torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1210 of 2103

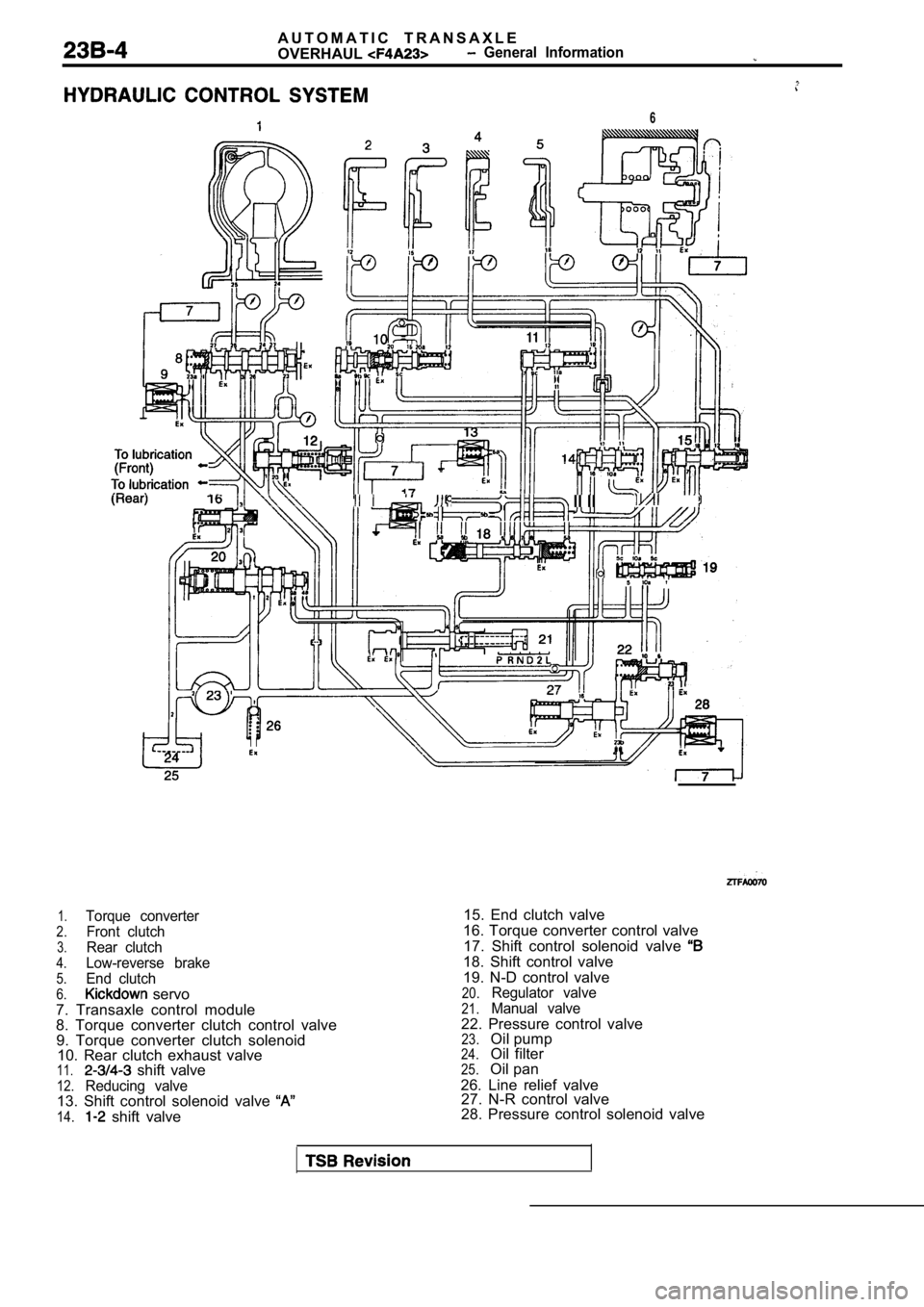

A U T O M A T I C T R A N S A X L E

OVERHAUL General Information

6

II II

1.Torque converter

2.Front clutch

3.Rear clutch

4.Low-reverse brake

5.End clutch

6. servo

7. Transaxle control module

8. Torque converter clutch control valve 9. Torque converter clutch solenoid 10. Rear clutch exhaust valve

11. shift valve

12.Reducing valve13. Shift control solenoid valve

14. shift valve 15. End clutch valve

16. Torque converter control valve 17. Shift control solenoid valve

18. Shift control valve

19. N-D control valve

20.Regulator valve

21.Manual valve

22. Pressure control valve23.Oil pump24.Oil filter

25.Oil pan

26. Line relief valve 27. N-R control valve

28. Pressure control solenoid valve

Page 1211 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

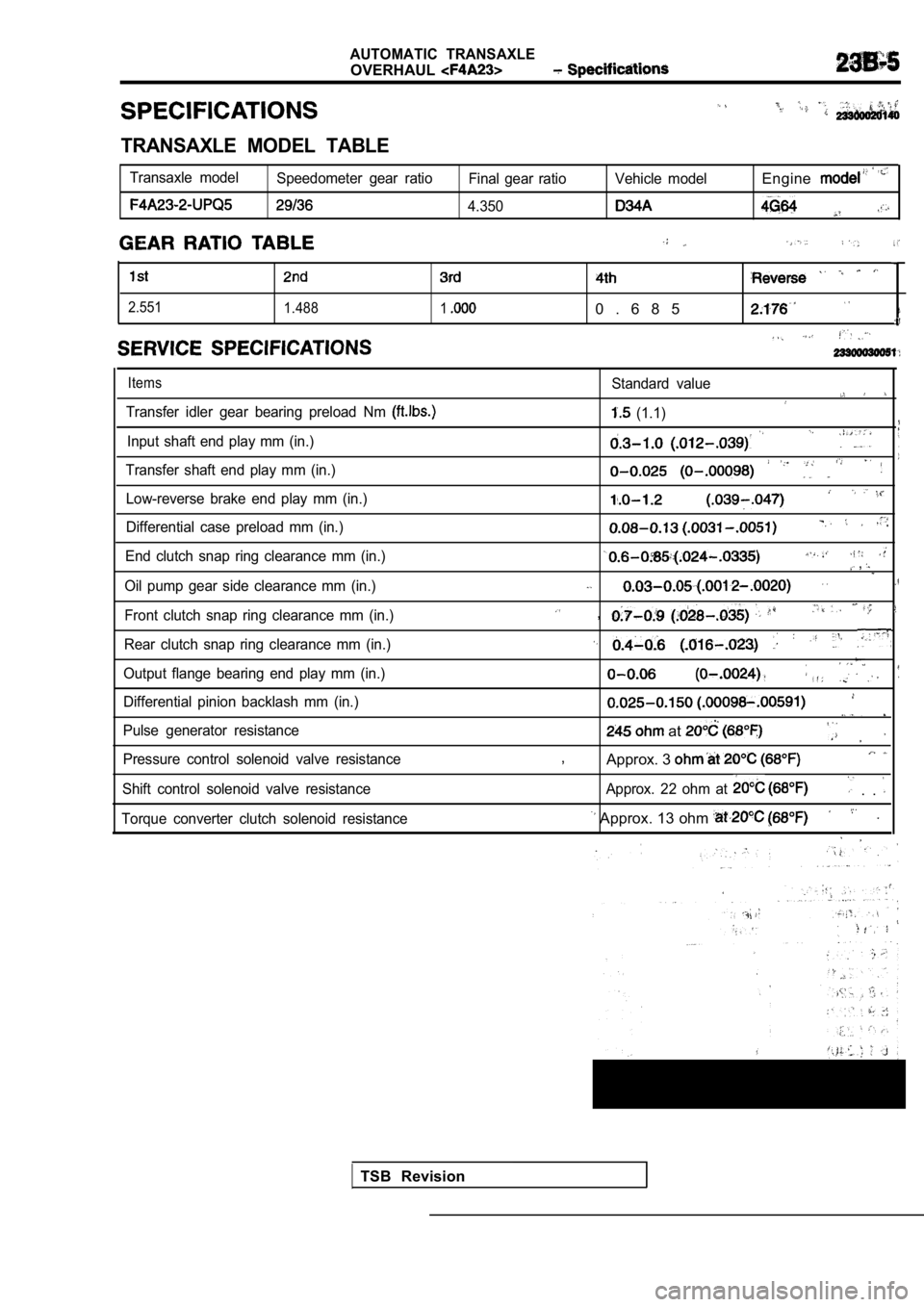

TRANSAXLE MODEL TABLE

Transaxle modelSpeedometer gear ratio Final gear ratio Vehicle modelEngine

4.350

2.551

1.488 10 . 6 8 5

ItemsStandard value

Transfer idler gear bearing preload Nm

Input shaft end play mm (in.)

Transfer shaft end play mm (in.) Low-reverse brake end play mm (in.)

Differential case preload mm (in.)

End clutch snap ring clearance mm (in.)

Oil pump gear side clearance mm (in.)

Front clutch snap ring clearance mm (in.)

Rear clutch snap ring clearance mm (in.)

Output flange bearing end play mm (in.)

Differential pinion backlash mm (in.)

Pulse generator resistance

Pressure control solenoid valve resistance

Shift control solenoid valve resistance

Torque converter clutch solenoid resistance

(1.1)

,

,

at

, Approx. 3

Approx. 22 ohm at . .

