display MITSUBISHI SPYDER 1990 Service Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1734 of 2103

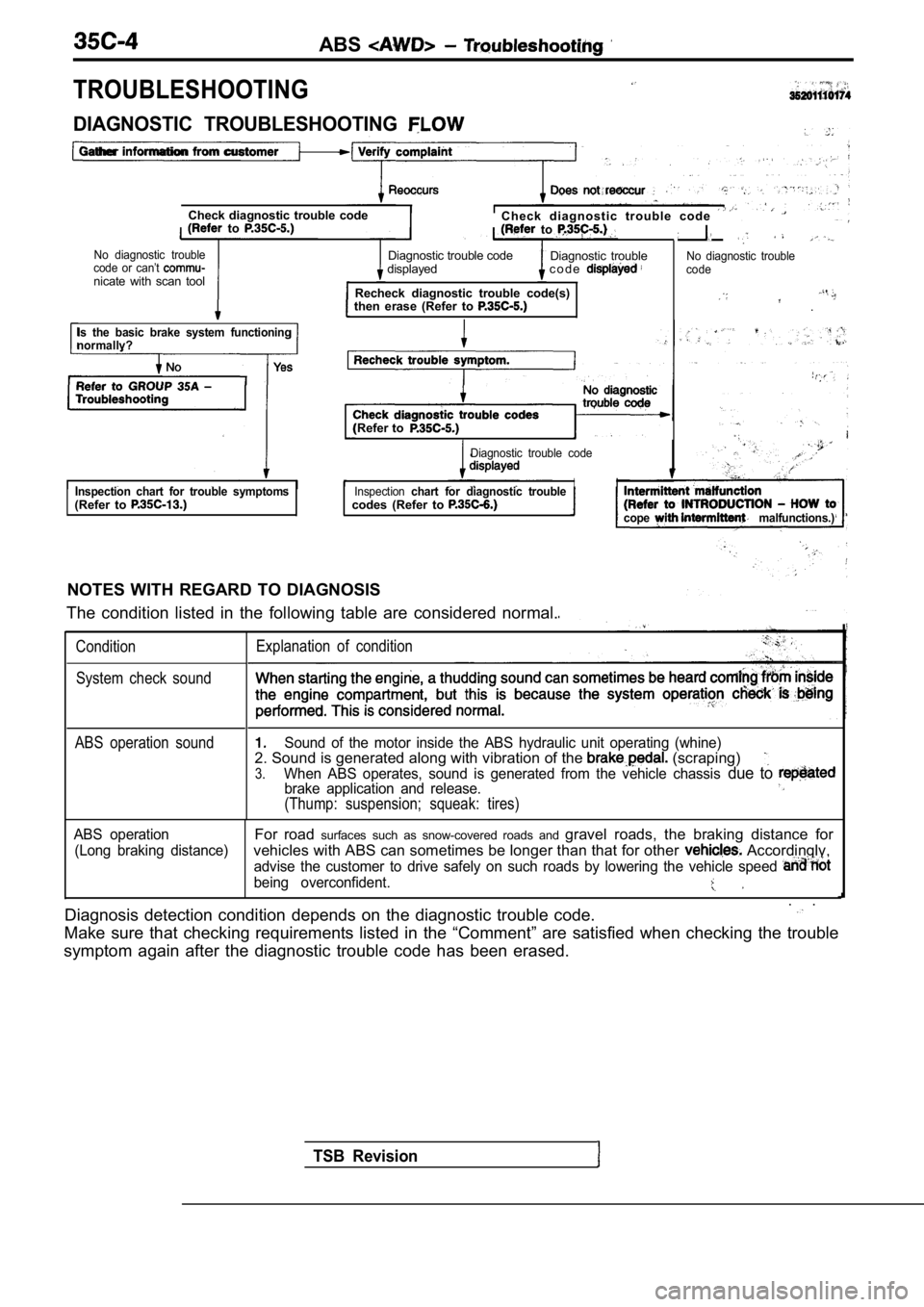

ABS

TROUBLESHOOTING

Check diagnostic trouble codeC h e c k d i a g n o s t i c t r o u b l e c o d e to to

No diagnostic troubleDiagnostic trouble codecode or can’t Diagnostic trouble

displayed c o d e

nicate with scan tool Recheck diagnostic trouble code(s)

then erase (Refer to

No diagnostic trouble

code

.

DIAGNOSTIC TROUBLESHOOTING

Gather information from customer

Is the basic brake system functioning

normallv?

(Refer to

Diagnostic trouble code

Inspection chart for trouble symptoms(Refer to Inspectionchart for diagnostic troubleII

codes (Refer to

cope malfunctions.)

NOTES WITH REGARD TO DIAGNOSIS

The condition listed in the following table are con sidered normal.

ConditionExplanation of condition

System check sound

TSB Revision

ABS operation soundSound of the motor inside the ABS hydraulic unit op erating (whine)2. Sound is generated along with vibration of the (scraping)

3.When ABS operates, sound is generated from the vehi cle chassis due to brake application and release.

(Thump: suspension; squeak: tires)

ABS operationFor road surfaces such as snow-covered roads and gravel roads, the braking distance for

(Long braking distance)vehicles with ABS can sometimes be longer than that for other Accordingly,

advise the customer to drive safely on such roads by lowering the vehicle speed

being overconfident.

. .

Diagnosis detection condition depends on the diagno stic trouble code.

Make sure that checking requirements listed in the “Comment” are satisfied when checking the trouble

symptom again after the diagnostic trouble code has been erased.

Page 1747 of 2103

![MITSUBISHI SPYDER 1990 Service Owners Guide , , .

PROCEDURE 7

Break operation is

[Comment] o f w h e e l This depending on the driving conditions and the road surface conditions, so ‘ M a l f u n c t i o n _ _

problem diagno MITSUBISHI SPYDER 1990 Service Owners Guide , , .

PROCEDURE 7

Break operation is

[Comment] o f w h e e l This depending on the driving conditions and the road surface conditions, so ‘ M a l f u n c t i o n _ _

problem diagno](/img/19/57345/w960_57345-1746.png)

, , .

PROCEDURE 7

Break operation is

[Comment] o f w h e e l This depending on the driving conditions and the road surface conditions, so ‘ M a l f u n c t i o n _ _

problem diagnosis is difficult. However, if a normal diagnostic trouble code is displayed,l

carry out the following Malfunction of bearing. . .l of: .

W h e e l s p e e d -NG: Repair(Refer to

N G N G speed sensor check(Refer to GROUP -Wheel SpeedReplace the wheel speed sensor.

OKSensor Check.)

OK

Hydraulic unit check (Refer to N GABS rotor check (Refer to Replace the rotor.

OK

Wheel bearing end play check

Refer to GROUP 26 On-vehicle Repair

Refer to GROUP 27

On-vehide

Service.

Check trouble symptom.

N G

ABS-ECU connector Disconnect the connector and measure at the harness side.

Resistance value between termi-nals and

NG Repair

O K

The sensor harness and connector s h o u l d b e m o v e d w h i l e t h e s e

inspections are carried out.

the .

TSB Revision

Page 1999 of 2103

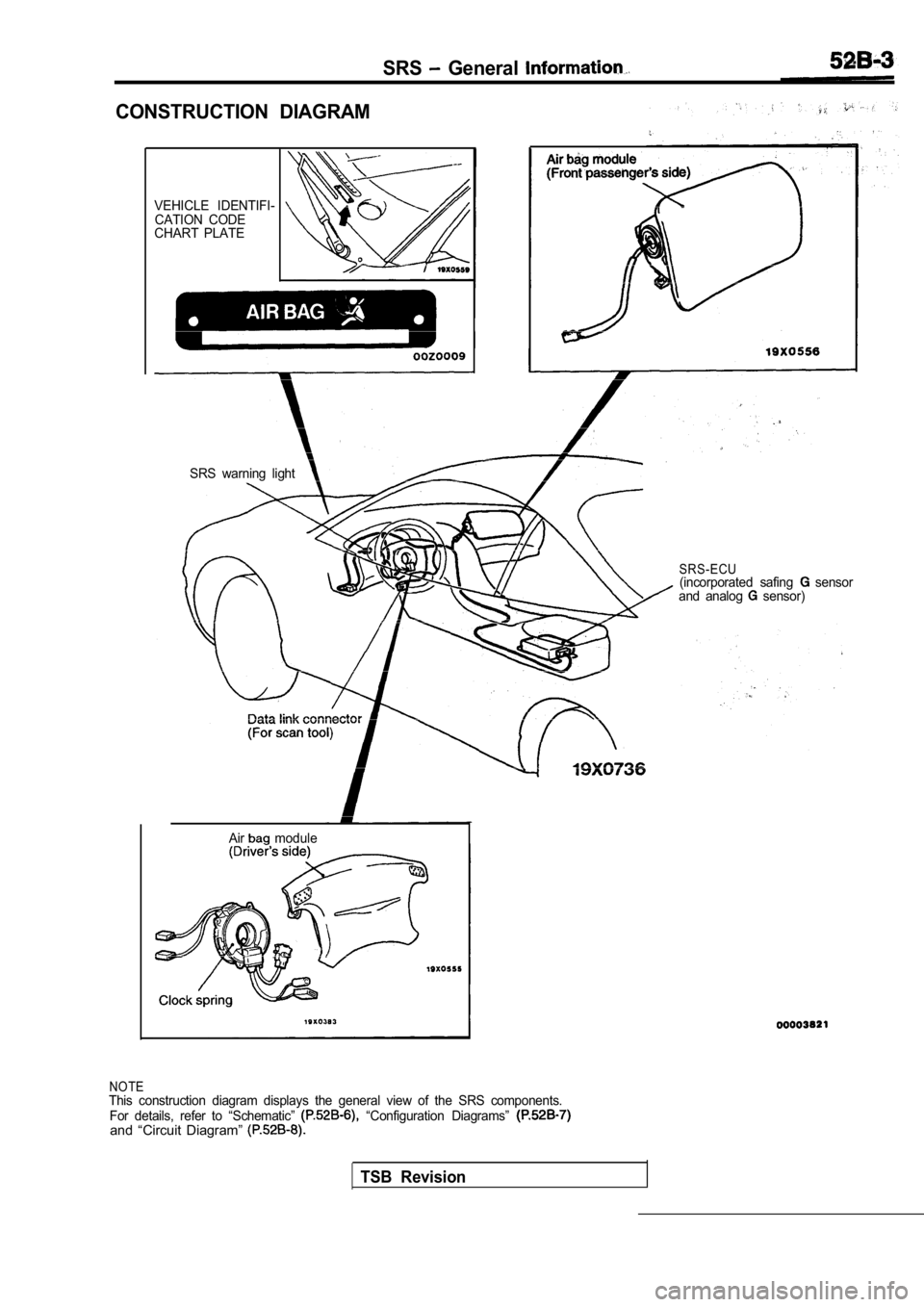

SRS General

CONSTRUCTION DIAGRAM

VEHICLE IDENTIFI-CATION CODE

CHART PLATE

Air

module

SRS warning light

SRS-ECU(incorporated safing sensor

and analog sensor)

NOTEThis construction diagram displays the general view of the SRS components.

For details, refer to “Schematic” “Configuration Diagrams” and “Circuit Diagram”

TSB Revision

Page 2011 of 2103

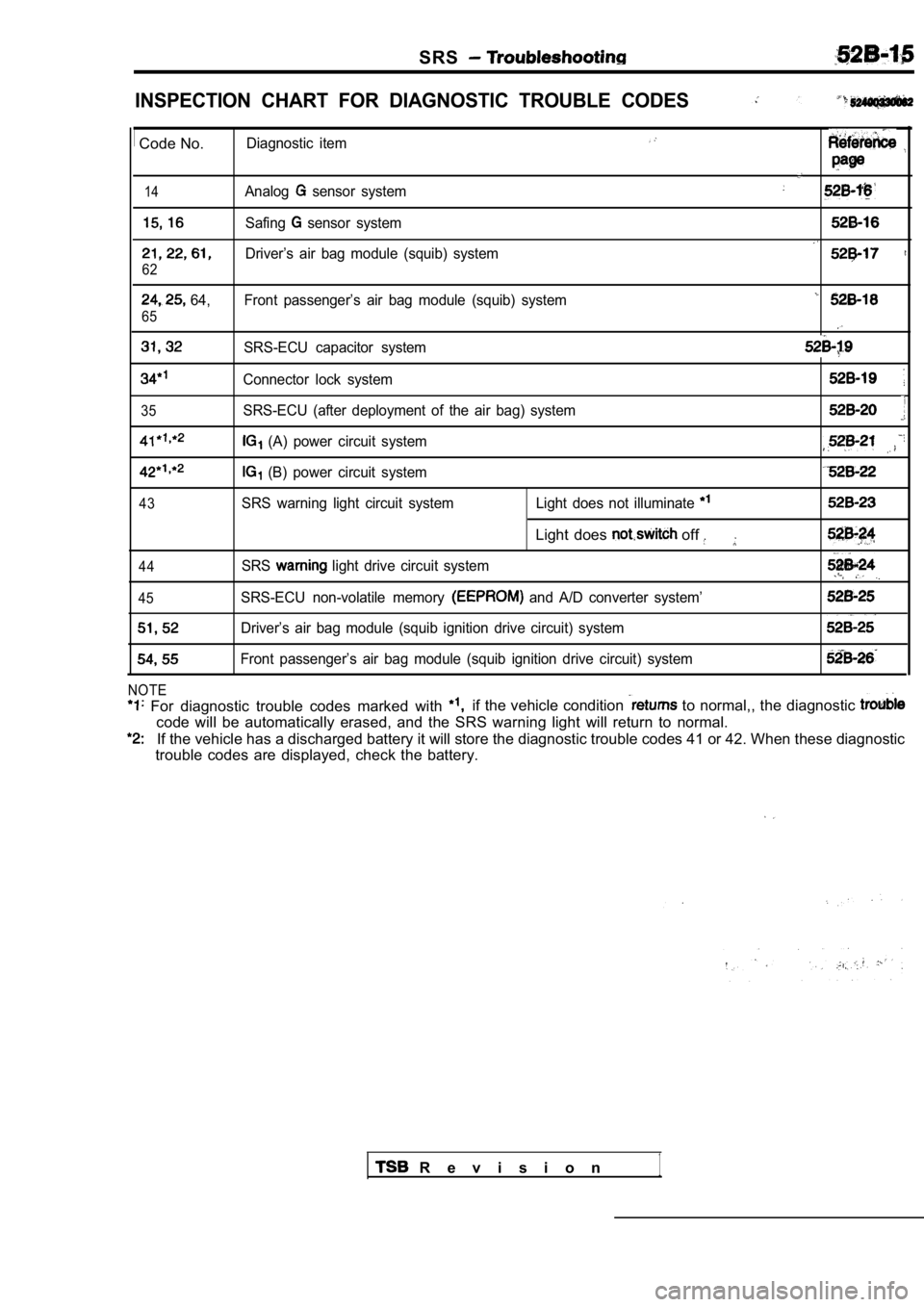

SRS

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

Code No.Diagnostic item

14Analog sensor system

Safing sensor system

Driver’s air bag module (squib) system

62

64, Front passenger’s air bag module (squib) system

65

SRS-ECU capacitor system

Connector lock system

35SRS-ECU (after deployment of the air bag) system

(A) power circuit system

(B) power circuit system

43SRS warning light circuit system Light does not illuminate

Light does off

44SRS light drive circuit system

45SRS-ECU non-volatile memory and A/D converter system’

Driver’s air bag module (squib ignition drive circuit) system

Front passenger’s air bag module (squib ignition dr ive circuit) system

NOTE

For diagnostic trouble codes marked with if the vehicle condition to normal,, the diagnostic

code will be automatically erased, and the SRS warn ing light will return to normal.

If the vehicle has a discharged battery it will store the diagnostic trouble codes 41 or 42. When thes e diagnostic

trouble codes are displayed, check the battery.

R e v i s i o n1

Page 2025 of 2103

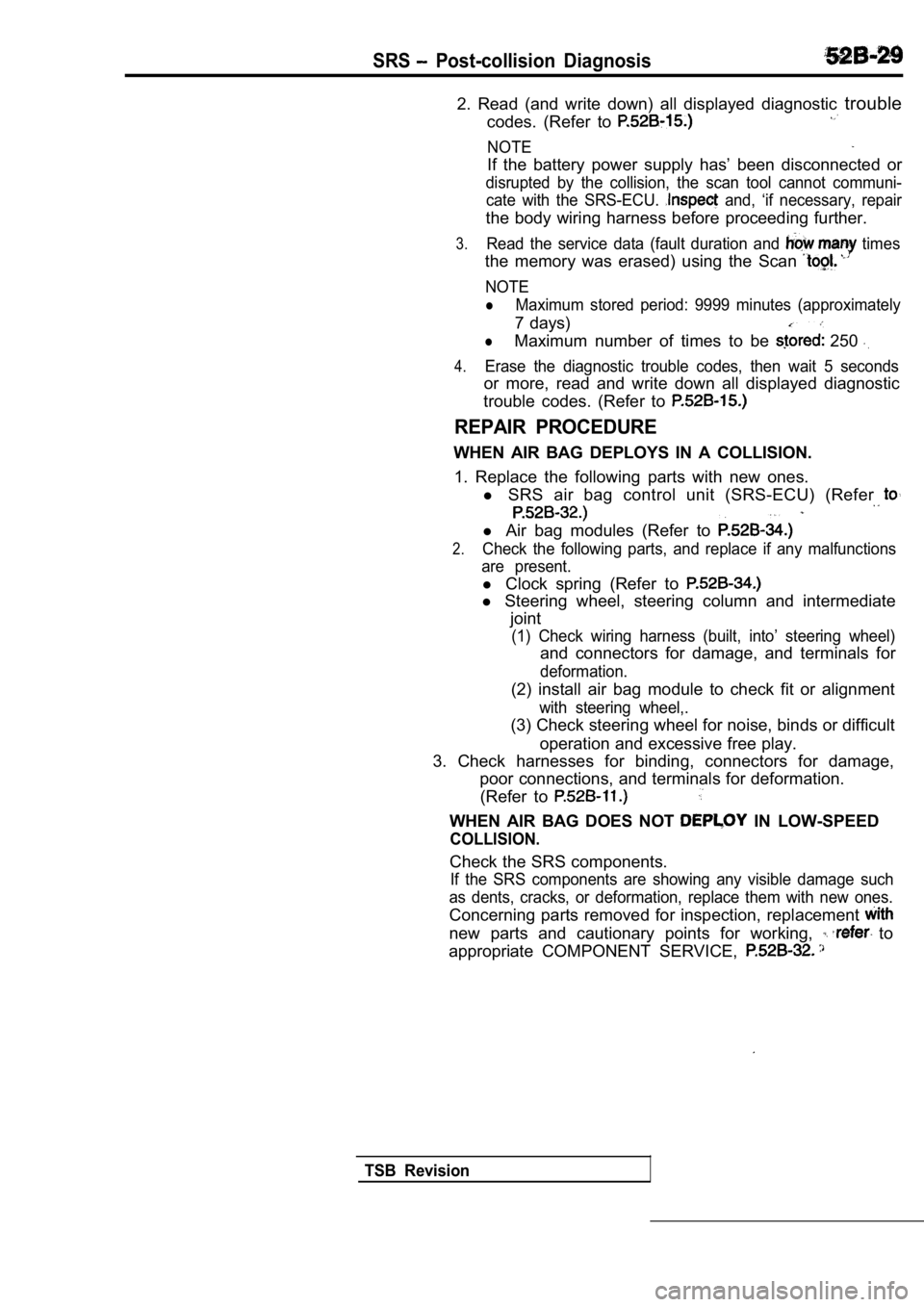

SRS Post-collision Diagnosis

2. Read (and write down) all displayed diagnostic trouble

codes. (Refer to

NOTE

If the battery power supply has’ been disconnected or

disrupted by the collision, the scan tool cannot communi-

cate with the SRS-ECU.

and, ‘if necessary, repair

the body wiring harness before proceeding further.

3.Read the service data (fault duration and times

the memory was erased) using the Scan

NOTE

lMaximum stored period: 9999 minutes (approximately

7 days)

lMaximum number of times to be 250

4.Erase the diagnostic trouble codes, then wait 5 sec onds

or more, read and write down all displayed diagnost ic

trouble codes. (Refer to

REPAIR PROCEDURE

WHEN AIR BAG DEPLOYS IN A COLLISION.

1. Replace the following parts with new ones. l SRS air bag control unit (SRS-ECU) (Refer

l Air bag modules (Refer to

2.Check the following parts, and replace if any malfu nctions

are present.

l Clock spring (Refer to

l Steering wheel, steering column and intermediate

joint

(1) Check wiring harness (built, into’ steering whe el)

and connectors for damage, and terminals for

deformation.

(2) install air bag module to check fit or alignment

with steering wheel,.

(3) Check steering wheel for noise, binds or difficult

operation and excessive free play.

3. Check harnesses for binding, connectors for dama ge,

poor connections, and terminals for deformation.

(Refer to

WHEN AIR BAG DOES NOT IN LOW-SPEED

COLLISION.

Check the SRS components.

If the SRS components are showing any visible damag e such

as dents, cracks, or deformation, replace them with new ones.

Concerning parts removed for inspection, replacemen t

new parts and cautionary points for working, to

appropriate COMPONENT SERVICE,

TSB Revision