display MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 8 of 2103

G E N E R A L How to Use Troubleshooting/Inspection Service Points

Troubleshooting of electronic control systems for which the scan tool the basic outline

described below. Furthermore, even in systems for w hich the scan tool cannot be used, part of these

systems still follow this outline.

TROUBLESHOOTING CONTENTS

1. STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

The main procedures for diagnostic troubleshooting are shown.

2. SYSTEM OPERATION AND SYMPTOM VERIFICATION TESTS If verification of the trouble symptoms is difficul t, procedures for checking operation and verifying

trouble symptoms are shown.

3. DIAGNOSTIC FUNCTION The following diagnostic functions are shown.

l ,Method of reading diagnostic trouble codes

Method of erasing diagnostic trouble codes

lInput inspection service points

4. INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

5. INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODE S

Indicates the inspection procedures corresponding t o each diagnostic trouble code. (Refer to the

next page on how to use the inspection procedures.)

6. INSPECTION CHART FOR TROUBLE SYMPTOMS

If there are trouble symptoms, even though the scan tool displays no diagnostic inspection

procedures for each trouble symptom will be found b y means of this chart.

7. INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Indicates the inspection procedures corresponding t o each trouble symptoms the Inspection

Chart for Trouble Symptoms. (Refer to the next page on how to use the inspection procedures.)

8. DATA LIST REFERENCE TABLE

Inspection items and normal judgement values have b een provided in this chart as reference

9. CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspection items and standard values have been provided

in this chart as reference information.

Terminal Voltage Checks

1. Connect a needle-nosed wire probe or paper clip to a voltmeter probe.

2.Insert the needle-nosed wire probe into each of the ECU connector from the wire side,

and measure the voltage while referring to the chec k chart.

NOTE

1. Measure voltage with the ECU connectors connecte d.

2. You may find it convenient to pull out the ECU t o make it easier to reach the connector

terminals.

3. Checks don’t have to be carried out in the order given in the chart.

Short-circuiting the positive probe between a connector damage

the vehicle wiring, the sensor, the ECU, or all thr ee.

Use care to prevent this

3. If voltage readings differ from Normal Condition values, related actuators, and

wiring, then replace or repair.

TSB Revision

Page 35 of 2103

GENERAL Lubrication arid Maintenance,

00100120067

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual ve-

hicle owner’s driving habits, the area in which the

vehicle is operated and the type of to which

the vehicle is subjected, it is necessary to prescr ibe

lubrication and maintenance service on a time fre-

quency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by

the Society of Automotive Engineers (SAE), the

American Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”. Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item

in the “MAINTENANCE SERVICE” section.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information is included in ap-

propriate units for vehicles operating under one

or more of the following conditions:

1. Police, taxi, or commercial type operation

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traf-

fic during hot weather above

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

Either of the following engine oils should be used:

(1) Engine oil displaying EOLCS certification mark

(2) Engine oil conforming to the API classification SH

or ECII.

For further details, refer to “LUBRICANTS SELEC-

TION” section.

Caution

Test to EPA have shown

laboratory animals develop skin after

prolonged contact with used engine oil. Accord-

ingly, the potential exists for

to

a number:, of skin disorders, including

from such exposure to used

Care should be taken, when changing

engine oil, to minimize the

of exposure time to used your

skin. Protective clothing and that

be penetrated by worn.

should be thoroughly with soap

use waterless hand remove,

any used engine oil. Do not use gasoline, thin- ners, or solvents.

GEAR LUBRICANTS

The SAE grade number indicates

of Multi-purpose Gear Lubricants.

The API classification system

cants in terms of gear lubricants

conforming to API

or ‘with a

of SAE are recommended for

transaxle.

LUBRICANTS GREASES

Semi-solid lubricants bear the

designation

and are further classified as grades 0, 1, 2; 3 etc .

Whenever “Chassis Lubricant” is specified, Multi-

purpose Grease,

grade 2, should be used.

FUEL USAGE

Your car must use unleaded

This car has a fuel filler tube especially

to accept only the smaller-diameter unleaded gaso- line dispensing nozzle.

Caution

Using leaded gasoline in your car will damage

the catalytic converter and oxygen sensor, and

affect the warranty coverage validity.

Your car is designed to operate on premium

leaded gasoline having a minimum octane rating

of 91 or 95 RON (Research Octane

If premium unleaded gasoline is not

leaded gasoline having a octane rating of 87,

91 RON (Research Octane Number) may be used. In this case, the performance and fuel consumption

will suffer a little degradation.

Gasolines Containing Alcohol

Some gasolines sold at service stations contain

alcohol, although they may not be so identified.

TSB Revision

Page 36 of 2103

Lubrication and

GENERAL Lubricants and Lubricant Capacities Table

Use of fuels containing alcohol is not recommended

unless the nature of the blend can be determined

as being satisfactory.

Gasohol

A mixture of 10% ethanol (grain alcohol)

and 90% unleaded gasoline may be used in your

car.

If problems are experienced as a result

of using gasohol, it is recommended that the car

be operated on gasoline.

Methanol Do not use gasolines containing

methanol (wood alcohol). Use of this type of alcohol

can result in vehicle performance deterioration and

damage critical parts in the fuel system compo-

nents. Fuel system damage and performance prob-

lems, resulting from the use of gasolines containin g

methanol, may not be covered by the new car war-

ranty.

Gasolines containing

Ether)

Unleaded gasoline containing 15% or

may be used in car. Fuel containing MTBE

over 15% vol. may cause reduced engine perfor-

mance and produce vapor lock or hard starting.

