diagram MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 291 of 2103

ENGINECamshaft

Install the rocker spring installing,

Remove the the

.

.,

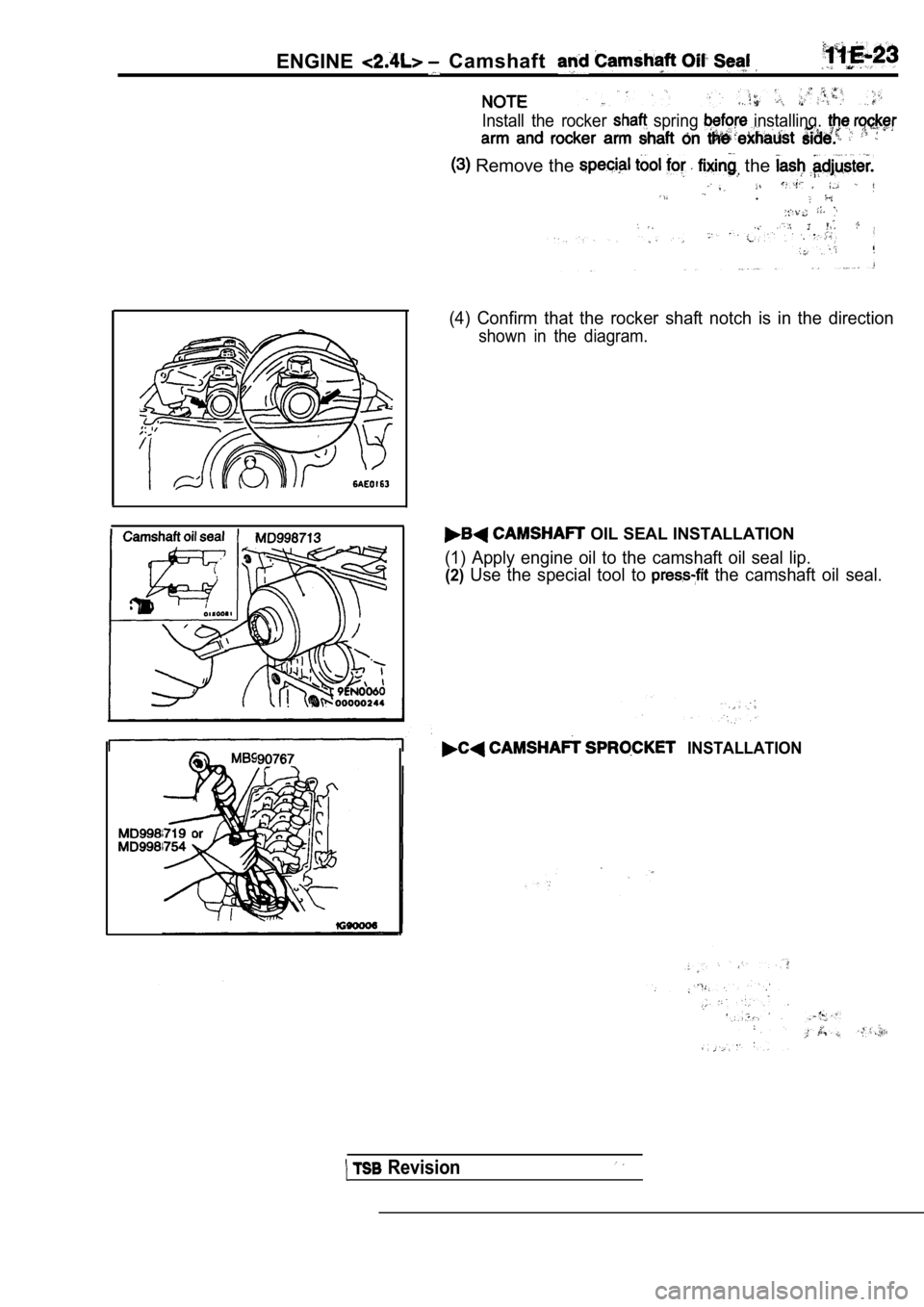

(4) Confirm that the rocker shaft notch is in the direction

shown in the diagram.

OIL SEAL INSTALLATION

(1) Apply engine oil to the camshaft oil seal lip.

(2)Use the special tool to the camshaft oil seal.

INSTALLATION

Revision

Page 522 of 2103

E N G I N E ( T U R B O )

AND

ENGINE> General . .

