torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1323 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL

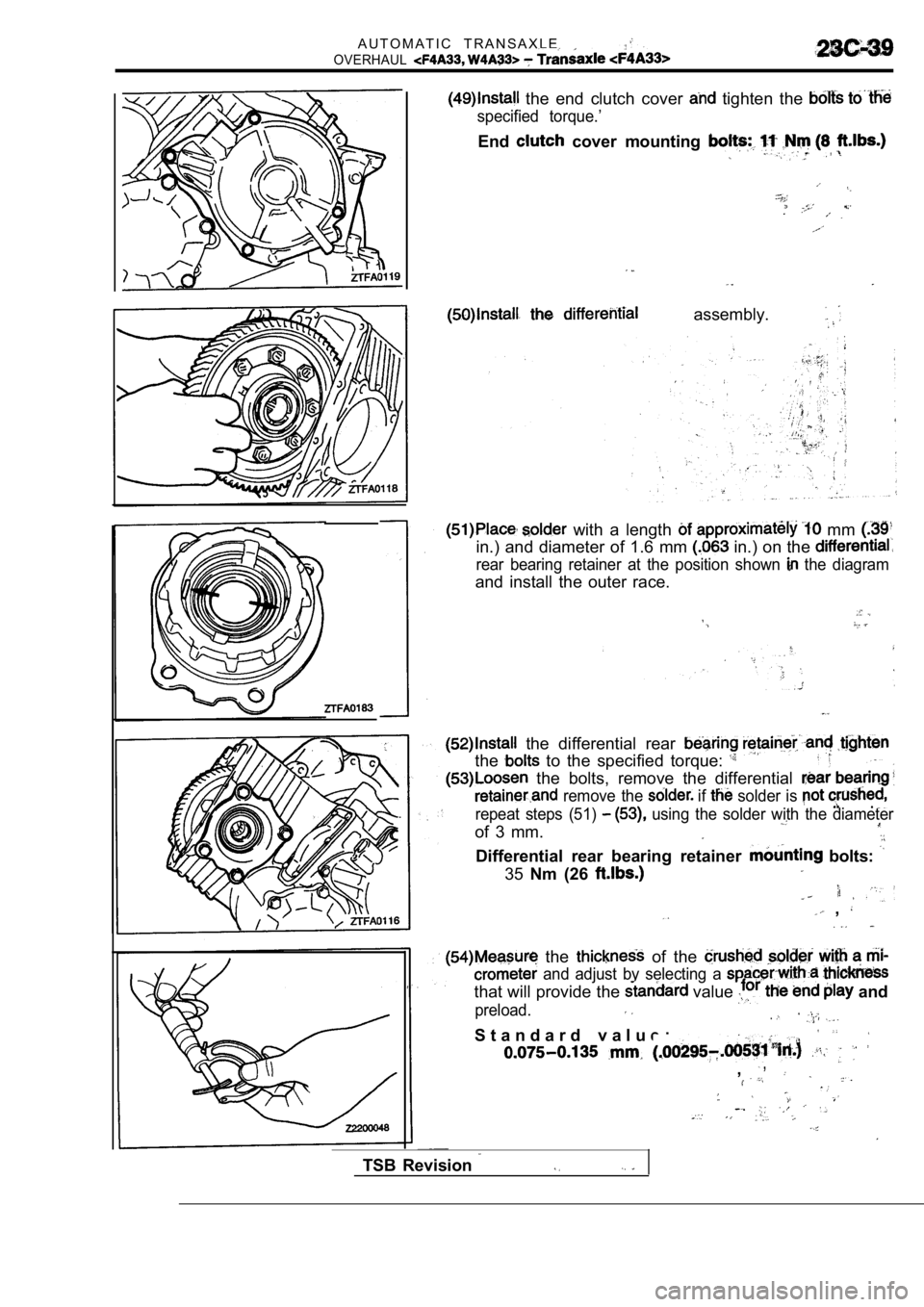

the end clutch cover tighten the

specified torque.’

End cover mounting

assembly.

with a length mm

in.) and diameter of 1.6 mm in.) on the

rear bearing retainer at the position shown the diagram

and install the outer race.

the differential rear

the to the specified torque:

the bolts, remove the differential

remove the if solder is

repeat steps (51) using the solder with the diameter

of 3 mm.

Differential rear bearing retainer bolts:

35Nm (26

,

the of the

and adjust by selecting a

that will provide the value and

preload..

S t a n d a r d v a l u e :

