battery location MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 22 of 2103

GENERAL before Service

PRECAUTIONS BEFORE SERVICE.

SUPPLEMENTAL RESTRAINT SYSTEM

1. to follow when servicing SRS

(1) Be sure to read GROUP Supplemental Restraint System

For safe operations, please follow the directions a nd heed all

(2) Always use the designated special tools and tes t equipment.

(3) Wait at least 60 seconds after disconnecting the battery cable before” further work;

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the bat tery cable is disconnected.

(4) Never attempt to disassemble or repair the SRS components (SRS-ECU air bag module and

clock spring). If faulty, replace it.

(5) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

Sun visor

l Glove box

. S R S - E C U

l Steering wheel

l Air bag module

l Clock spring

l Steering gear and linkage clamp

(6) Store components removed from the SRS

a clean and dry place.

The air bag module should be stored on a flat surfa ce and placed so that the pad surface is’

facing upward.

Do not place anything on top of it.

(7) Be sure to deploy the air bag before disposing of the air bag’module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP

Air Bag Module Disposal Procedures.)

(8) Whenever you finish servicing the

check the SRS warning light operation to make sure

that the system functions properly.

2.Observe the following when carrying out operations on places where SRS components are installed,’

.,

including operations not directly related to the SR S air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat over so remove the SRS compo-

nents before drying or baking the vehicle after painting.

After re-installing them, check the SRS warning lig ht operation to make sure that the system

functions properly.

