torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1248 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL . .

Manual control

shaft

O-ring

groove

Set screw

,

the end clutch cover by tightening its mounting,

bolts to the specified torque.

Tightening torque: 7 Nm (5

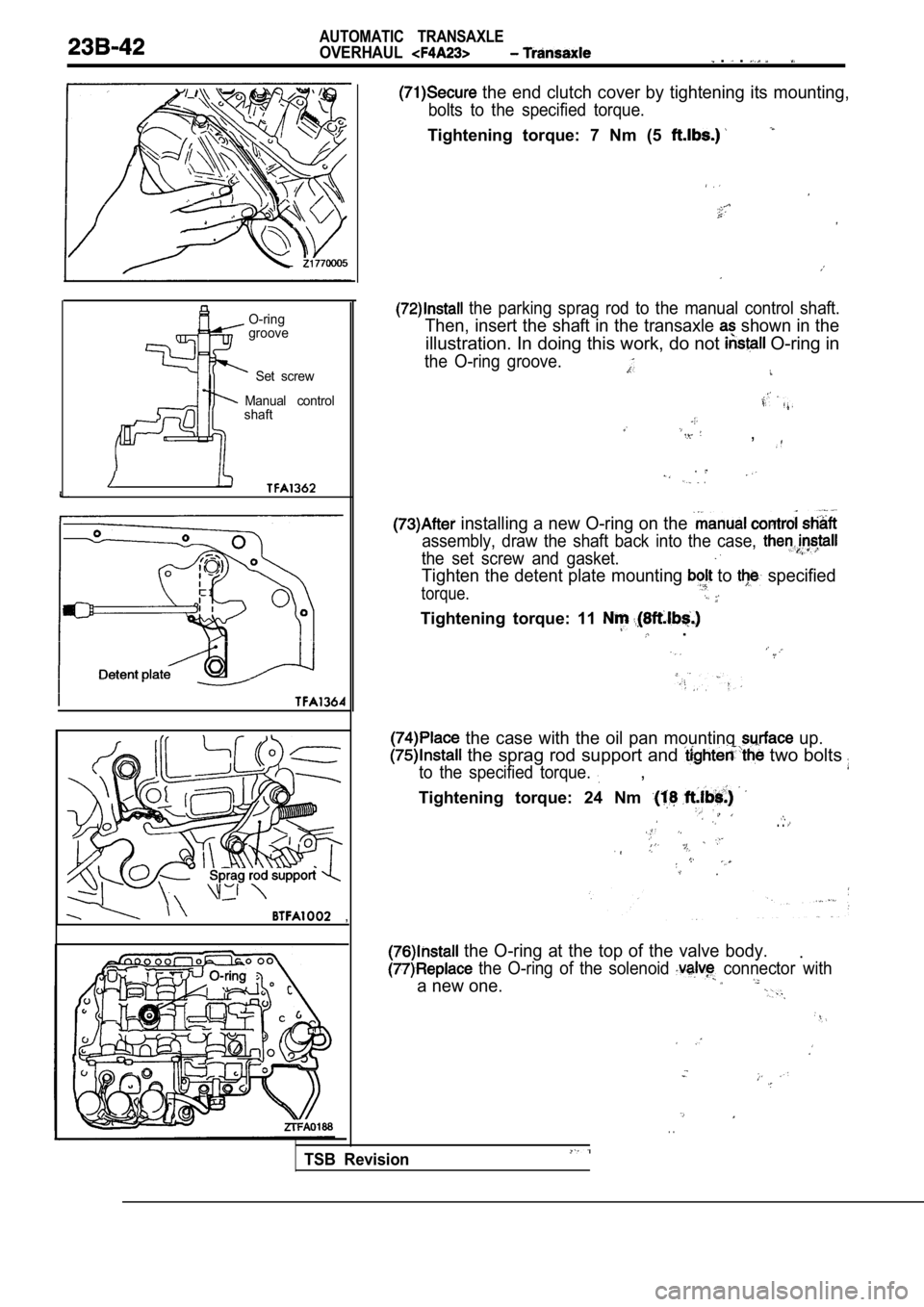

the parking sprag rod to the manual control shaft.

Then, insert the shaft in the transaxle shown in the

illustration. In doing this work, do not O-ring in

the O-ring groove.

,

installing a new O-ring on the

assembly, draw the shaft back into the case,

the set screw and gasket.

Tighten the detent plate mounting to specified

torque.

Tightening torque: 11 .

the case with the oil pan mounting up.

the sprag rod support and two bolts

to the specified torque. ,

Tightening torque: 24 Nm

. .

the O-ring at the top of the valve body..

the O-ring of the solenoid connector with

a new one.

. .

