door lock MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 17 of 2103

GENERAL Vehicle

Heat

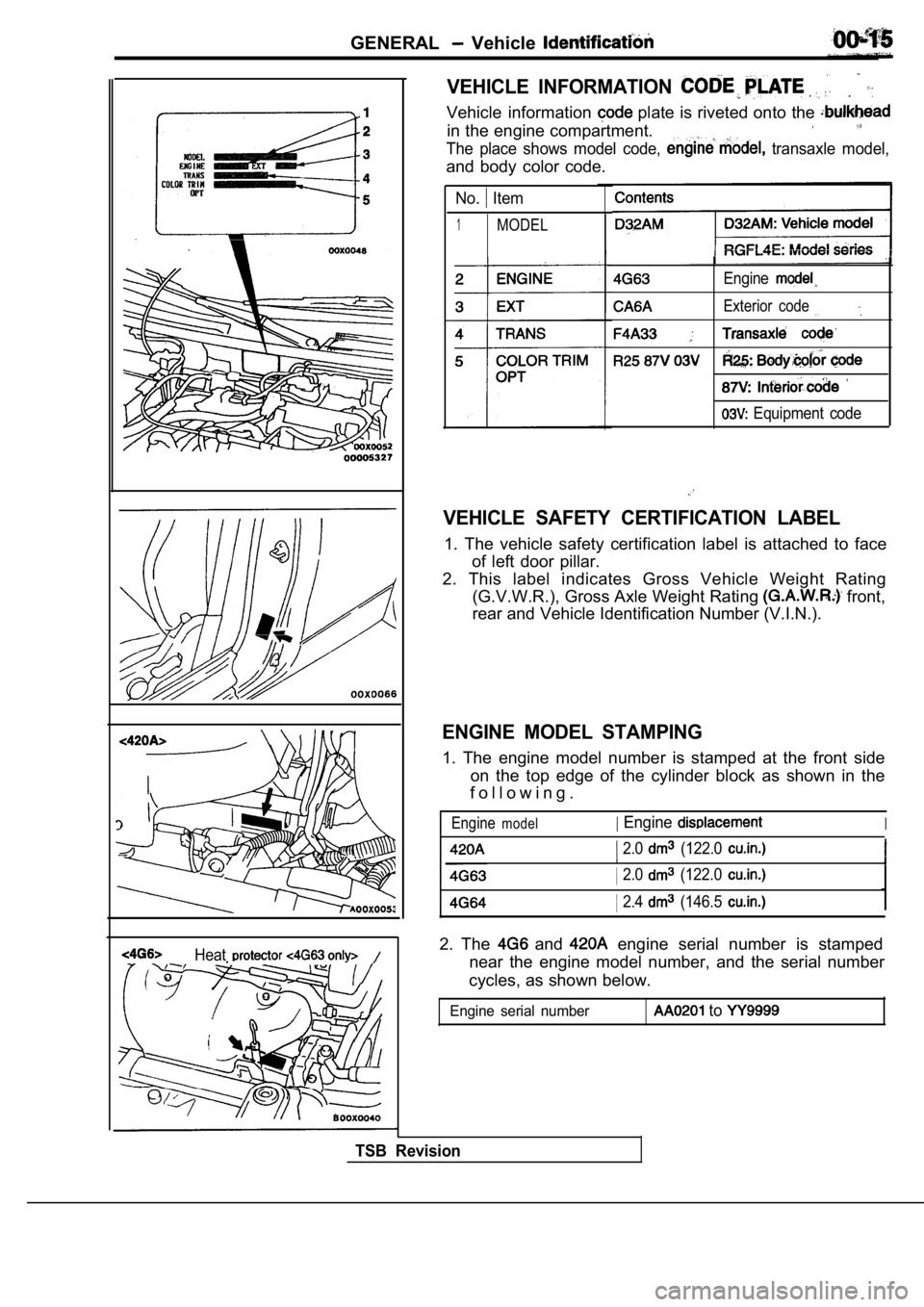

VEHICLE INFORMATION

Vehicle information plate is riveted onto the

in the engine compartment.

The place shows model code, transaxle model,

and body color code.

No. Item

1MODEL

Engine

Exterior code

Equipment code

VEHICLE SAFETY CERTIFICATION LABEL

1. The vehicle safety certification label is attached to face

of left door pillar.

2. This label indicates Gross Vehicle Weight Rating (G.V.W.R.), Gross Axle Weight Rating

front,

rear and Vehicle Identification Number (V.I.N.).

ENGINE MODEL STAMPING

1. The engine model number is stamped at the front side

on the top edge of the cylinder block as shown in t he

f o l l o w i n g .

Enginemodel Engine

2.0 (122.0

I

I 2.0 (122.0

2.4 (146.5

2. The and engine serial number is stamped

near the engine model number, and the serial number

cycles, as shown below.

Engine serial number to

TSB Revision

Page 18 of 2103

GENERAL Vehicle Identification

Theft protection label

Fororiginal parts

MITSUBISHI

0 0 2 0 0 1 4

Forreplacement parts

MITSUBISHI

0 0 2 0 0 1 5

0 0 0 0 4 7 4 3THEFT

PROTECTION

In order to protect against theft, a Vehicle Identification Number

is stamped in, or attached as a label to, the foll owing

major parts of the engine and transaxle,

as main

outer panels:

Engine cylinder block, Transaxle housing. Door, Quar-

ter panel, Hood, Liftgate, Trunk lid, Bumpers

In addition, a theft-protection label is attached t o replacement

parts for the body outer panel main and the

same data are stamped into replacement parts for th e engine

and the transaxle.

Cautions regarding panel repairs:‘

1.When repainting original so first mask-

ing the theft-protection label, and, after be

sure to peel off the masking tape.