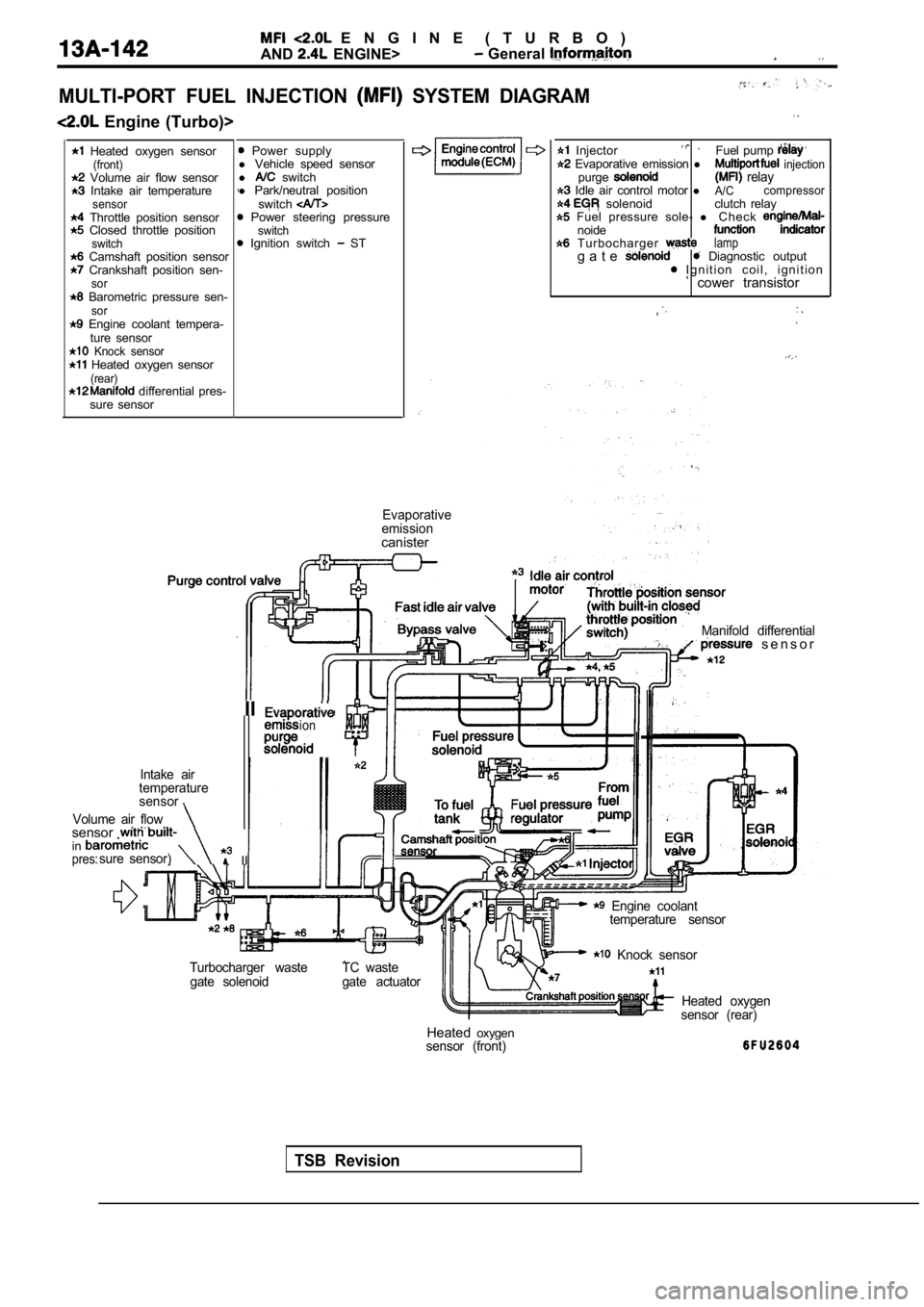

MULTI-PORT FUEL INJECTION SYSTEM DIAGRAM

Engine (Turbo)>

Heated oxygen sensor(front) Volume air flow sensor Intake air temperaturesensor Throttle position sensor Closed throttle positionswitch Camshaft position sensor Crankshaft position sen-sor Barometric pressure sen-sor Engine coolant tempera- ture sensor

Knock sensor Heated oxygen sensor(rear) differential pres-

sure sensor

Power supply

l Vehicle speed sensor

l

switch

l Park/neutral position

switch

Power steering pressureswitch Ignition switch ST

Enginecontrol Injector . Fuel pump

Evaporative emission l injectionpurge relay Idle air control motor lA/Ccompressor solenoid clutch relay Fuel pressure sole-

l C h e c knoide T u r b o c h a r g e r lampg a t e Diagnostic output I g n i t i o n c o i l , i g n i t i o n cower transistor

,

Evaporative

emission

canister

TSB Revision

Manifold differential s e n s o r

IIion. .

