tyre MITSUBISHI PAJERO IV 2011 User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2011, Model line: PAJERO IV, Model: MITSUBISHI PAJERO IV 2011Pages: 377, PDF Size: 29.43 MB

Page 166 of 377

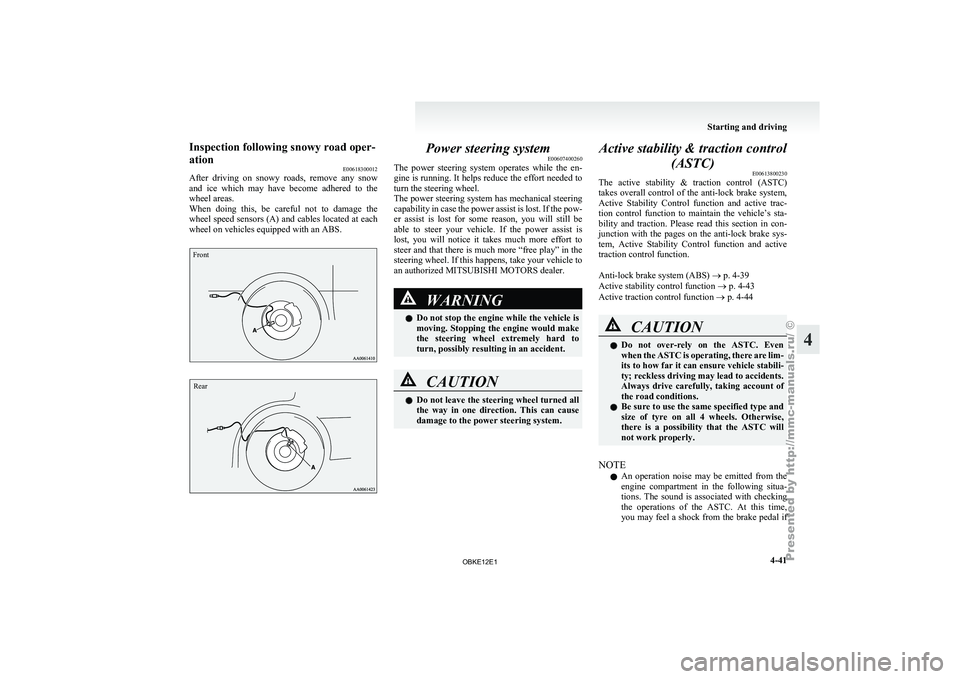

Inspection following snowy road oper-

ation

E00618300012

After driving on

snowy roads, remove any snow

and ice which may have become adhered to the

wheel areas.

When doing this, be careful not to damage the

wheel speed sensors (A) and cables located at each

wheel on vehicles equipped with an ABS.

Front

Rear Power steering system

E00607400260

The power steering

system operates while the en-

gine is running. It helps reduce the effort needed to

turn the steering wheel.

The power steering system has mechanical steering

capability in case the power assist is lost. If the pow-

er assist is lost for some reason, you will still be

able to steer your vehicle. If the power assist is

lost, you will notice it takes much more effort to

steer and that there is much more “free play” in the

steering wheel. If this happens, take your vehicle to

an authorized MITSUBISHI MOTORS dealer. WARNING

l Do not

stop

the engine while the vehicle is

moving. Stopping the engine would make

the steering wheel extremely hard to

turn, possibly resulting in an accident. CAUTION

l

Do not leave

the steering wheel turned all

the way in one direction. This can cause

damage to the power steering system. Active stability & traction control

(ASTC) E00613800230

The active stability

& traction control (ASTC)

takes overall control of the anti-lock brake system,

Active Stability Control function and active trac-

tion control function to maintain the vehicle’s sta-

bility and traction. Please read this section in con-

junction with the pages on the anti-lock brake sys-

tem, Active Stability Control function and active

traction control function.

Anti-lock brake system (ABS) ® p. 4-39

Active stability control function ® p. 4-43

Active traction control function ® p. 4-44 CAUTION

l

Do not

over-rely

on the ASTC. Even

when the ASTC is operating, there are lim-

its to how far it can ensure vehicle stabili-

ty; reckless driving may lead to accidents.