2.The theft-protection label for parts cov-

ered bymasking tape, such part&an be

as is. The masking tape should removed

ing is finished.

3.The theft-protection label should not be from

original or replacement parts.

,

. .

TSB Revision

Page 25 of 2103

GENERAL Towing and Hoisting

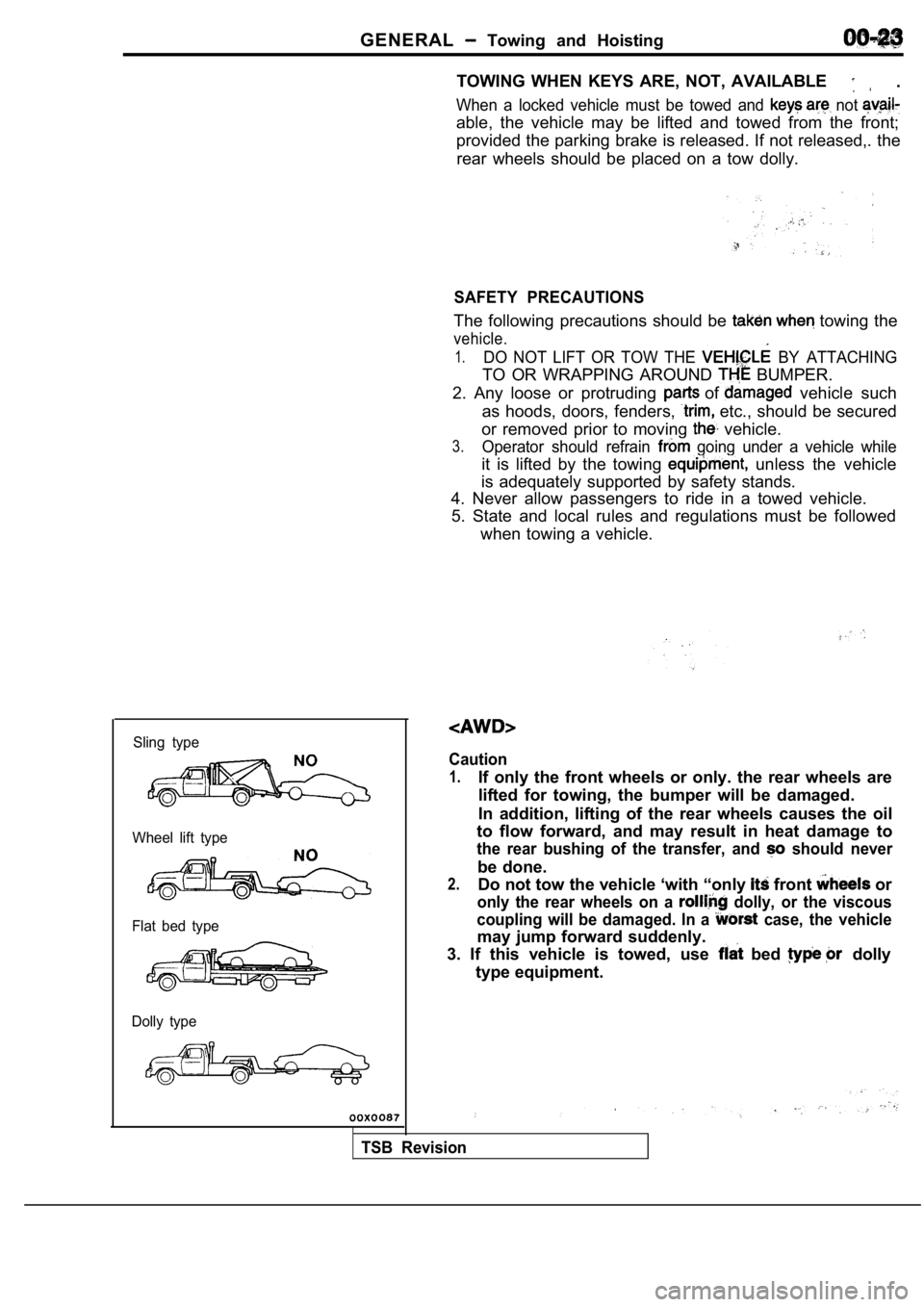

Sling type

Wheel lift type

Flat bed type

Dolly type

TOWING WHEN KEYS ARE, NOT, AVAILABLE .

When a locked vehicle must be towed and not

able, the vehicle may be lifted and towed from the front;

provided the parking brake is released. If not rele ased,. the

rear wheels should be placed on a tow dolly.

SAFETY PRECAUTIONS

The following precautions should be towing the

vehicle.

1.DO NOT LIFT OR TOW THE BY ATTACHING

TO OR WRAPPING AROUND BUMPER.

2. Any loose or protruding

of vehicle such

as hoods, doors, fenders,

etc., should be secured

or removed prior to moving

vehicle.

3.Operator should refrain going under a vehicle while

it is lifted by the towing unless the vehicle

is adequately supported by safety stands.

4. Never allow passengers to ride in a towed vehicl e.

5. State and local rules and regulations must be fo llowed

when towing a vehicle.

Caution

1.If only the front wheels or only. the rear wheels a re

lifted for towing, the bumper will be damaged.

In addition, lifting of the rear wheels causes the oil

to flow forward, and may result in heat damage to

the rear bushing of the transfer, and should never

be done.

2.Do not tow the vehicle ‘with “only front or

only the rear wheels on a dolly, or the viscous

coupling will be damaged. In a

case, the vehicle

may jump forward suddenly.

3. If this vehicle is towed, use

bed dolly

type equipment.

