ABS MITSUBISHI SPYDER 1990 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1621 of 2103

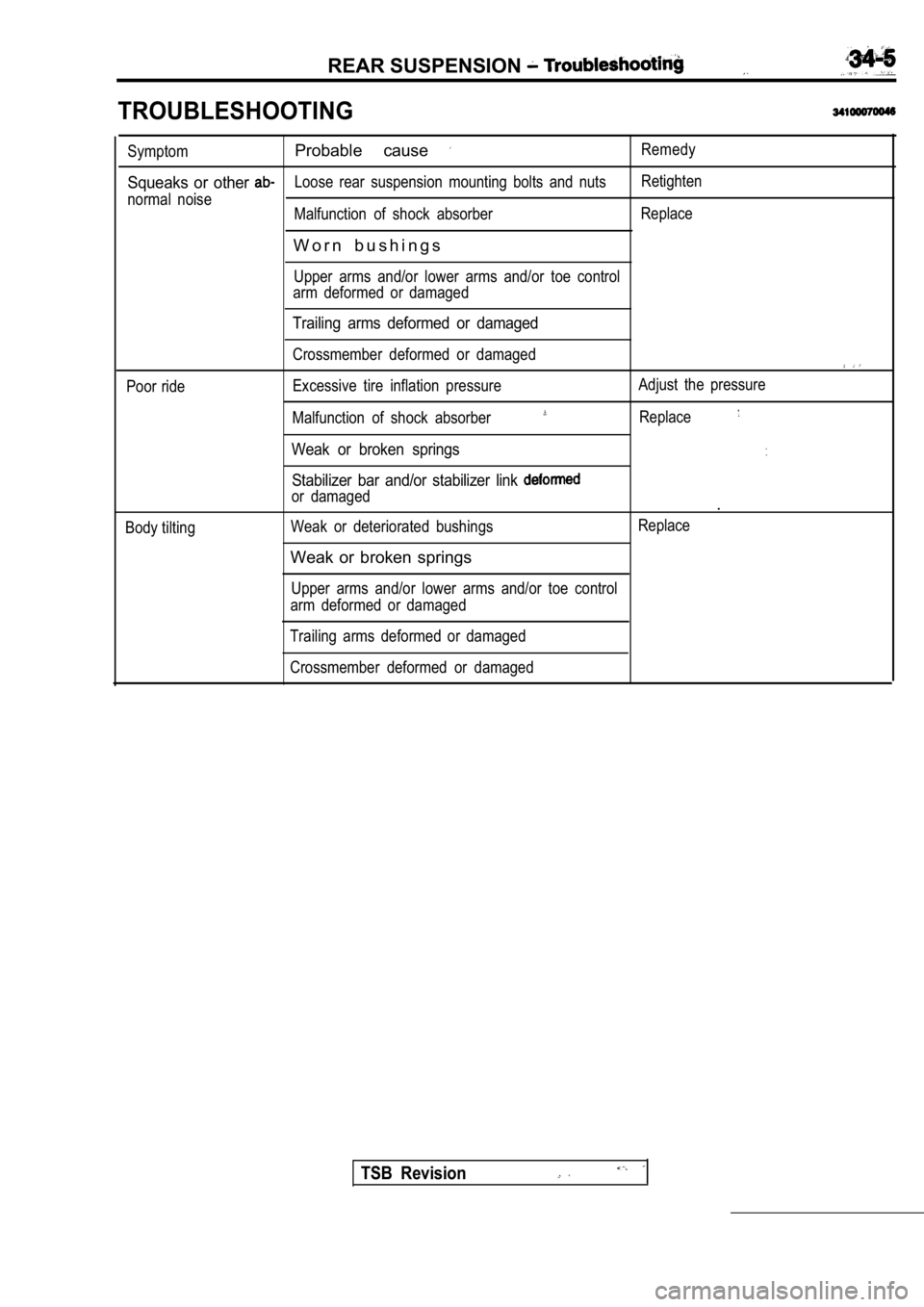

SymptomProbable cause Remedy

Squeaks or other Loose rear suspension mounting bolts and nutsRetighten

normal noise Malfunction of shock absorber Replace

W o r n b u s h i n g s

Upper arms and/or lower arms and/or toe control

arm deformed or damaged

Trailing arms deformed or damaged

Crossmember deformed or damaged

Poor ride Excessive tire inflation pressure Adjust the pressure

Malfunction of shock absorber

Replace

Weak or broken springs

Stabilizer bar and/or stabilizer link

or damaged.