Always drive carefully, taking account of

the road conditions.

l Be sure to use the same specified type and

size of tyre on all 4 wheels. Otherwise,

there is a possibility that the ASTC will

not work properly.

NOTE l An

operation noise

may be emitted from the

engine compartment in the following situa-

tions. The sound is associated with checking

the operations of the ASTC. At this time,

you may feel a shock from the brake pedal if Starting and driving

4-41 4

OBKE12E1

Page 175 of 377

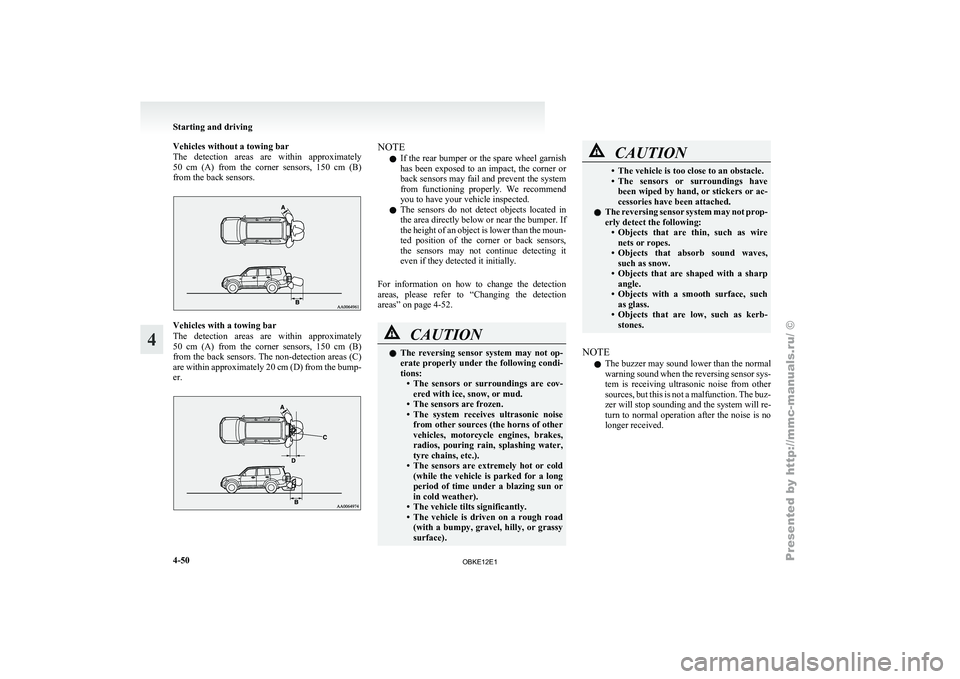

Vehicles without a towing bar

The detection areas

are within approximately

50 cm (A) from the corner sensors, 150 cm (B)

from the back sensors. Vehicles with a towing bar

The detection

areas

are within approximately

50 cm (A) from the corner sensors, 150 cm (B)

from the back sensors. The non-detection areas (C)

are within approximately 20 cm (D) from the bump-

er. NOTE

l If

the rear

bumper or the spare wheel garnish

has been exposed to an impact, the corner or

back sensors may fail and prevent the system

from functioning properly. We recommend

you to have your vehicle inspected.

l The sensors do not detect objects located in

the area directly below or near the bumper. If

the height of an object is lower than the moun-

ted position of the corner or back sensors,

the sensors may not continue detecting it

even if they detected it initially.

For information on how to change the detection

areas, please refer to “Changing the detection

areas” on page 4-52. CAUTION

l

The reversing

sensor

system may not op-

erate properly under the following condi-

tions: • The sensors or surroundings are cov-ered with ice, snow, or mud.

• The sensors are frozen.

• The system receives ultrasonic noise from other sources (the horns of other

vehicles, motorcycle engines, brakes,

radios, pouring rain, splashing water,

tyre chains, etc.).

• The sensors are extremely hot or cold (while the vehicle is parked for a long

period of time under a blazing sun or

in cold weather).

• The vehicle tilts significantly.