Approx. 13 ohm

TSB Revision

Page 1212 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL Specifications

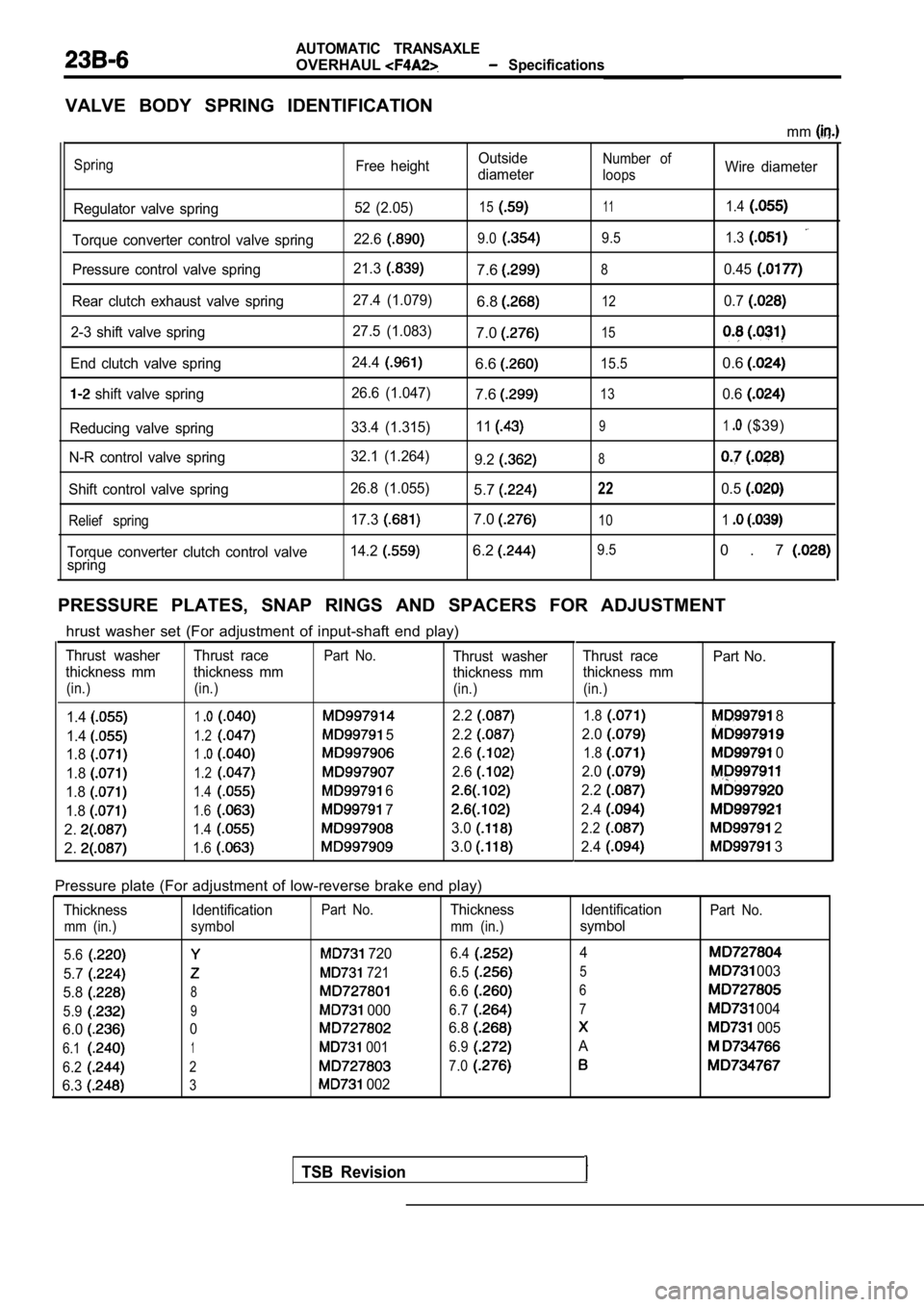

VALVE BODY SPRING IDENTIFICATION

mm

Spring

Regulator valve spring

Torque converter control valve spring

Pressure control valve spring

Rear clutch exhaust valve spring

2-3 shift valve spring

End clutch valve spring

shift valve spring

Reducing valve spring

N-R control valve spring

Shift control valve spring

Relief spring

Torque converter clutch control valve

spring Free height

52 (2.05)

22.6

21.3

27.4 (1.079)

27.5 (1.083)

24.4

26.6 (1.047)

33.4 (1.315)

32.1 (1.264)

26.8 (1.055) 17.3

14.2

Outside

diameter

15

9.0

7.6

6.8

7.0

6.6

7.6

11

9.2

5.7

7.0

6.2

Number of

loops

11

9.5

8

12

15

15.5

13

9

8

22

10

9.5

Wire diameter

1.4

1.3

0.45

0.7

0.6

0.6

1($39)

0.5

1

0 . 7

PRESSURE PLATES, SNAP RINGS AND SPACERS FOR ADJUSTM ENT

TSB Revision

hrust washer set (For adjustment of input-shaft end play)

Thrust washer Thrust racePart No.Thrust washer

thickness mm thickness mm thickness mm

(in.) (in.) (in.)

1.412.2

1.41.2 52.2

1.812.6

1.81.22.6

1.81.4 6

1.81.6 7

2.1.43.0

2.1.63.0

Thrust race

thickness mm

(in.)

Part No.

1.8 8

2.0

1.8 0

2.0

2.2

2.4

2.2 2

2.4

3

Pressure plate (For adjustment of low-reverse brake end play)

Thickness IdentificationPart No.Thickness

mm (in.) symbol mm (in.)

5.6

7206.4

5.7 721 6.5

5.886.6

5.99 0006.7

6.006.8

6.11 0016.9

6.227.0

6.33 002 Identification

symbol

4

5

6 7

A

Part No.