Intake air

temperature

sensor

Volume air flow

sensor . insure sensor) IIpres:

Engine coolant temperature sensor

Turbocharger waste gate solenoid TC waste

gate actuator

Knock sensor

Heated oxygen

sensor (rear)

Heated oxygensensor (front)

Page 673 of 2103

1.4

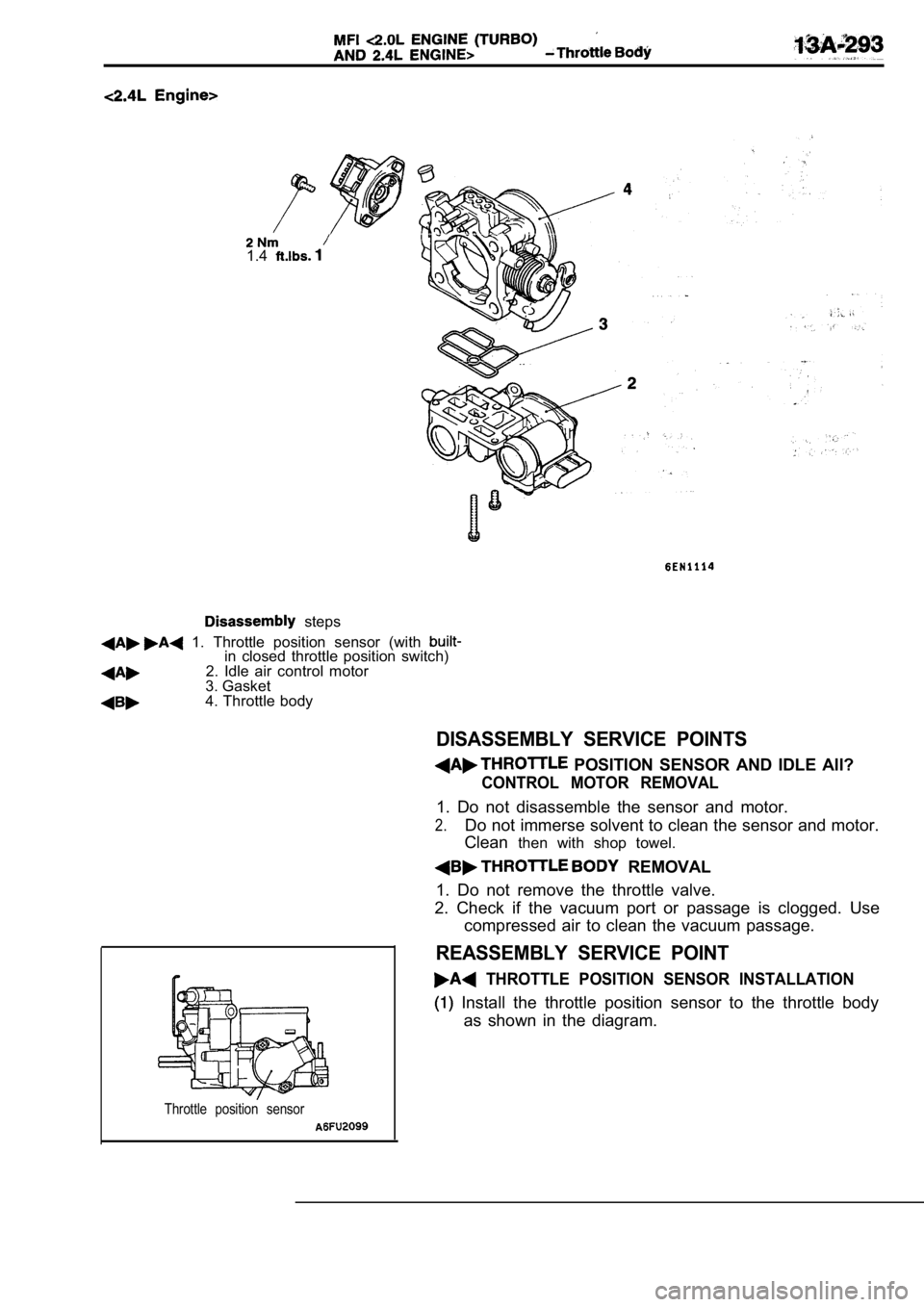

steps

1. Throttle position sensor (with in closed throttle position switch)2. Idle air control motor

3. Gasket

4. Throttle body

DISASSEMBLY SERVICE POINTS

POSITION SENSOR AND IDLE All?

CONTROL MOTOR REMOVAL

1. Do not disassemble the sensor and motor.

2.Do not immerse solvent to clean the sensor and moto r.

Clean then with shop towel.

REMOVAL

1. Do not remove the throttle valve.

2. Check if the vacuum port or passage is clogged. Use

compressed air to clean the vacuum passage.