MATERIALS

TO FUEL

Indiscriminate use of fuel system -cleaning’

should be avoided. Many of these materials in-

tended for gum and varnish removal

highly active solvents or similar ingredients that

can be harmful to gasket and diaphragm materials

used in fuel system component

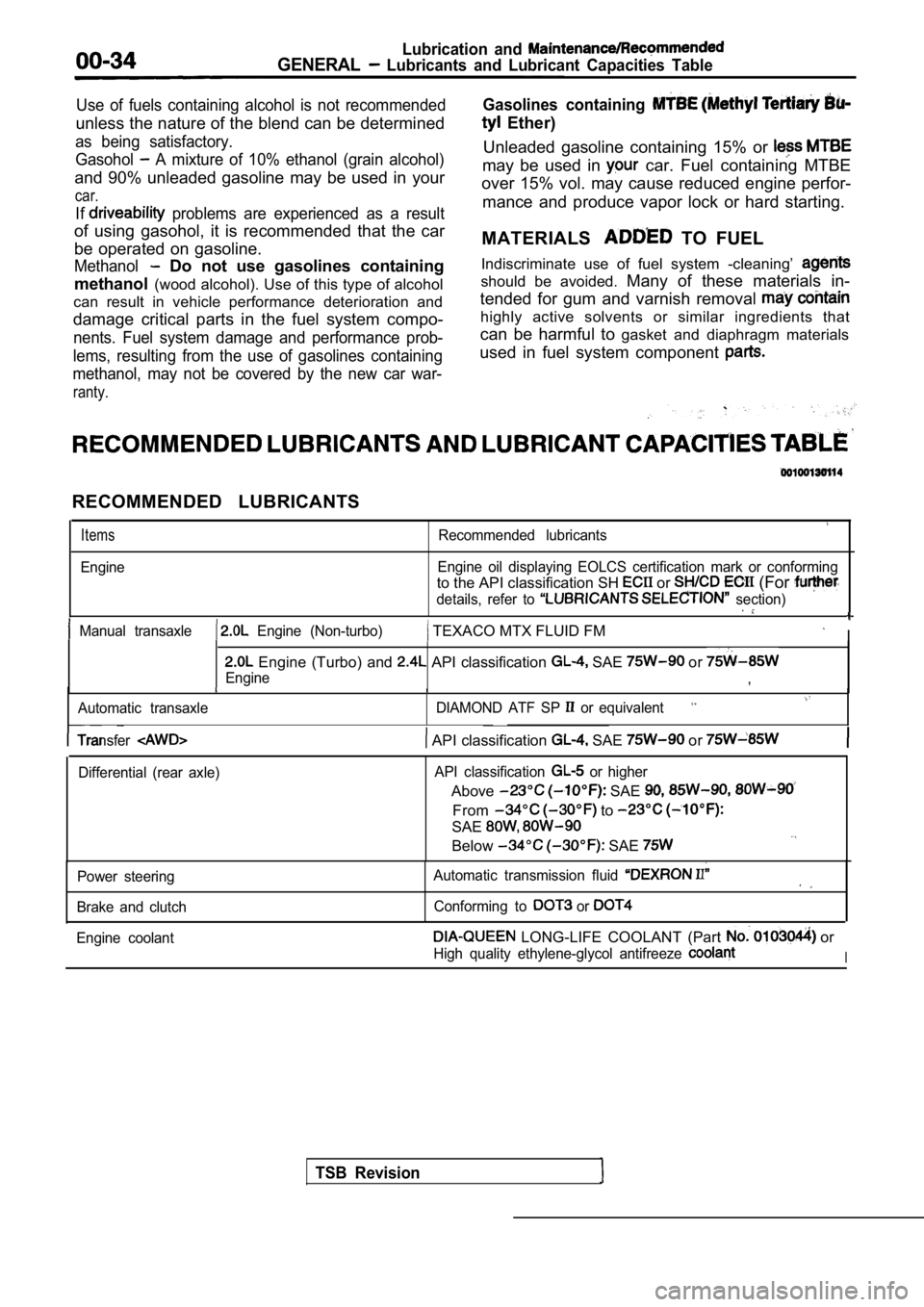

RECOMMENDED LUBRICANTS

Items

Engine

Recommended lubricants

Engine oil displaying EOLCS certification mark or c onforming

to the API classification SH or (For

details, refer to section)

