ABS MITSUBISHI SPYDER 1990 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1464 of 2103

AUTOMATIC TRANSAXLE OVERHAUL

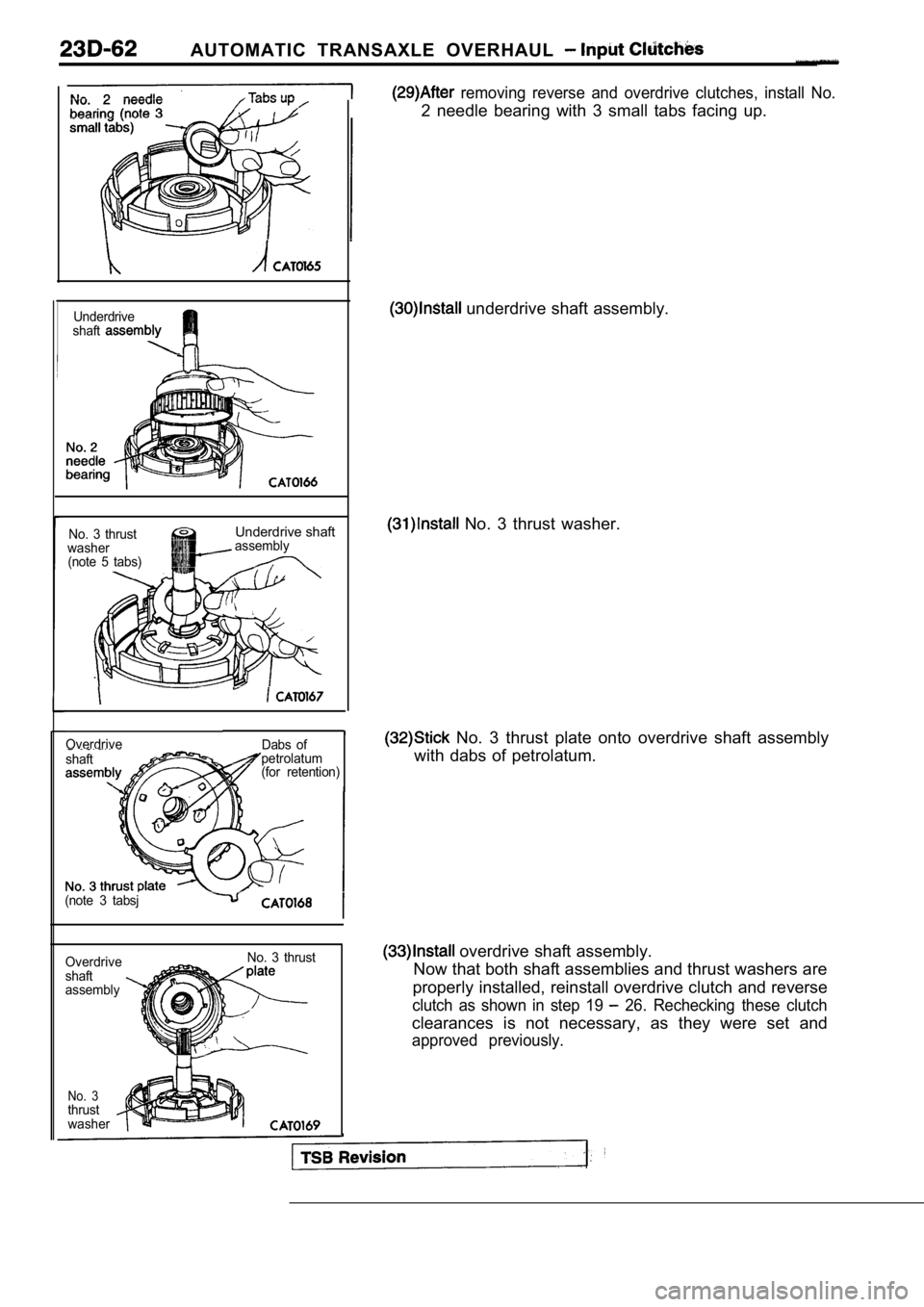

removing reverse and overdrive clutches, install No.

2 needle bearing with 3 small tabs facing up.

Underdrive

shaft

No. 3 thrust

washer (note 5 tabs)Underdrive shaftassembly

Overdriveshaft Dabs of

petrolatum

(for retention)

(note 3 tabsj

underdrive shaft assembly.

No. 3 thrust washer.

No. 3 thrust plate onto overdrive shaft assembly

with dabs of petrolatum.

overdrive shaft assembly.

Now that both shaft assemblies and thrust washers a re

properly installed, reinstall overdrive clutch and reverse

clutch as shown in step 19 26. Rechecking these clutch

clearances is not necessary, as they were set and

approved previously.