REASSEMBLY SERVICE POINT

THROTTLE POSITION SENSOR INSTALLATION

Install the throttle position sensor to the thrott le body

as shown in the diagram.

Throttle position sensor

Page 692 of 2103

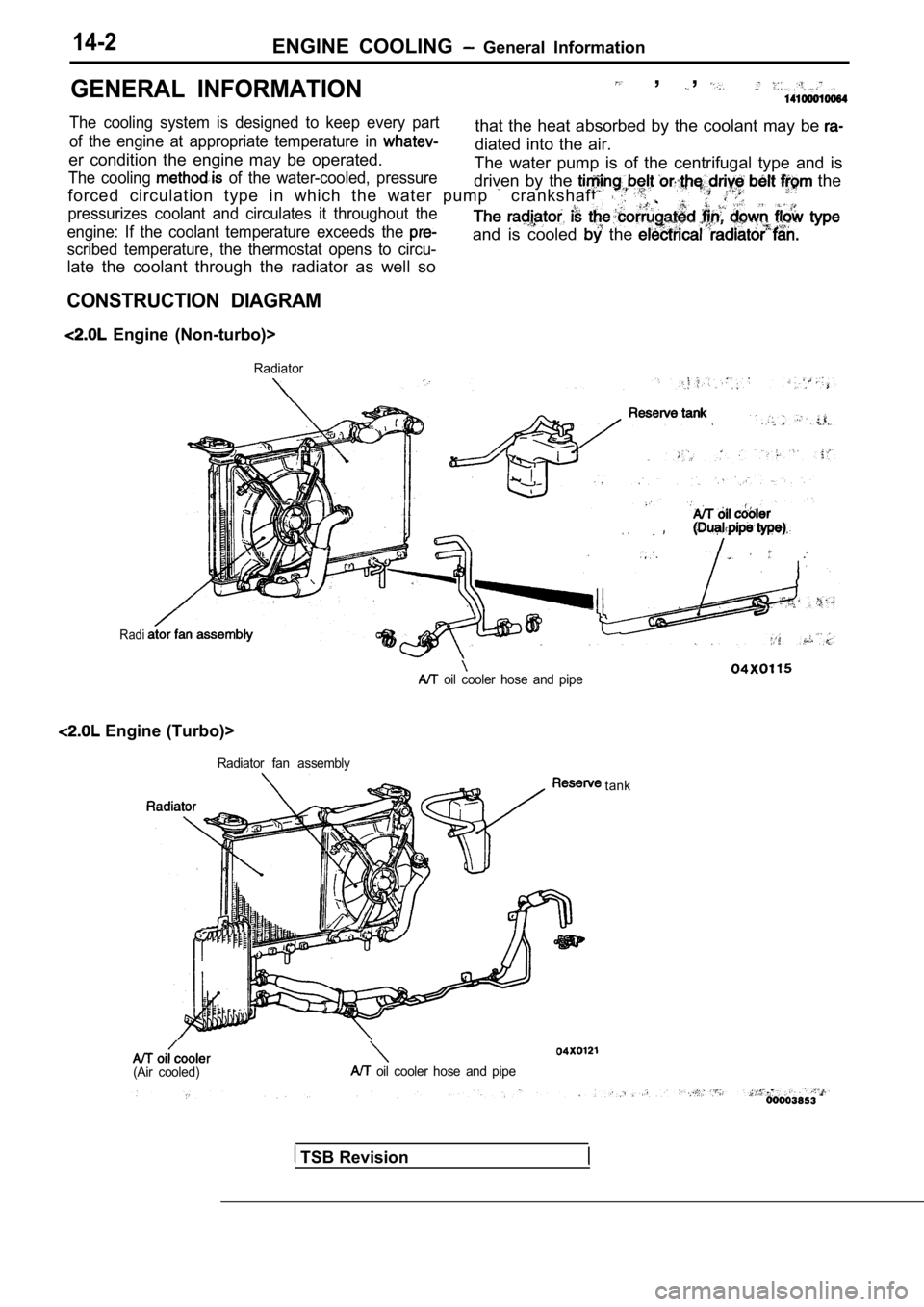

14-2ENGINE COOLING General Information

GENERAL INFORMATION , ,

The cooling system is designed to keep every partthat the heat absorbed by the coolant may be of the engine at appropriate temperature in diated into the air.

er condition the engine may be operated.