• The vehicle is driven on a rough road (with a bumpy, gravel, hilly, or grassy

surface). CAUTION

• The vehicle is too close to an obstacle.

• The sensors

or

surroundings have

been wiped by hand, or stickers or ac-

cessories have been attached.

l The reversing sensor system may not prop-

erly detect the following:

• Objects that are thin, such as wirenets or ropes.

• Objects that absorb sound waves, such as snow.

• Objects that are shaped with a sharp angle.

• Objects with a smooth surface, such as glass.

• Objects that are low, such as kerb- stones.

NOTE l The

buzzer may

sound lower than the normal

warning sound when the reversing sensor sys-

tem is receiving ultrasonic noise from other

sources, but this is not a malfunction. The buz-

zer will stop sounding and the system will re-

turn to normal operation after the noise is no

longer received. Starting and driving

4-50

4

OBKE12E1

Page 183 of 377

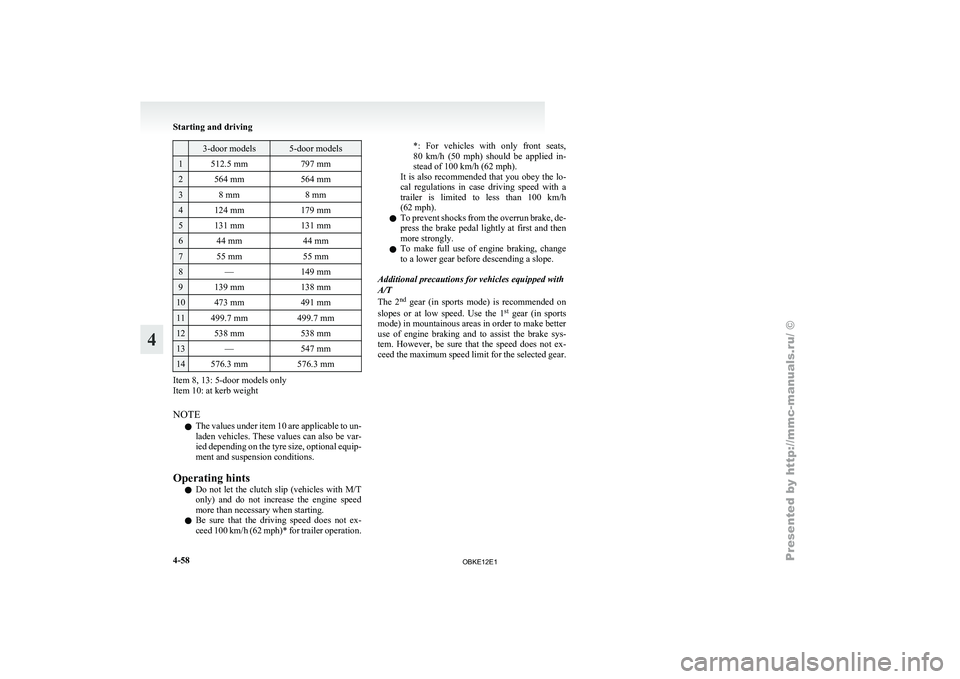

3-door models 5-door models

1 512.5 mm

797 mm2 564 mm

564 mm3 8 mm

8 mm4 124 mm

179 mm5 131 mm

131 mm6 44 mm

44 mm7 55 mm

55 mm8 —

149 mm9 139 mm

138 mm10 473 mm

491 mm11 499.7 mm

499.7 mm12 538 mm

538 mm13 —

547 mm14 576.3 mm

576.3 mmItem 8, 13: 5-door models only

Item 10: at kerb weight

NOTE

l The

values under

item 10 are applicable to un-

laden vehicles. These values can also be var-

ied depending on the tyre size, optional equip-

ment and suspension conditions.

Operating hints l Do not let the clutch slip (vehicles with M/T

only) and do not increase the engine speed

more than necessary when starting.

l Be sure that the driving speed does not ex-

ceed 100 km/h (62 mph)* for trailer operation. *: For vehicles with only front seats,

80

km/h

(50

mph) should be applied in-

stead of 100 km/h (62 mph).