TSB Revision

Page 1249 of 2103

,

body in

plate pin

the valve,

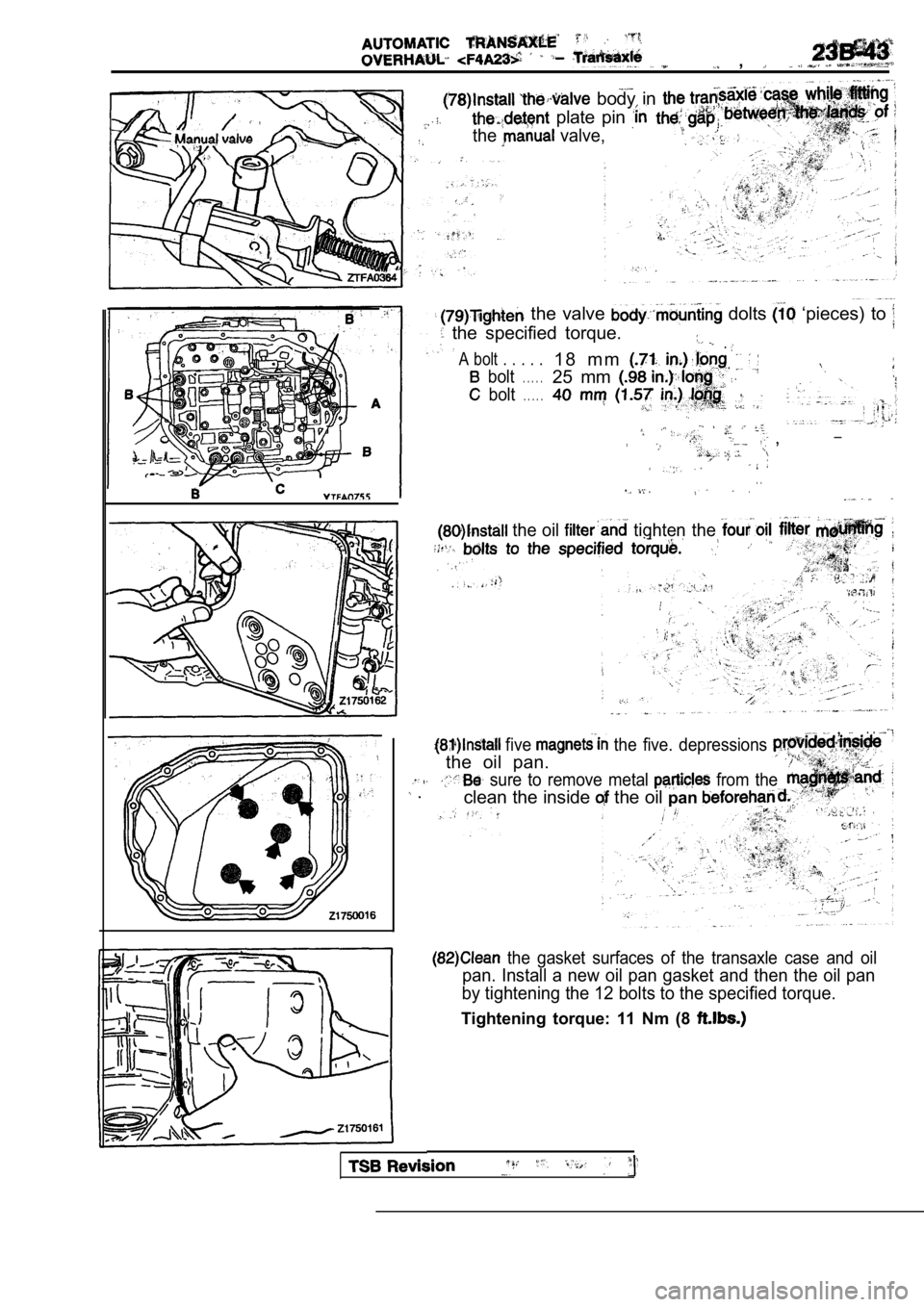

the valve dolts ‘pieces) to

the specified torque.

A bolt . . . . .

.

bolt

1 8 m m

. . . . .

bolt

25 mm

. . . . .

__ ,

. .

the oil tighten the

five the five. depressions

, . .

the oil pan.

sure to remove metal from the .clean the inside the oil pan

the gasket surfaces of the transaxle case and oil

pan. Install a new oil pan gasket and then the oil pan

by tightening the 12 bolts to the specified torque.