,,

TSB Revision

Page 1324 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

-Transaxle

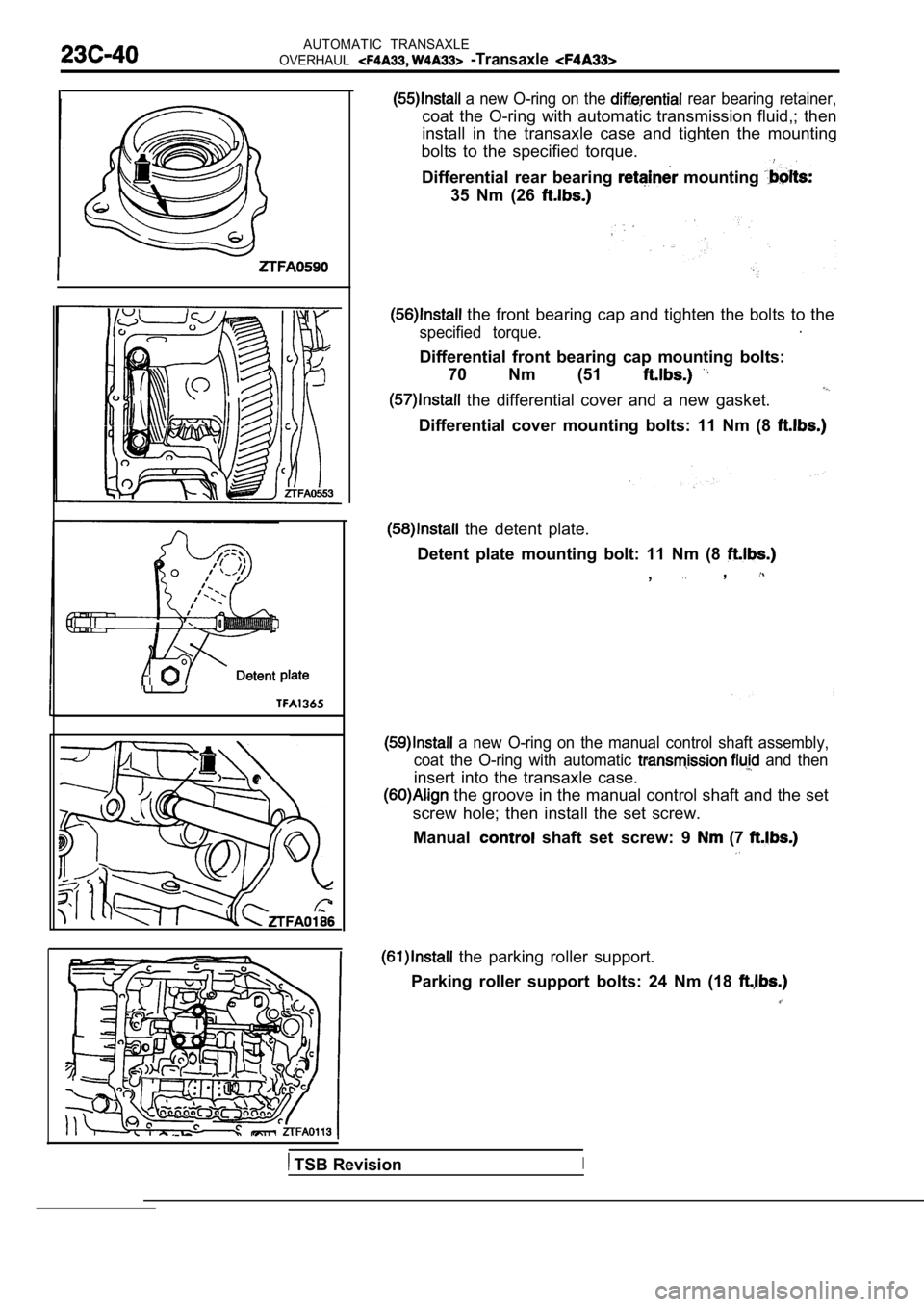

a new O-ring on the rear bearing retainer,

coat the O-ring with automatic transmission fluid,; then

install in the transaxle case and tighten the mount ing

bolts to the specified torque.

Differential rear bearing

mounting

35 Nm (26

the front bearing cap and tighten the bolts to the

specified torque..

Differential front bearing cap mounting bolts: 70 Nm (51

the differential cover and a new gasket.

Differential cover mounting bolts: 11 Nm (8

the detent plate.

Detent plate mounting bolt: 11 Nm (8

,,

a new O-ring on the manual control shaft assembly,

coat the O-ring with automatic

and then

insert into the transaxle case.

the groove in the manual control shaft and the set

screw hole; then install the set screw.

Manual

shaft set screw: 9 (7

the parking roller support.

