light MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1835 of 2103

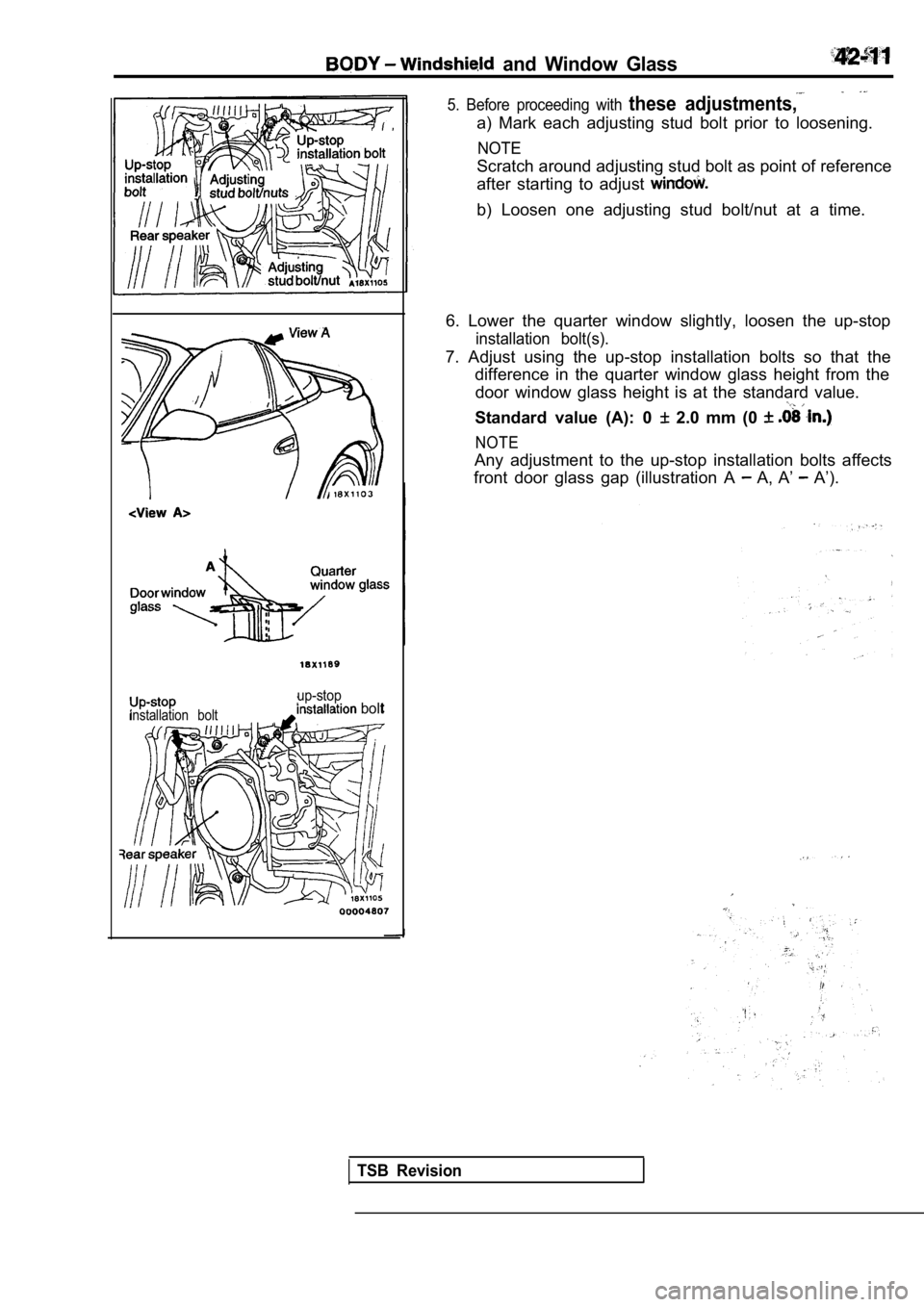

and Window Glass

installation bolt

up-stop bolt

5. Before proceeding with these adjustments,

a) Mark each adjusting stud bolt prior to loosening.

NOTE

Scratch around adjusting stud bolt as point of reference

after starting to adjust

b) Loosen one adjusting stud bolt/nut at a time.

6. Lower the quarter window slightly, loosen the up -stop

installation bolt(s).

7. Adjust using the up-stop installation bolts so that the

difference in the quarter window glass height from the

door window glass height is at the standard value.

Standard value (A): 0 2.0 mm (0

NOTE

Any adjustment to the up-stop installation bolts af fects

front door glass gap (illustration A

A, A’ A’).