Tightening torque: 11 Nm (8

Page 1250 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

I

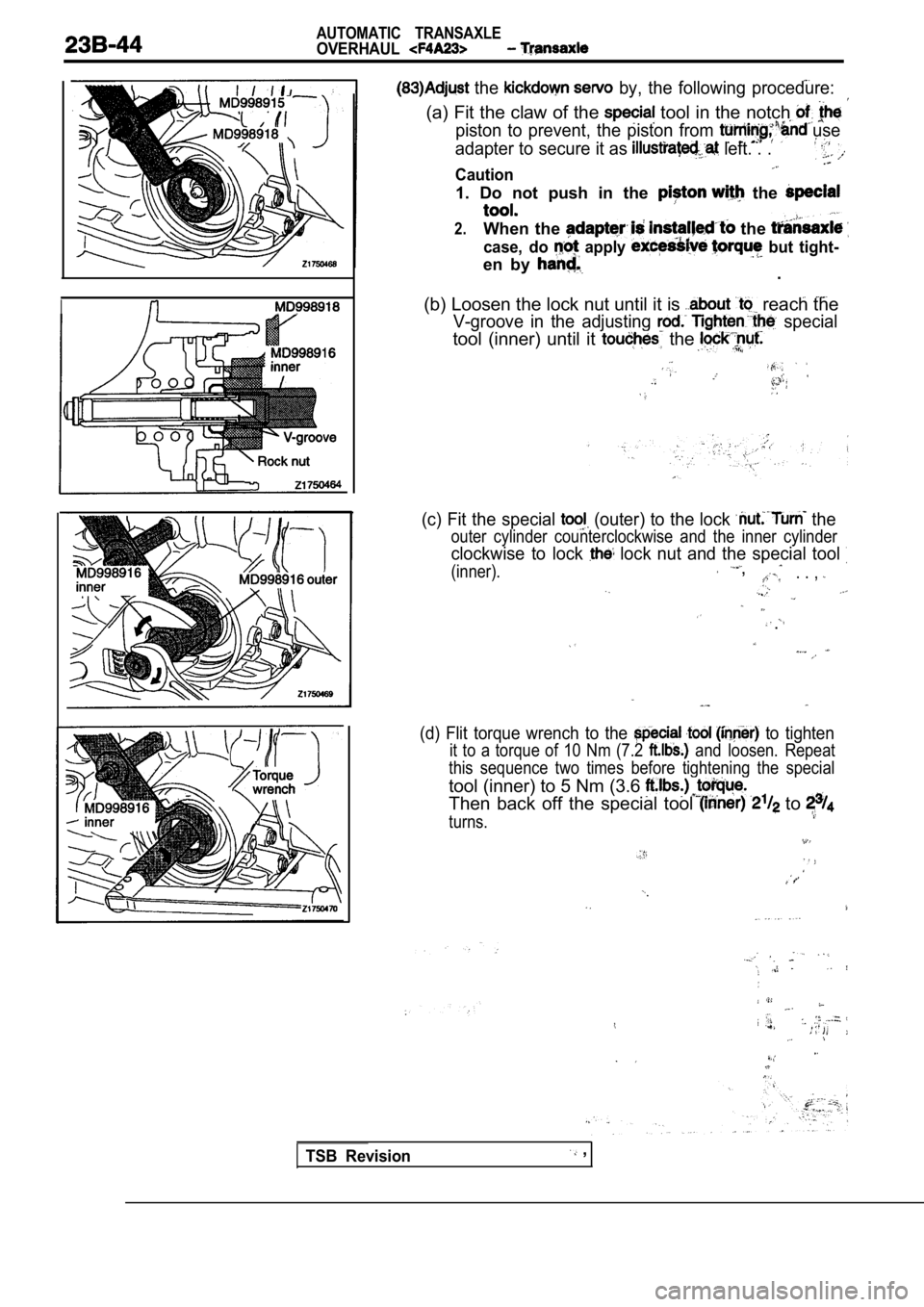

the by, the following procedure:

(a) Fit the claw of the tool in the notch

piston to prevent, the piston from use

adapter to secure it as

left. . .

Caution

1. Do not push in the the

2.When the the

case, do apply but tight-

en by .

(b) Loosen the lock nut until it is reach the

V-groove in the adjusting special

tool (inner) until it the

(c) Fit the special (outer) to the lock the

outer cylinder counterclockwise and the inner cylin der

clockwise to lock lock nut and the special tool

(inner). ,. . ,

.

(d) Flit torque wrench to the to tighten

it to a torque of 10 Nm (7.2 and loosen. Repeat

this sequence two times before tightening the speci al

tool (inner) to 5 Nm (3.6

Then back off the special tool to

turns.

