engine MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 176 of 2103

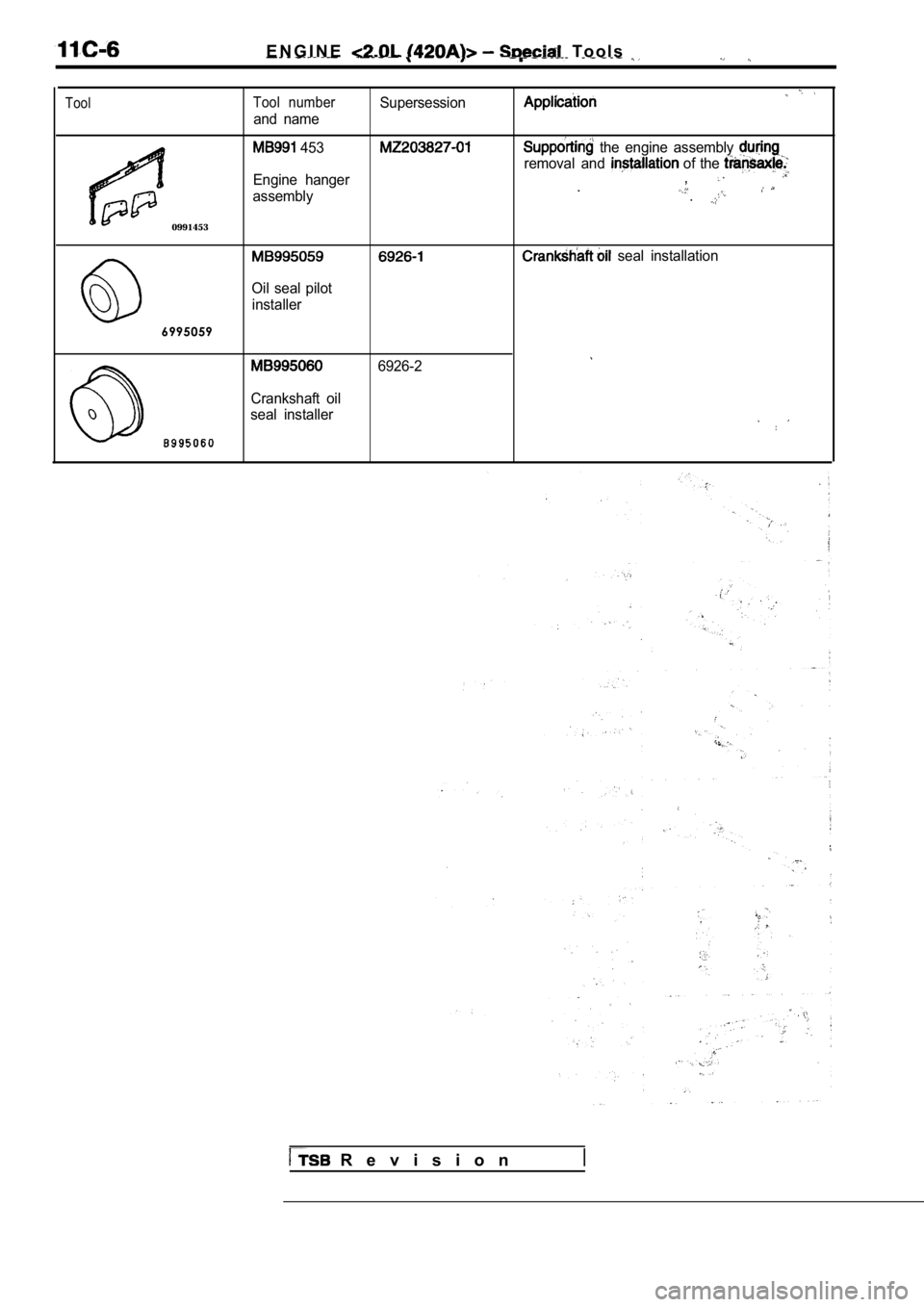

E N G I N E T o o l s

ToolTool numberSupersession

and name

0991453

453

Engine hanger

assembly the engine assembly

removal and of the ,..