It is also recommended that you obey the lo-

cal regulations in case driving speed with a

trailer is limited to less than 100 km/h

(62 mph).

l To prevent shocks from the overrun brake, de-

press the brake pedal lightly at first and then

more strongly.

l To make full use of engine braking, change

to a lower gear before descending a slope.

Additional precautions for vehicles equipped with

A/T

The 2 nd

gear (in sports mode) is recommended on

slopes or at low speed. Use the 1 st

gear (in sports

mode) in mountainous areas in order to make better

use of engine braking and to assist the brake sys-

tem. However, be sure that the speed does not ex-

ceed the maximum speed limit for the selected gear. Starting and driving

4-58

4

OBKE12E1

Page 282 of 377

If the vehicle breaks down

............................................................ 6-02

Emergency starting ....................................................................... 6-02

Engine overheating ....................................................................... 6-04

Bleeding the fuel system (diesel-powered vehicles only) ............6-06

Removal of water from the fuel filter (diesel-powered vehicles only) ........................................................................... 6-06

Tool, jack and jack handle ............................................................ 6-07

How to change a tyre .................................................................... 6-09

Towing.......................................................................................... 6-15

Operation under adverse driving conditions .................................6-18For emergencies

6

OBKE12E1

Page 290 of 377

To use the jack handle

E00802400023

1. While pushing the

snap pin (A), remove the

inside handle (B). 2. With the snap pin (C) pushed, insert the in-

side handle until it is locked. How to change a tyre

E00801201601

Before changing a

tyre, first stop your vehicle in a

safe, flat location. 1. Park the vehicle on level and stable ground.

2. Set the parking brake firmly.

3. On vehicles with M/T, turn the ignitionswitch to the “LOCK” position, move the

gearshift lever to the “R” (Reverse) position.

On vehicles with A/T, move the selector lev-

er to the “P” (PARK) position, turn the igni-

tion key to the “LOCK” position.

4. Turn on the hazard warning flashers and set up a warning triangle, flashing signal lamp,

etc., at an adequate distance from the vehi-

cle, and have all your passengers leave the ve-

hicle.

5. To prevent the vehicle from rolling when it is raised on the jack, place chocks or blocks

(A) at the tyre that is diagonally opposite

from the tyre (B) you are changing. WARNING

l Be sure to

apply chocks or blocks to the

correct tyre when jacking up the vehicle.

If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.

NOTE l The

chocks shown

in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if nee-

ded.

l If chocks are not available, use stones or any

other objects that are large enough to hold

the wheel in position.

6. Get the spare wheel, jack, jack handle and wheel nut wrench ready. Refer to “Tool, jack

and jack handle” on page 6-07.

Spare wheel information E00803600266

Check the air pressure of the spare tyre frequently

and make sure

it is ready for emergency use at any

time.

