check engine light MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 23 of 2103

GENERAL Precautions before Service . .

Caution

1.Before connecting or disconnecting the negative

be sure to turn off the ignition and

the lighting switch.

(if this is not done, the possibility semi-

conductor parts being damaged.)

2.After completion of the work steps [when the bat-

tery’s negative terminal is connected], warm

up the engine and allow it for approximately

five minutes under the conditions be-

low, in order to stabilize the engine condi-

tions, and then check to be sure that idling’ is

satisfactory.

Engine temperature:

Lights, electric fans, accessories: OFF

Transaxle: Neutral position

(A/T models: “N” or “P”)

Steering

neutral (center) position

mm (in.)

Scan tool

ROM pack

VEHICLE WASHING

If high-pressure car-washing equipment or steam car -washing

equipment is used to wash the vehicle, be maintain

the spray nozzle at a distance of at ‘least 300 mm (12 in.)

from any plastic parts and all opening parts (doors , luggage

compartment, etc.).

APPLYING ANTI-CORROSION

OTHER UNDERCOAT AGENTS.,

Be careful not to adhere oil or grease to the heate d oxygen

sensor. If adhered, the sensor may malfunction.

Protect the heated oxygen sensor with a cover befor e applying

anti-corrosion agent, etc.

SCAN TOOL

To operate the scan tool, refer to the “MUT-II OPER ATING

INSTRUCTIONS”.

Caution

Turn the ignition switch off befoie connecting and discon-

necting the scan tool.

Page 69 of 2103

ENGINE On-vehicle

A/C COMPRESSOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen tension pulley fixing bolt A.

2. Adjust belt tension with adjusting bolt B.

Standard value:

Items

Tension

(Ibs.)

Deflection

When a new belt isWhen a used belt is

installedinstalled

382-411255-333

6.5-7.5

3. Tighten fixing nut A.

Tightening torque: 23-26 Nm

4.Check the belt deflection and readjust if neces-

sary.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

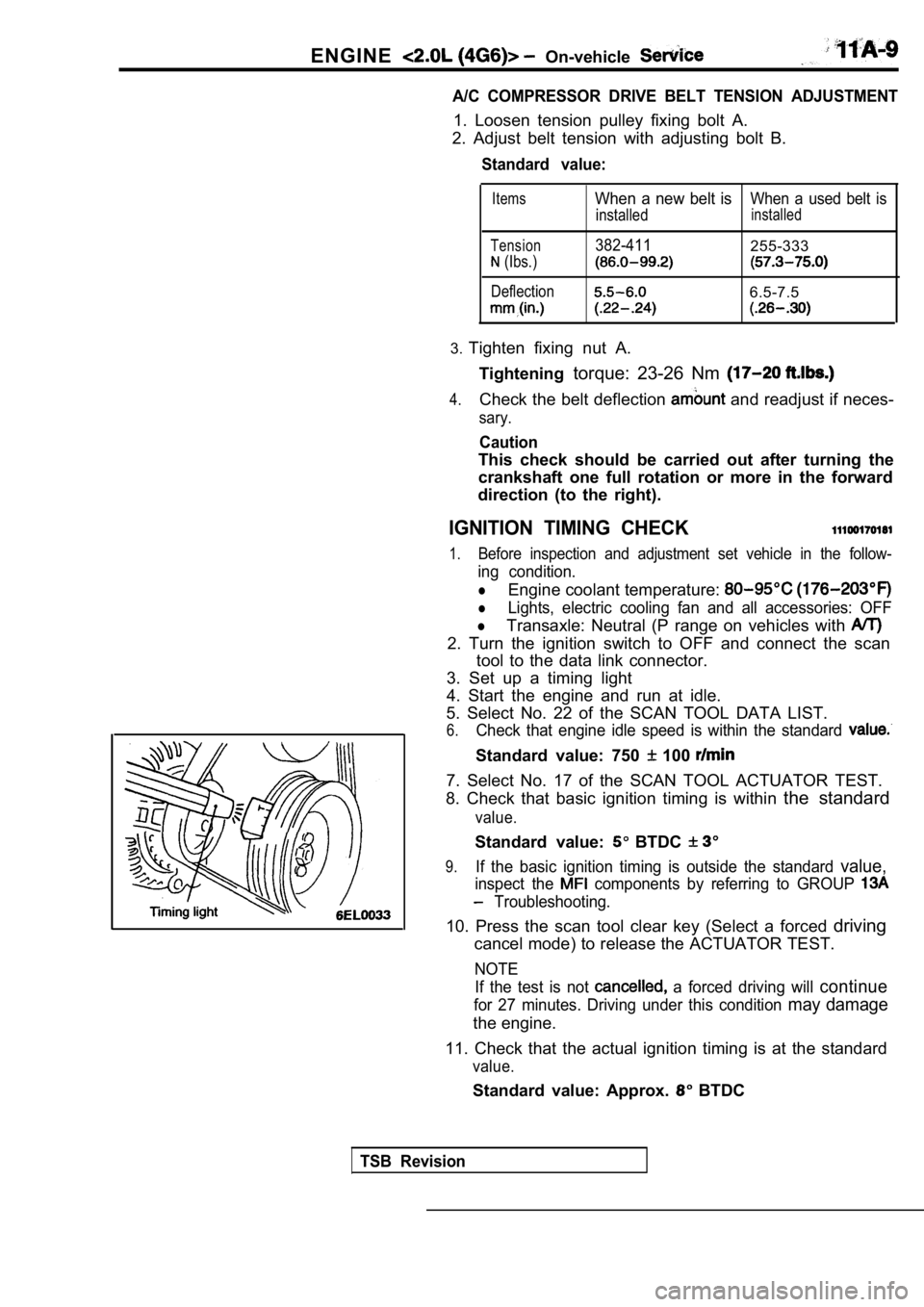

IGNITION TIMING CHECK

1.Before inspection and adjustment set vehicle in the follow-

ing condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Set up a timing light

4. Start the engine and run at idle.

5. Select No. 22 of the SCAN TOOL DATA LIST.

6.Check that engine idle speed is within the standard

Standard value: 750 100

7. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

8. Check that basic ignition timing is within the standard

value.

