display MITSUBISHI SPYDER 1990 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 510 of 2103

On-vehicle of

ENGINE ( N O N - T U R B O ) >

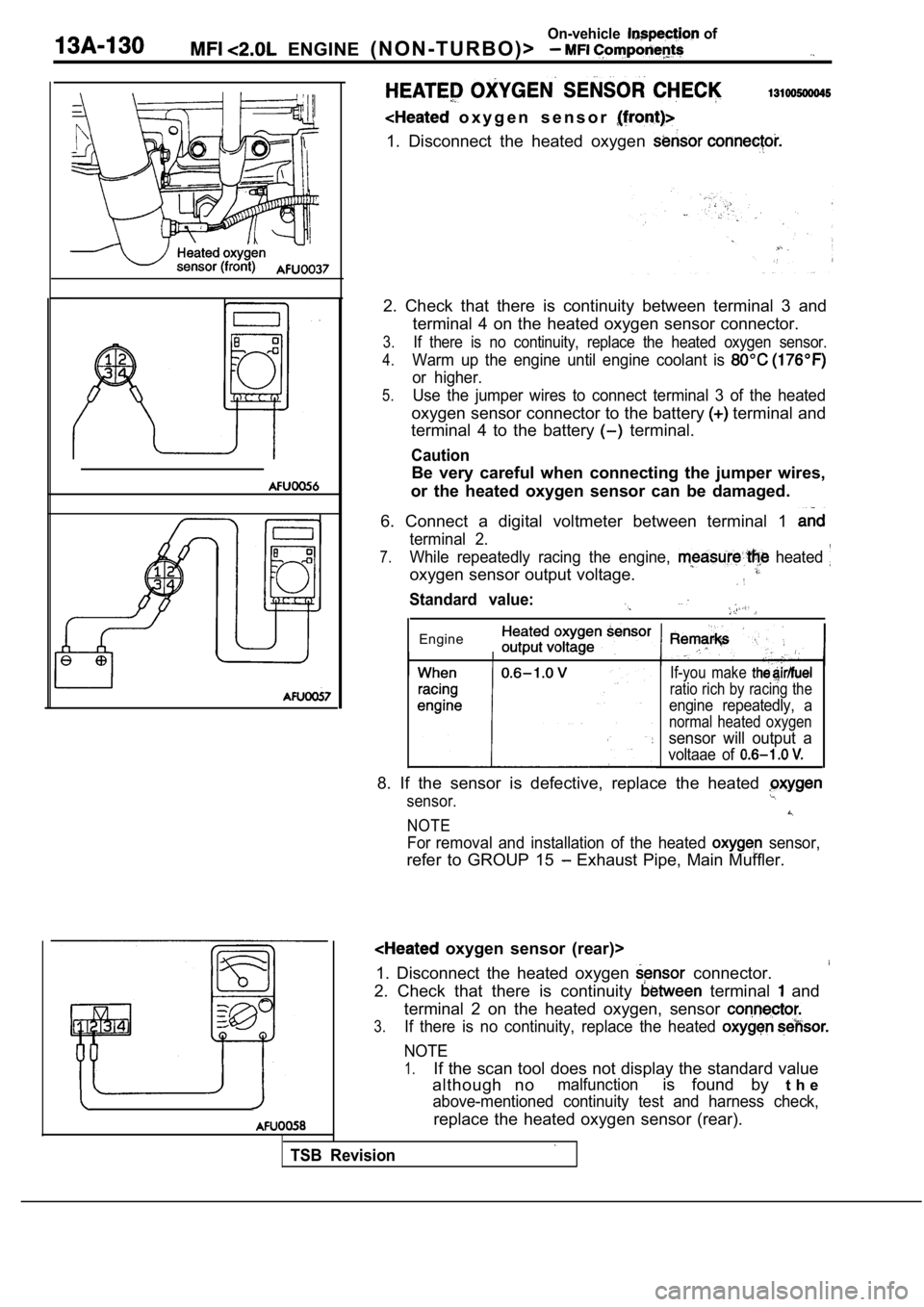

o x y g e n s e n s o r

1. Disconnect the heated oxygen

2. Check that there is continuity between terminal 3 and

terminal 4 on the heated oxygen sensor connector.

3.If there is no continuity, replace the heated oxyge n sensor.

4.Warm up the engine until engine coolant is

or higher.

5.Use the jumper wires to connect terminal 3 of the h eated

oxygen sensor connector to the battery terminal and

terminal 4 to the battery

terminal.

Caution

Be very careful when connecting the jumper wires,

or the heated oxygen sensor can be damaged.

6. Connect a digital voltmeter between terminal 1

terminal 2.

7.While repeatedly racing the engine, heated

oxygen sensor output voltage.

Standard value:

Engine

TSB Revision

If-you make

ratio rich by racing the

engine repeatedly, a

normal heated oxygen

sensor will output a

voltaae of

8. If the sensor is defective, replace the heated

sensor.

NOTE

For removal and installation of the heated sensor,

refer to GROUP 15 Exhaust Pipe, Main Muffler.

oxygen sensor (rear)>

1. Disconnect the heated oxygen

connector.

2. Check that there is continuity terminal and

terminal 2 on the heated oxygen, sensor

3.If there is no continuity, replace the heated

NOTE

1.If the scan tool does not display the standard valu e

although no

malfunctionis found by t h e

above-mentioned continuity test and harness check,

replace the heated oxygen sensor (rear).

Page 607 of 2103

![MITSUBISHI SPYDER 1990 Service User Guide ENGINE (TURBO)

AND

ENGINE> Troubleshooting

INSPECTION PROCEDURE 35

Idle air control motor (DC motor) Engine>P r o b a b l e c a u s e

[Comment]l Malfunction of idle air control mo MITSUBISHI SPYDER 1990 Service User Guide ENGINE (TURBO)

AND

ENGINE> Troubleshooting

INSPECTION PROCEDURE 35

Idle air control motor (DC motor) Engine>P r o b a b l e c a u s e

[Comment]l Malfunction of idle air control mo](/img/19/57345/w960_57345-606.png)

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

INSPECTION PROCEDURE 35

Idle air control motor (DC motor) Engine>P r o b a b l e c a u s e

[Comment]l Malfunction of idle air control motor

The ECM controls the intake air volume during idlin g by opening and closing the I m p r o p e r c o n n e c t o r open “circuit’ servo valve located in the bypass passage.

l Malfunction of the

at the idle air control motor connector Connect the connector. (Use test harness: Voltage between 5 and ground (Ignition switch: ON)

OK: 2 or more to 0 (momentarily) Voltage between 6 and ground (Ignition switch: ON)OK: 4 or more to 0 (momentarily)

OK

the idle air control motor.1

Check symptom.

Replace

INSPECTION PROCEDURE 36

Scan tool: Inspection when no initial combustion oc curs

SCAN TOOL Data listNGCheck the power and ignition 16 Voltage of ECM power source (Refer to (Refer to I PROCEDURE 27.)

(Whenoil filler cap is removed.)

SCAN TOOL DTC

Are the diagnostic trouble codes output

Check timing belt for breakage.

INSPECTION CHART FOR TROUBLE CODES.

(Refer to

SCAN TOOL list NG

22 Crankshaft position sensor OK: Cranking speed is displayed.

OK

Check the crankshaft position sensor circuit malfu nction. (Refer to INSPECTION PROCEDURE FOR DIAGNOSTIC

TROUBLE CODES

SCAN TOOL Actuator testCheck the fuel pump system Engine 07 Fuel pump (Refer to (Refer to INSPECTION PROCEDURE 28.)

OKCheck the fuel pump system (Refer to INSPECTION PROCEDURE 29) .

SCAN TOOL list21 Check the engine coolant temperature circuit (Refer to INSPECTION PROCEDURE FOR DIAGNOSTICTROUBLE CODES

TSB Revision

Page 608 of 2103

ENGINE (TURBO)

AND ENGINE> Troubleshooting

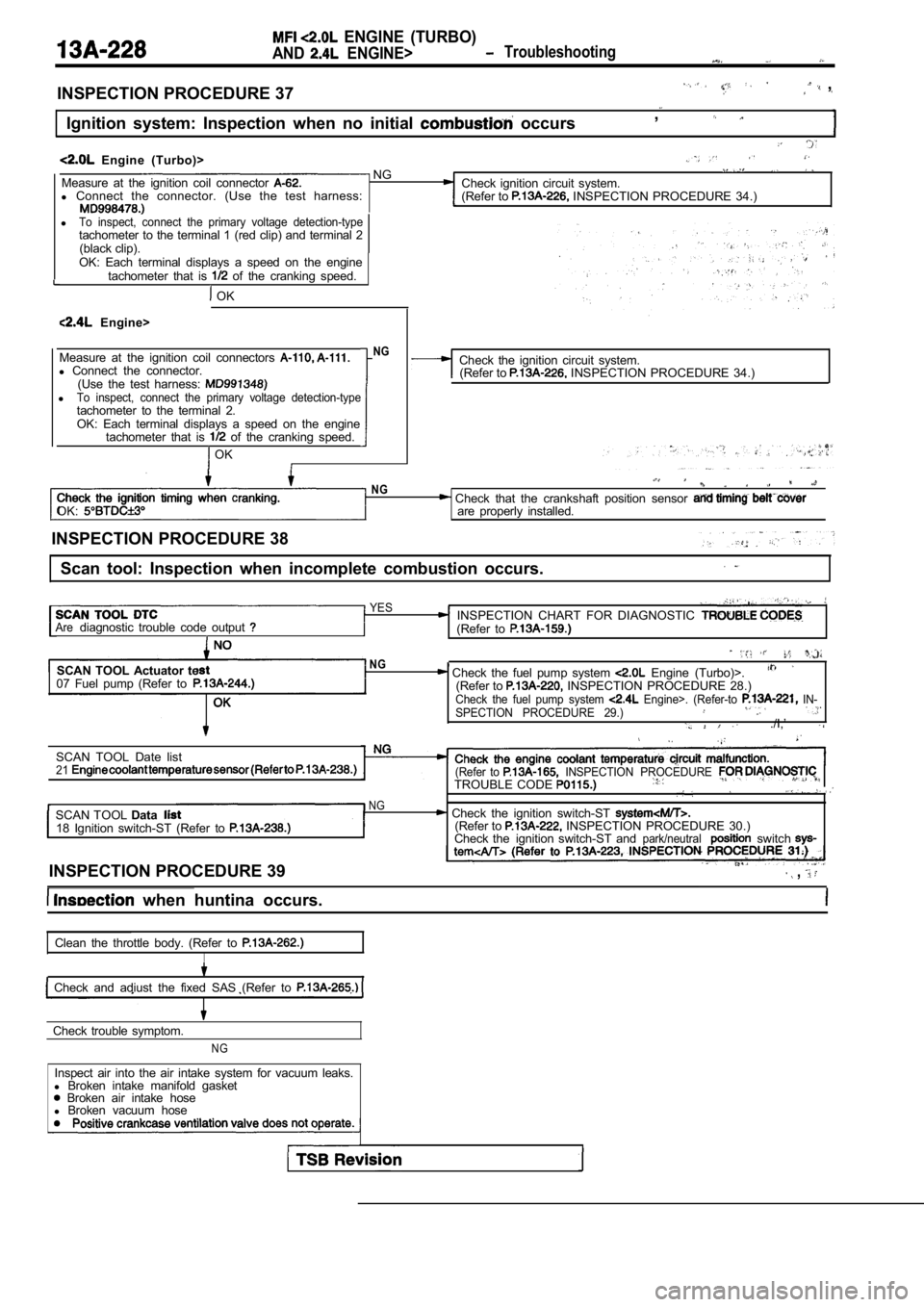

INSPECTION PROCEDURE 37 ,

Ignition system: Inspection when no initial occurs,

Engine (Turbo)> NGMeasure at the ignition coil connector Check ignition circuit system.

l Connect the connector. (Use the test harness:

(Refer to INSPECTION PROCEDURE 34.)

lTo inspect, connect the primary voltage detection-typetachometer to the terminal 1 (red clip) and terminal 2

(black clip).

OK: Each terminal displays a speed on the engine tachometer that is

of the cranking speed.

OK

Engine>

Measure at the ignition coil connectors

l Connect the connector.

(Use the test harness:

lTo inspect, connect the primary voltage detection-t ypetachometer to the terminal 2.OK: Each terminal displays a speed on the engine

tachometer that is of the cranking speed.

OK

NGCheck the ignition circuit system.(Refer to INSPECTION PROCEDURE 34.)

OK:

NG Check that the crankshaft position sensor are properly installed.

INSPECTION PROCEDURE 38

Scan tool: Inspection when incomplete combustion oc curs.

YESINSPECTION CHART FOR DIAGNOSTIC Arediagnostic trouble code output (Refer to

SCAN TOOL Actuator te

07 Fuel pump (Refer toNG, Check the fuel pump system Engine (Turbo)>.(Refer to INSPECTION PROCEDURE 28.)Check the fuel pump system Engine>. (Refer-to IN-

SPECTION PROCEDURE 29.)

./I,’

SCAN TOOL Date list21(Refer to INSPECTION PROCEDURE TROUBLE CODE

NGSCAN TOOL Data Check the ignition switch-ST 18 Ignition switch-ST (Refer to (Refer to INSPECTION PROCEDURE 30.)

Check the ignition switch-ST andpark/neutralswitch

INSPECTION PROCEDURE 39 ,

when huntina occurs.

Clean the throttle body. (Refer to

I

Check and adiust the fixed SAS (Refer to

Check trouble symptom.

NG

Inspect air into the air intake system for vacuum l eaks.

l Broken intake manifold gasket

Broken air intake hose

l Broken vacuum hose

Page 633 of 2103

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

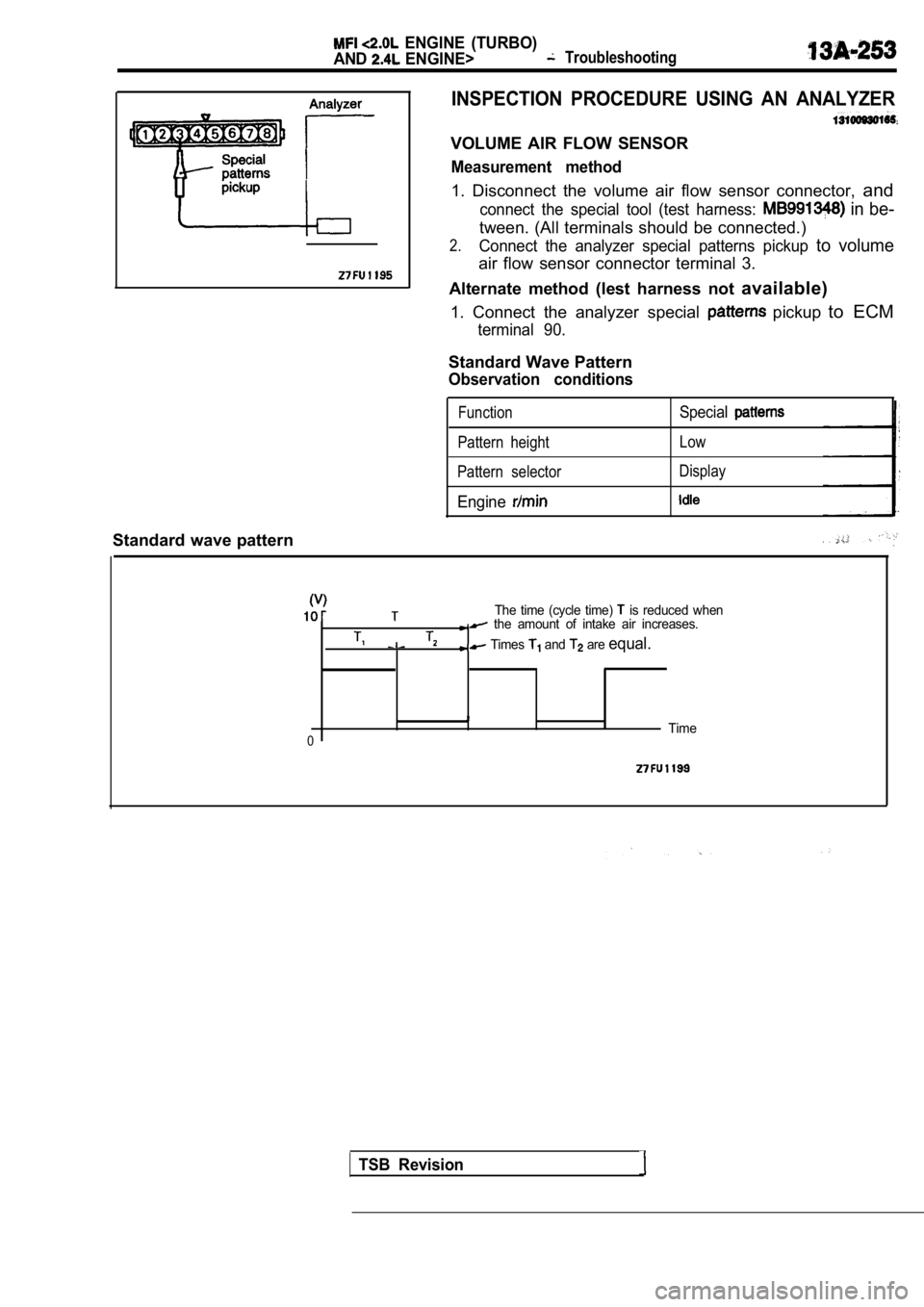

INSPECTION PROCEDURE USING AN ANALYZER

VOLUME AIR FLOW SENSOR

Measurement method

1. Disconnect the volume air flow sensor connector, and

connect the special tool (test harness: in be-

tween. (All terminals should be connected.)

2.Connect the analyzer special patterns pickup to volume

air flow sensor connector terminal 3.

Alternate method (lest harness not available)

1. Connect the analyzer special

pickup to ECM

terminal 90.

Standard Wave Pattern

Observation conditions

FunctionSpecial

Pattern height Low

Pattern selector Display

Engine

Standard wave pattern

The time (cycle time) is reduced when the amount of intake air increases.

Times and are equal.

0Time

TSB Revision

Page 635 of 2103

ENGINE (TURBO)

AND ENGINE>

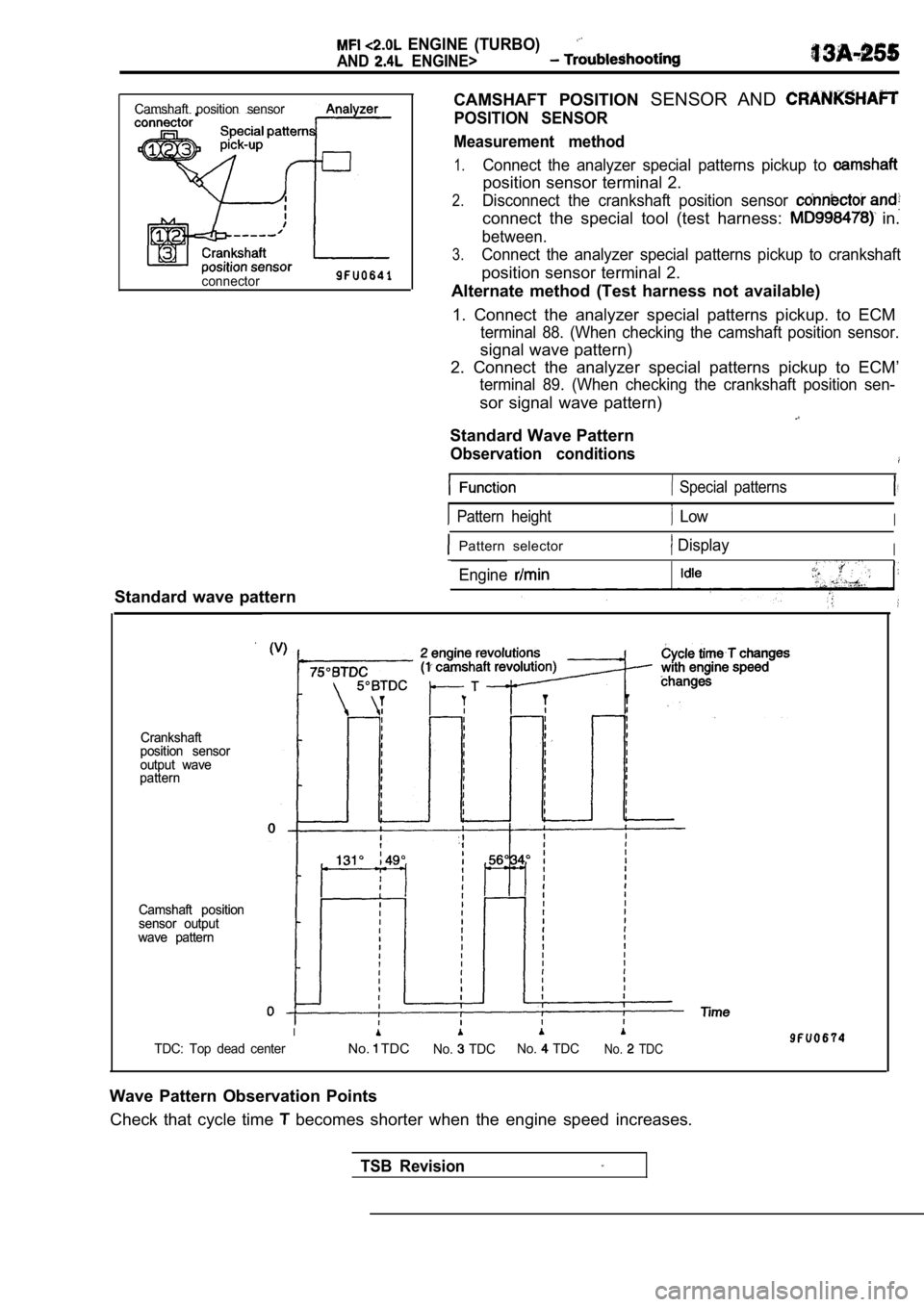

CAMSHAFT POSITION SENSOR AND

POSITION SENSOR

Measurement method

1.Connect the analyzer special patterns pickup to

position sensor terminal 2.

2.Disconnect the crankshaft position sensor

connect the special tool (test harness: in.

between.

3.Connect the analyzer special patterns pickup to cra nkshaft

position sensor terminal 2.

Alternate method (Test harness not available)

1. Connect the analyzer special patterns pickup. to ECM

terminal 88. (When checking the camshaft position sensor.

signal wave pattern)

2. Connect the analyzer special patterns pickup to ECM’

terminal 89. (When checking the crankshaft position sen-

sor signal wave pattern)

Standard Wave Pattern

Observation conditions

Camshaft position sensor

connector

Standard wave pattern

Crankshaft

Crankshaft

position sensor

position sensor

output wave

output wave

pattern

pattern

Camshaft position

Camshaft position

sensor output

sensor output

wave pattern

wave pattern

Special patterns

Pattern height LowI

Pattern selector DisplayI

Engine

I

TDC: Top dead centerNo. TDCNo. TDC No. TDCNo. TDC

Wave Pattern Observation Points

Check that cycle time

becomes shorter when the engine speed increases.

TSB Revision

Page 637 of 2103

ENGINE (TURBO)

AND ENGINE> Troubleshooting

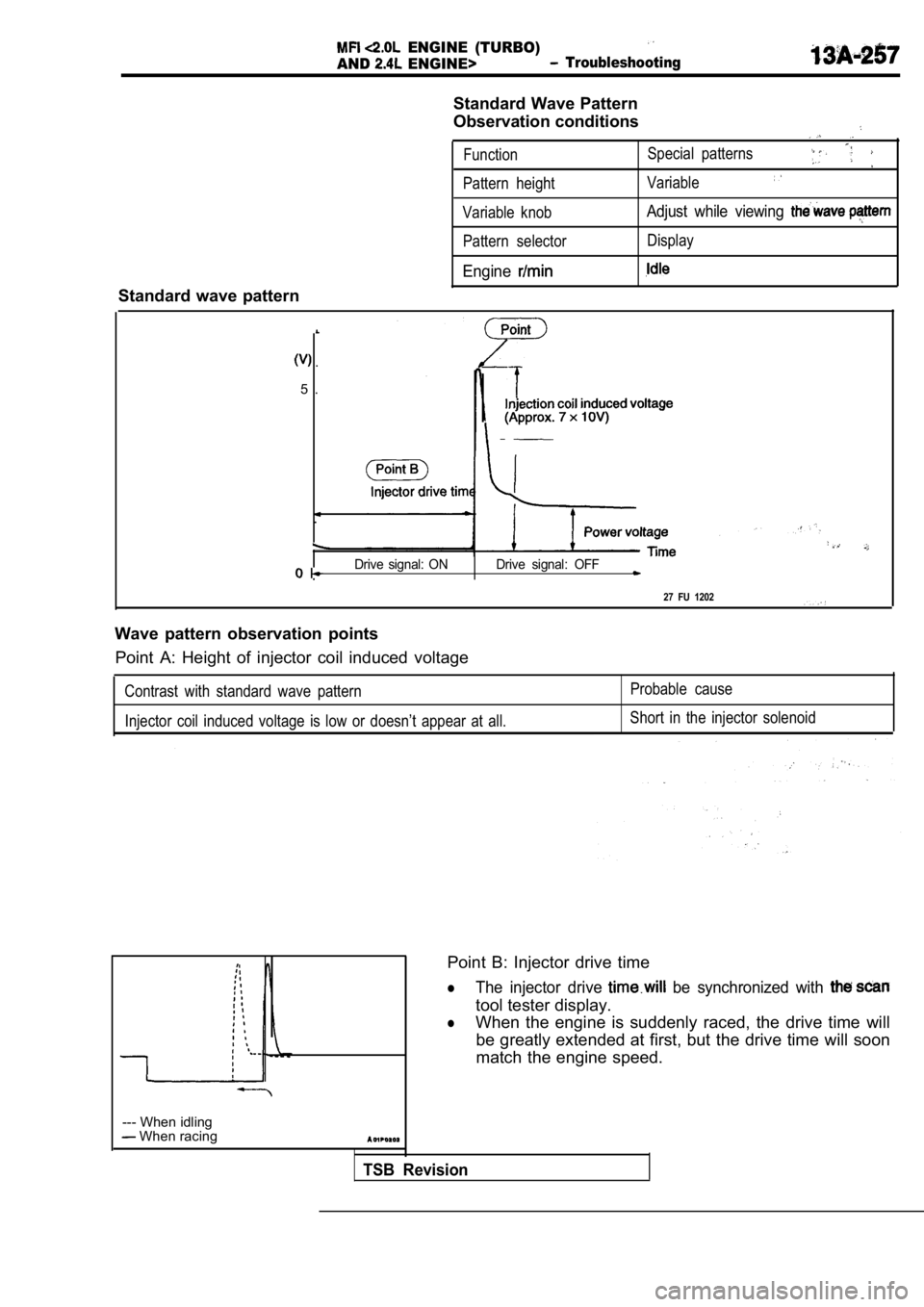

Standard Wave Pattern

Observation conditions

FunctionSpecial patterns

Pattern height

Variable

Standard wave pattern

Variable knobAdjust while viewing

Pattern selector Display

Engine

.

5 .

Drive signal: ON Drive signal: OFF

27 FU 1202

Wave pattern observation points Point A: Height of injector coil induced voltage

Contrast with standard wave pattern

Injector coil induced voltage is low or doesn’t app ear at all.Probable cause

Short in the injector solenoid

TSB Revision

--- When idling When racing

Point B: Injector drive time

lThe injector drive be synchronized with

tool tester display.

lWhen the engine is suddenly raced, the drive time w ill

be greatly extended at first, but the drive time wi ll soon

match the engine speed.

Page 638 of 2103

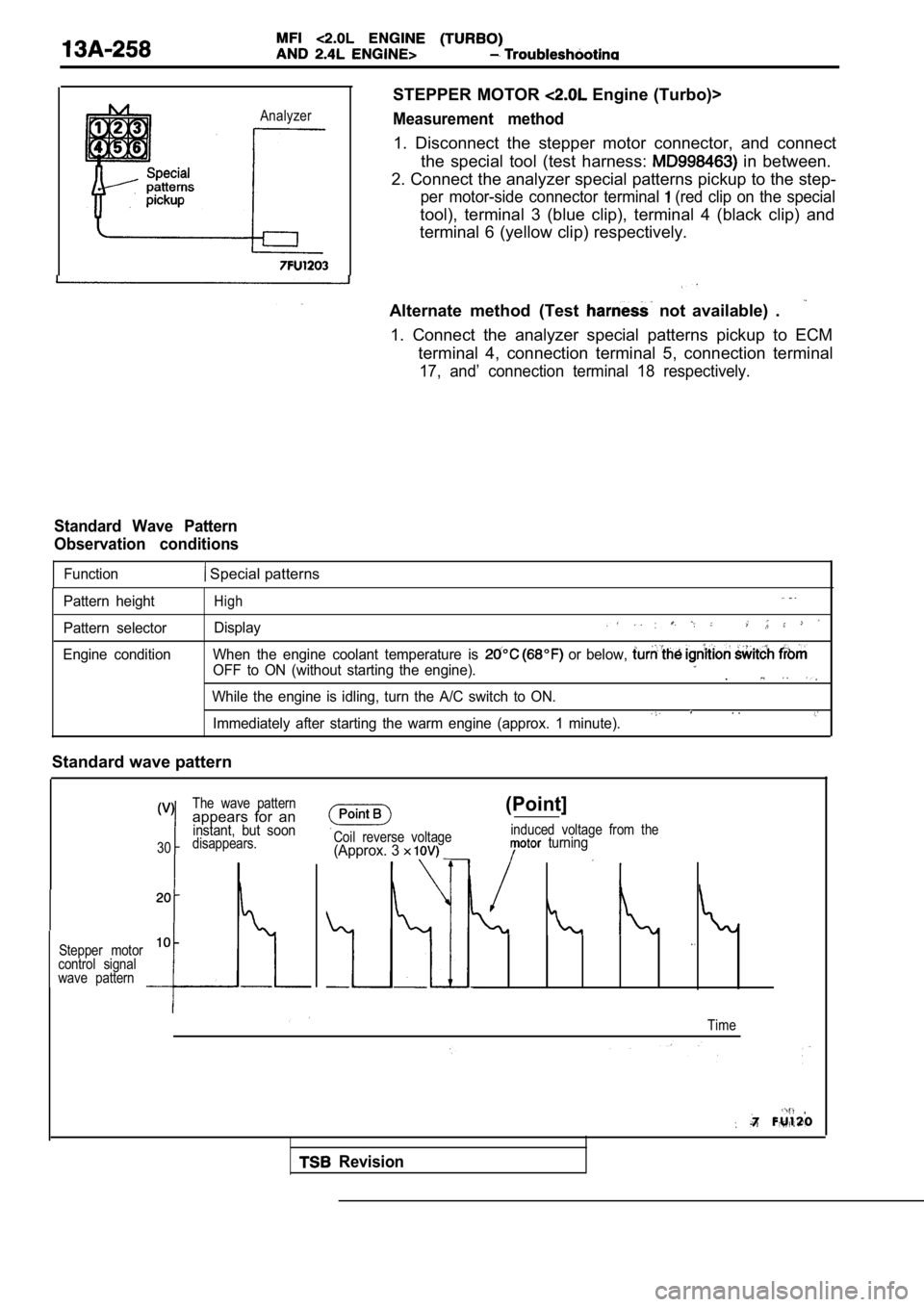

Analyzer

STEPPER MOTOR Engine (Turbo)>

Measurement method

1. Disconnect the stepper motor connector, and connect

the special tool (test harness:

in between.

2. Connect the analyzer special patterns pickup to the step-

per motor-side connector terminal (red clip on the special

tool), terminal 3 (blue clip), terminal 4 (black clip) and

terminal 6 (yellow clip) respectively.

Alternate method (Test

not available) .

1. Connect the analyzer special patterns pickup to ECM

terminal 4, connection terminal 5, connection termi nal

17, and’ connection terminal 18 respectively.

Standard Wave Pattern

Observation conditions

Function Special patterns

Pattern height

Pattern selector

Engine conditionHigh

Display

When the engine coolant temperature is or below,

OFF to ON (without starting the engine)..

While the engine is idling, turn the A/C switch to ON.. .Immediately after starting the warm engine (approx. 1 minute).

Standard wave pattern

The wave patternappears for aninstant, but soon

30disappears.

Stepper motor

10

control signal

wave pattern

Coil reverse voltage(Approx. 3

(Point]

induced voltage from the turning

Time

Revision

Page 664 of 2103

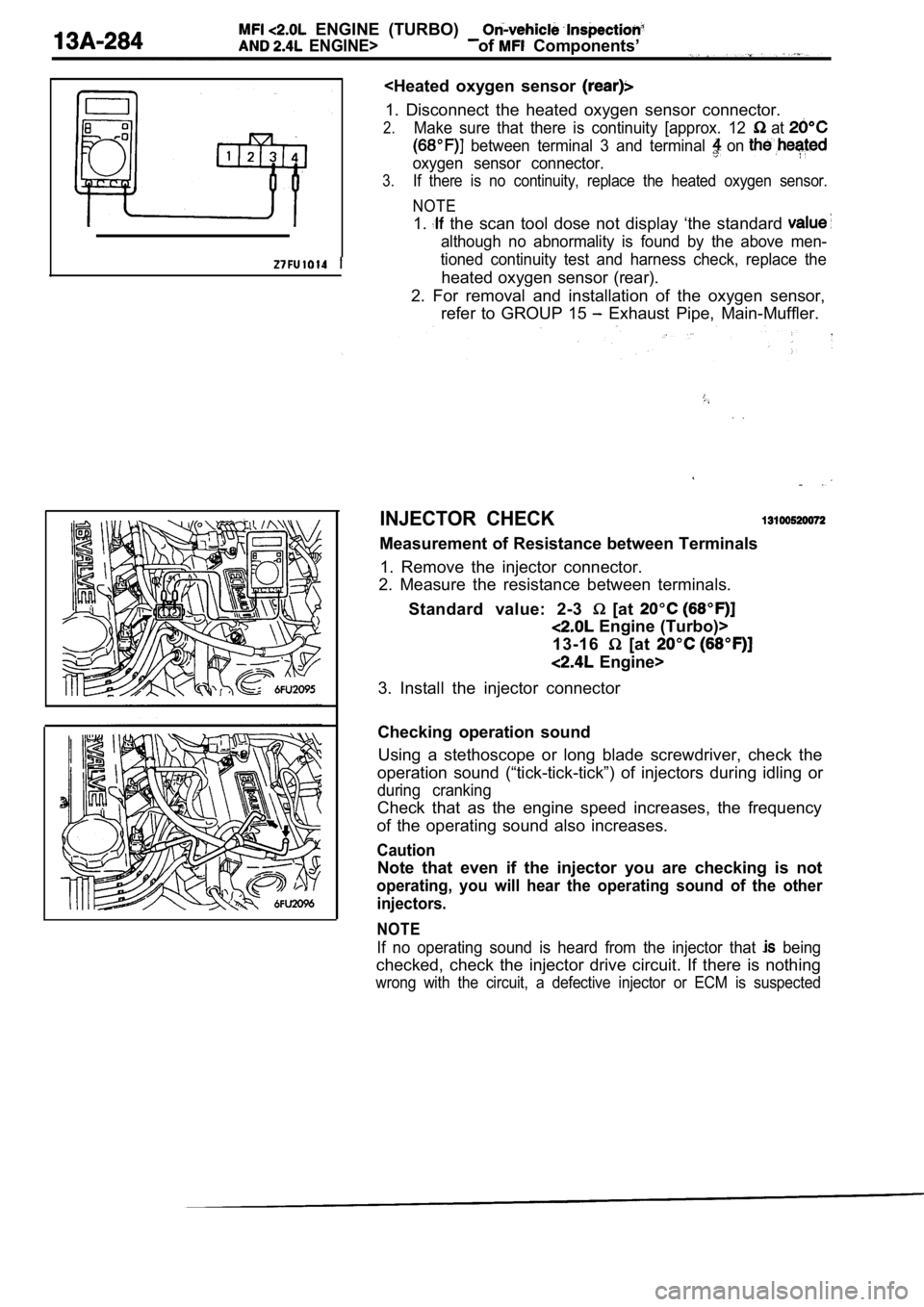

ENGINE (TURBO)

ENGINE>of Components’

2.Make sure that there is continuity [approx. 12 at

between terminal 3 and terminal on

oxygen sensor connector.

3.If there is no continuity, replace the heated oxyge n sensor.

NOTE

1. the scan tool dose not display ‘the standard

although no abnormality is found by the above men-

tioned continuity test and harness check, replace t he

heated oxygen sensor (rear).

2. For removal and installation of the oxygen senso r,

refer to GROUP 15

Exhaust Pipe, Main-Muffler.

INJECTOR CHECK

Measurement of Resistance between Terminals

1. Remove the injector connector.

2. Measure the resistance between terminals.

Standard value: 2-3

[at

Engine (Turbo)>

13-16

[at

Engine>

3. Install the injector connector

Checking operation sound Using a stethoscope or long blade screwdriver, chec k the

operation sound (“tick-tick-tick”) of injectors dur ing idling or

during cranking

Check that as the engine speed increases, the frequ ency

of the operating sound also increases.

Caution

Note that even if the injector you are checking is not

operating, you will hear the operating sound of the other

injectors.

NOTE

If no operating sound is heard from the injector th at being

checked, check the injector drive circuit. If there is nothing

wrong with the circuit, a defective injector or ECM is suspected

Page 749 of 2103

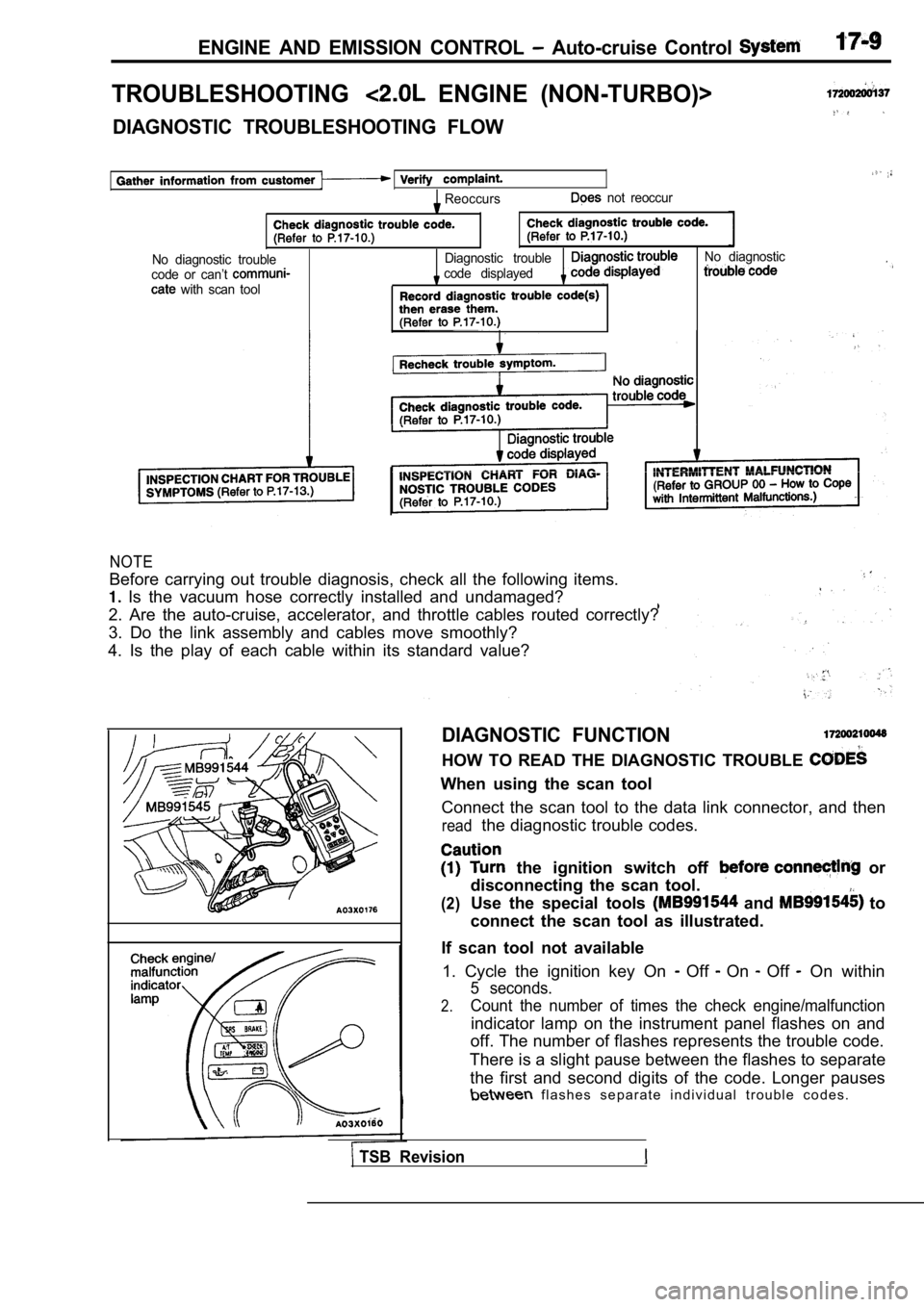

ENGINE AND EMISSION CONTROL Auto-cruise Control

TROUBLESHOOTING ENGINE (NON-TURBO)>

DIAGNOSTIC TROUBLESHOOTING FLOW

Reoccurs not reoccur

No diagnostic troubleDiagnostic troubleNo diagnostic

code or can’t code displayed

with scan tool

NOTE

Before carrying out trouble diagnosis, check all th e following items.

Is the vacuum hose correctly installed and undamag ed?

2. Are the auto-cruise, accelerator, and throttle c ables routed correctly?

3. Do the link assembly and cables move smoothly?

4. Is the play of each cable within its standard va lue?

DIAGNOSTIC FUNCTION

HOW TO READ THE DIAGNOSTIC TROUBLE

When using the scan tool

Connect the scan tool to the data link connector, a nd then

readthe diagnostic trouble codes.

the ignition switch off or

disconnecting the scan tool.

(2)Use the special tools and to

connect the scan tool as illustrated.

If scan tool not available 1. Cycle the ignition key On

Off On Off On within

5 seconds.

2.Count the number of times the check engine/malfunct ion

indicator lamp on the instrument panel flashes on and

off. The number of flashes represents the trouble c ode.

There is a slight pause between the flashes to sepa rate

the first and second digits of the code. Longer pau ses

f l a s h e s s e p a r a t e i n d i v i d u a l t r o u b l e c o d e s .

TSB Revision

Page 757 of 2103

ENGINE AND EMISSION CONTROL Auto-cruise System

TROUBLESHOOTING ENGINE (TURBO) AND ENGINE>

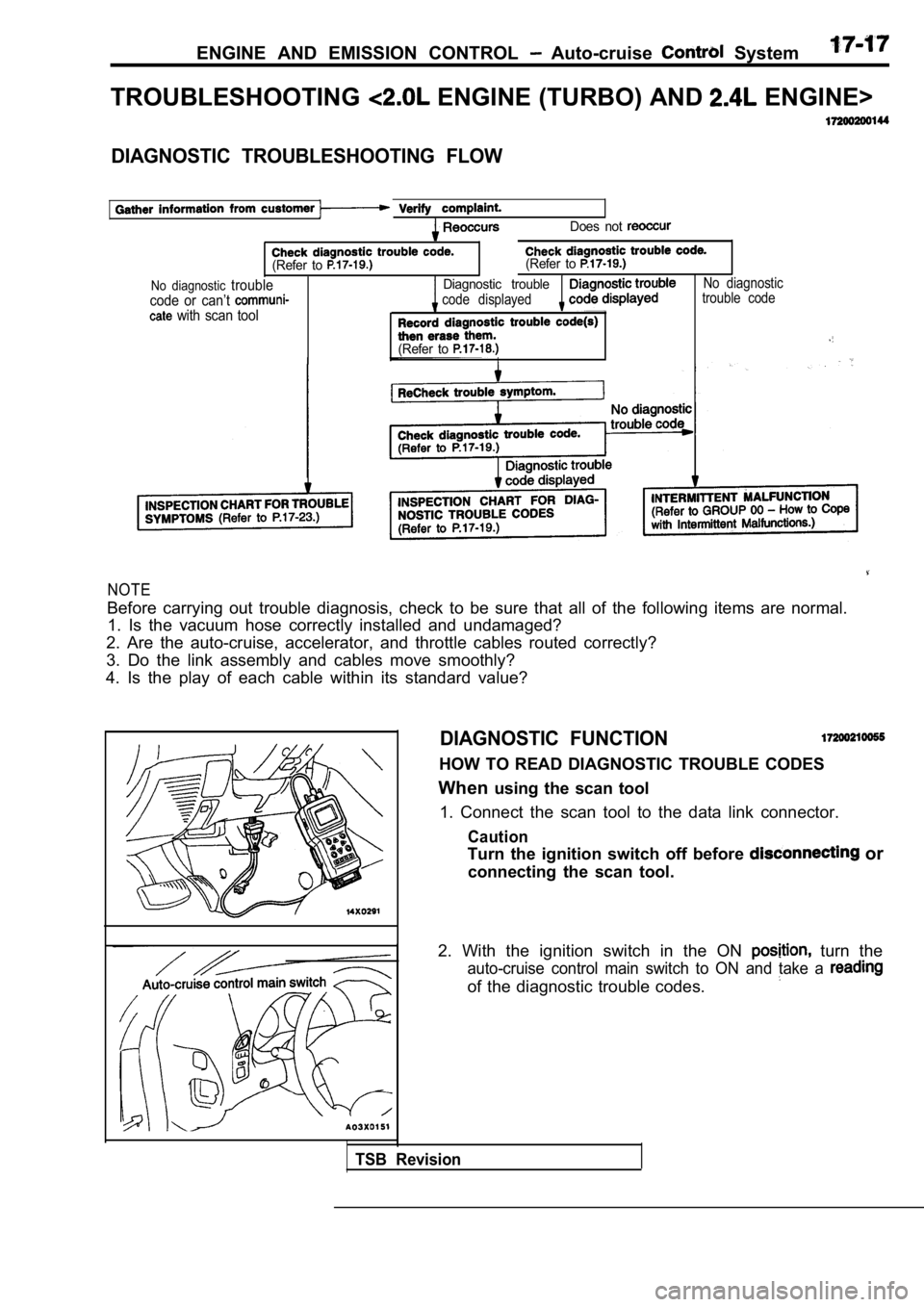

DIAGNOSTIC TROUBLESHOOTING FLOW

Does not

(Refer to (Refer to

No diagnostic troubleDiagnostic troubleNo diagnostic

code or can’t code displayedtrouble code

with scan tool

(Refer to

NOTE

Before carrying out trouble diagnosis, check to be

sure that all of the following items are normal.

1. Is the vacuum hose correctly installed and undam aged?

2. Are the auto-cruise, accelerator, and throttle c ables routed correctly?

3. Do the link assembly and cables move smoothly?

4. Is the play of each cable within its standard va lue?

DIAGNOSTIC FUNCTION

HOW TO READ DIAGNOSTIC TROUBLE CODES

When using the scan tool

1. Connect the scan tool to the data link connector .

Caution

Turn the ignition switch off before or

connecting the scan tool.

2. With the ignition switch in the ON

turn the

auto-cruise control main switch to ON and take a

of the diagnostic trouble codes.

TSB Revision