003

004

005

Page 1215 of 2103

AUTOMATIC

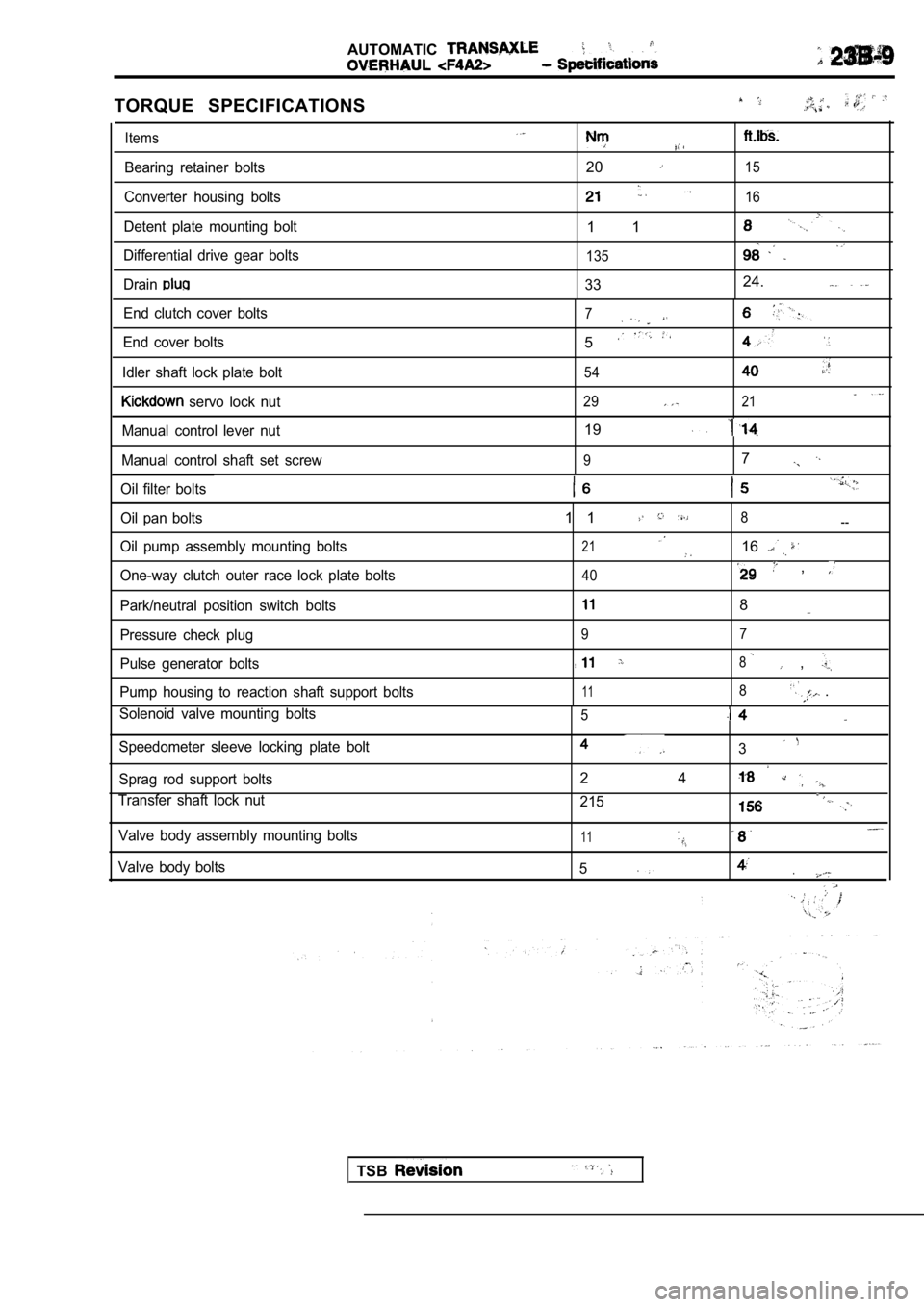

TORQUE SPECIFICATIONS

Items

Bearing retainer bolts2015

Converter housing bolts16

Detent plate mounting bolt1 1

Differential drive gear bolts135

Drain3324.

End clutch cover bolts

End cover bolts

Idler shaft lock plate bolt

servo lock nut

7

5

54

2921

Manual control lever nut19

Manual control shaft set screw97

Oil filter bolts

Oil pan bolts

Oil pump assembly mounting bolts

One-way clutch outer race lock plate bolts

Park/neutral position switch bolts

Pressure check plug

Pulse generator bolts

Pump housing to reaction shaft support bolts1 18--

21

16

40 ,

8

9 7

8 ,

118 .

Solenoid valve mounting bolts5

Speedometer sleeve locking plate bolt3

Sprag rod support bolts

Transfer shaft lock nut2 4

215