TSB Revision ,

Page 1251 of 2103

AUTOMATIC

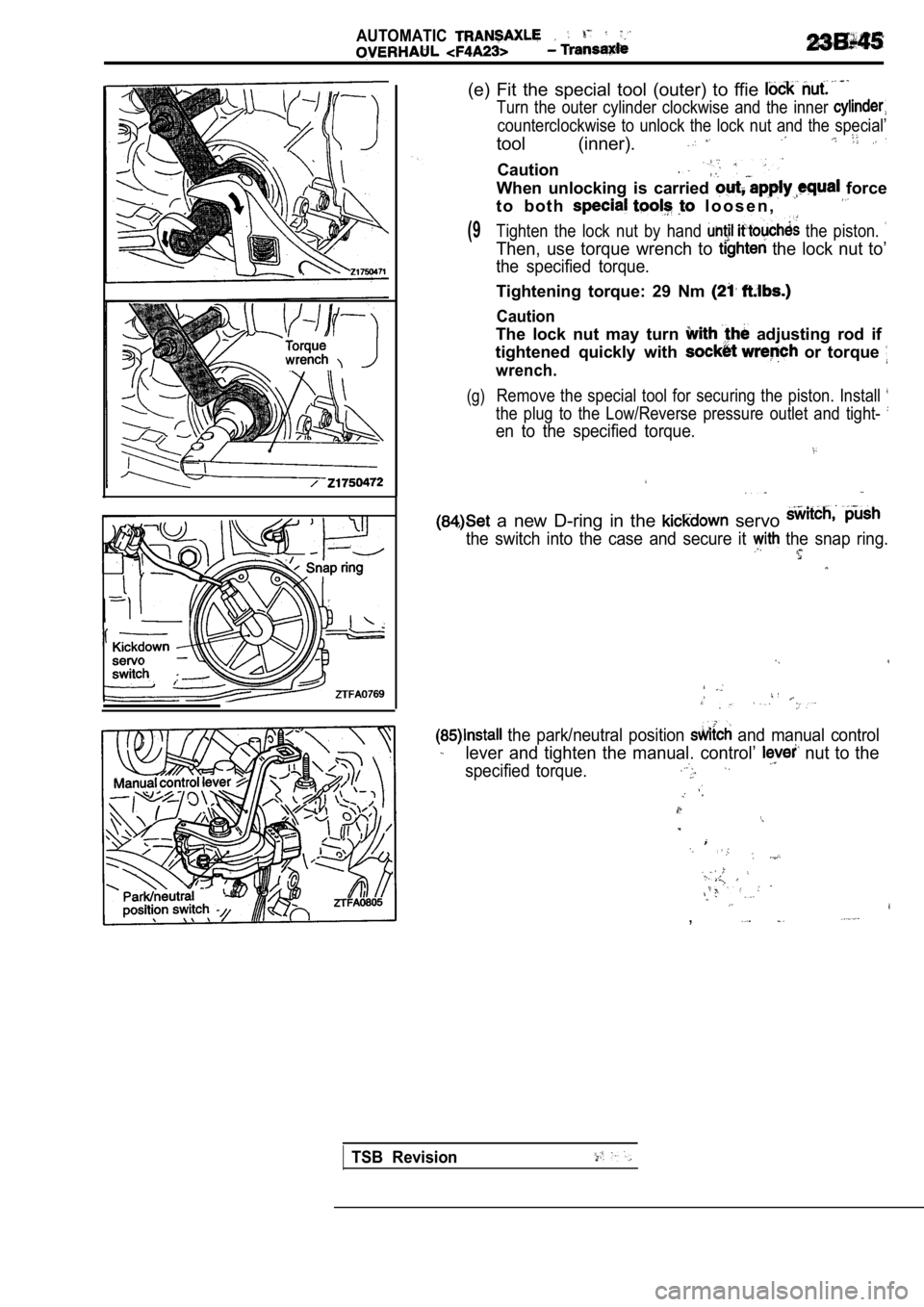

(e) Fit the special tool (outer) to ffie

Turn the outer cylinder clockwise and the inner

counterclockwise to unlock the lock nut and the special’

tool (inner).

Caution

When unlocking is carried force

t o b o t h

l o o s e n ,

(9Tighten the lock nut by hand the piston.

Then, use torque wrench to the lock nut to’

the specified torque.

Tightening torque: 29 Nm

Caution

The lock nut may turn adjusting rod if

tightened quickly with

or torque

wrench.

(g)Remove the special tool for securing the piston. In stall

the plug to the Low/Reverse pressure outlet and tig ht-

en to the specified torque.

a new D-ring in the servo

the switch into the case and secure it the snap ring.

the park/neutral position and manual control

lever and tighten the manual. control’ nut to the

specified torque.