Manual transaxle Engine (Non-turbo) TEXACO MTX FLUID FM I

Engine (Turbo) and API classification SAE or

Engine,

Automatic transaxle DIAMOND ATF SP or equivalent

TSB Revision

Transfer API classification SAE or

Differential (rear axle)API classification or higher

Above SAE

From to

SAE

Below SAE

Power steering

Brake and clutch Automatic transmission fluid

Conforming to or

Engine coolant LONG-LIFE COOLANT (Part or

High quality ethylene-glycol antifreeze I

Page 37 of 2103

GENERAL Recommended Lubricants and Lubricant Table

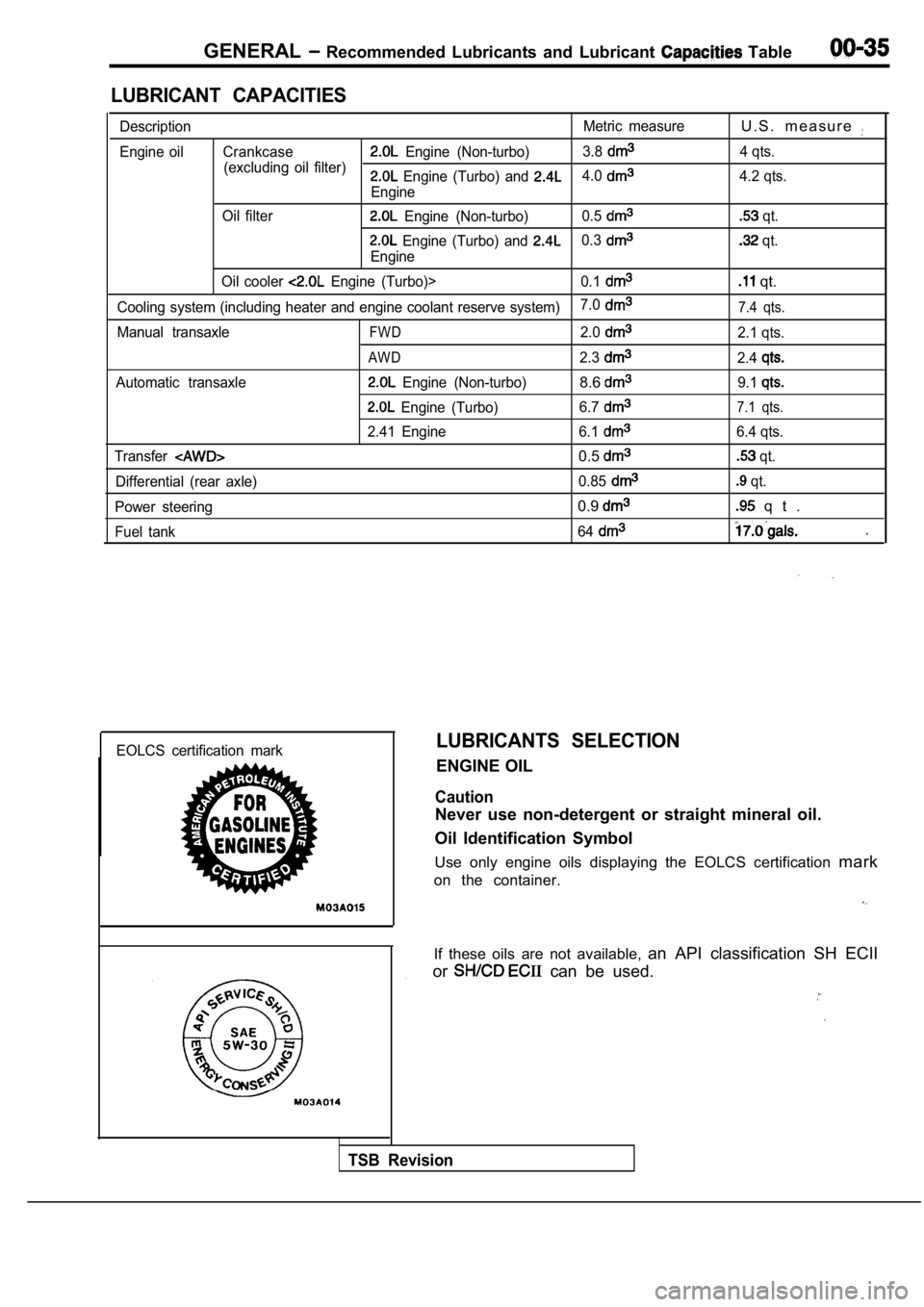

LUBRICANT CAPACITIES

DescriptionMetric measureU . S . m e a s u r e

Engine oil Crankcase Engine (Non-turbo)3.8

(excluding oil filter) 4 qts. Engine (Turbo) and 4.0

Engine4.2 qts.

Oil filter

Engine (Non-turbo) 0.5 qt.

Engine (Turbo) and 0.3

Engine

qt.

Oil cooler

Engine (Turbo)> 0.1 qt.

Cooling system (including heater and engine coolant reserve system)7.07.4 qts.

Manual transaxleFWD2.02.1 qts.

AWD2.32.4

Automatic transaxle Engine (Non-turbo)8.69.1

Engine (Turbo)

6.77.1 qts.

2.41 Engine 6.16.4 qts.

Transfer

0.5 qt.

Differential (rear axle) 0.85

qt.

Power steering

0.9 q t .

Fuel tank 64

EOLCS certification markLUBRICANTS SELECTION

ENGINE OIL

Caution

Never use non-detergent or straight mineral oil.

Oil Identification Symbol

Use only engine oils displaying the EOLCS certifica tion mark

on the container.

If these oils are not available, an API classification SH ECII

or

can be used.

TSB Revision

Page 374 of 2103

ENGINE LUBRICATION General Information/Lubricants

G E N E R A L I N F O R M A T I O N

The lubrication method is a fully force-fed, full-f low

filtration type.

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis .

In addition, used engine oil

potentially

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example

by using enclosed systems for handling used engine

oil and by degreasing components, where

practicable, before handling them.

Other precautions:

lAvoid prolonged and repeated contact with oils,

particularly used engine oils.

l Wear protective clothing, including impervious

gloves where practicable.

l Avoid contaminating clothes, particularly

underpants, with oil.

l Do not put oily rags in packets, the use of

overalls without pockets will avoid this.

l Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.