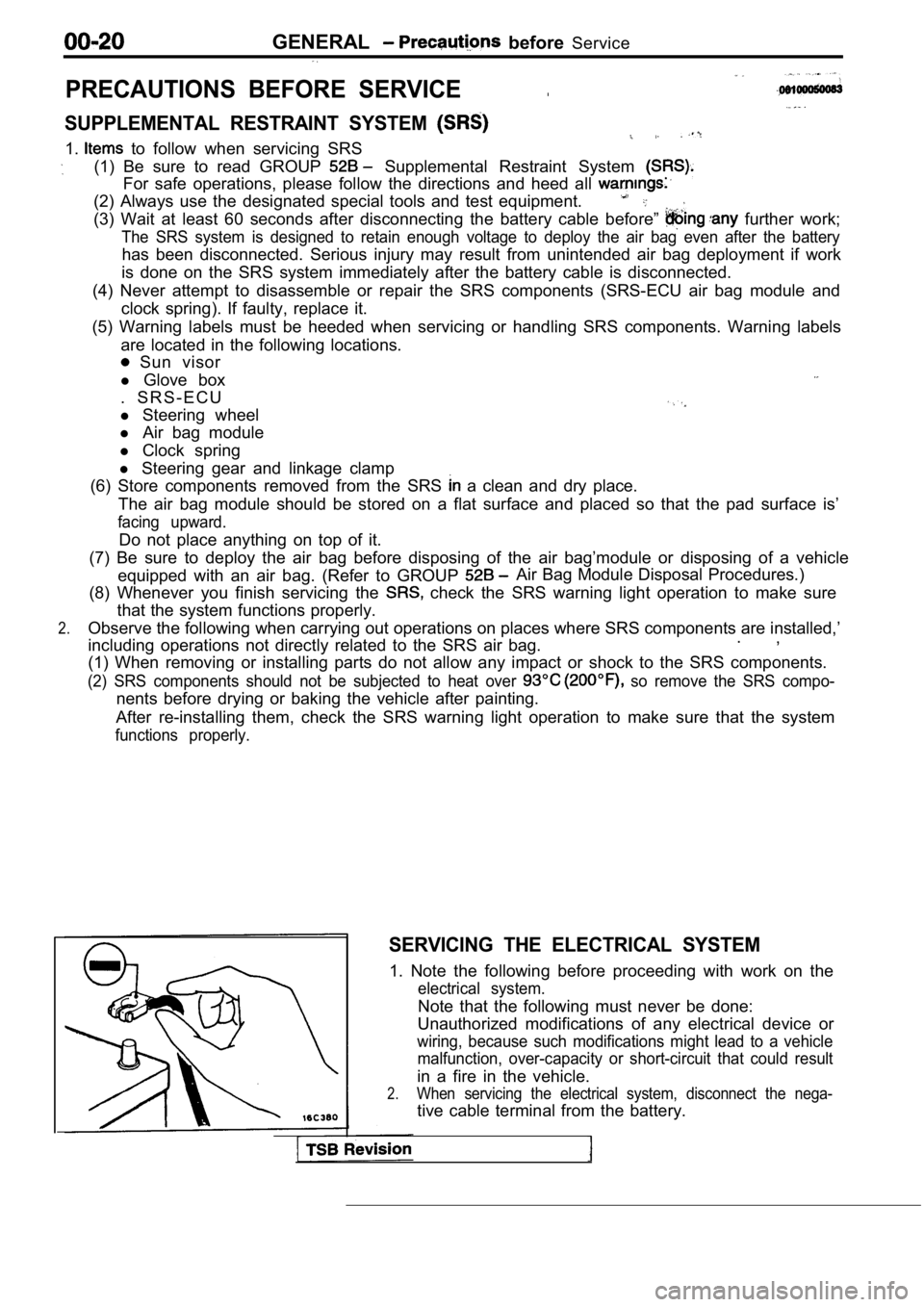

SERVICING THE ELECTRICAL SYSTEM

1. Note the following before proceeding with work o n the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that co uld result

in a fire in the vehicle.

2.When servicing the electrical system, disconnect th e nega-

tive cable terminal from the battery.