Body tilting Weak or deteriorated bushings Replace

Weak or broken springs

Upper arms and/or lower arms and/or toe control

arm deformed or damaged

Trailing arms deformed or damaged

Crossmember deformed or damaged

REAR SUSPENSION

TROUBLESHOOTING

TSB Revision

Page 1623 of 2103

REAR SUSPENSION Rear Suspension

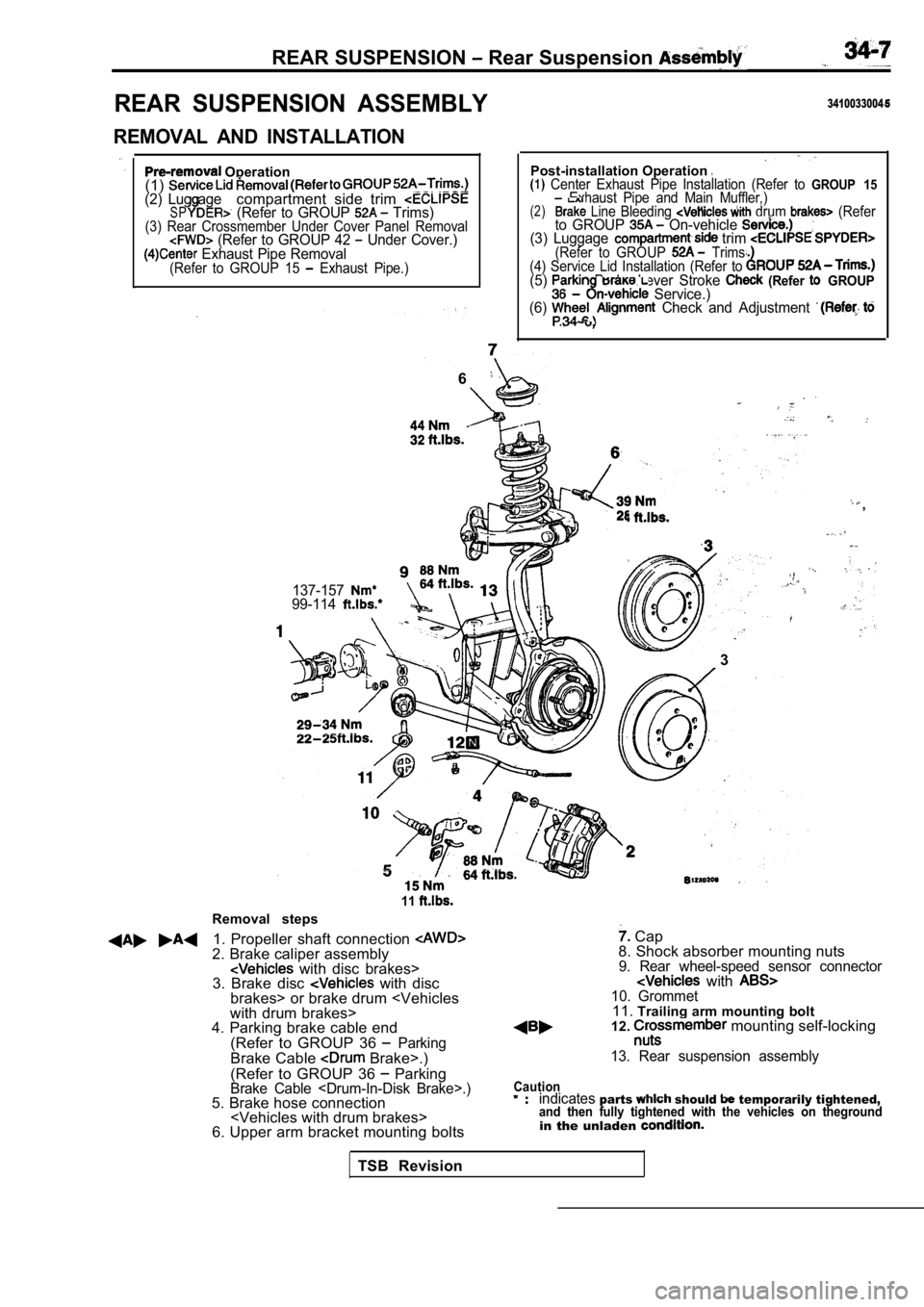

REAR SUSPENSION ASSEMBLY

REMOVAL AND INSTALLATION

Operation

(1)

(2) Lug agecompartment side trim SP (Refer to GROUP Trims)(3) Rear Crossmember Under Cover Panel Removal (Refer to GROUP 42 Under Cover.) Exhaust Pipe Removal(Refer to GROUP 15 Exhaust Pipe.)

3410033004

Post-installation Operation Center Exhaust Pipe Installation (Refer to GROUP 15Exhaust Pipe and Main Muffler,)(2) Line Bleeding drum (Referto GROUP On-vehicle (3) Luggage trim (Refer to GROUP Trims.

(4) Service Lid Installation (Refer to

(5) Brake Lever Stroke (Refer GROUP Service.)

(6) Check and Adjustment .

6

,

137-15799-114

.

l. .

3

Removal steps

11

1. Propeller shaft connection 2. Brake caliper assembly with disc brakes>

3. Brake disc with disc

brakes> or brake drum

4. Parking brake cable end

(Refer to GROUP 36

ParkingBrake Cable Brake>.)

(Refer to GROUP 36

ParkingBrake Cable

6. Upper arm bracket mounting bolts

Cap

8. Shock absorber mounting nuts

9. Rear wheel-speed sensor connector with 10. Grommet11. Trailing arm mounting bolt

12. mounting self-locking

13. Rear suspension assembly

Cautionindicatesparts should temporarily tightened,and then fully tightened with the vehicles on thegr oundin the unladen

