ECO mode MITSUBISHI SPYDER 1990 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1133 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

Data Check item

62Speed/ratio error 15 second counter

‘Display

Counts

63Engine model identification

64General flag

E n g i n e M o d e l

S t a t u s

65Actuator test statusIStatusI

66Element mask register StatusI

67

EEPROM flag register

68Output teeth count StatusTeeth

69Wheel speed coefficient in EEPROM

Coefficient

Current production MY/application MY Model Year

ACTUATOR R

E FER E N CE TA BL E

Item No.

Check item Drive contents Check conditions Remarks

01 solenoid

022-4 solenoid

03UD solenoid

04OD solenoid Current flows to the solenoid

Engine:Check the actuator

for 6 seconds at 50% duty. Idle (Vehicle stopped)test status (Display)

Selector lever position:

range

Throttle opening angle: Fully closed

Page 1134 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

FAIL-SAFE FUNCTION

If a problem which interferes with the continuous safe operation of the transaxle is identified, the TCM

records a diagnostic trouble code in memory, all so lenoids are turned off, and the module is switched

to limp-in mode.

When limp-in mode is started, the transaxle is locked in gear if a drive gear had previously been

selected. Meanwhile, if

or range was selected, operation is as usual.

If the ignition key is turned to OFF and then back to ON again, limp-in mode is

(a record

is retained).

HOW TO READ AND ERASE DIAGNOSTIC

CODES

TSB Revision

1.

2.If battery voltage is low,

trouble

not be output. Be sure to check the battery and

system before, .

If the battery is if connector’

is disconnected,

trouble code memory’

will be erased. Do not ‘disconnect the battery or

until after the diagnostic trouble codes are record ed.,

3.

1.

2.

3.

4.

5.

6.

Turn the ignition switch off before connecting or

disconnecting the scan tool.

Install the interface cartridge cartridge) to the scan

tool

Use the cartridge adapter harness to connect the

scan tool

to the data link connector.

Read the diagnostic trouble codes.

Repair the malfunction while referring to the INSPE CTION

CHART FOR DIAGNOSTIC TROUBLE CODES.

Turn the ignition switch to OFF and then back to ON

again.

Erase the PCM diagnostic trouble code

immediately after erasing the TCM diagnostic troubl e

code.

7.Check that the diagnostic trouble code is normal.

Caution

NOTE

�If the transaxle DTC has been set, (excluding cases where

only part of the DTC has been set), the TCM will le t

the PCM know that a DTC has been sent to the PCM

and a problem has occurred. As a result of this, th e PCM

records the DTC for a transaxle problem

After the transaxle has been repaired, the DTC

which has been stored in the PCM will remain

there without being erased, even after the DTC whic h

is store in the TCM has been erased. Therefore the DTC

in the PCM needs to be erased also.

Page 1904 of 2103

Entry System

METHOD OF REGISTERING A SECRET CODE

Each individual secret code is registered inside the transmitter,

and so it is necessary to register these codes with the received

in the following cases.

lWhen either the transmitter or receiver is replaced;

lIf a second transmitter is to be used;

lIf it appears that a problem is occurring because o f faulty

registration of a code.

A maximum of two different codes per transmitter ca n be

stored in the memory area of the EEPROM, and up to two

different transmitters can be used. When the codes for the

first transmitter are registered, the previously-registered codes

for both transmitters are cleared. Therefore, if yo u are using

two transmitters or are adding a second transmitter , the

for both transmitters must be the same time.

(1) Check that the door locking function works norm ally using

the door key.

(2) Connect the scan tool to the data link connecto r.

NOTE

This grounds the data link connector

and gets ready

for a code registration.

Caution

Turn the ignition switch to OFF before connecting

or disconnecting the scan tool.

(3) Close all doors.

(4) Turn the ignition switch to ACC and return it t o OFF.

NOTE

This locks and unlocks the door once, and then a co de

can be registered.

(5) After pressing any switch on the transmitter on ce, press

it two more times within 10 seconds to register the same

code for SET I and SET II.

(6) After registration is completed, the doors will automatically

be locked and unlocked once.

(7) If you are using two transmitters or have added asecond

transmitter, the same registration procedure should be

carried out for the second transmitter, and it shou ld be

carried out within one minute after registration of the codes

for the first transmitter has been completed. After the

second registration is completed, the doors will au tomati-

cally be locked and unlocked once.