The cooling of the water-cooled, pressureThe water pump is of the centrifugal type and is

driven by the

the

forced circulation type in which the water pump crankshaft. .

pressurizes coolant and circulates it throughout th e

engine: If the coolant temperature exceeds the

scribed temperature, the thermostat opens to circu-

late the coolant through the radiator as well so

and is cooled the

CONSTRUCTION DIAGRAM

Engine (Non-turbo)>

Radiator

Radi

.

oil cooler hose and pipe

Engine (Turbo)>

Radiator fan assembly

(Air cooled) oil cooler hose and pipetank

TSB Revision

Page 742 of 2103

17-2

Evaporative Emission Canister/Air Filter/

Evaporative Emission Ventilation Solenoid

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Evaporative Emission Purge Solenoid

Check. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . .

General Information. . .. . .. . . . . . . . . . . . . . .

Purge Control System Check. . . . . . . . . . . . .

Purge Port Vacuum Check. . . . . . . . . . . . . . . .51

EXHAUST GAS (EGR)

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Component Location. . . . . . . . . . . . . . . . . . . . .54

EGR Port Vacuum Check. . . . . . . . . . . . . . . . .56

EGR System Check. . . . . . . . . . . . . . . . . . . . . .55

EGR Valve Check. . . . . . . . . . . . . . . . . . . . . . . .55

Electric EGR Transducer Solenoid Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

General Information. . . . . . . . . . . . . . . . . . . . . .54

GENERAL INFORMATION. . . . . . . . . . . . . . .44

POSITIVE CRANKCASE VENTILATION

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Component Location. . . . . . . . . . . . . . . . . . . . .48

Crankcase Ventilation System Check. . . . . .49

General Information. . . . . . . . . . . . . . . . . . . . . .48

Positive Crankcase Ventilation Valve

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

SERVICE SPECIFICATIONS. . . . . . . . . . . . .45

TROUBLESHOOTING’

. . . . . . . . . . . . . . . . . . .45

VACUUM HOSES. . . . . . . . . . . . . . . . . . . . . ..4 8

Vacuum Circuit Diagram. . . . . . . . . . . . . . . . . .47

Vacuum Hose Routing

. . . . . . . . . . . . . . . . . . . .46

CONTROL SYSTEM

ENGINE (TURBO) AND

ENGINE>. . . . . . . . . . . . . . . . . . . . . 6 0

CATALYTIC CONVERTER. . . . . . . . . . . . . . .89

General Information. . . . . . . . . . . . . . . . . . . . . .89

EVAPORATIVE EMISSION CONTROL

SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69’

Air Conditioning Switch

. . . . . . . . . . . . . . . . . . .77

Component Location Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

Component Location Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70

Evaporative Emission Canister/Fuel Tank

Pressure Relief Valve/Purge Control Valve

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Evaporative Emission Purge Solenoid

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

General Information Engine (Turbo)> G e n e r a l I n f o r m a t i o n

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .70

Purge Control System Check

. . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . .71

Purge Control ‘System

(Purge Flow Check) Engine>. . . . . . .73

Purge Control Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purge Port Vacuum Check. . . . . . . . . . . . . . . .75

Volume Air Flow Sensor, Engine Coolant

Temperature Sensor and Intake Air

Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . .77

RECIRCULATION (EGR)

.... . .. . . . . . . . . . . . . . . . . . . . . . . .81

Component Location. . . . . . . . . . . . . . . . . . . . .82

EGR Port Vacuum Check . . . . . . . . . . . . . . . . .86

EGR Solenoid Check Engine (Turbo)>

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

87

EGR Solenoid Check Engine>. . . . . .

EGR System Check . . . . . . . . . . . . . . . . . .

EGR Valve Check. . . . . . . . . . . . .. . .

General Information... . . . . . . . . . . . . .....81

Vacuum Control Valve Check

. . . . . . . . .

.......................................

POSITIVE CRANKCASE VENTILATION

SYSTEM

. . . . . . . ... . .. . . . . . . . . . . . . . . . . 65

Component Location. . . . . . . . . . . . .. . . . . . . . .66

Crankcase Ventilation. System . .67

General Information

. . . .. . . . . ... . ........

Positive Crankcase Ventilation Valve

Check. . . . . . . . . . . . . . . . . . . . . ... . ............

SERVICE SPECIFICATIONS. .. . . . . . . . . 60

SPECIAL TOOL . . . . . . . . . . . . . . . . . . . . . . .

. . .. .

HOSES

. . . . ..

. . . . . . . . . . . . . . . . . . . . .,

Circuit Diagram.. . . . . . . . . . . . . . . . . . ,

Vacuum Hose Routing. . . . . . . ...... . . . 6 1

ENGINE CONTROL

3

ACCELERATOR

......