Page 2037 of 2103

SRS Air Baa Module Disposal

Body wiring harness

Air bag (red) connector

Connection

Insulation

side>

passenger’s

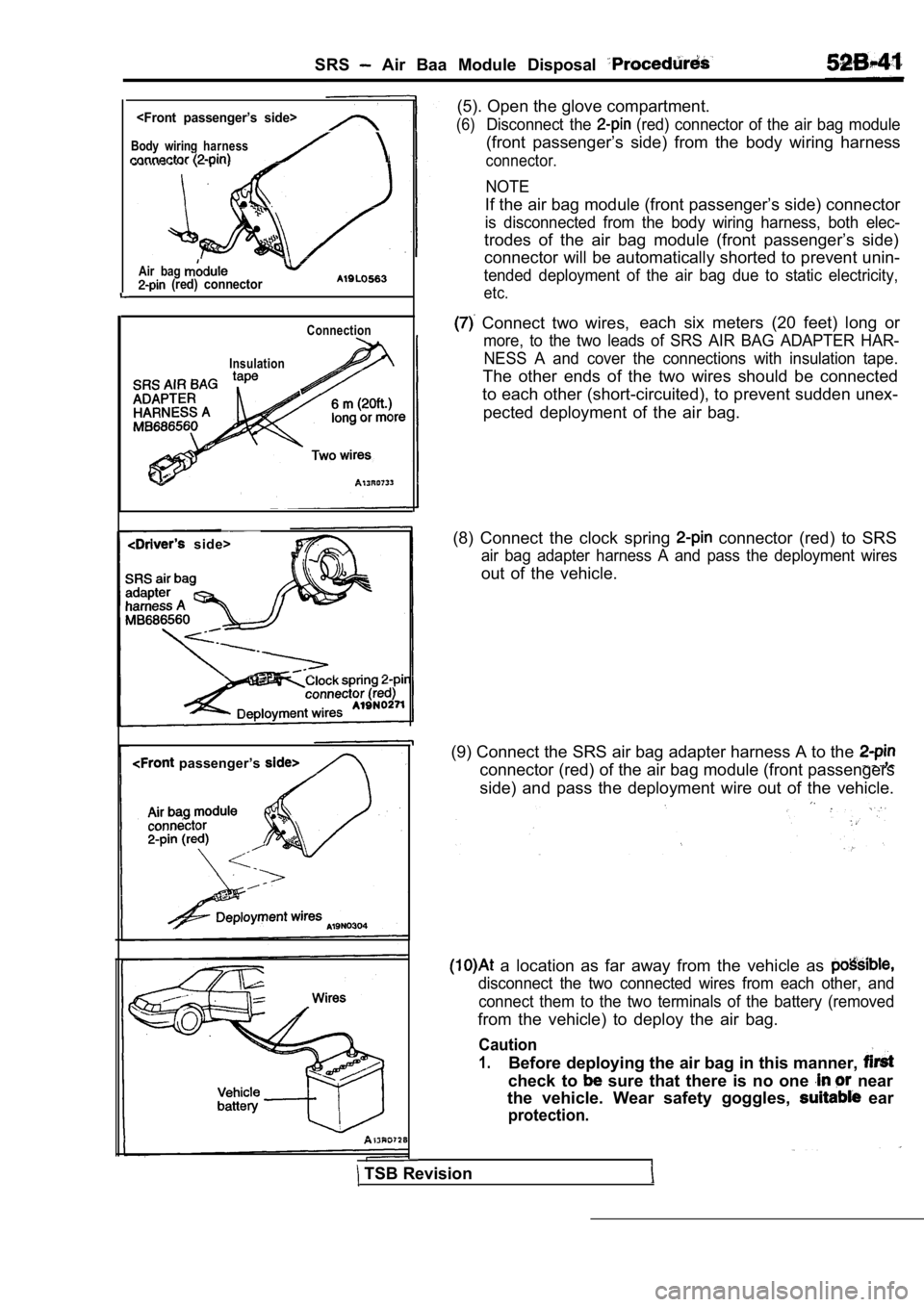

TSB Revision (5). Open the glove compartment.

(6)Disconnect the (red) connector of the air bag module

(front passenger’s side) from the body wiring harne

ss

connector.

NOTE

If the air bag module (front passenger’s side) connector

is disconnected from the body wiring harness, both elec-

trodes of the air bag module (front passenger’s side)

connector will be automatically shorted to prevent unin-

tended deployment of the air bag due to static elec tricity,

etc.

Connect two wires,each six meters (20 feet) long or

more, to the two leads of SRS AIR BAG ADAPTER HAR-

NESS A and cover the connections with insulation ta pe.

The other ends of the two wires should be connected

to each other (short-circuited), to prevent sudden unex-

pected deployment of the air bag.

(8) Connect the clock spring

connector (red) to SRS

air bag adapter harness A and pass the deployment w ires

out of the vehicle.

(9) Connect the SRS air bag adapter harness A to th e

connector (red) of the air bag module (front passengers

side) and pass the deployment wire out of the vehic le.

a location as far away from the vehicle as

disconnect the two connected wires from each other, and

connect them to the two terminals of the battery (r emoved

from the vehicle) to deploy the air bag.

Caution

1.Before deploying the air bag in this manner,

check to sure that there is no one near

the vehicle. Wear safety goggles,

ear

protection.