TSB Revision

Page 1628 of 2103

2 REAR SUSPENSION Lower Arm and Toe

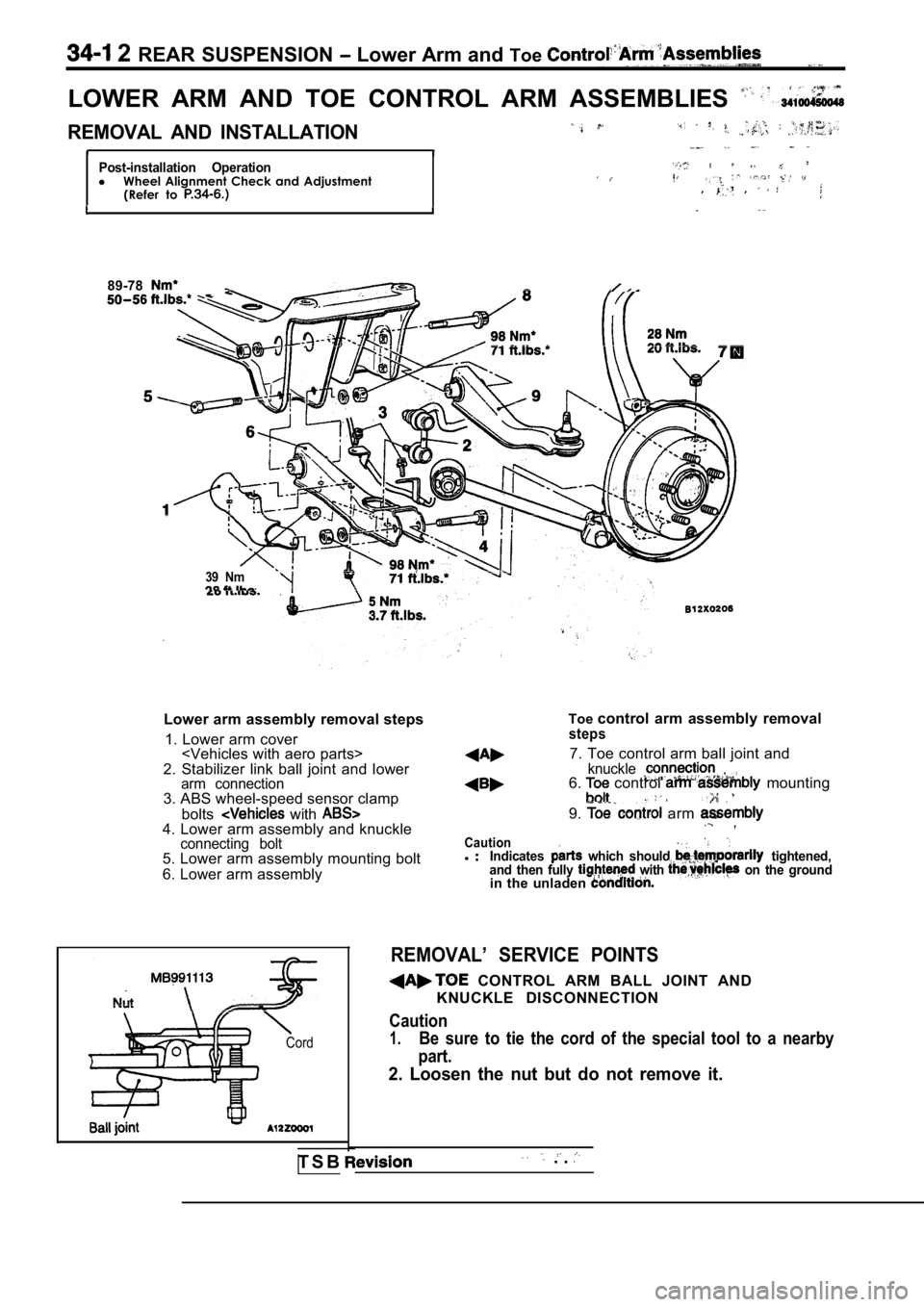

LOWER ARM AND TOE CONTROL ARM ASSEMBLIES

REMOVAL AND INSTALLATION

Post-installation OperationlWheel Alignment Check and Adjustment

(Refer to , ,

89-78

39 Nm

Lower arm assembly removal steps

1. Lower arm cover

2. Stabilizer link ball joint and lower

arm connection3. ABS wheel-speed sensor clamp

bolts

with 4. Lower arm assembly and knuckleconnecting bolt5. Lower arm assembly mounting bolt

6. Lower arm assembly Toe

control arm assembly removal

steps

7. Toe control arm ball joint andknuckle , 6. control mounting

9. arm ,

Cautionl Indicates which should tightened,

and then fully with on the groundin the unladen

Cord

REMOVAL’ SERVICE POINTS

CONTROL ARM BALL JOINT AND

KNUCKLE DISCONNECTION

Caution

1.Be sure to tie the cord of the special tool to a ne arby

part.

2. Loosen the nut but do not remove it.

T S B. .

Page 1630 of 2103

REAR SUSPENSION Shock Absorber

. .

