fuel cap MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 30 of 2103

GENERAL General Data and Specifications“

00199999191

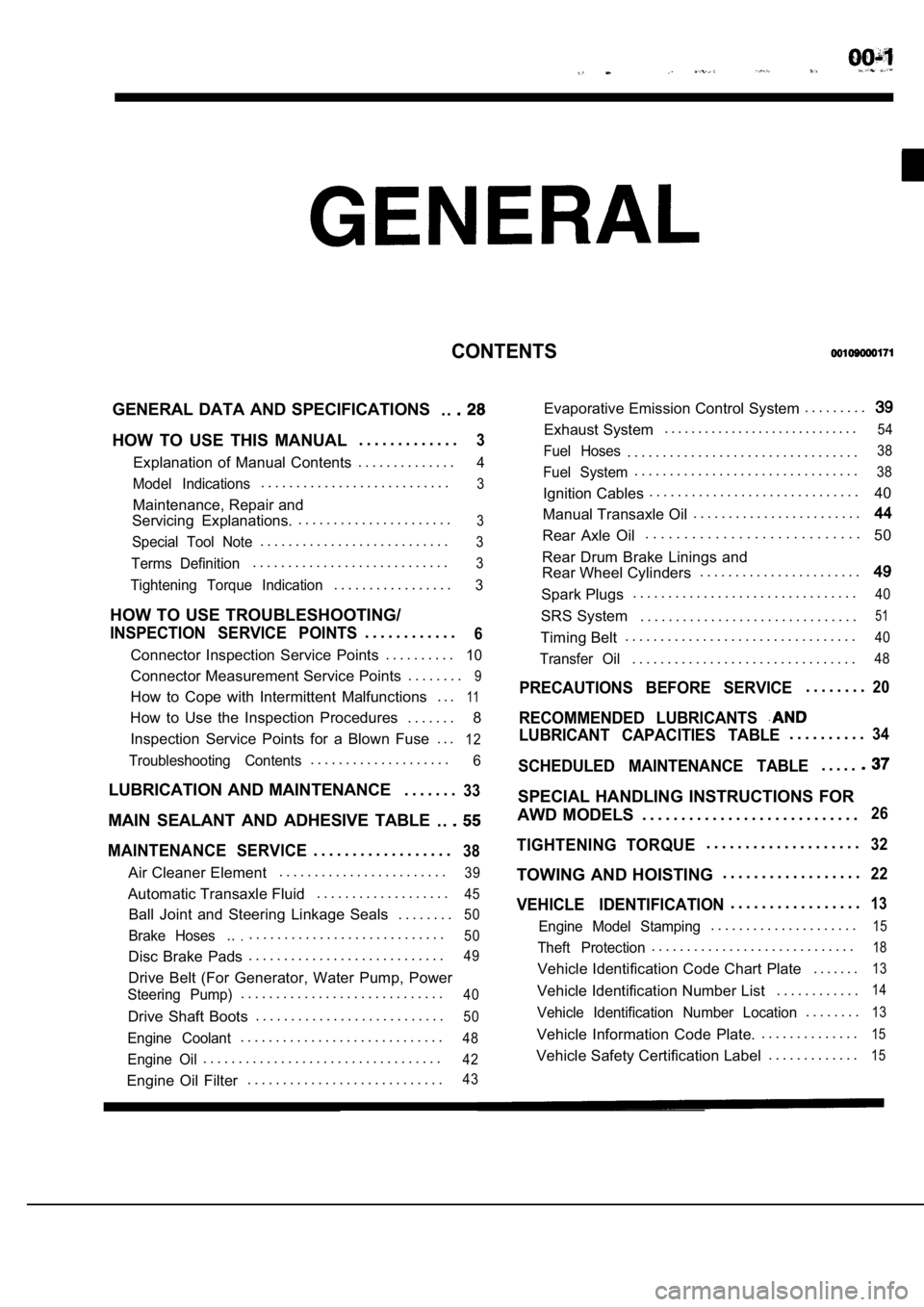

ECLIPSE

74

1l ‘: MD

.