TSB Revision

Page 1840 of 2103

BODY Windshield and Window Glass

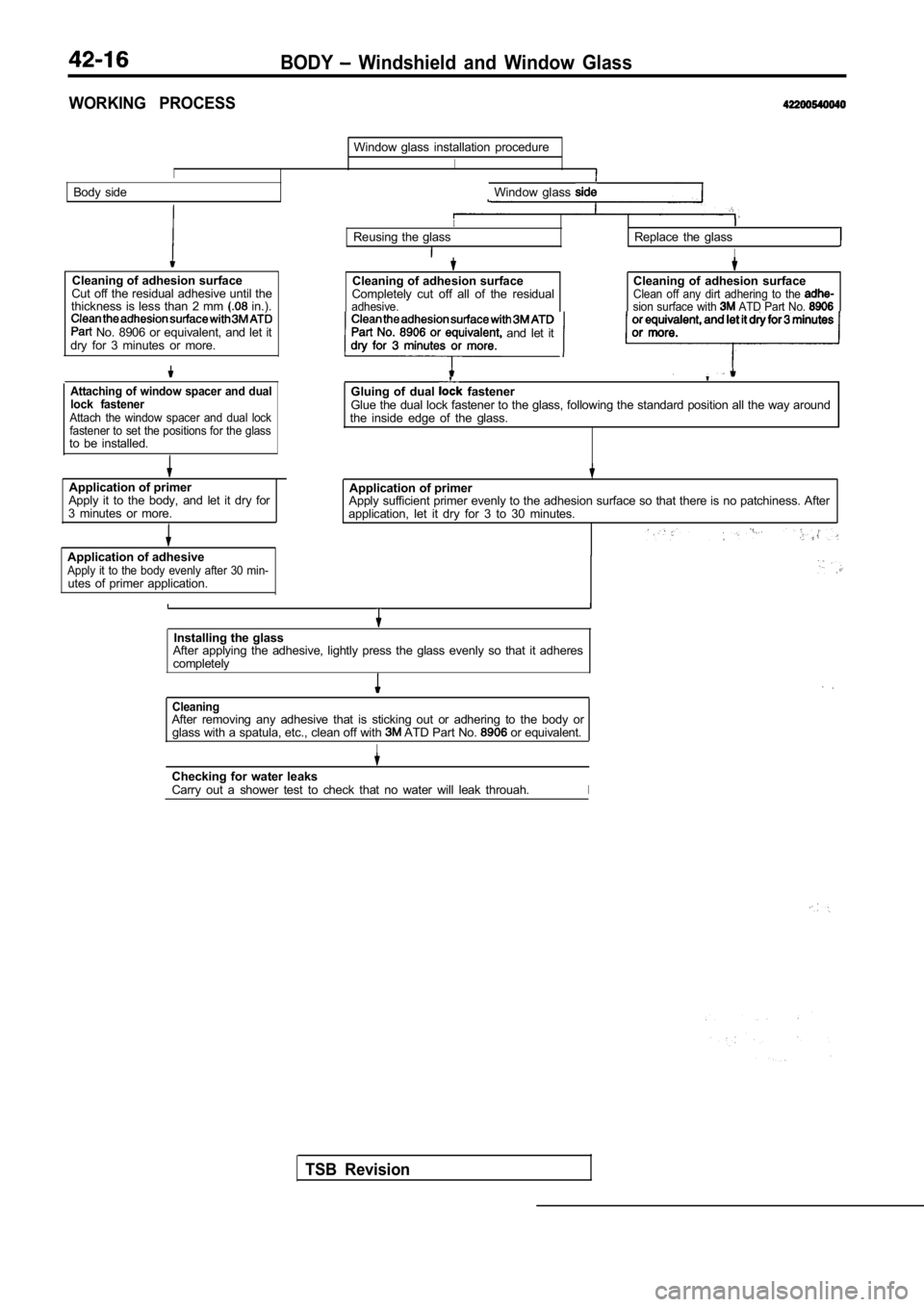

WORKING PROCESS

I

Window glass installation procedure

I

Body sideWindow glass

Cleaning of adhesion surface

Cut off the residual adhesive until the

thickness is less than 2 mm

in.).

No. 8906 or equivalent, and let it

dry for 3 minutes or more.

Attaching of window spacer and dual

lock fastener

Attach the window spacer and dual lock

fastener to set the positions for the glass

to be installed.

Application of primer Application of primer

Apply it to the body, and let it dry for

3 minutes or more. Apply sufficient primer evenly to the adhesion surf

ace so that there is no patchiness. After

application, let it dry for 3 to 30 minutes.

Application of adhesive

Apply it to the body evenly after 30 min-utes of primer application.

IReusing the glassReplace the glass

I

Cleaning of adhesion surface

Completely cut off all of the residual

adhesive.

Cleaning of adhesion surfaceClean off any dirt adhering to the sion surface with ATD Part No. or equivalent, and let it dry for 3 minutesPart No. 8906 or equivalent and let it

Gluing of dual fastenerGlue the dual lock fastener to the glass, following the standard position all the way around

the inside edge of the glass.

Installing the glass

After applying the adhesive, lightly press the glas s evenly so that it adheres

completely

TSB Revision

CleaningAfter removing any adhesive that is sticking out or adhering to the body or

glass with a spatula, etc., clean off with ATD Part No. or equivalent.

I

Checking for water leaks

Carry out a shower test to check that no water will leak throuah.I

Page 1845 of 2103

B O D Y and Window

(4) aligning

and evenly so that” it “adheres completely.

glass), place it somewhere where it will not disturbed,

Caution

If heat is applied with an infra-red light to shorten

the setting time, keep the surface temperature of t he

a d h e s i v e

(6) After attaching the windshield to the body, let it stand

far 30 minutes or more, then test for water leakage.

1. If moving the vehicle: should be done gently.

2.When testing for water do not pinch the

end of the to spray the water.