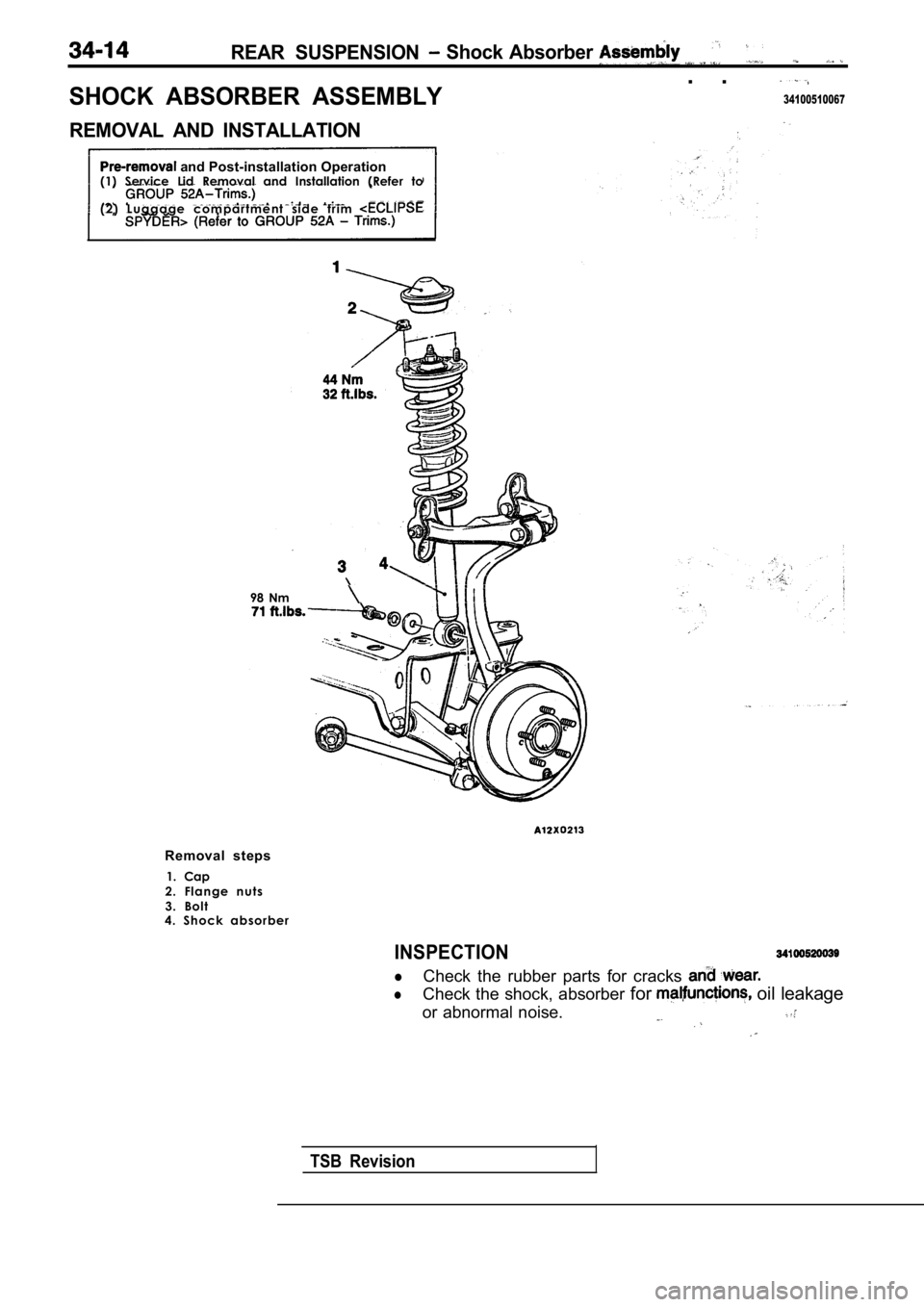

SHOCK ABSORBER ASSEMBLY34100510067

REMOVAL AND INSTALLATION

and Post-installation Operation

(1) Service Lid Removal and Installation (Refer to

( 2 ) L u g g a g e c o m p a r t m e n t s i d e t r i m

98 Nm

Removal steps

1. Cap

2 . F l a n g e n u t s

3. Bolt

4 . S h o c k a b s o r b e r

INSPECTION

lCheck the rubber parts for cracks

lCheck the shock, absorber for oil leakage

or abnormal noise.