Overdrive

shaft

assemblyNo. 3 thrust

No. 3thrust

washer

Page 1511 of 2103

FRONT AXLE Front Hub Assembly

196-255 Nm

145-188

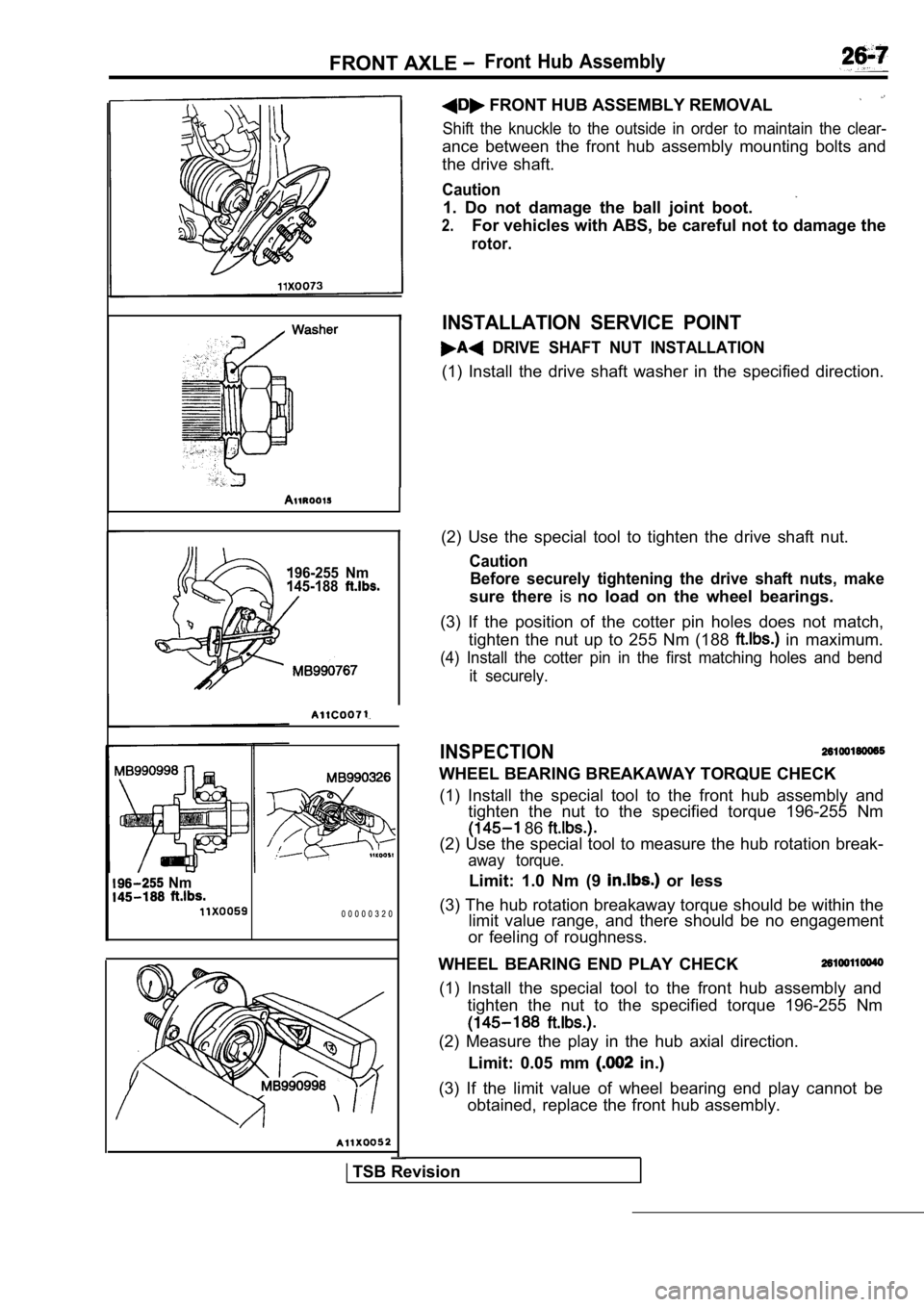

I(2) Use the special tool to tighten the drive shaft nut.

Caution

Before securely tightening the drive shaft nuts, ma ke

sure there isno load on the wheel bearings.

(3) If the position of the cotter pin holes does no t match,

tighten the nut up to 255 Nm (188

in maximum.

(4) Install the cotter pin in the first matching ho les and bend

it securely.

INSPECTION

WHEEL BEARING BREAKAWAY TORQUE CHECK

(1) Install the special tool to the front hub assem bly and

tighten the nut to the specified torque 196-255 Nm

86

(2) Use the special tool to measure the hub rotatio n break-

away torque.

Limit: 1.0 Nm (9 or less

(3) The hub rotation breakaway torque should be wit hin the

limit value range, and there should be no engagemen t

or feeling of roughness. Nm

0 0 0 0 0 3 2 0

FRONT HUB ASSEMBLY REMOVAL

Shift the knuckle to the outside in order to mainta in the clear-

ance between the front hub assembly mounting bolts and

the drive shaft.

Caution

1. Do not damage the ball joint boot.

2.For vehicles with ABS, be careful not to damage the

rotor.

INSTALLATION SERVICE POINT

DRIVE SHAFT NUT INSTALLATION

(1) Install the drive shaft washer in the specified direction.

WHEEL BEARING END PLAY CHECK

(1) Install the special tool to the front hub assem bly and

tighten the nut to the specified torque 196-255 Nm

(2) Measure the play in the hub axial direction.

Limit: 0.05 mm

in.)

(3) If the limit value of wheel bearing end play ca nnot be

obtained, replace the front hub assembly.