seal installation

Oil seal pilot installer

6995059

6926-2

Crankshaft oil

seal installer

R e v i s i o n

Page 177 of 2103

ENGINE Troubleshooting,

TROUBLESHOOTING

Symptom Probable causeRemedy

Compression too low Cylinder head gasket blown Replace gasket

Piston ring worn or damaged Replace rings

Piston or cylinder worn Repair or replace piston

cylinder

block

Valve seat worn or damaged Repair or replace valve seat ring

Oil pressure drop Engine oil level too low Check engi ne oil level

Oil pressure switch faulty Replace oil pressure switch

Oil filter clogged

Install new filter

Oil pump gears or cover

Replace gears and/or cover

Thin or diluted engine oil Change engine correct

Oil relief valve stuck (open) Repair relief valve

Excessive bearing clearance Replace bearings

pressure too highOil relief valve stuck (closed) Repair relief valve

valves Incorrect lash adjuster Bleed air or replace lash adjuster

Thin or diluted engine oil (low oil pressure) Change engine oil

Valve stem or valve guide worn or damaged Replace va lve

guide

rod noise/lnsuff oil supplyCheck engine oil level

nain bearing noise Low oil pressure Refer

pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

belt noiseIncorrect belt tension

Adjust belt tension replace-timing

belt

engine rolling Loose engine roll stopper (Front, Re

ar)Retighten

vibration

Loose transaxle mount bracket Retighten

Loose engine mount bracket Retighten

Loose center member Retighten

Broken transaxle mount insulator

Replace

Broken engine mount insulatorReplace

Broken roll stopper insulatorReplace

TSB Revision

Page 179 of 2103

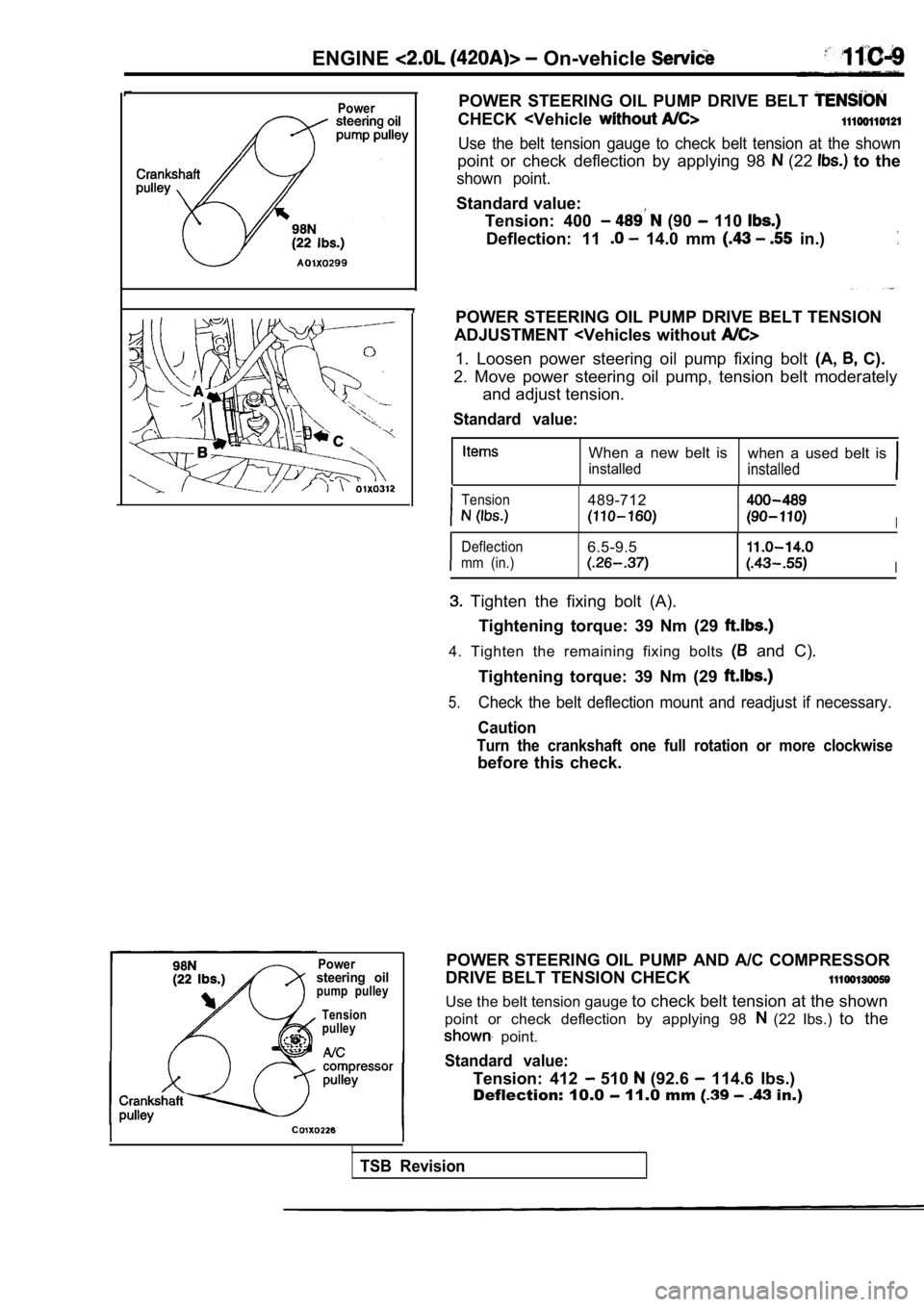

ENGINE On-vehicle

Power

Powersteering oilpump pulleyTension

pulley

POWER STEERING OIL PUMP DRIVE BELT

CHECK

point or check deflection by applying 98 (22 to the

shown point.

Standard value:

Tension: 400

(90 110

Deflection: 11 14.0 mm in.)

POWER STEERING OIL PUMP DRIVE BELT TENSION

ADJUSTMENT

2. Move power steering oil pump, tension belt moder ately

and adjust tension.

Standard value:

When a new belt is when a used belt is

installedinstalled

Tension489-712

I

Deflection6.5-9.5

mm (in.)I

Tighten the fixing bolt (A).

Tightening torque: 39 Nm (29

4. Tighten the remaining fixing bolts and C).

Tightening torque: 39 Nm (29

5.Check the belt deflection mount and readjust if nec essary.

Caution

Turn the crankshaft one full rotation or more clock wise

before this check.