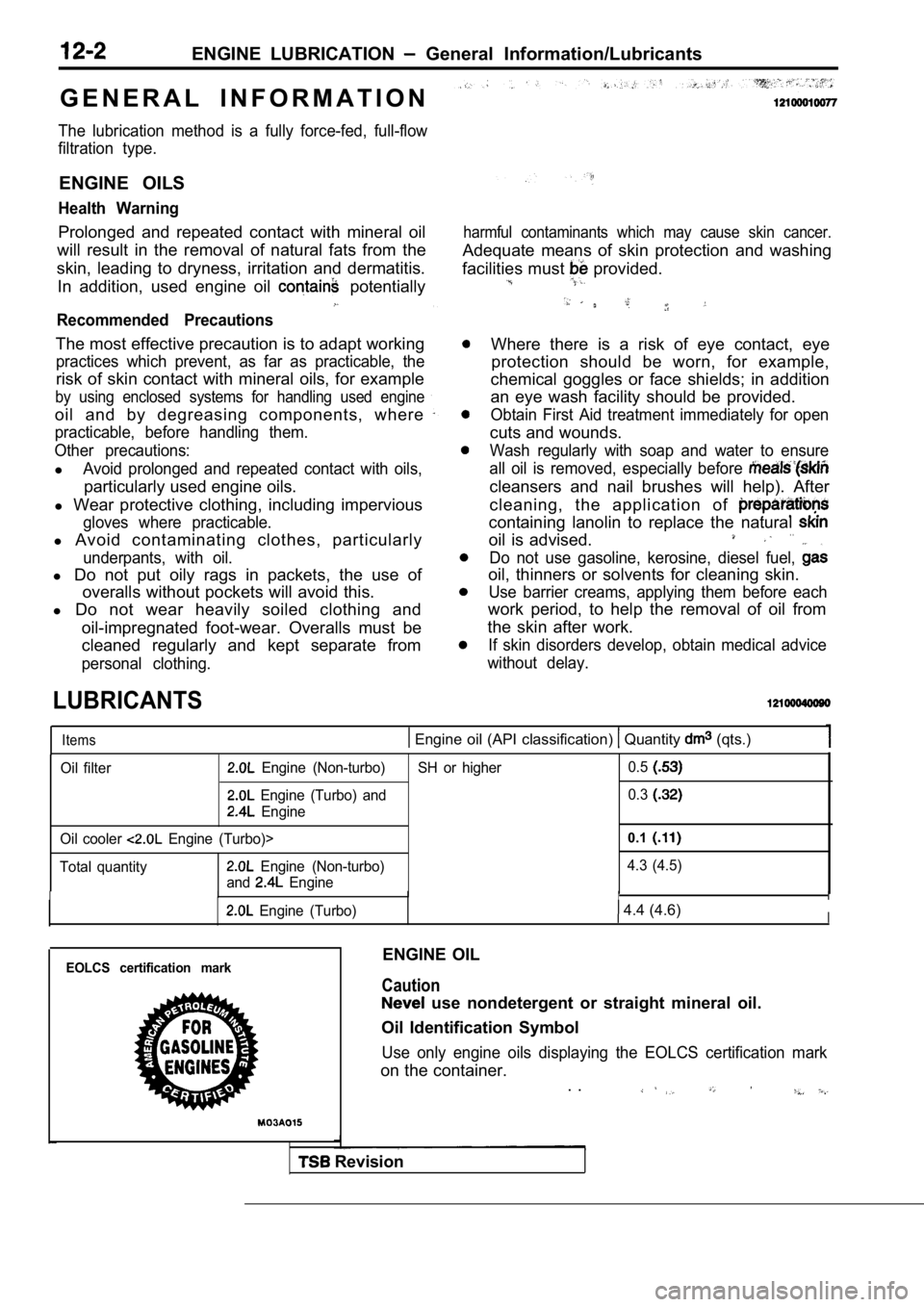

LUBRICANTS

harmful contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must

provided.

Where there is a risk of eye contact, eye protection should be worn, for example,

chemical goggles or face shields; in addition

an eye wash facility should be provided.

Obtain First Aid treatment immediately for open

cuts and wounds.

Wash regularly with soap and water to ensure

all oil is removed, especially before

cleansers and nail brushes will help). After

cleaning, the application of

containing lanolin to replace the natural

oil is advised.. .

Do not use gasoline, kerosine, diesel fuel,

oil, thinners or solvents for cleaning skin.

Use barrier creams, applying them before each

work period, to help the removal of oil from

the skin after work.

If skin disorders develop, obtain medical advice

without delay.

Items Engine oil (API classification) Quantity (qts.)

Oil filter Engine (Non-turbo)

Engine (Turbo) and

Engine

Oil cooler

Engine (Turbo)>

Total quantity

Engine (Non-turbo)

and

Engine SH or higher

0.5

0.3

0.1

4.3 (4.5)

IIIII

Engine (Turbo) 4.4 (4.6)I

EOLCS certification markENGINE OIL

Caution

use nondetergent or straight mineral oil.

Oil Identification Symbol

Use only engine oils displaying the EOLCS certifica tion mark

on the container.

. .

Revision

Page 391 of 2103

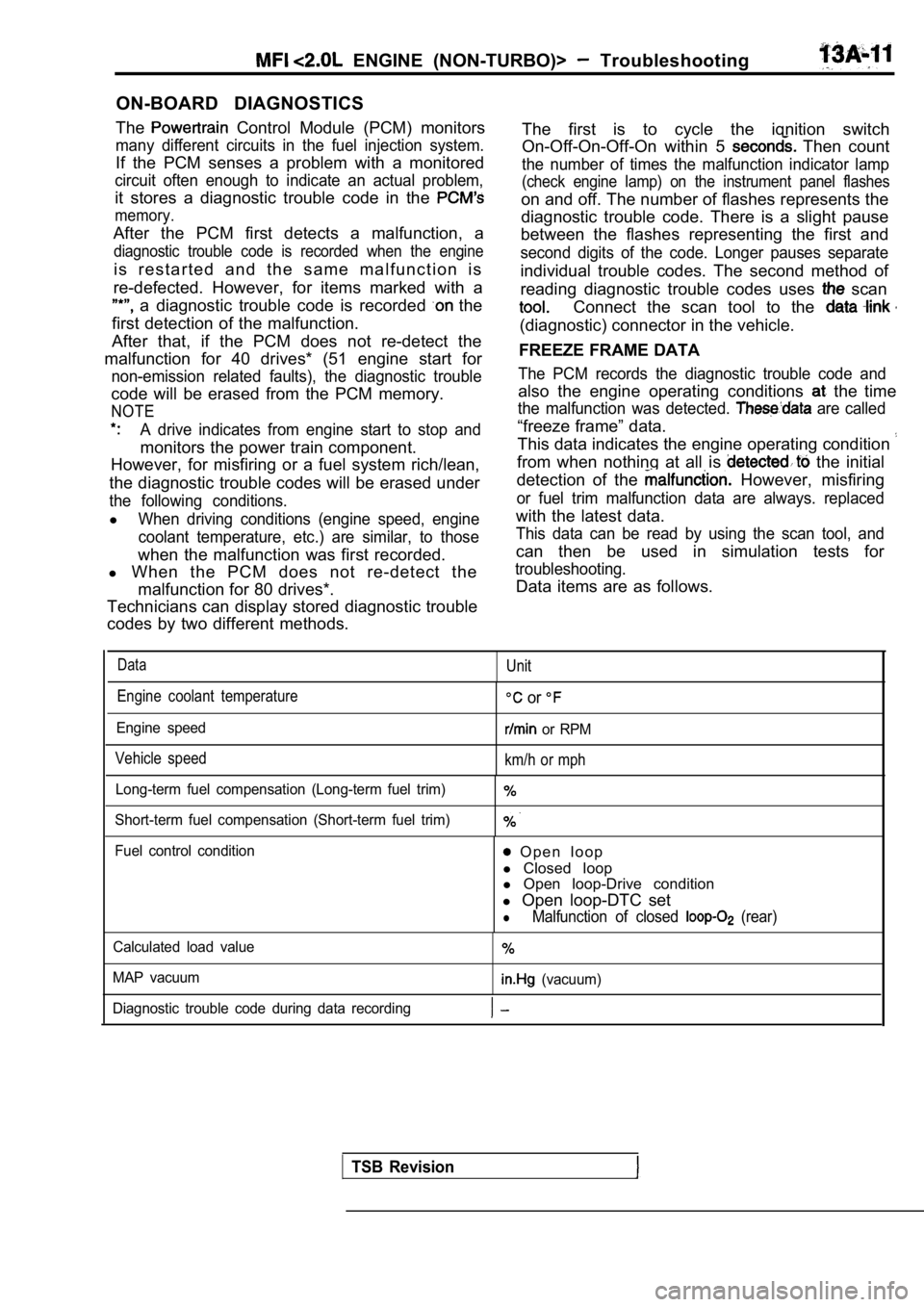

ON-BOARD DIAGNOSTICS

The

Control Module (PCM) monitors

many different circuits in the fuel injection syste m.