TSB Revision

Page 1631 of 2103

REAR SUSPENSION Shock Absorber

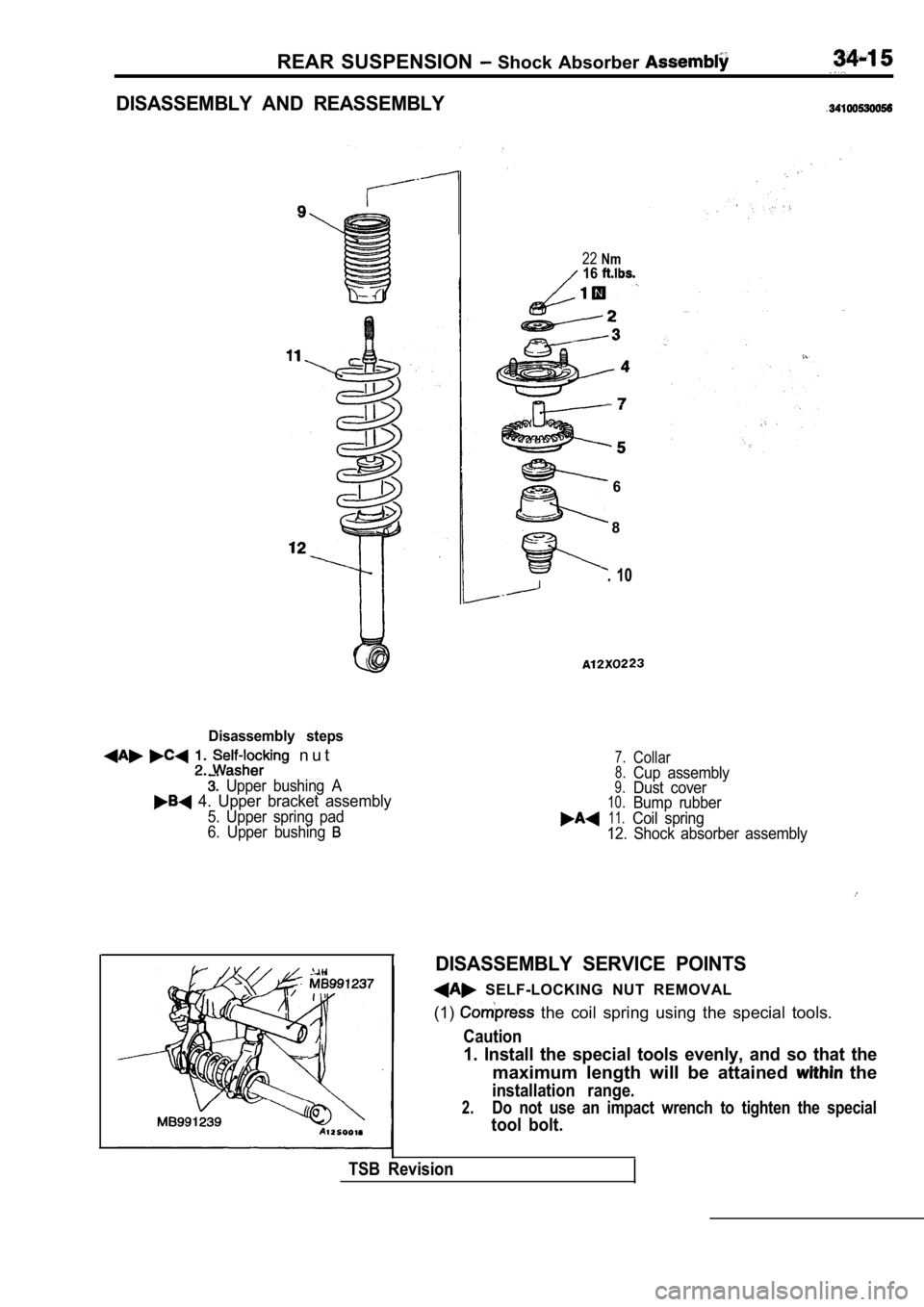

DISASSEMBLY AND REASSEMBLY

Disassembly steps

n u t

Upper bushing A 4. Upper bracket assembly

5. Upper spring pad

6. Upper bushing

22Nm16

6

8

. 10

7.Collar8.Cup assembly9.Dust cover10.Bump rubber11.Coil spring

12. Shock absorber assembly

DISASSEMBLY SERVICE POINTS

SELF-LOCKING NUT REMOVAL

(1)

the coil spring using the special tools.

Caution

1. Install the special tools evenly, and so that th e

maximum length will be attained the

installation range.

2.Do not use an impact wrench to tighten the special

tool bolt.