TSB Revision

Page 1536 of 2103

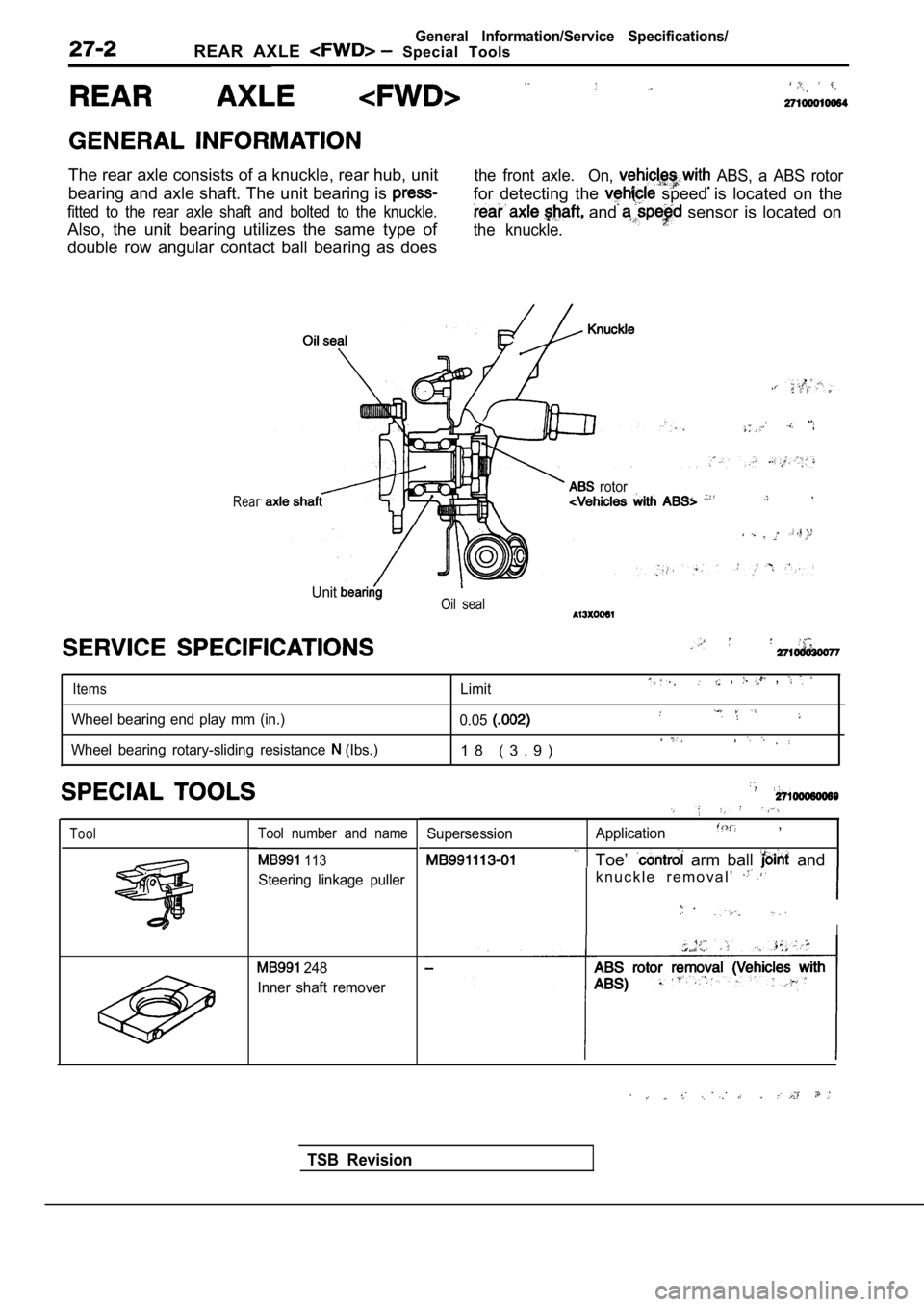

General Information/Service Specifications/

REAR AXLE Special Tools

The rear axle consists of a knuckle, rear hub, unit

bearing and axle shaft. The unit bearing is

fitted to the rear axle shaft and bolted to the knuckle.

Also, the unit bearing utilizes the same type of

double row angular contact ball bearing as does

the front axle.

On, ABS, a ABS rotor

for detecting the speed is located on the

and sensor is located on

the knuckle.

Rear rotor

UnitOil seal

Items

Wheel bearing end play mm (in.)

Wheel bearing rotary-sliding resistance

(Ibs.) Limit

, ,

0.05

1 8 ( 3 . 9 )

ToolTool number and name

113

Steering linkage puller

248

Inner shaft remover

Supersession Application,

Toe’ arm ball and

k n u c k l e r e m o v a l ’

.

I

. .