Parking roller support bolts: 24 Nm (18

TSB RevisionI

Page 1325 of 2103

AUTOMATIC

OVERHAUL Transaxle

A

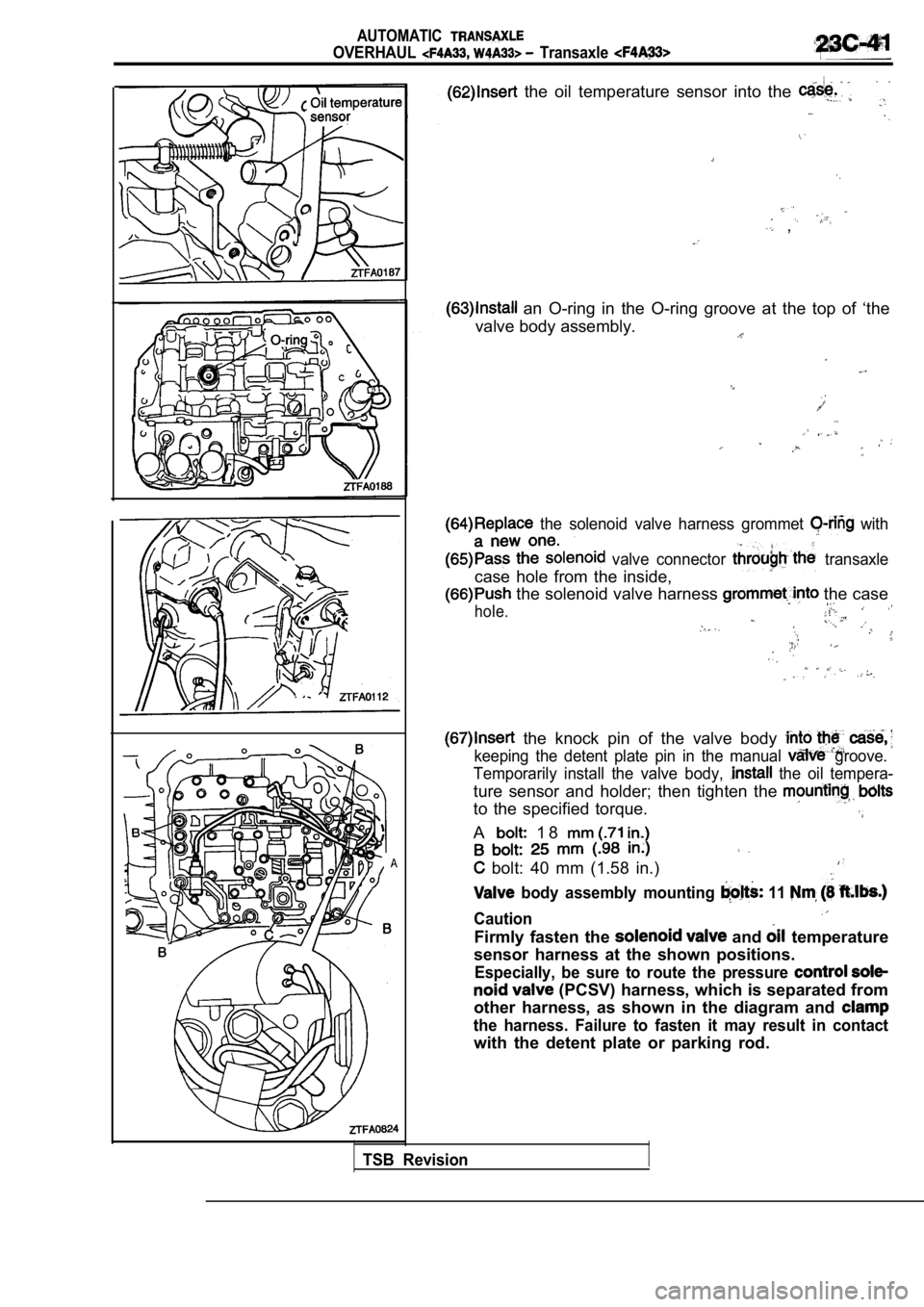

the oil temperature sensor into the

,

an O-ring in the O-ring groove at the top of ‘the

valve body assembly.

the solenoid valve harness grommet with

valve connector transaxle

case hole from the inside,

the solenoid valve harness the case

hole.

the knock pin of the valve body

keeping the detent plate pin in the manual groove.

Temporarily install the valve body,

the oil tempera-

ture sensor and holder; then tighten the

to the specified torque.

A 1 8

bolt: 40 mm (1.58 in.)

body assembly mounting 11

Caution

Firmly fasten the and temperature

sensor harness at the shown positions.

Especially, be sure to route the pressure

(PCSV) harness, which is separated from

other harness, as shown in the diagram and

the harness. Failure to fasten it may result in con tact

with the detent plate or parking rod.

TSB Revision

Page 1327 of 2103

.

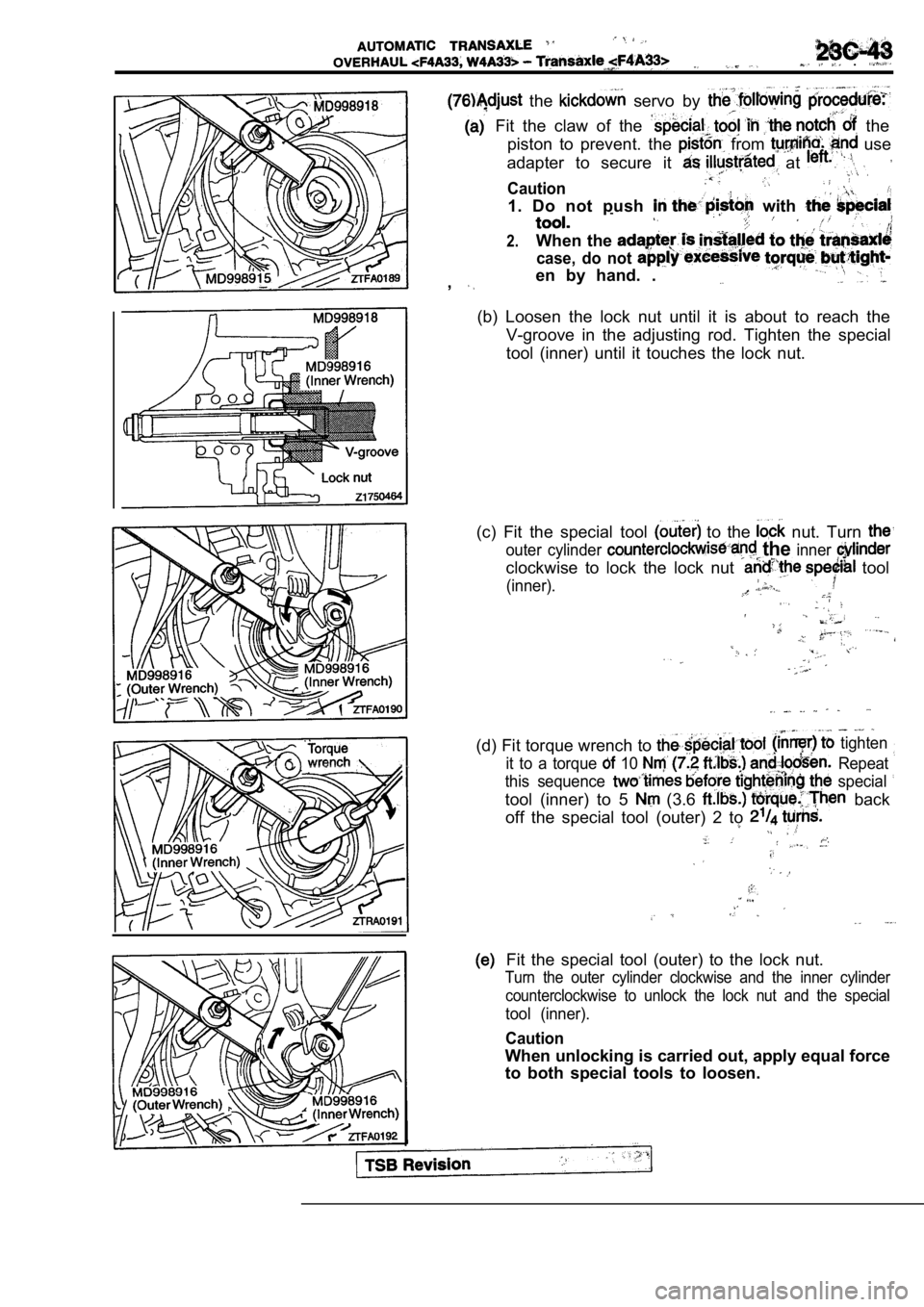

the servo by

Fit the claw of the the

piston to prevent. the

from use

adapter to secure it

at

Caution

1. Do not push with

2.When the

case, do not

en by hand. .,

(b) Loosen the lock nut until it is about to reach the

V-groove in the adjusting rod. Tighten the special

tool (inner) until it touches the lock nut.

