turn signal MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 181 of 2103

ENGINE On-vehicle Service

IDLE MIXTURE CHECK

11100210081

1.Before inspection, set vehicles in the following co ndition:

lEngine coolant temperature:

l Lights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2.After turning the ignition switch to OFF, connect t he scan

tool to the data link connector.

3.Start the engine and run it at 2,500 for 2 minutes.

4. Set the CO, HC tester.

5. Check the CO contents and the HC contents at idl e.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

6. If the idle speed is outside the standard value, check

the following items: l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the three-way catalyst whenever the CO and

HC contents do not remain inside the standard value .

(even though the result of the inspection is normal on

all items.)

COMPRESSION PRESSURE CHECK

1.Before inspection, check that the engine oil, start er and

battery are normal. Also, set the vehicle to the fo llowing

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicle with

2. Disconnect the spark plug cables.

3. Remove all spark plugs.

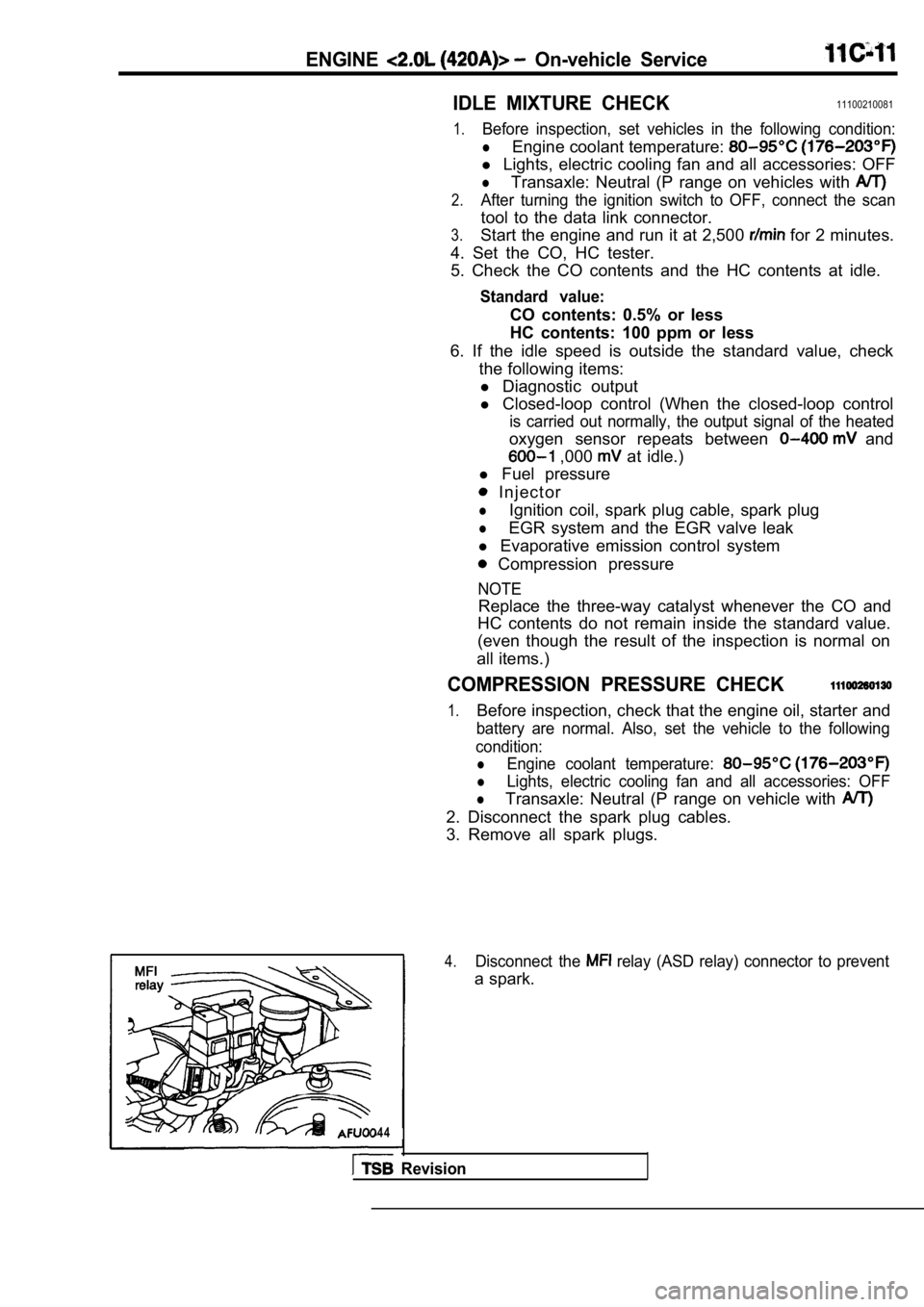

4.Disconnect the relay (ASD relay) connector to prevent

a spark.

4 4

Revision

Page 383 of 2103

ENGINE (NON-TURBO)> General

FUEL INJECTION

ENGINE (NON-TURBO)>

GENERAL INFORMATION

The Fuel Injection System consists

of sensors which detect the engine conditions,

the POWERTRAIN CONTROL MODULE(PCM) which controls the system based on

signals from these sensors, and actuators

which operate under the control of the PCM.

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation condi-

tions.

A single injector is mounted at the intake port

of each cylinder. Fuel is sent under pressure

from the fuel tank by the fuel pump, with the

pressure regulated by the fuel pressureregulator. The regulated fuel is distributed

to each of the injectors. Fuel injection is normally carried out once for

each cylinder for every two rotations of the

crankshaft. The firing order is

This

IDLE AIR CONTROL The idle speed’ is kept at the optimum speed

by controlling the amount of air that bypasses

the throttle valve in accordance with changes in idling conditions and engine load during

idling.

The PCM drives the idle air control (IAC) motor

to keep the engine running at the idle

target speed in accordance with the engine

IGNITION TIMING CONTROL

The ignition power transistor is built into the

PCM. It turns the ignition primary circuit on

and off to respectively supply and cut off primary

current flow to the ignition coil. The PCM carries

activities such fuel

injection control, idle air control and ignition

timing control.

In addition, the

diagnostict e s twhich simplify

troubleshooting when a problem develops.

is called The PCM

air/fuel mixture by carrying out “open-loop”

control when the engine is cold or operating

under high load conditions in to maintain

engine performance.