,

TSB Revision

Page 1252 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

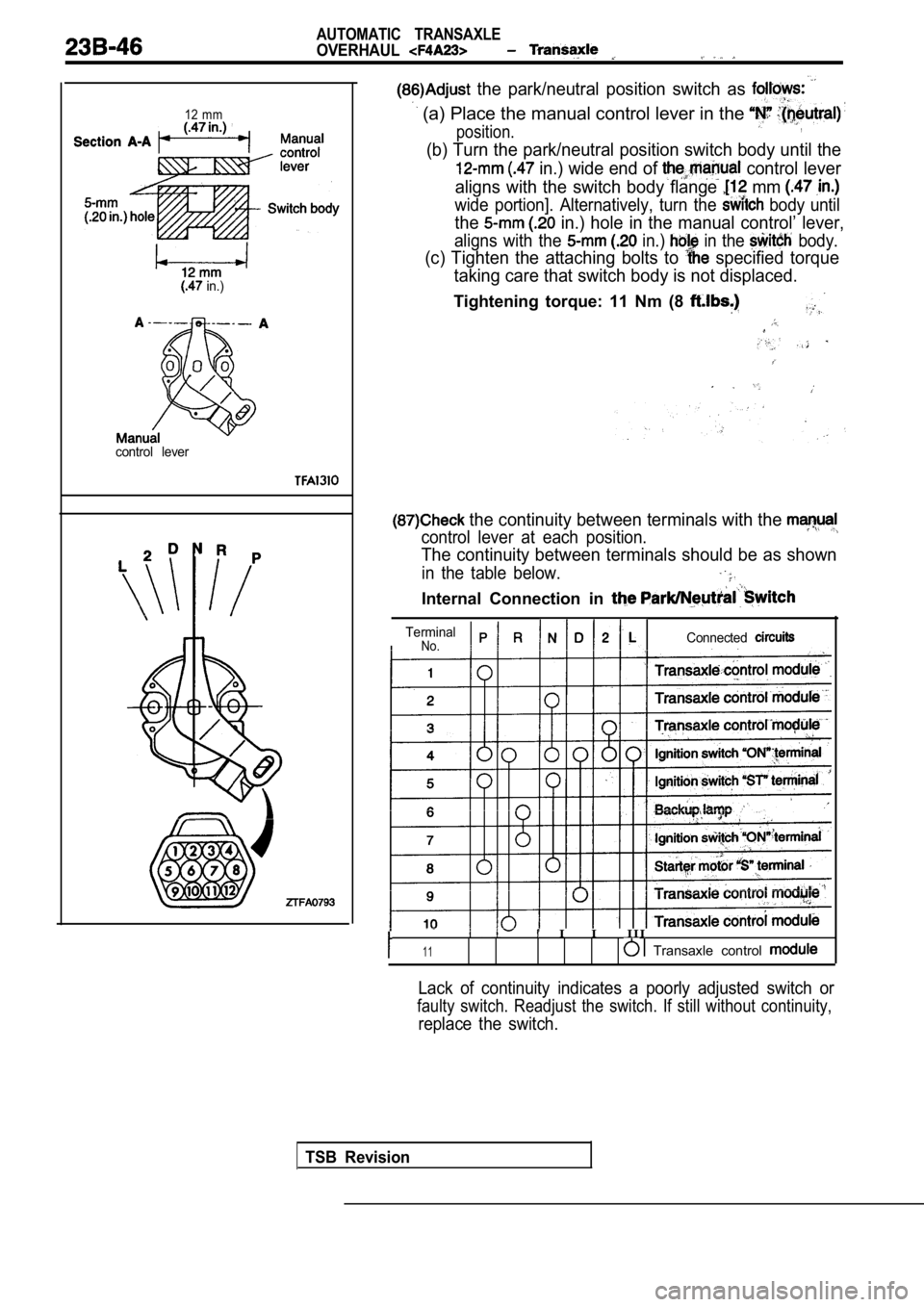

12 mm

in.)

control lever

the park/neutral position switch as

(a) Place the manual control lever in the

position.,

(b) Turn the park/neutral position switch body unti l the

in.) wide end of control lever

aligns with the switch body flange

mm

wide portion]. Alternatively, turn the body until

the in.) hole in the manual control’ lever,

aligns with the in.) in the body.

(c) Tighten the attaching bolts to specified torque

taking care that switch body is not displaced.

Tightening torque: 11 Nm (8

the continuity between terminals with the

control lever at each position.

The continuity between terminals should be as shown

in the table below.

Internal Connection in

TSB Revision

Lack of continuity indicates a poorly adjusted swit ch or

faulty switch. Readjust the switch. If still without continuity,

replace the switch.