Valve body assembly mounting bolts

Valve body bolts11

.5

TSB

Page 1220 of 2103

4AUTOMATIC Transaxle

TRANSAXLE

16

18

16

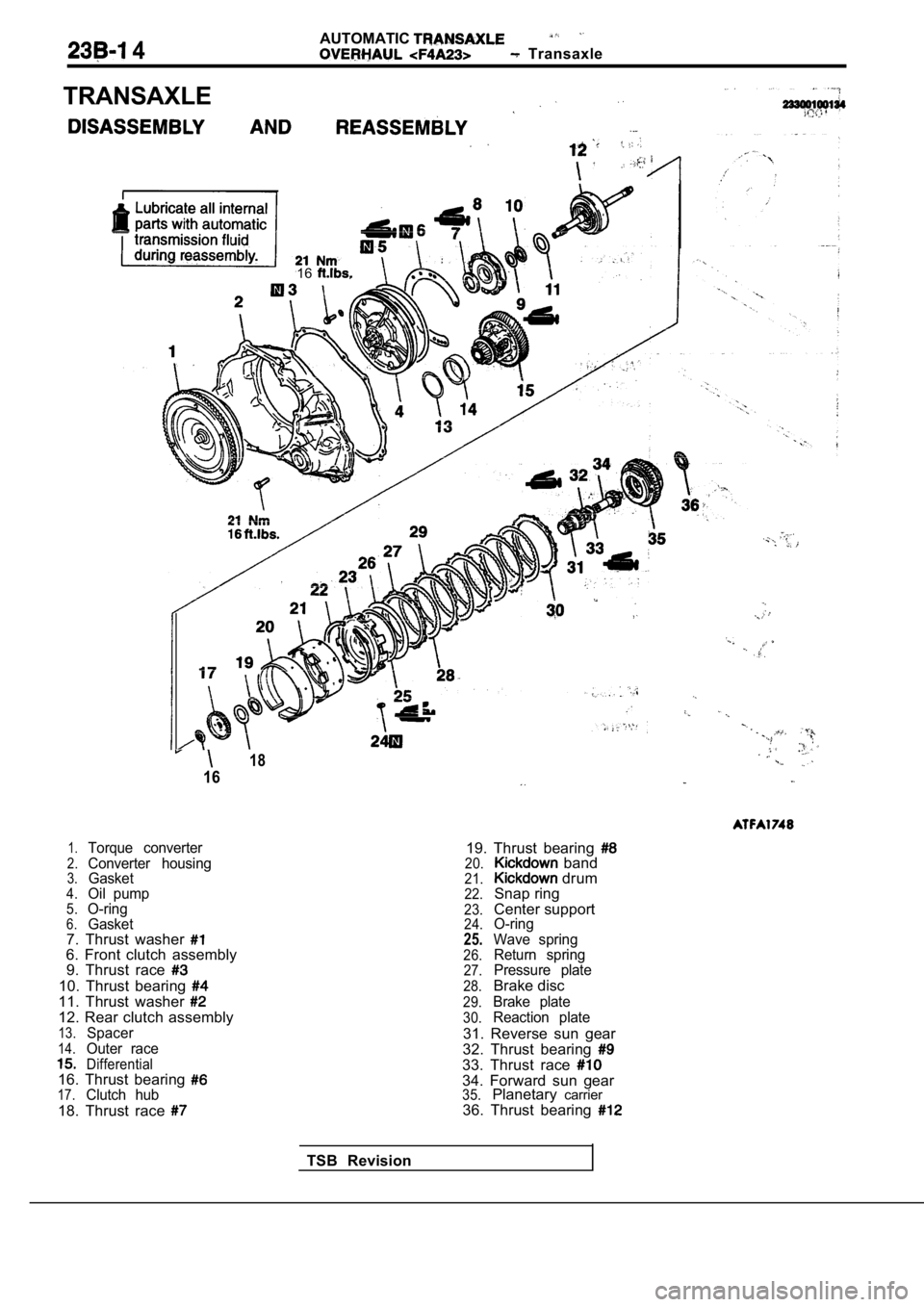

1.Torque converter

2.Converter housing3.Gasket4.Oil pump5.O-ring6.Gasket7. Thrust washer 6. Front clutch assembly 9. Thrust race

10. Thrust bearing

11. Thrust washer

12. Rear clutch assembly

13.Spacer

14.Outer race

Differential16. Thrust bearing 17.Clutch hub

18. Thrust race

19. Thrust bearing 20. band

21. drum

22.Snap ring

23.Center support24.O-ring

25.Wave spring

26.Return spring

27.Pressure plate

28.Brake disc

29.Brake plate

30.Reaction plate

31. Reverse sun gear

32. Thrust bearing

33. Thrust race

34. Forward sun gear35.Planetary carrier

36. Thrust bearing

TSB Revision

Page 1222 of 2103

6AUTOMATIC TRANSAXLE

OVERHAUL Transaxle

70. Clamp

71.