TSB Revision

Page 1539 of 2103

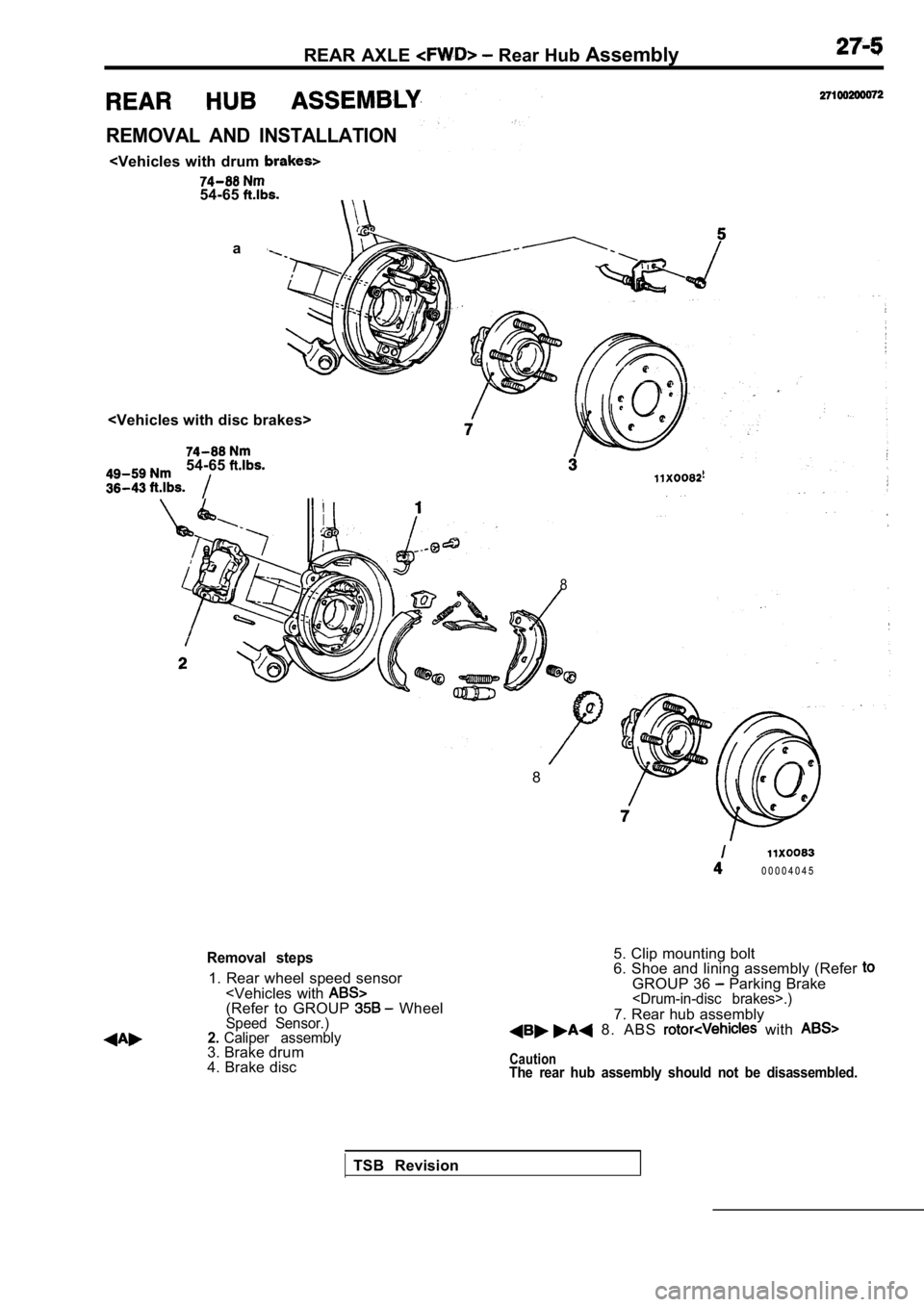

REAR AXLE Rear Hub Assembly

REMOVAL AND INSTALLATION

a

54-65

8

8

0 0 0 0 4 0 4 5

Removal steps

1. Rear wheel speed sensor

4. Brake disc 5. Clip mounting bolt

6. Shoe and lining assembly (Refer

GROUP 36 Parking Brake

7. Rear hub assembly 8. ABS with

CautionThe rear hub assembly should not be disassembled.

TSB Revision

Page 1540 of 2103

REAR AXLE Rear Hub

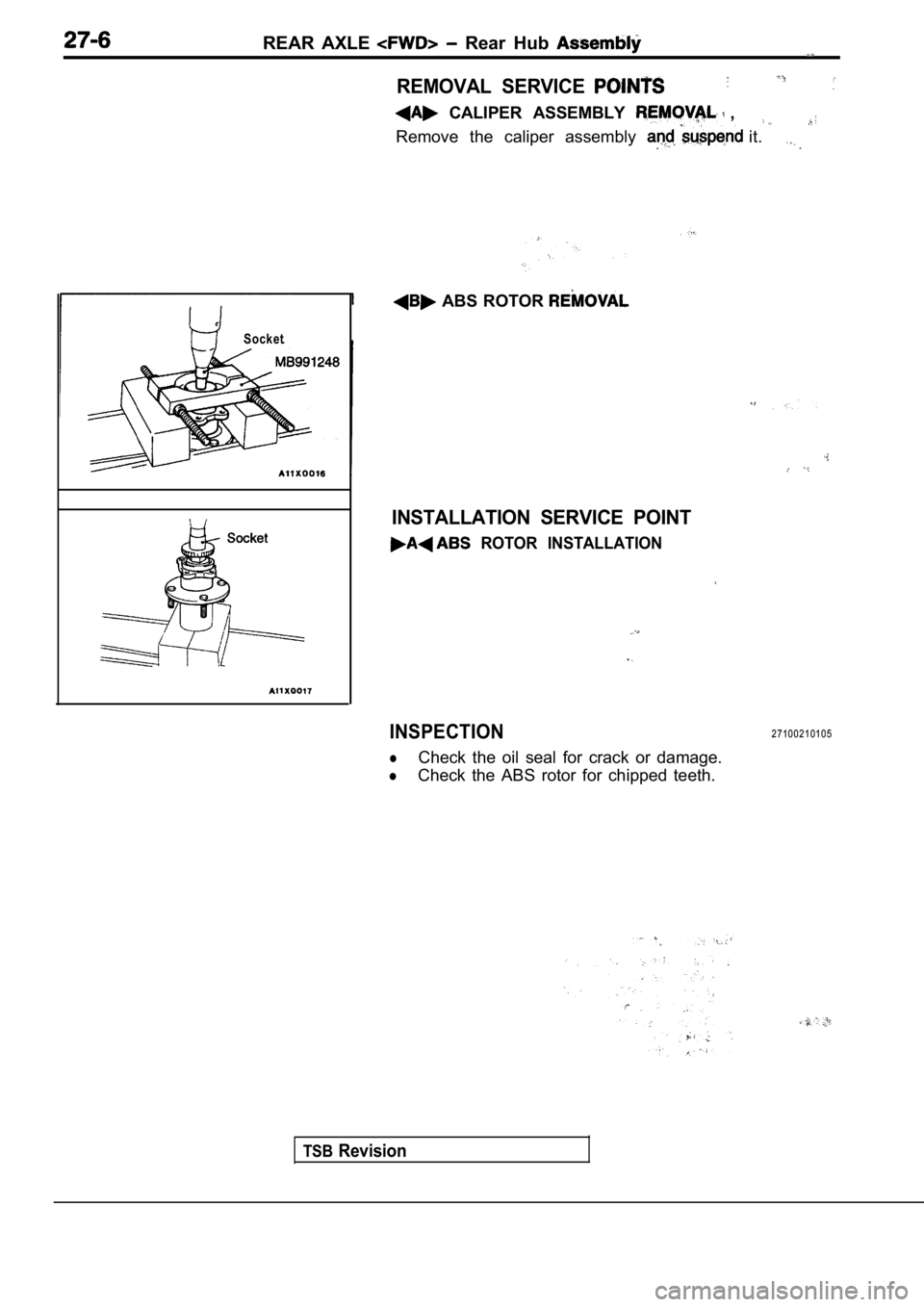

REMOVAL SERVICE

CALIPER ASSEMBLY ,

Remove the caliper assembly it.

Socket

ABS ROTOR

TSBRevision

INSTALLATION SERVICE POINT

ROTOR INSTALLATION

INSPECTION

lCheck the oil seal for crack or damage.

lCheck the ABS rotor for chipped teeth.

27100210105

Page 1541 of 2103

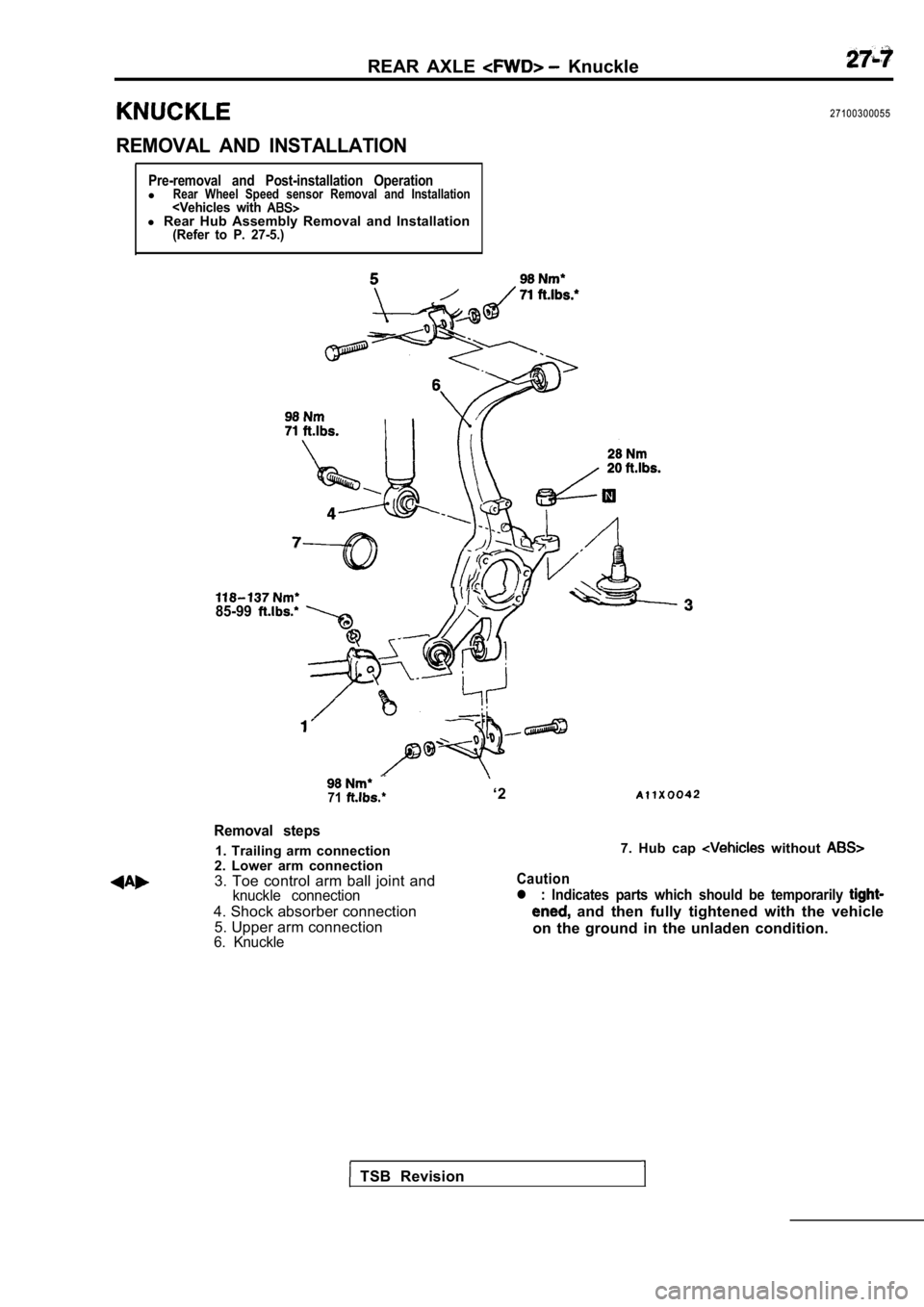

REAR AXLE Knuckle

REMOVAL AND INSTALLATION

27100300055

Pre-removal and Post-installation OperationlRear Wheel Speed sensor Removal and Installation

71‘2

Removal steps

1. Trailing arm connection

2. Lower arm connection

3. Toe control arm ball joint and

knuckle connection

4. Shock absorber connection

5. Upper arm connection

6. Knuckle

Caution

7. Hub cap without

l : Indicates parts which should be temporarily

and then fully tightened with the vehicle

on the ground in the unladen condition.

