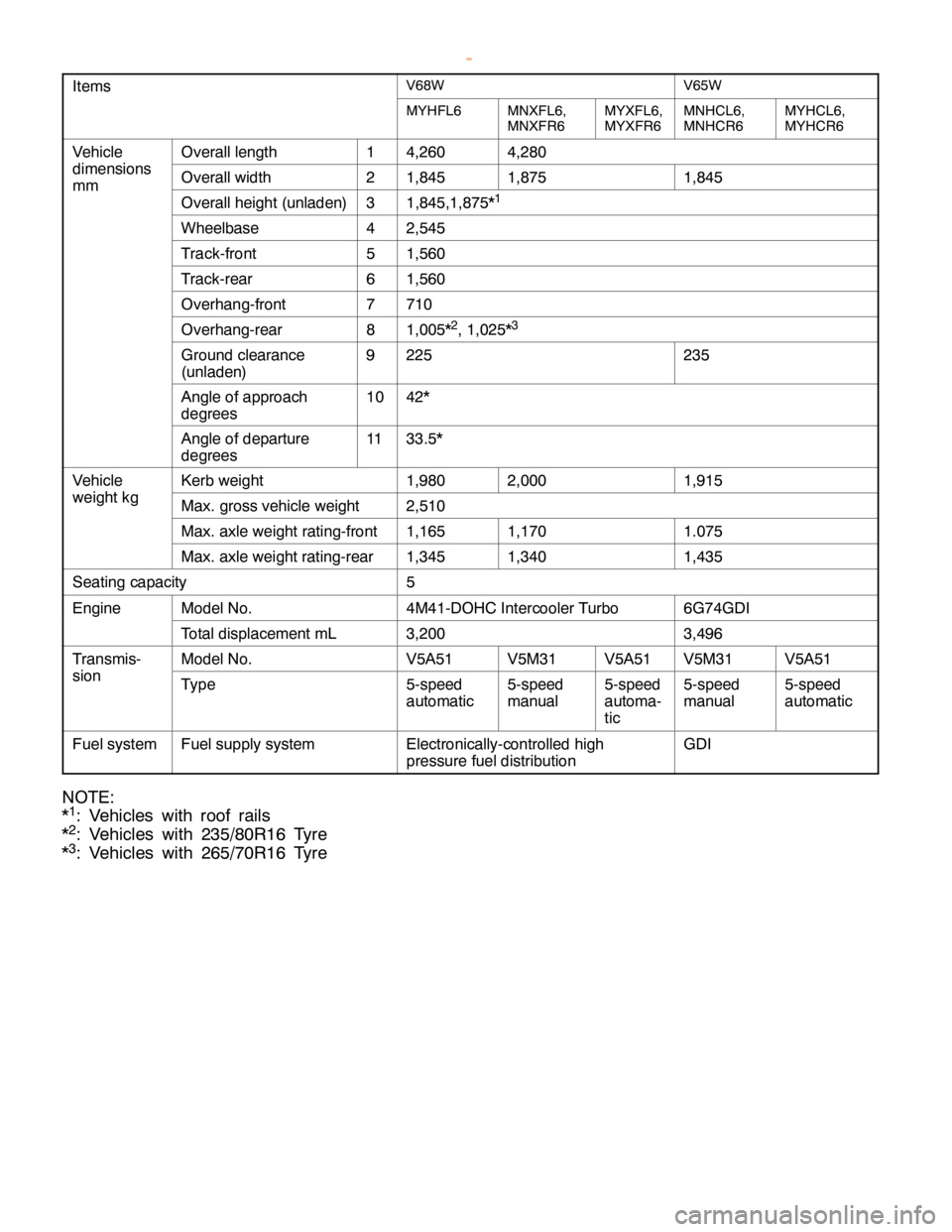

GENERAL -Major Specifications00-24

ItemsV68WV65W

MYHFL6MNXFL6,

MNXFR6MYXFL6,

MYXFR6MNHCL6,

MNHCR6MYHCL6,

MYHCR6

VehicleOverall length14,2604,280

dimensionsOverall width21,8451,8751,845mm

Overall height (unladen)31,845,1,875*1

Wheelbase42,545

Track-front51,560

Track-rear61,560

Overhang-front7710

Overhang-rear81,005*2, 1,025*3

Ground clearance

(unladen)9225235

Angle of approach

degrees1042*

Angle of departure

degrees1133.5*

VehicleKerb weight1,9802,0001,915

weight kgMax. gross vehicle weight2,510

Max. axle weight rating-front1,1651,1701.075

Max. axle weight rating-rear1,3451,3401,435

Seating capacity5

EngineModel No.4M41-DOHC Intercooler Turbo6G74GDI

Total displacement mL3,2003,496

Transmis-Model No.V5A51V5M31V5A51V5M31V5A51

sionType5-speed

automatic5-speed

manual5-speed

automa-

tic5-speed

manual5-speed

automatic

Fuel systemFuel supply systemElectronically-controlled high

pressure fuel distributionGDI

NOTE:

*1: Vehicles with roof rails

*2: Vehicles with 235/80R16 Tyre

*3: Vehicles with 265/70R16 Tyre

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 26 of 1839

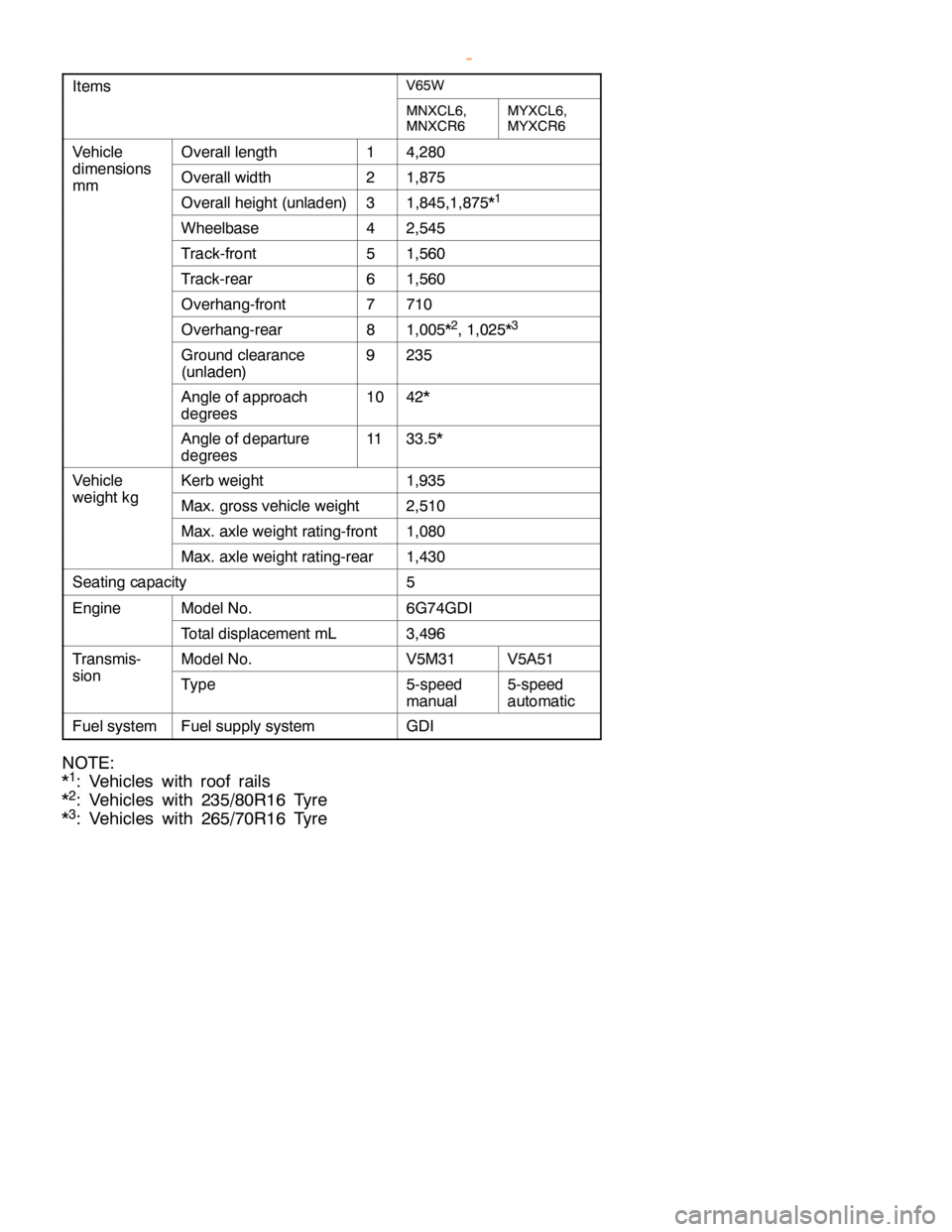

GENERAL -Major Specifications00-25

ItemsV65W

MNXCL6,

MNXCR6MYXCL6,

MYXCR6

VehicleOverall length14,280

dimensionsOverall width21,875mm

Overall height (unladen)31,845,1,875*1

Wheelbase42,545

Track-front51,560

Track-rear61,560

Overhang-front7710

Overhang-rear81,005*2, 1,025*3

Ground clearance

(unladen)9235

Angle of approach

degrees1042*

Angle of departure

degrees1133.5*

VehicleKerb weight1,935

weight kgMax. gross vehicle weight2,510

Max. axle weight rating-front1,080

Max. axle weight rating-rear1,430

Seating capacity5

EngineModel No.6G74GDI

Total displacement mL3,496

Transmis-Model No.V5M31V5A51

sionType5-speed

manual5-speed

automatic

Fuel systemFuel supply systemGDI

NOTE:

*1: Vehicles with roof rails

*2: Vehicles with 235/80R16 Tyre

*3: Vehicles with 265/70R16 Tyre

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 28 of 1839

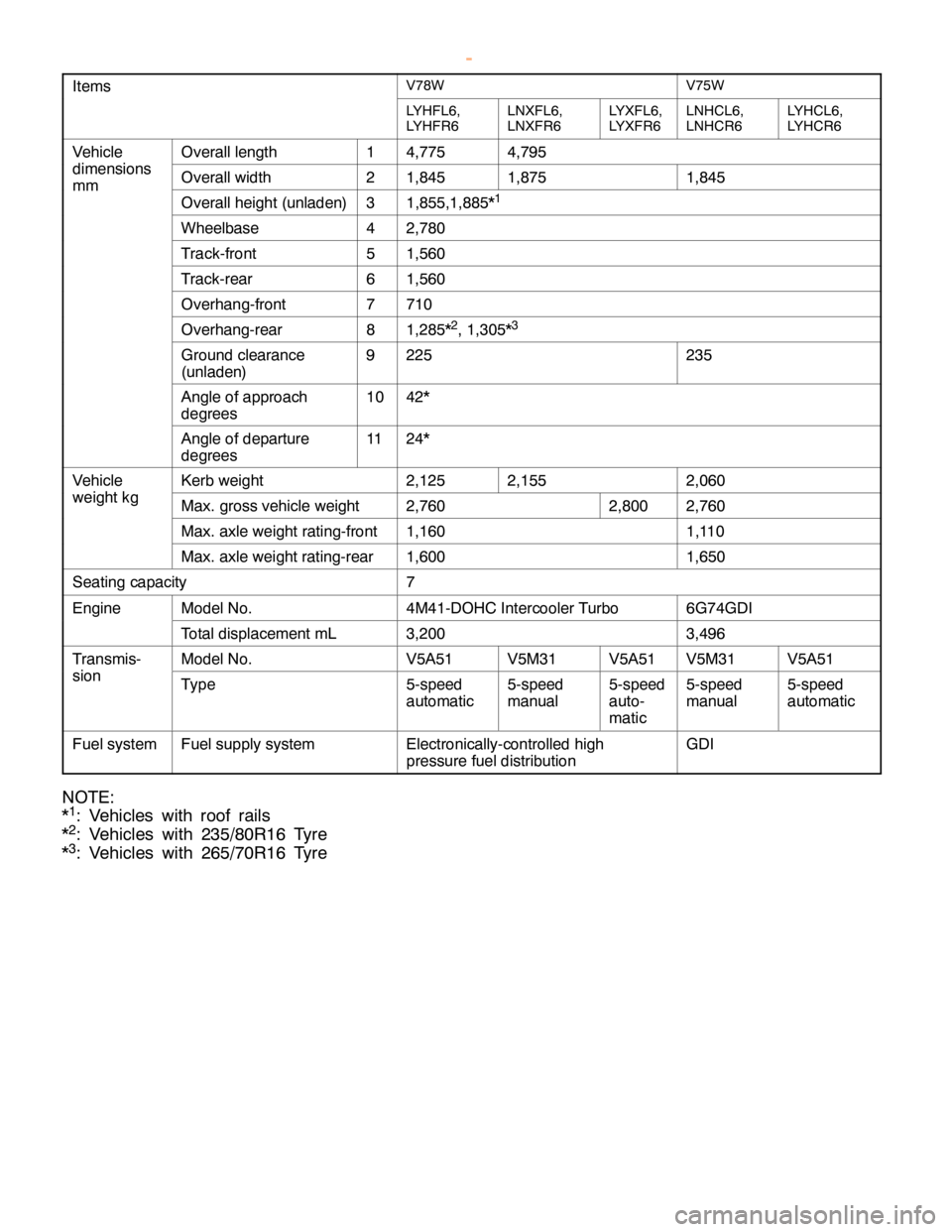

GENERAL -Major Specifications00-27

ItemsV78WV75W

LYHFL6,

LYHFR6LNXFL6,

LNXFR6LYXFL6,

LYXFR6LNHCL6,

LNHCR6LYHCL6,

LYHCR6

VehicleOverall length14,7754,795

dimensionsOverall width21,8451,8751,845mm

Overall height (unladen)31,855,1,885*1

Wheelbase42,780

Track-front51,560

Track-rear61,560

Overhang-front7710

Overhang-rear81,285*2, 1,305*3

Ground clearance

(unladen)9225235

Angle of approach

degrees1042*

Angle of departure

degrees1124*

VehicleKerb weight2,1252,1552,060

weight kgMax. gross vehicle weight2,7602,8002,760

Max. axle weight rating-front1,1601,110

Max. axle weight rating-rear1,6001,650

Seating capacity7

EngineModel No.4M41-DOHC Intercooler Turbo6G74GDI

Total displacement mL3,2003,496

Transmis-Model No.V5A51V5M31V5A51V5M31V5A51

sionType5-speed

automatic5-speed

manual5-speed

auto-

matic5-speed

manual5-speed

automatic

Fuel systemFuel supply systemElectronically-controlled high

pressure fuel distributionGDI

NOTE:

*1: Vehicles with roof rails

*2: Vehicles with 235/80R16 Tyre

*3: Vehicles with 265/70R16 Tyre

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 29 of 1839

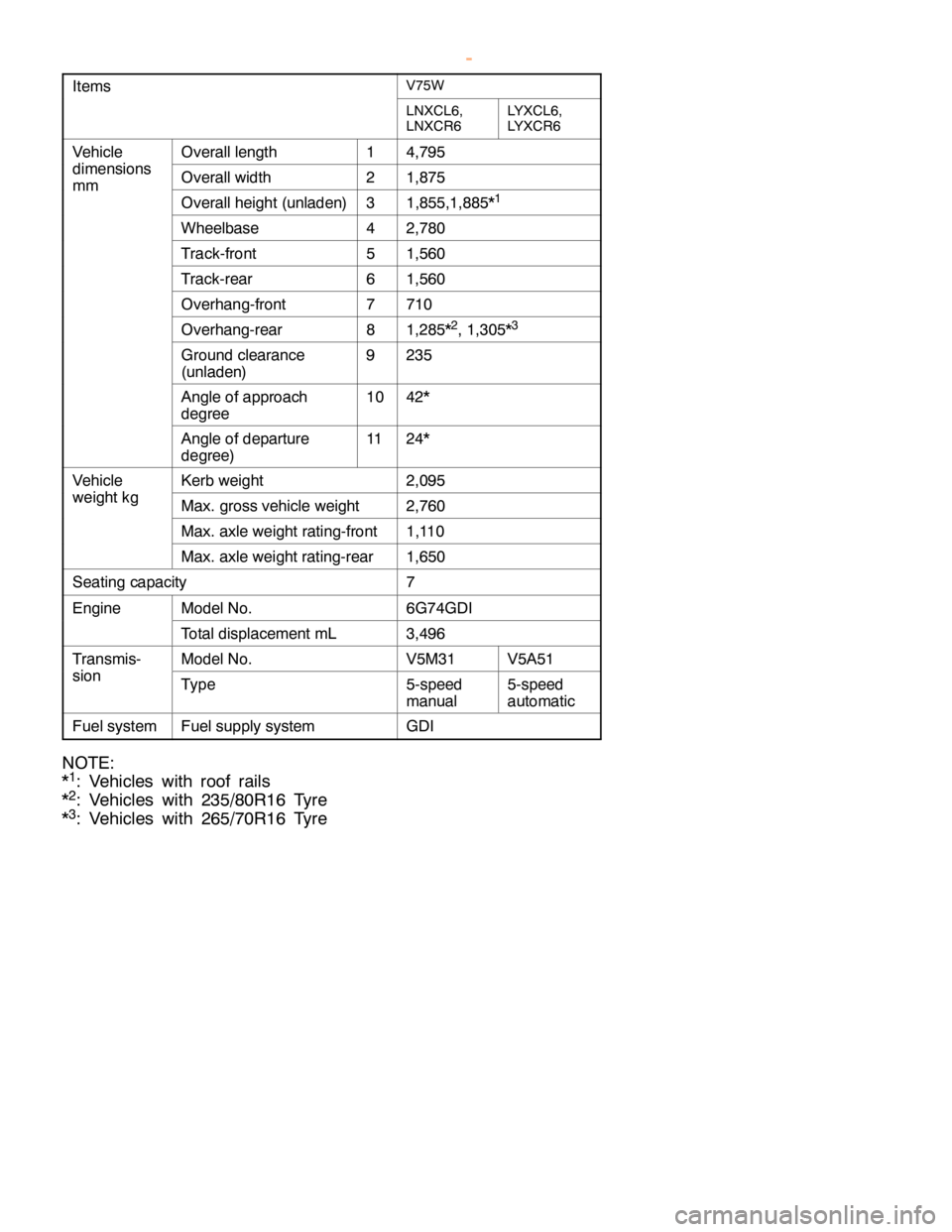

GENERAL -Major Specifications00-28

ItemsV75W

LNXCL6,

LNXCR6LYXCL6,

LYXCR6

VehicleOverall length14,795

dimensionsOverall width21,875mm

Overall height (unladen)31,855,1,885*1

Wheelbase42,780

Track-front51,560

Track-rear61,560

Overhang-front7710

Overhang-rear81,285*2, 1,305*3

Ground clearance

(unladen)9235

Angle of approach

degree1042*

Angle of departure

degree)1124*

VehicleKerb weight2,095

weight kgMax. gross vehicle weight2,760

Max. axle weight rating-front1,110

Max. axle weight rating-rear1,650

Seating capacity7

EngineModel No.6G74GDI

Total displacement mL3,496

Transmis-Model No.V5M31V5A51

sionType5-speed

manual5-speed

automatic

Fuel systemFuel supply systemGDI

NOTE:

*1: Vehicles with roof rails

*2: Vehicles with 235/80R16 Tyre

*3: Vehicles with 265/70R16 Tyre

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 52 of 1839

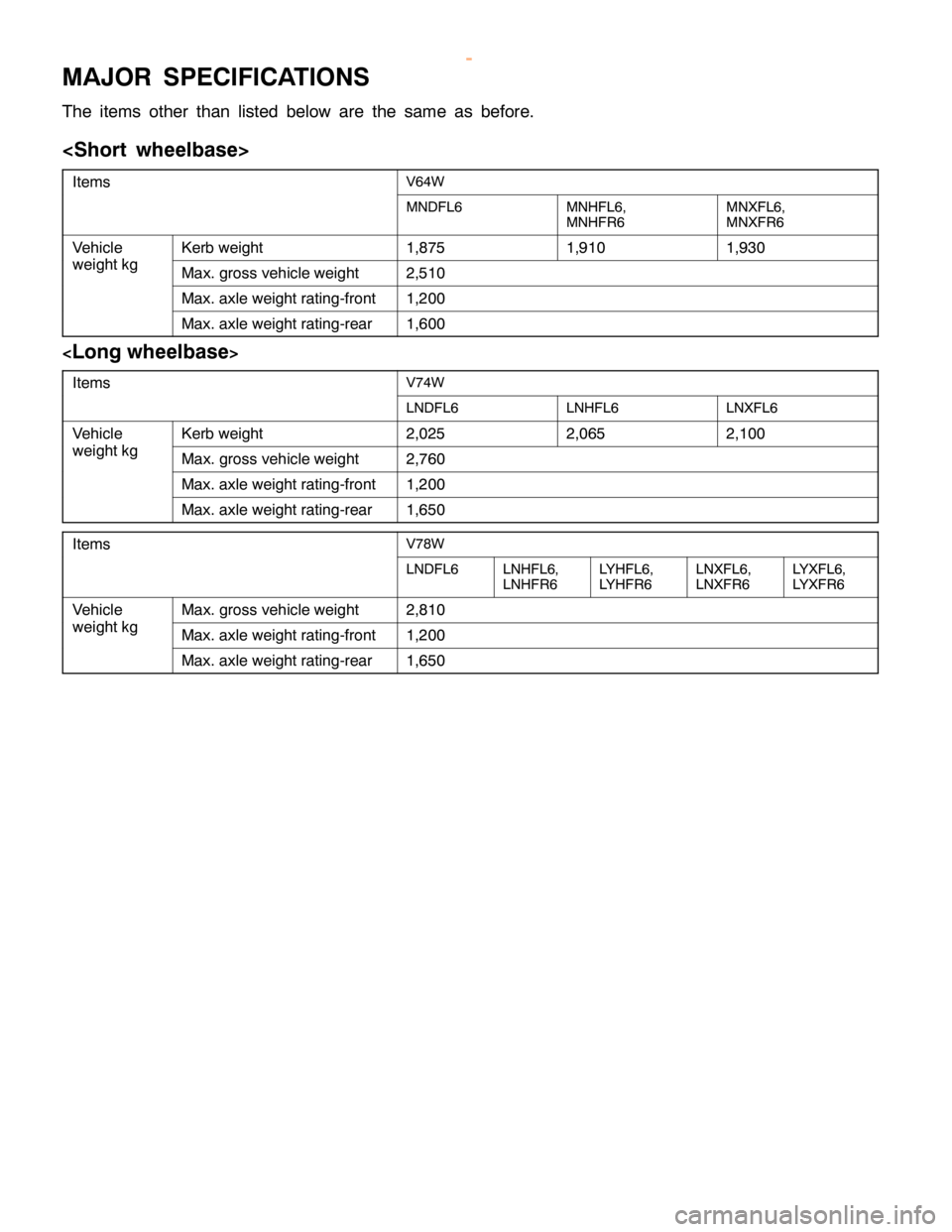

GENERAL -Major Specifications00-4

MAJOR SPECIFICATIONS

The items other than listed below are the same as before.