Maintaining the spare wheel at the highest speci-

fied air pressure will ensure that it can always be

used under any conditions (city/high-speed driving,

varying load weight, etc.). For emergencies

6-09 6

OBKE12E1

Page 291 of 377

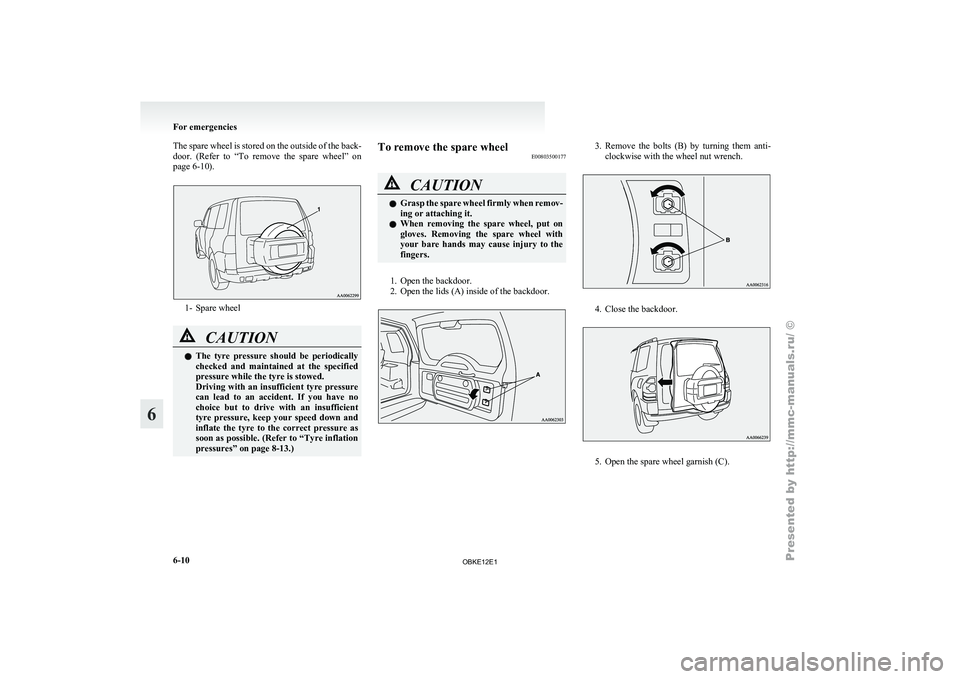

The spare wheel is stored on the outside of the back-

door. (Refer to

“To remove the spare wheel” on

page 6-10). 1- Spare wheel

CAUTION

l

The tyre pressure

should be periodically

checked and maintained at the specified

pressure while the tyre is stowed.

Driving with an insufficient tyre pressure

can lead to an accident. If you have no

choice but to drive with an insufficient

tyre pressure, keep your speed down and

inflate the tyre to the correct pressure as

soon as possible. (Refer to “Tyre inflation

pressures” on page 8-13.) To remove the spare wheel

E00803500177 CAUTION

l

Grasp the

spare

wheel firmly when remov-

ing or attaching it.

l When removing the spare wheel, put on

gloves. Removing the spare wheel with

your bare hands may cause injury to the

fingers.

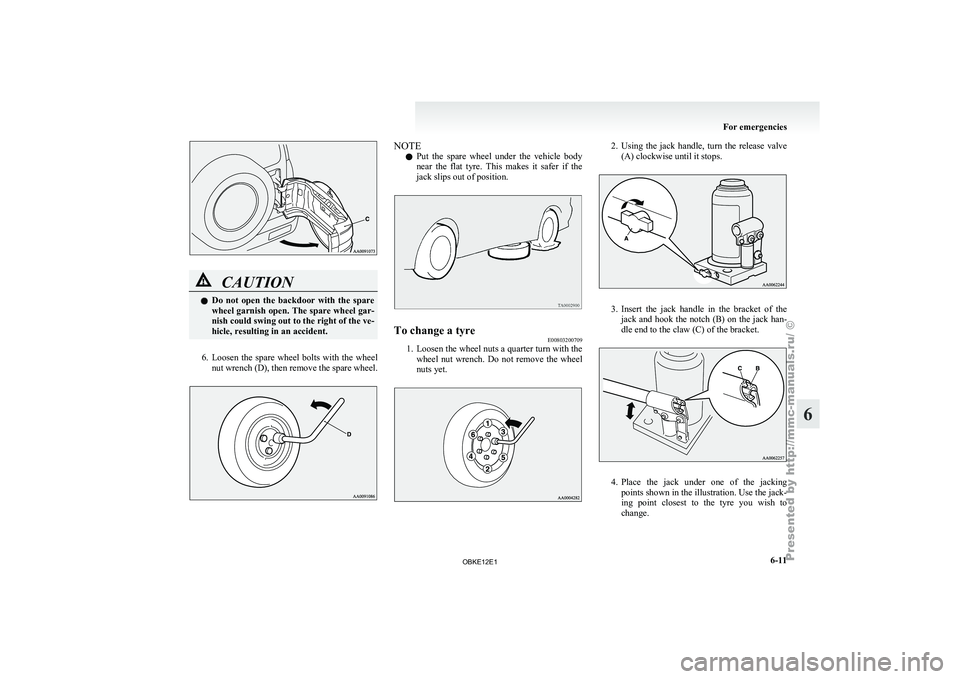

1. Open the backdoor.

2. Open the lids (A) inside of the backdoor. 3. Remove the bolts (B) by turning them anti-

clockwise with the wheel nut wrench. 4. Close the backdoor.