TSB Revision

Page 1632 of 2103

REAR SUSPENSION Shock

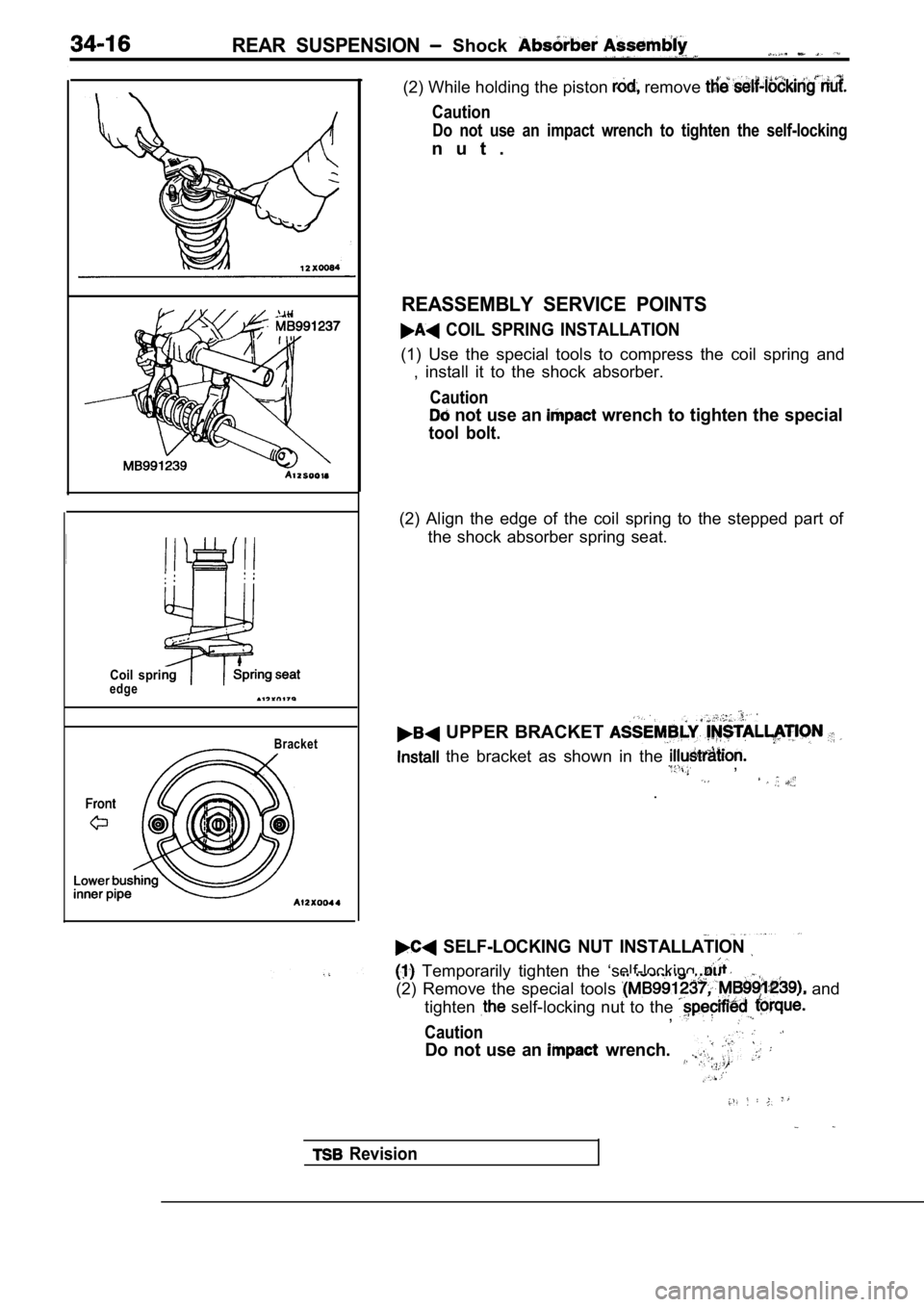

Coil spriedgeBracket

(2) While holding the piston remove

Caution

Do not use an impact wrench to tighten the self-loc king

n u t .

REASSEMBLY SERVICE POINTS

COIL SPRING INSTALLATION

(1) Use the special tools to compress the coil spring and

, install it to the shock absorber.

Caution

not use an wrench to tighten the special

tool bolt.

(2) Align the edge of the coil spring to the steppe d part of

the shock absorber spring seat.

UPPER BRACKET

the bracket as shown in the ,

.

SELF-LOCKING NUT INSTALLATION

Temporarily tighten the ‘self-locking

(2) Remove the special tools and

tighten

self-locking nut to the ,

Caution

Do not use an wrench.

Revision

Page 1637 of 2103

SERVICE BRAKES

CONTENTS

BASIC BRAKE SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANTI-LOCK BRAKING SYSTEM (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . .358

ANTI-LOCK BRAKING SYSTEM (ABS) . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 1640 of 2103

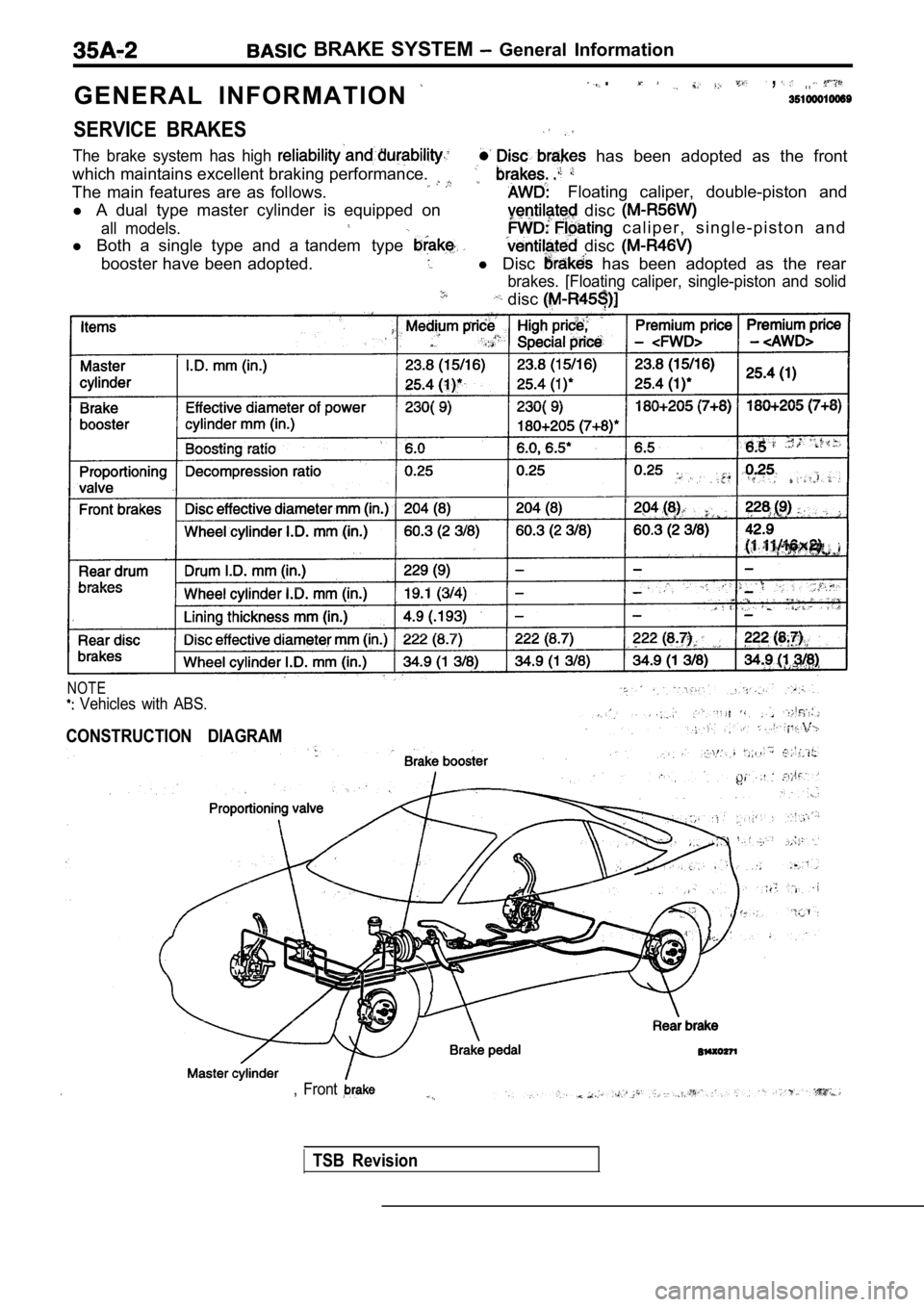

BRAKE SYSTEM General Information

G E N E R A L I N F O R M A T I O N

. , . .

SERVICE BRAKES

The brake system has high

which maintains excellent braking performance.

has been adopted as the front

The main features are as follows. Floating caliper, double-piston and

l A dual type master cylinder is equipped on

disc

all models.

l Both a single type and a tandem type

c a l i p e r , s i n g l e - p i s t o n a n d

disc

booster have been adopted.l Disc has been adopted as the rear

brakes. [Floating caliper, single-piston and solid

disc

NOTE

Vehicles with ABS.

CONSTRUCTION DIAGRAM

, Front

TSB Revision

Page 1641 of 2103

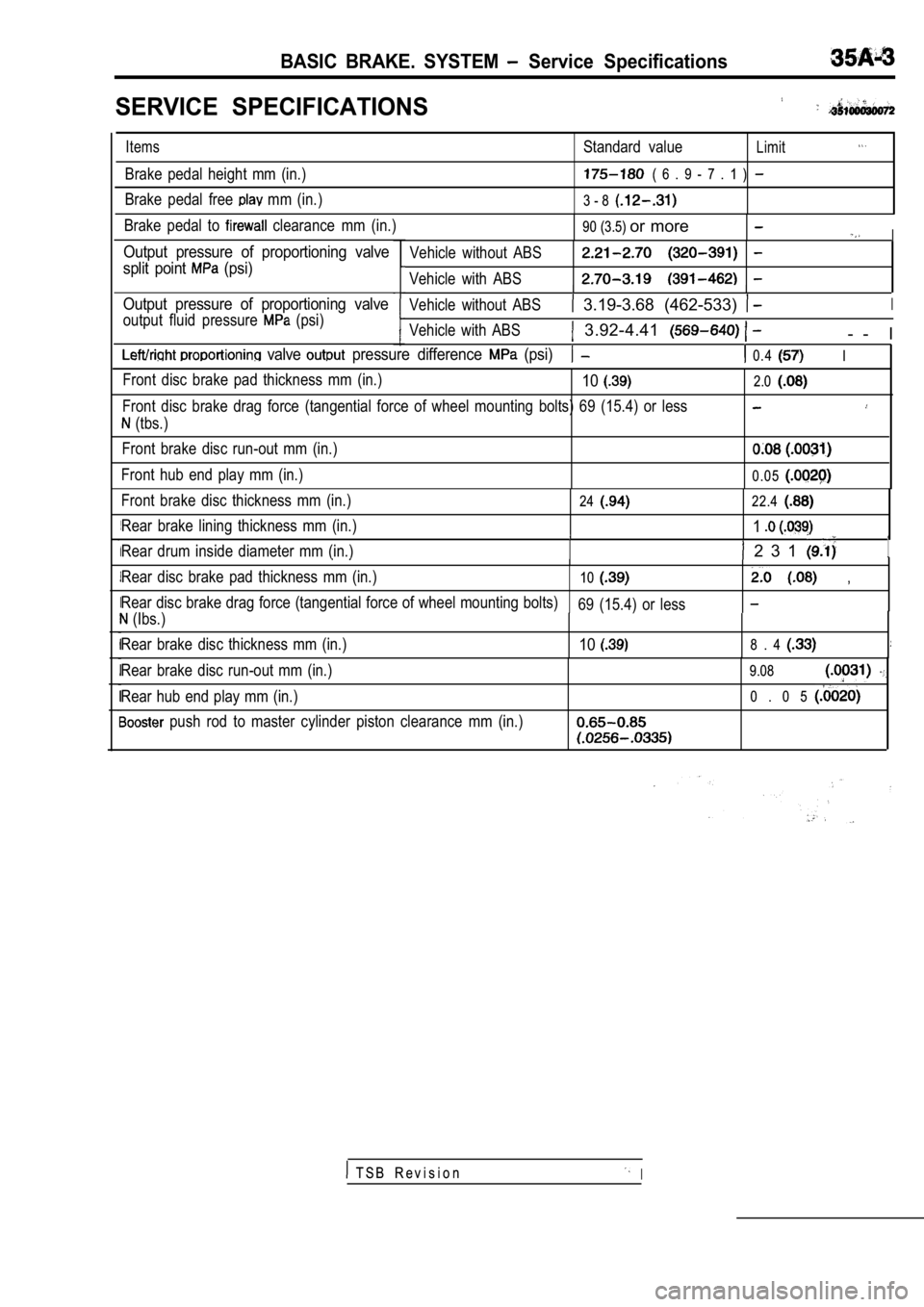

BASIC BRAKE. SYSTEM Service Specifications

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

Brake pedal height mm (in.) ( 6 . 9 - 7 . 1 )

Brake pedal free mm (in.)3 - 8

Brake pedal to clearance mm (in.)90 (3.5) or moreI

Output pressure of proportioning valve

split point

(psi)

Output pressure of proportioning valve

output fluid pressure (psi) Vehicle without ABS

Vehicle with ABSII

Vehicle without ABS 3.19-3.68 (462-533) I

Vehicle with ABS 3.92-4.41 - - I

valve pressure difference (psi) 0.4 I

Front disc brake pad thickness mm (in.)10

Front disc brake drag force (tangential force of wh

eel mounting bolts) 69 (15.4) or less

(tbs.)

Front brake disc run-out mm (in.)

Front hub end play mm (in.)

2.0

0.05

Front brake disc thickness mm (in.)