Standard value: BTDC

9.If the basic ignition timing is outside the standar d value,

inspect the components by referring to GROUP

Troubleshooting.

10. Press the scan tool clear key (Select a forced driving

cancel mode) to release the ACTUATOR TEST.

NOTE

If the test is not

a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

11. Check that the actual ignition timing is at the standard

value.

Standard value: Approx. BTDC

TSB Revision

Page 70 of 2103

ENGINE On-vehicle Service

NOTE

1.Ignition timing is variable within about even under

operating.

2. And it is automatically further advanced by abou t

from BTDC at higher altitudes.

CURB IDLE SPEED CHECK

1. Before inspection and adjustment, set vehicles in the

following condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

4. Check the basic ignition timing.

Standard

BTDC

5. Run the engine at idle for 2 minutes.

6. Select No. 22 of the SCAN TOOL DATA LIST.

7. Check the curb idle speed.

Standard value: 750

100

NOTE

The idle speed is controlled automatically by the i dle air

control system.

8. If the idle speed is outside the standard value, inspect

the components by referring to GROUP Trou-

bleshooting.

IDLE MIXTURE CHECK .

1.Before inspection, set in following

lEngine coolant temperature:

lLights, electric cooling fan all

lTransaxle: Neutral (P range on

2. Turn the ignition switch to OFF and, connect the scan

tool to the data link ,

3. Select No. 17 of the SCAN TOOL

4.Check that the basic ignition

value.

Standard value: BTDC

5. Run the engine 2,500 for 2 minutes.

6. Set the CO, HC tester.

7. Check the CO contents and the HC contents, at id le.

Standard value: CO contents: 0.5% or less

HC contents: 100 rpm or less

Revision

Page 71 of 2103

ENGINE On-vehicle

8. If the standard value is exceeded, check the following

items:

l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the catalyst whenever the

HC contents do not remain inside the standard value .

(even though the result of the inspection is

all items.).

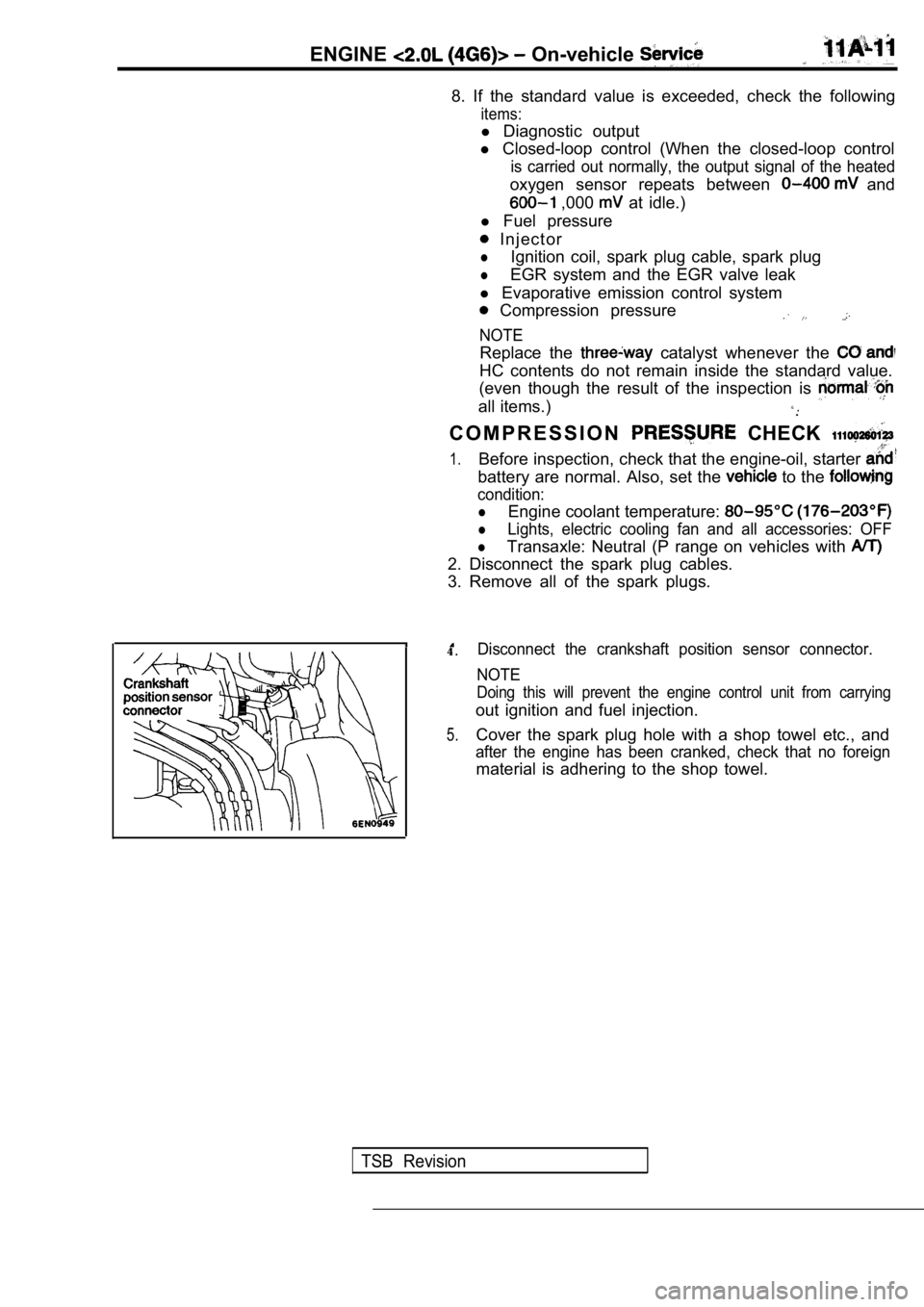

C O M P R E S S I O N

CHECK

1.Before inspection, check that the engine-oil, start er

battery are normal. Also, set the to the

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2. Disconnect the spark plug cables.

3. Remove all of the spark plugs.

4.

5.

Disconnect the crankshaft position sensor connector .

NOTE

Doing this will prevent the engine control unit fro m carrying

out ignition and fuel injection.

Cover the spark plug hole with a shop towel etc., a nd

after the engine has been cranked, check that no fo reign

material is adhering to the shop towel.

TSB Revision

Page 73 of 2103

ENGINE On-vehicle Service

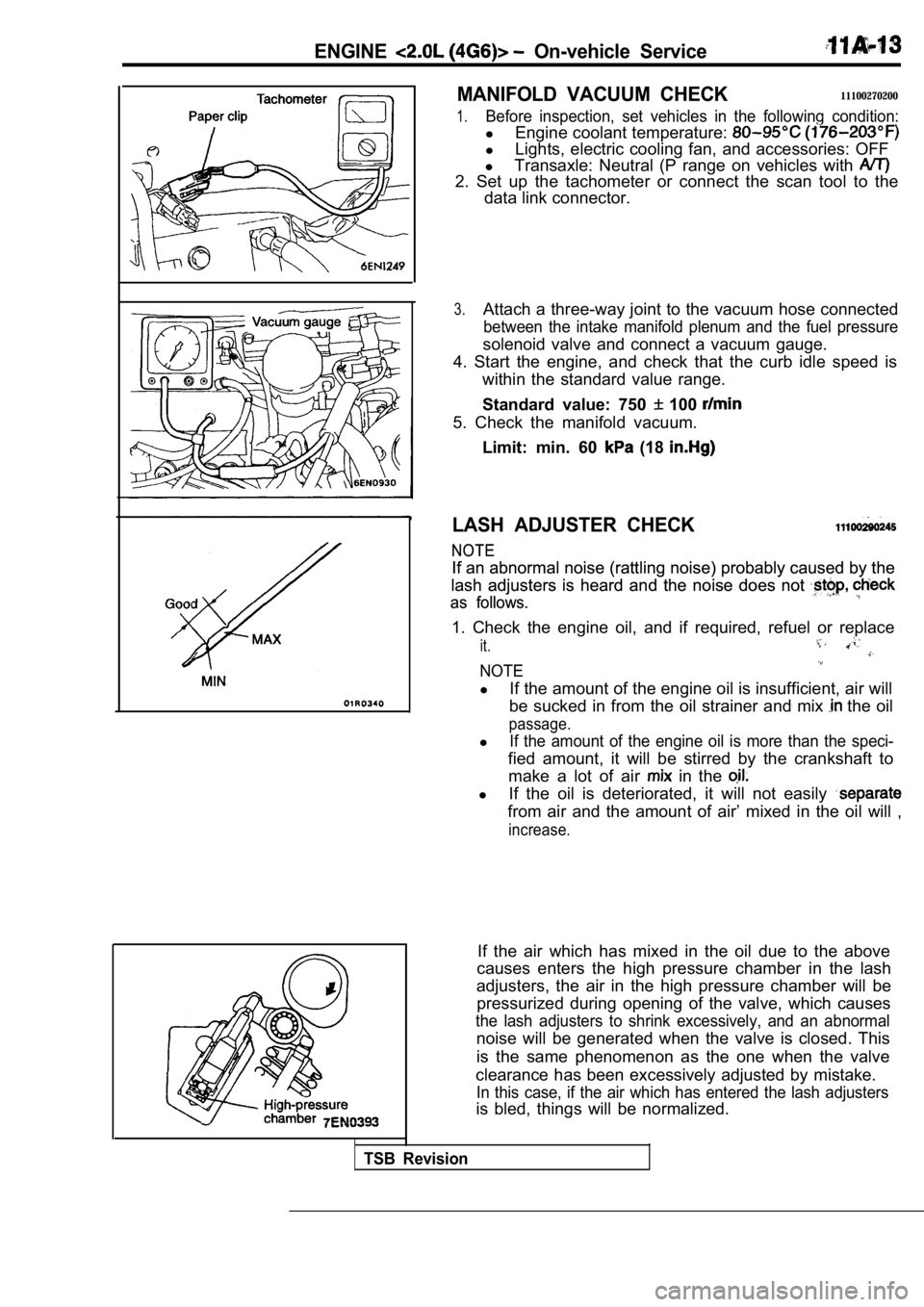

MANIFOLD VACUUM CHECK11100270200

1.Before inspection, set vehicles in the following condition:

lEngine coolant temperature:

lLights, electric cooling fan, and accessories: OFF

l Transaxle: Neutral (P range on vehicles with

2. Set up the tachometer or connect the scan tool t o the

data link connector.

3.Attach a three-way joint to the vacuum hose connect ed

between the intake manifold plenum and the fuel pressure

solenoid valve and connect a vacuum gauge.

4. Start the engine, and check that the curb idle s peed is

within the standard value range.

Standard value: 750

100

5. Check the manifold vacuum.

Limit: min. 60

(18

LASH ADJUSTER CHECK

NOTE

NOTE

If an abnormal noise (rattling noise) probably caus ed by the

If an abnormal noise (rattling noise) probably caus ed by the

lash adjusters is heard and the noise does not

lash adjusters is heard and the noise does not

as follows.

as follows.

1. Check the engine oil, and if required, refuel or replace

it.

NOTE

lIf the amount of the engine oil is insufficient, ai r will

be sucked in from the oil strainer and mix

the oil

passage.

lIf the amount of the engine oil is more than the sp eci-

fied amount, it will be stirred by the crankshaft to

make a lot of air

in the

l If the oil is deteriorated, it will not easily

from air and the amount of air’ mixed in the oil wi ll ,

increase.

If the air which has mixed in the oil due to the ab ove

causes enters the high pressure chamber in the lash

adjusters, the air in the high pressure chamber wil l be

pressurized during opening of the valve, which caus es

the lash adjusters to shrink excessively, and an abnormal

noise will be generated when the valve is closed. T his

is the same phenomenon as the one when the valve

clearance has been excessively adjusted by mistake.

In this case, if the air which has entered the lash adjusters

is bled, things will be normalized.

TSB Revision

Page 136 of 2103

ENGINE OVERHAUL Rocker, Arms

Camshaft sprocket side

sidecamshaft

Dowel pin

n0

Cap number

Symbol identifying

intake or exhaust

0

Camshaft sprocket side1197 810 12

2 6

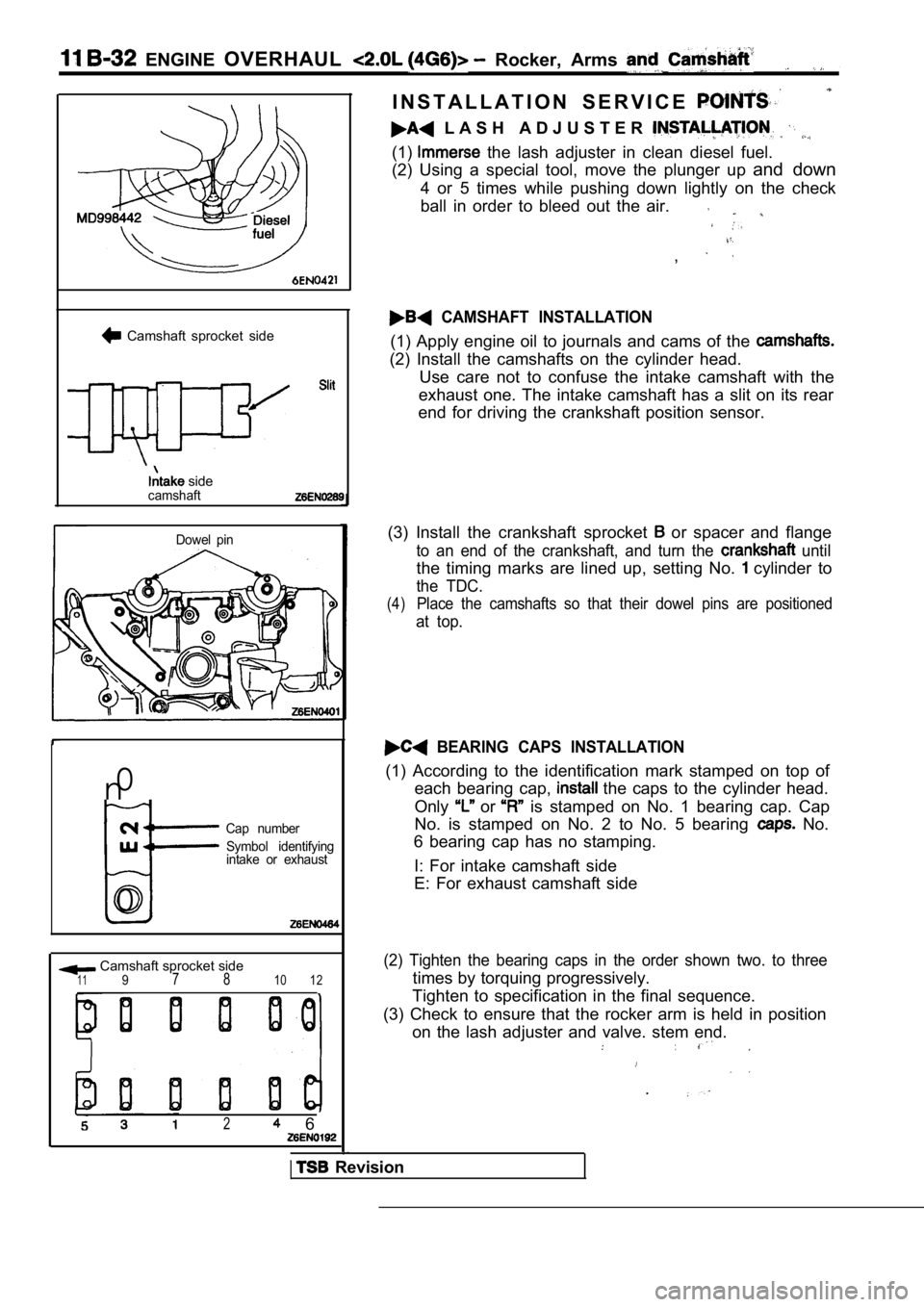

I N S T A L L A T I O N S E R V I C E

L A S H A D J U S T E R

(1) the lash adjuster in clean diesel fuel.

(2) Using a special tool, move the plunger up and down

4 or 5 times while pushing down lightly on the chec k

ball in order to bleed out the air.

,

CAMSHAFT INSTALLATION

(1) Apply engine oil to journals and cams of the

(2) Install the camshafts on the cylinder head. Use care not to confuse the intake camshaft with th e

exhaust one. The intake camshaft has a slit on its rear

end for driving the crankshaft position sensor.

(3) Install the crankshaft sprocket

or spacer and flange

to an end of the crankshaft, and turn the until

the timing marks are lined up, setting No. cylinder to

the TDC.

(4)Place the camshafts so that their dowel pins are po sitioned

at top.

BEARING CAPS INSTALLATION

(1) According to the identification mark stamped on top of

each bearing cap,

the caps to the cylinder head.

Only

or is stamped on No. 1 bearing cap. Cap

No. is stamped on No. 2 to No. 5 bearing

No.

6 bearing cap has no stamping.

I: For intake camshaft side

E: For exhaust camshaft side

(2) Tighten the bearing caps in the order shown two . to three

times by torquing progressively.

Tighten to specification in the final sequence.

(3) Check to ensure that the rocker arm is held in position

on the lash adjuster and valve. stem end.

.

Revision

Page 138 of 2103

11 ENGINE OVERHAUL Rocker

.

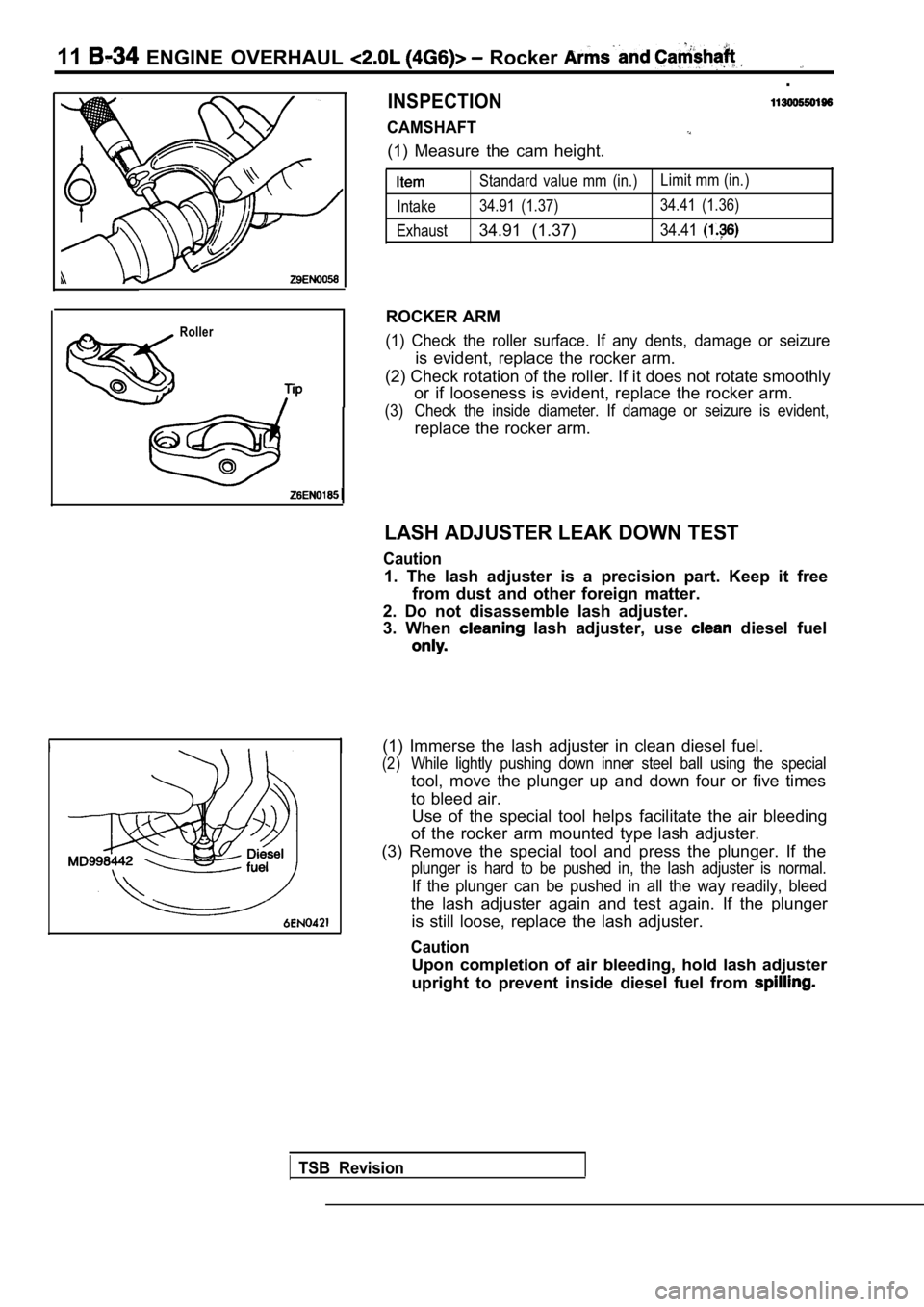

INSPECTION

CAMSHAFT

(1) Measure the cam height.

Roller

Standard value mm (in.)Limit mm (in.)

Intake 34.91 (1.37) 34.41 (1.36)

Exhaust

34.91 (1.37)34.41

ROCKER ARM

(1) Check the roller surface. If any dents, damage or seizure

is evident, replace the rocker arm.

(2) Check rotation of the roller. If it does not ro tate smoothly

or if looseness is evident, replace the rocker arm.

(3) Check the inside diameter. If damage or seizure is evident,

replace the rocker arm.

LASH ADJUSTER LEAK DOWN TEST

Caution

1. The lash adjuster is a precision part. Keep it f ree

from dust and other foreign matter.

2. Do not disassemble lash adjuster.

3. When

lash adjuster, use diesel fuel

(1) Immerse the lash adjuster in clean diesel fuel.

(2)While lightly pushing down inner steel ball using t he special

tool, move the plunger up and down four or five tim es

to bleed air. Use of the special tool helps facilitate the air bl eeding

of the rocker arm mounted type lash adjuster.

(3) Remove the special tool and press the plunger. If the

plunger is hard to be pushed in, the lash adjuster is normal.

If the plunger can be pushed in all the way readily, bleed

the lash adjuster again and test again. If the plun ger

is still loose, replace the lash adjuster.

Caution

Upon completion of air bleeding, hold lash adjuster

upright to prevent inside diesel fuel from

TSB Revision

Page 161 of 2103

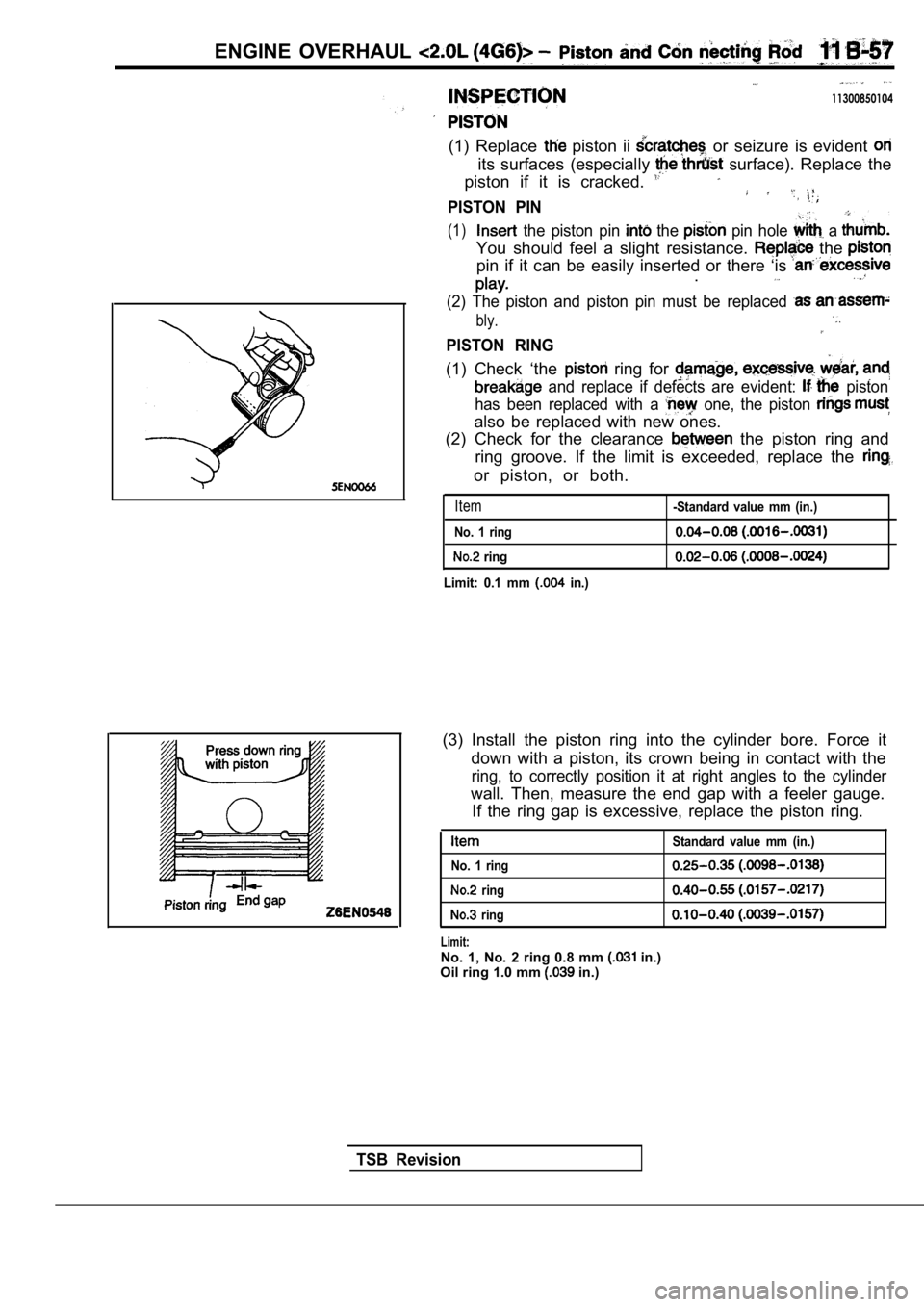

ENGINE OVERHAUL

11300850104

(1) Replace piston ii or seizure is evident

its surfaces (especially surface). Replace the

piston if it is cracked.

PISTON PIN

(1) the piston pin the pin hole a

You should feel a slight resistance. the

pin if it can be easily inserted or there ‘is .

(2) The piston and piston pin must be replaced

bly.

PISTON RING

(1) Check ‘the ring for

and replace if defects are evident: piston

has been replaced with a

one, the piston

also be replaced with new ones.

(2) Check for the clearance

the piston ring and

ring groove. If the limit is exceeded, replace the

or piston, or both.

Item

No. 1 ring

ring

Limit: 0.1 mm

in.)

-Standard value mm (in.)

(3) Install the piston ring into the cylinder bore. Force it

down with a piston, its crown being in contact with the

ring, to correctly position it at right angles to the cylinder

wall. Then, measure the end gap with a feeler gauge .

If the ring gap is excessive, replace the piston ri ng.

Standard value mm (in.)

No. 1 ring

ring

ring

Limit:No. 1, No. 2 ring 0.8 mm in.)

Oil ring 1.0 mm in.)

TSB Revision

Page 180 of 2103

ENGINE On-vehicle Service

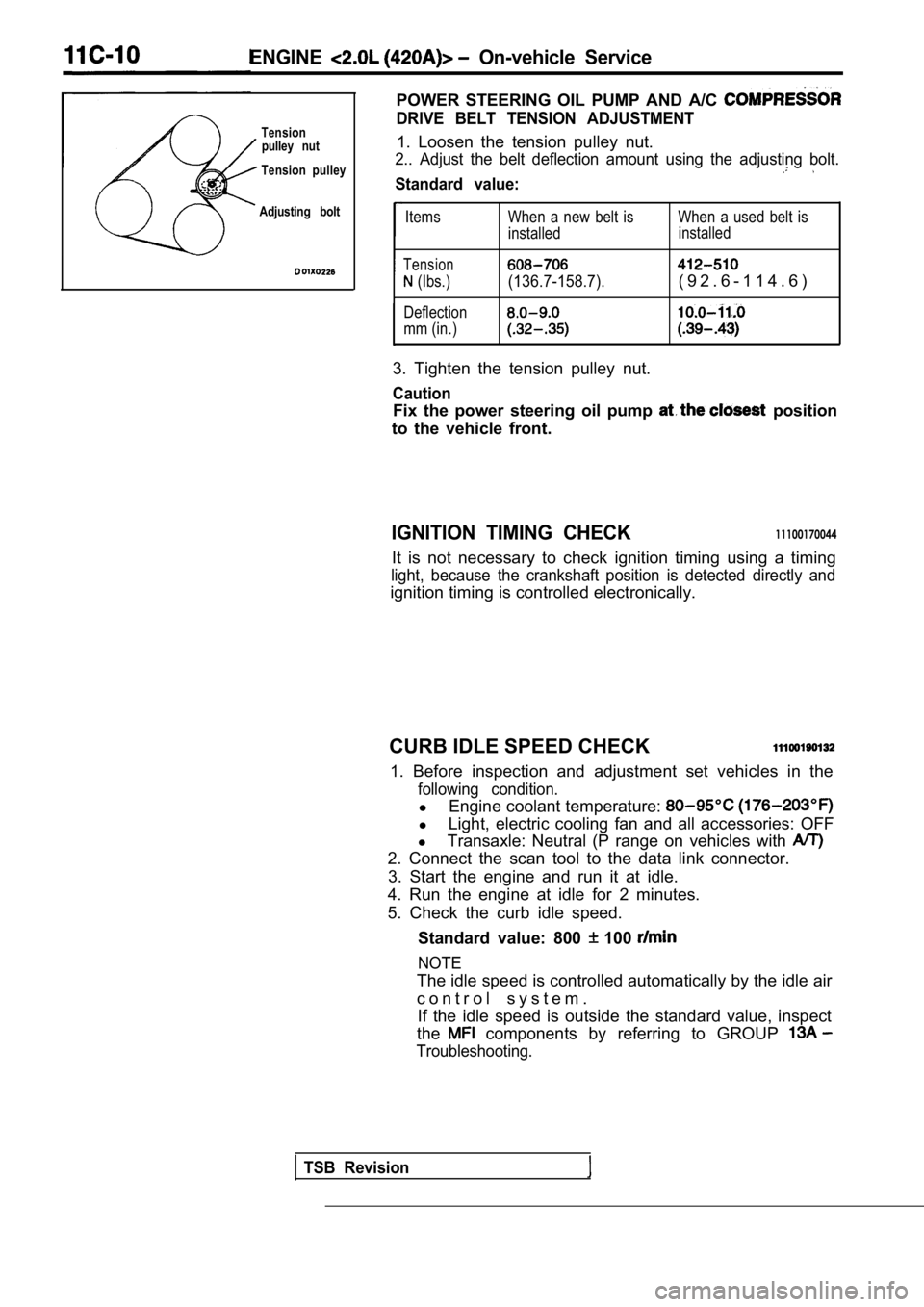

POWER STEERING OIL PUMP AND A/C

DRIVE BELT TENSION ADJUSTMENTTensionpulley nut1. Loosen the tension pulley nut.

Tension pulley2.. Adjust the belt deflection amount using the adj usting bolt.

Standard value:

Adjusting boltItems

Tension

(Ibs.)

Deflection

mm (in.) When a new belt is When a used belt is

installed

installed(136.7-158.7).( 9 2 . 6 - 1 1 4 . 6 )

3. Tighten the tension pulley nut.

Caution

Fix the power steering oil pump position

to the vehicle front.

IGNITION TIMING CHECK11100170044

It is not necessary to check ignition timing using a timing

light, because the crankshaft position is detected directly and

ignition timing is controlled electronically.