If the PCM senses a problem with a monitored

circuit often enough to indicate an actual problem,

it stores a diagnostic trouble code in the

memory.

After the PCM first detects a malfunction, a

diagnostic trouble code is recorded when the engine

i s r e s t a r t e d a n d t h e s a m e m a l f u n c t i o n i s

re-defected. However, for items marked with a

a diagnostic trouble code is recorded the

first detection of the malfunction.

After that, if the PCM does not re-detect the

malfunction for 40 drives* (51 engine start for

non-emission related faults), the diagnostic troubl e

code will be erased from the PCM memory.

NOTE

A drive indicates from engine start to stop and

monitors the power train component.

However, for misfiring or a fuel system rich/lean,

the diagnostic trouble codes will be erased under

the following conditions.

lWhen driving conditions (engine speed, engine

coolant temperature, etc.) are similar, to those

when the malfunction was first recorded.

l When the PCM does not re-detect the

malfunction for 80 drives*.

Technicians can display stored diagnostic trouble

codes by two different methods.

ENGINE (NON-TURBO)> Troubleshooting

The first is to cycle the ignition switch

On-Off-On-Off-On within 5

Then count

the number of times the malfunction indicator lamp

(check engine lamp) on the instrument panel flashes

on and off. The number of flashes represents the

diagnostic trouble code. There is a slight pause

between the flashes representing the first and

second digits of the code. Longer pauses separate

individual trouble codes. The second method of

reading diagnostic trouble codes uses

scan

Connect the scan tool to the

(diagnostic) connector in the vehicle.

FREEZE FRAME DATA

The PCM records the diagnostic trouble code and

also the engine operating conditions the time

the malfunction was detected. are called

“freeze frame” data.

This data indicates the engine operating condition

from when nothing at all is the initial

detection of the

However, misfiring

or fuel trim malfunction data are always. replaced

with the latest data.

This data can be read by using the scan tool, and

can then be used in simulation tests for

troubleshooting.

Data items are as follows.

DataUnit

Engine coolant temperature

Engine speed

Vehicle speed

or

or RPM

km/h or mph

Long-term fuel compensation (Long-term fuel trim)

Short-term fuel compensation (Short-term fuel trim)

Fuel control condition O p e n l o o p

l Closed loop

l Open loop-Drive condition

l Open loop-DTC set

lMalfunction of closed (rear)

Calculated load value

MAP vacuum

(vacuum)

Diagnostic trouble code during data recording

TSB Revision

Page 421 of 2103

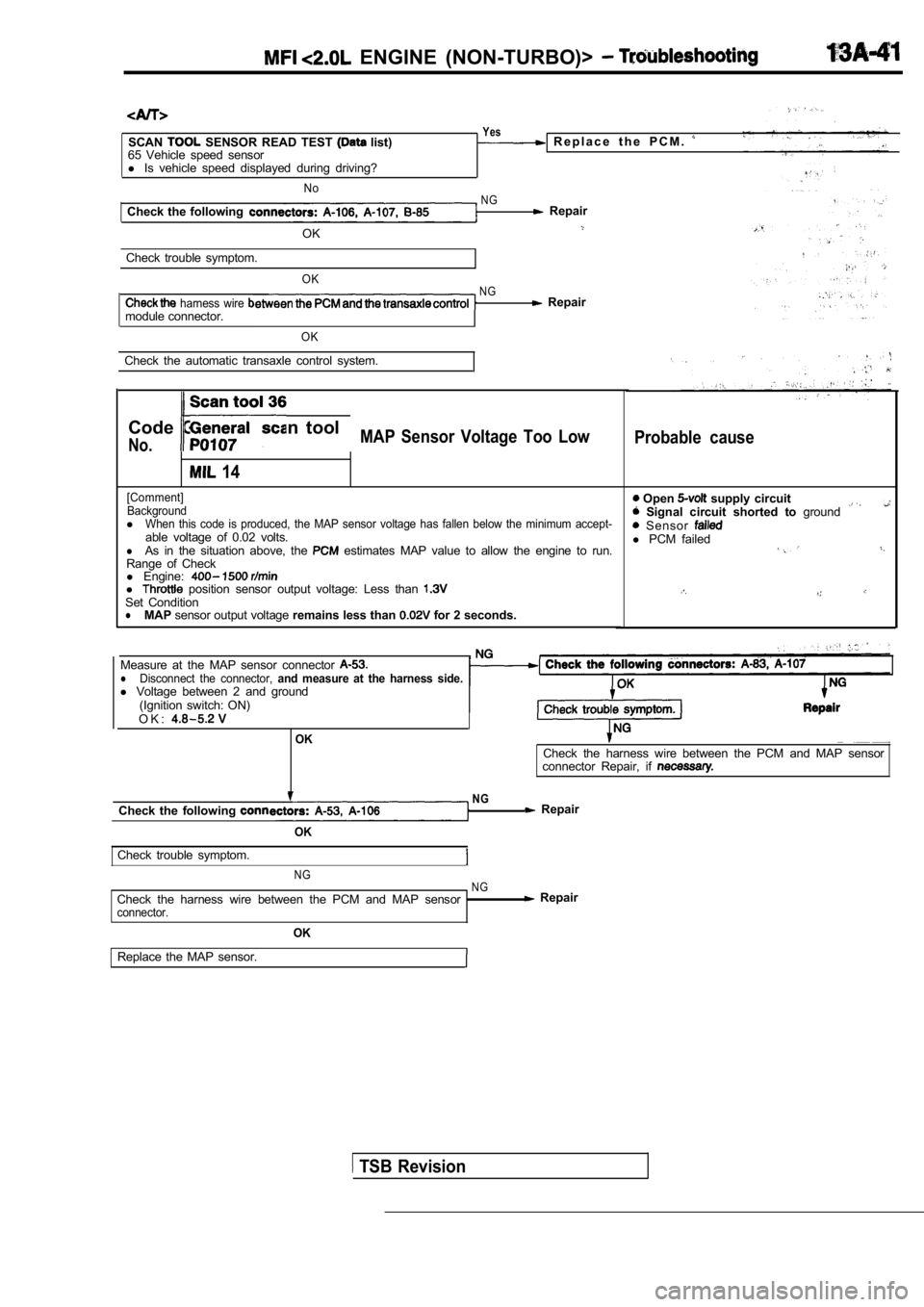

ENGINE (NON-TURBO)>

SCAN SENSOR READ TEST list)

65 Vehicle speed sensor

l Is vehicle speed displayed during driving?