(c) Fit the special tool

to the nut. Turn

outer cylinder the inner

clockwise to lock the lock nut tool

(inner).

(d) Fit torque wrench to tighten

it to a torque 10 Repeat

this sequence

special

tool (inner) to 5 (3.6 back

off the special tool (outer) 2 to

Fit the special tool (outer) to the lock nut.

Turn the outer cylinder clockwise and the inner cyl inder

counterclockwise to unlock the lock nut and the spe cial

tool (inner).

Caution

When unlocking is carried out, apply equal force

to both special tools to loosen.

Page 1328 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

Transaxle

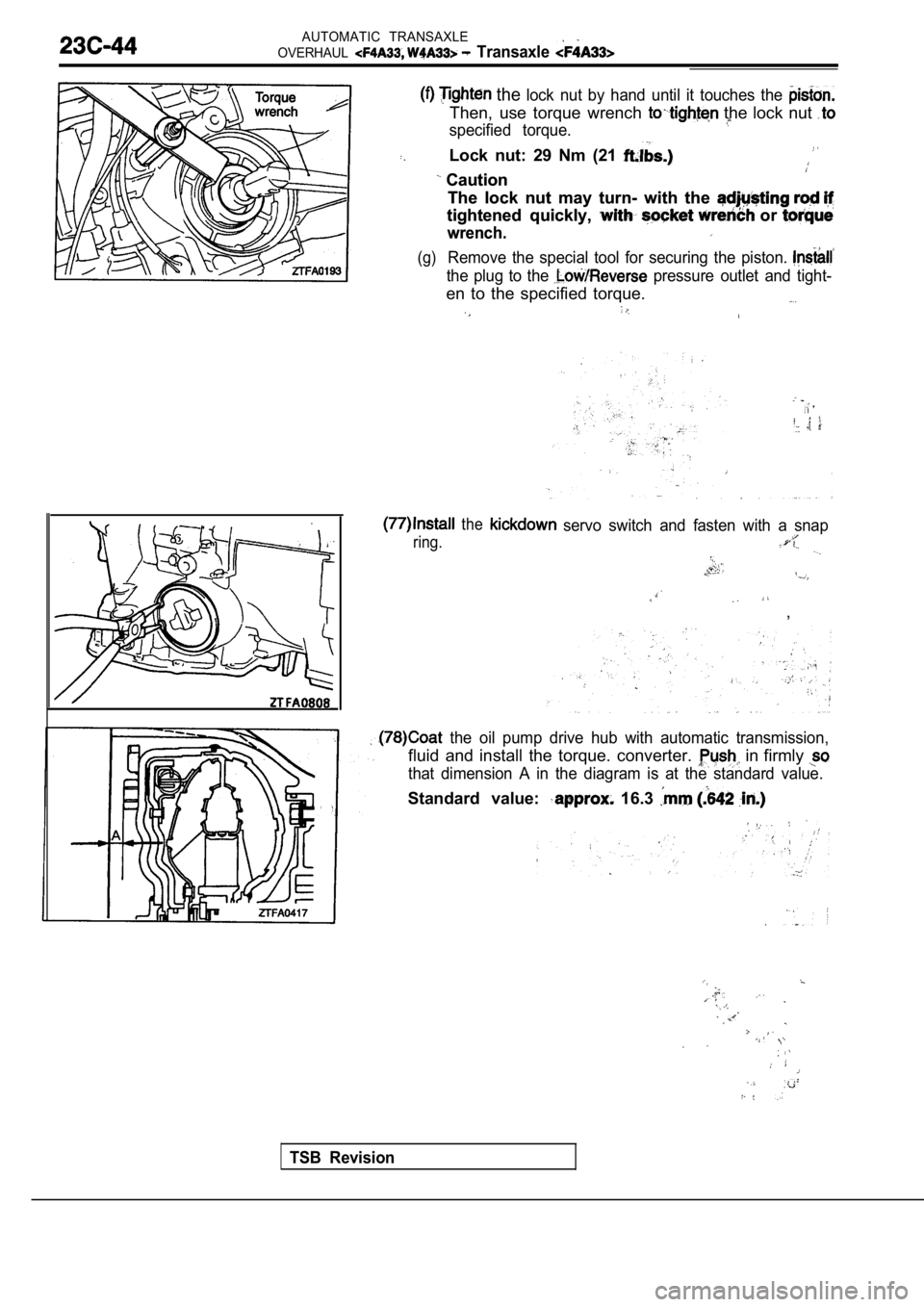

the lock nut by hand until it touches the

Then, use torque wrench the lock nut

specified torque.

Lock nut: 29 Nm (21

Caution Caution

The lock nut may turn- with the The lock nut may turn- with the

tightened quickly, or tightened quickly, or

wrench.

wrench.

(g)Remove the special tool for securing the piston.

the plug to the pressure outlet and tight-

en to the specified torque.

ring. the

servo switch and fasten with a snap

,

the oil pump drive hub with automatic transmission

,

fluid and install the torque. converter. in firmly

that dimension A in the diagram is at the standard value.