ItemsV64W

MNDFL6MNHFL6,

MNHFR6MNXFL6,

MNXFR6

Vehicle

ihtk

Kerb weight1,8751,9101,930

weight kgMax. gross vehicle weight2,510

Max. axle weight rating-front1,200

Max. axle weight rating-rear1,600

ItemsV74W

LNDFL6LNHFL6LNXFL6

Vehicle

ihtk

Kerb weight2,0252,0652,100

weight kgMax. gross vehicle weight2,760

Max. axle weight rating-front1,200

Max. axle weight rating-rear1,650

ItemsV78W

LNDFL6LNHFL6,

LNHFR6LYHFL6,

LYHFR6LNXFL6,

LNXFR6LYXFL6,

LYXFR6

Vehicle

ihtk

Max. gross vehicle weight2,810

weight kgMax. axle weight rating-front1,200

Max. axle weight rating-rear1,650

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1148 of 1839

WHEEL AND TYRE -Troubleshooting31-5

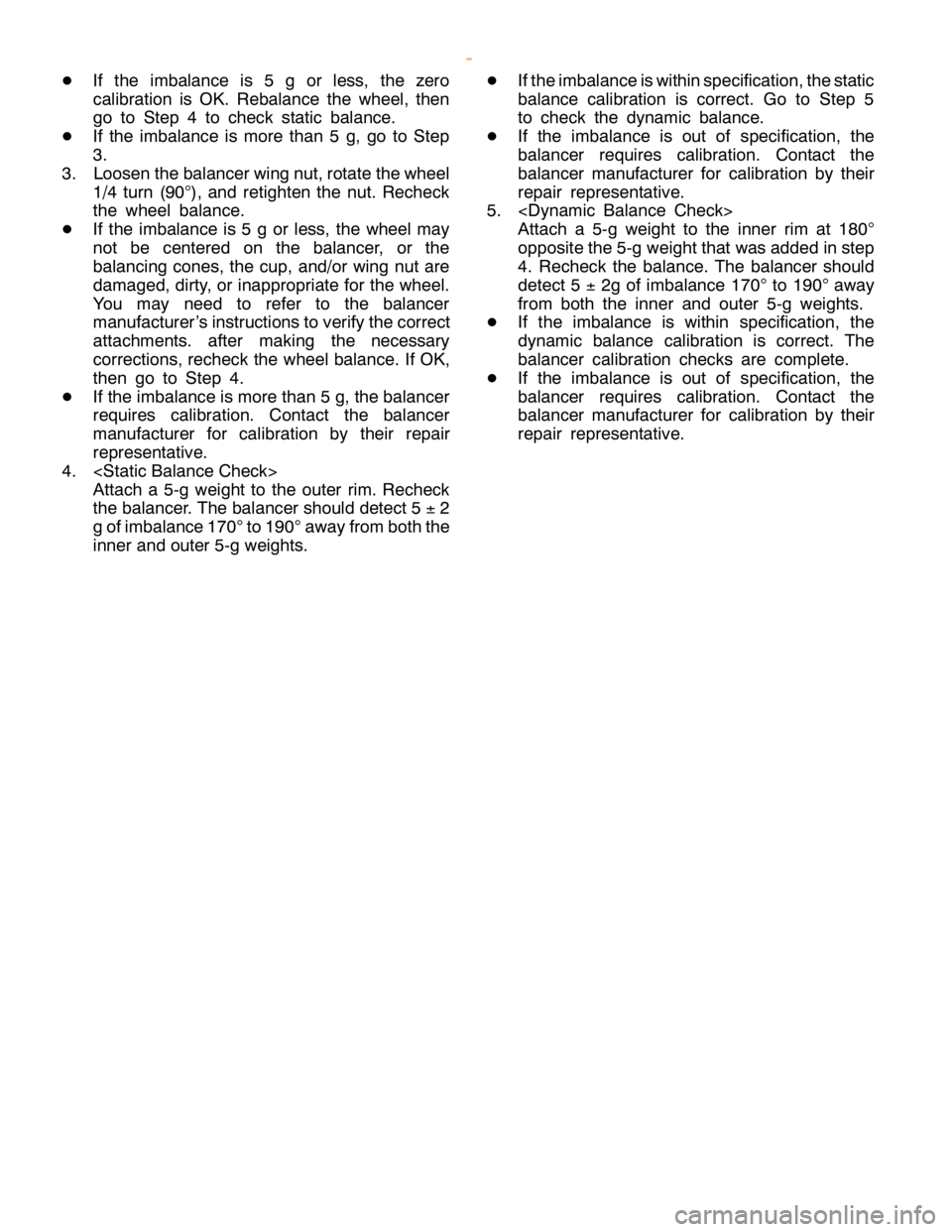

DIf the imbalance is 5 g or less, the zero

calibration is OK. Rebalance the wheel, then

go to Step 4 to check static balance.

DIf the imbalance is more than 5 g, go to Step

3.

3. Loosen the balancer wing nut, rotate the wheel

1/4 turn (90

°), and retighten the nut. Recheck

the wheel balance.

DIf the imbalance is 5 g or less, the wheel may

not be centered on the balancer, or the

balancing cones, the cup, and/or wing nut are

damaged, dirty, or inappropriate for the wheel.

You may need to refer to the balancer

manufacturer’s instructions to verify the correct

attachments. after making the necessary

corrections, recheck the wheel balance. If OK,

then go to Step 4.

DIf the imbalance is more than 5 g, the balancer

requires calibration. Contact the balancer

manufacturer for calibration by their repair

representative.

4.

Attach a 5-g weight to the outer rim. Recheck

the balancer. The balancer should detect 5

±2

g of imbalance 170

°to 190

°away from both the

inner and outer 5-g weights.DIf the imbalance is within specification, the static

balance calibration is correct. Go to Step 5

to check the dynamic balance.

DIf the imbalance is out of specification, the

balancer requires calibration. Contact the

balancer manufacturer for calibration by their

repair representative.

5.

Attach a 5-g weight to the inner rim at 180

°

opposite the 5-g weight that was added in step

4. Recheck the balance. The balancer should

detect 5

±2g of imbalance 170

°to 190

°away

from both the inner and outer 5-g weights.

DIf the imbalance is within specification, the

dynamic balance calibration is correct. The

balancer calibration checks are complete.