No

Check the following

OK

Check trouble symptom.

OK

harness wire module connector.

OK

Yes R e p l a c e t h e P C M .

N G Repair

NG Repair

Check the automatic transaxle control system.

Code General scan tool

No.MAP Sensor Voltage Too Low

14

[Comment]Background

lWhen this code is produced, the MAP sensor voltage has fallen below the minimum accept-able voltage of 0.02 volts.lAs in the situation above, the estimates MAP value to allow the engine to run.

Range of Check

l Engine:

l position sensor output voltage: Less than Set ConditionlMAP sensor output voltage remains less than for 2 seconds.

Probable cause

Open supply circuit Signal circuit shorted to ground Sensor l PCM failed

Measure at the MAP sensor connector lDisconnect the connector, and measure at the harness side.l Voltage between 2 and ground

(Ignition switch: ON)

O K :

OKCheck the harness wire between the PCM and MAP sens or

connector Repair, if

NGCheck the following Repair

OK

Check trouble symptom.

N G NG

Check the harness wire between the PCM and MAP sens or Repairconnector.

OK

Replace the MAP sensor.

TSB Revision

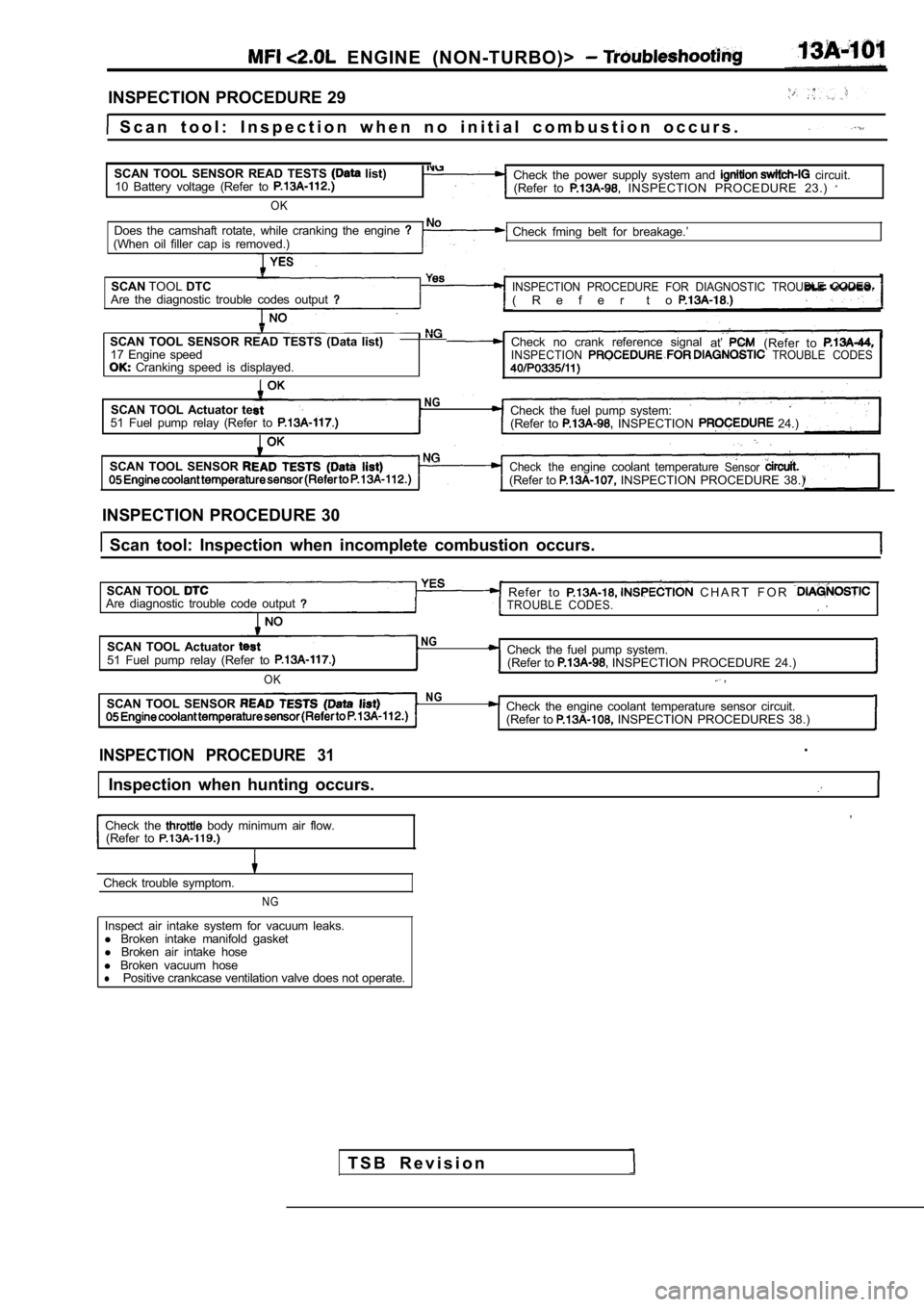

Page 481 of 2103

ENGINE (NON-TURBO)>

INSPECTION PROCEDURE 29

S c a n t o o l : I n s p e c t i o n w h e n n o i n i t i a l c o m b u s t i o n oc c u r s .

SCAN TOOL SENSOR READ TESTS

list)

10 Battery voltage (Refer to

OK

Check the power supply system and circuit.

(Refer to INSPECTION PROCEDURE 23.)

Does the camshaft rotate, while cranking the engine (When oil filler cap is removed.) Check fming belt for breakage.’

SCAN TOOLDTC

INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODES.Are the diagnostic trouble codes output( R e f e r t o

SCAN TOOL SENSOR READ TESTS (Data list) Check no crank reference signal

at’(Refer to 17 Engine speedINSPECTION TROUBLE CODES Cranking speed is displayed.