TerminalNo.Connected

I I III

11 Transaxle control

Page 1253 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

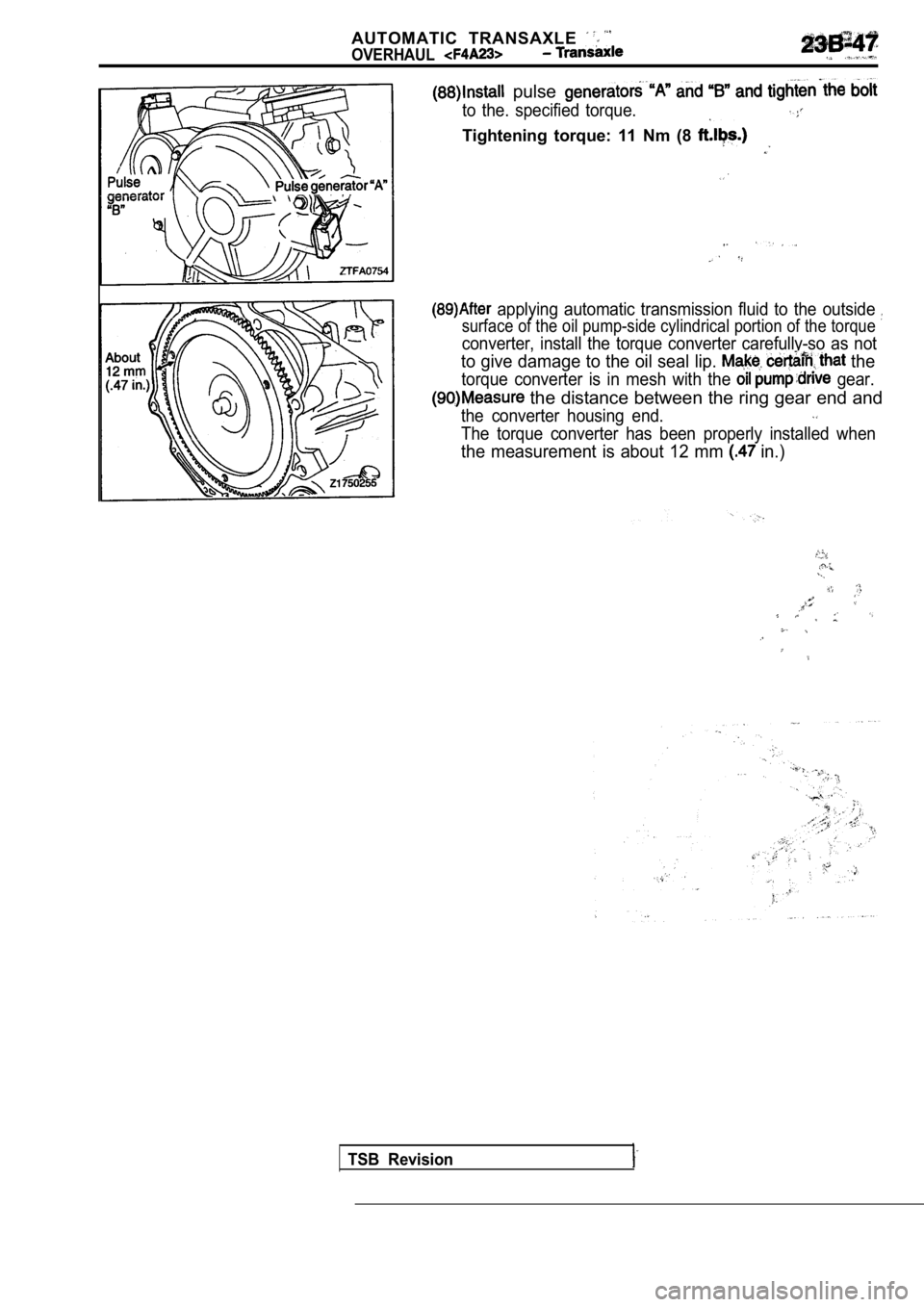

pulse

to the. specified torque.

Tightening torque: 11 Nm (8

applying automatic transmission fluid to the outside

surface of the oil pump-side cylindrical portion of the torque

converter, install the torque converter carefully-so as not

to give damage to the oil seal lip. the

torque converter is in mesh with the gear.

the distance between the ring gear end and

the converter housing end.

The torque converter has been properly installed wh en

the measurement is about 12 mm in.)

TSB Revision

Page 1254 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL Transaxle

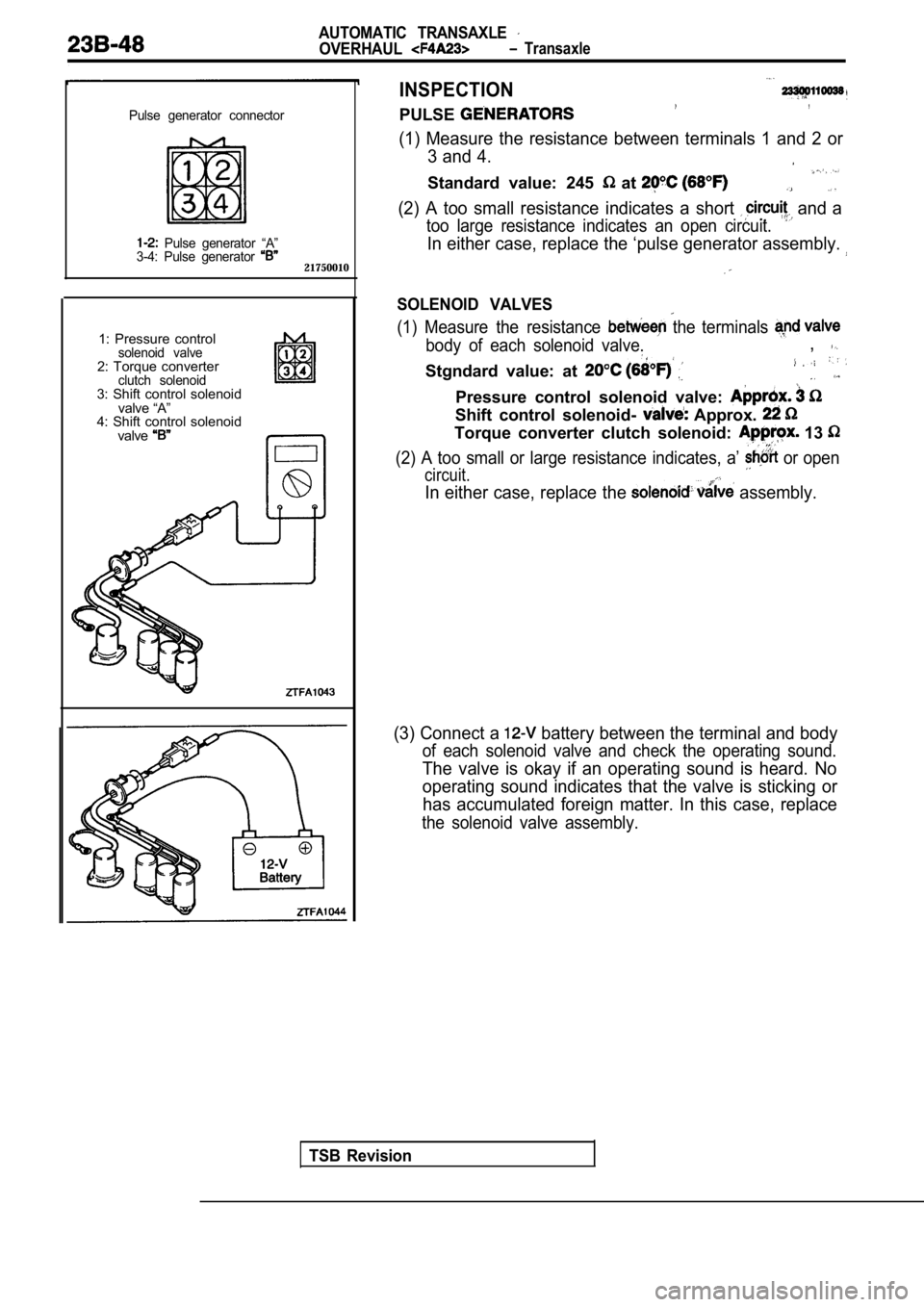

Pulse generator connector

Pulse generator “A”

3-4: Pulse generator

21750010

1: Pressure controlsolenoid valve2: Torque converterclutch solenoid3: Shift control solenoid

valve “A”

4: Shift control solenoid

valve

INSPECTION

PULSE,

(1) Measure the resistance between terminals 1 and 2 or

3 and 4.