5. Open the spare wheel garnish (C).For emergencies

6-10

6

OBKE12E1

Page 292 of 377

CAUTION

l

Do not

open the backdoor with the spare

wheel garnish open. The spare wheel gar-

nish could swing out to the right of the ve-

hicle, resulting in an accident.

6. Loosen the spare wheel bolts with the wheel

nut wrench

(D), then remove the spare wheel. NOTE

l Put

the spare

wheel under the vehicle body

near the flat tyre. This makes it safer if the

jack slips out of position. To change a tyre

E00803200709

1. Loosen the wheel nuts a quarter turn with the

wheel nut

wrench. Do not remove the wheel

nuts yet. 2. Using the jack handle, turn the release valve

(A) clockwise until it stops. 3. Insert the jack handle in the bracket of the

jack and

hook the notch (B) on the jack han-

dle end to the claw (C) of the bracket. 4. Place

the jack under one of the jacking

points shown in the illustration. Use the jack-

ing point

closest to the tyre you wish to

change. For emergencies

6-11 6

OBKE12E1

Page 293 of 377

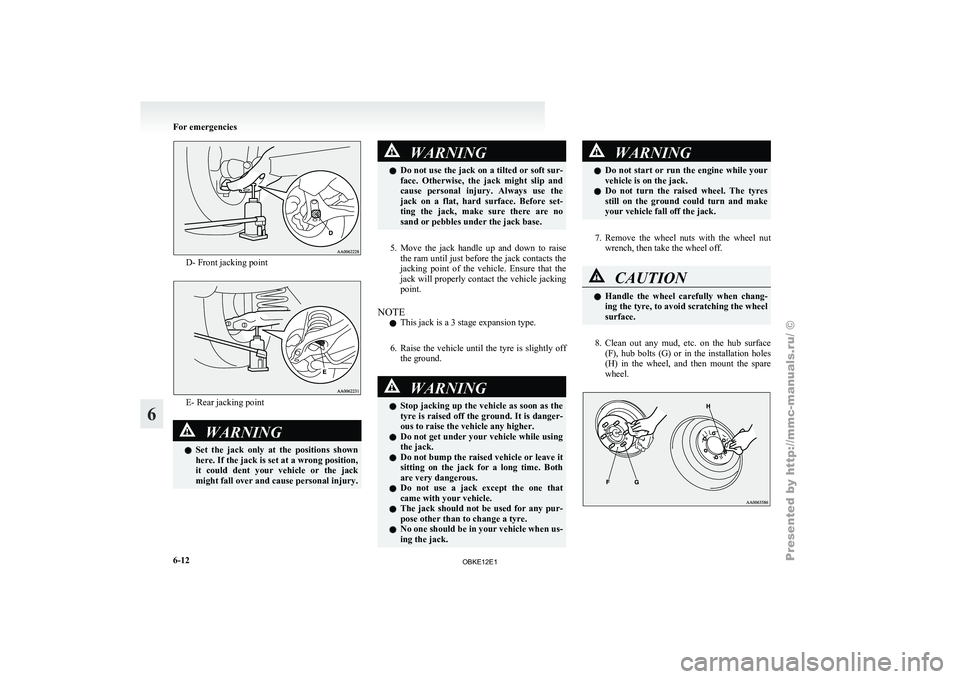

D- Front jacking point

E- Rear jacking point

WARNING

l Set the

jack only at the positions shown

here. If the jack is set at a wrong position,

it could dent your vehicle or the jack

might fall over and cause personal injury. WARNING

l Do not use

the jack on a tilted or soft sur-

face. Otherwise, the jack might slip and

cause personal injury. Always use the

jack on a flat, hard surface. Before set-

ting the jack, make sure there are no

sand or pebbles under the jack base.

5. Move the jack handle up and down to raise

the ram

until just before the jack contacts the

jacking point of the vehicle. Ensure that the

jack will properly contact the vehicle jacking

point.

NOTE l This jack is a 3 stage expansion type.