SCAN TOOL Actuator teNGCheck the fuel pump system:51 Fuel pump relay (Refer to (Refer to INSPECTION 24.)

SCAN TOOL SENSOR

Check theengine coolant temperatureSensor(Refer to INSPECTION PROCEDURE 38.)

INSPECTION PROCEDURE 30

Scan tool: Inspection when incomplete combustion o ccurs.

SCAN TOOL

Refer to C H A R T F O R Are diagnostic trouble code outputTROUBLE CODES.

SCAN TOOL Actuator NG

51 Fuel pump relay (Refer to Check the fuel pump system. (Refer to INSPECTION PROCEDURE 24.)

OK ,

SCAN TOOL SENSOR NGCheck the engine coolant temperature sensor circuit .

(Refer to INSPECTION PROCEDURES 38.)

INSPECTION PROCEDURE 31.

Inspection when hunting occurs.

,

Check the body minimum air flow.

(Refer to

Check trouble symptom.

NG

Inspect air intake system for vacuum leaks.

l Broken intake manifold gasket

l Broken air intake hose

l Broken vacuum hose

lPositive crankcase ventilation valve does not opera te.

T S B R e v i s i o n

Page 497 of 2103

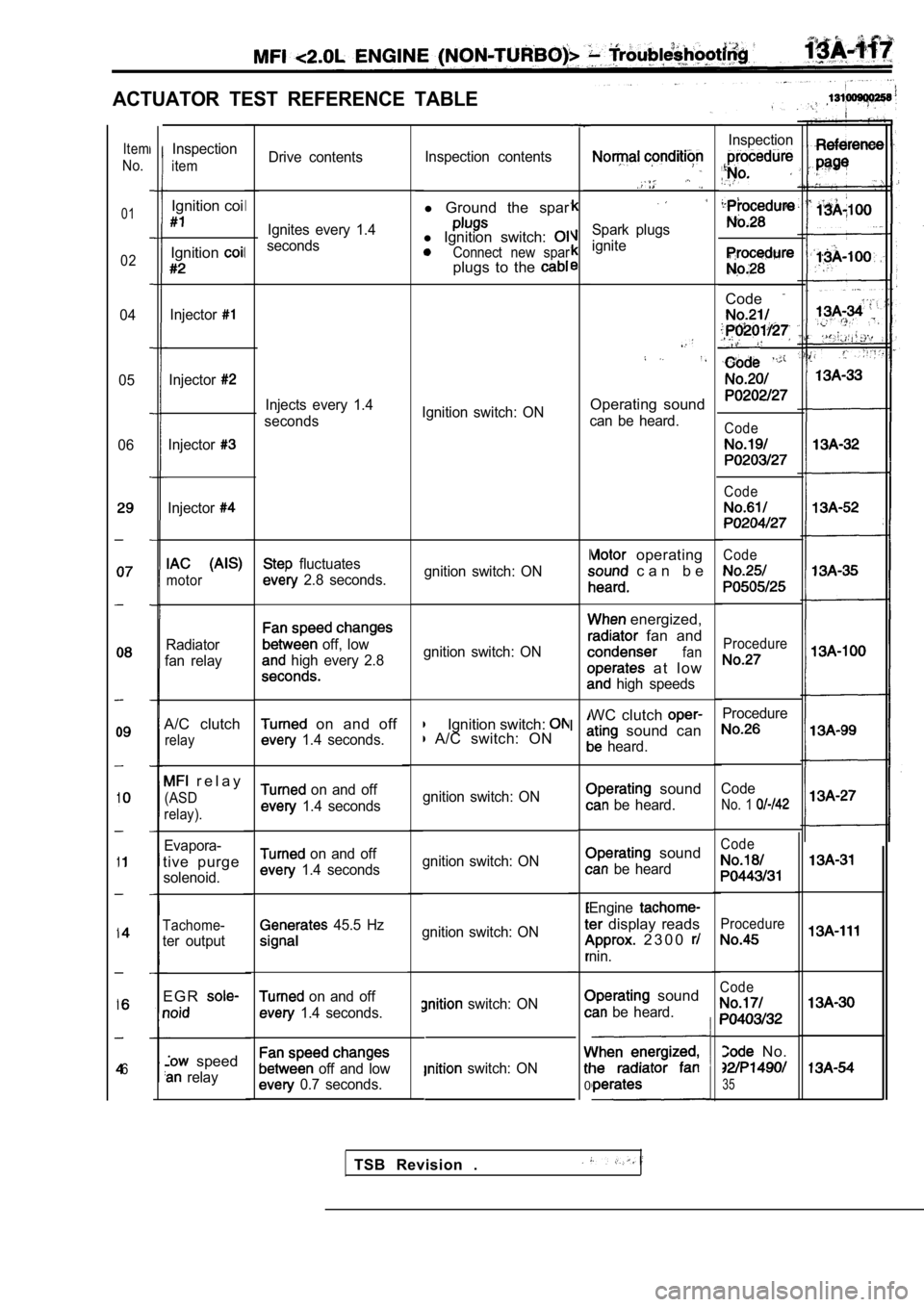

ACTUATOR TEST REFERENCE TABLE

Drive contentsInspection contents

l

Ground the spar

l Ignition switch: Connect new sparplugs to the

Spark plugs

ignite

Ignition switch: ONOperating sound

can be heard.

gnition switch: ON

operating

c a n b e

gnition switch: ON

energized,

fan and

fan

a t l o w

high speeds

Ignition switch: A/C switch: ON WC clutch sound can

heard.

gnition switch: ON

sound

be heard.

gnition switch: ON

sound

be heard

gnition switch: ON Engine

display reads

2 3 0 0

nin.

switch: ON

switch: ON

I

I

0

sound

be heard.

Item

No.

01

02

04

05

06

6

Inspection

Code

,

Code

Code

Code

Procedure

Procedure

Code

No. 1

Code

Procedure

Code

No.

35

Inspection

item

Ignition coi

Ignition

Injector

Injector

Injector

Injector

motor

Radiator

fan relay

A/C clutch

relay

r e l a y

(ASD

relay).

Evapora-

tive purge

solenoid.