Standard value: 245 at

(2) A too small resistance indicates a short and a

too large resistance indicates an open circuit.

In either case, replace the ‘pulse generator assemb ly.

SOLENOID VALVES

(1) Measure the resistance the terminals

body of each solenoid valve.,

Stgndard value: at

TSB Revision

Pressure control solenoid valve:

Shift control solenoid- Approx.

Torque converter clutch solenoid: 13

(2) A too small or large resistance indicates, a’ or open

circuit.

In either case, replace the assembly.

(3) Connect a

battery between the terminal and body

of each solenoid valve and check the operating soun d.

The valve is okay if an operating sound is heard. No

operating sound indicates that the valve is stickin g or

has accumulated foreign matter. In this case, repla ce

the solenoid valve assembly.

Page 1272 of 2103

AUTOMATIC TRANSAXLE

OVERHAUL

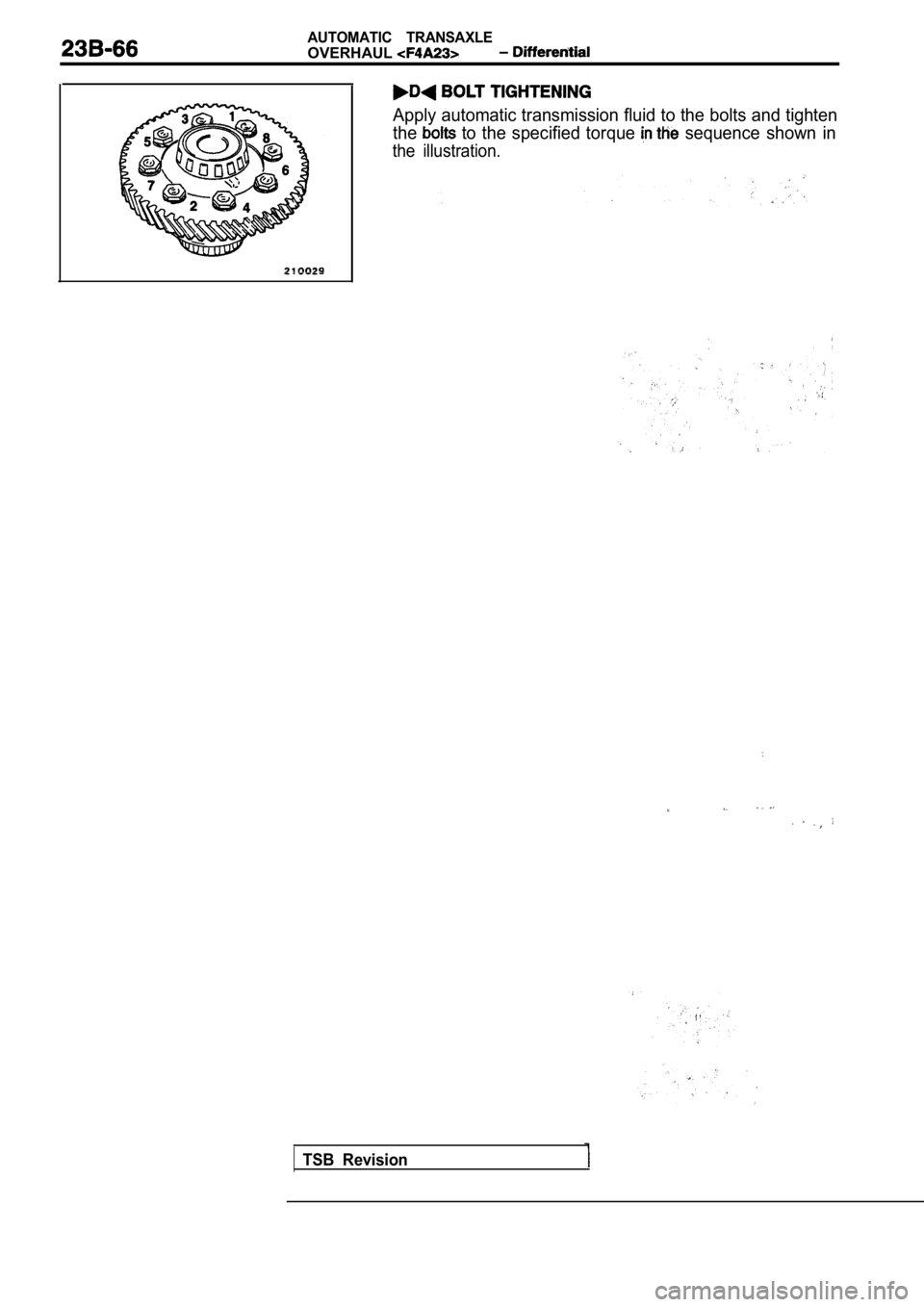

Apply automatic transmission fluid to the bolts and tighten

the

to the specified torque sequence shown in

the illustration.