DIf the imbalance is out of specification, the

balancer requires calibration. Contact the

balancer manufacturer for calibration by their

repair representative.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1149 of 1839

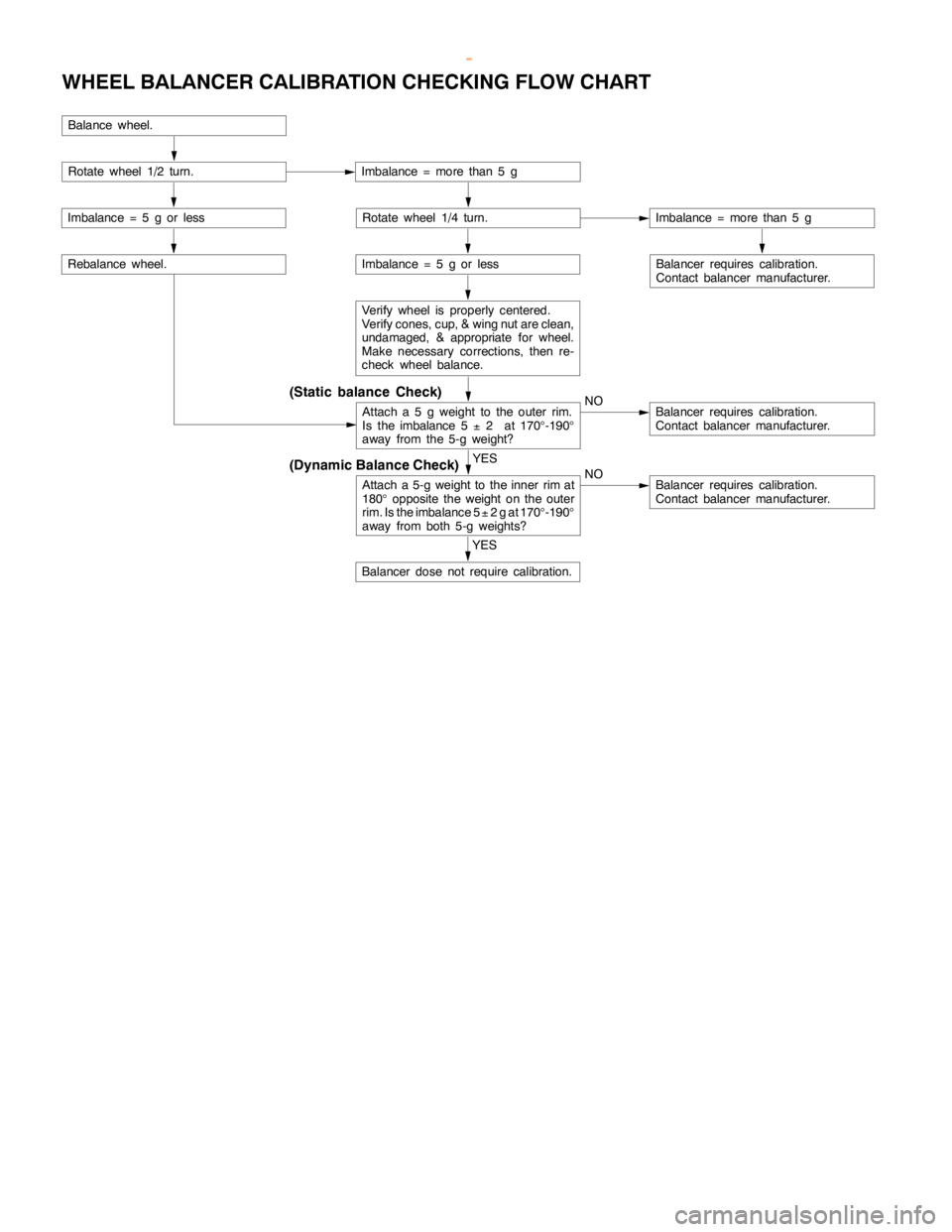

WHEEL AND TYRE -Troubleshooting31-6

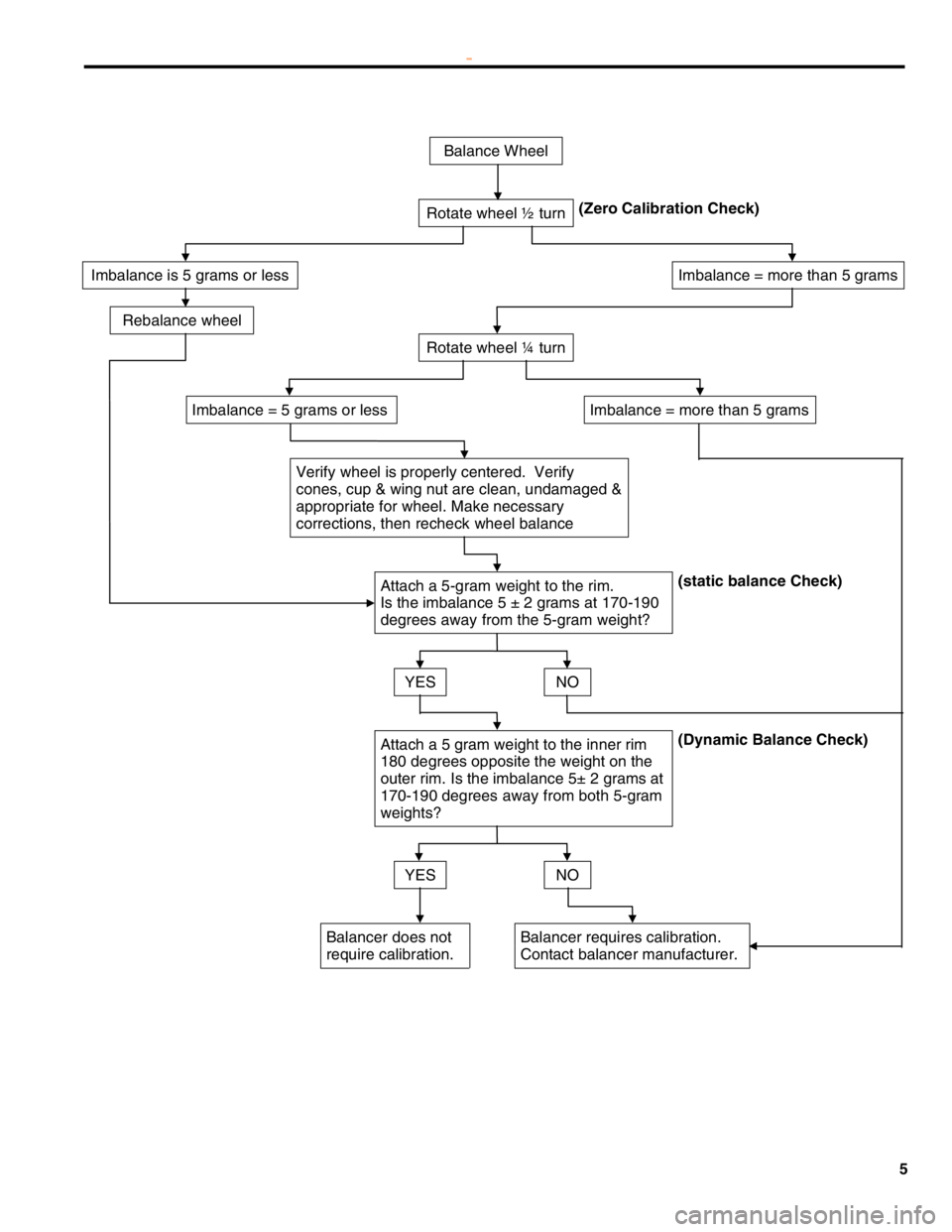

WHEEL BALANCER CALIBRATION CHECKING FLOW CHART

(Dynamic Balance Check)

(Static balance Check)

Balance wheel.

Rotate wheel 1/2 turn.Imbalance = more than 5 g

Imbalance = 5 g or lessRotate wheel 1/4 turn.Imbalance = more than 5 g

Imbalance = 5 g or less

Verify wheel is properly centered.

Verify cones, cup, & wing nut are clean,

undamaged, & appropriate for wheel.