TSB Revision

Page 57 of 2103

GENERAL Main and Adhesive Table

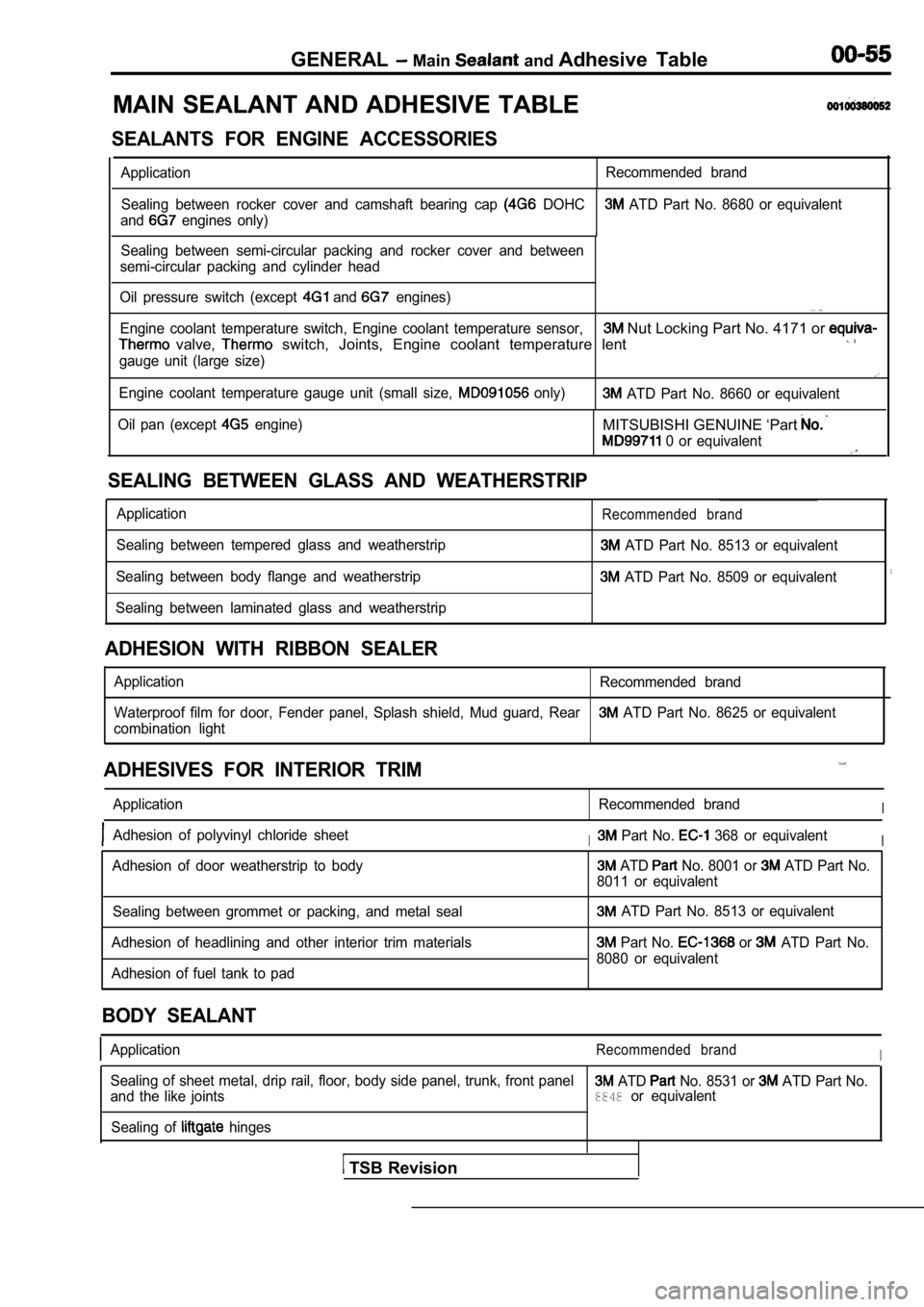

MAIN SEALANT AND ADHESIVE TABLE

SEALANTS FOR ENGINE ACCESSORIES

Application Recommended brand

Sealing between rocker cover and camshaft bearing c ap

DOHC ATD Part No. 8680 or equivalent

and

engines only)

1Sealing between semi-circular packing and rocker co ver and between

semi-circular packing and cylinder head

Oil pressure switch (except

and engines). . .

Engine coolant temperature switch, Engine coolant t emperature sensor, Nut Locking Part No. 4171 or

valve, switch, Joints, Engine coolant temperature lent

gauge unit (large size)

Engine coolant temperature gauge unit (small size, only) ATD Part No. 8660 or equivalent

Oil pan (except

engine)MITSUBISHI GENUINE ‘Part

0 or equivalent

SEALING BETWEEN GLASS AND WEATHERSTRIP

Application

Sealing between tempered glass and weatherstrip

Sealing between body flange and weatherstrip

Sealing between laminated glass and weatherstripRecommended brand

ATD Part No. 8513 or equivalent

ATD Part No. 8509 or equivalent

ADHESION WITH RIBBON SEALER

Application Recommended brand

Waterproof film for door, Fender panel, Splash shie ld, Mud guard, Rear

ATD Part No. 8625 or equivalent

combination light

ADHESIVES FOR INTERIOR TRIM

Application Recommended brandI

Adhesion of polyvinyl chloride sheetI Part No. 368 or equivalentI

Adhesion of door weatherstrip to body ATD No. 8001 or ATD Part No.

8011 or equivalent

Sealing between grommet or packing, and metal seal

Adhesion of headlining and other interior trim mate rials

Adhesion of fuel tank to pad

ATD Part No. 8513 or equivalent

Part No. or ATD Part No.