Page 2039 of 2103

SRS Air Bag Module Disposal Procedures

Wires

Air bag module

Tires without wheels

battery

Air bag module

wire

side>

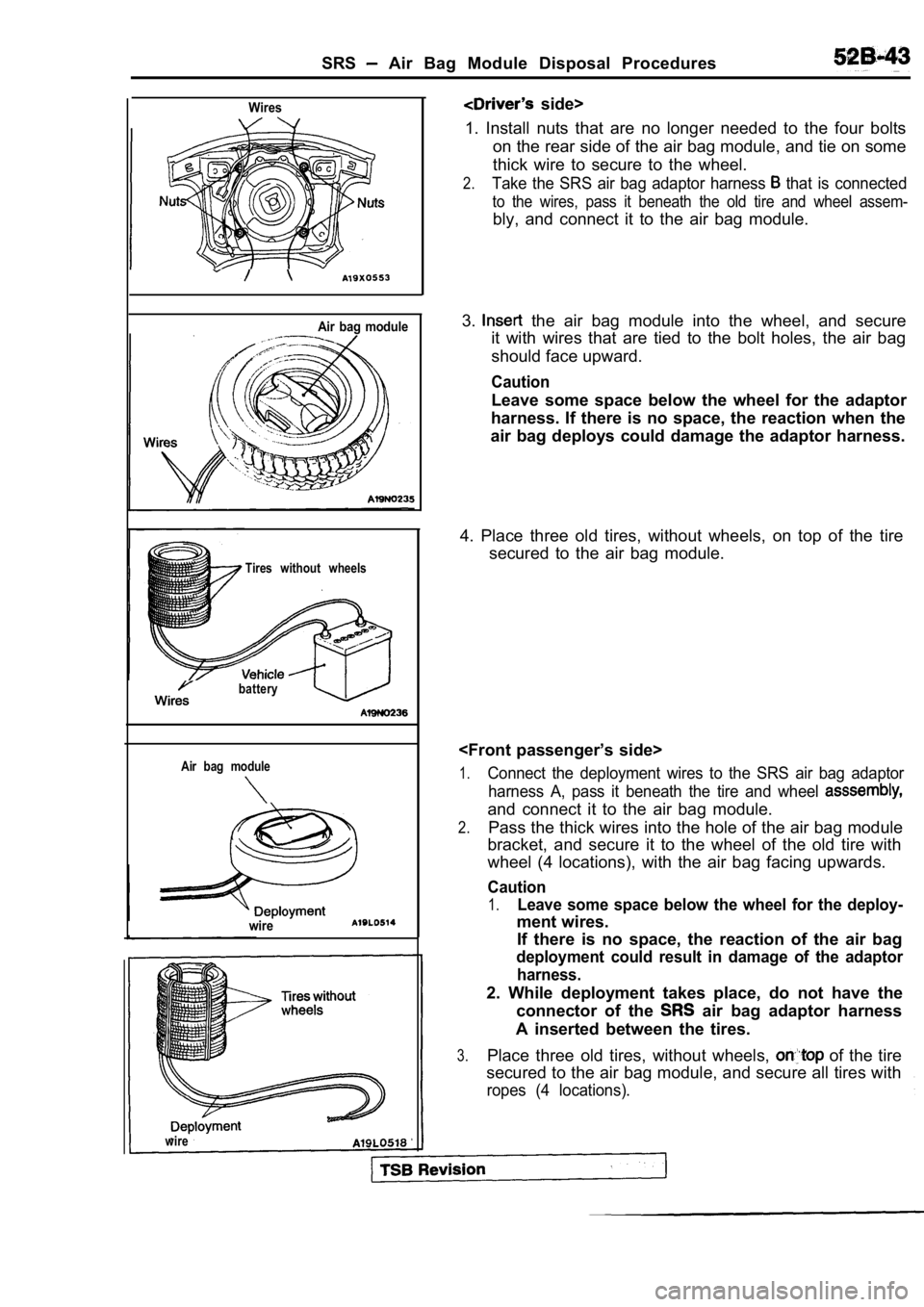

1. Install nuts that are no longer needed to the fo ur bolts

on the rear side of the air bag module, and tie on some

thick wire to secure to the wheel.

2.Take the SRS air bag adaptor harness that is connected

to the wires, pass it beneath the old tire and whee l assem-

bly, and connect it to the air bag module.

3.

the air bag module into the wheel, and secure

it with wires that are tied to the bolt holes, the air bag

should face upward.

Caution

Leave some space below the wheel for the adaptor

harness. If there is no space, the reaction when th e

air bag deploys could damage the adaptor harness.

4. Place three old tires, without wheels, on top of the tire

secured to the air bag module.

1.Connect the deployment wires to the SRS air bag ada ptor

harness A, pass it beneath the tire and wheel

and connect it to the air bag module.

2.Pass the thick wires into the hole of the air bag m odule

bracket, and secure it to the wheel of the old tire with

wheel (4 locations), with the air bag facing upward s.

Caution

1.Leave some space below the wheel for the deploy-

ment wires.

If there is no space, the reaction of the air bag

deployment could result in damage of the adaptor

harness.

2. While deployment takes place, do not have the connector of the

air bag adaptor harness

A inserted between the tires.

3.Place three old tires, without wheels, of the tire

secured to the air bag module, and secure all tires with

ropes (4 locations).

wire

Page 2040 of 2103

SRS Air Baa Module Procedures

Strong

bag module

At alocation as far away from the air bag as

possible, and from a shielded position, if possible , discon-

nect the two connected wires from each other and co nnect

them to the two terminals of- the battery (removed from

the vehicle) to deploy the air bag.

Caution

1. Before deployment, check carefully to be sure that no one is nearby.

2.The inflator will be quite hot immediately followin g’

deployment, so wait at least 30 minutes to allow

it to cool before attempting. to handle it.

Although not poisonous, do not inhale gas from

air bag deployment. See Deployed Air Bag Module

Disposal Procedures for post-deploy-

ment handling instructions.

3. If the air bag module fails to deploy when the

procedures above are followed, do not go near

the module. Contact the MMSA Tech. Line.

5.Dispose of the air bag module after according

to the Deployed Air Bag Module Disposal Procedures (Refer to

DEPLOYED AIR BAG DISPOSAL

After deployment, the air bag module should be

of in the same manner as any other scrap parts, exc ept

the following points should be carefully noted during disposal.

(1) The inflator will be quite hot immediately foll owing

ment, so wait at least 30 minutes to allow it to co ol before

attempting to handle it.

(2) Do not put water or oil on the air bag after de ployment.