(8) Registration mode finishes under the following conditions.

lRegistration of two transmitter codes are completed .

lOne minute has passed since the registration mode

setting.

l Scan tool is disconnected. (ground released.)

l Ignition switch is turned ON.

l Any of the doors are opened.

TSB Revision

Page 2043 of 2103

HEATER, AIR

AND VENTILATION General Information

GENERAL INFORMATION

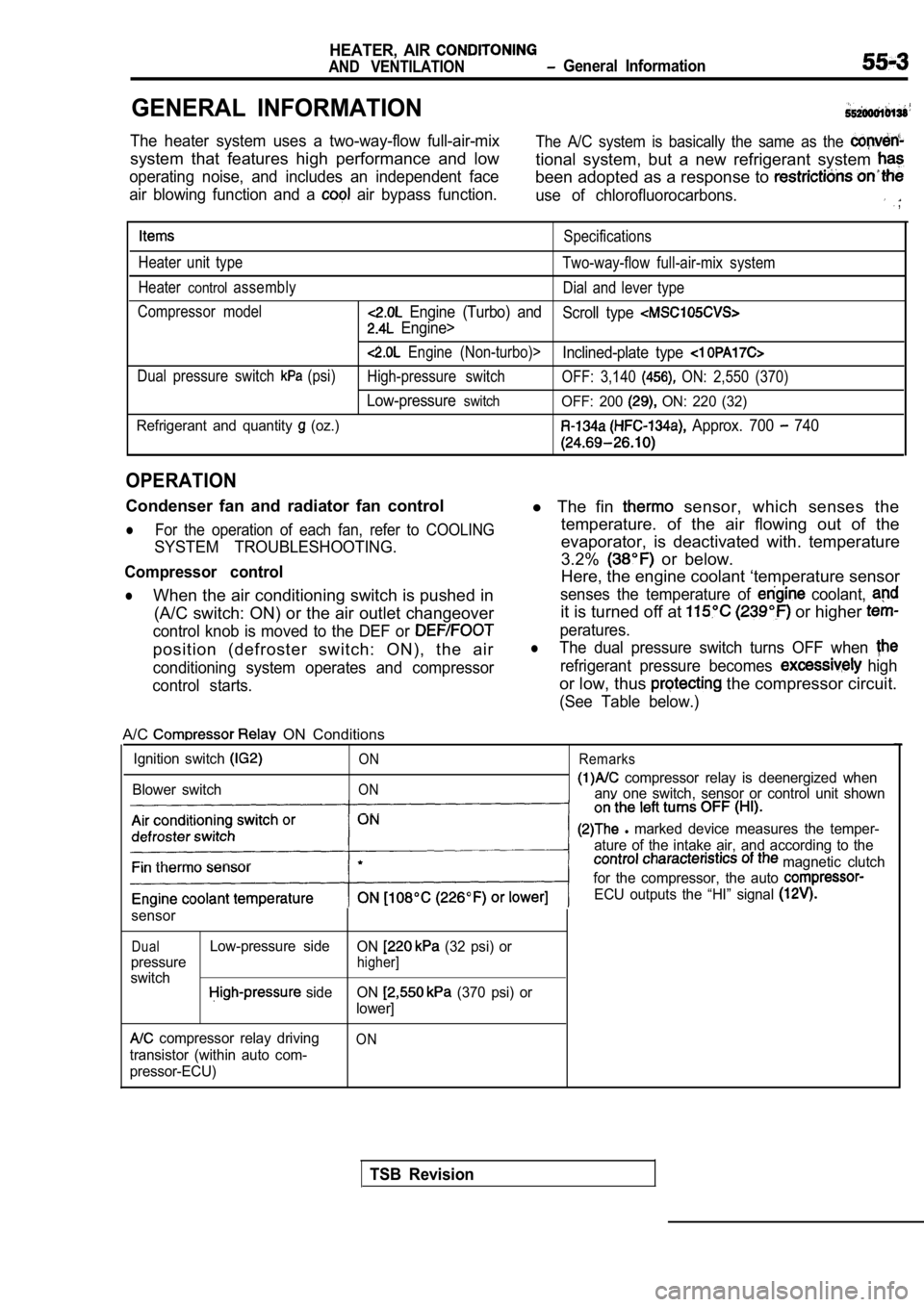

The heater system uses a two-way-flow full-air-mixThe A/C system is basically the same as the