6. Raise the vehicle until the tyre is slightly off the ground. WARNING

l Stop jacking

up

the vehicle as soon as the

tyre is raised off the ground. It is danger-

ous to raise the vehicle any higher.

l Do not get under your vehicle while using

the jack.

l Do not bump the raised vehicle or leave it

sitting on the jack for a long time. Both

are very dangerous.

l Do not use a jack except the one that

came with your vehicle.

l The jack should not be used for any pur-

pose other than to change a tyre.

l No one should be in your vehicle when us-

ing the jack. WARNING

l Do not start

or run the engine while your

vehicle is on the jack.

l Do not turn the raised wheel. The tyres

still on the ground could turn and make

your vehicle fall off the jack.

7. Remove the wheel nuts with the wheel nut

wrench, then take the wheel off. CAUTION

l

Handle the

wheel

carefully when chang-

ing the tyre, to avoid scratching the wheel

surface.

8. Clean out any mud, etc. on the hub surface

(F), hub

bolts (G) or in the installation holes

(H) in the wheel, and then mount the spare

wheel. For emergencies

6-12

6

OBKE12E1

Page 294 of 377

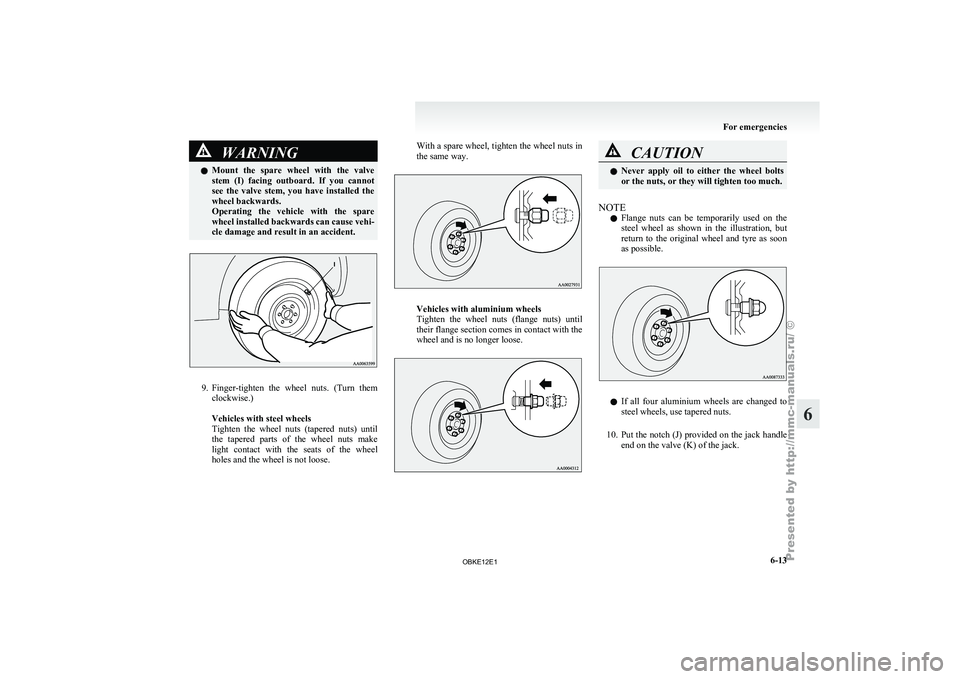

WARNING

l Mount the spare wheel with the valve

stem (I) facing outboard. If you cannot

see the valve stem, you have installed the

wheel backwards.

Operating the vehicle with the spare

wheel installed backwards can cause vehi-

cle damage and result in an accident. 9. Finger-tighten the

wheel

nuts. (Turn them

clockwise.)

Vehicles with steel wheels

Tighten the wheel nuts (tapered nuts) until

the tapered parts of the wheel nuts make

light contact with the seats of the wheel

holes and the wheel is not loose. With a spare wheel, tighten the wheel nuts in

the same way.

Vehicles with aluminium wheels

Tighten the

wheel

nuts (flange nuts) until

their flange section comes in contact with the

wheel and is no longer loose. CAUTION

l

Never apply oil

to either the wheel bolts

or the nuts, or they will tighten too much.