Tachome-

ter output

E G R

speed

relay Ignites every 1.4

seconds

I

I

Injects every 1.4

seconds

fluctuates

2.8 seconds.

off, low

high every 2.8

on and off

1.4 seconds.

on and off

1.4 seconds

on and off

1.4 seconds

45.5 Hz

on and off

1.4 seconds.

off and low

0.7 seconds.

TSB Revision .

Page 499 of 2103

ENGINE (NON-TURBO)>

ON-VEHICLE SERVICE

THROTTLE BODY MINIMUM AIR FLOW

CHECK

1.Start the engine and warm it up until the engine co olant

is heated to

or higher and then stop the

engine.

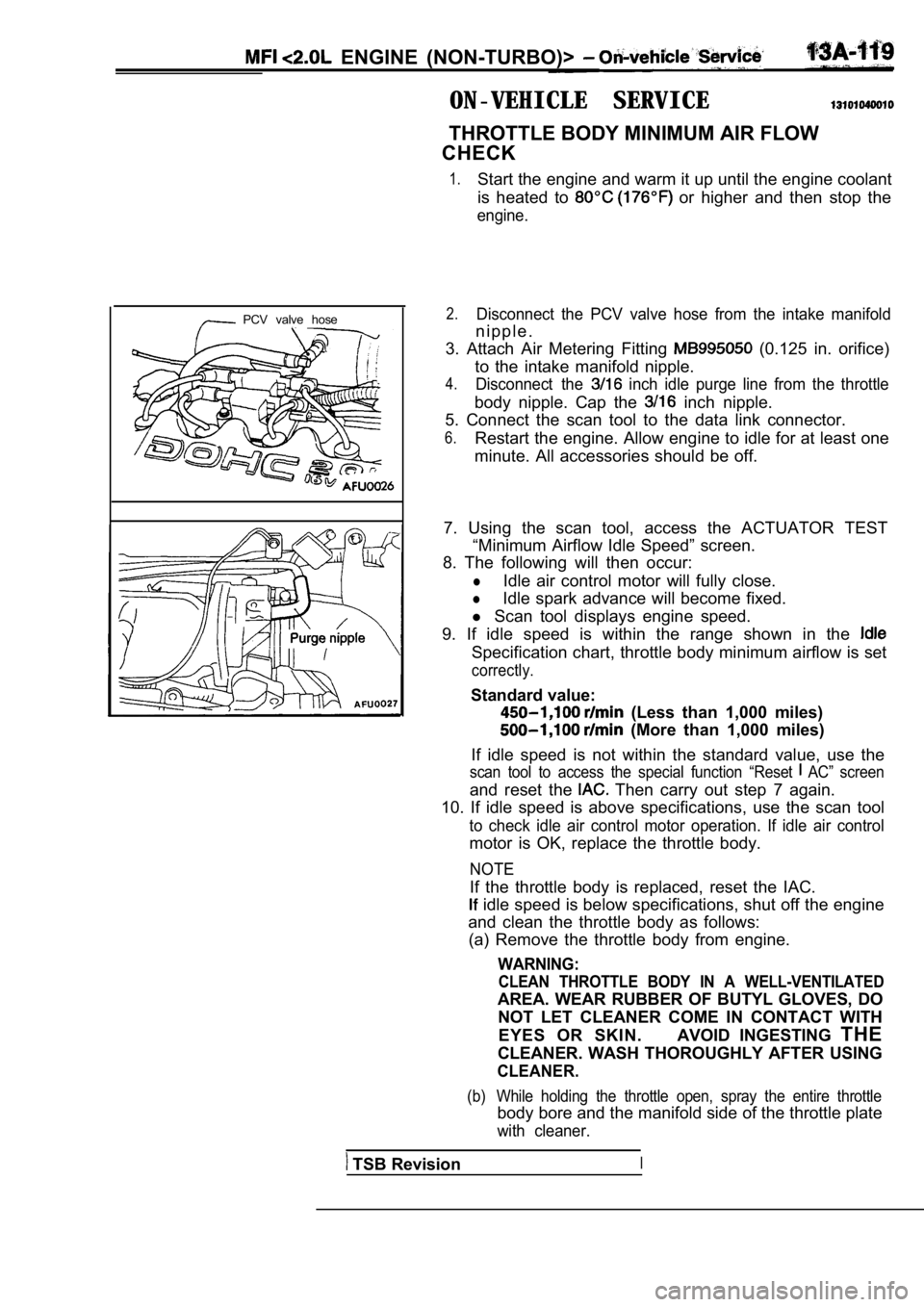

PCV valve hose2.Disconnect the PCV valve hose from the intake manif old

n i p p l e .

3. Attach Air Metering Fitting

(0.125 in. orifice)

to the intake manifold nipple.

4.Disconnect the inch idle purge line from the throttle

body nipple. Cap the inch nipple.

5. Connect the scan tool to the data link connector .

6.Restart the engine. Allow engine to idle for at least one

minute. All accessories should be off.

7. Using the scan tool, access the ACTUATOR TEST “Minimum Airflow Idle Speed” screen.

8. The following will then occur:

lIdle air control motor will fully close.

lIdle spark advance will become fixed.

l Scan tool displays engine speed.

9. If idle speed is within the range shown in the

Specification chart, throttle body minimum airflow is set

correctly.

Standard value:

(Less than 1,000 miles)

(More than 1,000 miles)

If idle speed is not within the standard value, use the

scan tool to access the special function “Reset AC” screen

and reset the Then carry out step 7 again.

10. If idle speed is above specifications, use the scan tool

to check idle air control motor operation. If idle air control

motor is OK, replace the throttle body.

NOTE

If the throttle body is replaced, reset the IAC.

idle speed is below specifications, shut off the e ngine

and clean the throttle body as follows: (a) Remove the throttle body from engine.

WARNING:

CLEAN THROTTLE BODY IN A WELL-VENTILATED

AREA. WEAR RUBBER OF BUTYL GLOVES, DO

NOT LET CLEANER COME IN CONTACT WITH

EYES OR SKIN. AVOID INGESTING THE

CLEANER. WASH THOROUGHLY AFTER USING

CLEANER.

(b) While holding the throttle open, spray the entir e throttle

body bore and the manifold side of the throttle plate

with cleaner.

TSB RevisionI