system that features high performance and lowtional system, but a new refrigerant system

operating noise, and includes an independent facebeen adopted as a response to

air blowing function and a air bypass function.use of chlorofluorocarbons. ,

Specifications

Heater unit type Two-way-flow full-air-mix system

Heater

controlassembly Dial and lever type

Compressor model

Engine (Turbo) and Scroll type

Engine>

Engine (Non-turbo)>Inclined-plate type

Dual pressure switch (psi)High-pressure switch OFF: 3,140 ON: 2,550 (370)

Low-pressureswitchOFF: 200 ON: 220 (32)

Refrigerant and quantity

(oz.) Approx. 700 740

OPERATION

Condenser fan and radiator fan control

lFor the operation of each fan, refer to COOLING

SYSTEM TROUBLESHOOTING.

Compressor control

lWhen the air conditioning switch is pushed in (A/C switch: ON) or the air outlet changeover

control knob is moved to the DEF or

position (defroster switch: ON), the air

conditioning system operates and compressor

control starts.

l The fin sensor, which senses the

temperature. of the air flowing out of the

evaporator, is deactivated with. temperature

3.2%

or below.

Here, the engine coolant ‘temperature sensor

senses the temperature of coolant,

it is turned off at or higher

peratures.

lThe dual pressure switch turns OFF when

refrigerant pressure becomes high

or low, thus the compressor circuit.

(See Table below.)

A/C ON Conditions

Ignition switch

Blower switch

ON

ON Remarks

compressor relay is deenergized when

anv one switch, sensor or control unit shown

l marked device measures the temper-

ature of the intake air, and according to the

magnetic clutch

for the compressor, the auto

ECU outputs the “HI” signal

sensor

DualLow-pressure side ON (32 psi) or

pressure

higher]

switch side ON (370 psi) or

lower]

compressor relay driving

transistor (within auto com-

pressor-ECU)ON

TSB Revision

Page 2044 of 2103

55-4HEATER, AIR

AND VENTILATION General Information

SAFETY PRECAUTIONS

Because R-l refrigerant is a, hydrofluorocarbon

(HFC) which contains hydrogen atoms in place of

chlorine atoms, it will not cause damage to the

ozone layer.

Ozone filters out harmful radiation from the sun.

To assist in protecting the ozone layer, Chrysler

Corporation recommends an R-l refrigerant re-

cycling device.

Refrigerant R-l is transparent and colorless

in both the liquid and vapor state. Since it has

a boiling point of at atmospher-

ic pressure, it will be a vapor at all normal tempe ra-

tures and pressures. The vapor is heavier than

air, non-flammable, and nonexplosive. The follow-

ing precautions must be observed when handling

R-l

Caution

Wear safety goggles when servicing the refrig-

eration system.

R-l evaporates so rapidly at normal atmospher-

ic pressures and temperatures that it tends to free ze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant fro m

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigeratio n

part of the A/C system. Keep a bottle of sterile

mineral oil handy when working on the refrigeration

system. Should any liquid refrigerant get into the

eyes, use a few drops of mineral oil to wash them

out. is rapidly absorbed by the oil. Next

splash the eyes with plenty of cool water. Call your

doctor immediately even though irritation has

ceased after treatment.

Caution

Do not heat above

In most instances, moderate heat is required to

bring the pressure of the refrigerant inits

above the pressure of the system when charging

or adding refrigerant.

A bucket or large pan of hot water

over

is all the heat required for this purpose.

Do not heat the refrigerant container with a blow

torch or any other means that would raise tempera-

ture and pressure above this temperature. Do not

weld or steam clean on or near the system compo-

nents or refrigerant lines.

Caution

Keep

containers upright when charging

the system.

When adding into the refrigeration system

keep the supply tank or cans in an upright

position.

If the refrigerant container is on its or upside

down, liquid refrigerant will enter the

damage the compressor.

Caution

1.A leak detector designed

be used to check refrigerant gas

2.Do not allow liquid refrigerant to

metal.

Refrigerant will tarnish bright metal and chrome

surfaces, and in combination with moisture can

severely corrode all metal surfaces.

TSB Revision