TSB Revision

Page 1280 of 2103

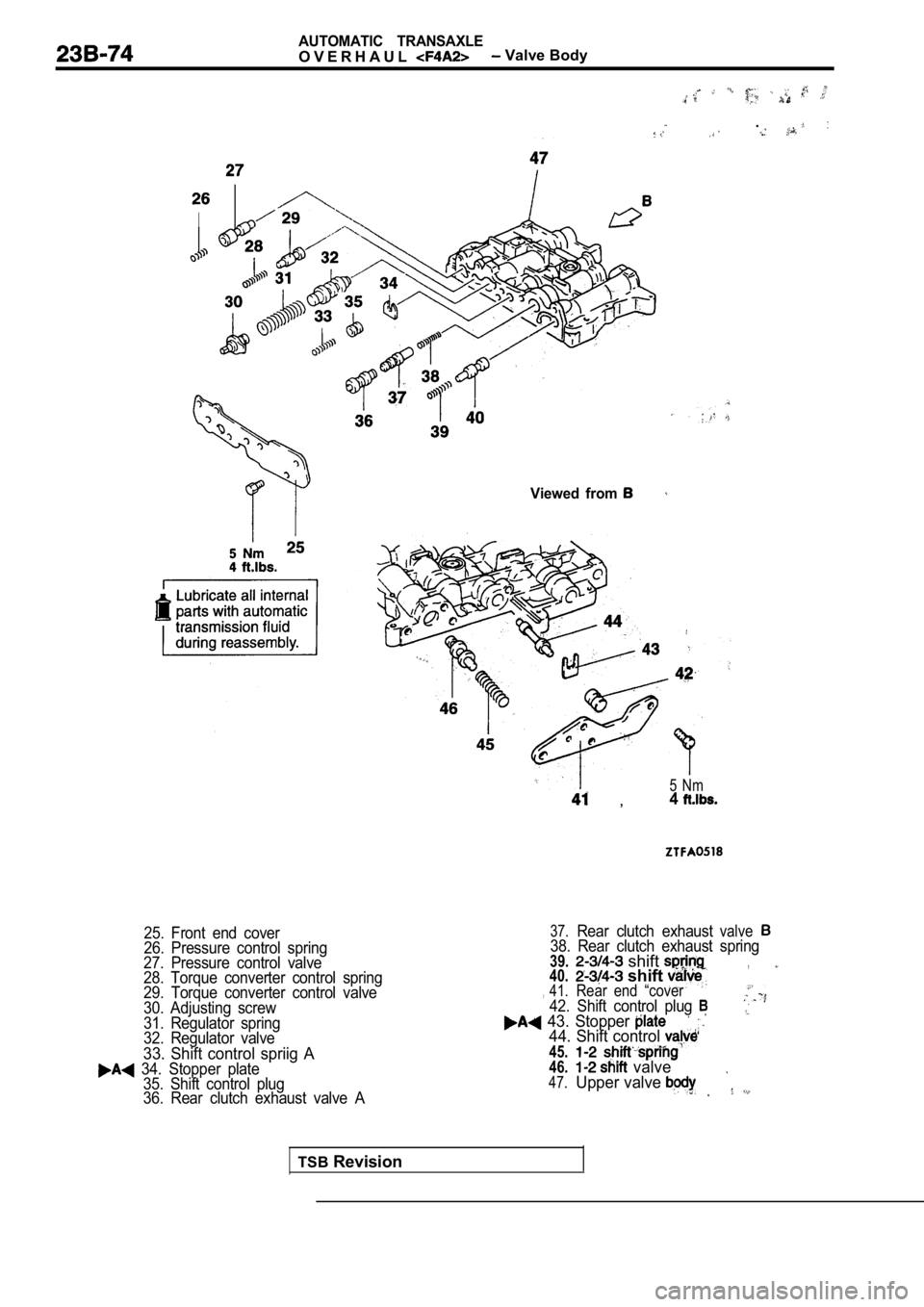

AUTOMATIC TRANSAXLE

O V E R H A U L Valve Body

.

I

Viewed from

25. Front end cover

26. Pressure control spring

27. Pressure control valve

28. Torque converter control spring

29. Torque converter control valve

30. Adjusting screw

31. Regulator spring

32. Regulator valve

33. Shift control spriig A 34. Stopper plate 35. Shift control plug

36. Rear clutch exhaust valve A

5 Nm ,4

37.Rear clutch exhaustvalve38. Rear clutch exhaust spring39. shift ,40.41. shift Rear end “cover,42. Shift control plug 43. Stopper 44. Shift control

45.46. valve47.Upper valve

TSB Revision

Page 1281 of 2103

AUTOMATIC TRANSAXLE Body

48. Pin49. Stopper50. End clutch plug

51. End clutch spring

52. End clutch valve

53. End cover

54. Torque converter clutch control sleeve

55. Torque converter clutch control valve

56. Torque spring

57. N-R control valve58. N-R control 59.60. spnng61. valve62.Lower valve body

TSB Revision