GENERAL INFORMATION . . . . . .. . . . . . . . . .3

ON-VEHICLE SERVICE. . . . . . . . . . . .4

Accelerator Cable Check and

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATION. . . . . . . . . . . . . . .3

. ... . . . . ...3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69

Page 787 of 2103

Emission

ENGINE AND EMISSION

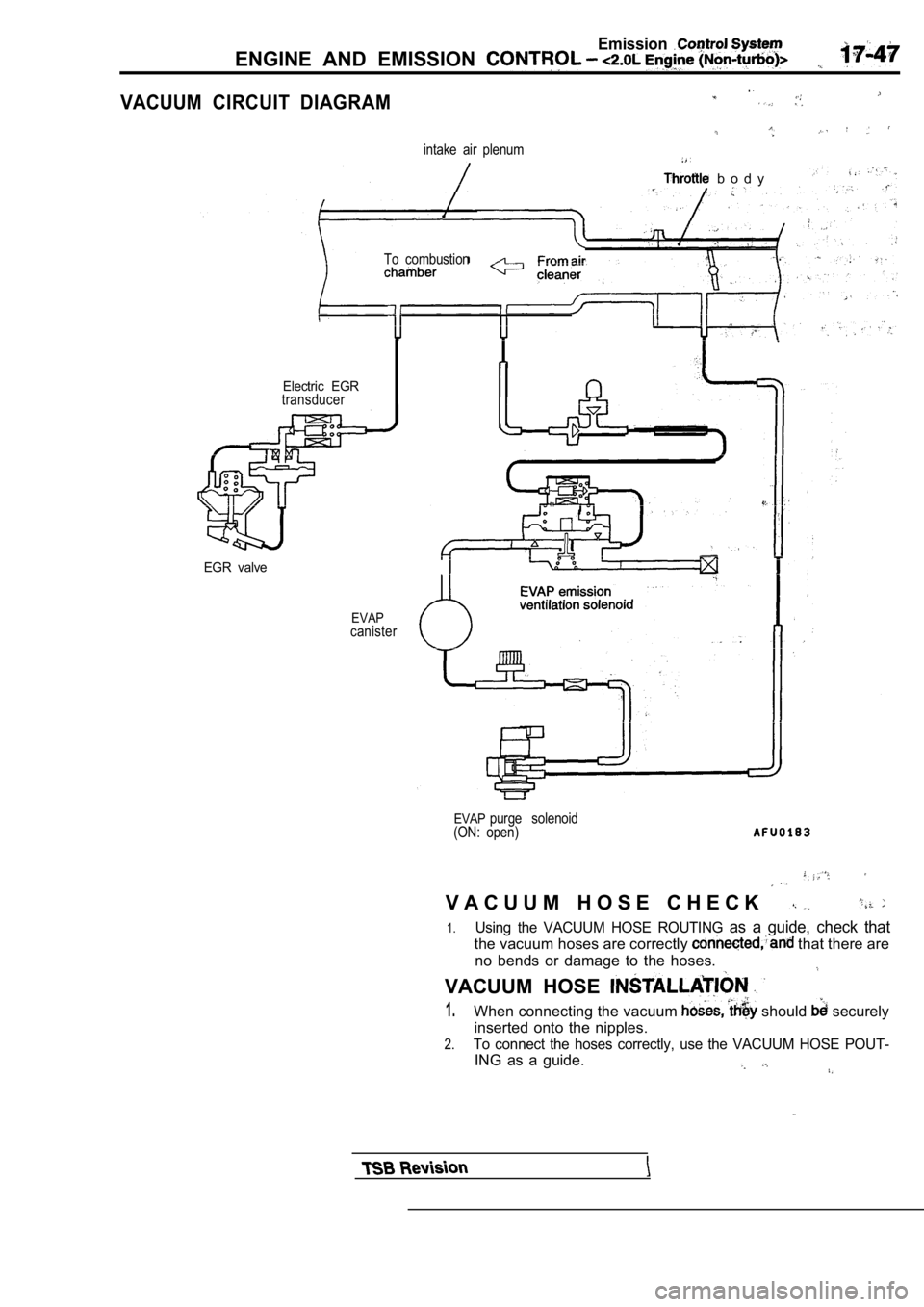

VACUUM CIRCUIT

.

DIAGRAM

intake air plenum

b o d y

To combustion

Electric EGRtransducer

EGR valve

EVAPcanister

EVAPpurge solenoid

(ON: open)

V A C U U M H O S E C H E C K

1.Using the VACUUM HOSE ROUTING as a guide, check that

the vacuum hoses are correctly that there are

no bends or damage to the hoses.

VACUUM HOSE

1.When connecting the vacuum should securely

inserted onto the nipples.

2.To connect the hoses correctly, use the VACUUM HOSE POUT-

ING as a guide.