Gasket

72. Oil pan

73.

Gasket

74.Drain plug

75.O-ring

76.Set screw77.O-ring78.Detent plate

79. Sprag rod support

80. Parking sprag rod

2170046

81.Control shaft

82. D-ring

83. Transfer shaft cover

84.Lock nut

85. Driven gear

86.Outer race

87.Spacer

-88.Outer race89.Transaxle case

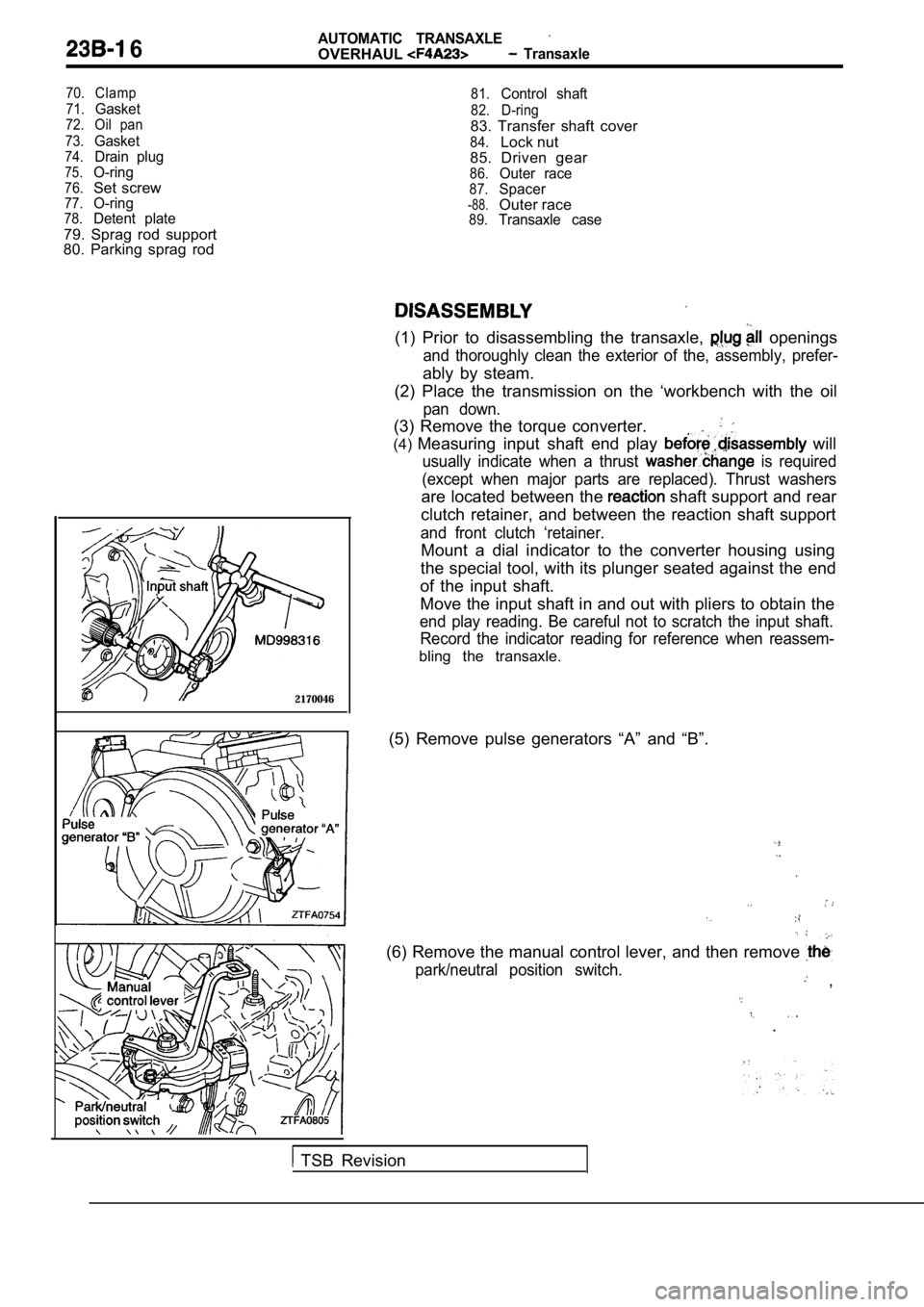

(1) Prior to disassembling the transaxle, openings

and thoroughly clean the exterior of the, assembly, prefer-

ably by steam.

(2) Place the transmission on the ‘workbench with t he oil

pan down.

(3) Remove the torque converter.

.

(4)Measuring input shaft end play will

usually indicate when a thrust is required

(except when major parts are replaced). Thrust wash ers

are located between the shaft support and rear

clutch retainer, and between the reaction shaft sup port

and front clutch ‘retainer.

Mount a dial indicator to the converter housing usi ng

the special tool, with its plunger seated against t he end

of the input shaft.

Move the input shaft in and out with pliers to obta in the

end play reading. Be careful not to scratch the inp ut shaft.

Record the indicator reading for reference when rea ssem-

bling the transaxle.

(5) Remove pulse generators “A” and “B”.

(6) Remove the manual control lever, and then remov e

park/neutral position switch. ,

.