In addition, when the engine warm or

operating under normal

the PCM

controls the air/fuel mixture by using the heated

oxygen sensor signal to carry out “closed-loop”

control in order to obtain the theoretical air/fuel

mixture ratio that provides the maximum

cleaning

from the three way

catalyst.

coolant temperature and air conditioning load.

In addition, when the air conditioning switch

is turned off and on while the engine is idling,

the

motor operates to adjust the throttle

valve bypass air amount in accordance with

the engine load conditions in order to avoid

fluctuations in the engine speed.

This controls the ignition timing in order to

provide the optimum ignition timing with respect

to the engine operating conditions. The ignition

timing is determined by the PCM from the

engine speed, intake air volume, engine coolant

temperature and atmospheric pressure.

TSB Revision

Page 384 of 2103

ENGINE (NON-TURBO)>

DIAGNOSTIC TEST MODE

l When an abnormality is detected in one

of the sensors or actuators related to

emission control, the CHECK

MALFUNCTION INDICATOR LAMP

nates as a warning to the driver.

l When an abnormality is detected in one

of the sensors or actuators, a diagnostic

OTHER CONTROL FUNCTIONS

t r o u b l e c o d e

a b n o r m a l i t y i s o u t p u t .

lThe RAM data inside the PCM that is

to the sensors and

by means of the scan tool.

In addition, the actuators can be controlled

under certain circumstances. . ,

1. Fuel Pump Control

Turns the fuel pump relay ON so that current

is supplied to the fuel pump while the engine

is cranking or running.

2. A/C Compressor Clutch Relay Control Turns the A/C compressor clutch ON and

OFF.

3. Fan Relay Control

The radiator fan and condenser fan speeds

are controlled in response to the engine

coolant temperature and vehicle speed. 4. Generator

Controls the generator in order

to control the generated current.

5. Engine Speedometer or Tachometer

Control.

Sends a pulse signal which ‘corresponds

to the engine speed to the’ speedometer

unit..

6. Evaporative Emission Purge

C o n t r o l

Refer to GROUP 17.

7. Electric EGR Transducer Solenoid Control Refer to GROUP 17.

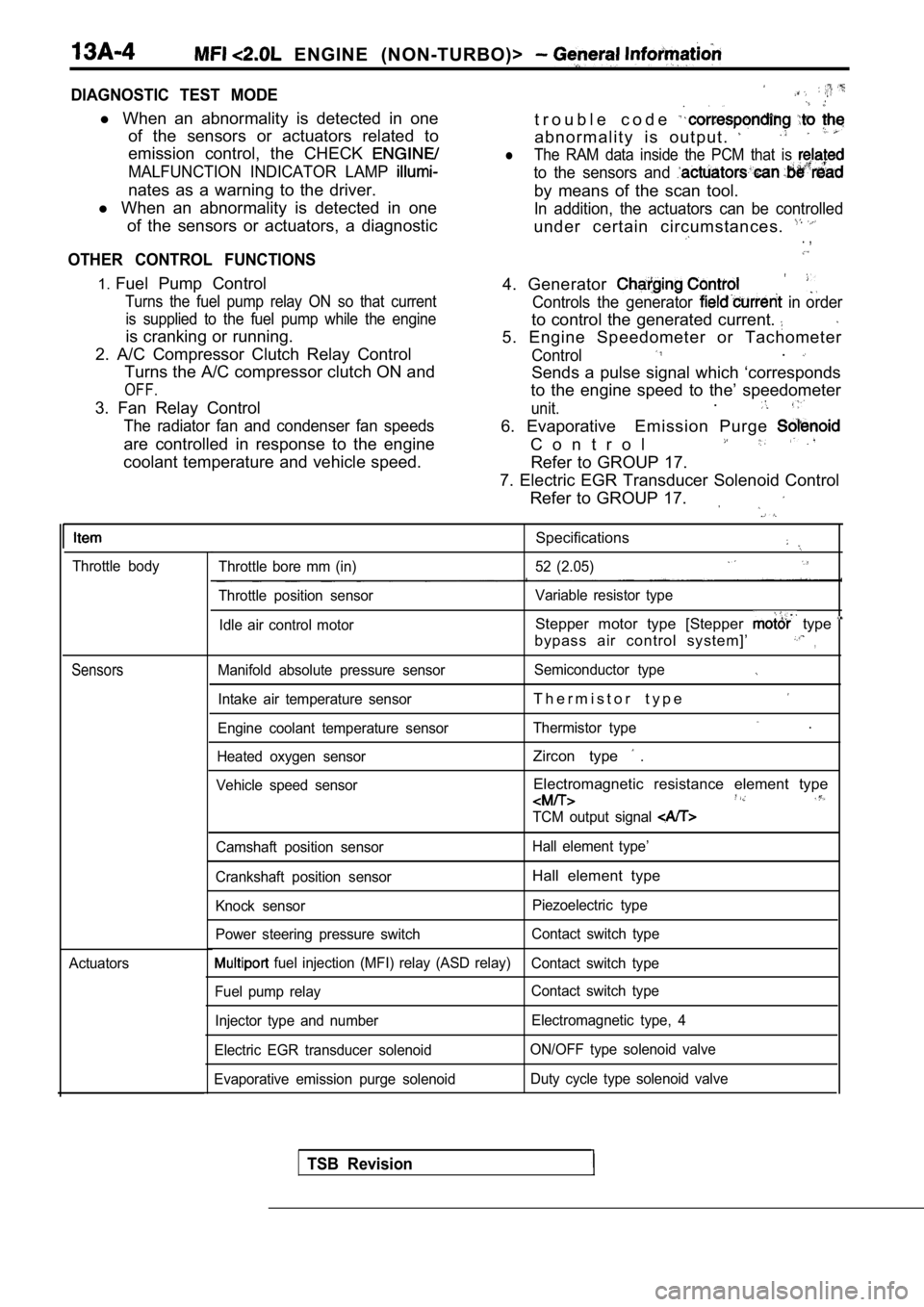

Throttle body

Sensors

Actuators

Specifications

Throttle bore mm (in) 52 (2.05)

Throttle position sensor Variable resistor type

Idle air control motor

Stepper motor type [Stepper type

bypass air control system]’,

Manifold absolute pressure sensor Semiconductor type

Intake air temperature sensorT h e r m i s t o r t y p e

Engine coolant temperature sensorThermistor type .