Rear brake lining thickness mm (in.)

Rear drum inside diameter mm (in.)2422.4

1

2 3 1 1

Rear disc brake pad thickness mm (in.)10 ,

Rear disc brake drag force (tangential force of whe el mounting bolts)

69 (15.4) or less

(Ibs.)

Rear brake disc thickness mm (in.)

108 . 4

Rear brake disc run-out mm (in.)

Rear hub end play mm (in.)

push rod to master cylinder piston clearance mm (i n.)

9.08

0 . 0 5

T S B R e v i s i o nI

Page 1650 of 2103

BASIC BRAKE SYSTEM

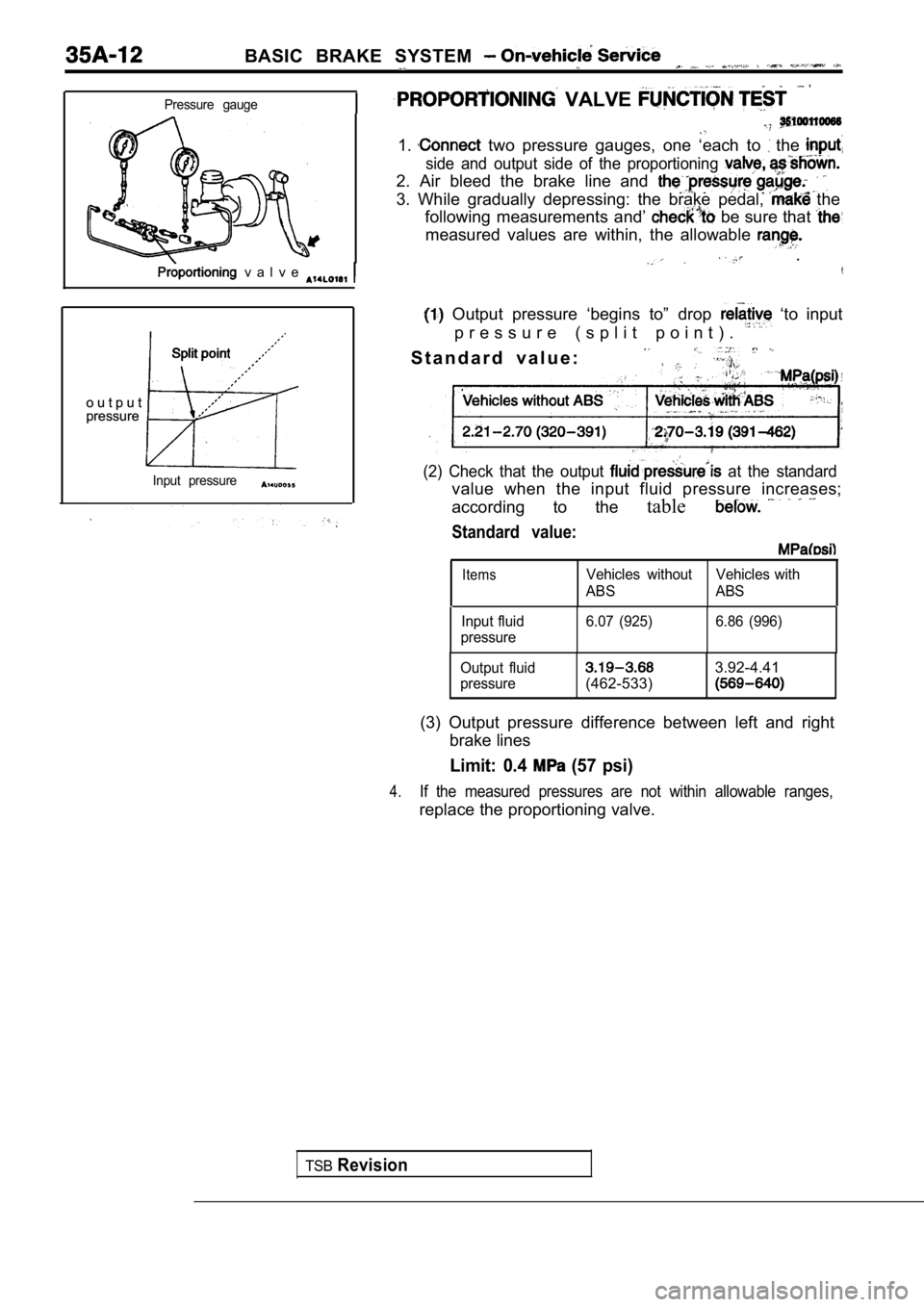

Pressure gauge

v a l v e

S p l i t p o i n t S p l i t p o i n t

o u t p u t

o u t p u tpressurepressure

Input pressure

VALVE

.

1. two pressure gauges, one ‘each to the

side and output side of the proportioning

2. Air bleed the brake line and

3. While gradually depressing: the brake pedal, the

following measurements and’

be sure that

measured values are within, the allowable

.

Output pressure ‘begins to” drop ‘to input

p r e s s u r e ( s p l i t p o i n t ) .

S t a n d a r d v a l u e :

(2) Check that the output at the standard

value when the input fluid pressure increases;

according to the table

Standard value:

ItemsVehicles without Vehicles with

ABS ABS

TSB

Revision

Input fluid

pressure 6.07 (925) 6.86 (996)

Output fluid

pressure

3.92-4.41

(462-533)

(3) Output pressure difference between left and rig ht

brake lines

Limit: 0.4 (57 psi)

4.If the measured pressures are not within allowable ranges,

replace the proportioning valve.