NOTE l Flange

nuts can

be temporarily used on the

steel wheel as shown in the illustration, but

return to the original wheel and tyre as soon

as possible. l

If all

four

aluminium wheels are changed to

steel wheels, use tapered nuts.

10. Put the notch (J) provided on the jack handle end on the valve (K) of the jack. For emergencies

6-13 6

OBKE12E1

Page 295 of 377

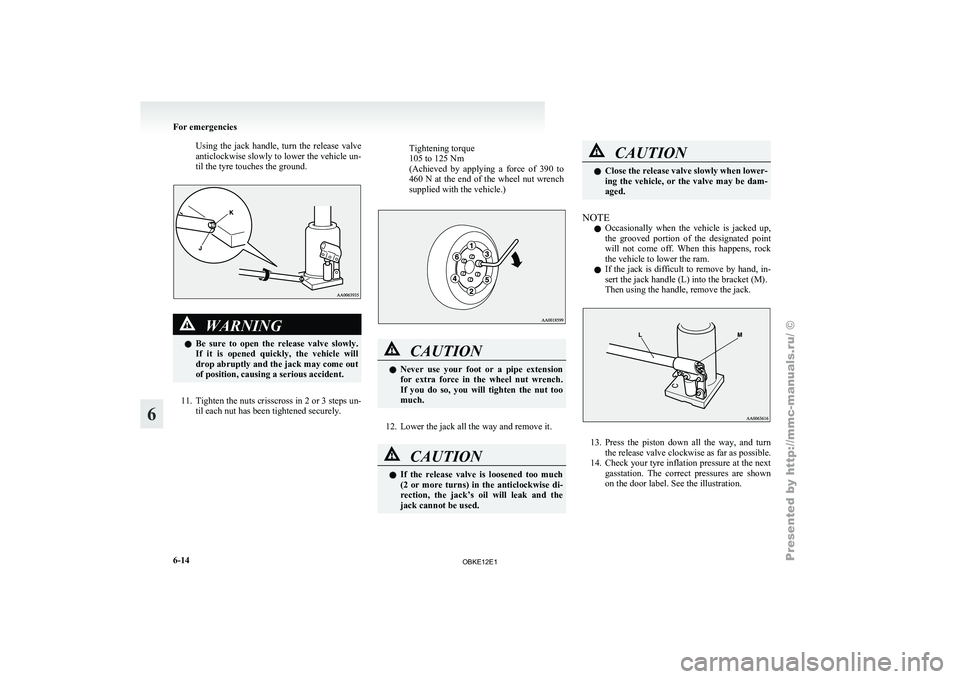

Using the jack handle, turn the release valve

anticlockwise slowly to lower the vehicle un-

til the tyre touches the ground.

WARNING

l Be sure

to open the release valve slowly.

If it is opened quickly, the vehicle will

drop abruptly and the jack may come out

of position, causing a serious accident.

11. Tighten the nuts crisscross in 2 or 3 steps un-

til each nut has been tightened securely.

Tightening torque

105 to 125 Nm

(Achieved by

applying

a force of 390 to

460 N at the end of the wheel nut wrench

supplied with the vehicle.) CAUTION

l

Never use

your

foot or a pipe extension

for extra force in the wheel nut wrench.

If you do so, you will tighten the nut too

much.

12. Lower the jack all the way and remove it. CAUTION

l

If the

release

valve is loosened too much

(2 or more turns) in the anticlockwise di-

rection, the jack’s oil will leak and the

jack cannot be used. CAUTION

l

Close the release

valve slowly when lower-

ing the vehicle, or the valve may be dam-

aged.

NOTE l Occasionally

when the

vehicle is jacked up,

the grooved portion of the designated point

will not come off. When this happens, rock

the vehicle to lower the ram.

l If the jack is difficult to remove by hand, in-

sert the jack handle (L) into the bracket (M).

Then using the handle, remove the jack. 13. Press the piston down all the way, and turn

the release valve clockwise as far as possible.

14. Check

your tyre inflation pressure at the next

gasstation. The correct pressures are shown

on the door label. See the illustration. For emergencies

6-14

6

OBKE12E1