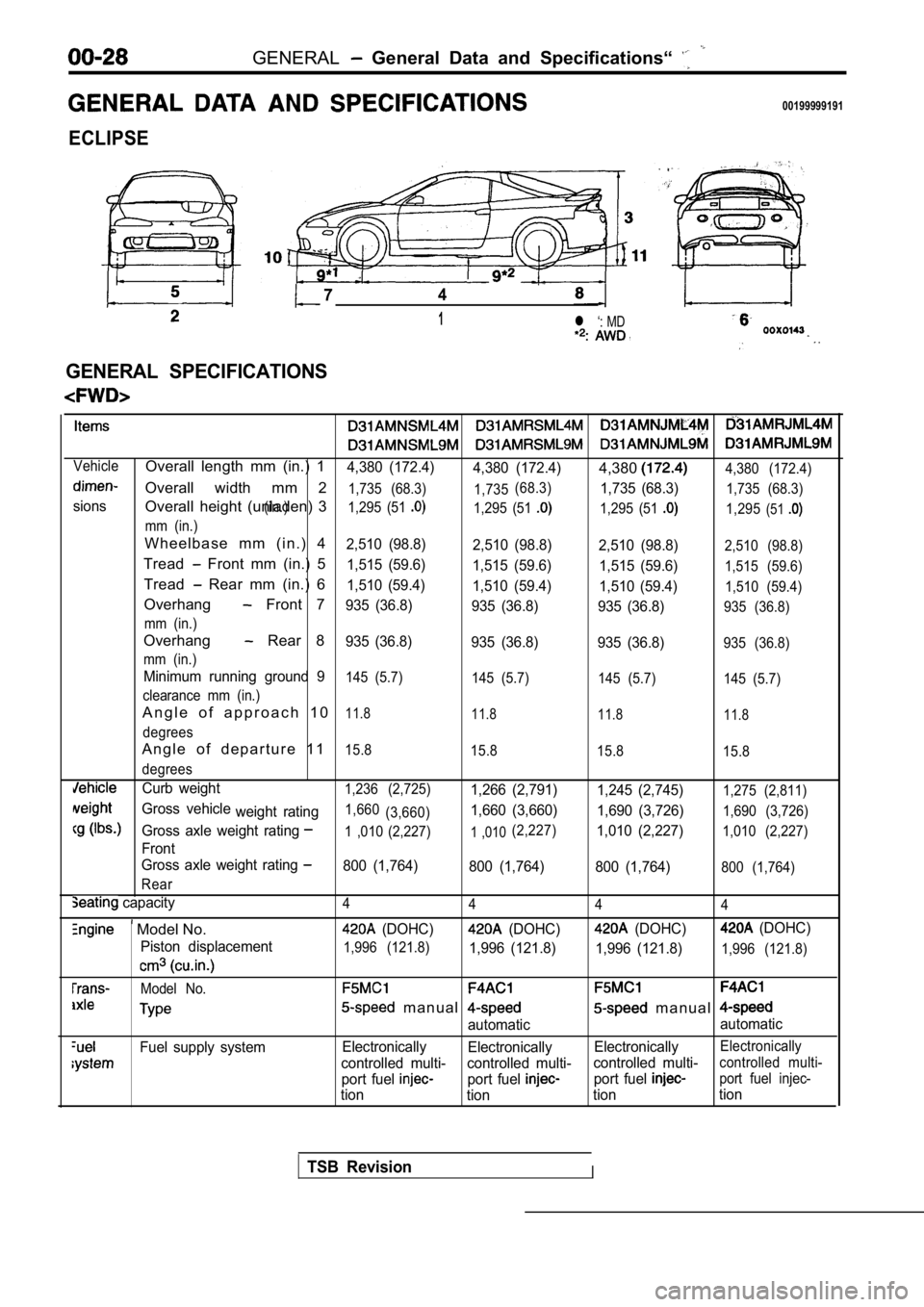

GENERAL SPECIFICATIONS

VehicleOverall length mm (in.) 14,380 (172.4)4,380 (172.4)4,3804,380 (172.4)

Overall width mm 21,735 (68.3) 1,735

sions(in.) (68.3)

1,735 (68.3)1,735 (68.3)

Overall height (unladen) 31,295 (51 1,295 (51 1,295 (51 1,295(51

mm (in.)

W h e e l b a s e m m ( i n . ) 42,510 (98.8)

2,510 (98.8)2,510 (98.8)2,510 (98.8)

Tread Front mm (in.) 51,515 (59.6)

1,515 (59.6) 1,515 (59.6)1,515 (59.6)

Tread Rear mm (in.) 61,510 (59.4)

1,510 (59.4) 1,510 (59.4)1,510 (59.4)

Overhang Front 7935 (36.8)

935 (36.8) 935 (36.8)935 (36.8)

mm (in.)

Overhang Rear 8935 (36.8) 935 (36.8) 935 (36.8)935 (36.8)

mm (in.)

Minimum running ground 9145 (5.7) 145 (5.7) 145 (5.7)145 (5.7)

clearance mm (in.)

A n g l e o f a p p r o a c h 1 011.8 11.8 11.811.8

degrees

A n g l e o f d e p a r t u r e 1 115.8

15.8 15.815.8

degrees

Curb weight1,236 (2,725)1,266 (2,791) 1,245 (2,745)1,275 (2,811)

Gross vehicle

weight rating1,660(3,660)1,660 (3,660) 1,690 (3,726)1,690 (3,726)

Gross axle weight rating1 ,010 (2,227)1 ,010(2,227)1,010 (2,227)1,010 (2,227)

Front

Gross axle weight rating

800 (1,764) 800 (1,764) 800 (1,764)800 (1,764)

Rear

capacity4 4 44

Model No. (DOHC) (DOHC) (DOHC) (DOHC)

Piston displacement

1,996 (121.8)1,996 (121.8) 1,996 (121.8)1,996 (121.8)

Model No.

m a n u a l m a n u a l

automatic automatic

Fuel supply system

Electronically

Electronically ElectronicallyElectronically

controlled multi- controlled multi- controlled multi-controlled multi-

port fuel port fuel port fuel port fuel injec-

tion

tion tiontion

TSB RevisionI

Page 31 of 2103

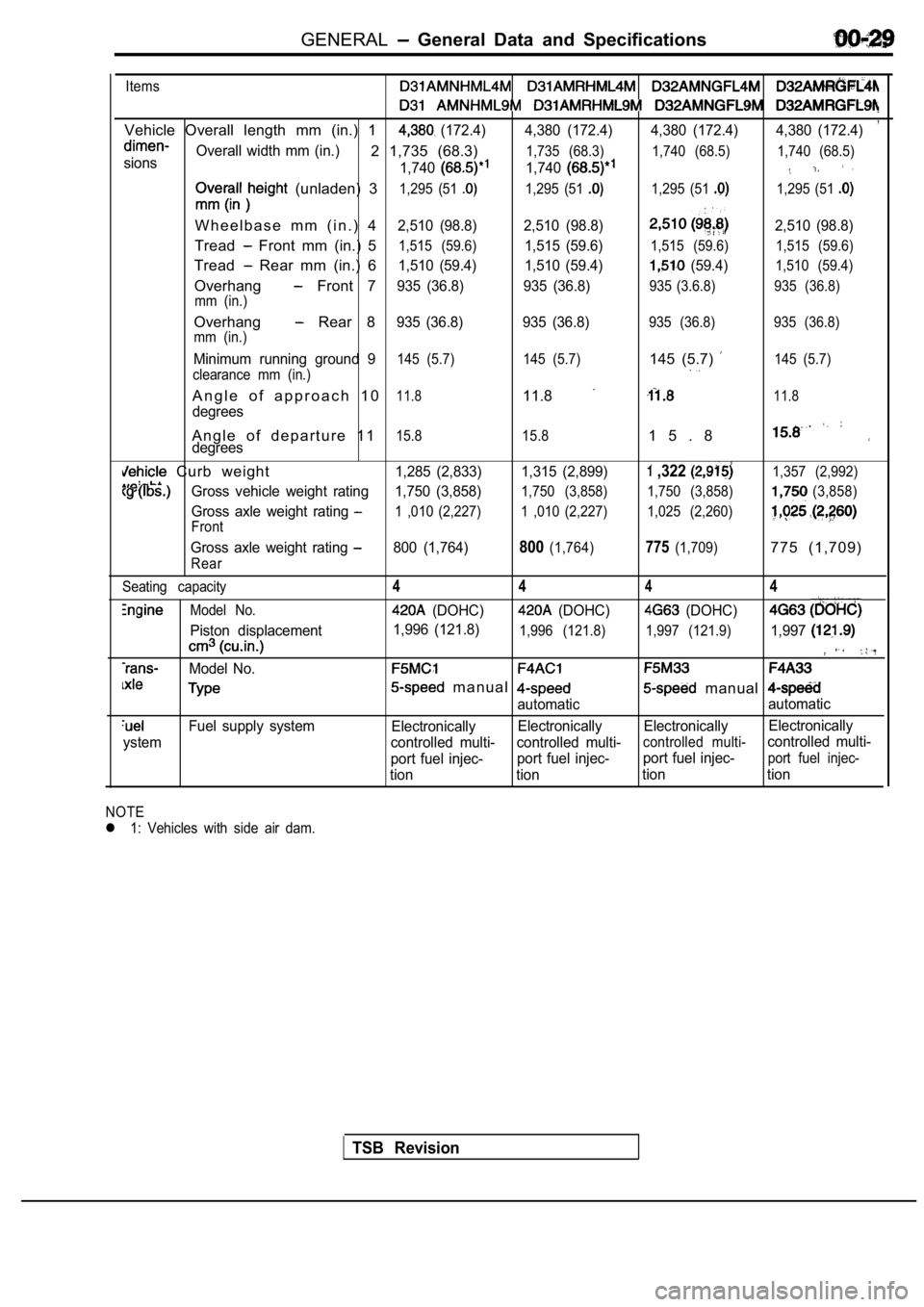

GENERAL General Data and Specifications

Items

,Vehicle Overall length mm (in.) 1 (172.4) 4,380 (172.4) 4,380 (172.4) 4,380 (172.4)

sionsOverall width mm (in.)2 1,735 (68.3)