TSB Revision

Page 1853 of 2103

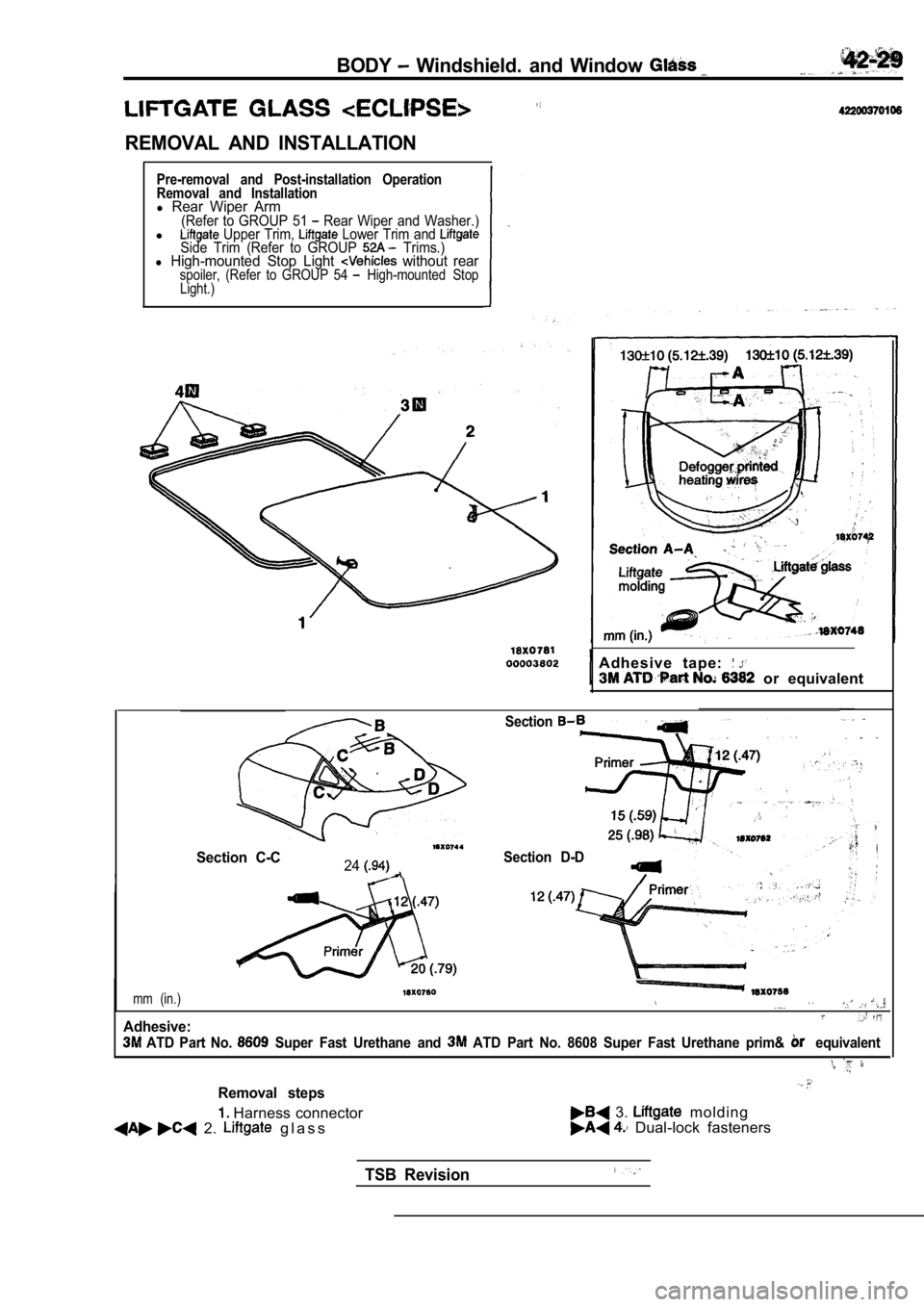

BODY Windshield. and Window

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Removal and Installation

l Rear Wiper Arm(Refer to GROUP 51 Rear Wiper and Washer.)l Upper Trim, Lower Trim and Side Trim (Refer to GROUP Trims.)l High-mounted Stop Light without rearspoiler, (Refer to GROUP 54 High-mounted Stop

Light.)

Adhesive tape:

or equivalent

Section C-C24

Section

Section D-D

mm (in.). .

Adhesive:

ATD Part No. Super Fast Urethane and ATD Part No. 8608 Super Fast Urethane prim& equivalent