POWER STEERING OIL PUMP AND A/C COMPRESSOR

DRIVE BELT TENSION CHECK

Use the belt tension gauge to check belt tension at the shown

point or check deflection by applying 98

(22 Ibs.) to the

point.

Standard value:

Tension: 412 510 (92.6 114.6 Ibs.)

Deflection: 10.0

11.0 mm in.)

TSB Revision

Page 180 of 2103

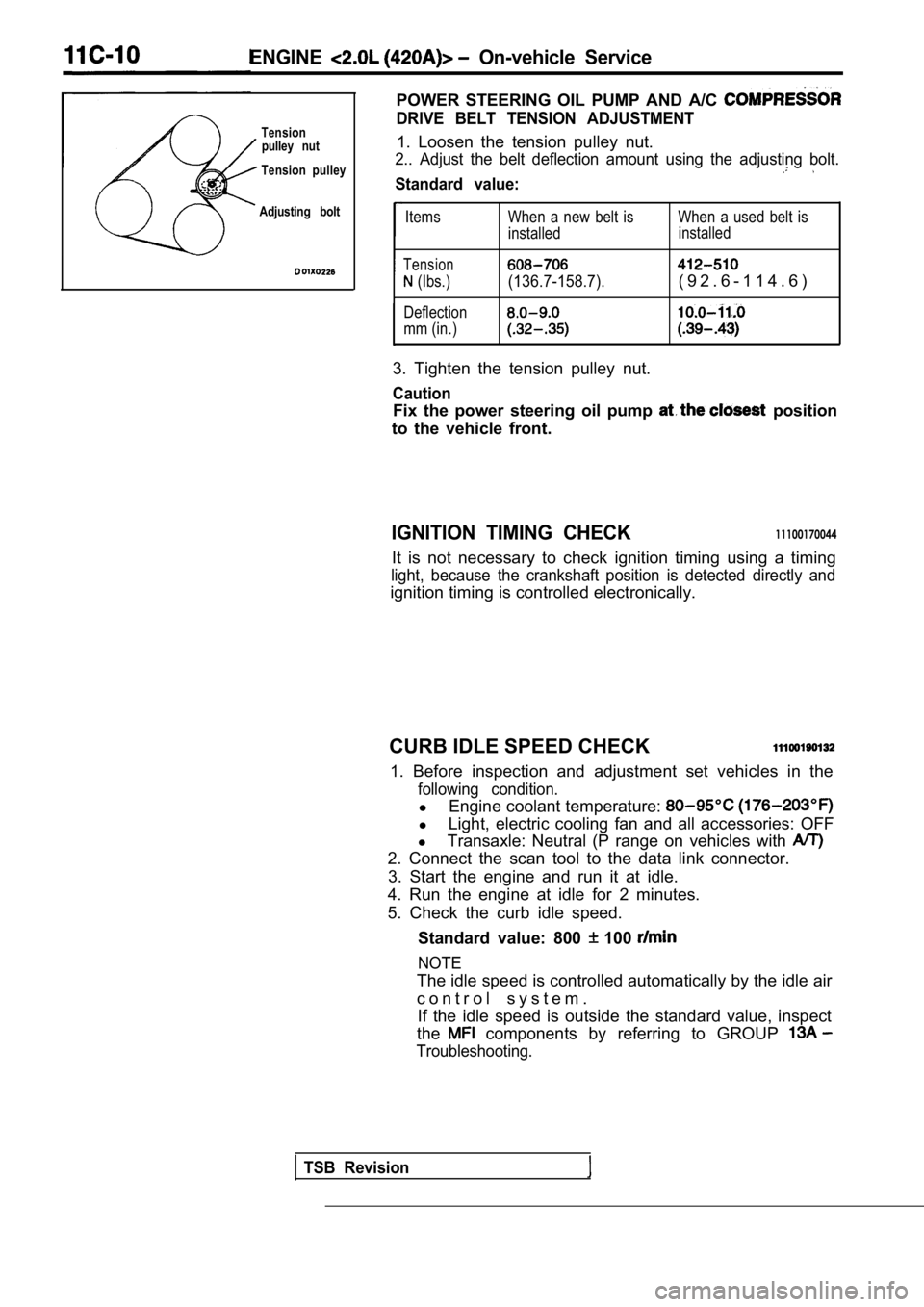

ENGINE On-vehicle Service

POWER STEERING OIL PUMP AND A/C

DRIVE BELT TENSION ADJUSTMENTTensionpulley nut1. Loosen the tension pulley nut.

Tension pulley2.. Adjust the belt deflection amount using the adj usting bolt.

Standard value:

Adjusting boltItems

Tension

(Ibs.)

Deflection

mm (in.) When a new belt is When a used belt is

installed

installed(136.7-158.7).( 9 2 . 6 - 1 1 4 . 6 )

3. Tighten the tension pulley nut.

Caution

Fix the power steering oil pump position

to the vehicle front.

IGNITION TIMING CHECK11100170044

It is not necessary to check ignition timing using a timing

light, because the crankshaft position is detected directly and

ignition timing is controlled electronically.