Make necessary corrections, then re-

check wheel balance.

Attacha 5 g weight to the outer rim.

Is the imbalance 5

±2 at 170

°-190

°

away from the 5-g weight?NOBalancer requires calibration.

Contact balancer manufacturer.

Balancer requires calibration.

Contact balancer manufacturer.

YES

Attach a 5-g weight to the inner rim at

180

°opposite the weight on the outer

rim. Is the imbalance 5

±2 g at 170

°-190

°

away from both 5-g weights?NOBalancer requires calibration.

Contact balancer manufacturer.

Rebalance wheel.

YES

Balancer dose not require calibration.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1156 of 1839

4

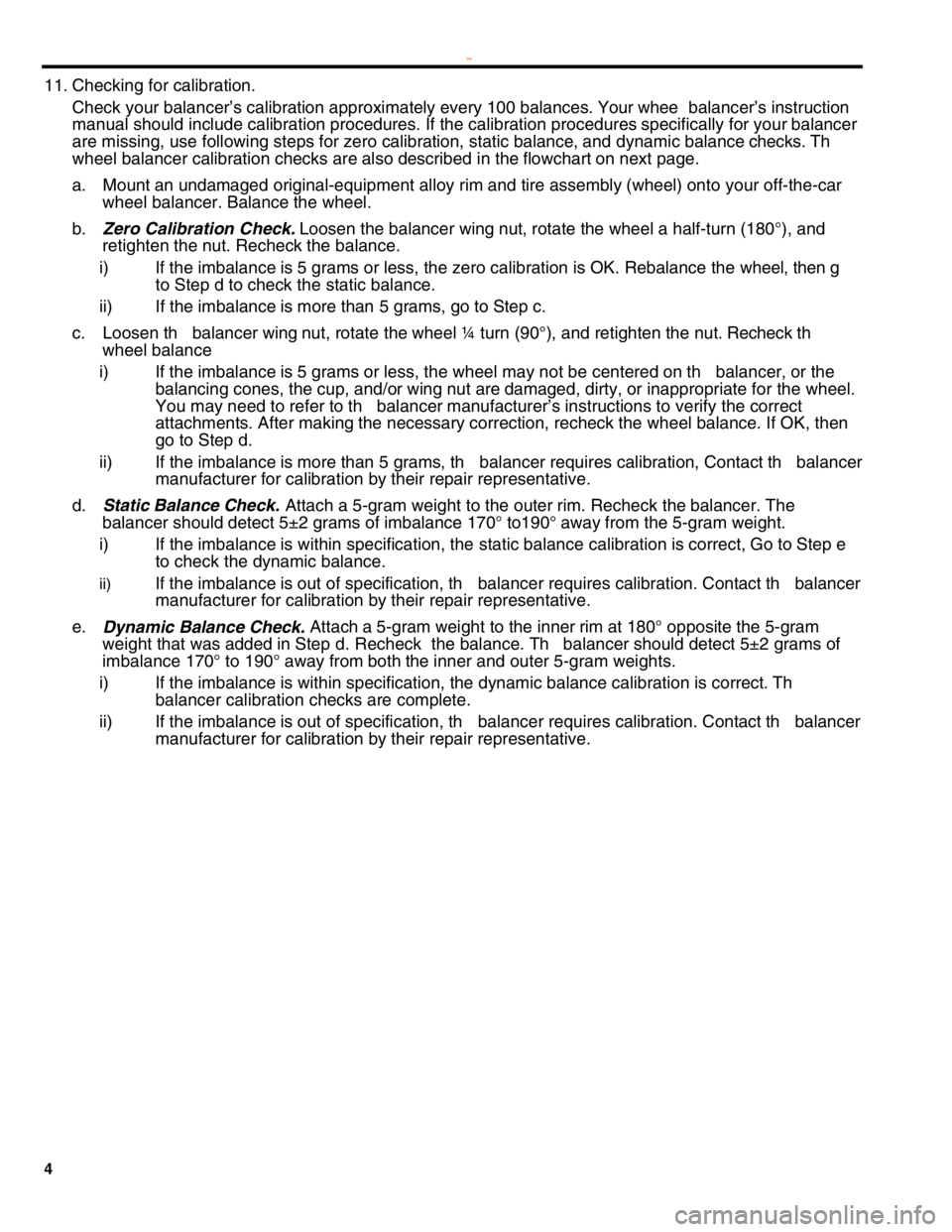

11.