Heated oxygen sensorZircon type .

Vehicle speed sensorElectromagnetic resistance element type

TCM output signal

Camshaft position sensor Hall element type’

Crankshaft position sensor

Hall element type

Knock sensor Piezoelectric type

Power steering pressure switch Contact switch type

fuel injection (MFI) relay (ASD relay)

Contact switch type

Fuel pump relay Contact switch type

Injector type and number Electromagnetic type, 4

Electric EGR transducer solenoid ON/OFF type solenoid valve

Evaporative emission purge solenoid Duty cycle type solenoid valve

TSB Revision

Page 396 of 2103

ENGINE (NON-TURBO)> Troubleshooting

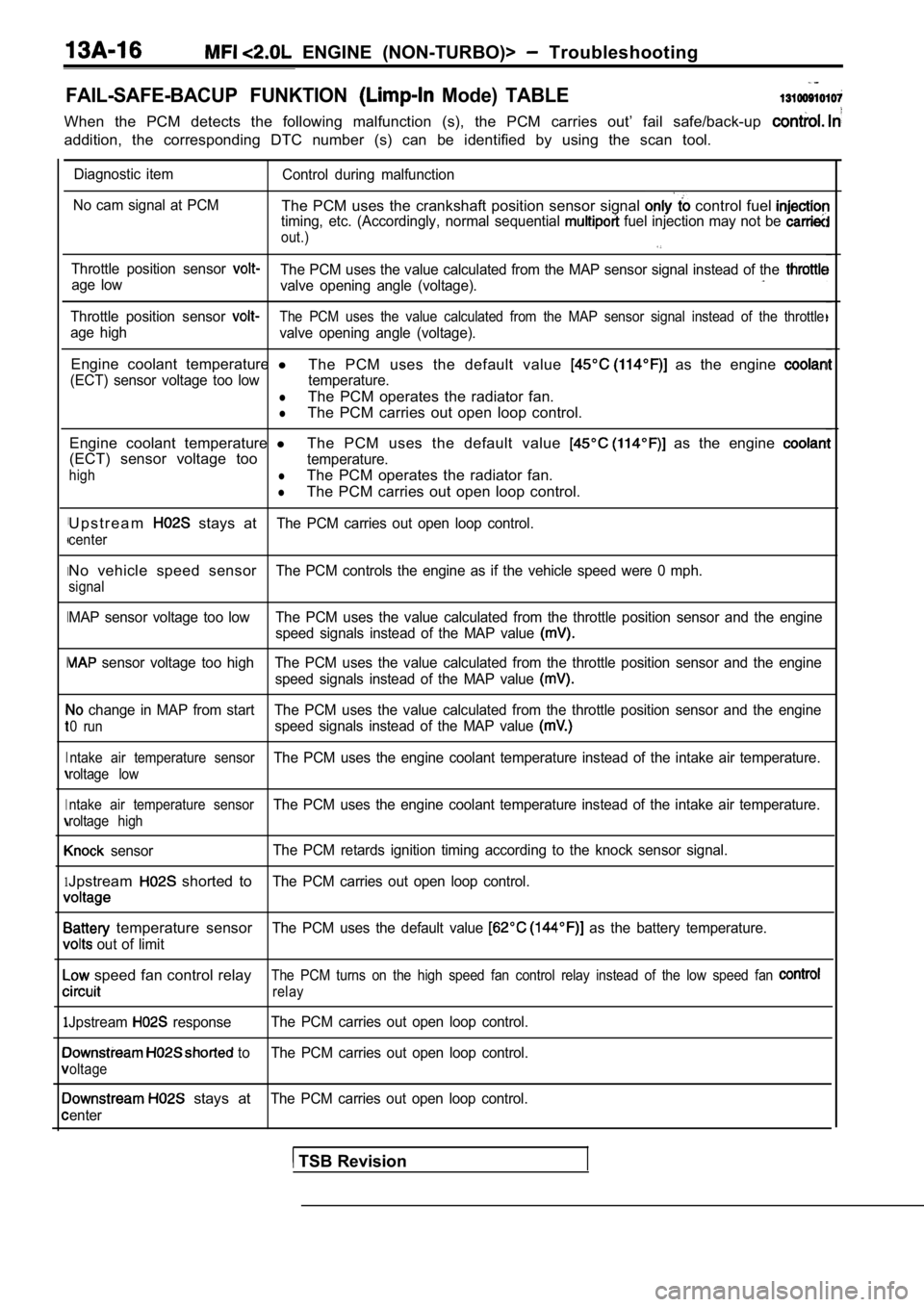

FAIL-SAFE-BACUP FUNKTION Mode) TABLE

When the PCM detects the following malfunction (s), the PCM carries out’ fail safe/back-up

addition, the corresponding DTC number (s) can be i dentified by using the scan tool.

I

I

I

I

I

1

1

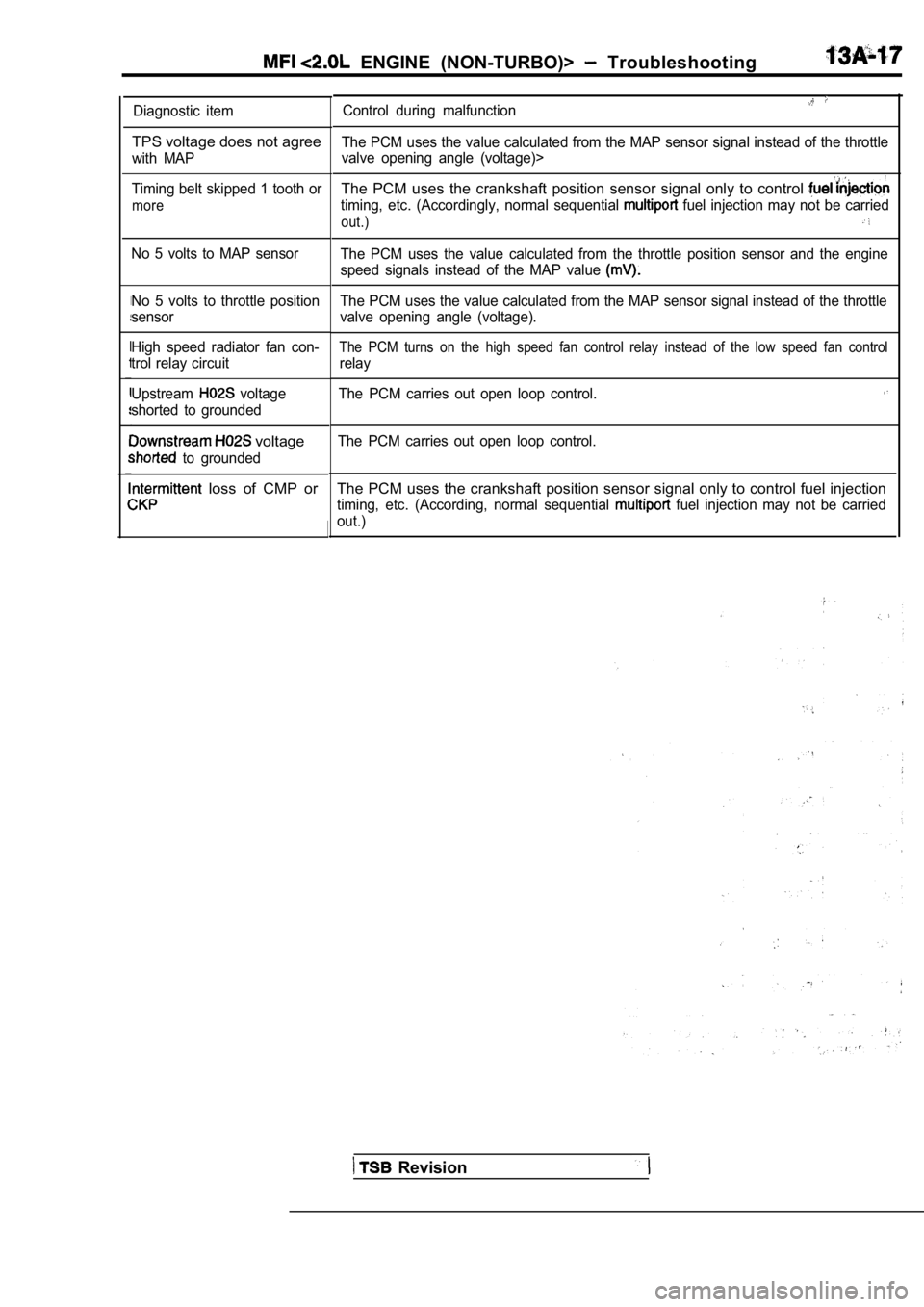

Diagnostic item

Control during malfunction

No cam signal at PCM

The PCM uses the crankshaft position sensor signal control fuel timing, etc. (Accordingly, normal sequential fuel injection may not be

out.)

Throttle position sensor The PCM uses the value calculated from the MAP sens or signal instead of the age low

valve opening angle (voltage).

Throttle position sensor The PCM uses the value calculated from the MAP sens or signal instead of the throttle

age high

valve opening angle (voltage).

Engine coolant temperature l

The PCM uses the default value as the engine

(ECT) sensor voltage too low temperature.

lThe PCM operates the radiator fan.

lThe PCM carries out open loop control.

Engine coolant temperature lThe PCM uses the default value

as the engine

(ECT) sensor voltage tootemperature.

highlThe PCM operates the radiator fan.

lThe PCM carries out open loop control.

U p s t r e a m

stays atThe PCM carries out open loop control.

center

No vehicle speed sensorThe PCM controls the engine as if the vehicle speed were 0 mph.

signal

MAP sensor voltage too low The PCM uses the value ca lculated from the throttle position sensor and the engine

speed signals instead of the MAP value

sensor voltage too high The PCM uses the value calc ulated from the throttle position sensor and the engine

speed signals instead of the MAP value

change in MAP from start The PCM uses the value cal culated from the throttle position sensor and the engine

0 runspeed signals instead of the MAP value

ntake air temperature sensorThe PCM uses the engine coolant temperature instead of the intake air temperature.

roltage low

ntake air temperature sensor

The PCM uses the engine coolant temperature instead of the intake air temperature.

roltage high

sensorThe PCM retards ignition timing according to the kn

ock sensor signal.

Jpstream shorted toThe PCM carries out open loop control.

temperature sensorThe PCM uses the default value as the battery temperature.

out of limit

speed fan control relayThe PCM turns on the high speed fan control relay i nstead of the low speed fan

relay

Jpstream responseThe PCM carries out open loop control.

to The PCM carries out open loop control.

oltage

stays atThe PCM carries out open loop control.

enter

TSB Revision

Page 397 of 2103

ENGINE (NON-TURBO)> Troubleshooting

Diagnostic item

TPS voltage does not agree

with MAP

Timing belt skipped 1 tooth or

more

No 5 volts to MAP sensor

No 5 volts to throttle position

sensor

High speed radiator fan con-

trol relay circuit

Upstream

voltage

shorted to grounded

voltage

to grounded

loss of CMP or

Control during malfunction

The PCM uses the value calculated from the MAP sens or signal instead of the throttle

valve opening angle (voltage)>

The PCM uses the crankshaft position sensor signal only to control

timing, etc. (Accordingly, normal sequential fuel injection may not be carried

out.)

The PCM uses the value calculated from the throttle position sensor and the engine

speed signals instead of the MAP value

The PCM uses the value calculated from the MAP sens or signal instead of the throttle

valve opening angle (voltage).

The PCM turns on the high speed fan control relay i nstead of the low speed fan control

relay

The PCM carries out open loop control.

The PCM carries out open loop control.

The PCM uses the crankshaft position sensor signal only to control fuel injection

timing, etc. (According, normal sequential fuel injection may not be carried

out.)

Revision

Page 424 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 40

Code General scan tool No Crank Reference at

No.PCM

11

[Comment]

Background

lThe crankshaft position sensor is a Hall-effect sensor that prov MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 40

Code General scan tool No Crank Reference at

No.PCM

11

[Comment]

Background

lThe crankshaft position sensor is a Hall-effect sensor that prov](/img/19/57345/w960_57345-423.png)

ENGINE (NON-TURBO)>

Scan tool 40

Code General scan tool No Crank Reference at

No.PCM

11

[Comment]

Background

lThe crankshaft position sensor is a Hall-effect sensor that provides a voltage signal to

the PCM.

l Voltage alternates between 0 and 5 volts as the cra nkshaft turns.

lThis DTC would indicate a failure of the sensoror its circuit.

Range of Check

l The test is run at start-up.

l Camshaft position sensor indicates that the camshaf t is rotating.

Set Condition

l Crankshaft position sensor signal (High or Low) is not input.

Probable cause

l Open or shorted supply circuit

l Open sensor ground

l Open or shorted signal circuit lExcessive clearance between the sensor androtor Sensor failed l PCM failed

Check the

position sensor.

OK

Measure at the crankshaft position sensor connector lDisconnect the connector, and measure at the harness side.

l Voltage between 1 and ground

(Ignition switch: ON)

O K :

l Continuity between 2 and ground

OK: Continuity

l Voltage between 3 and ground

OK: 4.8-5.2

OK

Check following connectors:

Check the harness wire between the PCM and cranksha ft positionsensor connector.

Replace the PCM.Repair

Check the following

Check trouble symptom.

OK

NG Repair

1

Replace the crankshaft position sensor.

NG

Check trouble symptom.

N G

Replace the PCM.

TSB Revision1

Page 494 of 2103

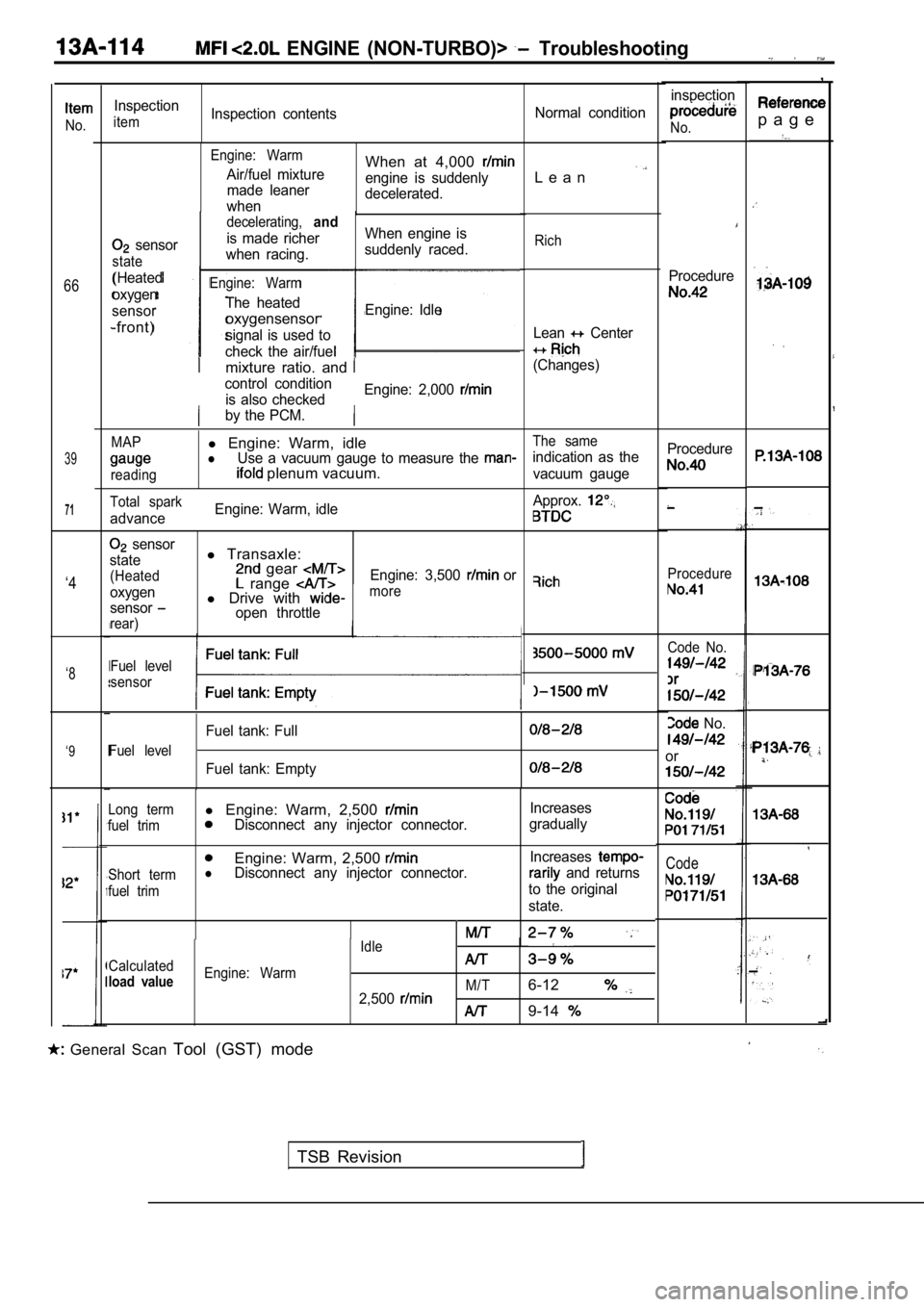

ENGINE (NON-TURBO)> Troubleshooting

,

p a g eNo.

66

39

71

inspection

No.

Procedure

Inspection

itemInspection contentsNormal condition

Engine: Warm

Air/fuel mixture

made leaner

whenWhen at 4,000

engine is suddenly

decelerated.L e a n

sensor

state

(Heated

oxygen

sensor

-front)

decelerating,and

is made richer When engine is

when racing. suddenly raced.

Engine: Warm

The heated

oxygensensorEngine: Idle

signal is used to

check the air/fuel

Rich

Lean Center

(Changes)mixture ratio. and

control condition is also checked Engine: 2,000

by the PCM.

MAPl

Engine: Warm, idleThe same

lUse a vacuum gauge to measure the indication as the

reading plenum vacuum.vacuum gauge Procedure

Procedure

Total spark

advance

Engine: Warm, idle

Approx.

sensor

state

(Heated

oxygen

sensor

rear)

l Transaxle: gear range l Drive with open throttle Engine: 3,500

or‘4more

Code No.

No.

or

Fuel level

sensor‘8

Fuel level

Fuel tank: Full

Fuel tank: Empty

‘9

Code

Long terml

Engine: Warm, 2,500 Increases

fuel trimDisconnect any injector connector. gradually

Engine: Warm, 2,500

Short termlDisconnect any injector connector. Increases and returns

fuel trimto the original

state.

Idle

Calculated

load valueEngine: Warm M/T

2,5006-12

9-14

General Scan Tool (GST) mode

TSB Revision

Page 518 of 2103

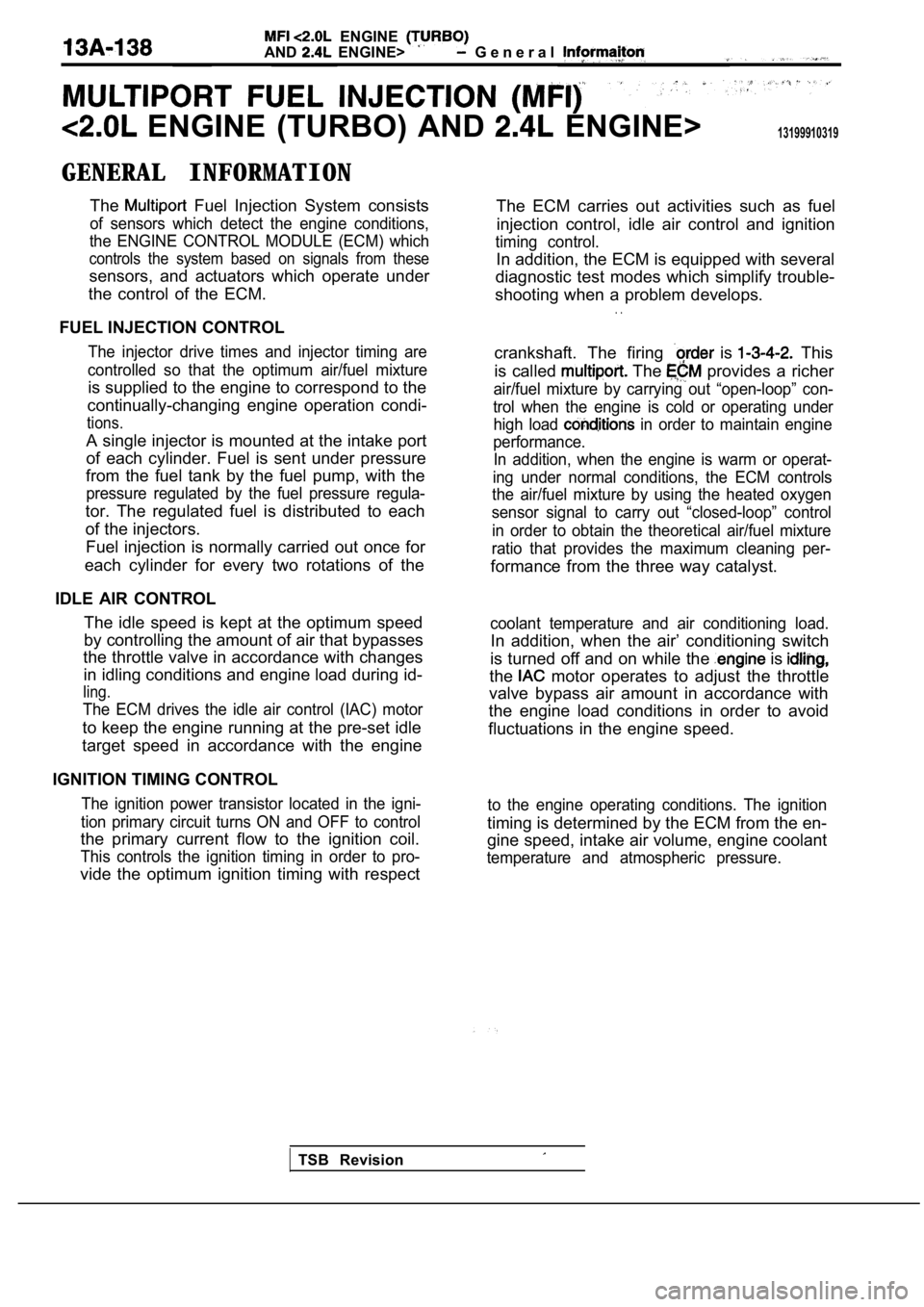

ENGINE

AND ENGINE> G e n e r a l

ENGINE (TURBO) AND ENGINE>13199910319

GENERAL INFORMATIONThe

Fuel Injection System consists

of sensors which detect the engine conditions,

the ENGINE CONTROL MODULE (ECM) which

controls the system based on signals from these

sensors, and actuators which operate under

the control of the ECM.

FUEL INJECTION CONTROL

The injector drive times and injector timing are

controlled so that the optimum air/fuel mixture

is supplied to the engine to correspond to the

continually-changing engine operation condi-

tions.

A single injector is mounted at the intake port

of each cylinder. Fuel is sent under pressure

from the fuel tank by the fuel pump, with the

pressure regulated by the fuel pressure regula-

tor. The regulated fuel is distributed to each

of the injectors.

Fuel injection is normally carried out once for

each cylinder for every two rotations of the

IDLE AIR CONTROL The idle speed is kept at the optimum speed

by controlling the amount of air that bypasses

the throttle valve in accordance with changes

in idling conditions and engine load during id-

ling.

The ECM drives the idle air control (IAC) motor

to keep the engine running at the pre-set idle

target speed in accordance with the engine

IGNITION TIMING CONTROL

The ignition power transistor located in the igni-

tion primary circuit turns ON and OFF to control

the primary current flow to the ignition coil.

This controls the ignition timing in order to pro-

vide the optimum ignition timing with respect The ECM carries out activities such as fuel

injection control, idle air control and ignition

timing control.

In addition, the ECM is equipped with several

diagnostic test modes which simplify trouble-

shooting when a problem develops.

. .

crankshaft. The firing is This

is called

The provides a richer

air/fuel mixture by carrying out “open-loop” con-

trol when the engine is cold or operating under high load

in order to maintain engine

performance. In addition, when the engine is warm or operat-

ing under normal conditions, the ECM controls

the air/fuel mixture by using the heated oxygen

sensor signal to carry out “closed-loop” control

in order to obtain the theoretical air/fuel mixture

ratio that provides the maximum cleaning per-

formance from the three way catalyst.

coolant temperature and air conditioning load.

In addition, when the air’ conditioning switch

is turned off and on while the

is

the motor operates to adjust the throttle

valve bypass air amount in accordance with

the engine load conditions in order to avoid

fluctuations in the engine speed.

to the engine operating conditions. The ignition

timing is determined by the ECM from the en-

gine speed, intake air volume, engine coolant

temperature and atmospheric pressure.

TSB Revision

Page 527 of 2103

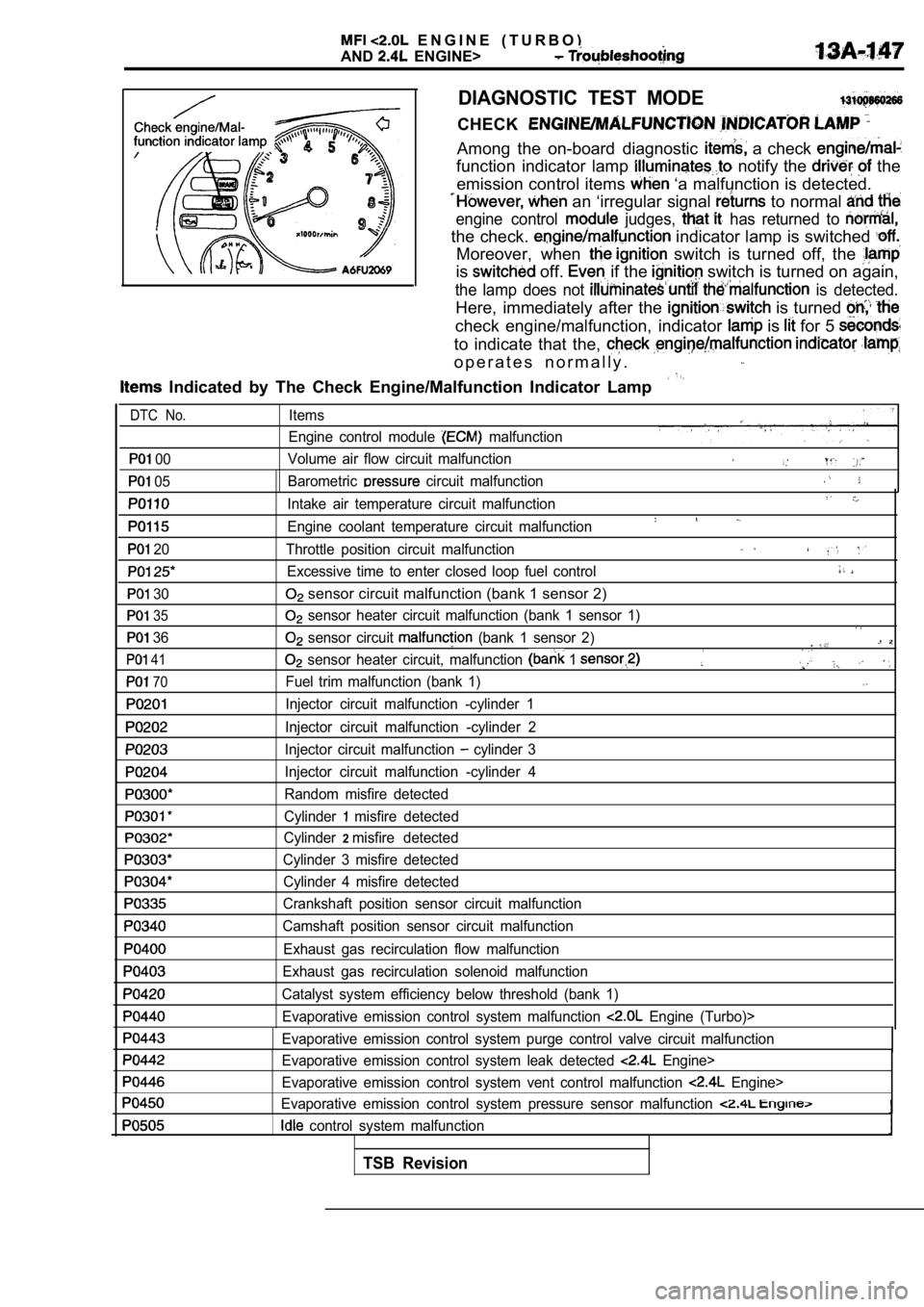

E N G I N E ( T U R B O )

AND

ENGINE>

DIAGNOSTIC TEST MODE

CHECK

Among the on-board diagnostic a check

function indicator lamp notify the the

emission control items

‘a malfunction is detected.

an ‘irregular signal to normal

engine control judges, has returned to

the check. indicator lamp is switched

Moreover, when switch is turned off, the

is off. if the switch is turned on again,

the lamp does not is detected.

Here, immediately after the is turned

check engine/malfunction, indicator is for 5

to indicate that the,

o p e r a t e s n o r m a l l y .

Indicated by The Check Engine/Malfunction Indicato r Lamp

00

05

20

30

35

36

41

70

Items

Engine control module

malfunction

Volume air flow circuit malfunction

Barometric

circuit malfunction

Intake air temperature circuit malfunction

Engine coolant temperature circuit malfunction

Throttle position circuit malfunction

Excessive time to enter closed loop fuel control

sensor circuit malfunction (bank 1 sensor 2)

sensor heater circuit malfunction (bank 1 sensor 1 )

sensor circuit (bank 1 sensor 2).

sensor heater circuit, malfunction 1

Fuel trim malfunction (bank 1)

Injector circuit malfunction -cylinder 1

Injector circuit malfunction -cylinder 2

Injector circuit malfunction

cylinder 3

Injector circuit malfunction -cylinder 4

Random misfire detected

Cylinder

misfire detected

Cylinder

2misfire detected

Cylinder 3 misfire detected Cylinder 4 misfire detected

Crankshaft position sensor circuit malfunction

Camshaft position sensor circuit malfunction

Exhaust gas recirculation flow malfunction

Exhaust gas recirculation solenoid malfunction

Catalyst system efficiency below threshold (bank 1) Evaporative emission control system malfunction

Engine (Turbo)>

Evaporative emission control system purge control v alve circuit malfunction

Evaporative emission control system leak detected

Engine>

Evaporative emission control system vent control ma lfunction

Engine>

Evaporative emission control system pressure sensor malfunction

control system malfunction

DTC No.

TSB Revision

Page 529 of 2103

E N G I N E

AND ENGINE>

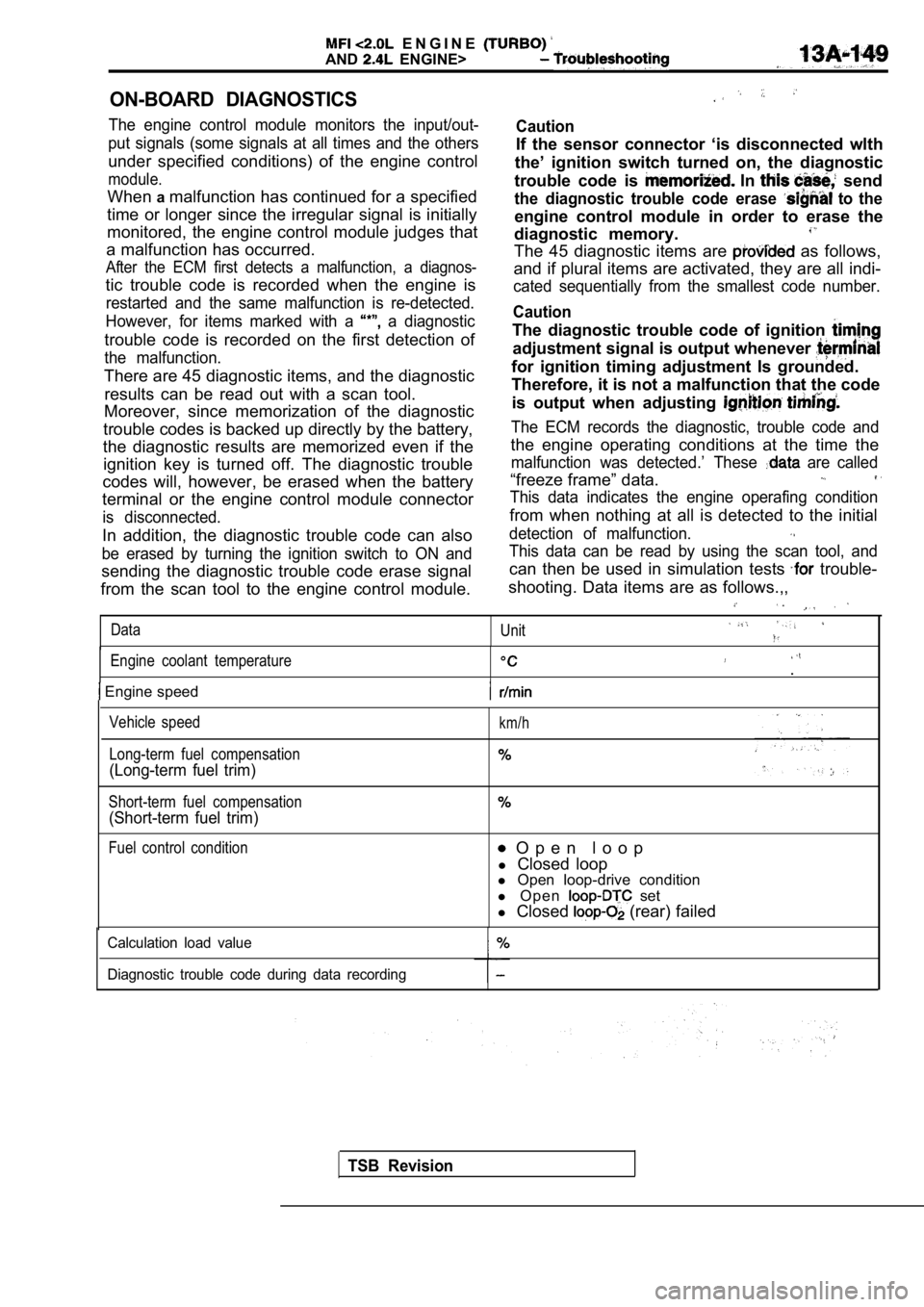

ON-BOARD DIAGNOSTICS

The engine control module monitors the input/out-

put signals (some signals at all times and the othe rs

under specified conditions) of the engine control

module.

Whenamalfunction has continued for a specified

time or longer since the irregular signal is initia lly

monitored, the engine control module judges that

a malfunction has occurred.

After the ECM first detects a malfunction, a diagno s-

tic trouble code is recorded when the engine is

restarted and the same malfunction is re-detected.

However, for items marked with a

a diagnostic

trouble code is recorded on the first detection of

the malfunction.

There are 45 diagnostic items, and the diagnostic results can be read out with a scan tool.

Moreover, since memorization of the diagnostic

trouble codes is backed up directly by the battery,

the diagnostic results are memorized even if the ignition key is turned off. The diagnostic trouble

codes will, however, be erased when the battery

terminal or the engine control module connector

is disconnected.

In addition, the diagnostic trouble code can also

be erased by turning the ignition switch to ON and

sending the diagnostic trouble code erase signal

from the scan tool to the engine control module.

Caution

If the sensor connector ‘is disconnected wlth

the’ ignition switch turned on, the diagnostic

trouble code is

In send

the diagnostic trouble code erase to the

engine control module in order to erase the

diagnostic memory.

The 45 diagnostic items are as follows,

and if plural items are activated, they are all ind i-

cated sequentially from the smallest code number.

Caution

The diagnostic trouble code of ignition

adjustment signal is output whenever

for ignition timing adjustment Is grounded.

Therefore, it is not a malfunction that the code

is output when adjusting

The ECM records the diagnostic, trouble code and

the engine operating conditions at the time the

malfunction was detected.’ These are called

“freeze frame” data.

This data indicates the engine operafing condition

from when nothing at all is detected to the initial

detection of malfunction.

This data can be read by using the scan tool, and

can then be used in simulation tests trouble-

shooting. Data items are as follows.,,

Data Unit

Engine coolant temperature.

Engine speed

Vehicle speed

Long-term fuel compensation

(Long-term fuel trim)

Short-term fuel compensation

(Short-term fuel trim)

km/h

Fuel control condition O p e n l o o p

l Closed loop

l Open loop-drive condition

l O p e n

set

l Closed

(rear) failed

Calculation load value

Diagnostic trouble code during data recording

TSB Revision