CURB IDLE SPEED CHECK

1. Before inspection and adjustment set vehicles in the

following condition.

lEngine coolant temperature:

lLight, electric cooling fan and all accessories: OF F

l Transaxle: Neutral (P range on vehicles with

2. Connect the scan tool to the data link connector .

3. Start the engine and run it at idle.

4. Run the engine at idle for 2 minutes.

5. Check the curb idle speed.

Standard value: 800

100

NOTE

The idle speed is controlled automatically by the i dle air

c o n t r o l s y s t e m . If the idle speed is outside the standard value, in spect

the

components by referring to GROUP

Troubleshooting.

TSB Revision

Page 181 of 2103

ENGINE On-vehicle Service

IDLE MIXTURE CHECK

11100210081

1.Before inspection, set vehicles in the following co ndition:

lEngine coolant temperature:

l Lights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2.After turning the ignition switch to OFF, connect t he scan

tool to the data link connector.

3.Start the engine and run it at 2,500 for 2 minutes.

4. Set the CO, HC tester.

5. Check the CO contents and the HC contents at idl e.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

6. If the idle speed is outside the standard value, check

the following items: l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the three-way catalyst whenever the CO and

HC contents do not remain inside the standard value .

(even though the result of the inspection is normal on

all items.)

COMPRESSION PRESSURE CHECK

1.Before inspection, check that the engine oil, start er and

battery are normal. Also, set the vehicle to the fo llowing

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicle with

2. Disconnect the spark plug cables.

3. Remove all spark plugs.

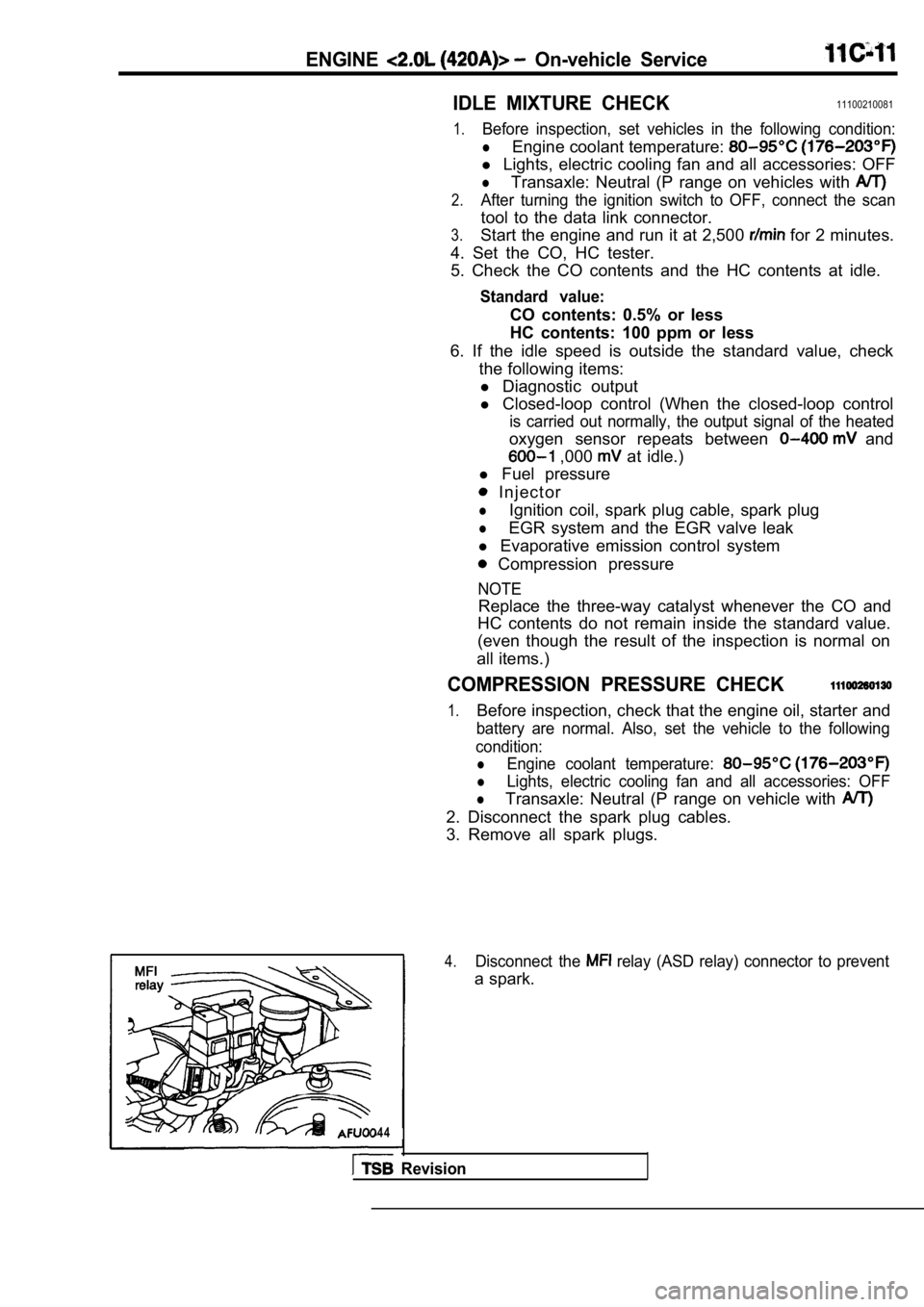

4.Disconnect the relay (ASD relay) connector to prevent

a spark.

4 4

Revision

Page 182 of 2103

E N G I N E On-vehicle Service’

5. Cover the spark plug hole with a shop towel etc. , and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

. Caution

1.Keep away from the spark plug hole when crank-

ing.

2. If compression is measured with water, oil, fuel ,

etc., that has come from cracks inside the cylinder ,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

6.Set compression gauge to one of the spark plug hole s.

7. Crank the engine with the throttle valve fully o pen and

measure the compression pressure.

Standard value (at engine speed of

p s i )

Limit (at engine speed of

min. 689 (100 psi)

8.Measure the compression pressure for all the cylind ers,

and check that the pressure differences of the cylinders

are below the limit.

Limit:

NOTE

The limit value can be derived by calculating the d ifference

between the maximum and minimum values for the

compression pressure and dividing this value by the

maximum value.

9.If there is a cylinder with compression or a compre ssion

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 7 and 8. (1) If the compression increases after oil is added , the

cause of the malfunction is a worn or damaged pisto n

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is a dded,

the cause is a burnt or defective valve seat, or pr essure

is leaking from the gasket.

10. Connect the

relay (ASD relay) connector.

11. Install the spark plug and spark plug cable.

12. Use the scan tool to erase the diagnostic troub le codes.

NOTE

This will erase the diagnostic trouble code resulti ng

the relay (ASD relay) being disconnected.

TSB Revision

Page 183 of 2103

ENGINE On-vehicle.’

M A N I F O L D V A C U U M

1.Before inspection, set vehicles. in the condition:

Engine coolant

lLights, electric cooling and

lTransaxle: Neutral (P

2. Connect the scan tool to the data link connector.

,

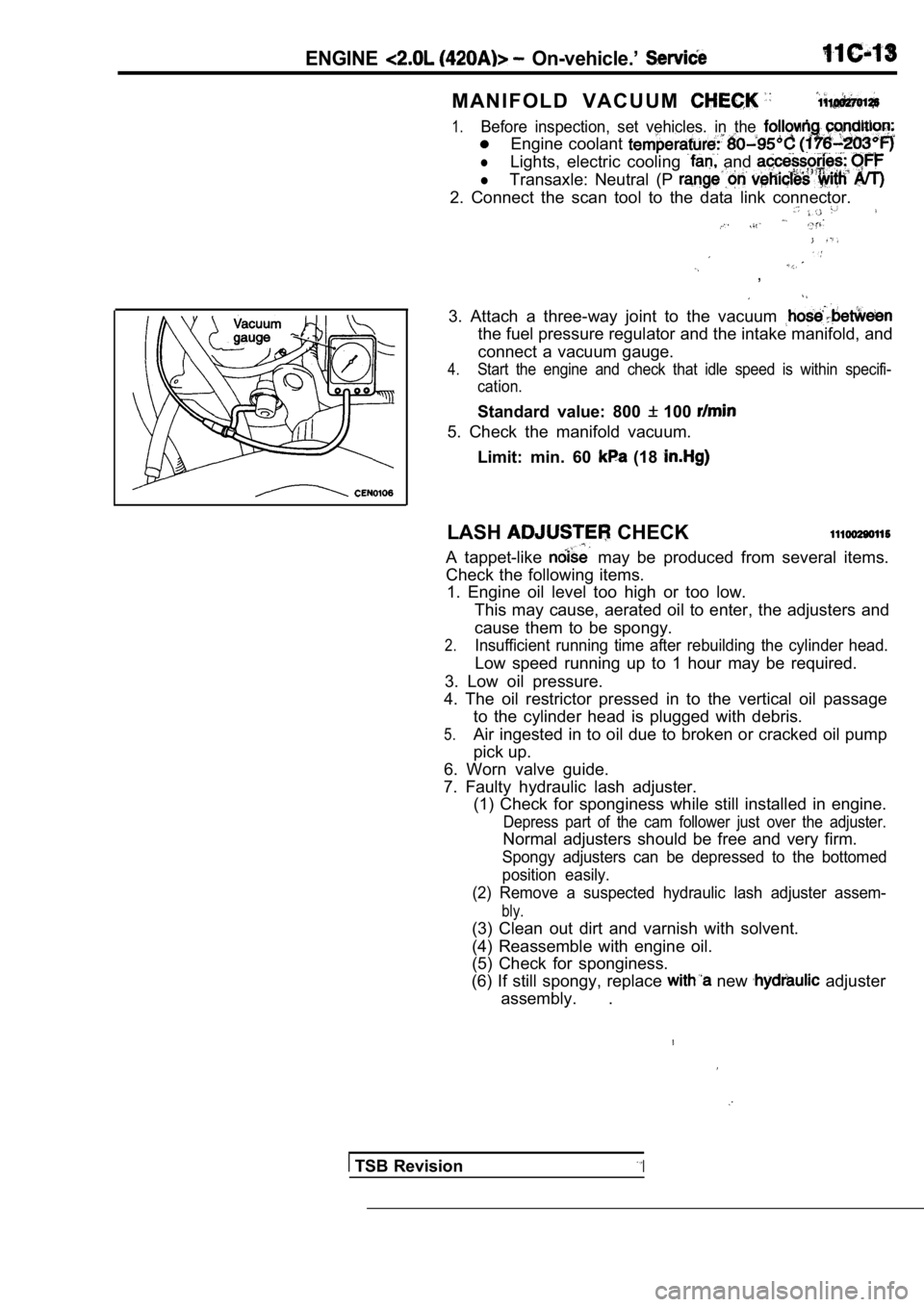

3. Attach a three-way joint to the vacuum

the fuel pressure regulator and the intake manifold, and

connect a vacuum gauge.