8080 or equivalent

BODY SEALANT

ApplicationRecommended brandI

Sealing of sheet metal, drip rail, floor, body side panel, trunk, front panel ATD No. 8531 or ATD Part No.

and the like joints8848or equivalent

Sealing of

hinges

TSB Revision

Page 1825 of 2103

CONTENTS

DOOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Door Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Door Glass and Regulator . . . . . . . . . . . . . . . . . . .56

Door Handle and Latch. . . . . . . . . . . . . . . . . . . . .59

Door Opening Weatherstrip. . . . . . . . . . . . . . . . . .63

Door Trim and Waterproof Film . . . . . . . . . . . . . .54

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .48

Sealant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Service Specifications. . . . . . . . . . . . . . . . . . . . . . .33

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

ELECTRIC CONVERTIBLE TOP. . . . . . . . . . . .91

Balance Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Convertible Top Assembly. . . . . . . . . . . . . . . . . . .94

Convertible Top Bypass Switch . . . . . . . . . . . . . .104

Convertible Top Control Module. . . . . . . . . . . . .105

Convertible Top Switch. . . . . . . . . . . . . . . . . . . . .103

Front Roof Weatherstrip. . . . . . . . . . . . . . . . . . . .100

Headliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .94

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Drive Motor. . . . . . . . . . . . . . . . . . . . . . . .99

Driven Gear . . . . . . . . . . . . . . . . . . . . . . .96

Rail Weatherstrip and

Top Cover Retainer . . . . . . . . . . . . . . . . . . . . . . . .

101

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

FENDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sealants

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUEL FILLER DOOR . . . . . . . . . . . . . . . . . . . . . . .6

HOOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ENTRY SYSTEM . . . . . . . . . . . . . . . .72

Entry System

. . . . . . . . . . . . . . . . . . . . . . .77

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

SUNROOF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .82

Sealant and Adhesive . . . . . . . . . . . . . . . . . . . . . . .82

Sunroof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

UNDER COVER. . . . . . . . . . . . . . . . . . . . . . . . . . .81

WINDSHIELD AND WINDOW GLASS . . . . . . . .

7

Glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

On-vehicle Service

. . . . . . . . . . . . . . . . . . . . . . . . . .10

Quarter Window Glass . . . . . . . . . . . . . . . . . . . . . .22

Quarter Window Glass and

Regulator Assembly. . . . . . . . . . . . . . . . . . . . . . . . .26

Sealant and Adhesive. . . . . . . . . . . . . . . . . . . . . . . .7

Service Specifications. . . . . . . . . . . . . . . . . . . . . . . .7

Special Tool

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Windshield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Windshield and Window Glass . . . . . . . . . . . . . . .15