Checking for calibration.

Check your balancer’s calibration approximately every 100 balances. Your whee balancer’s instruction

manual should include calibration procedures. If the calibration procedures specifically for your balancer

are missing, use following steps for zero calibration, static balance, and dynamic balance checks. Th

wheel balancer calibration checks are also described in the flowchart on next page.

a.

Mount an undamaged original-equipment alloy rim and tire assembly (wheel) onto your off-the-car

wheel balancer. Balance the wheel.

b.

Zero Calibration Check. Loosen the balancer wing nut, rotate the wheel a half-turn (180°), and

retighten the nut. Recheck the balance.

i)

If the imbalance is 5 grams or less, the zero calibration is OK. Rebalance the wheel, then g

to Step d to check the static balance.

ii)

If the imbalance is more than 5 grams, go to Step c.

c.

Loosen th balancer wing nut, rotate the wheel ¼ turn (90°), and retighten the nut. Recheck th

wheel balance

i)

If the imbalance is 5 grams or less, the wheel may not be centered on th balancer, or the

balancing cones, the cup, and/or wing nut are damaged, dirty, or inappropriate for the wheel.

You may need to refer to th balancer manufacturer’s instructions to verify the correct

attachments. After making the necessary correction, recheck the wheel balance. If OK, then

go to Step d.

ii)

If the imbalance is more than 5 grams, th balancer requires calibration, Contact th balancer

manufacturer for calibration by their repair representative.

d.

Static Balance Check. Attach a 5-gram weight to the outer rim. Recheck the balancer. The

balancer should detect 5±2 grams of imbalance 170° to190° away from the 5-gram weight.

i)

If the imbalance is within specification, the static balance calibration is correct, Go to Step e

to check the dynamic balance.

ii)

If the imbalance is out of specification, th balancer requires calibration. Contact th balancer

manufacturer for calibration by their repair representative.

e.

Dynamic Balance Check. Attach a 5-gram weight to the inner rim at 180° opposite the 5-gram

weight that was added in Step d. Recheck the balance. Th balancer should detect 5±2 grams of

imbalance 170° to 190° away from both the inner and outer 5-gram weights.

i)

If the imbalance is within specification, the dynamic balance calibration is correct. Th

balancer calibration checks are complete.

ii)

If the imbalance is out of specification, th balancer requires calibration. Contact th balancer

manufacturer for calibration by their repair representative.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1157 of 1839

5 Balance Wheel

Rotate wheel ½ turn(Zero Calibration Check)

Imbalance is 5 grams or less Imbalance = more than 5 grams

Rebalance wheel

Rotate wheel ¼ turn

Imbalance = 5 grams or less Imbalance = more than 5 grams

Verify wheel is properly centered. Verify

cones, cup & wing nut are clean, undamaged &

appropriate for wheel. Make necessary

corrections, then recheck wheel balance

Attach a 5-gram weight to the rim.

Is the imbalance 5 ± 2 grams at 170-190

degrees away from the 5-gram weight?(static balance Check)

YES NO

Attach a 5 gram weight to the inner rim

180 degrees opposite the weight on the

outer rim. Is the imbalance 5± 2 grams at

170-190 degrees away from both 5-gram

weights?(Dynamic Balance Check)

YES NO

Balancer does not

require calibration.Balancer requires calibration.

Contact balancer manufacturer.

WHEEL BALANCER CALIBRATION CHECKS

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1165 of 1839

POWER PLANT MOUNT - No.1 Crossmember32-7

No.1 CROSSMEMBER

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and airbag module assembly, always refer to GROUP 52B

- Service Precautions, Airbag Module and Clock Spring. Also, set the front wheels so that

they are facing straight forward, and remove the ignition key. If you fail to do this, the SRS

clock spring will be damaged, causing the SRS airbag to be inoperative and serious injury.

2. *: Indicates parts which should be initially tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal

DDrive Shaft Removal

(Refer to GROUP 26.)

DDifferential Carrier and No.2 Crossmember

Assembly Removal (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DUpper Arm Removal

(Refer to GROUP 33A.)

DLower Arm Removal

(Refer to GROUP 33A.)

DStabilizer Bar Removal

(Refer to GROUP 33A.)

DEngine Oil Cooler Removal<6G7>

(Refer to GROUP 12.)

DAir Cleaner Removal<4M4>

(Refer to GROUP 15.)

DIntercooler Removal<4M4>

(Refer to GROUP 15.)

DEngine Cover Removal

(Refer to GROUP 11A - Timing Belt.)

DRadiator Removal

(Refer to GROUP 14.)

DPower Steering Fluid Draining

(Refer to GROUP 37A - On - vehicle Service.)Post - installation Operations

DDifferential Carrier and No.2 Crossmember

Assembly Installation (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DDrive Shaft Installation

(Refer to GROUP 26.)

DLower Arm Installation

(Refer to GROUP 33A.)

DUpper Arm Installation

(Refer to GROUP 33A.)

DStabilizer Bar Installation

(Refer to GROUP 33A.)

DAir Cleaner Installation<4M4>

(Refer to GROUP 15.)

DIntercooler Installation<4M4>

(Refer to GROUP 15.)

DRadiator Installation

(Refer to GROUP 14.)

DEngine Oil Cooler Installation

(Refer to GROUP 12.)

DPower Steering Fluid Supplying

(Refer to GROUP 37A - On - vehicle Service.)

DPower Steering Fluid Line Bleeding

(Refer to GROUP 37A - On - vehicle Service.)

DPress the dust cover with a finger tocheck whether

the dust cover is cracked or damaged.

DChecking Steering Wheel Position with Wheels

StraightAhead

DFront Wheel AlignmentCheck and Adjustment

(Refer to GROUP 37A - On - vehicle Service.)

DUnder Cover Installation

DEngine Cover Installation

(Refer to GROUP 11A - Timing Belt.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk