ABS MITSUBISHI SPYDER 1990 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 532 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

3 . H e a t e d o x y g e n s e n s o r m o n i t o r

Test conditions/procedure

1. All of the following conditions should be satisf ied when the drive test is out.

(1) Engine coolant temperature: or higher (when engine is fully warmed up)

(2) Outside air temperature: or higher

(3) condition:

lSelector lever position: range

l Overdrive switch: ON.

lPower/economy changeover switch: Power

2. Carry out one trip monitoring according to the f ollowing drive pattern (from starting of the engine

until ignition is turned off). (Takes approximately 5 minutes.),

After the engine is fully warmed up, turn the igni

tion switch to OFF.

Start the engine and accelerate to a speed of betw een 56 64 km/h (35 mph).

Monitoring period: drive for 120 seconds or more w hile maintaining the throttle opening angle

at a constant angle (keeping throttle variations as small as absolutely possible) and the vehicle

speed at between 56

64 km/h (35 40 mph). Drive consistently as possible during this

time, without making any sudden

wheel movements.

to a stop. After the vehicle has stopped, turn the ignition switch to OFF.

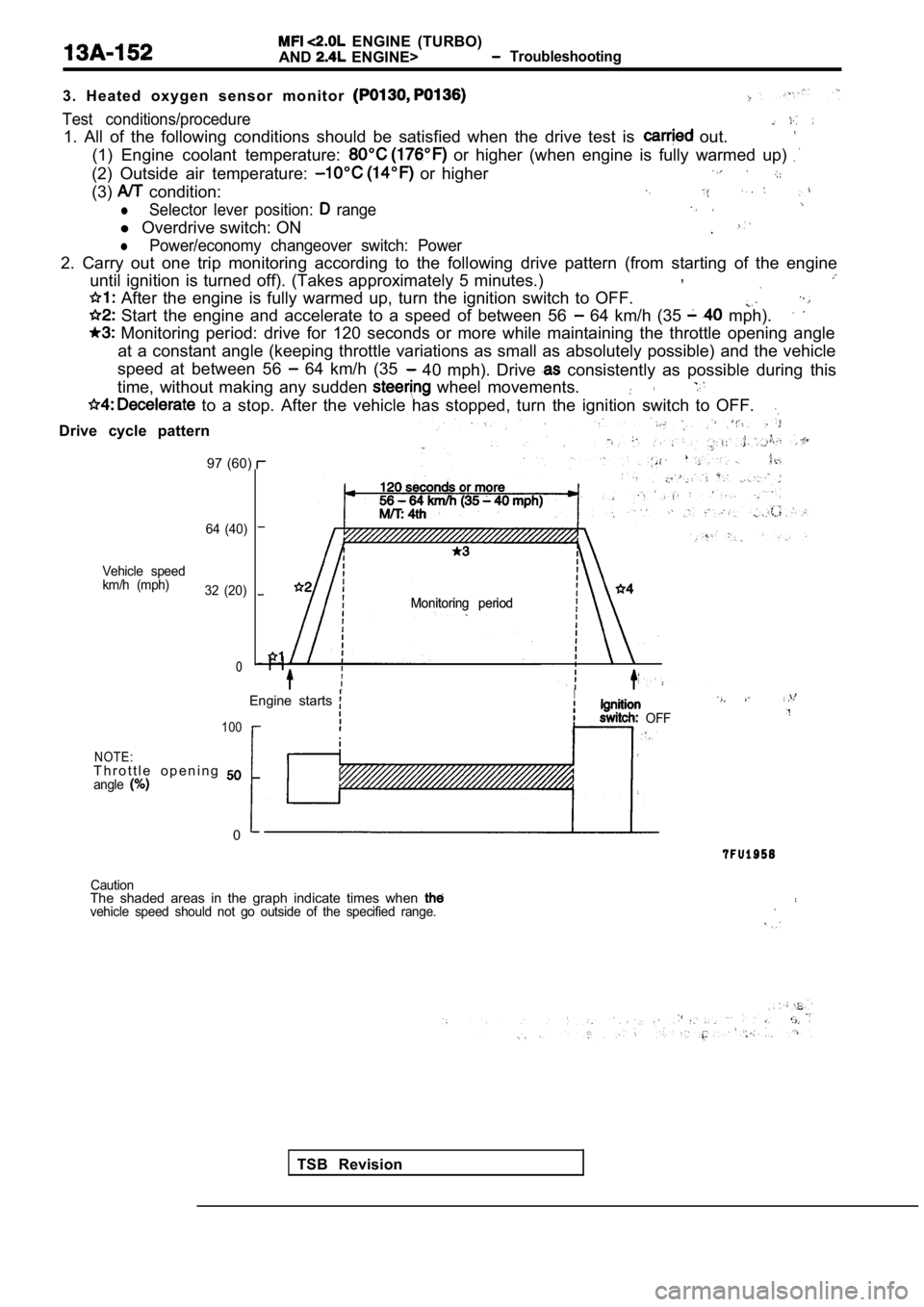

Drive cycle pattern

97 (60)

64 (40)

Vehicle speed

km/h (mph) 32 (20)

0

Monitoring period

Monitoring period

TSB Revision

Engine starts

I. .

OFF100

NOTE:T h r o t t l e o p e n i n g angle

0

CautionThe shaded areas in the graph indicate times when vehicle speed should not go outside of the specifie

d range.

Page 574 of 2103

![MITSUBISHI SPYDER 1990 Service User Guide E N G I N E

A N D ,

Code No. Differential

Malfunction

[Comment]BackgroundManifold differential se.

l pressure in the intake manifold. o r l o o s e Engine control. lThe engine co MITSUBISHI SPYDER 1990 Service User Guide E N G I N E

A N D ,

Code No. Differential

Malfunction

[Comment]BackgroundManifold differential se.

l pressure in the intake manifold. o r l o o s e Engine control. lThe engine co](/img/19/57345/w960_57345-573.png)

E N G I N E

A N D ,

Code No. Differential

Malfunction

[Comment]BackgroundManifold differential se.

l pressure in the intake manifold. o r l o o s e Engine control. lThe engine control module checks whether the voltage output by manifold differential sure sensor is within a specified range.

Check Area, Judgement Criteria.

1. Check Areal min or more have passed after the engine was start ed.[However, this is only when the engine coolant temperature is or lower

when the engine is started.]

Engine coolant temperature is not lower than Intake air temperature is not lower than Barometric pressure is 76 (11 psi.) or higher. Volumetric efficiency is 30% 55%.

Judgement Criteria . ,

Sensor output voltage has continued to be not lowe

r than [corresponding toan absolute pressure of 118 (17 psi) or higher] for 4 sec.orSensoroutput voltage has continued to be not higher than 0.1 [corresponding to ---

an absolute pressure of 2.4 (0.3 psi) or lower] for 4 sec.

2. Check Area

8 min or more have passed engine Started.

[However, this is only when the engine coolant or lower when the engine is Engine coolant temperature is not lower than Intake air temperature is not lower than Barometric pressure is 76 (11 psi.) or higher. Volumetric efficiency is 30% or lower.

Judgement Criteria ,

l Sensor output voltage is 4.2 or higher for 4 seconds [absolute pressure is 108 (16 psi.) or more]

Check Area 8 min or more have passed after the engine was sta rted.

,

.

. , ,

[However, this is only when the engine coolant temperature is or lowerwhen engine is started.]

l Engine coolant temperature is not lower than .l Intake air temperature is not lower than l Barometric pressure is 76 (11 psi.) or higher. Volumetric efficiency is 70% or higher.

Judgement Criterial Sensor output voltage is or lower for 4 seconds [absolute pressure is 46 (6.7 psi.) or less]I

TSB Revision.

Page 639 of 2103

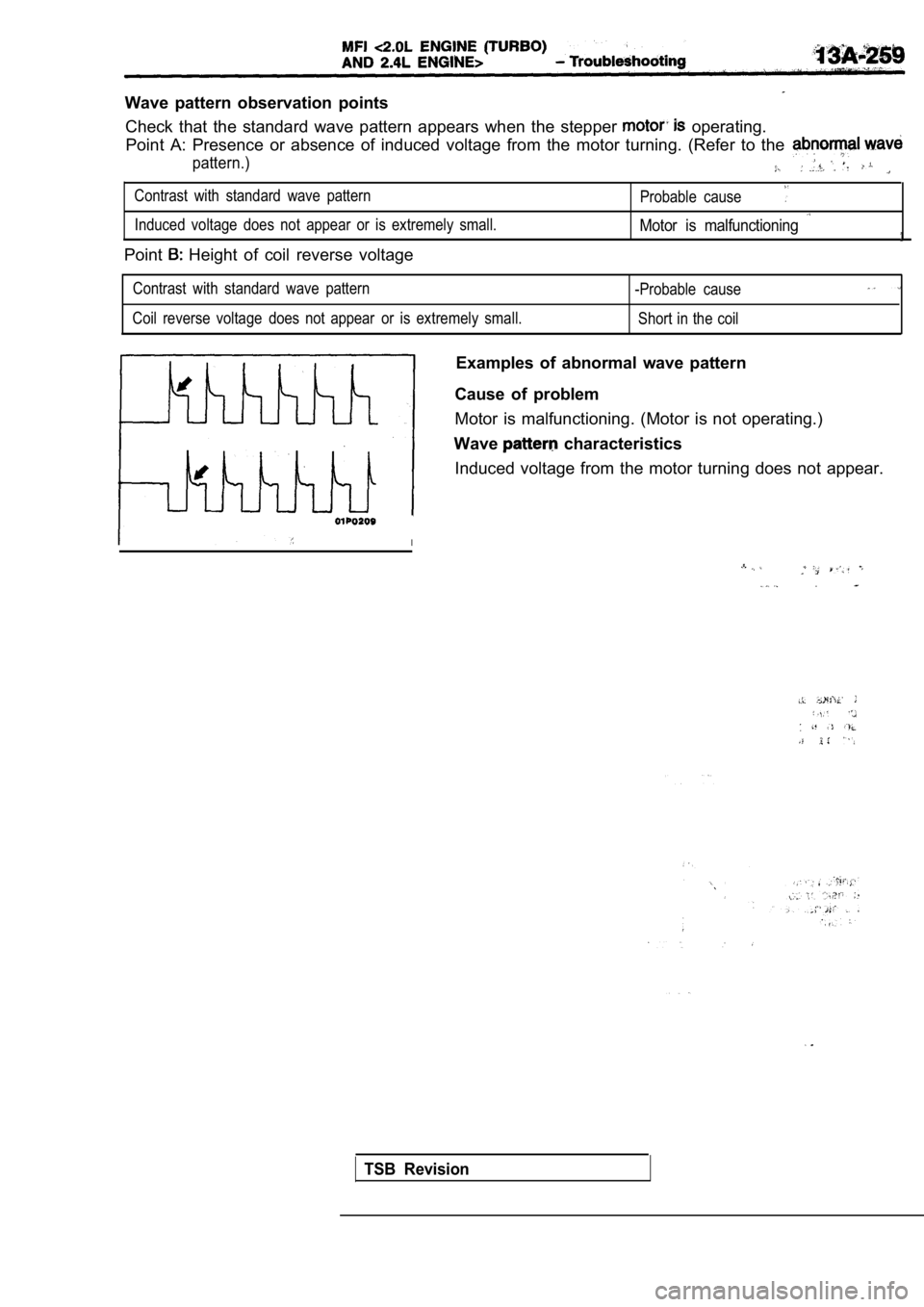

Wave pattern observation pointsCheck that the standard wave pattern appears when t he stepper

operating.

Point A: Presence or absence of induced voltage fro m the motor turning. (Refer to the

pattern.)

Contrast with standard wave pattern

Probable cause

Induced voltage does not appear or is extremely small.Motor is malfunctioning

Point Height of coil reverse voltage

Contrast with standard wave pattern

-Probable cause

Coil reverse voltage does not appear or is extremely small.

Short in the coil

Examples of abnormal wave pattern

Cause of problem

Motor is malfunctioning. (Motor is not operating.)

Wave

characteristics

Induced voltage from the motor turning does not app ear.

I

.

TSB Revision

Page 692 of 2103

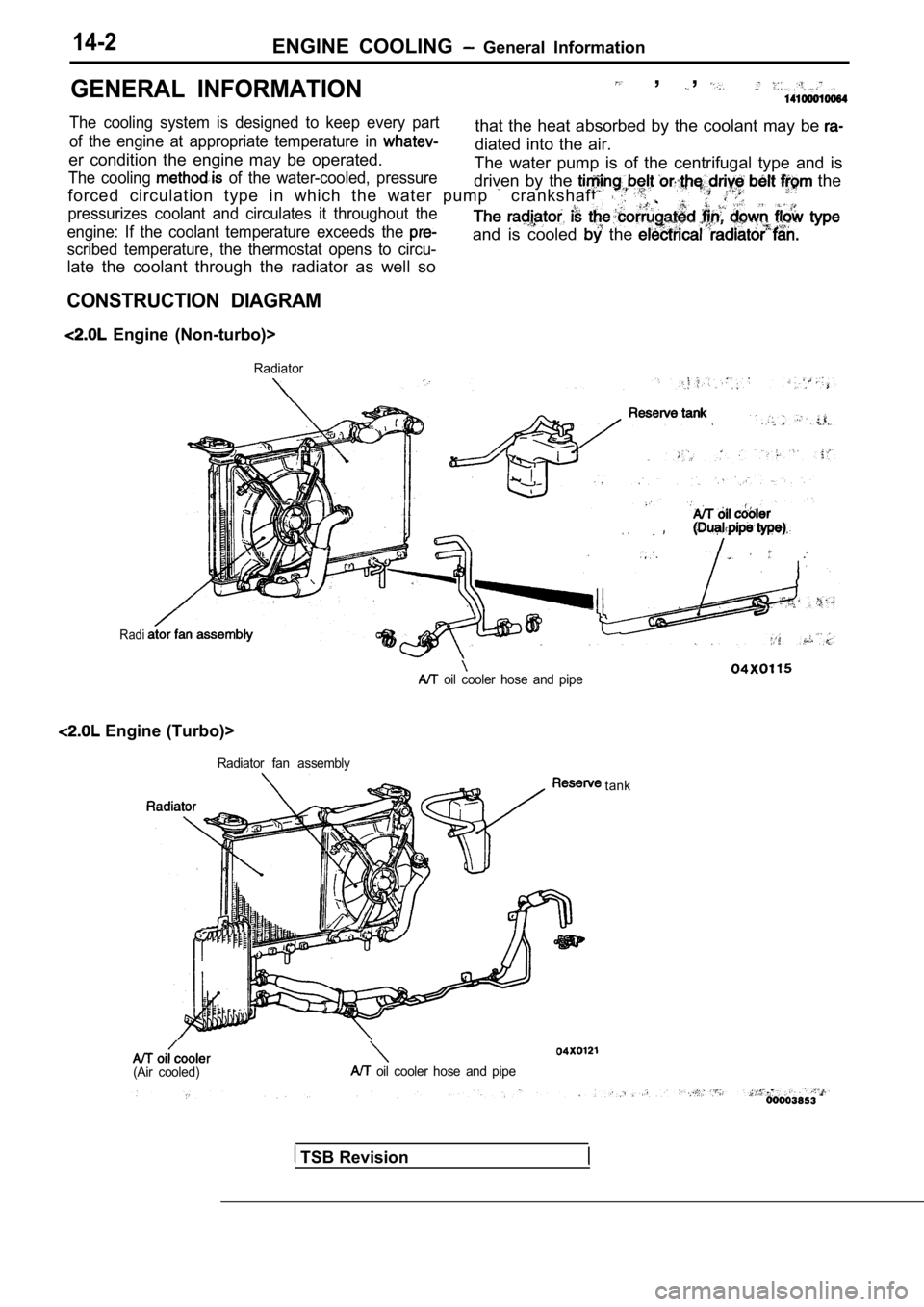

14-2ENGINE COOLING General Information

GENERAL INFORMATION , ,

The cooling system is designed to keep every partthat the heat absorbed by the coolant may be of the engine at appropriate temperature in diated into the air.

er condition the engine may be operated.

The cooling of the water-cooled, pressureThe water pump is of the centrifugal type and is

driven by the

the

forced circulation type in which the water pump crankshaft. .

pressurizes coolant and circulates it throughout th e

engine: If the coolant temperature exceeds the

scribed temperature, the thermostat opens to circu-

late the coolant through the radiator as well so

and is cooled the

CONSTRUCTION DIAGRAM

Engine (Non-turbo)>

Radiator

Radi

.

oil cooler hose and pipe

Engine (Turbo)>

Radiator fan assembly

(Air cooled) oil cooler hose and pipetank

TSB Revision

Page 704 of 2103

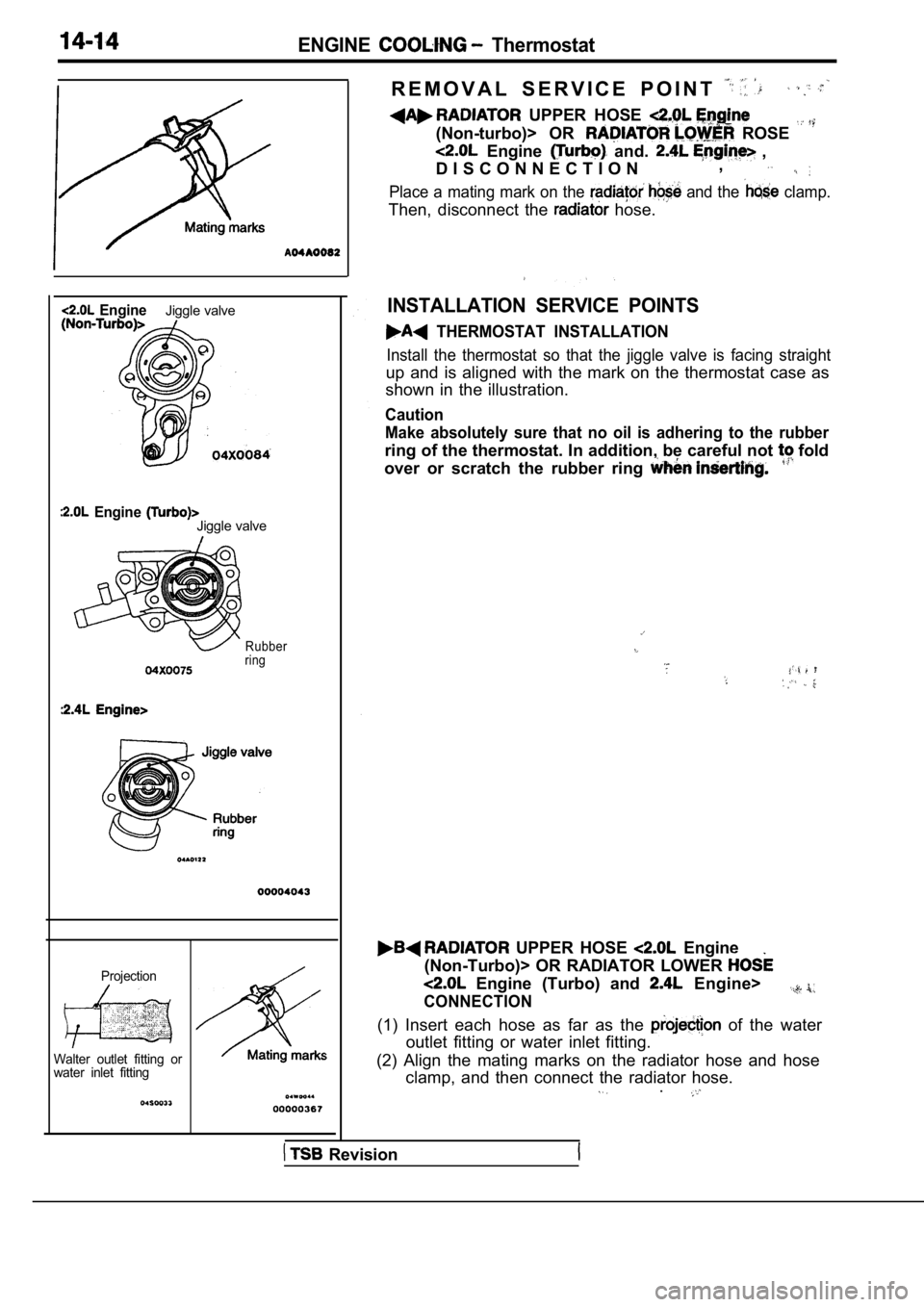

ENGINE Thermostat

EngineJiggle valve

Engine Jiggle valve

Rubber

ring

Projection

Walter outlet fitting or

water inlet fitting

R E M O V A L S E R V I C E P O I N T

UPPER HOSE

(Non-turbo)> OR ROSE

Engine and. ,

D I S C O N N E C T I O N ,

Place a mating mark on the and the clamp.

Then, disconnect the hose.

INSTALLATION SERVICE POINTS

THERMOSTAT INSTALLATION

Install the thermostat so that the jiggle valve is

facing straight

up and is aligned with the mark on the thermostat c ase as

shown in the illustration.

Caution

Make absolutely sure that no oil is adhering to the rubber

ring of the thermostat. In addition, be careful not fold

over or scratch the rubber ring

UPPER HOSE Engine

(Non-Turbo)> OR RADIATOR LOWER

Engine (Turbo) and Engine>

CONNECTION

(1) Insert each hose as far as the of the water

outlet fitting or water inlet fitting.

(2) Align the mating marks on the radiator hose and hose

clamp, and then connect the radiator hose.

.

Revision

Page 740 of 2103

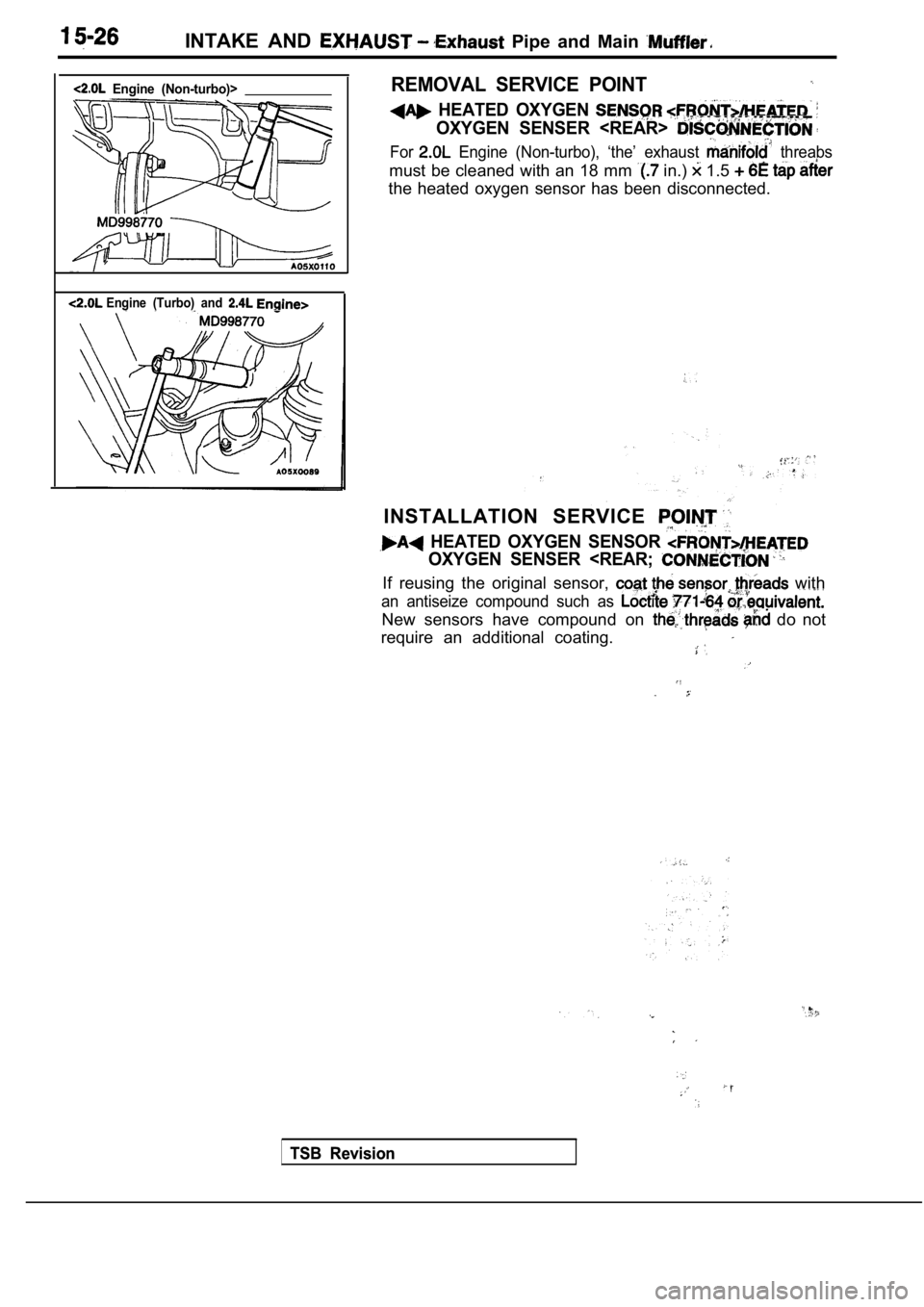

INTAKE AND Pipe and Main

Engine (Non-turbo)>

Engine (Turbo) and

REMOVAL SERVICE POINT

HEATED OXYGEN

OXYGEN SENSER

For Engine (Non-turbo), ‘the’ exhaust threabs

must be cleaned with an 18 mm in.) 1.5

the heated oxygen sensor has been disconnected.

INSTALLATION SERVICE

HEATED OXYGEN SENSOR

OXYGEN SENSER

an antiseize compound such as

New sensors have compound on do not

require an additional coating.

TSB Revision

TSB Revision

Page 772 of 2103

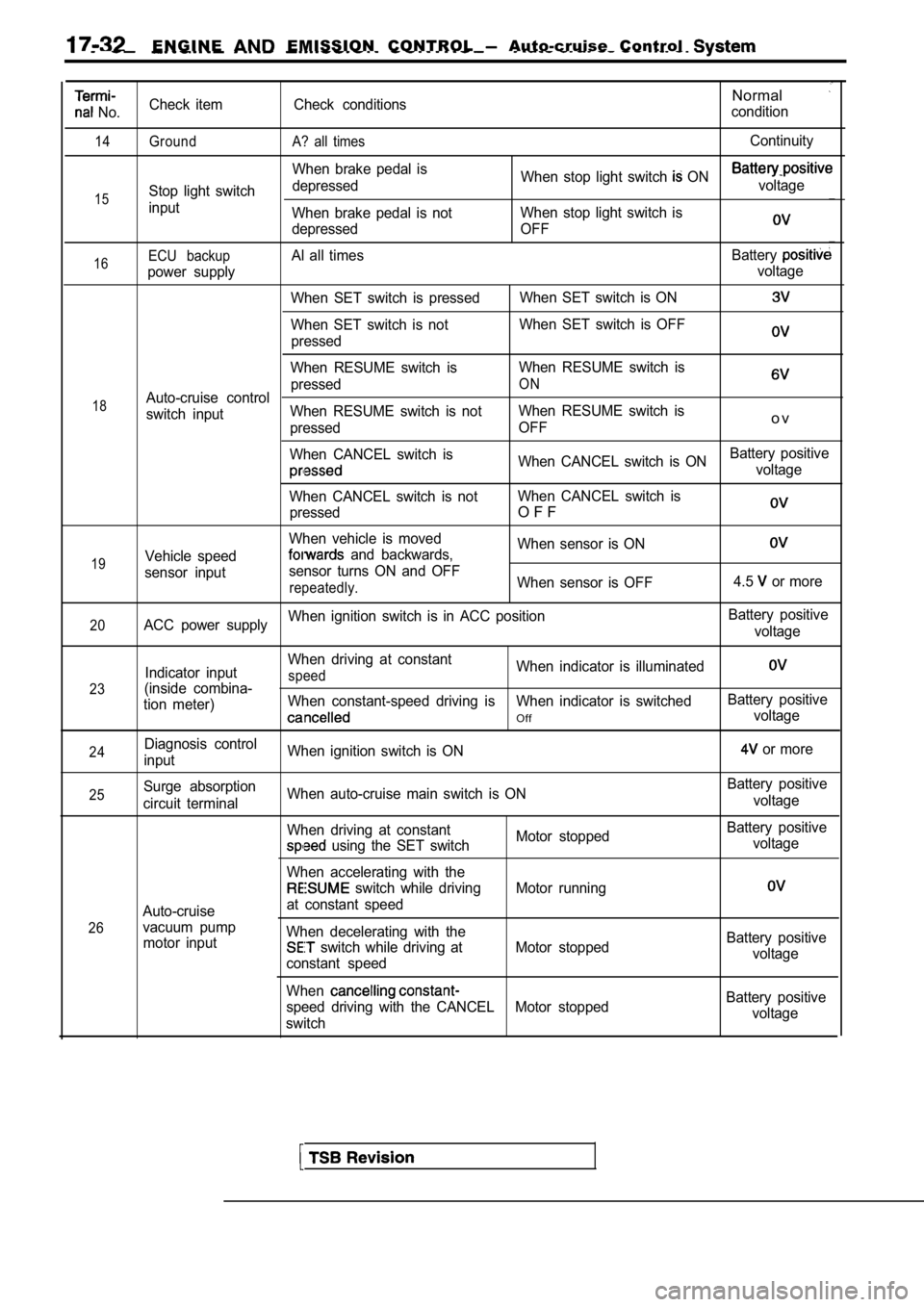

E N G I N E EMISSION CONTROL Auto-cruise Control

No.

14

15

Check item

Ground

Stop light switch

inputCheck conditions

A? all times

When brake pedal is

depressed

When brake pedal is not

depressed

Normal

condition

Continuity

When stop light switch ON voltage

When stop light switch is

OFF

16

18

19ECU backupAl all times Battery

power supply voltage

When SET switch is pressed When SET switch is ON

When SET switch is notWhen SET switch is OFF

pressed

When RESUME switch is When RESUME switch is

pressed

ONAuto-cruise control

switch input When RESUME switch is not

When RESUME switch is

pressed OFF

o v

When CANCEL switch is

When CANCEL switch is ONBattery positivevoltage

When CANCEL switch is not When CANCEL switch is

pressed

O F F

When vehicle is moved When sensor is ON

Vehicle speed and backwards,

sensor input sensor turns ON and OFF

repeatedly.When sensor is OFF

4.5 or more

20ACC power supplyWhen ignition switch is in ACC position

Battery positive

voltage

23

24

Indicator input

(inside combina-

tion meter)

Diagnosis control

input When driving at constantspeedWhen indicator is illuminated

When constant-speed driving is When indicator is swi

tchedBattery positive

Offvoltage

When ignition switch is ON

or more

25

26Surge absorption

circuit terminal

Auto-cruise

vacuum pump motor input When auto-cruise main switch is ON

When driving at constant

Motor stopped

using the SET switch

When accelerating with the

switch while driving Motor running

at constant speed

When decelerating with the

switch while driving at Motor stopped

constant speed

When

speed driving with the CANCEL Motor stopped

switch Battery positive

voltage

Battery positive voltage

Battery positivevoltage

Battery positive voltage

Page 808 of 2103

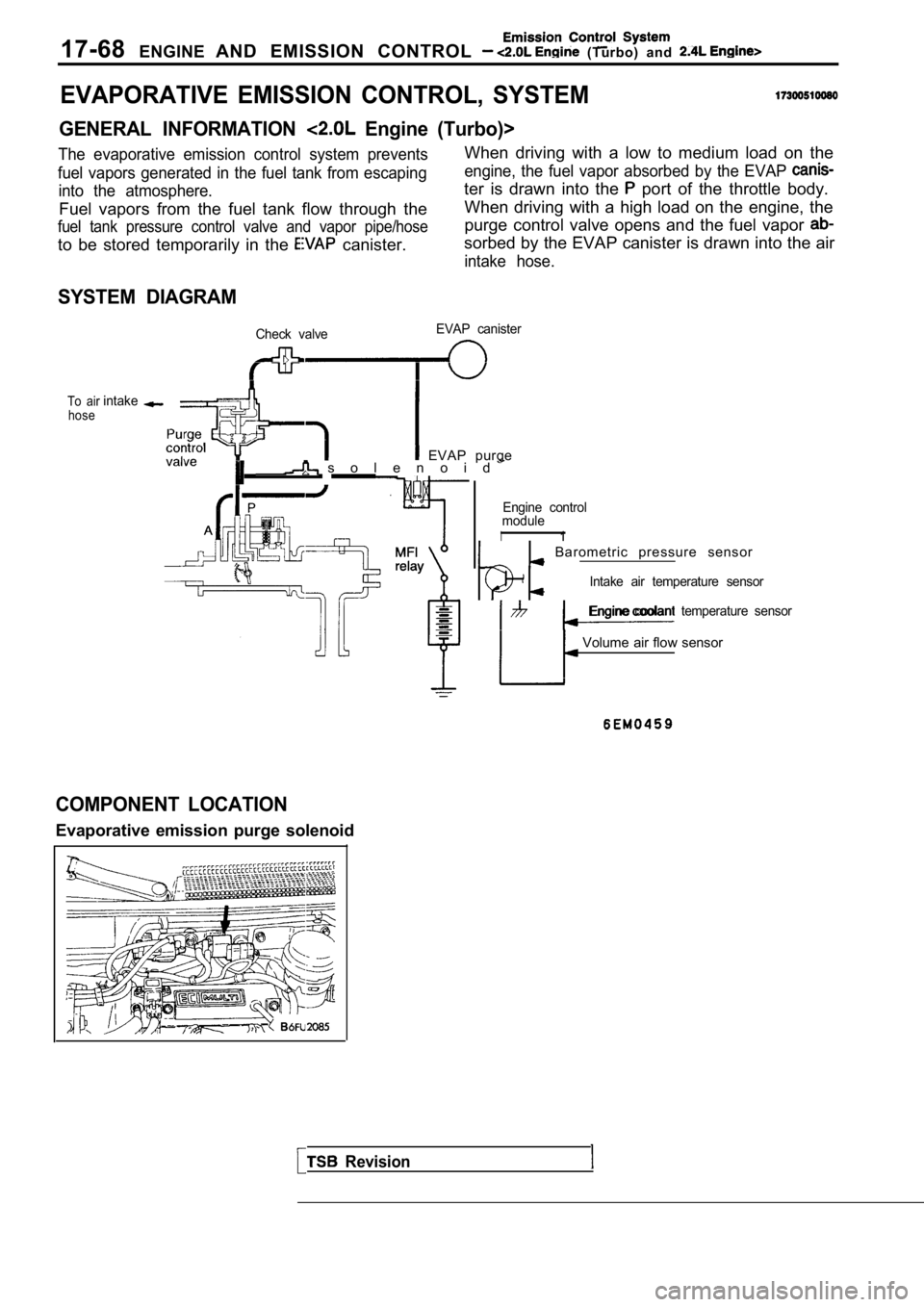

17-68ENGINEAND EMISSION CONTROL (Turbo) and

EVAPORATIVE EMISSION CONTROL, SYSTEM

GENERAL INFORMATION Engine (Turbo)>

The evaporative emission control system preventsWhen driving with a low to medium load on the

fuel vapors generated in the fuel tank from escapin gengine, the fuel vapor absorbed by the EVAP

into the atmosphere.ter is drawn into the port of the throttle body.

Fuel vapors from the fuel tank flow through the When driving with a high load on the engine, the

fuel tank pressure control valve and vapor pipe/hos

epurge control valve opens and the fuel vapor

to be stored temporarily in the canister.sorbed by the EVAP canister is drawn into the air

intake hose.

SYSTEM DIAGRAM

Check valve EVAP canister

To air

hoseintake

EVAP purge s o l e n o i d

Revision

Engine control

module

I1

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Volume air flow sensor

COMPONENT LOCATION

Evaporative emission purge solenoid

Page 1171 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)>: On-vehicle _ _

AUTOMATIC

COMPONENT CHECK

SPEED SENSOR

(1) Disconnect the input speed sensor connector.