TRUNK LID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Trunk Lid

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

TRUNK LID LOCK RELEASE HANDLE AND

CABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Page 1830 of 2103

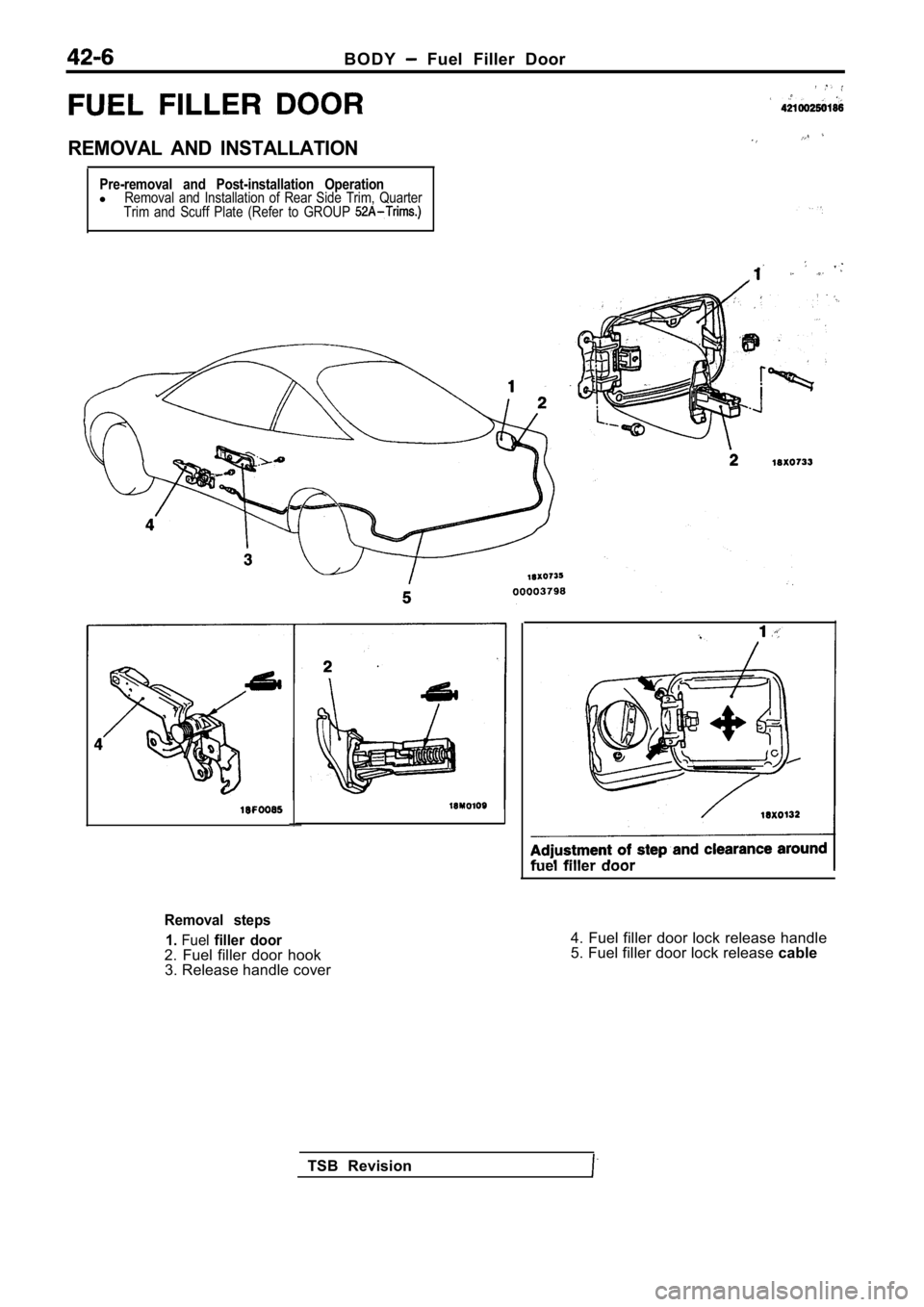

B O D Y Fuel Filler Door

REMOVAL AND INSTALLATION

Pre-removal and Post-installation OperationlRemoval and Installation of Rear Side Trim, Quarter

Trim and Scuff Plate (Refer to GROUP

fuel filler door

Removal steps

1.

Fuelfiller door2. Fuel filler door hook3. Release handle cover 4. Fuel filler door lock release handle