TSB Revision

Page 1554 of 2103

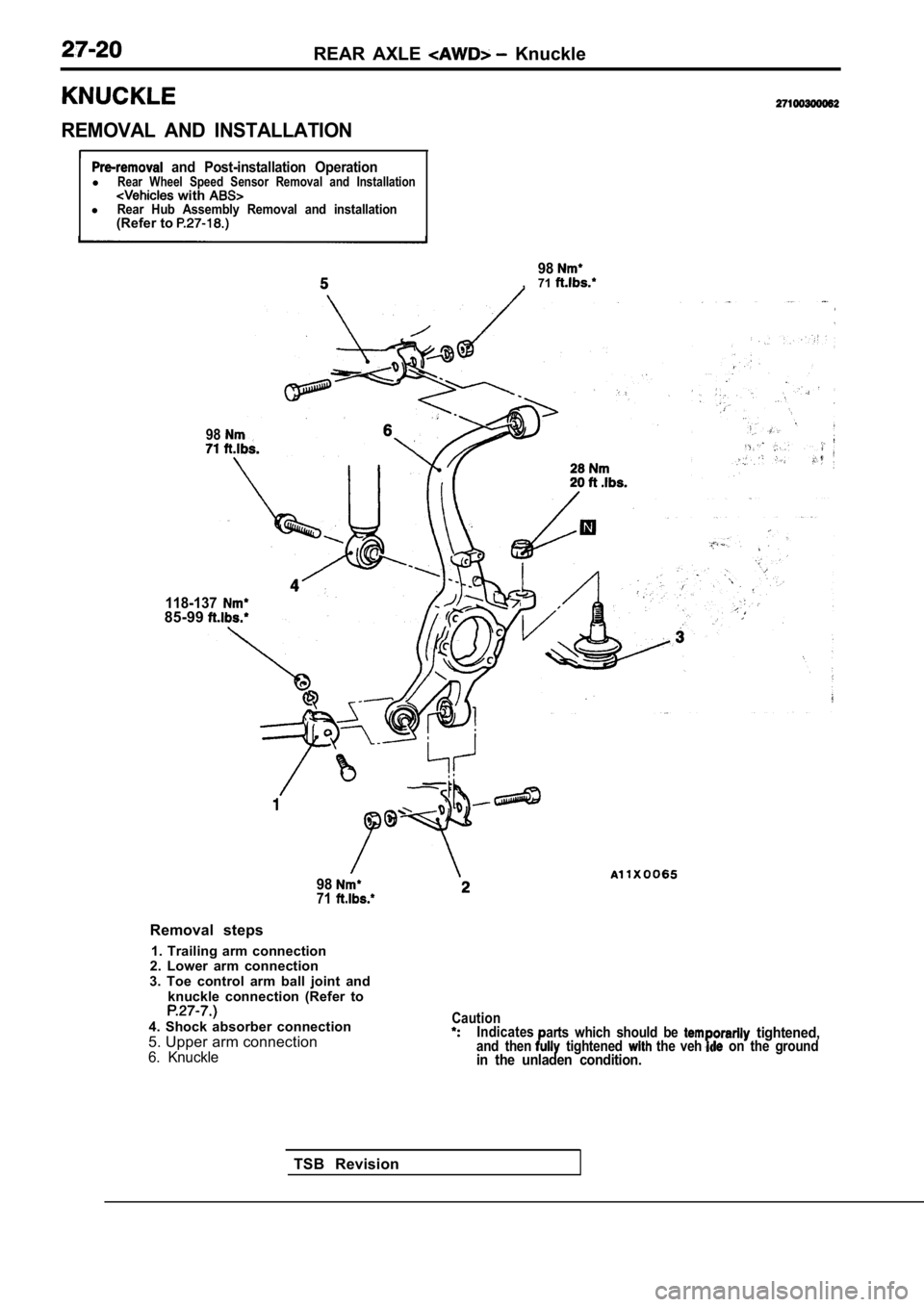

REAR AXLE Knuckle

REMOVAL AND INSTALLATION

II and Post-installation OperationlRear Wheel Speed Sensor Removal and Installation with lRear Hub Assembly Removal and installation(Refer to

98, 71

98

118-13785-99

TSB Revision

9871

Removal steps

1. Trailing arm connection

2. Lower arm connection

3. Toe control arm ball joint and knuckle connection (Refer to

4. Shock absorber connection

5. Upper arm connection

6. Knuckle

CautionIndicates

and thenarts which should be tightened, tightened the veh on the groundin the unladen condition.