Standard value: 16.3

TSB Revision

Page 1329 of 2103

-Transaxle

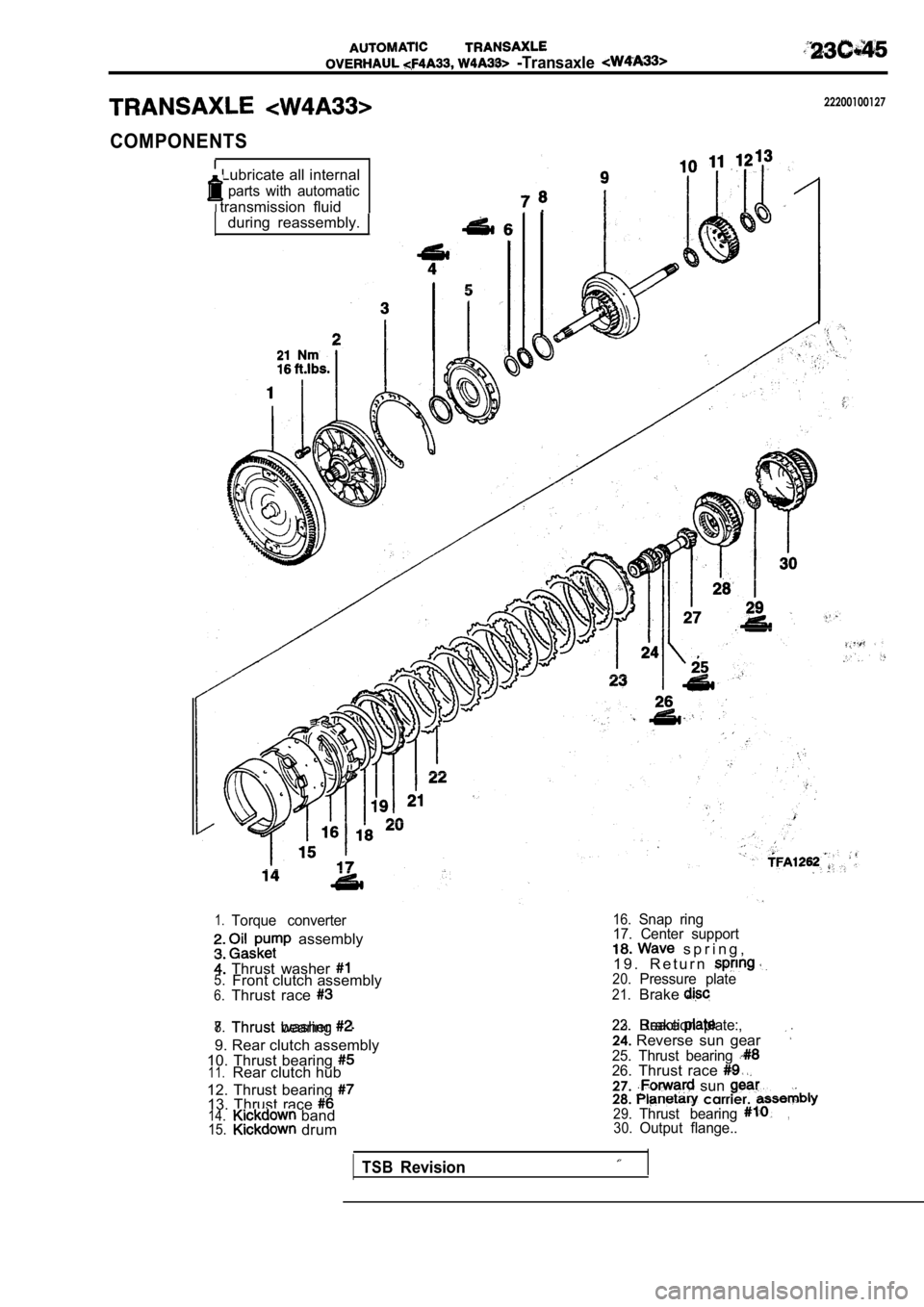

COMPONENTS

Lubricate all internal

parts with automatic

Itransmission fluid

during reassembly.

22200100127

1.Torque converter

assembly

Thrust washer 5.Front clutch assembly6.Thrust race

7.Thrust bearing 8.Thrust washer

9. Rear clutch assembly

10. Thrust bearing

11.Rear clutch hub

12. Thrust bearing

13. Thrust race 14. band15. drum

16.Snap ring

17. Center support

s p r i n g ,

1 9 . R e t u r n

20.Pressure plate

21.Brake

22.Brake23.Reaction plate:,.