5. Fuel filler door lock release

cable

TSB Revision

Page 1834 of 2103

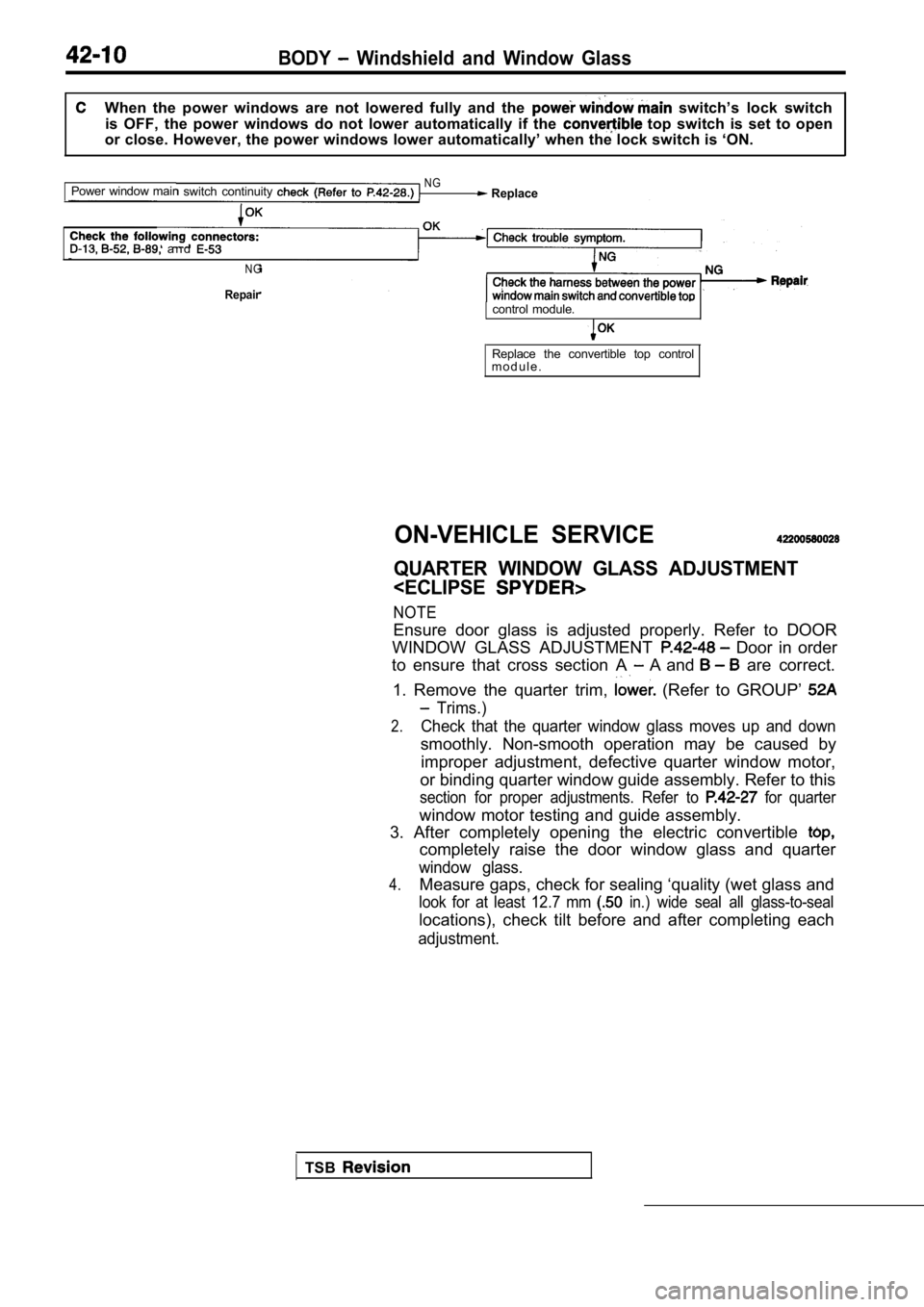

BODY Windshield and Window Glass

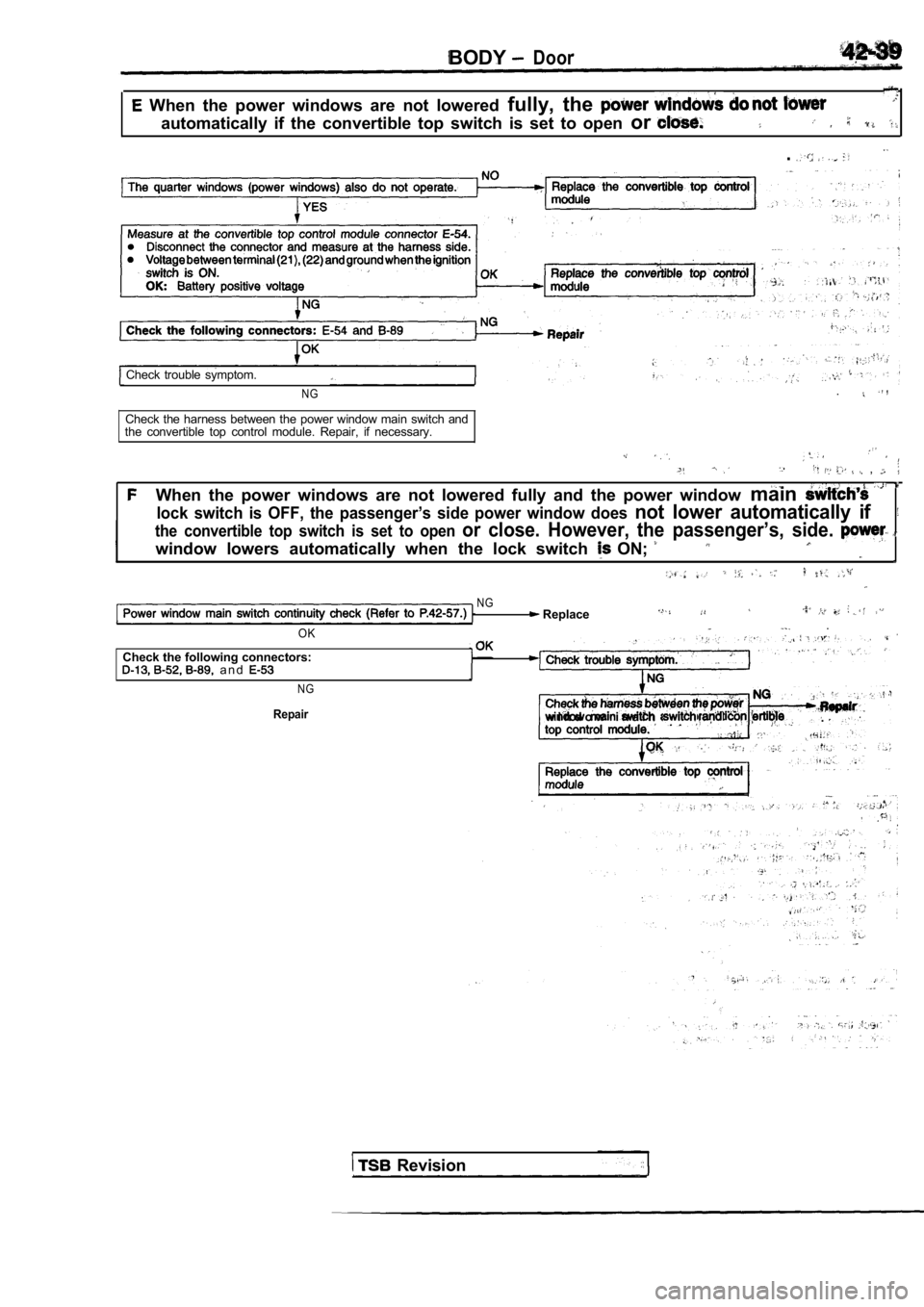

When the power windows are not lowered fully and the switch’s lock switch

is OFF, the power windows do not lower automaticall y if the

top switch is set to open

or close. However, the power windows lower automati cally’ when the lock switch is ‘ON.

Power window mair

switch continuity NG Replace

a n d

N G

Repaircontrol module.

Replace the convertible top control

m o d u l e .

ON-VEHICLE SERVICE

QUARTER WINDOW GLASS ADJUSTMENT

Ensure door glass is adjusted properly. Refer to DO OR

WINDOW GLASS ADJUSTMENT

Door in order

to ensure that cross section A

A and are correct.

1. Remove the quarter trim,

(Refer to GROUP’

Trims.)

2.Check that the quarter window glass moves up and do wn

smoothly. Non-smooth operation may be caused by

improper adjustment, defective quarter window motor ,

or binding quarter window guide assembly. Refer to this

section for proper adjustments. Refer to for quarter

window motor testing and guide assembly.

3. After completely opening the electric convertibl e

completely raise the door window glass and quarter

window glass.

4.Measure gaps, check for sealing ‘quality (wet glass and

look for at least 12.7 mm in.) wide seal all glass-to-seal

locations), check tilt before and after completing each

adjustment.

TSB

Page 1859 of 2103

‘ D o o r.