Page 788 of 2103

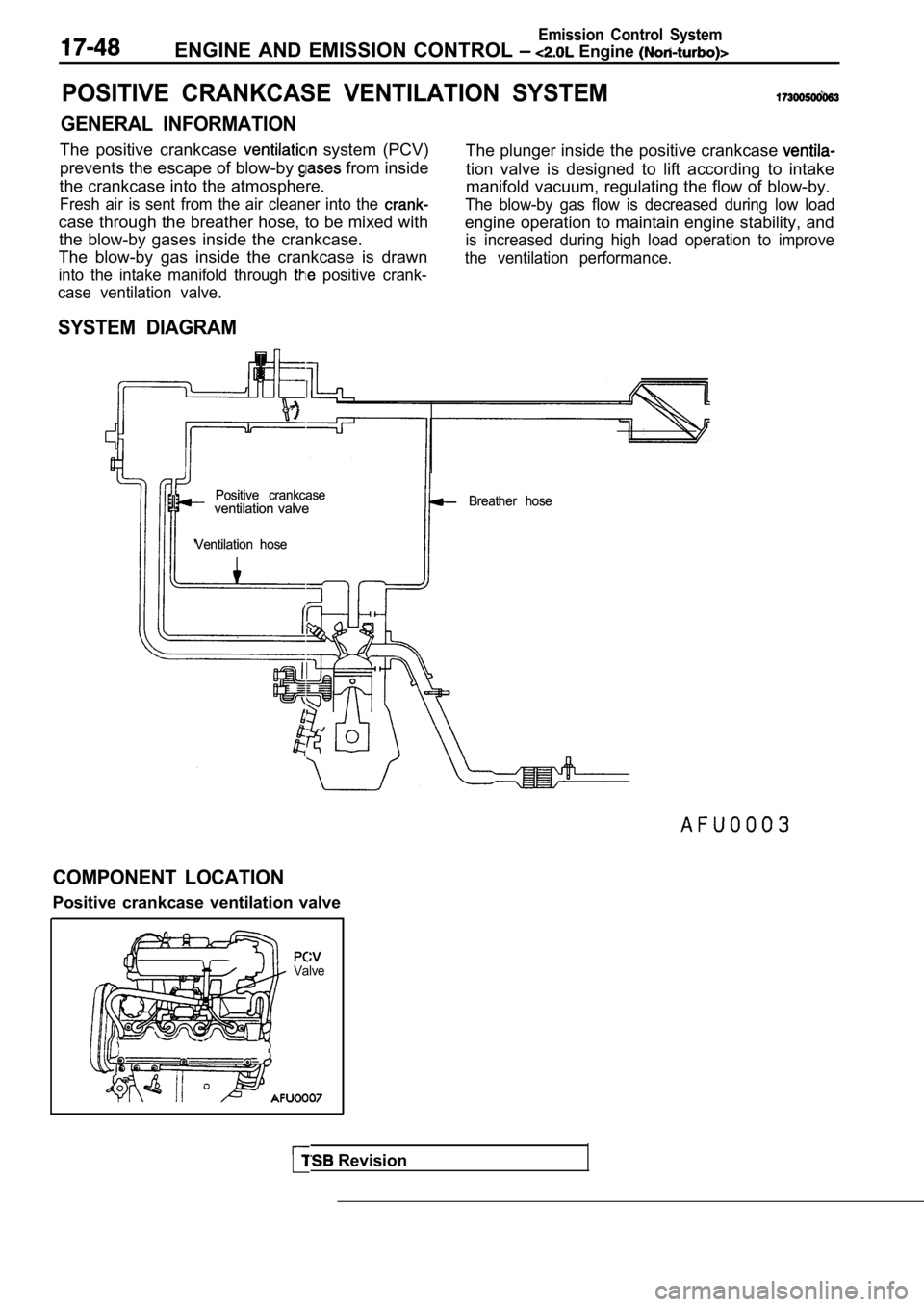

Emission Control System

ENGINE AND EMISSION CONTROL Engine

POSITIVE CRANKCASE VENTILATION SYSTEM

GENERAL INFORMATION

The positive crankcase system (PCV)

prevents the escape of blow-by

from inside

the crankcase into the atmosphere.

Fresh air is sent from the air cleaner into the

case through the breather hose, to be mixed with the blow-by gases inside the crankcase.

The blow-by gas inside the crankcase is drawn

into the intake manifold through positive crank-

case ventilation valve.

The plunger inside the positive crankcase

tion valve is designed to lift according to intake

manifold vacuum, regulating the flow of blow-by.

The blow-by gas flow is decreased during low load

engine operation to maintain engine stability, and

is increased during high load operation to improve

the ventilation performance.