(2) Measure the resistance

the input speed

side connector terminals 1 and 2.

Standard value:,

(3) If the resistance is outside the standard value , replace

the input speed sensor.

OUTPUT SPEED SENSOR CHECK

(1) Disconnect the output speed sensor connector.

(2) Measure the resistance between the input speed

side connector terminals 1 2.

Standard value:

(3) If the resistance is outside the standard value , replace

the output speed sensor.

TRANSAXLE RANGE SENSOR CONTINUITY CHECK

Refer to

OVERDRIVE SWITCH CONTINUITY CHECK

Refer to

POSITION SENSOR (TPS) CHECK

Refer to GROUP On-vehicle Inspection of Compo-

nents.

ENGINE COOLANT TEMPERATURE SENSOR CHECK

.

Refer to GROUP On-vehicle Inspection of

nents.

CRANKSHAFT CHECK

Refer to GROUP Troubleshooting.

ABSOLUTE PRESSURE SENSOR

Refer to On-vehicle Inspection of

nents.

Revision

Page 1453 of 2103

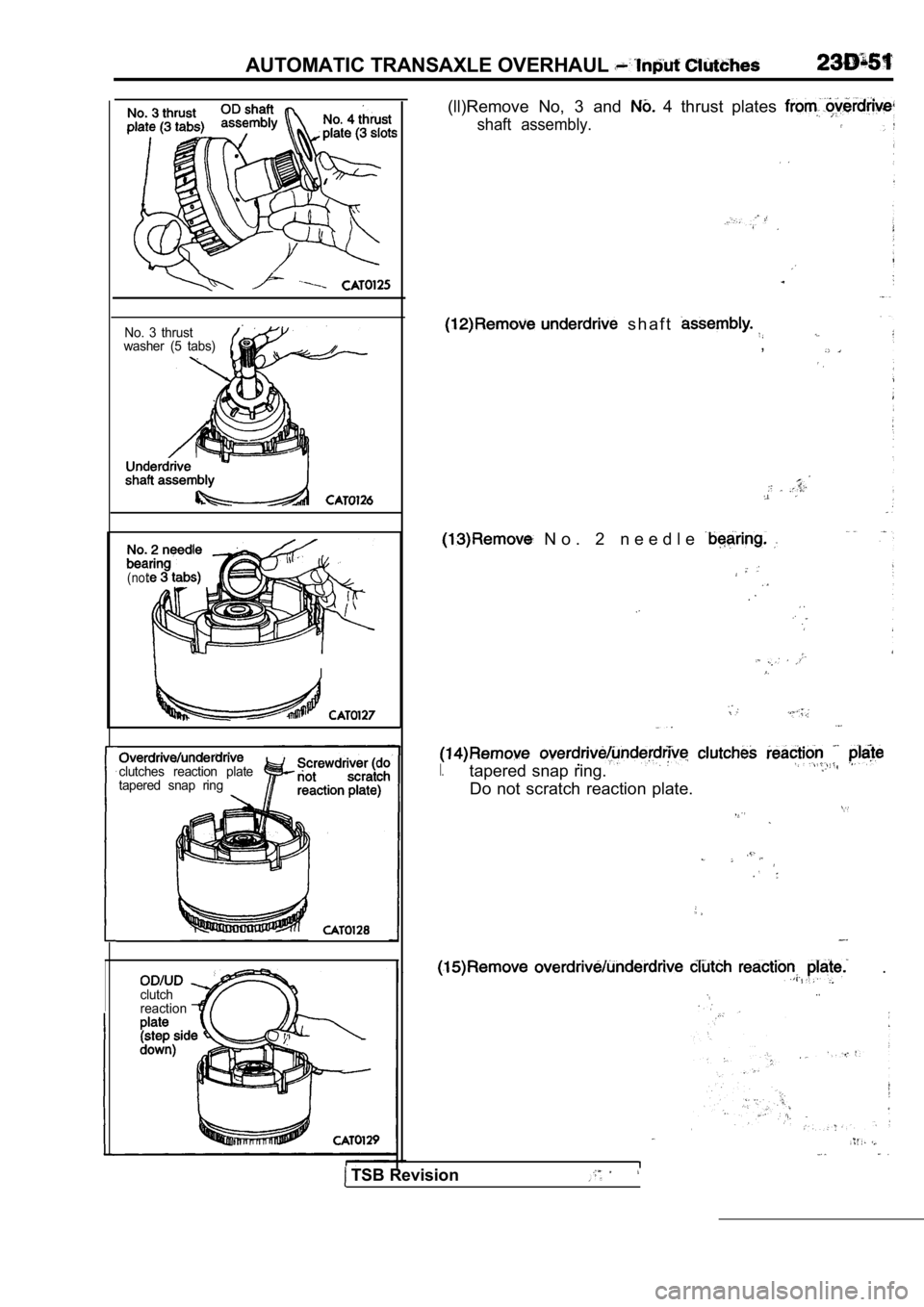

AUTOMATIC TRANSAXLE OVERHAUL

No. 3 thrust

washer (5 tabs)

(not

I

clutches reaction plate

tapered snap ring

clutch

reaction

(ll)Remove No, 3 and 4 thrust plates

shaft assembly.

s h a f t

,

N o . 2 n e e d l e

I.tapered snap ring.

Do not scratch reaction plate.

.

TSB Revision