display MITSUBISHI SPYDER 1990 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 763 of 2103

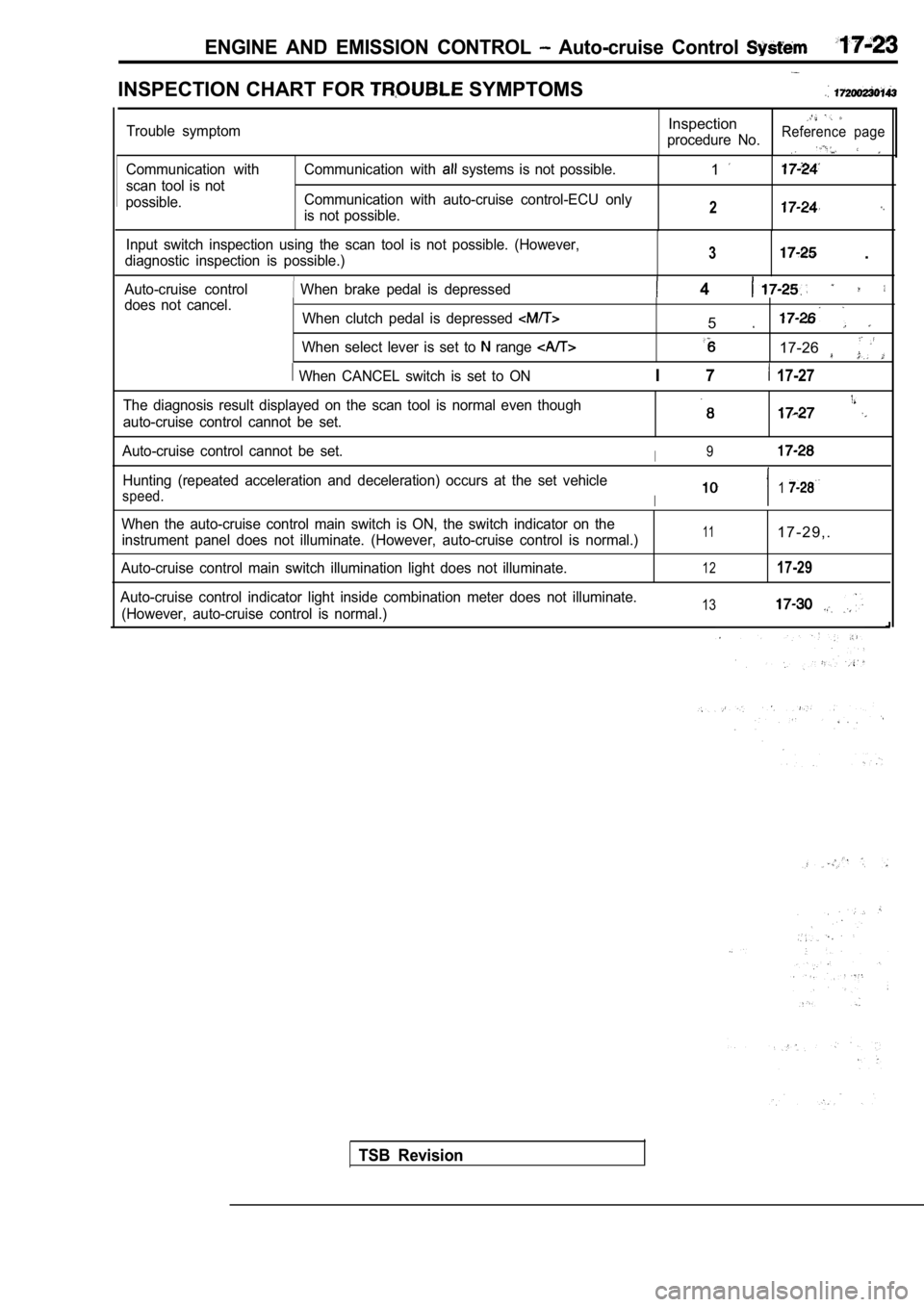

ENGINE AND EMISSION CONTROL Auto-cruise Control

INSPECTION CHART FOR SYMPTOMS

Communication with

scan tool is not

possible. Communication with systems is not possible.

Communication with auto-cruise control-ECU only

is not possible.1

2

Input switch inspection using the scan tool is not possible. (However,

diagnostic inspection is possible.)3 .

Auto-cruise control When brake pedal is depressed 4 does not cancel. When clutch pedal is depressed

When select lever is set to range

When CANCEL switch is set to ON

5

17-26

I 7 17-27

Trouble symptomInspection

procedure No.Reference page

The diagnosis result displayed on the scan tool is normal even though

auto-cruise control cannot be set.

Auto-cruise control cannot be set.I9

Hunting (repeated acceleration and deceleration) oc curs at the set vehicle

speed.I1

When the auto-cruise control main switch is ON, the switch indicator on the

instrument panel does not illuminate. (However, aut o-cruise control is normal.)

Auto-cruise control main switch illumination light does not illuminate.111 7 - 2 9 , .

1217-29

Auto-cruise control indicator light inside combinat ion meter does not illuminate.

(However, auto-cruise control is normal.)13

TSB Revision

Page 767 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE AND EMISSION CONTROL Control. System

INSPECTION PROCEDURE 7

When auto-cruise control CANCEL switch is set to ON,

auto-cruise control does not cancel.

[Comment]An open-circu MITSUBISHI SPYDER 1990 Service Owners Manual ENGINE AND EMISSION CONTROL Control. System

INSPECTION PROCEDURE 7

When auto-cruise control CANCEL switch is set to ON,

auto-cruise control does not cancel.

[Comment]An open-circu](/img/19/57345/w960_57345-766.png)

ENGINE AND EMISSION CONTROL Control. System

INSPECTION PROCEDURE 7

When auto-cruise control CANCEL switch is set to ON,

auto-cruise control does not cancel.

[Comment]An open-circuit in the circuit inside the CANCEL sw itch may be present.

Replace the auto-cruise control switch.

INSPECTION PROCEDURE 8l the

The diagnostic result displayed on the scan tool is normal

even though auto-cruise control cannot be set.

[Comment]Because of an open-circuit in the battery backup ci rcuit system, the fail-safe function preventsdiagnostic trouble codes from being memorized and d isplayed even though auto-cruise controlis canceled.

Probable cause

l Malfunction of the connector.

l Malfunction the harness.

l Malfunction of the

Measure at auto-cruise control-ECU

connector

l sure at the harness side.lVoltage between terminal (16) and

around

Battery positive voltage

OKCheck the harness between the

auto-cruise control-ECU and power

supply. Repair, if necessary.

Check the following connector:

Replace the auto-cruise control-ECU.

TSB Revision

Page 1030 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual AUTOMATIC TRANSAXLE

(TURBO) AND ENGINE> Troubleshdoting

Code No.

servo switch c a u s e

[Comment]l Malfunction of servo If the servo switch does not ON in 1 and 3 range MITSUBISHI SPYDER 1990 Service Owners Manual AUTOMATIC TRANSAXLE

(TURBO) AND ENGINE> Troubleshdoting

Code No.

servo switch c a u s e

[Comment]l Malfunction of servo If the servo switch does not ON in 1 and 3 range](/img/19/57345/w960_57345-1029.png)

AUTOMATIC TRANSAXLE

(TURBO) AND ENGINE> Troubleshdoting

Code No.

servo switch c a u s e

[Comment]l Malfunction of servo If the servo switch does not ON in 1 and 3 range within 5 seconds, there is l

Malfunction of connector

an open circuit in the servo switch and diagnostic trouble code No. 21 is output. l

Malfunction of TCM

If the servo switch does not OFF in 2 and 4 range, there is a circuit in

the servo switch and diagnostic trouble code No. 22 is output,

(Refer to

OK

N G Replace

Repair

lDisconnect the connector and I

sure at the harnessside. OK

servo switch and TCM

Check trouble Replace the TCM.

NG

Check the harness wire between the servo switch and TCM con-

nectors. if

TSB Revision

Code No. 23 Ignition signal Probable cause

[Comment]l Malfunction of ignition coil

If ignition pulses are not input to the TCM while t he engine is idling, there is an open circuit l

in the ignition signal line and diagnostic trouble code No. 23 is output.Malfunction of power transistor

l Malfunction of connector

l Malfunction of TCM

Is the engine speed displayed on the

tachometer correct?

Yes

lInspection procedures circuit system (Refer to GROUP

.

NG Repair

OK

Check trouble symptom.

NG

N G Repairpower transistor andTCMconnectors.

the TCM.

Page 1050 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Troubleshooting

INSPECTION PROCEDURES 12

l Some points (Early, late shifting points) P r o b a b l e c a u s e

[Comment]Some shift poi MITSUBISHI SPYDER 1990 Service Owners Manual AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Troubleshooting

INSPECTION PROCEDURES 12

l Some points (Early, late shifting points) P r o b a b l e c a u s e

[Comment]Some shift poi](/img/19/57345/w960_57345-1049.png)

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Troubleshooting

INSPECTION PROCEDURES 12

l Some points (Early, late shifting points) P r o b a b l e c a u s e

[Comment]Some shift points occurs early, late while driving.

In such cases, the cause is probably al

Malfunction of valve body

defective valve body, or it is a phenomenon related control and is not an abnormality.

Refer to Automatic Transaxle Overhaul

Does fuzzy shifting occur normally? No problem because it is a phenomenon that appears due to

Nofactors associated with control.

YesDeviations at some shift points occurs only when the ATF is cold or less].

NoYes Deviations at some shift hot or more].

Valve body disassembly, cleaning and reassembly

Pay particular attention to loosening of bolts, and to damage,

If it is considered that the damage or chipping can not be

repaired, replace the valve body assembly.

INSPECTION PROCEDURE 13

lNo fail-safe codes (Does not shift)Probable cause

[Comment]l Malfunction of overdrive switch

Shifting does not occur while driving, and no fail- safe codes are output. In such cases, the l

cause is probably a defective overdrive switch or P ark/Neutral position switch.Malfunction of Park/ Neutral position switch

l Malfunction of power supply circuit

l Malfunction of TCM

No

Yes

Check to be sure that backup power is being supplie d to

the TCM.Does overdrive operate?

Yes

SCAN TOOL Data list

l 35 Overdrive switchCheck to be sure that power is being supplied to th e TCM

SCAN TOOL Data list

l 37 Park/ Neutral position switch

I OK: TCM input signal and selector lever position

should match.

Check the overdrive switch system according to insp ection

NGOK

, procedure (Refer to

Replace the TCM. ,

OK: When overdrive switch turns from OFF to ON,

scan tool display turns from OFF to ON.

Code No. 36, 37

Park/Neutral position switch system

(Refer to

Power circuit check

lPay particular attention to open circuits in the ha rness,defective connector connections and open circuits i nfuses.lIf there is an open circuit in a fuse, the cause of

the should be located and it should be

TSB Revision

Page 1127 of 2103

AUTOMATIC TRANSAXLE

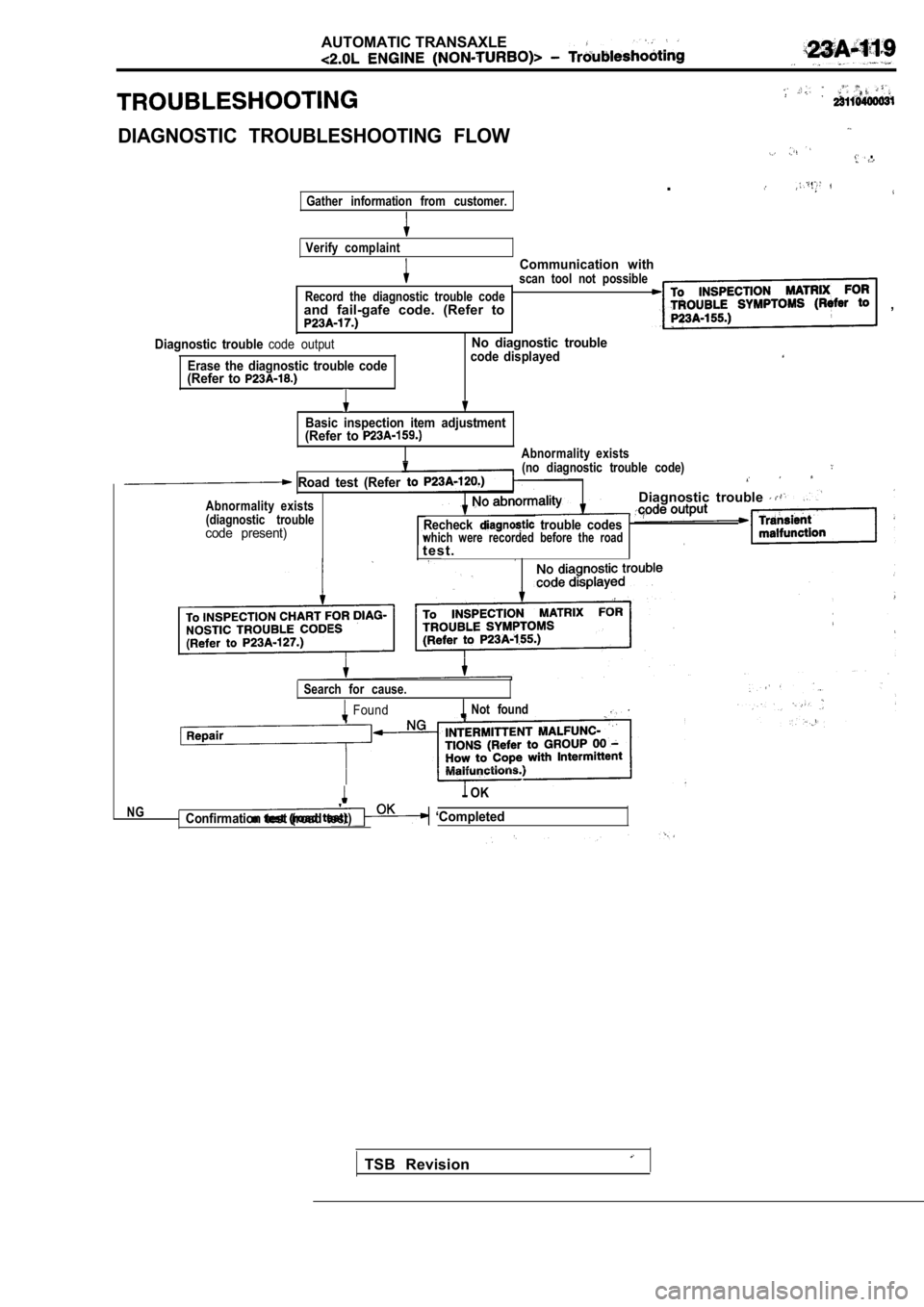

DIAGNOSTIC TROUBLESHOOTING FLOW

.

.Gather information from customer.

Verify complaint

Communication withscan tool not possible

Record the diagnostic trouble code

and fail-gafe code. (Refer to ,

Diagnostic trouble code outputNo diagnostic trouble

Erase the diagnostic trouble code code displayed(Refer to

Basic inspection item adjustment(Refer to

Abnormality exists

(no diagnostic trouble code)

Road test (Refer

Abnormality exists

(diagnostic trouble

code present)

Diagnostic trouble

Recheck trouble codeswhich were recorded before the roadt e s t .

Search for cause.

FoundNot found

NG

OK

‘CompletedConfirmation test (road test)

TSB Revision

Page 1128 of 2103

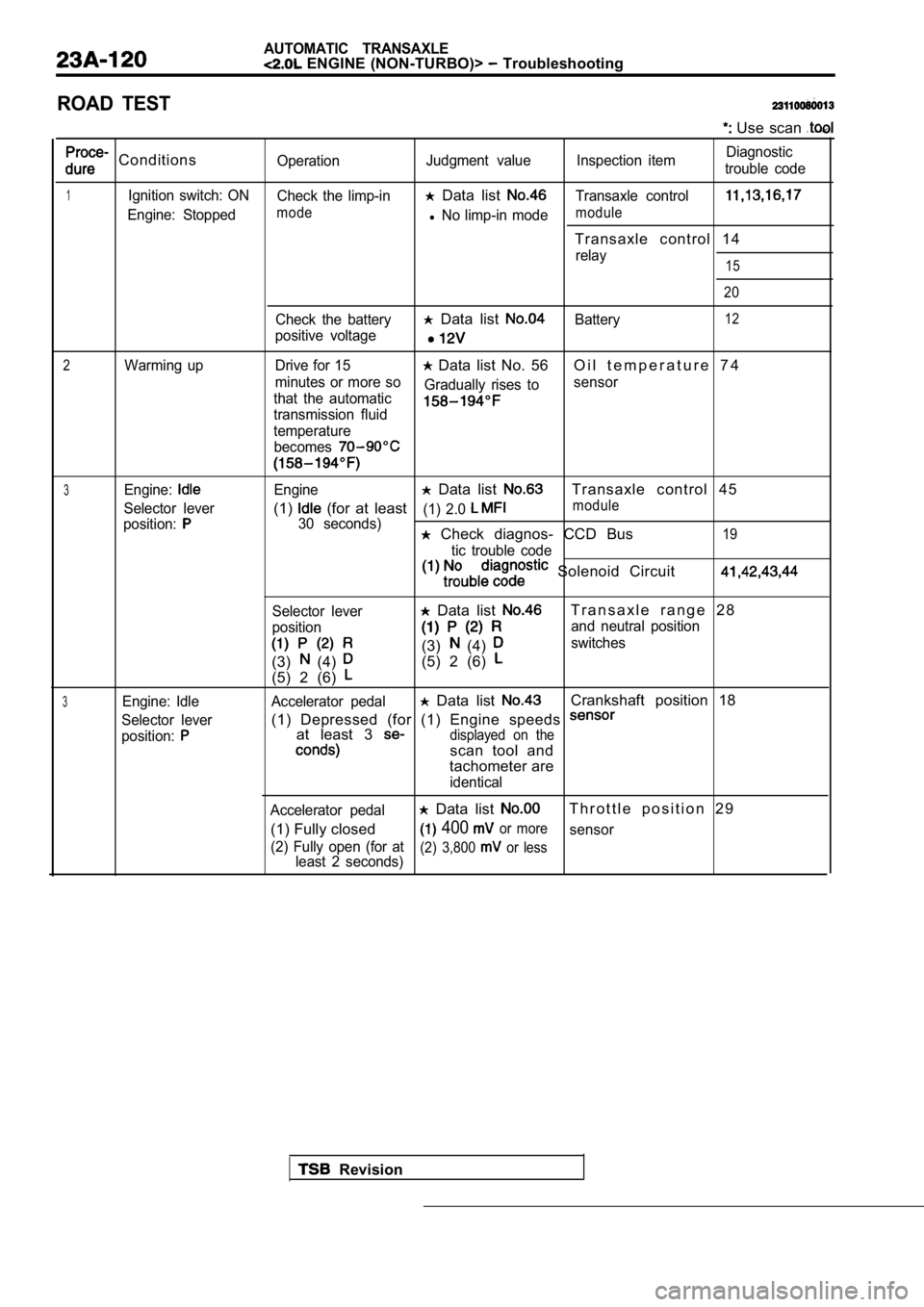

AUTOMATIC TRANSAXLE ENGINE (NON-TURBO)> Troubleshooting

ROAD TEST

Use scan

ConditionsOperationJudgment value Inspection item Diagnostic

trouble code

1Ignition switch: ON Check the limp-in Data list Transaxle control

Engine: Stoppedmodel No limp-in modemodule

Transaxle control 14

relay15

20

Check the battery Data list Battery12

positive voltage

2Warming up Drive for 15 Data list No. 56 O i l t e m p e r a t u r e 7 4

minutes or more so

that the automatic Gradually rises to

sensor

transmission fluid

temperature

becomes

3Engine:Engine Data list Transaxle control 45

Selector lever(1) (for at least(1) 2.0 module

position:30 seconds) Check diagnos- CCD Bus19

tic trouble code

Solenoid Circuit

Selector lever

position

(3) (4)

(5) 2 (6)

Data list T r a n s a x l e r a n g e 2 8

and neutral position

(3) (4) switches

(5) 2 (6)

3Engine: Idle Accelerator pedal Data list Crankshaft position 18

Selector lever(1) Depressed (for (1) Engine speeds

position:at least 3 displayed on the

scan tool and

tachometer are

identical

Accelerator pedal

Data list T h r o t t l e p o s i t i o n 2 9

(1) Fully closed

400 or moresensor

(2) Fully open (for at least 2 seconds)

(2) 3,800 or less

Revision

Page 1132 of 2103

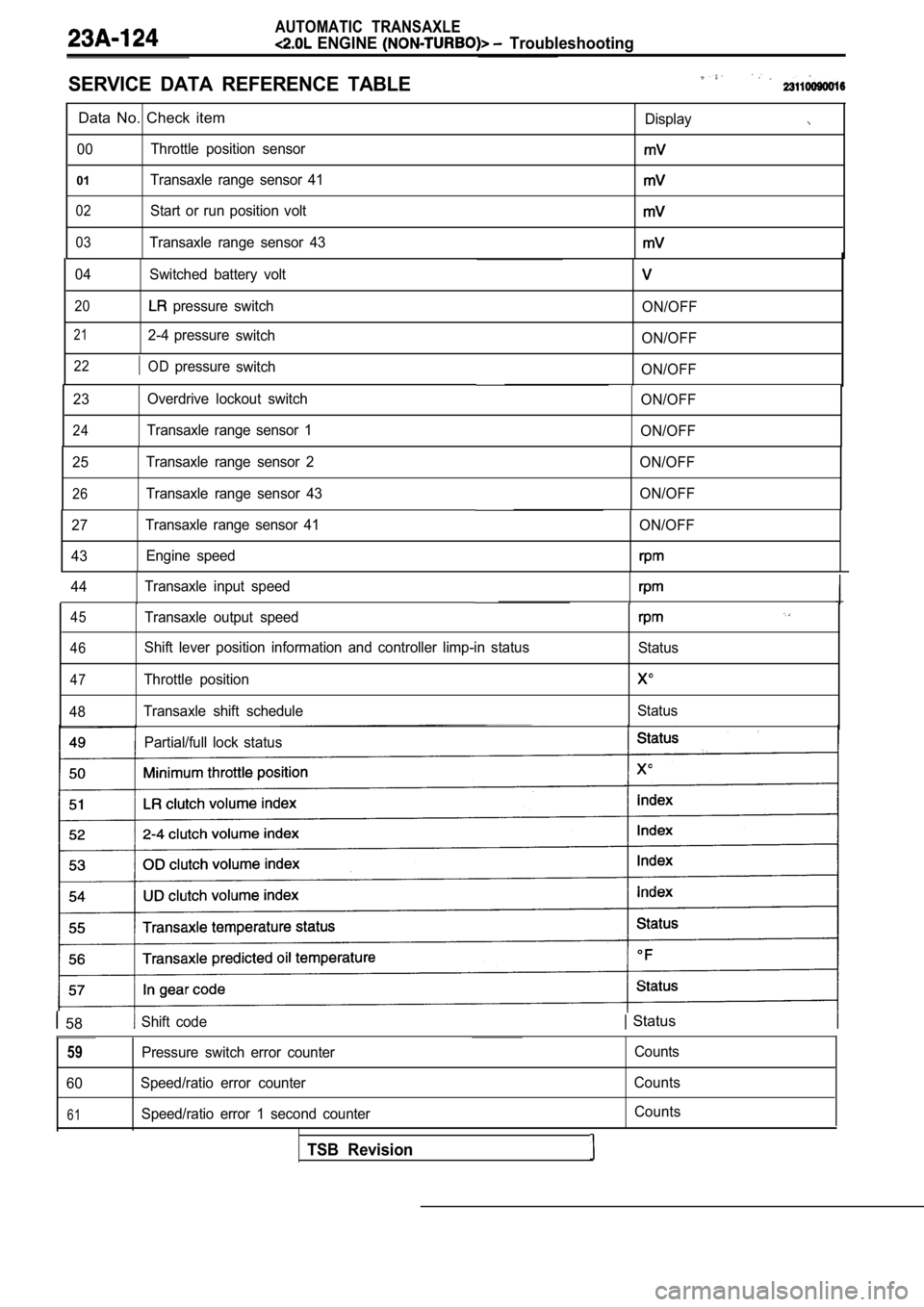

AUTOMATIC TRANSAXLE

ENGINE Troubleshooting

SERVICE DATA REFERENCE TABLE

Data No. Check itemDisplay

00 Throttle position sensor

01Transaxle range sensor 41

02Start or run position volt

03Transaxle range sensor 43

04 Switched battery volt

20 pressure switch

ON/OFF

212-4 pressureswitch

ON/OFF

22ODpressureswitch

ON/OFF

23 Overdrive lockout switch

ON/OFF

24Transaxle range sensor 1ON/OFF

25 Transaxle range sensor 2

ON/OFF

26Transaxle range sensor 43ON/OFF

27 Transaxle range sensor 41

ON/OFF

43 Engine speed

44Transaxle input speed

45Transaxle output speed

46Shift lever position information and controller lim

p-in status

Status

47Throttle position

48Transaxle shift schedule

Status

Partial/full lock status

58Shift code Status

59

60

61

Pressure switch error counter Counts

Speed/ratio error counter Counts

Speed/ratio error 1 second counter Counts

TSB Revision

Page 1133 of 2103

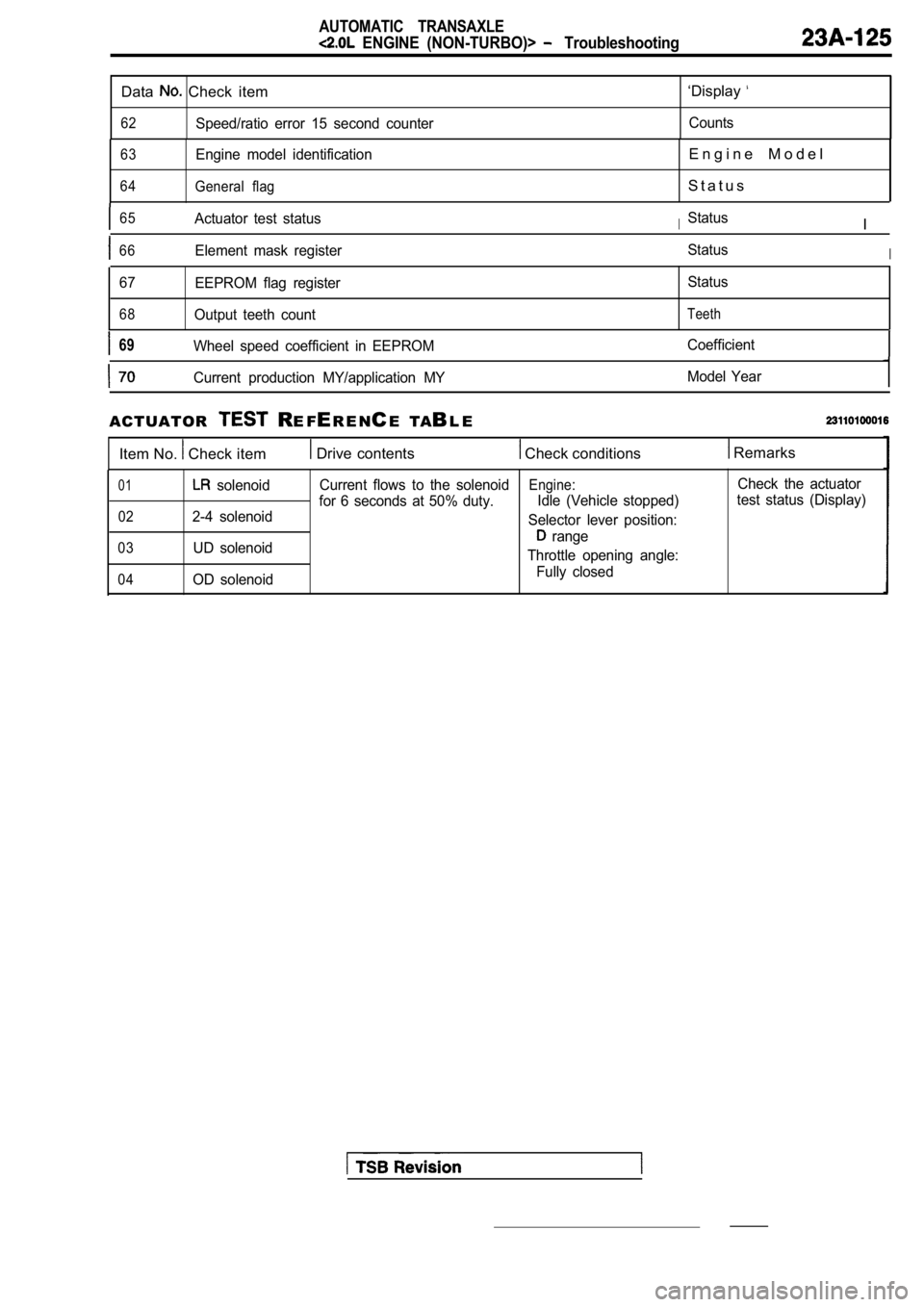

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> Troubleshooting

Data Check item

62Speed/ratio error 15 second counter

‘Display

Counts

63Engine model identification

64General flag

E n g i n e M o d e l

S t a t u s

65Actuator test statusIStatusI

66Element mask register StatusI

67

EEPROM flag register

68Output teeth count StatusTeeth

69Wheel speed coefficient in EEPROM

Coefficient

Current production MY/application MY Model Year

ACTUATOR R

E FER E N CE TA BL E

Item No.

Check item Drive contents Check conditions Remarks

01 solenoid

022-4 solenoid

03UD solenoid

04OD solenoid Current flows to the solenoid

Engine:Check the actuator

for 6 seconds at 50% duty. Idle (Vehicle stopped)test status (Display)

Selector lever position:

range

Throttle opening angle: Fully closed

Page 1139 of 2103

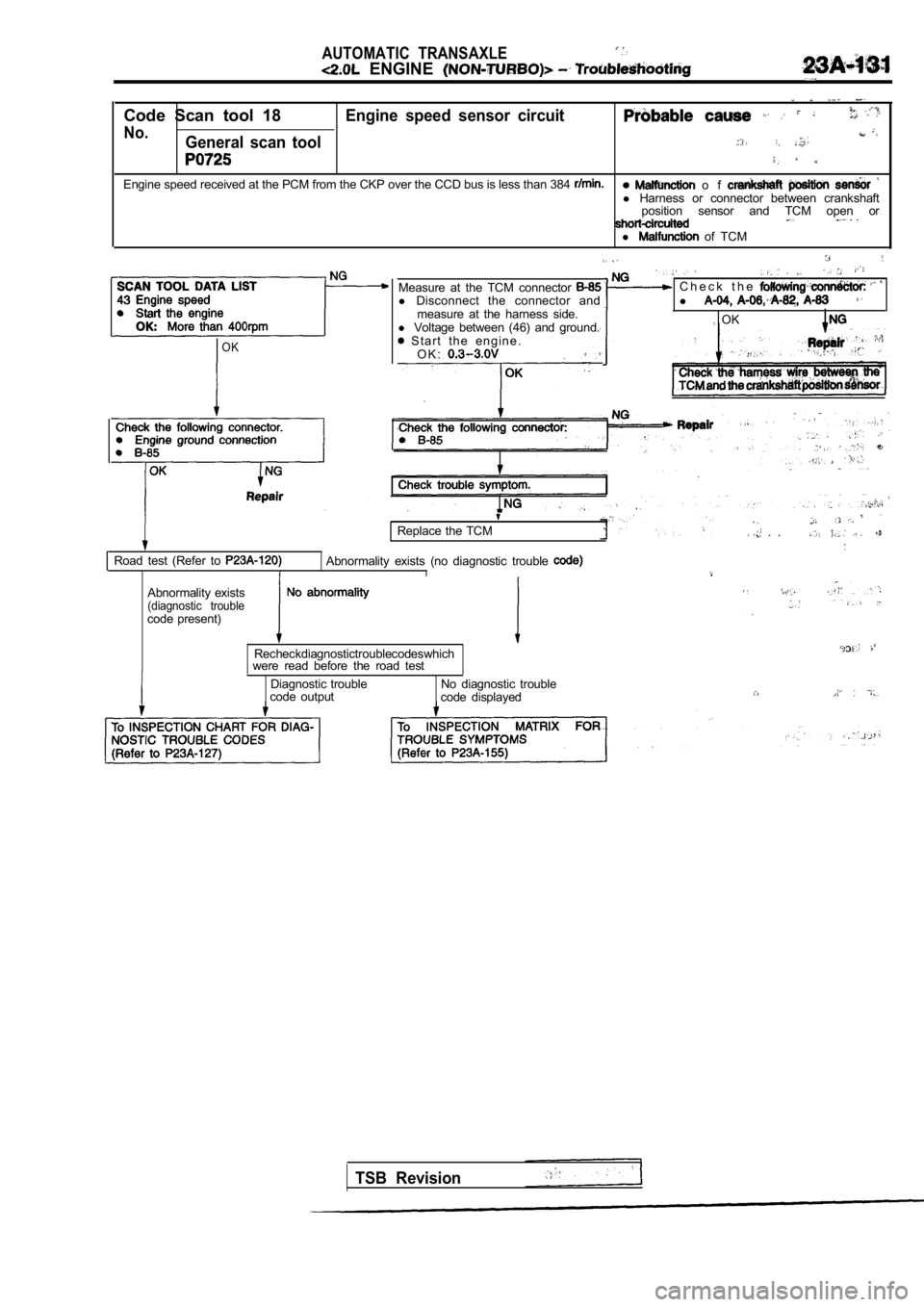

AUTOMATIC TRANSAXLE

ENGINE

Code Scan tool 18Engine speed sensor circuit

No.General scan tool

Engine speed received at the PCM from the CKP over the CCD bus is less than 384 o f l Harness or connector between crankshaft

position sensor and TCM open or

. .

l of TCM

OK

Measure at the TCM connector l Disconnect the connector and

measure at the harness side.

l Voltage between (46) and ground.

S t a r t t h e e n g i n e .

O K :

C h e c k t h e l

OK

Road test (Refer to

Replace the TCM

Abnormality exists (no diagnostic trouble

. .

Abnormality exists(diagnostic troublecode present)

Recheckdiagnostictroublecodeswhich

were read before the road test

Diagnostic trouble

code output No diagnostic trouble

code displayed

TSB Revision

Page 1708 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Manual ABS Troubfeshooting , .

INSPECTION PROCEDURE 7

Break operation is abnormal

[Comment]This varies depending on the driving conditions and the road surface conditions, soproblem diagnosis is d MITSUBISHI SPYDER 1990 Service Owners Manual ABS Troubfeshooting , .

INSPECTION PROCEDURE 7

Break operation is abnormal

[Comment]This varies depending on the driving conditions and the road surface conditions, soproblem diagnosis is d](/img/19/57345/w960_57345-1707.png)

ABS Troubfeshooting , .

INSPECTION PROCEDURE 7

Break operation is abnormal

[Comment]This varies depending on the driving conditions and the road surface conditions, soproblem diagnosis is difficult. However, if a normal diagnostic trouble code is displayed,carry out the following

l Malfunction of wheel speed l Malfunction of ABS rotor

l Malfunction of wheel bearing

of hydraulic Malfunction of ABS-ECU

NG Repair

(Refer to

Wheel speed sensor output voltage check [ R e p l a c e t h e w h e e l

Hydraulic unit check (Refer to 1NGABS rotor check (Refer to Replace the rotor.

O K NGWheel bearing end play check Refer to GROUP 26 On-vehicle Repair

Service.Refer to GROUP 27 On-vehicleIService.I

Check trouble symptom.

ABS-ECU connector l Disconnect the connector and

measure at the harness side.

l Resistance vaiue between termi-

nals

14-15, and

O KThe sensor harness and connector

should be moved while these checks

are carded out.

OK

Repair

TSB Revision

Repair

.

NG Repair

OK

Check trouble symptom.N G Replace ABS-ECU.