Removal steps

Harness connector 3. m o l d i n g

2. g l a s s Dual-lock fasteners

TSB Revision

Page 1890 of 2103

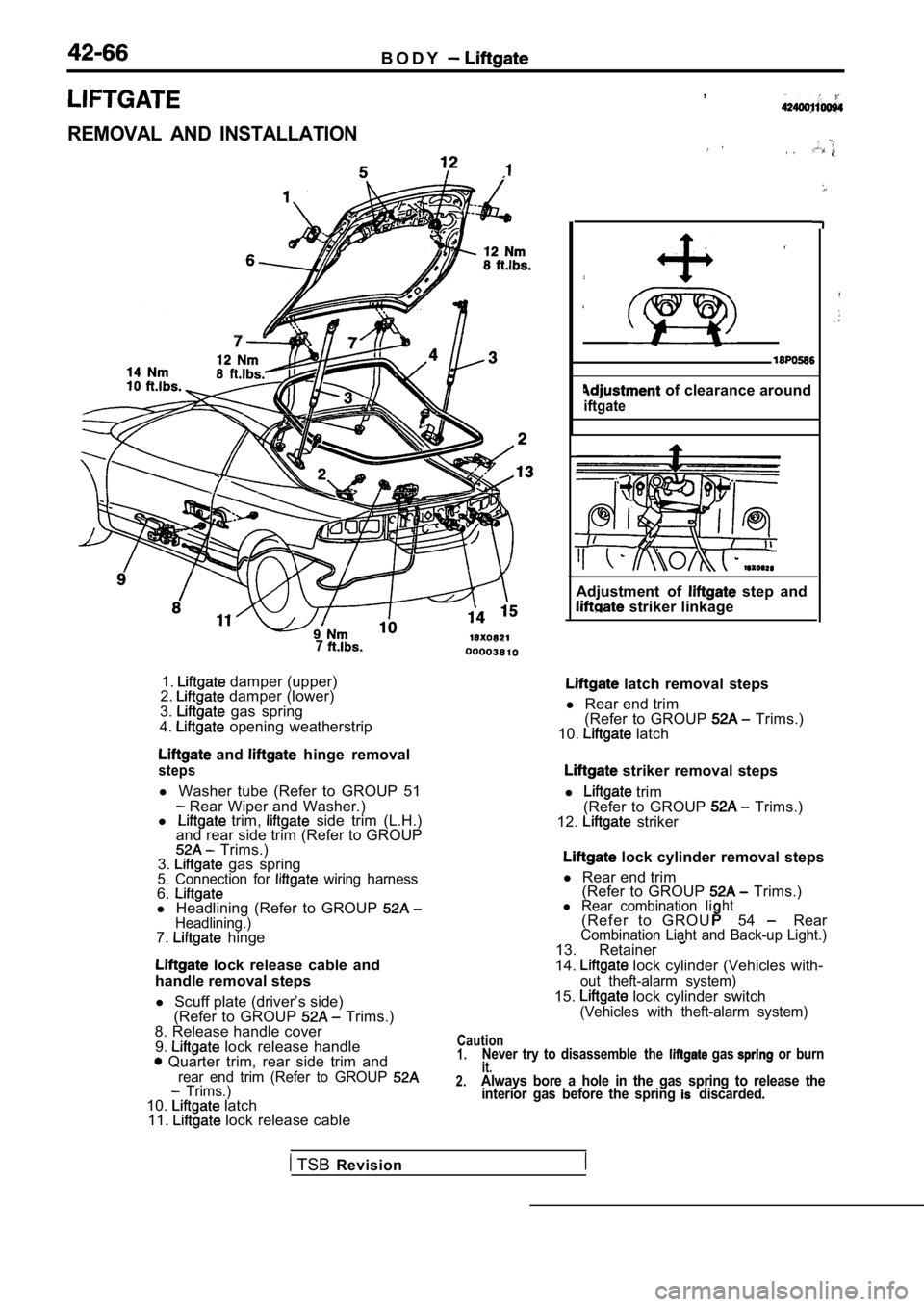

B O D Y

REMOVAL AND INSTALLATION

7

1. damper (upper)

2. damper (lower)

3. gas spring

4. opening weatherstrip

and hinge removal

steps

l Washer tube (Refer to GROUP 51 Rear Wiper and Washer.)

l trim, side trim (L.H.)

and rear side trim (Refer to GROUP

Trims.)

3. gas spring5. Connection for wiring harness6.l Headlining (Refer to GROUP Headlining.)7. hinge

lock release cable and

handle removal steps

l Scuff plate (driver’s side)

(Refer to GROUP

Trims.)

8. Release handle cover

9.

lock release handle Quarter trim, rear side trim andrear end trim (Refer to GROUP Trims.)10. latch

11. lock release cable ,

, ,

of clearance around

iftgate

Adjustment of step and striker linkage

latch removal steps

l Rear end trim

(Refer to GROUP

Trims.)

10. latch

striker removal steps

l

trim

(Refer to GROUP Trims.)

12. striker

lock cylinder removal steps

l Rear end trim

(Refer to GROUP

Trims.)l Rear combination Iiht( R e f e r t o G R O U54 RearCombination Liaht and Back-up Light.)13. Retainer

14. lock cylinder (Vehicles with-out theft-alarm system)

15. lock cylinder switch(Vehicles with theft-alarm system)

Caution1.Never try to disassemble the gas or burnit.2.Always bore a hole in the gas spring to release the interior gas before the spring discarded.

TSB Revision

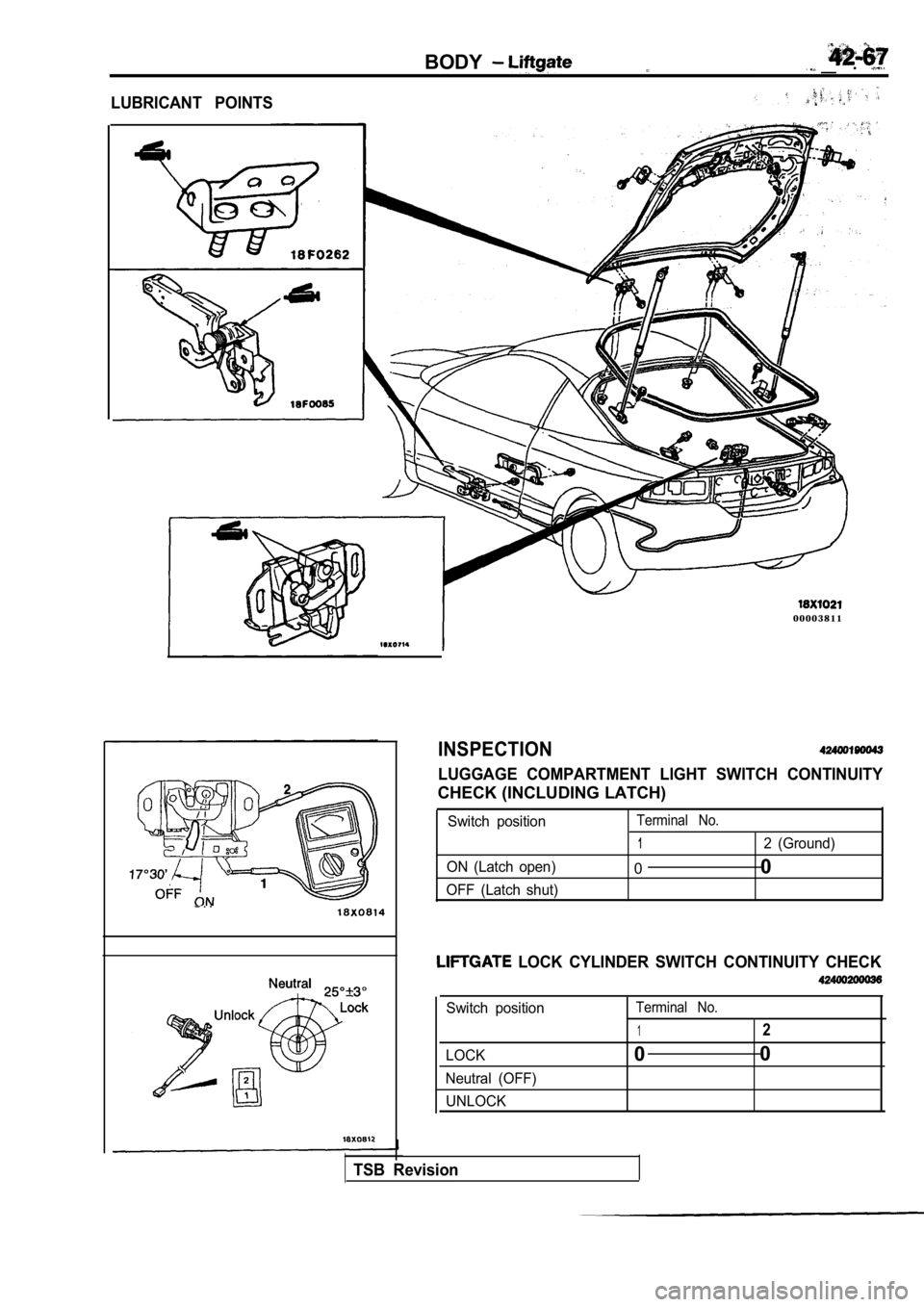

Page 1891 of 2103

BODY __.

LUBRICANT POINTS

0 0 0 0 3 8 1 1

INSPECTION

LUGGAGE COMPARTMENT LIGHT SWITCH CONTINUITY

CHECK (INCLUDING LATCH)

Switch positionTerminal No.

12 (Ground)

ON (Latch open)

0 0

OFF (Latch shut)

LOCK CYLINDER SWITCH CONTINUITY CHECK

Switch positionTerminal No.

12

LOCK00

Neutral (OFF)

UNLOCK

TSB Revision

Page 1896 of 2103

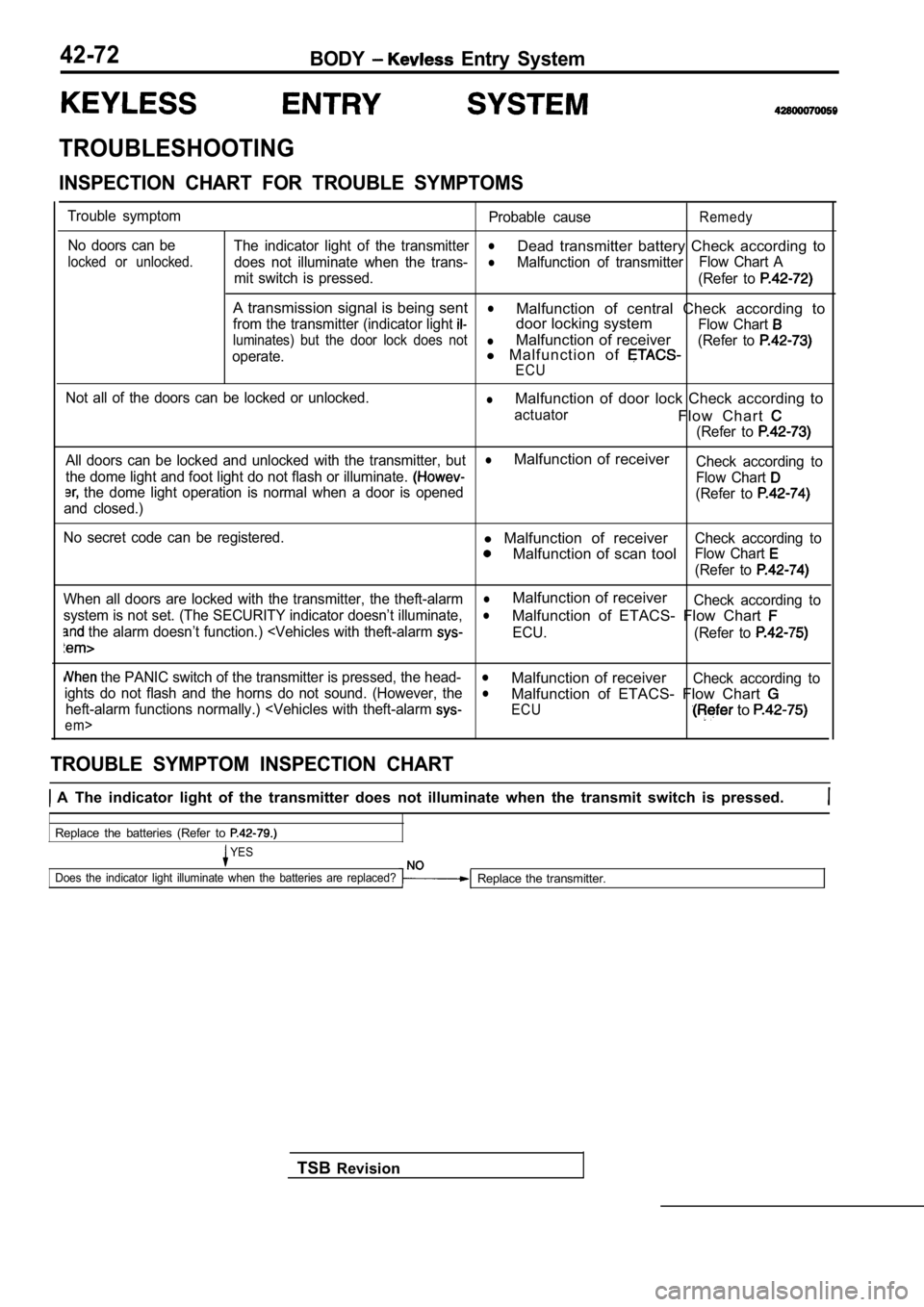

42-72BODY Entry System

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomNo doors can be

locked or unlocked.

Probable causeRemedy

The indicator light of the transmitterl

does not illuminate when the trans-

Dead transmitter battery Check according to

lMalfunction of transmitter Flow Chart A

mit switch is pressed. (Refer to

A transmission signal is being sentl

from the transmitter (indicator light Malfunction of central Check according to

door locking system

Flow Chart

luminates) but the door lock does notlMalfunction of receiver

operate.l M a l f u n c t i o n o f (Refer to

ECU

Not all of the doors can be locked or unlocked.lMalfunction of door lock Check according to

actuatorF l o w C h a r t

(Refer to

All doors can be locked and unlocked with the trans mitter, butlMalfunction of receiver

the dome light and foot light do not flash or illuminate. Check according to

the dome light operation is normal when a door is openedFlow Chart

and closed.) (Refer to

No secret code can be registered.l

Malfunction of receiver

Malfunction of scan tool

Check according to

Flow Chart

(Refer to

When all doors are locked with the transmitter, the theft-alarmlMalfunction of receiver

system is not set. (The SECURITY indicator doesn’t illuminate,Check according tol

the alarm doesn’t function.)

Malfunction of ETACS- Flow Chart

ECU.

(Refer to

the PANIC switch of the transmitter is pressed, th e head-lMalfunction of receiverights do not flash and the horns do not sound. (How ever, theCheck according tol

heft-alarm functions normally.)

em>

Malfunction of ETACS- Flow Chart

ECU to

TROUBLE SYMPTOM INSPECTION CHART

A The indicator light of the transmitter does not illuminate when the transmit switch is pressed.

Replace the batteries (Refer to

YES

Does the indicator light illuminate when the batter ies are replaced?

Replace the transmitter.

TSB Revision

Page 1898 of 2103

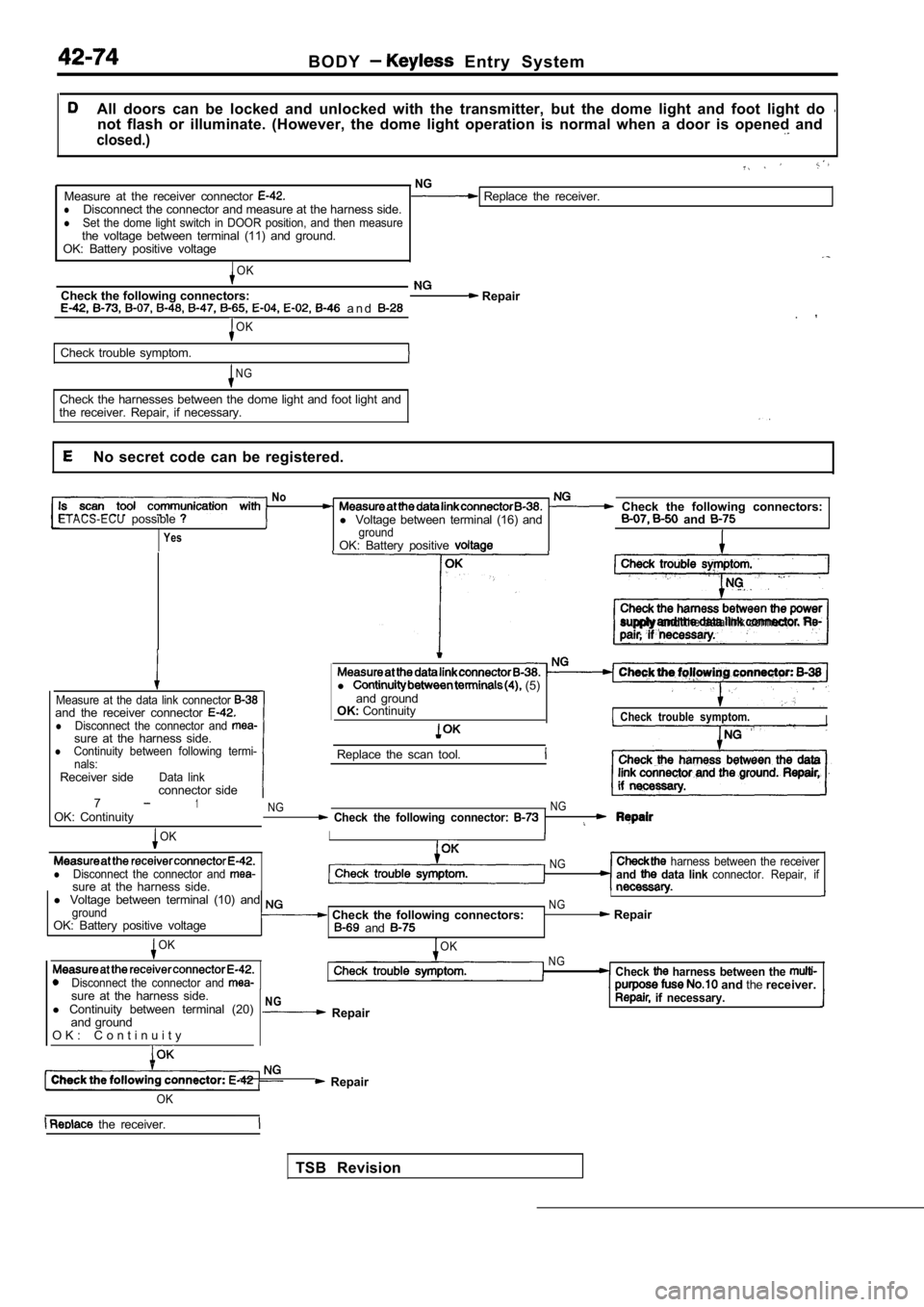

B O D Y Entry System

All doors can be locked and unlocked with the transmitter, but the dome light and foot light do not flash or illuminate. (However, the dome light operation is normal when a door is opened and

closed.)

NGMeasure at the receiver connector Replace the receiver.lDisconnect the connector and measure at the harness side.lSet the dome light switch in DOOR position, and then measurethe voltage between terminal (11) and ground.

OK: Battery positive voltage

OK

Check the following connectors: Repair a n d .OK

Check trouble symptom.

N G

Check the harnesses between the dome light and foot light and

the receiver. Repair, if necessary.

No secret code can be registered.

NoCheck the following connectors:ETACS-ECUpossiblel Voltage between terminal (16) and and

YesgroundOK: Battery positive

supply and the data link connector.

Measure at the data link connector and the receiver connector lDisconnect the connector and sure at the harness side.lContinuity between following termi-

nals:

Receiver sideData linkconnector side

l (5)

and ground

OK: Continuity

Check trouble symptom.I

Replace the scan tool.

71OK: ContinuityNG NG Check the following connector:

OKI

lDisconnect the connector and sure at the harness side.

NG harness between the receiverand data link connector. Repair, if

l

Voltage between terminal (10) and I

groundNG

OK: Battery positive voltage Check the following connectors: Repair and

OK

Disconnect the connector and

OKNGCheck harness between the and thereceiver.

sure at the harness side.

l Continuity between terminal (20)

and ground

O K : C o n t i n u i t y

NG Repair if necessary.

Repair

TSB Revision

OK

the receiver.

Page 1899 of 2103

B O D Y Entry System

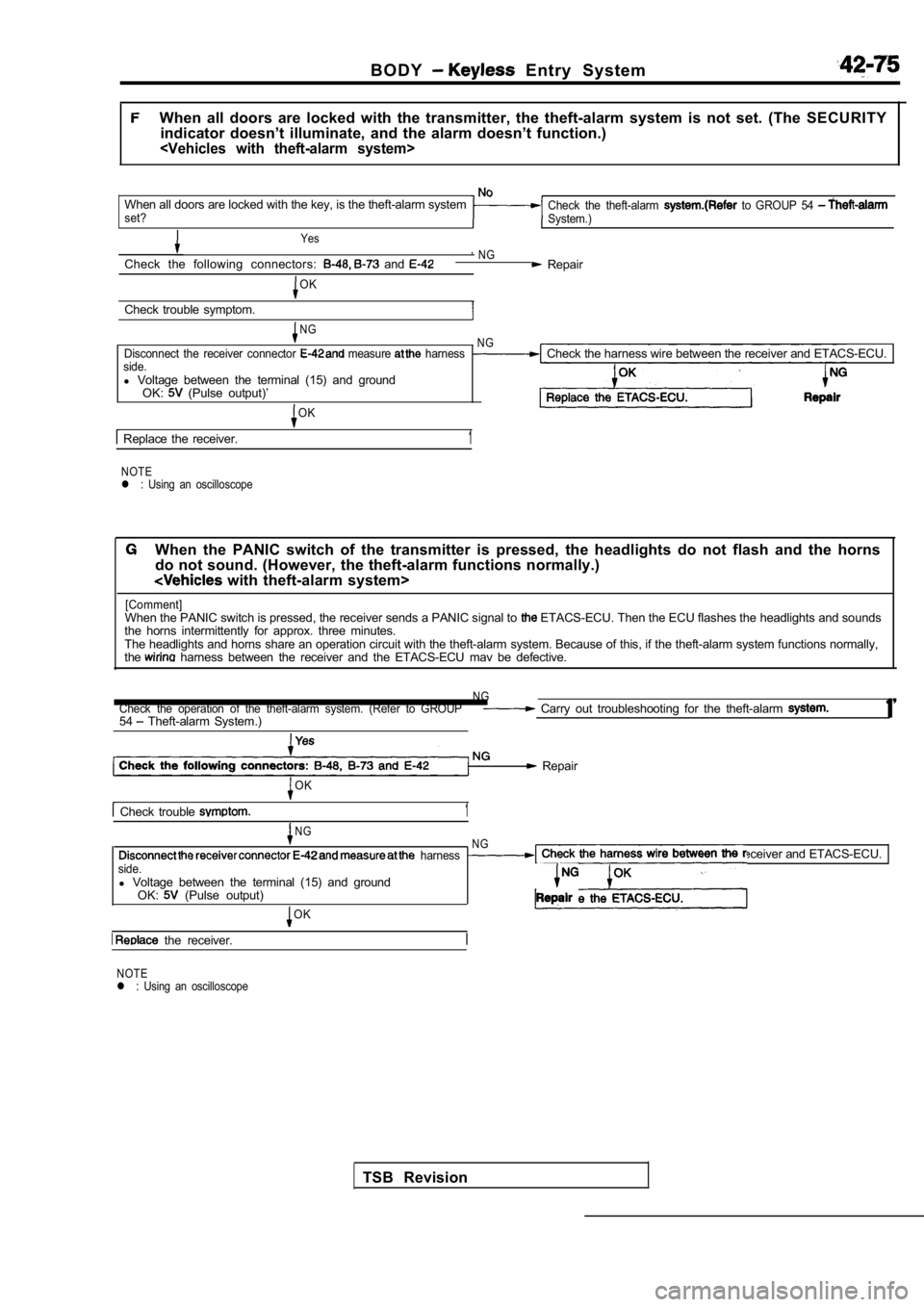

When all doors are locked with the transmitter, the theft-alarm system is not set. (The SECURITY

indicator doesn’t illuminate, and the alarm doesn’t function.)

When all doors are locked with the key, is the theft-alarm systemCheck the theft-alarm to GROUP 54 set?

System.)

Yes ,

Check the following connectors: and NG Repair

OK

Check trouble symptom.

NG NG

Disconnect the receiver connector measure harnessCheck the harness wire between the receiver and ETA CS-ECU.side.l Voltage between the terminal (15) and ground

OK: (Pulse output)’

OK

Replace the receiver.1

NOTEl : Using an oscilloscope

When the PANIC switch of the transmitter is pressed , the headlights do not flash and the horns

do not sound. (However, the theft-alarm functions n ormally.)

with theft-alarm system>

[Comment]When the PANIC switch is pressed, the receiver sends a PANIC signal to ETACS-ECU. Then the ECU flashes the headlights and sounds

the horns intermittently for approx. three minutes.

The headlights and horns share an operation circuit with the theft-alarm system. Because of this, if the theft-alarm system functions normally,

the

harness between the receiver and the ETACS-ECU mav be defective.

N GCheck the operation of the theft-alarm system. (Refer to GROUP Carry out troubleshooting for the theft-alarm 54 Theft-alarm System.) 1’

Repair

OK

Check trouble 1

NG

harness

side.

l Voltage between the terminal (15) and ground

OK: (Pulse output)

OK

the receiver.

N GCheck the harness wire between the receiver and ETA CS-ECU.

NOTEl : Using an oscilloscope

TSB Revision

Page 1900 of 2103

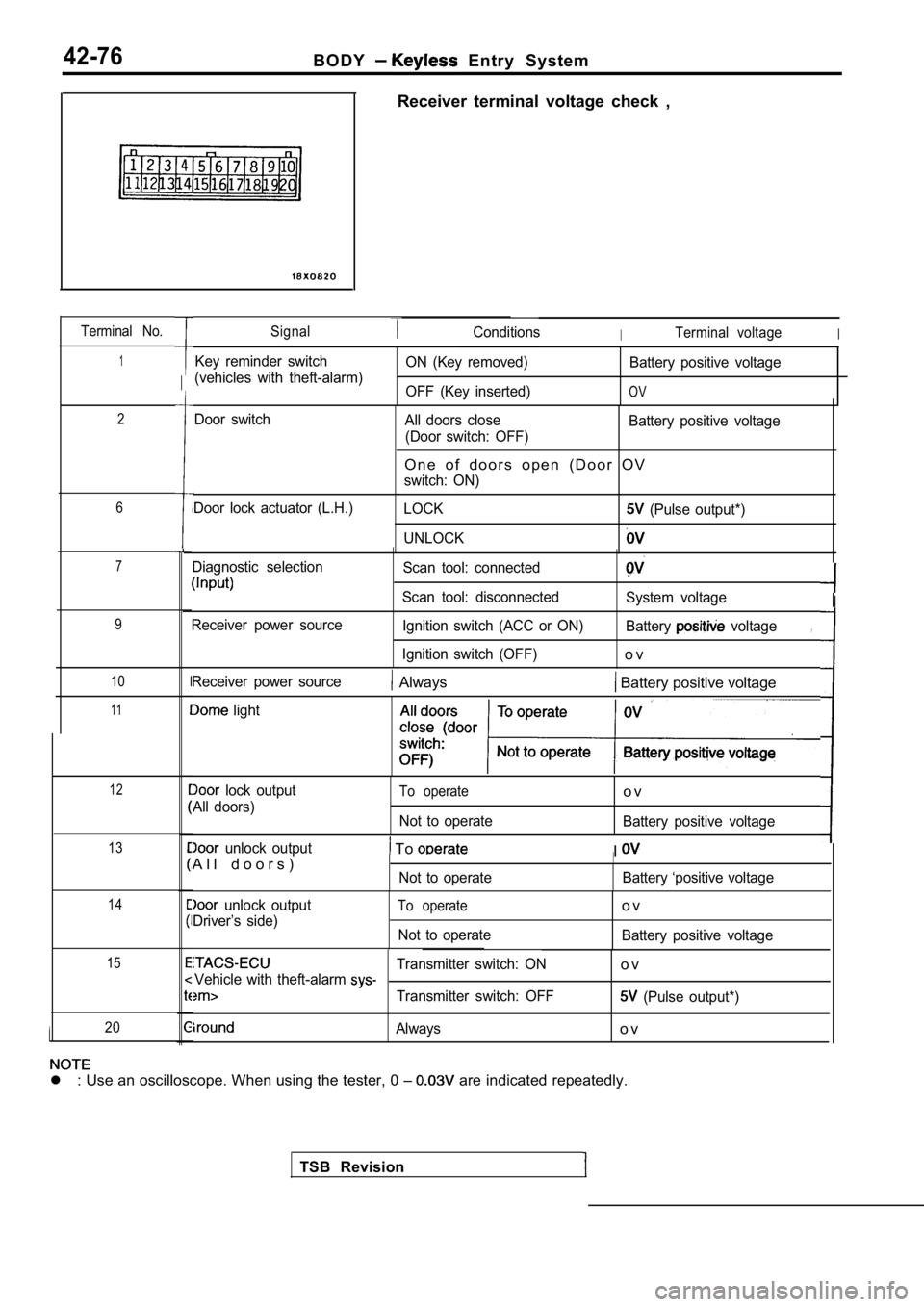

42-76B O D Y Entry System

Terminal No.

1

2

6

7

9

10

11

12

13

14

15

20

Receiver terminal voltage check ,

SignalConditionsITerminal voltageI

Key reminder switch

(vehicles with theft-alarm) ON (Key removed)

OFF (Key inserted) Battery positive voltage

OV

Door switch

Door lock actuator (L.H.) All doors close

(Door switch: OFF) Battery positive voltage

O n e o f d o o r s o p e n ( D o o r O V

switch: ON)

LOCK

(Pulse output*)

UNLOCK

Diagnostic selection

Receiver power source Scan tool: connected

Scan tool: disconnected Ignition switch (ACC or ON)

Ignition switch (OFF)

System voltage

Battery

voltage

o v

,

TSB Revision

Receiver power source Always Battery positive voltage

light

lock output

All doors)To operate

Not to operate

o v

Battery positive voltage

unlock output

A l l d o o r s ) To

Not to operate

II

Battery ‘positive voltage

unlock output

Driver’s side)To operate

Not to operate

o v

Battery positive voltage

Transmitter switch: ONo vVehicle with theft-alarm

Transmitter switch: OFF (Pulse output*)

Alwayso v

l : Use an oscilloscope. When using the tester, 0

are indicated repeatedly.

I