TSB Revision

Page 1235 of 2103

AUTOMATIC TRANSAXLE

O V E R H A U L

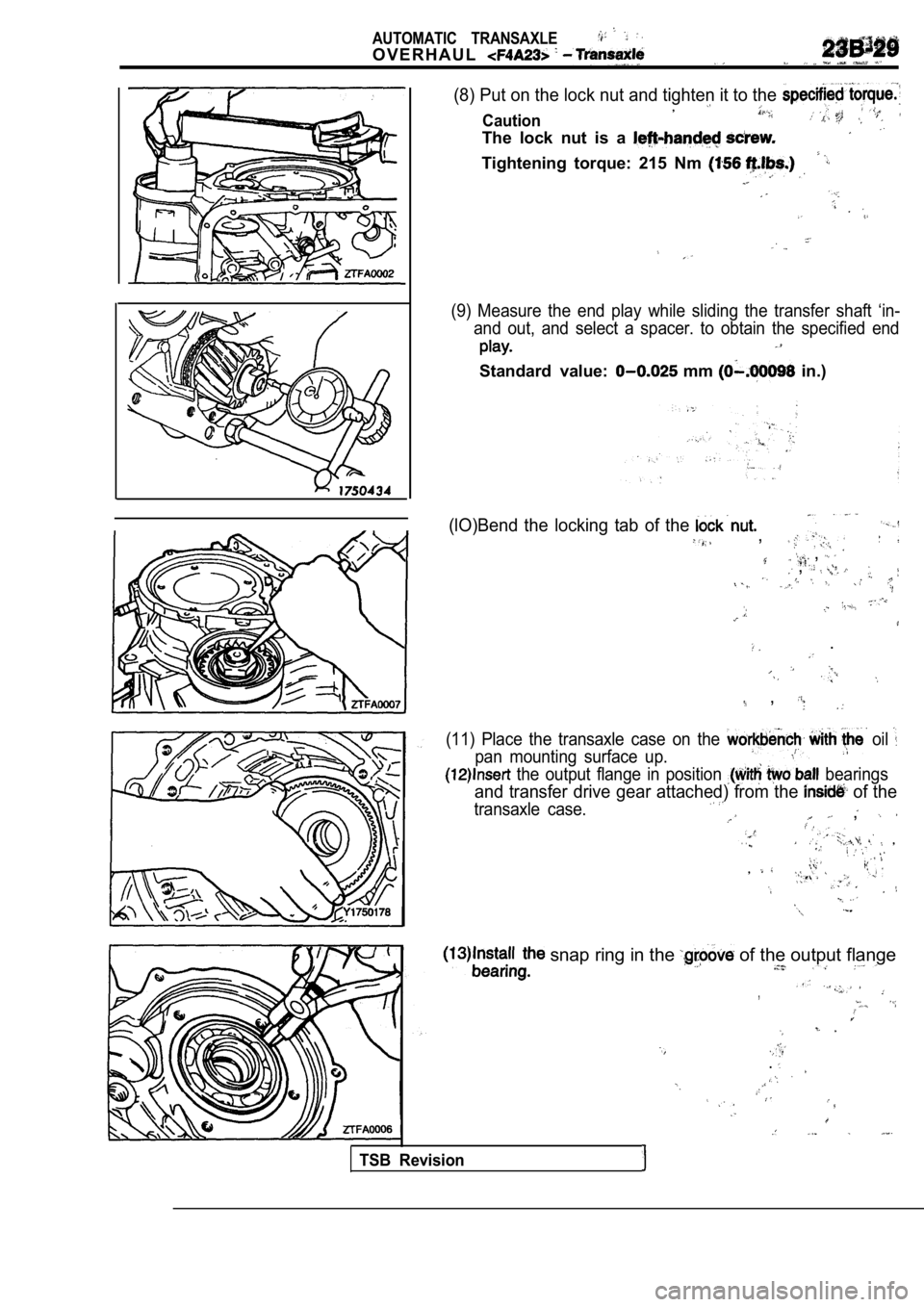

(8) Put on the lock nut and tighten it to the

Caution,

The lock nut is a

Tightening torque: 215 Nm

(9) Measure the end play while sliding the transfer shaft ‘in-

and out, and select a spacer. to obtain the specifi ed end

Standard value: mm in.)

(lO)Bend the locking tab of the ,

, ,

.

,

(11) Place the transaxle case on the oil

pan mounting surface up.

the output flange in position bearings

and transfer drive gear attached) from the of the

transaxle case. ,

. . ,

,

snap ring in the of the output flange

.

,

.