Page 1555 of 2103

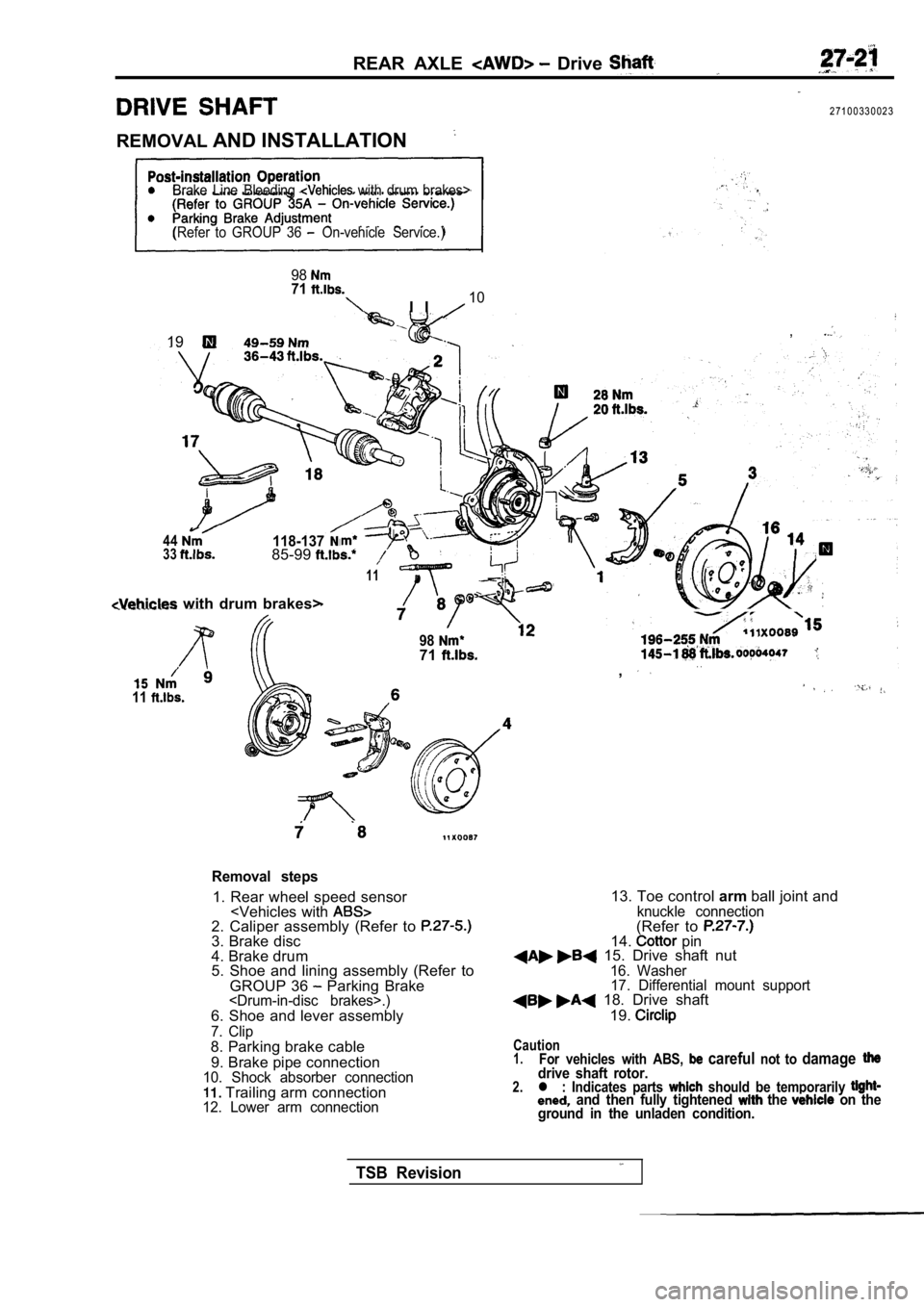

REAR AXLE Drive

2 7 1 0 0 3 3 0 0 2 3

REMOVAL AND INSTALLATION

Brake Line Bleeding with drum brakes>

(Refer to GROUP 36

On-vehicle Service.)

9871

I I10

,19

44118-1373385-99

11

with drum brakes>

11

9871. .,

Removal steps

1. Rear wheel speed sensor

4. Brake drum

5. Shoe and lining assembly (Refer to

GROUP 36

Parking Brake

7. Clip8. Parking brake cable

9. Brake pipe connection

10. Shock absorber connection Trailing arm connection12. Lower arm connection

13. Toe control armball joint andknuckle connection(Refer to 14. pin 15. Drive shaft nut16. Washer

17. Differential mount support

18. Drive shaft

19.

Caution1.For vehicles with ABS, careful not to damagedrive shaft rotor.2.l : Indicates parts should be temporarily and then fully tightened the on the

ground in the unladen condition.

TSB Revision

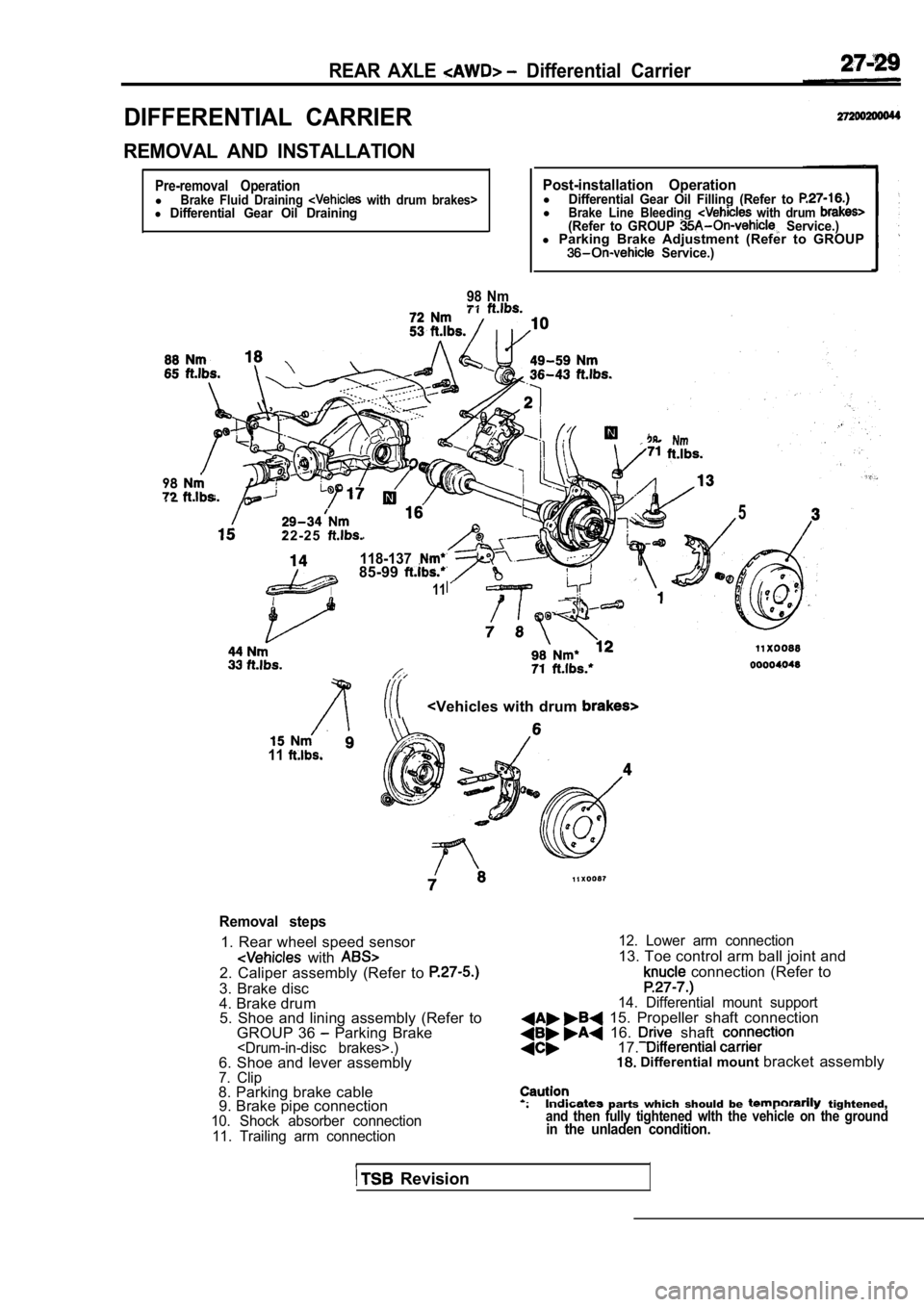

Page 1563 of 2103

REAR AXLE Differential Carrier

DIFFERENTIAL CARRIER

REMOVAL AND INSTALLATION

Pre-removal OperationlBrake Fluid Draining with drum brakes>l Differential Gear Oil Draining

98 Nm

Post-installation OperationlDifferential Gear Oil Filling (Refer to lBrake Line Bleeding with drum (Refer to GROUP Service.)l Parking Brake Adjustment (Refer to GROUP Service.)