(3) There may be, adhered to the deployed air bag module,

material that could irritate the eyes

skin, so wear

gloves and safety goggles when handling a deployed

air bag module. IF DESPITE THESE PRECAUTIONS,

THE MATERIAL DOES, GET INTO

OR ON

THE SKIN, IMMEDIATELY RINSE THE AFFECTED AREA

WITH A LARGE AMOUNT OF CLEAN WATER. IF ANY

IRRITATION DEVELOPS, SEEK ATTENTION.

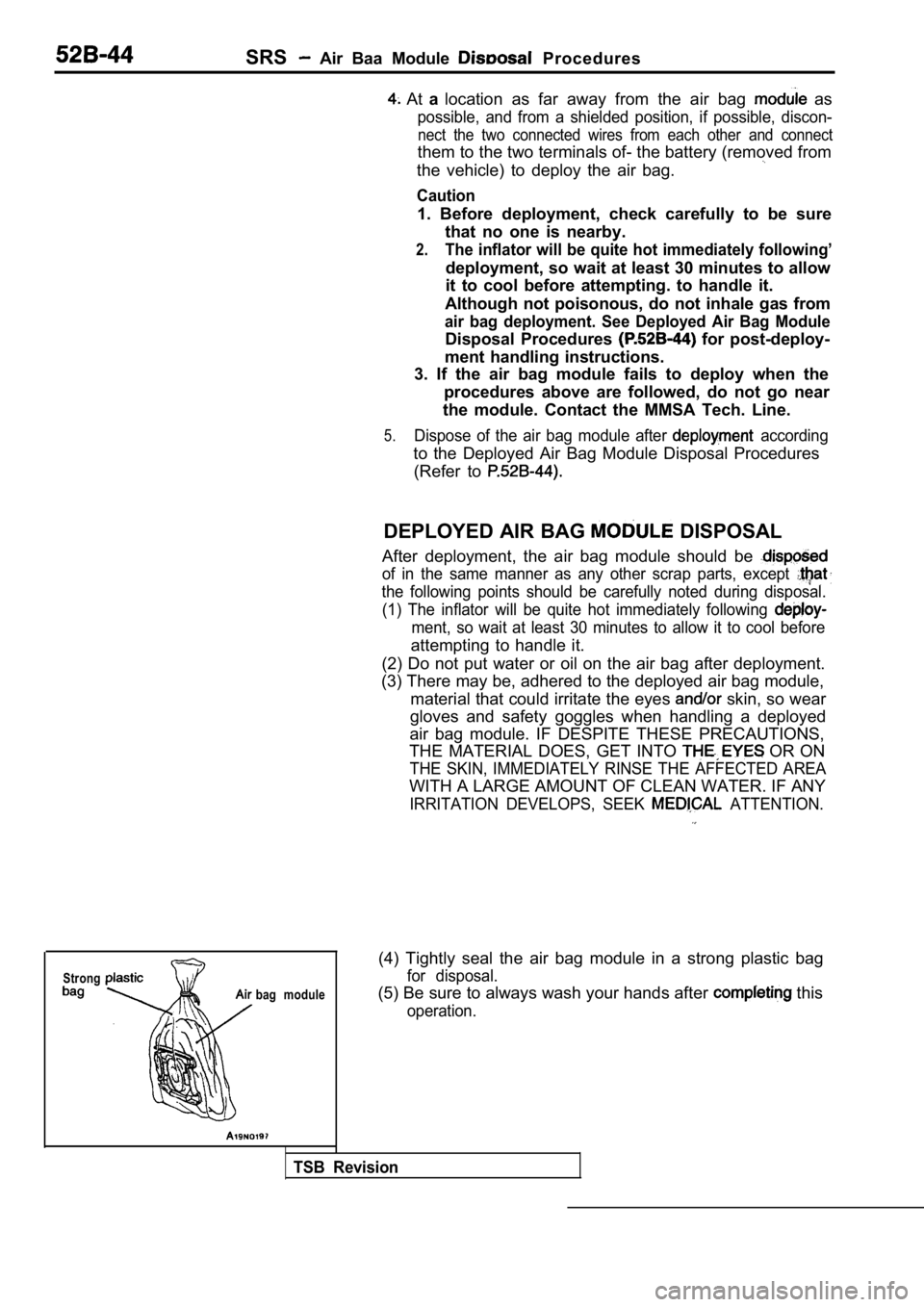

(4) Tightly seal the air bag module in a strong pla stic bag

for disposal.

(5) Be sure to always wash your hands after this

operation.

TSB Revision