CURB IDLE SPEED CHECK

1. Before inspection and adjustment set vehicles in the

following condition.

lEngine coolant temperature:

lLight, electric cooling fan and all accessories: OF F

l Transaxle: Neutral (P range on vehicles with

2. Connect the scan tool to the data link connector .

3. Start the engine and run it at idle.

4. Run the engine at idle for 2 minutes.

5. Check the curb idle speed.

Standard value: 800

100

NOTE

The idle speed is controlled automatically by the i dle air

c o n t r o l s y s t e m . If the idle speed is outside the standard value, in spect

the

components by referring to GROUP

Troubleshooting.

TSB Revision

Page 181 of 2103

ENGINE On-vehicle Service

IDLE MIXTURE CHECK

11100210081

1.Before inspection, set vehicles in the following co ndition:

lEngine coolant temperature:

l Lights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2.After turning the ignition switch to OFF, connect t he scan

tool to the data link connector.

3.Start the engine and run it at 2,500 for 2 minutes.

4. Set the CO, HC tester.

5. Check the CO contents and the HC contents at idl e.

Standard value:

CO contents: 0.5% or less

HC contents: 100 ppm or less

6. If the idle speed is outside the standard value, check

the following items: l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the three-way catalyst whenever the CO and

HC contents do not remain inside the standard value .

(even though the result of the inspection is normal on

all items.)

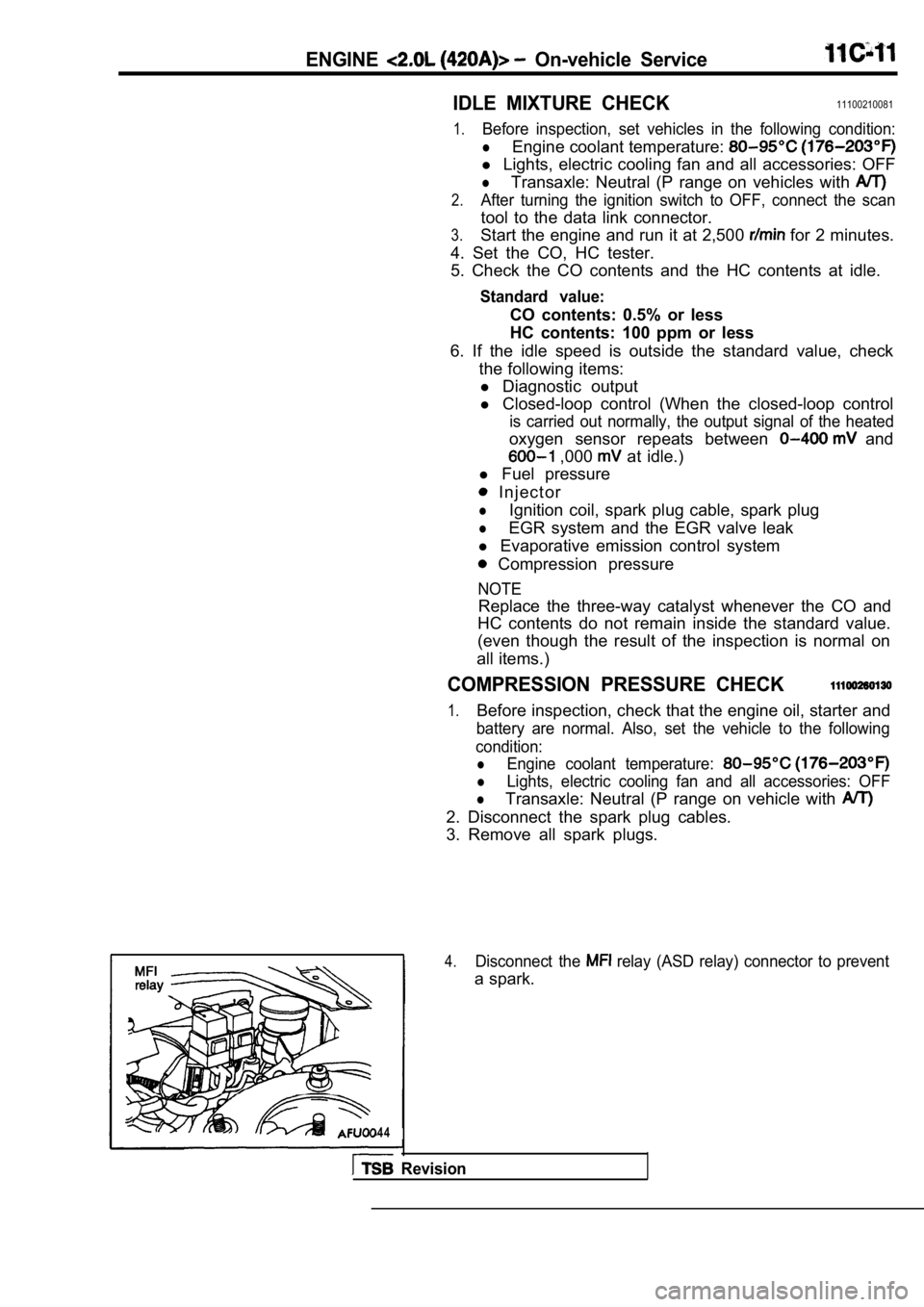

COMPRESSION PRESSURE CHECK

1.Before inspection, check that the engine oil, start er and

battery are normal. Also, set the vehicle to the fo llowing

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicle with

2. Disconnect the spark plug cables.

3. Remove all spark plugs.

4.Disconnect the relay (ASD relay) connector to prevent

a spark.

4 4

Revision