TSB Revision

Page 1236 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL Transaxle

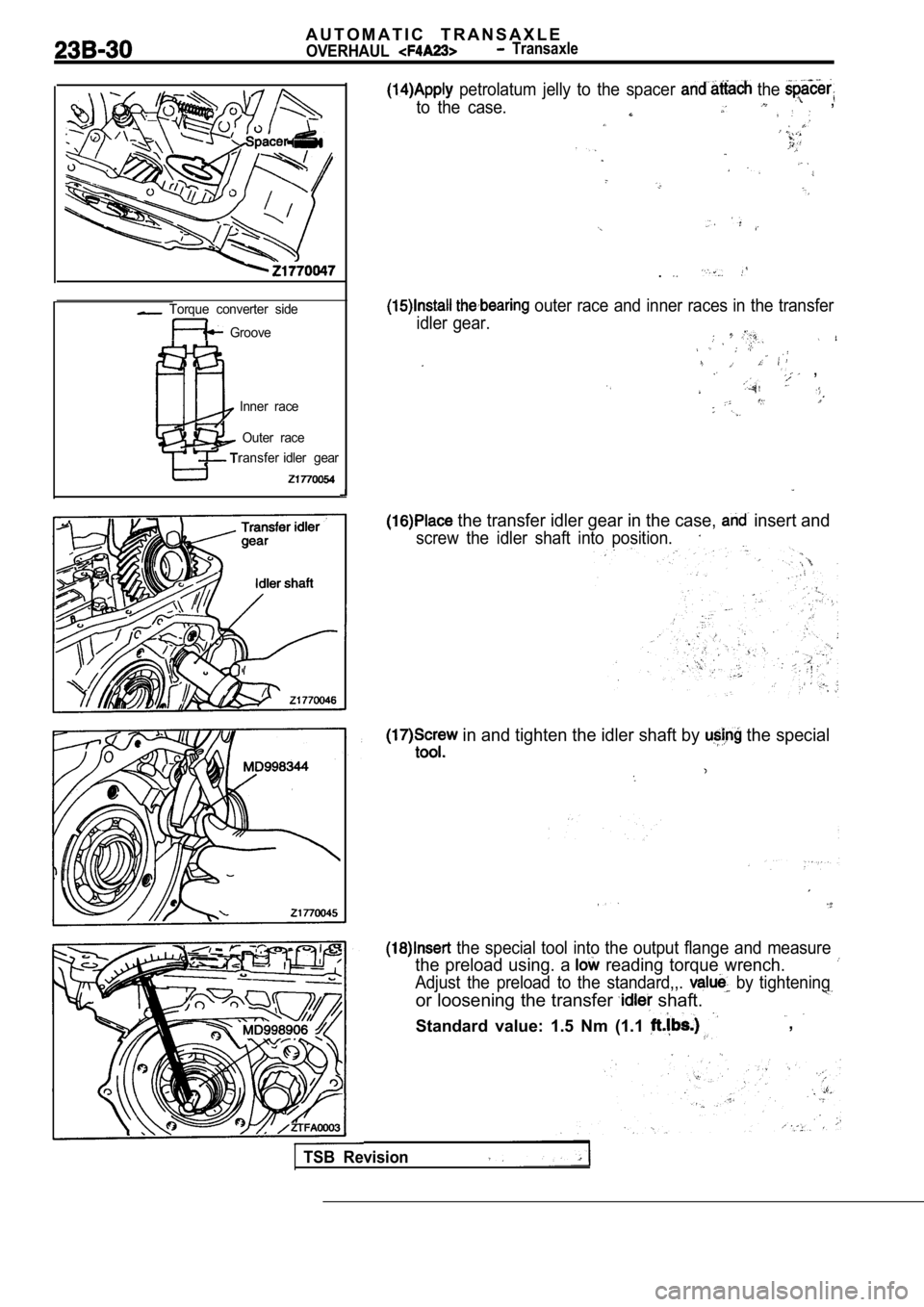

Torque converter side

GrooveInner raceOuter race

ransfer idler gear

petrolatum jelly to the spacer the

to the case. ,

.

outer race and inner races in the transfer

idler gear.

,

the transfer idler gear in the case, insert and

screw the idler shaft into position.

in and tighten the idler shaft by the special

the special tool into the output flange and measur e

the preload using. a reading torque wrench.

Adjust the preload to the standard,,. by tightening

or loosening the transfer shaft.

Standard value: 1.5 Nm (1.1 ,

TSB Revision

Page 1237 of 2103

OVERHAUL.

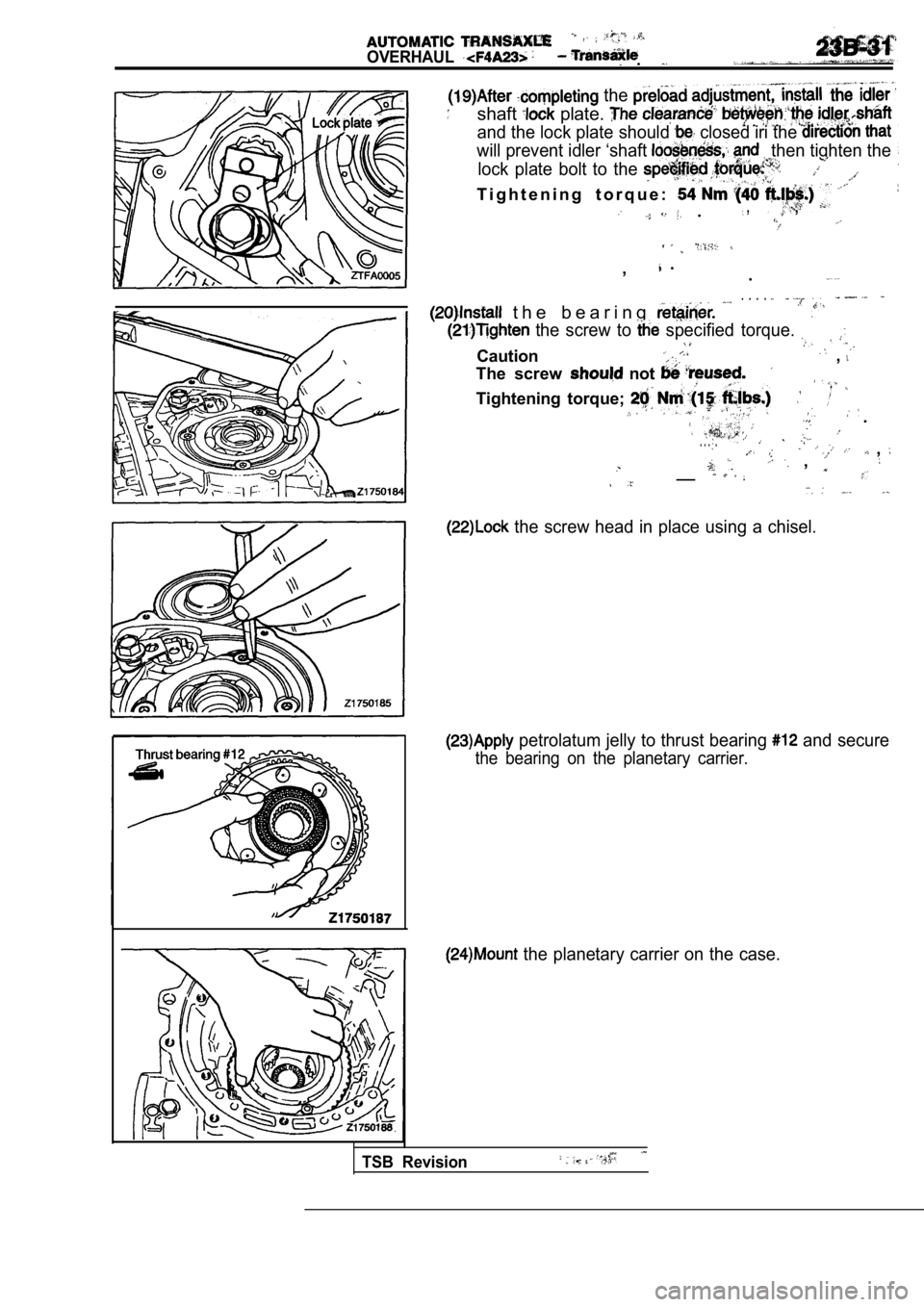

the

shaft plate.

and the lock plate should closed iri the

will prevent idler ‘shaft then tighten the

lock plate bolt to the

T i g h t e n i n g t o r q u e :

. , ,

, . .

t h e b e a r i n g

. . . .

the screw to specified torque.

Caution,

The screw not

Tightening torque;

.

. . . . , , __

the screw head in place using a chisel.

petrolatum jelly to thrust bearing and secure

the bearing on the planetary carrier.

the planetary carrier on the case.

TSB Revision

Page 1246 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL. .

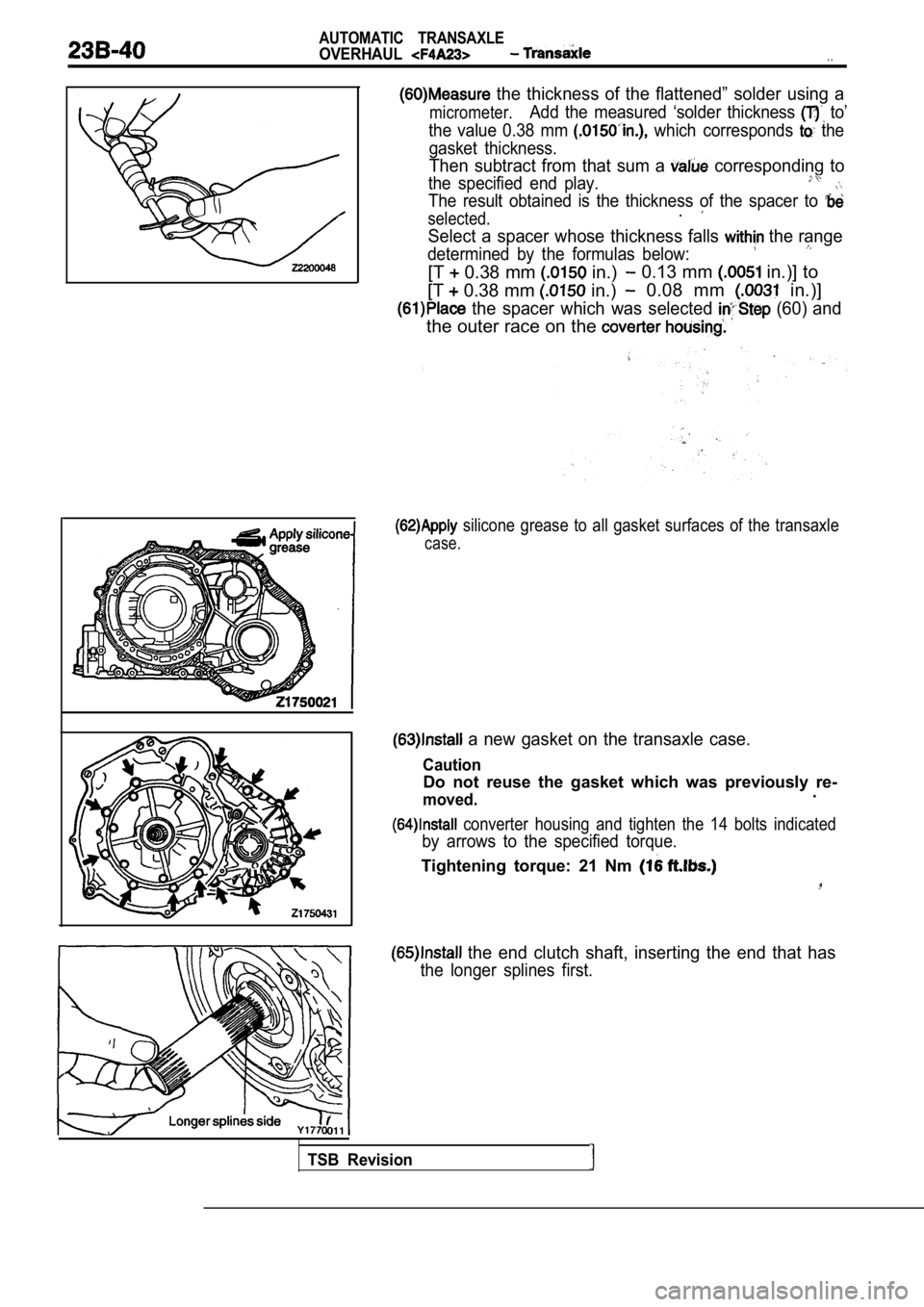

the thickness of the flattened” solder using a

micrometer.Add the measured ‘solder thickness to’

the value 0.38 mm

which corresponds the

gasket thickness.

Then subtract from that sum a corresponding to

the specified end play.

The result obtained is the thickness of the spacer to

selected..

Select a spacer whose thickness falls the range

determined by the formulas below:

[T 0.38 mm in.) 0.13 mm in.)] to

[T

0.38 mm in.) 0.08 mm in.)]

the spacer which was selected (60) and

the outer race on the

silicone grease to all gasket surfaces of the tran saxle

case.

a new gasket on the transaxle case.

Caution

Do not reuse the gasket which was previously re-

moved..

converter housing and tighten the 14 bolts indicat ed

by arrows to the specified torque.

Tightening torque: 21 Nm

the end clutch shaft, inserting the end that has

the longer splines first.

TSB Revision