24. Reverse sun gear25. Thrust bearing 26.Thrust race 27. sun 28. carrier. 29.Thrust bearing,30.Output flange..

TSBRevision

Page 1331 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL -Transaxle

56. End clutch cover57.Pulse58.Lock bolt59.Idler shaft60.Idler gear61.Spacer62.Gasket63. Idler gear cover

64. Differential bearing retainer

65.Spacer66. Differential front bearing cap

67.Differential assembly

6 8 . G a s k e t69. Differential cover70. Output retainer

71. Center differential assembly

72. Center bearing retainer’

73. Stopper ring

74. unit75. Center bearing retainer7 6 . F r o n t

77. Rear output shaft 78. Transaxle case

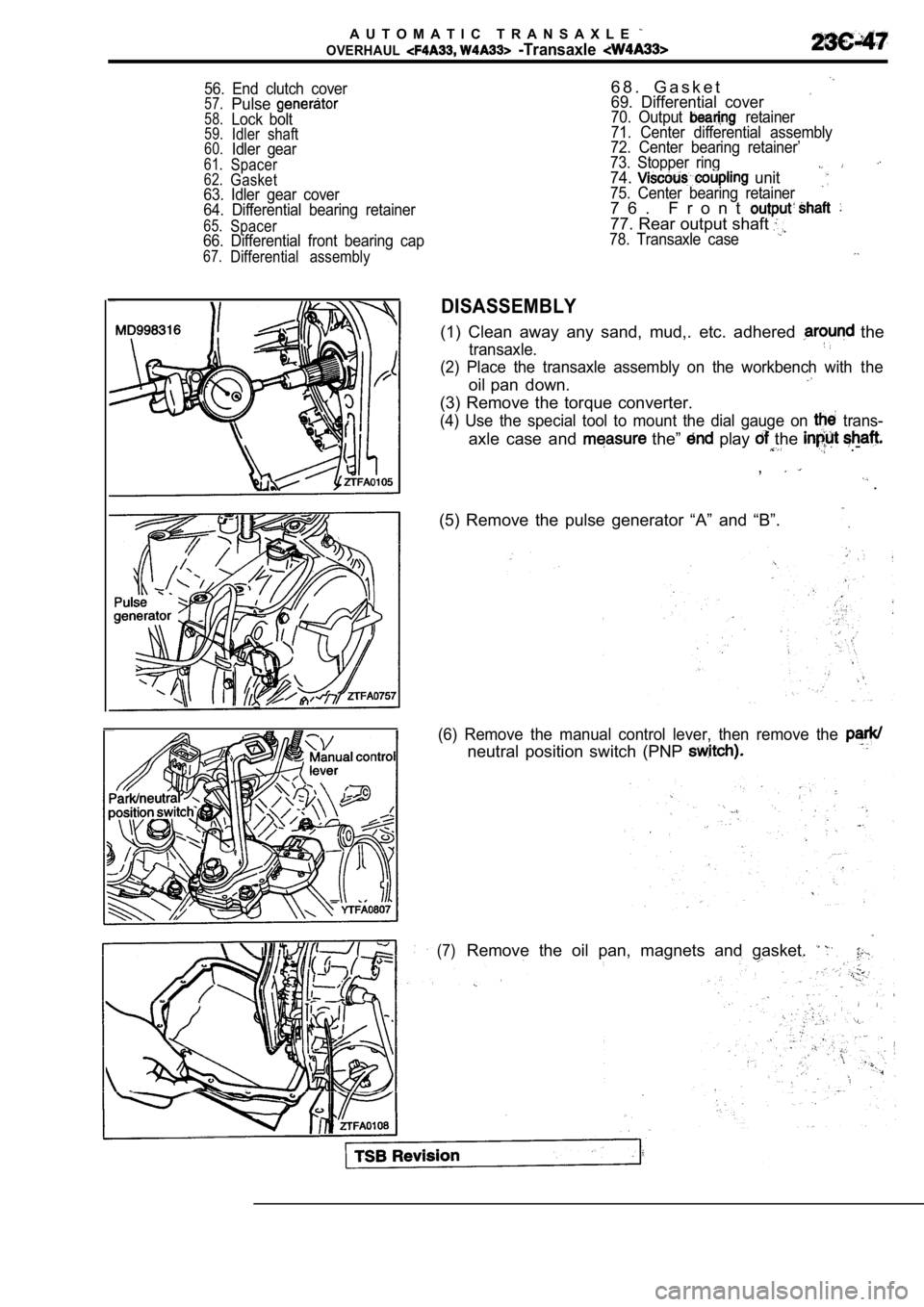

DISASSEMBLY

(1) Clean away any sand, mud,. etc. adhered the

transaxle.

(2) Place the transaxle assembly on the workbench w ith the

oil pan down.

(3) Remove the torque converter.

(4) Use the special tool to mount the dial gauge on trans-

axle case and the” play the .-

,

.

(5) Remove the pulse generator “A” and “B”.

(6) Remove the manual control lever, then remove th e

neutral position switch (PNP

(7)Remove the oil pan, magnets and gasket.