‘I-

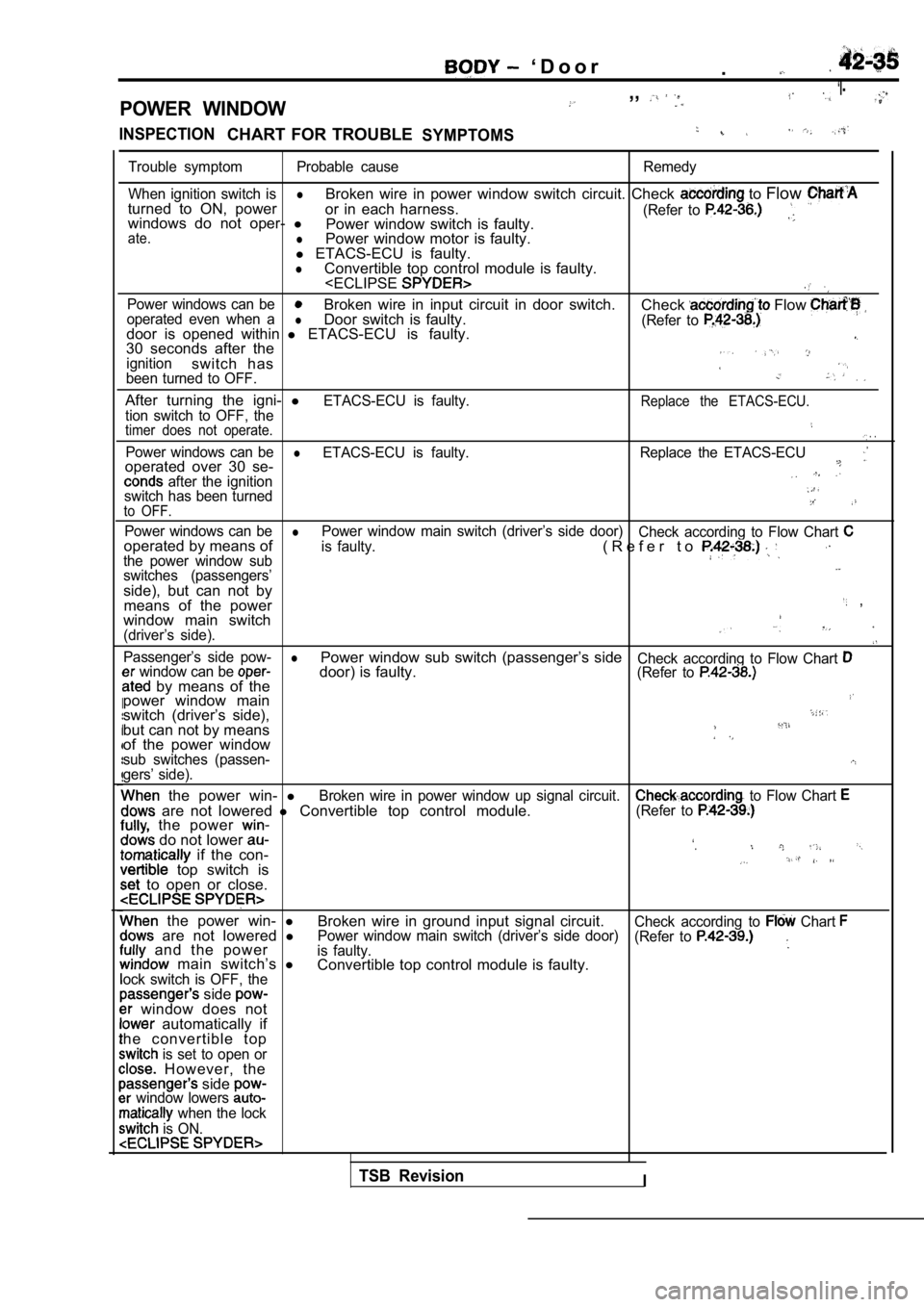

POWER WINDOW

,,

INSPECTIONCHART FOR TROUBLESYMPTOMS

Trouble symptom Probable causeRemedy

When ignition switch is

lturned to ON, power Broken wire in power window switch circuit. Check to

Flowor in each harness.(Refer to windows do not oper- l

Power window switch is faulty.ate.lPower window motor is faulty.

l ETACS-ECU is faulty.

lConvertible top control module is faulty.

l ETACS-ECU is faulty.30 seconds after theignitionswitch hasbeen turned to OFF.

After turning the igni- lETACS-ECU is faulty.Replace the ETACS-ECU.tion switch to OFF, thetimer does not operate. . .

Power windows can belETACS-ECU is faulty. Replace the ETACS-ECUoperated over 30 se- after the ignitionswitch has been turnedto OFF.

Power windows can belPower window main switch (driver’s side door)

Check according to Flow Chart operated by means ofis faulty.

the power window sub( R e f e r t o

switches (passengers’side), but can not by

means of the power ,

window main switch

(driver’s side).

Passenger’s side pow-lPower window sub switch (passenger’s sideCheck according to Flow Chart window can be (Refer to by means of the door) is faulty.

power window main

switch (driver’s side),but can not by meansof the power windowsub switches (passen-gers’ side).

the power win- lBroken wire in power window up signal circuit. to Flow Chart are not lowered l Convertible top control module.(Refer to the power do not lower if the con-‘.

top switch is to open or close.

the power win- l

Broken wire in ground input signal circuit.Check according to Chart are not lowered lPower window main switch (driver’s side door)

(Refer to and the poweris faulty. main switch’s l

Convertible top control module is faulty.ock switch is OFF, the side window does not automatically if

he convertible top

is set to open or However, the side window lowers when the lock

is ON.

TSB RevisionI

Page 1863 of 2103

BODYDoor

When the power windows are not lowered fully, the

automatically if the convertible top switch is set to open or

.

Check trouble symptom.

NG.

Check the harness between the power window main swi tch and

the convertible top control module. Repair, if nece ssary.

,

When the power windows are not lowered fully and th e power window main

lock switch is OFF, the passenger’s side power wind ow does not lower automatically if

the convertible top switch is set to open or close. However, the passenger’s, side.

window lowers automatically when the lock switch ON;

N G Replace

OK .

Check the following connectors: a n d

N G

Repairw i n d o w i n a i n .