1,740

1,735 (68.3)

1,740

1,740 (68.5) 1,740 (68.5)

(unladen) 31,295 (51 1,295 (51 1,295 (51 1,295 (51

W h e e l b a s e m m ( i n . ) 42,510 (98.8) 2,510 (98.8)2,510 (98.8)

Tread Front mm (in.) 51,515 (59.6)1,515 (59.6)1,515 (59.6) 1,515 (59.6)

Tread Rear mm (in.) 61,510 (59.4) 1,510 (59.4) (59.4)1,510 (59.4)

Overhang Front 7935 (36.8) 935 (36.8)935 (3.6.8) 935 (36.8)

mm (in.)

Overhang Rear 8935 (36.8) 935 (36.8)935 (36.8) 935 (36.8)

mm (in.)

Minimum running ground 9145 (5.7) 145 (5.7)145 (5.7) 145 (5.7)

clearance mm (in.)

A n g l e o f a p p r o a c h 1 011.811.811.8

degrees

A n g l e o f d e p a r t u r e 1 115.8 15.81 5 . 8degrees

Curb weight1,285 (2,833) 1,315 (2,899) ,322 1,357 (2,992)

Gross vehicle weight rating 1,750 (3,858)1,750 (3,858) 1,750 (3,858)(3,858)

Gross axle weight rating 1 ,010 (2,227) 1 ,010 (2,227) 1,025 (2,260)

Front

Gross axle weight rating 800 (1,764)800(1,764)775(1,709)775 (1,709)

Rear

Seating capacity

Model No.

Piston displacement

Model No.

Fuel supply system

ystem

4 444

(DOHC) (DOHC) (DOHC)

1,996 (121.8)1,996 (121.8) 1,997 (121.9)1,997

m a n u a l manual

automatic automatic

Electronically Electronically Electronically Electronically

controlled multi- controlled multi-

controlled multi-controlled multi-

port fuel injec- port fuel injec-port fuel injec-

port fuel injec-

tion tion tion tion

NOTE

l 1: Vehicles with side air dam.

TSB Revision

Page 32 of 2103

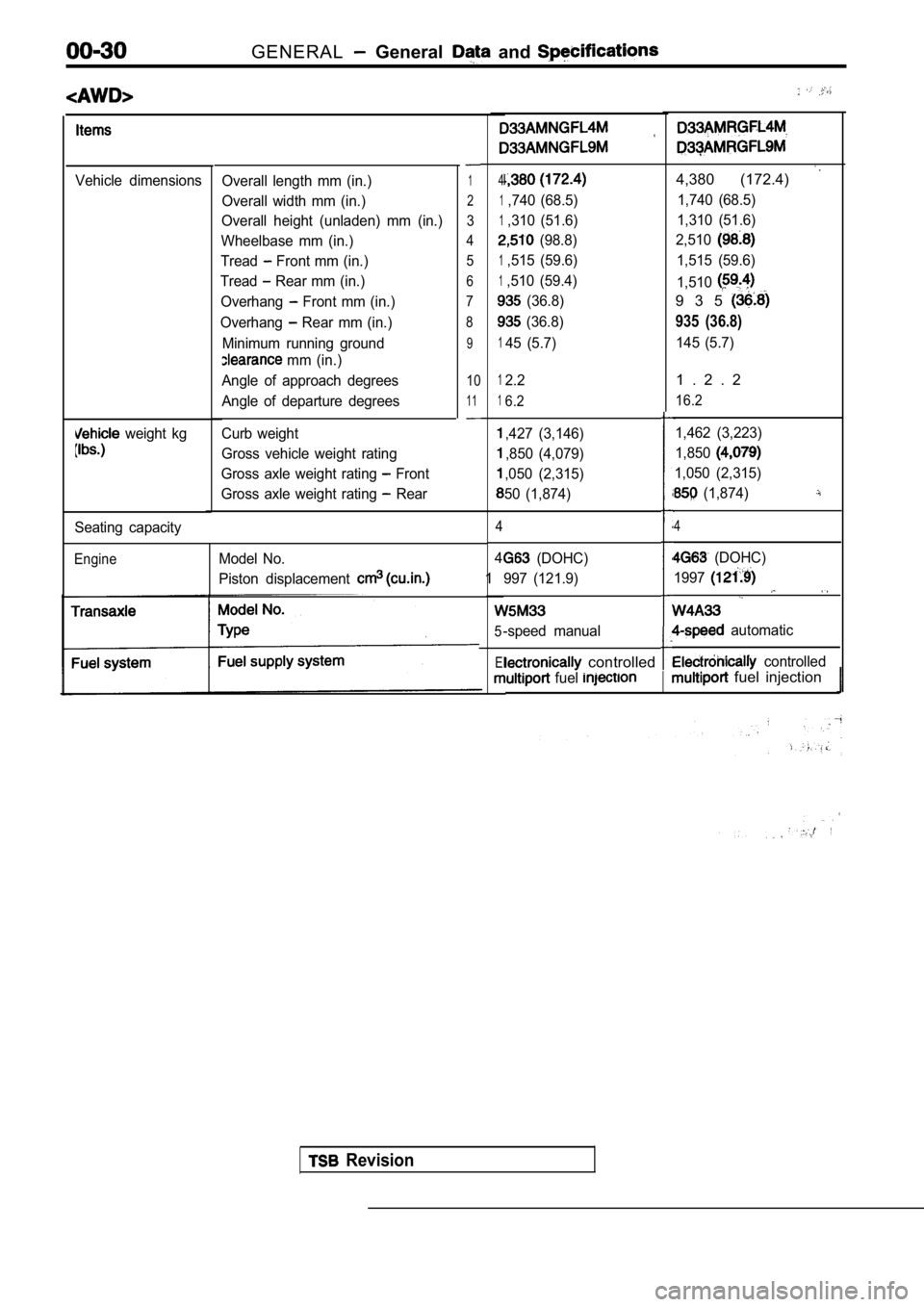

GENERAL General and

Vehicle dimensions

weight kg

Overall length mm (in.)

Overall width mm (in.)

Overall height (unladen) mm (in.)

Wheelbase mm (in.)

Tread

Front mm (in.)

Tread

Rear mm (in.)

Overhang

Front mm (in.)

Overhang

Rear mm (in.)

Minimum running ground

mm (in.)

Angle of approach degrees

Angle of departure degrees

Curb weight

Gross vehicle weight rating

Gross axle weight rating

Front

Gross axle weight rating

Rear

1

2

3

4 5

6

7

8

9

10

11

Seating capacity

EngineModel No.

Piston displacement

4

1,740 (68.5)

1,310 (51.6)

(98.8)

1,515 (59.6)

1,510 (59.4)

(36.8)

(36.8)

145 (5.7)

4,380 (172.4)

1,740 (68.5)

1,310 (51.6)

2,510

1,515 (59.6)

1,510

9 3 5

935 (36.8)

145 (5.7)

12.2

16.2

,427 (3,146)

,850 (4,079)

,050 (2,315)

50 (1,874)

4

4

1

5

El

1 . 2 . 2

16.2

1,462 (3,223)

1,850

1,050 (2,315)

(1,874)

4

(DOHC)

997 (121.9)

-speed manual

(DOHC)

1997

automatic

controlled controlled

fuel fuel injection

Revision

Page 33 of 2103

GENERAL General Data and Specifications

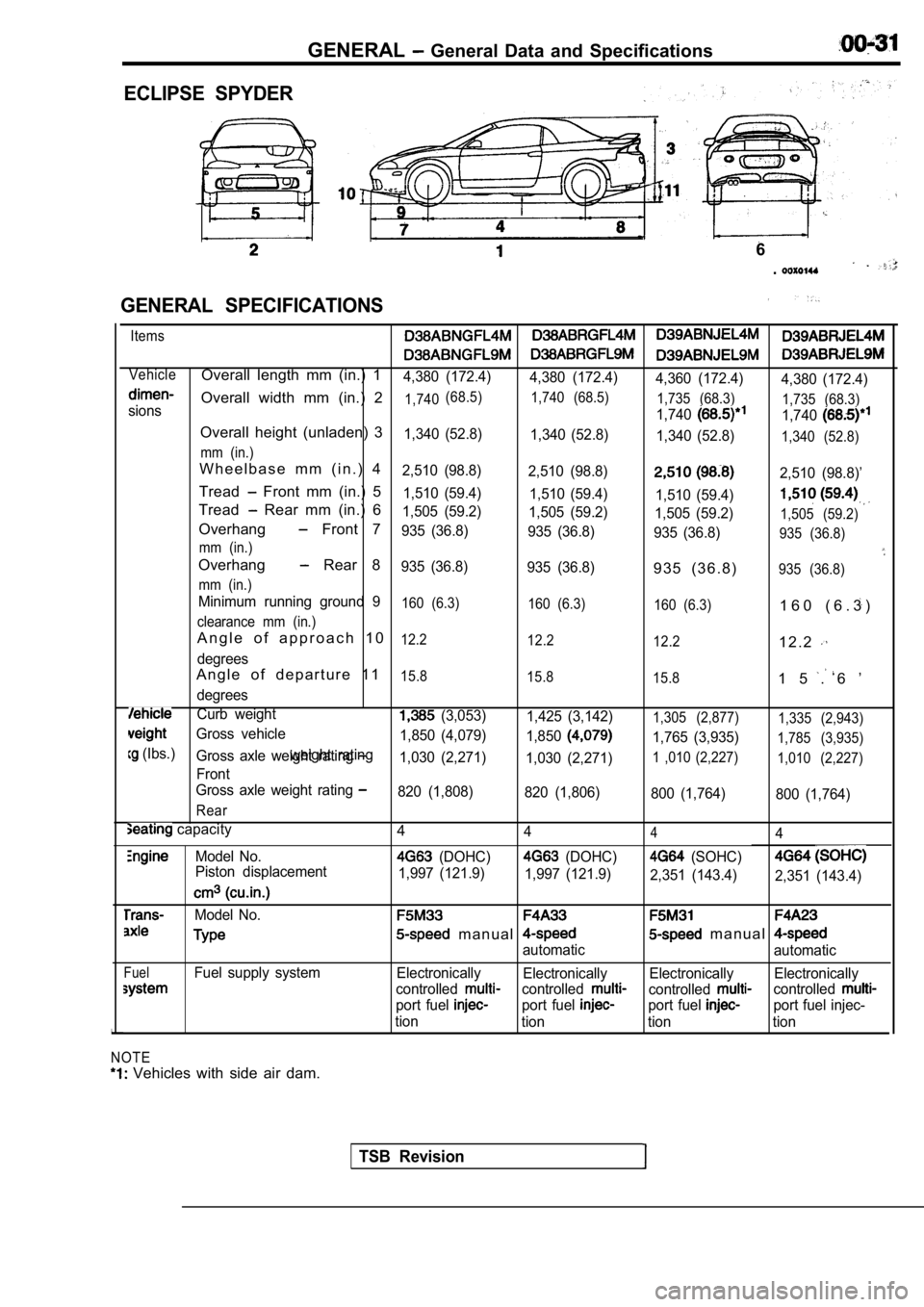

ECLIPSE SPYDER

GENERAL SPECIFICATIONS

6

.

Items

VehicleOverall length mm (in.) 14,380 (172.4) 4,380 (172.4)

4,360 (172.4)4,380 (172.4)

Overall width mm (in.) 21,740(68.5)

1,740 (68.5)

1,735 (68.3)1,7401,735 (68.3)sions

1,740

Overall height (unladen) 31,340 (52.8)1,340 (52.8)

1,340 (52.8)1,340 (52.8)

mm (in.)

W h e e l b a s e m m ( i n . ) 42,510 (98.8) 2,510 (98.8)2,510 (98.8)’

Tread Front mm (in.) 51,510 (59.4) 1,510 (59.4)

1,510 (59.4)

Tread Rear mm (in.) 61,505 (59.2) 1,505 (59.2)

1,505 (59.2)1,505 (59.2)Overhang Front 7935 (36.8) 935 (36.8)

935 (36.8)935 (36.8)

mm (in.)

Overhang Rear 8935 (36.8) 935 (36.8)9 3 5 ( 3 6 . 8 )935 (36.8)

mm (in.)

Minimum running ground 9160 (6.3) 160 (6.3)

160 (6.3)1 6 0 ( 6 . 3 )

clearance mm (in.)

A n g l e o f a p p r o a c h 1 012.2 12.2

12.21 2 . 2

degrees

A n g l e o f d e p a r t u r e 1 115.8 15.8

15.81 5 . 6 ’

degrees

Curb weight (3,053)1,425 (3,142)1,305 (2,877) 1,335 (2,943)

Gross vehicle

1,765 (3,935)1,785 (3,935)

(Ibs.)weight rating1,850 (4,079)

1,850Gross axle weight rating 1,030 (2,271)1,030 (2,271)1 ,010 (2,227) 1,010 (2,227)

Front

Gross axle weight rating

820 (1,808) 820 (1,806)

800 (1,764)800 (1,764)

Rear

capacity

Model No.

Piston displacement

Model No.

FuelFuel supply system

NOTE

Vehicles with side air dam. 4

444

(DOHC) (DOHC) (SOHC)

1,997 (121.9)

1,997 (121.9)

2,351 (143.4)2,351 (143.4)

m a n u a l m a n u a l

automatic automatic

Electronically Electronically Electronically Electronically

controlled

controlledcontrolledcontrolled

port fuel port fuel port fuel port fuel injec-

tion tion tion tion

TSB Revision

Page 36 of 2103

Lubrication and

GENERAL Lubricants and Lubricant Capacities Table

Use of fuels containing alcohol is not recommended

unless the nature of the blend can be determined

as being satisfactory.

Gasohol

A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used in your

car.

If problems are experienced as a result

of using gasohol, it is recommended that the car

be operated on gasoline.

Methanol Do not use gasolines containing

methanol (wood alcohol). Use of this type of alcohol

can result in vehicle performance deterioration and

damage critical parts in the fuel system compo-

nents. Fuel system damage and performance prob-

lems, resulting from the use of gasolines containin g

methanol, may not be covered by the new car war-

ranty.

Gasolines containing

Ether)

Unleaded gasoline containing 15% or

may be used in car. Fuel containing MTBE

over 15% vol. may cause reduced engine perfor-

mance and produce vapor lock or hard starting.

MATERIALS

TO FUEL

Indiscriminate use of fuel system -cleaning’

should be avoided. Many of these materials in-

tended for gum and varnish removal

highly active solvents or similar ingredients that

can be harmful to gasket and diaphragm materials

used in fuel system component

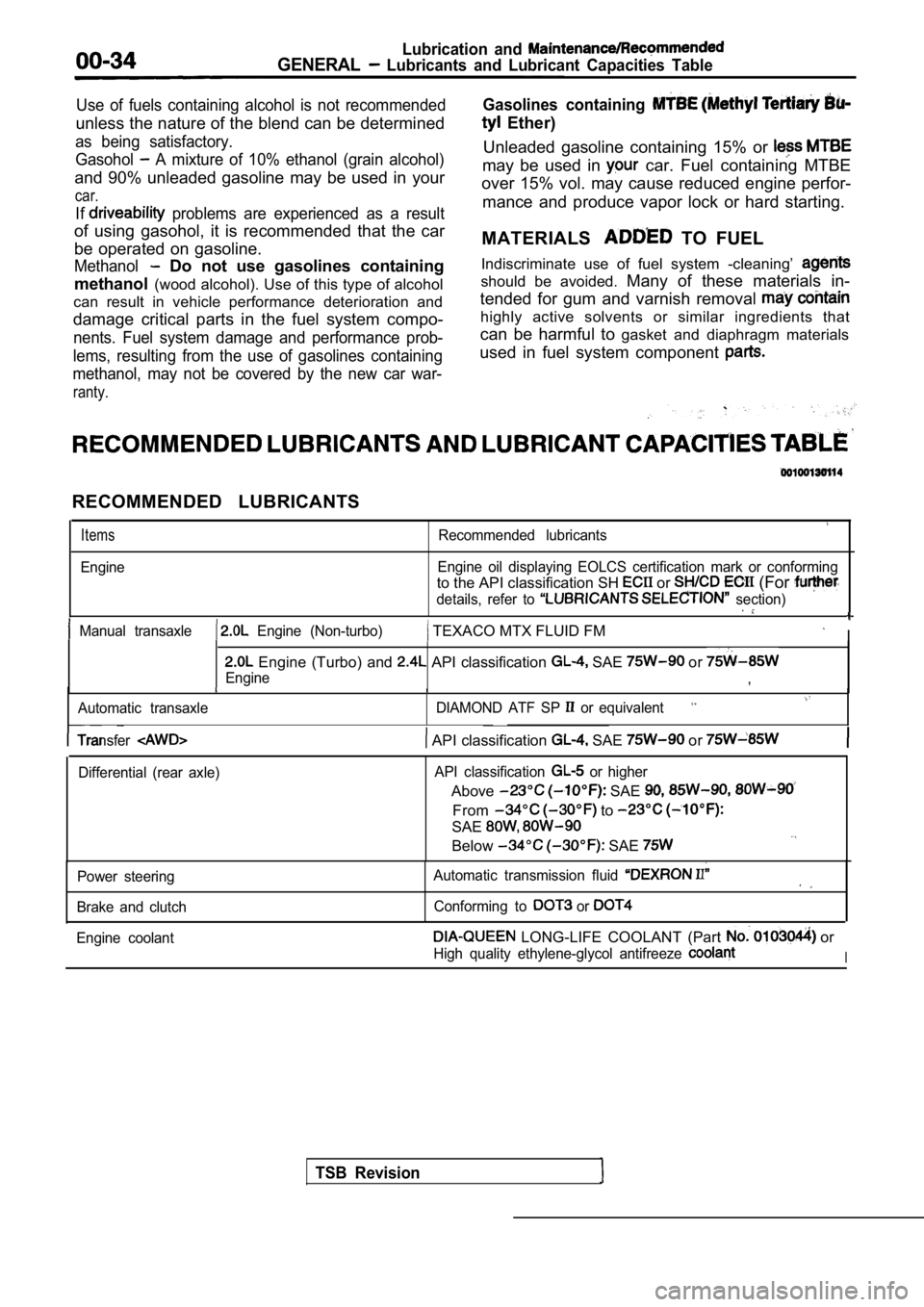

RECOMMENDED LUBRICANTS

Items

Engine

Recommended lubricants

Engine oil displaying EOLCS certification mark or c onforming

to the API classification SH or (For

details, refer to section)

Manual transaxle Engine (Non-turbo) TEXACO MTX FLUID FM I

Engine (Turbo) and API classification SAE or

Engine,

Automatic transaxle DIAMOND ATF SP or equivalent

TSB Revision

Transfer API classification SAE or

Differential (rear axle)API classification or higher

Above SAE

From to

SAE

Below SAE

Power steering

Brake and clutch Automatic transmission fluid

Conforming to or

Engine coolant LONG-LIFE COOLANT (Part or

High quality ethylene-glycol antifreeze I

Page 37 of 2103

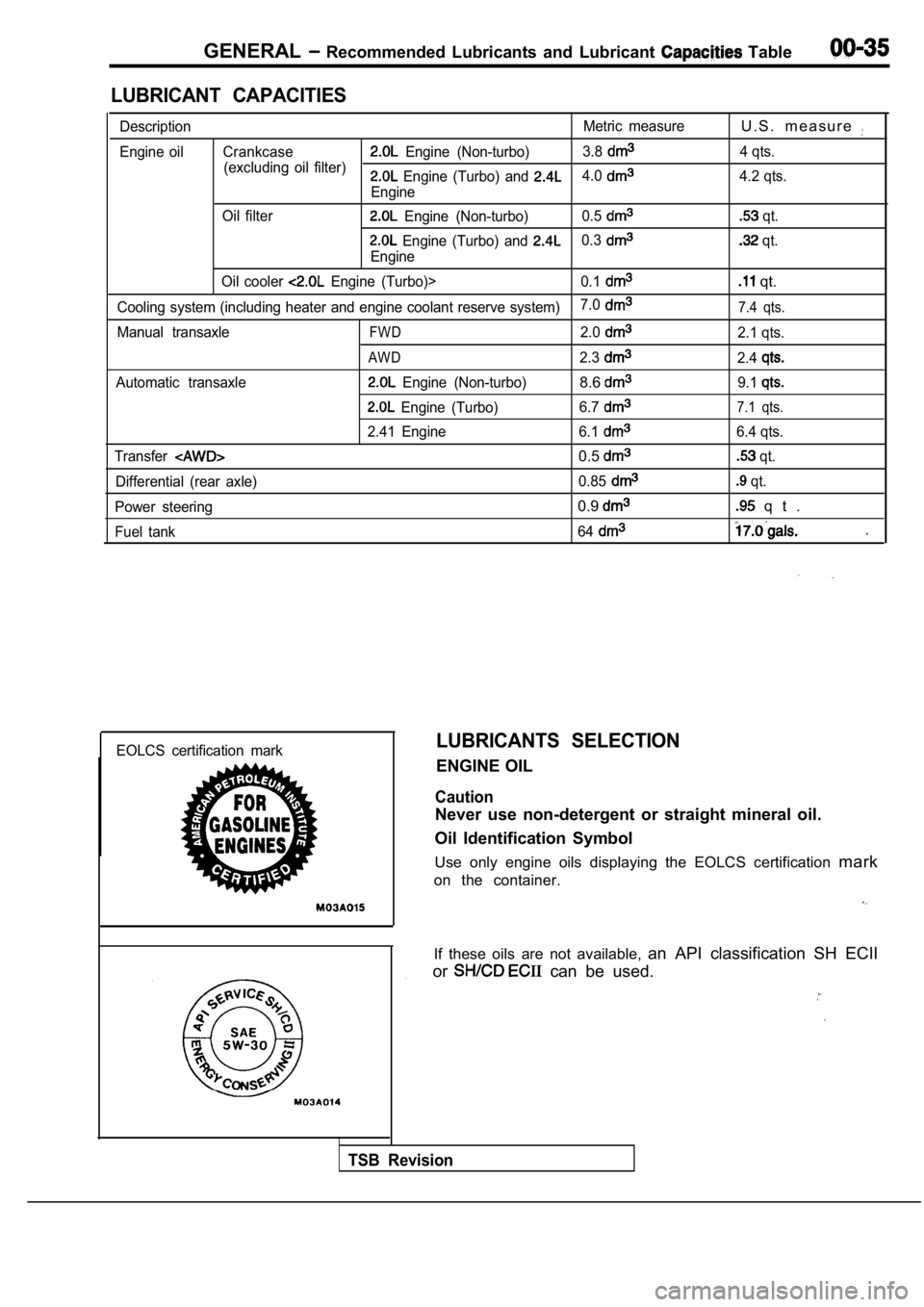

GENERAL Recommended Lubricants and Lubricant Table

LUBRICANT CAPACITIES

DescriptionMetric measureU . S . m e a s u r e

Engine oil Crankcase Engine (Non-turbo)3.8

(excluding oil filter) 4 qts. Engine (Turbo) and 4.0

Engine4.2 qts.

Oil filter

Engine (Non-turbo) 0.5 qt.

Engine (Turbo) and 0.3

Engine

qt.

Oil cooler

Engine (Turbo)> 0.1 qt.

Cooling system (including heater and engine coolant reserve system)7.07.4 qts.

Manual transaxleFWD2.02.1 qts.

AWD2.32.4

Automatic transaxle Engine (Non-turbo)8.69.1

Engine (Turbo)

6.77.1 qts.

2.41 Engine 6.16.4 qts.

Transfer

0.5 qt.

Differential (rear axle) 0.85

qt.

Power steering

0.9 q t .

Fuel tank 64

EOLCS certification markLUBRICANTS SELECTION

ENGINE OIL

Caution

Never use non-detergent or straight mineral oil.

Oil Identification Symbol

Use only engine oils displaying the EOLCS certifica tion mark

on the container.

If these oils are not available, an API classification SH ECII

or

can be used.

TSB Revision

Page 41 of 2103

GENERAL Maintenance Service

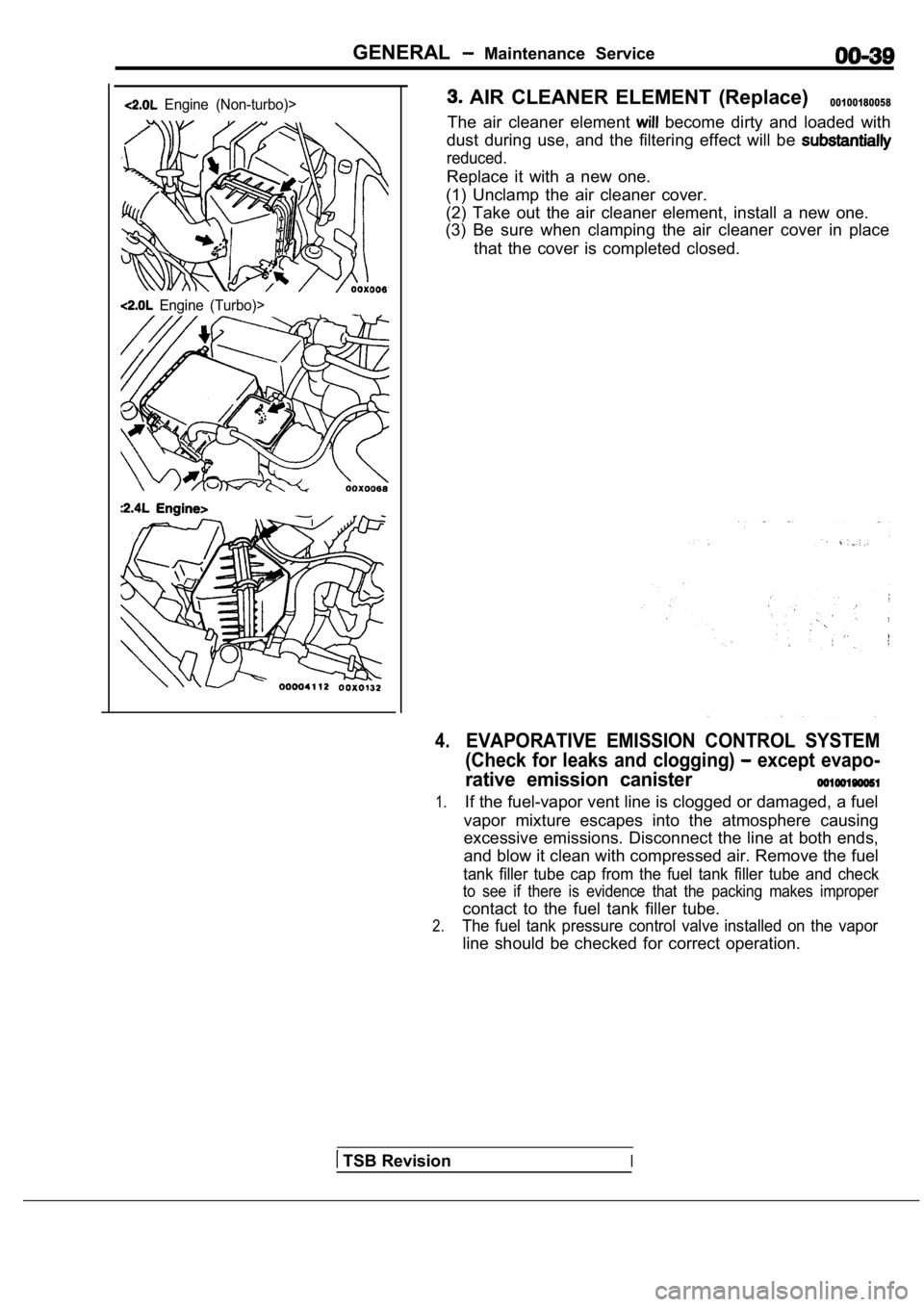

Engine (Non-turbo)>

Engine (Turbo)>

AIR CLEANER ELEMENT (Replace)00100180058

The air cleaner element become dirty and loaded with

dust during use, and the filtering effect will be

reduced.

Replace it with a new one.

(1) Unclamp the air cleaner cover.

(2) Take out the air cleaner element, install a new one.

(3) Be sure when clamping the air cleaner cover in place

that the cover is completed closed.

4.EVAPORATIVE EMISSION CONTROL SYSTEM

(Check for leaks and clogging)

except evapo-

rative emission canister

1.If the fuel-vapor vent line is clogged or damaged, a fuel

vapor mixture escapes into the atmosphere causing

excessive emissions. Disconnect the line at both en ds,

and blow it clean with compressed air. Remove the f uel

tank filler tube cap from the fuel tank filler tube and check

to see if there is evidence that the packing makes improper

contact to the fuel tank filler tube.

2.The fuel tank pressure control valve installed on the vapor

line should be checked for correct operation.

TSB RevisionI

Page 77 of 2103

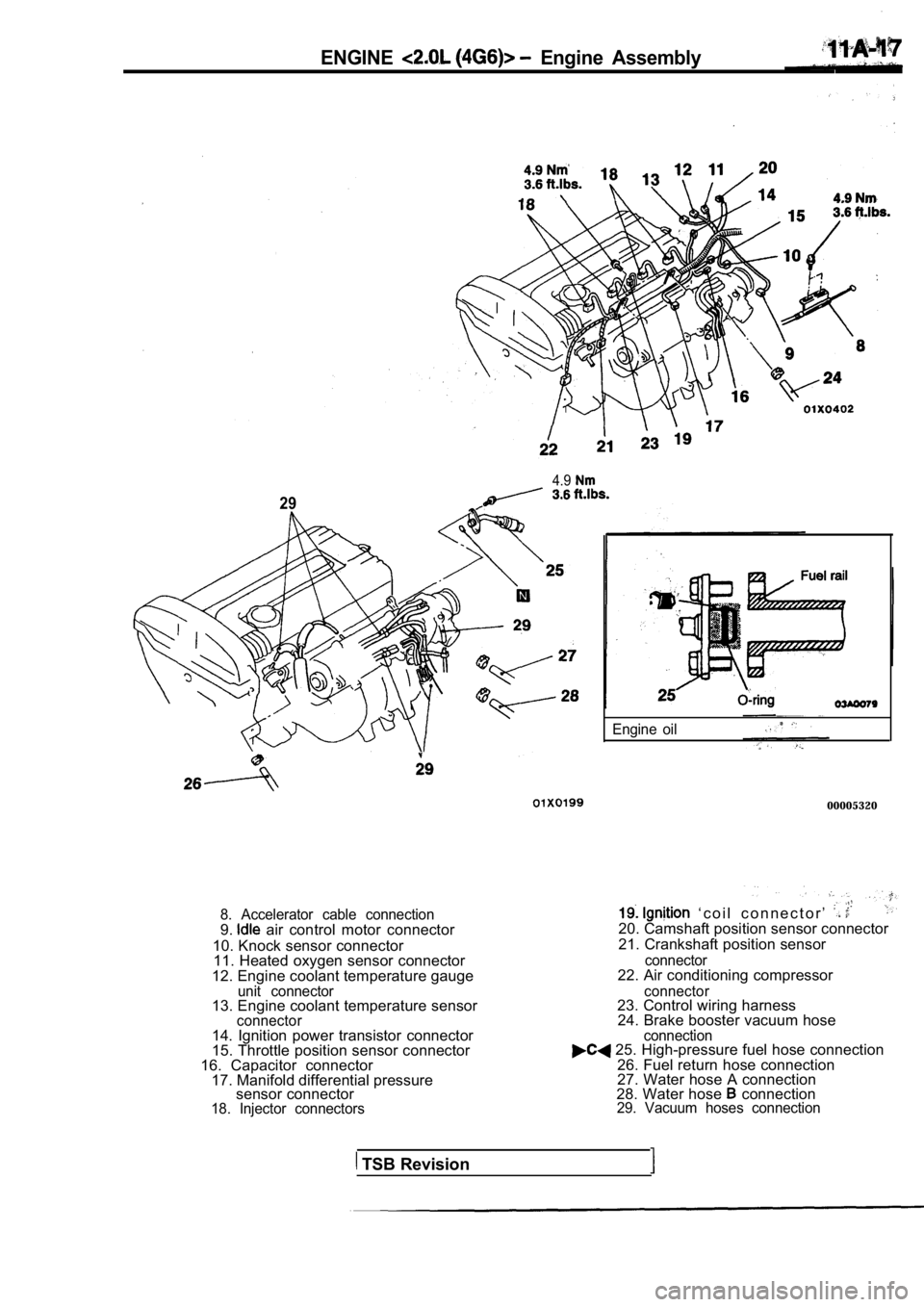

ENGINE Engine Assembly

4.9

29

8. Accelerator cable connection9. air control motor connector

10. Knock sensor connector 11. Heated oxygen sensor connector

12. Engine coolant temperature gauge

unit connector13. Engine coolant temperature sensorconnector

Engine oil

00005320

‘ c o i l c o n n e c t o r ’ 20. Camshaft position sensor connector

21. Crankshaft position sensor

connector22. Air conditioning compressor

connector23. Control wiring harness 24. Brake booster vacuum hose .

14. Ignition power transistor connector

15. Throttle position sensor connector

16. Capacitor connector 17. Manifold differential pressure sensor connector

18. Injector connectors connection

25. High-pressure fuel hose connection

26. Fuel return hose connection

27. Water hose A connection

28. Water hose

connection29. Vacuum hoses connection

TSB Revision

Page 91 of 2103

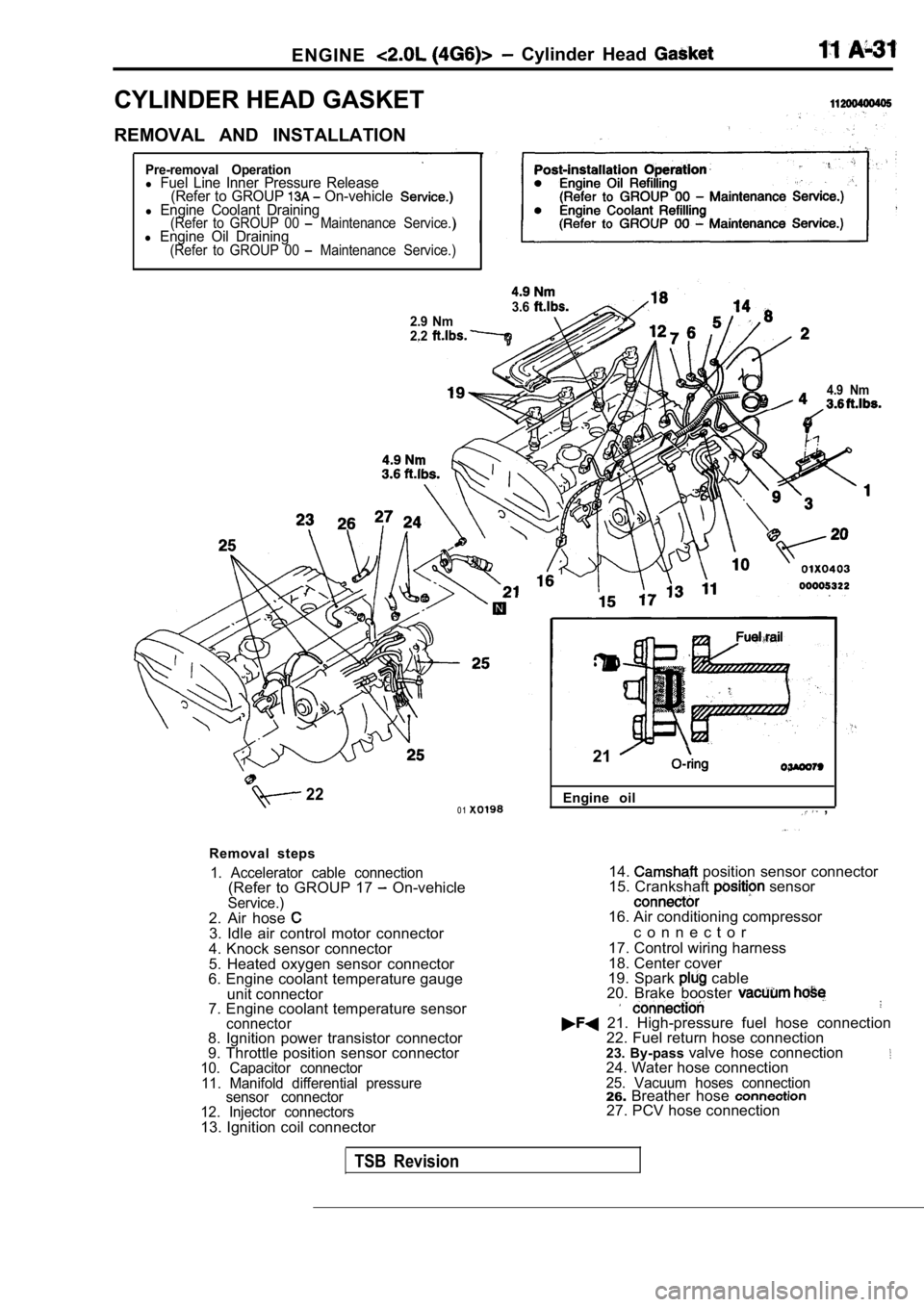

ENGINE Cylinder Head

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal Operationl Fuel Line Inner Pressure Release(Refer to GROUP On-vehiclel Engine Coolant Draining(Refer to GROUP 00 Maintenance Service.)l Engine Oil Draining(Refer to GROUP 00 Maintenance Service.)

3.62.9 Nm

2.2

4.9 Nm

220 1

Removal steps

1. Accelerator cable connection(Refer to GROUP 17 On-vehicleService.)2. Air hose 3. Idle air control motor connector

4. Knock sensor connector

5. Heated oxygen sensor connector

6. Engine coolant temperature gauge

unit connector

7. Engine coolant temperature sensor

connector8. Ignition power transistor connector

9. Throttle position sensor connector

10. Capacitor connector

11. Manifold differential pressure sensor connector

12. Injector connectors

13. Ignition coil connector Engine oil

,

21

14. position sensor connector

15. Crankshaft sensor

16. Air conditioning compressor

c o n n e c t o r

17. Control wiring harness

18. Center cover

19. Spark

cable

20. Brake booster

21. High-pressure fuel hose connection 22. Fuel return hose connection

23. By-pass valve hose connection

24. Water hose connection25. Vacuum hoses connection26.Breather hose 27. PCV hose connection

TSB Revision