Page 1342 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL Transaxle

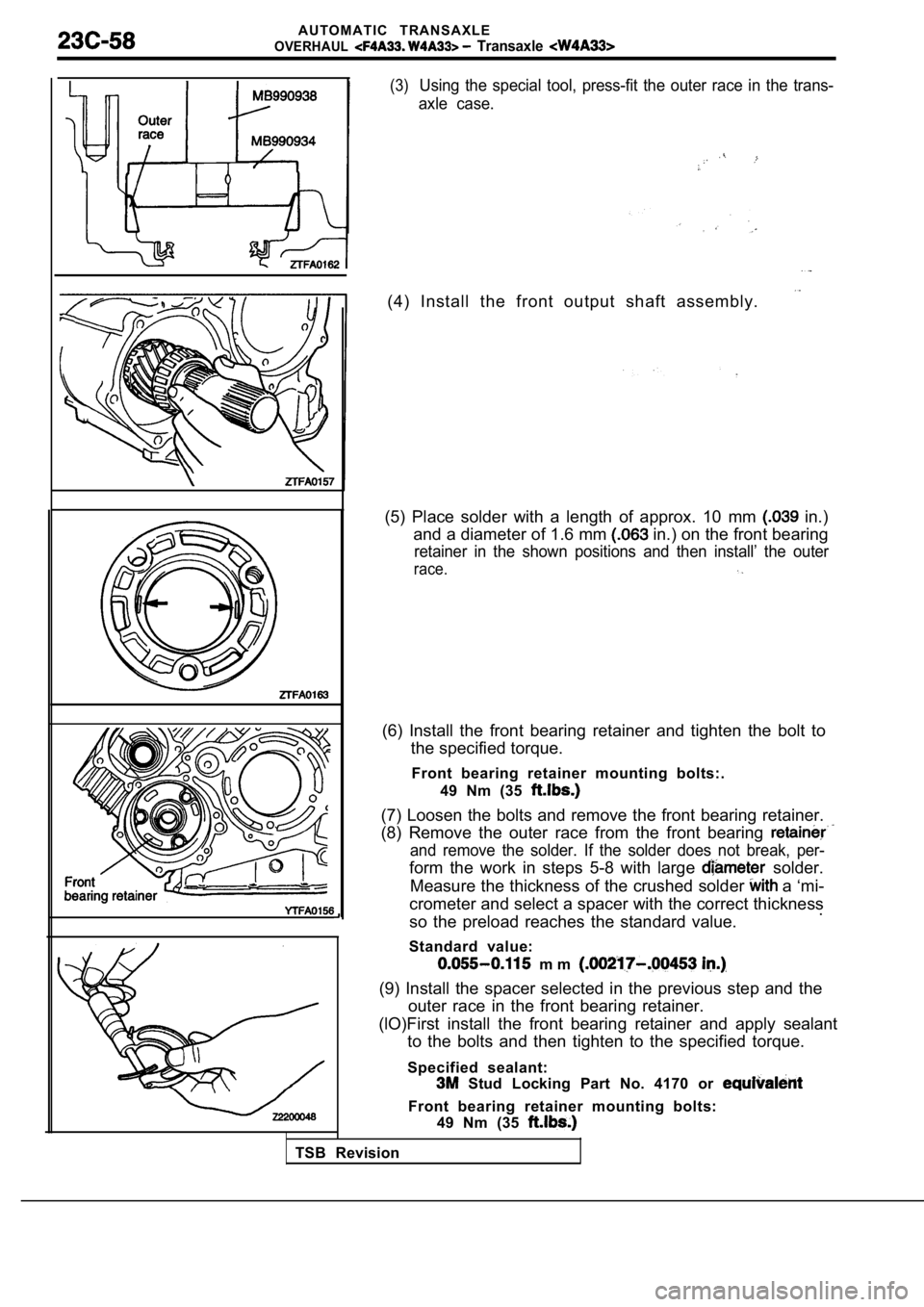

(3)Using the special tool, press-fit the outer race in the trans-

axle case.

(4) Install the front output shaft assembly.

(5) Place solder with a length of approx. 10 mm in.)

and a diameter of 1.6 mm

in.) on the front bearing

retainer in the shown positions and then install’ t he outer

race.

(6) Install the front bearing retainer and tighten the bolt to

the specified torque.

Front bearing retainer mounting bolts:. 49 Nm (35

(7) Loosen the bolts and remove the front bearing r etainer.

(8) Remove the outer race from the front bearing

and remove the solder. If the solder does not break , per-

form the work in steps 5-8 with large solder.

Measure the thickness of the crushed solder

a ‘mi-

crometer and select a spacer with the correct thick ness

so the preload reaches the standard value. .

Standard value:

m m

(9) Install the spacer selected in the previous ste p and the

outer race in the front bearing retainer.

(lO)First install the front bearing retainer and ap ply sealant

to the bolts and then tighten to the specified torq ue.

Specified sealant:

Stud Locking Part No. 4170 or

Front bearing retainer mounting bolts: 49 Nm (35

TSB Revision

Page 1344 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL -Transaxle

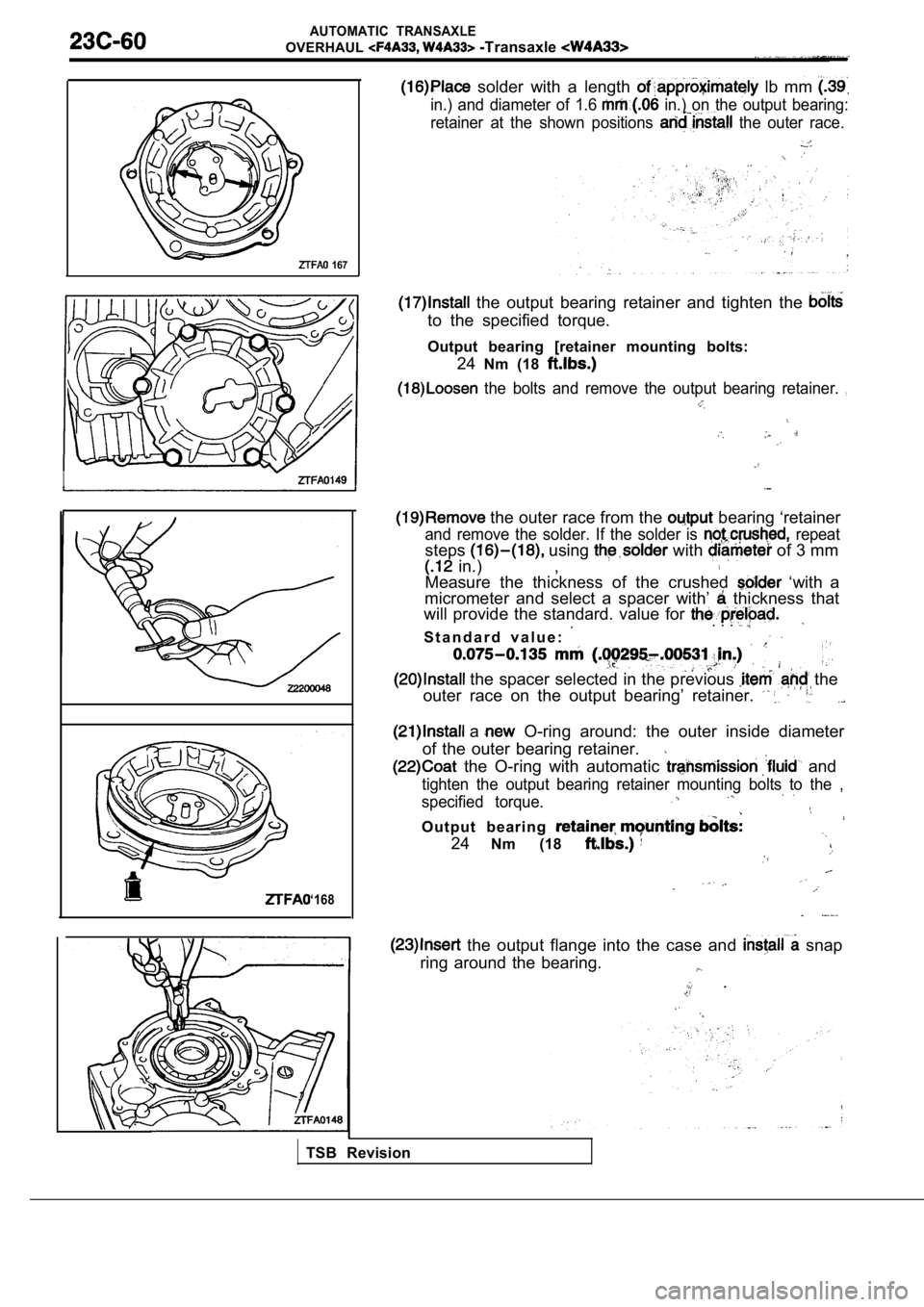

solder with a length lb mm

in.) and diameter of 1.6 in.) on the output bearing:

retainer at the shown positions

the outer race.