4.Start the engine and check that idle speed is withi n specifi-

cation.

Standard value: 800 100

5. Check the manifold vacuum.

Limit: min. 60

(18

LASH CHECK

A tappet-like may be produced from several items.

Check the following items. 1. Engine oil level too high or too low.

This may cause, aerated oil to enter, the adjusters and

cause them to be spongy.

2.Insufficient running time after rebuilding the cyli nder head.

Low speed running up to 1 hour may be required.

3. Low oil pressure.

4. The oil restrictor pressed in to the vertical oi l passage

to the cylinder head is plugged with debris.

5.Air ingested in to oil due to broken or cracked oil pump

pick up.

6. Worn valve guide.

7. Faulty hydraulic lash adjuster. (1) Check for sponginess while still installed in e ngine.

Depress part of the cam follower just over the adju ster.

Normal adjusters should be free and very firm.

Spongy adjusters can be depressed to the bottomed

position easily.

(2) Remove a suspected hydraulic lash adjuster asse m-

bly.

(3) Clean out dirt and varnish with solvent.

(4) Reassemble with engine oil.

(5) Check for sponginess.

(6) If still spongy, replace

new adjuster

assembly. .

TSB RevisionI

Page 184 of 2103

ENGINE Engine

ENGINE ASSEMBLY

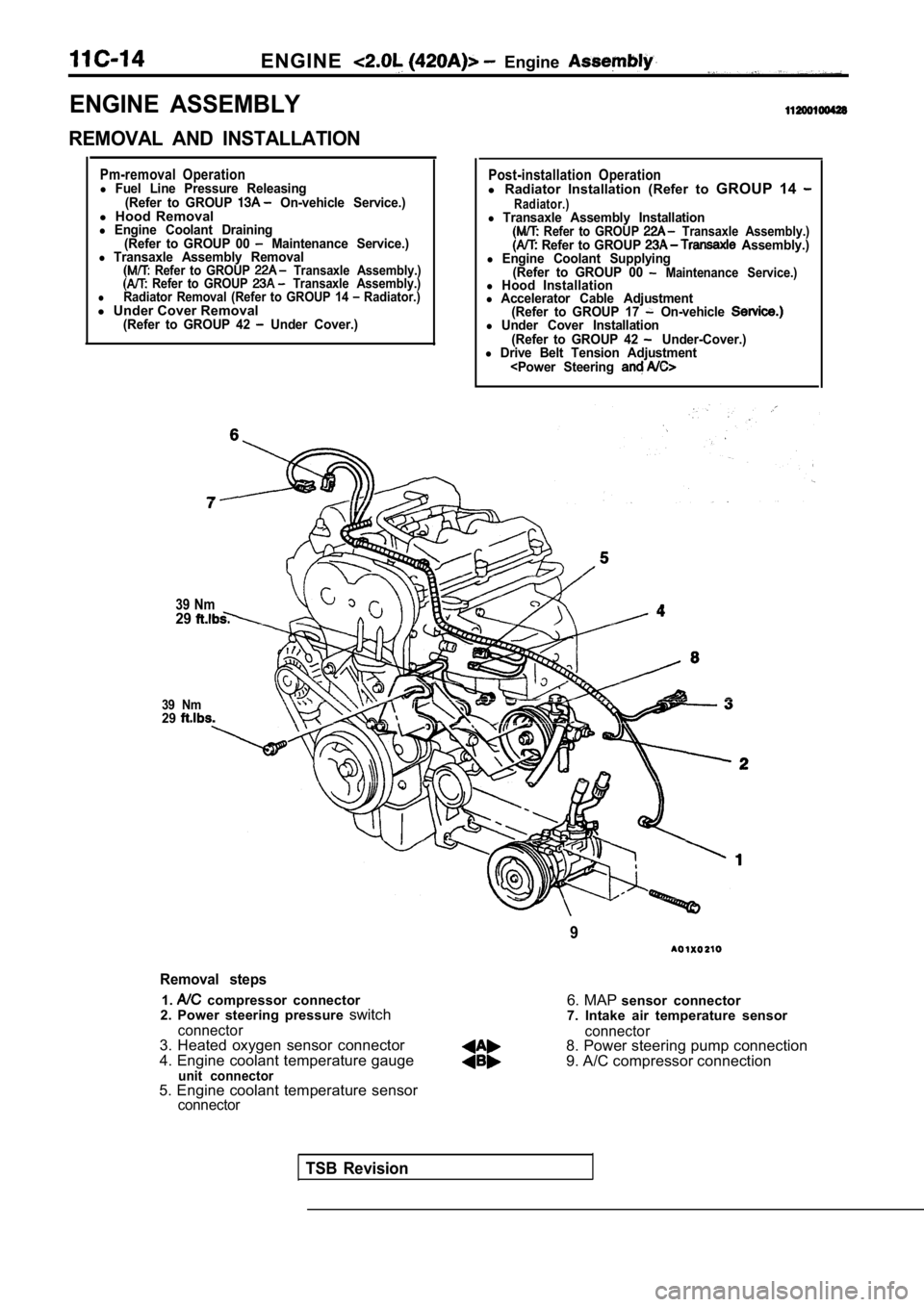

REMOVAL AND INSTALLATION

Pm-removal Operationl Fuel Line Pressure Releasing(Refer to GROUP On-vehicle Service.)l Hood Removall Engine Coolant Draining