Revision

Page 1864 of 2103

BODY Door

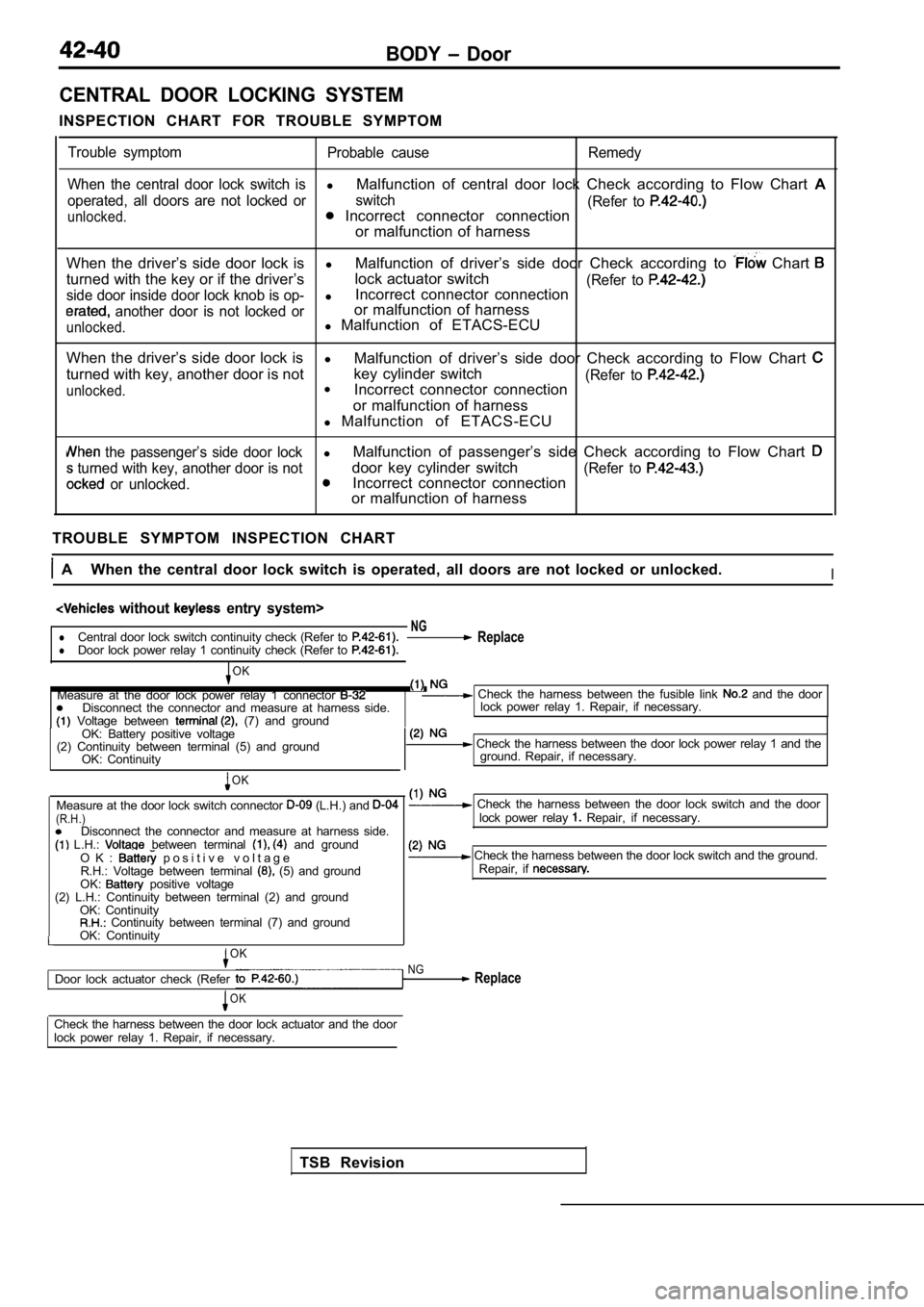

CENTRAL DOOR LOCKING SYSTEM

INSPECTION CHART FOR TROUBLE SYMPTOM

Trouble symptom Probable cause Remedy

When the central door lock switch is

l Malfunction of central door lock Check according to Flow Chart A

operated, all doors are not locked or switch

(Refer to

unlocked. Incorrect connector connection

or malfunction of harness

When the driver’s side door lock is lMalfunction of driver’s side door Check according t o

Chart

turned with the key or if the driver’slock actuator switch(Refer to side door inside door lock knob is op-lIncorrect connector connection

another door is not locked oror malfunction of harness

unlocked.l

Malfunction of ETACS-ECU

When the driver’s side door lock is l

Malfunction of driver’s side door Check according t o Flow Chart

turned with key, another door is notkey cylinder switch(Refer to

unlocked.l

Incorrect connector connection

or malfunction of harness

l Malfunction of ETACS-ECU

the passenger’s side door lockl Malfunction of passenger’s side Check according to

Flow Chart

turned with key, another door is notdoor key cylinder switch(Refer to

or unlocked.Incorrect connector connection

or malfunction of harness

TROUBLE SYMPTOM INSPECTION CHART

A When the central door lock switch is operated, al l doors are not locked or unlocked.I

without entry system>

NGlCentral door lock switch continuity check (Refer to ReplacelDoor lock power relay 1 continuity check (Refer to

TSB Revision

OK

Measure at the door lock power relay 1 connector Check the harness between the fusible link and the door

Disconnect the connector and measure at harness sid e.

Voltage between (7) and groundlock power relay 1. Repair, if necessary.

OK: Battery positive voltage

(2) Continuity between terminal (5) and ground OK: Continuity

OK

Measure at the door lock switch connector (L.H.) and (R.H.)Disconnect the connector and measure at harness sid e. L.H.: between terminal and groundO K : p o s i t i v e v o l t a g eR.H.: Voltage between terminal (5) and ground

OK: positive voltage

(2) L.H.: Continuity between terminal (2) and groun d

OK: Continuity

Continuity between terminal (7) and ground

OK: Continuity

OK

Door lock actuator check (Refer

OK

Check the harness between the door lock power rela y 1 and the

ground. Repair, if necessary.

Check the harness between the door lock switch and the door

lock power relay Repair, if necessary.

Check the harness between the door lock switch and the ground.

Repair, if

NG Replace

Check the harness between the door lock actuator an d the door

lock power relay 1. Repair, if necessary.