167

I

‘168

the output bearing retainer and tighten the

to the specified torque.

Output bearing [retainer mounting bolts: 24Nm (18

the bolts and remove the output bearing retainer.

the outer race from the bearing ‘retainer

and remove the solder. If the solder is repeat

steps using with of 3 mm

in.) ,

Measure the thickness of the crushed ‘with a

micrometer and select a spacer with’

thickness that

will provide the standard. value for

S t a n d a r d v a l u e :

. . .

the spacer selected in the previous the

outer race on the output bearing’ retainer.

a O-ring around: the outer inside diameter

of the outer bearing retainer.

the O-ring with automatic and

tighten the output bearing retainer mounting bolts to the ,

specified torque.

Output bearing

24 Nm (18

the output flange into the case and snap

ring around the bearing.

.

TSB Revision

Page 1352 of 2103

A U T O M A T I C T R A N S A X L E

OVERHAUL -Transaxle

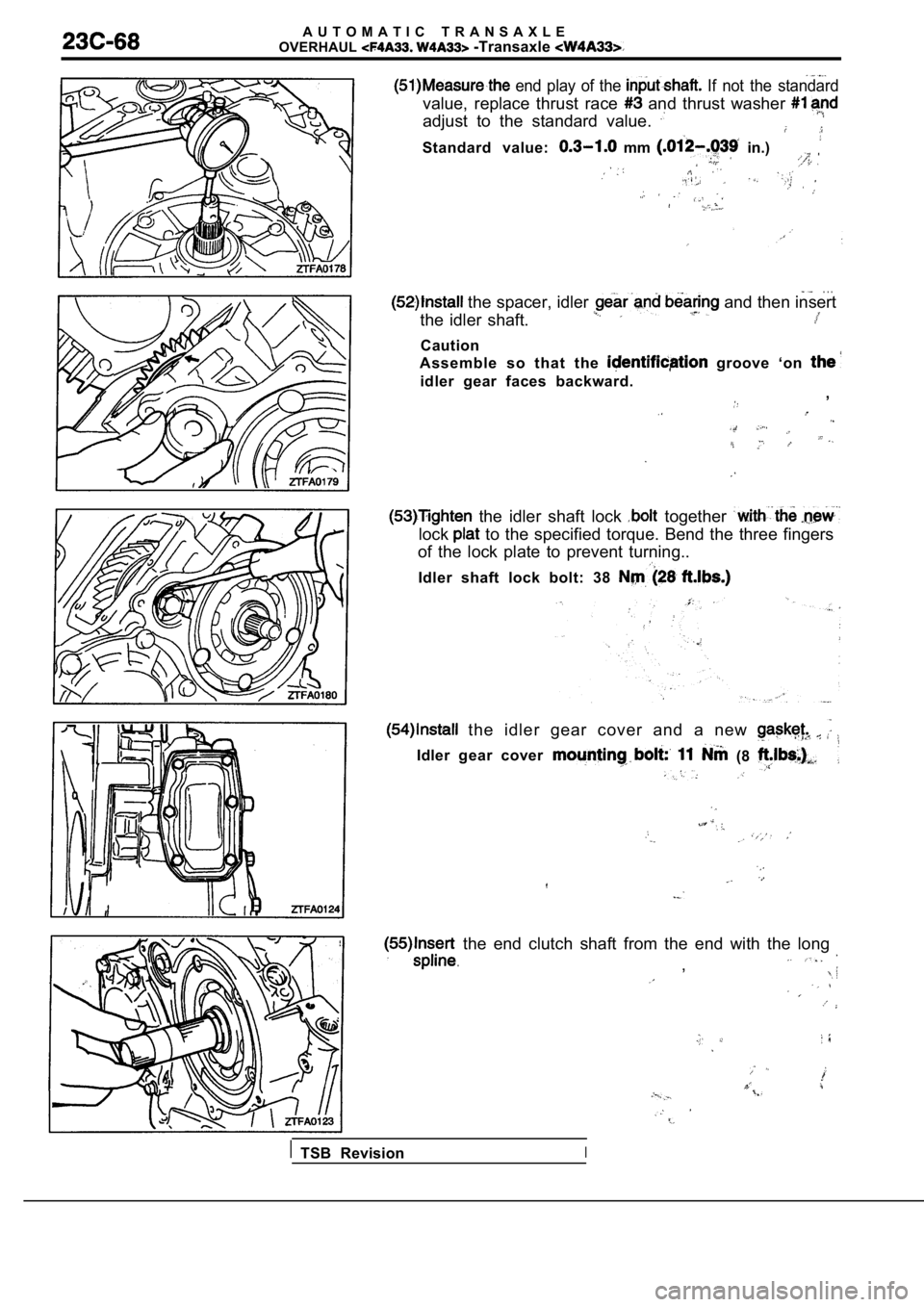

end play of the If not the standard

value, replace thrust race and thrust washer

adjust to the standard value.

Standard value: mm in.)

. . . the spacer, idler and then insert

the idler shaft.

Caution

Assemble so that the

groove ‘on

idler gear faces backward. ,

the idler shaft lock together

lock to the specified torque. Bend the three fingers

of the lock plate to prevent turning..

Idler shaft lock bolt: 38

the idler gear cover and a new

Idler gear cover(8

the end clutch shaft from the end with the long

.,

TSB RevisionI