98

2 2 - 2 5

118-13785-99

11

5

11

Removal steps

1. Rear wheel speed sensor

with 2. Caliper assembly (Refer to

3. Brake disc

4. Brake drum

5. Shoe and lining assembly (Refer to

GROUP 36

Parking Brake

10. Shock absorber connection

11. Trailing arm connection 12. Lower arm connection

13. Toe control arm ball joint and

connection (Refer to

14. Differential mount support 15. Propeller shaft connection 16. shaft 17. Differential mount

bracket assembly

parts which should be tightened,and then fully tightened wlth the vehicle on the gr oundin the unladen condition.

Revision

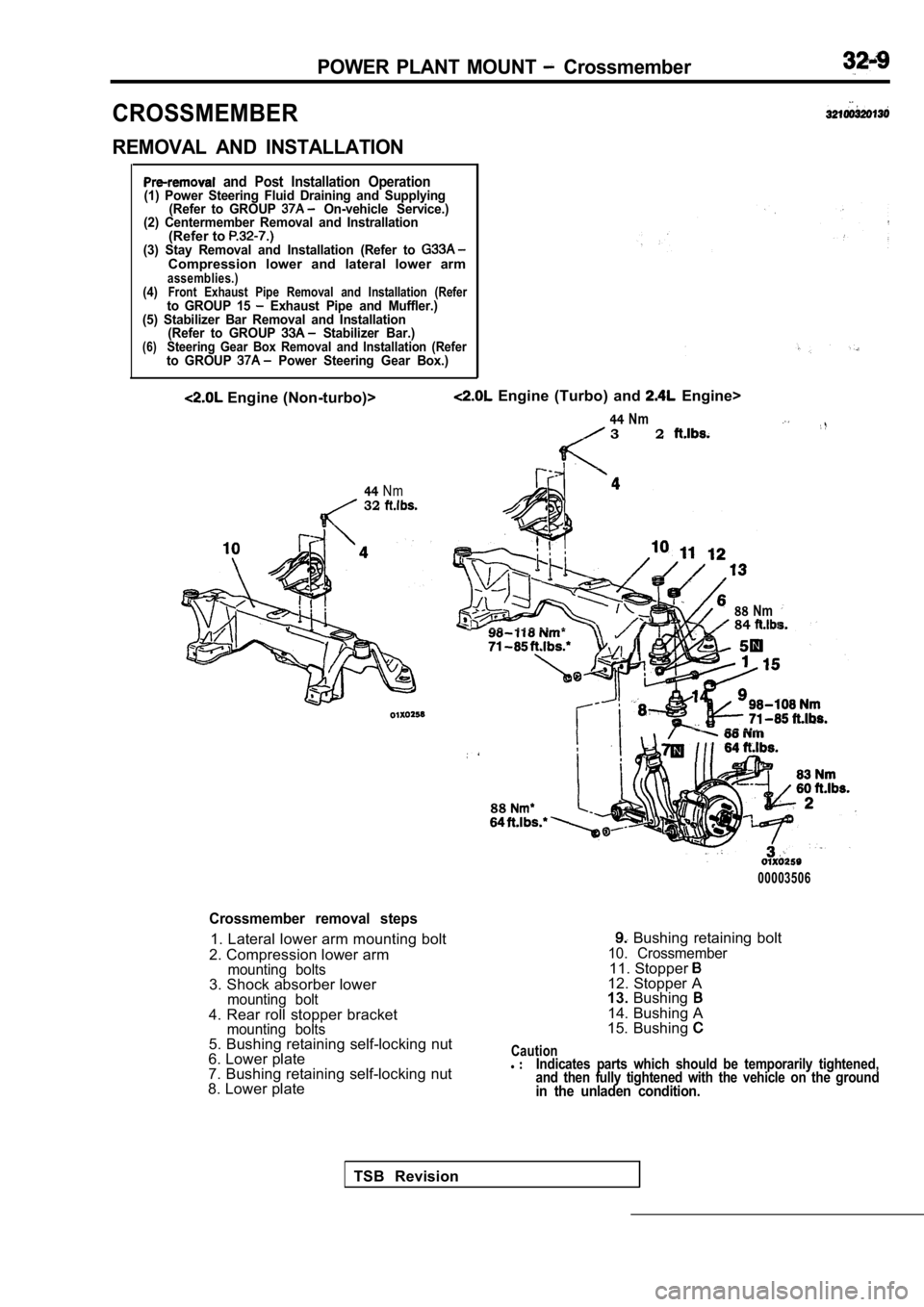

Page 1599 of 2103

POWER PLANT MOUNT Crossmember

CROSSMEMBER

REMOVAL AND INSTALLATION

and Post Installation Operation(1) Power Steering Fluid Draining and Supplying(Refer to GROUP On-vehicle Service.)

(2) Centermember Removal and Instrallation

(Refer to (3) Stay Removal and Installation (Refer to Compression lower and lateral lower armassemblies.)(4)Front Exhaust Pipe Removal and Installation (Referto GROUP 15 Exhaust Pipe and Muffler.)

(5) Stabilizer Bar Removal and Installation (Refer to GROUP

Stabilizer Bar.)(6)Steering Gear Box Removal and Installation (Referto GROUP Power Steering Gear Box.)

Engine (Non-turbo)>

44Nm32

Engine (Turbo) and Engine>

44Nm3 2

88Nm84

88

00003506

Crossmember removal steps

1. Lateral lower arm mounting bolt

2. Compression lower arm

mounting bolts3. Shock absorber lowermounting bolt4. Rear roll stopper bracketmounting bolts5. Bushing retaining self-locking nut

6. Lower plate

7. Bushing retaining self-locking nut

8. Lower plate

Bushing retaining bolt10. Crossmember11. Stopper 12. Stopper A

13. Bushing

14. Bushing A

15. Bushing

Cautionl Indicates parts which should be temporarily tighten ed,

and then fully tightened with the vehicle on the gr ound

in the unladen condition.

TSB Revision