(Refer to GROUP 00 Maintenance Service.)l Transaxle Assembly Removal Refer to GROUP Transaxle Assembly.) Refer to GROUP Transaxle Assembly.)lRadiator Removal (Refer to GROUP 14 Radiator.)l Under Cover Removal(Refer to GROUP 42 Under Cover.)

39 Nm29

39 Nm29

Post-installation Operationl Radiator Installation (Refer to GROUP 14 Radiator.)l Transaxle Assembly Installation Refer to GROUP Transaxle Assembly.) Refer to GROUP Assembly.)l Engine Coolant Supplying

(Refer to GROUP 00 Maintenance Service.)l Hood Installationl Accelerator Cable Adjustment(Refer to GROUP 17 On-vehicle l Under Cover Installation

(Refer to GROUP 42 Under-Cover.)l Drive Belt Tension Adjustment

Removal steps

1. compressor connector

2. Power steering pressure switch

connector3. Heated oxygen sensor connector

4. Engine coolant temperature gauge

unit connector

6. MAP sensor connector

7. Intake air temperature sensor

connector8. Power steering pump connection

9. A/C compressor connection

5. Engine coolant temperature sensor

connector

TSB Revision

Page 185 of 2103

ENGINE

Fuelrail

Engine oil

2.5 Nm

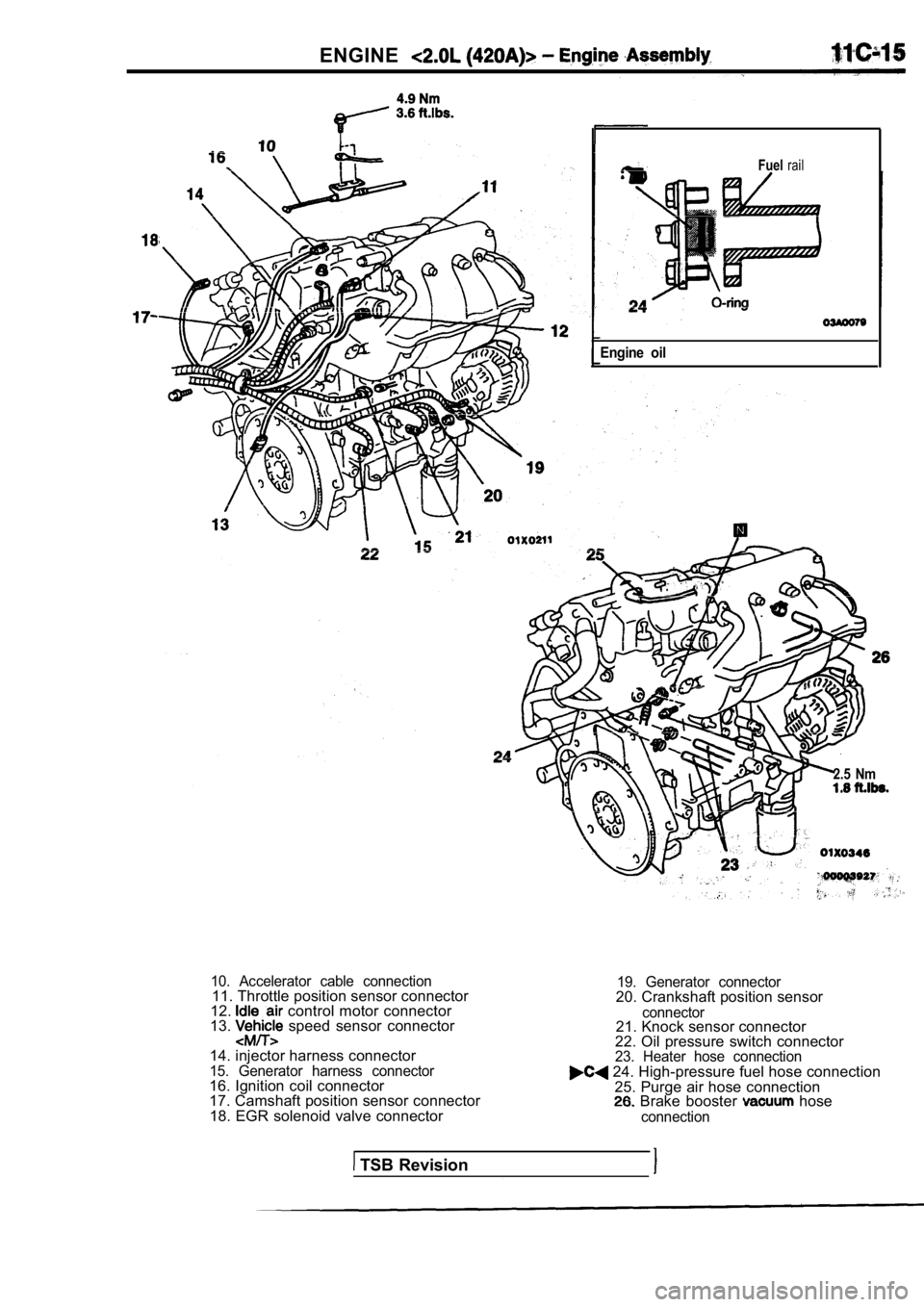

10. Accelerator cable connection11. Throttle position sensor connector

12. control motor connector

13. speed sensor connector

14. injector harness connector

15. Generator harness connector16. Ignition coil connector

17. Camshaft position sensor connector 18. EGR solenoid valve connector

19. Generator connector20. Crankshaft position sensor

connector21. Knock sensor connector

22. Oil pressure switch connector

23. Heater hose connection 24. High-pressure fuel hose connection

25. Purge air hose connection

Brake booster hose

connection

TSB Revision

Page 186 of 2103

E N G I N E ,

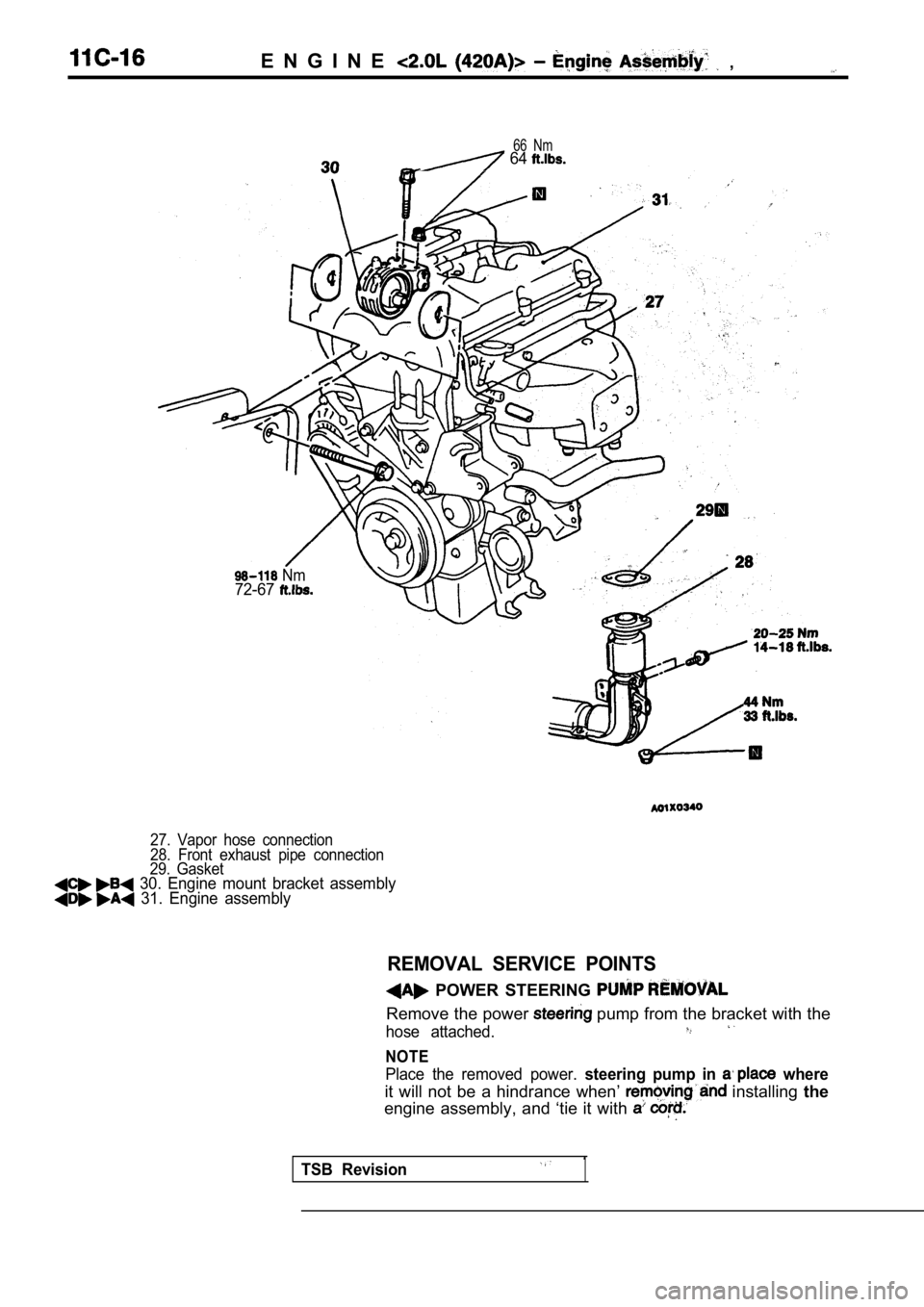

66 Nm 64

Nm72-67

27. Vapor hose connection

28. Front exhaust pipe connection

29. Gasket

30. Engine mount bracket assembly 31. Engine assembly

REMOVAL SERVICE POINTS

POWER STEERING

Remove the power pump from the bracket with the

hose attached.

NOTE

Place the removed power. steering pump in where

it will not be a hindrance when’ installing the

engine assembly, and ‘tie it with

TSB Revision1