SYSTEM DIAGRAM

Positive crankcase

Positive crankcaseventilation valve

ventilation valve

Ventilation hose

Ventilation hose Breather hose

Breather hose

COMPONENT LOCATION

Positive crankcase ventilation valve

Valve

Revision

Page 802 of 2103

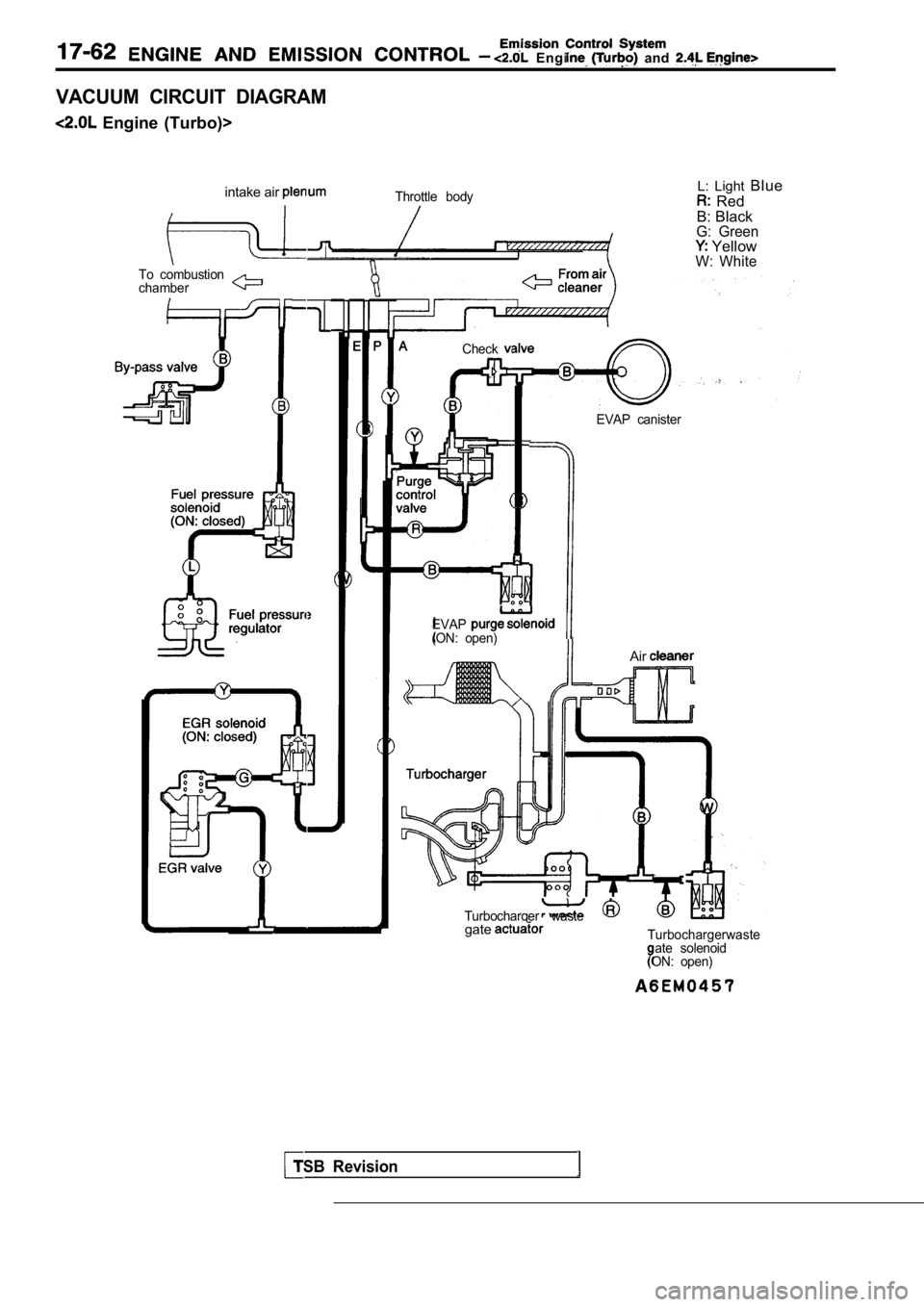

Engine and

VACUUM CIRCUIT DIAGRAM

Engine (Turbo)>intake air

Throttle bodyL: Light Blue

Red

B: Black

G: Green YellowW: WhiteTo combustion

chamber

Check

EVAP(ON: open)

EVAP canister

TSB Revision

Air

Turbocharger wastegateTurbochargerwasteate solenoid

ON: open)

Page 804 of 2103

(Turbo) and Engine>

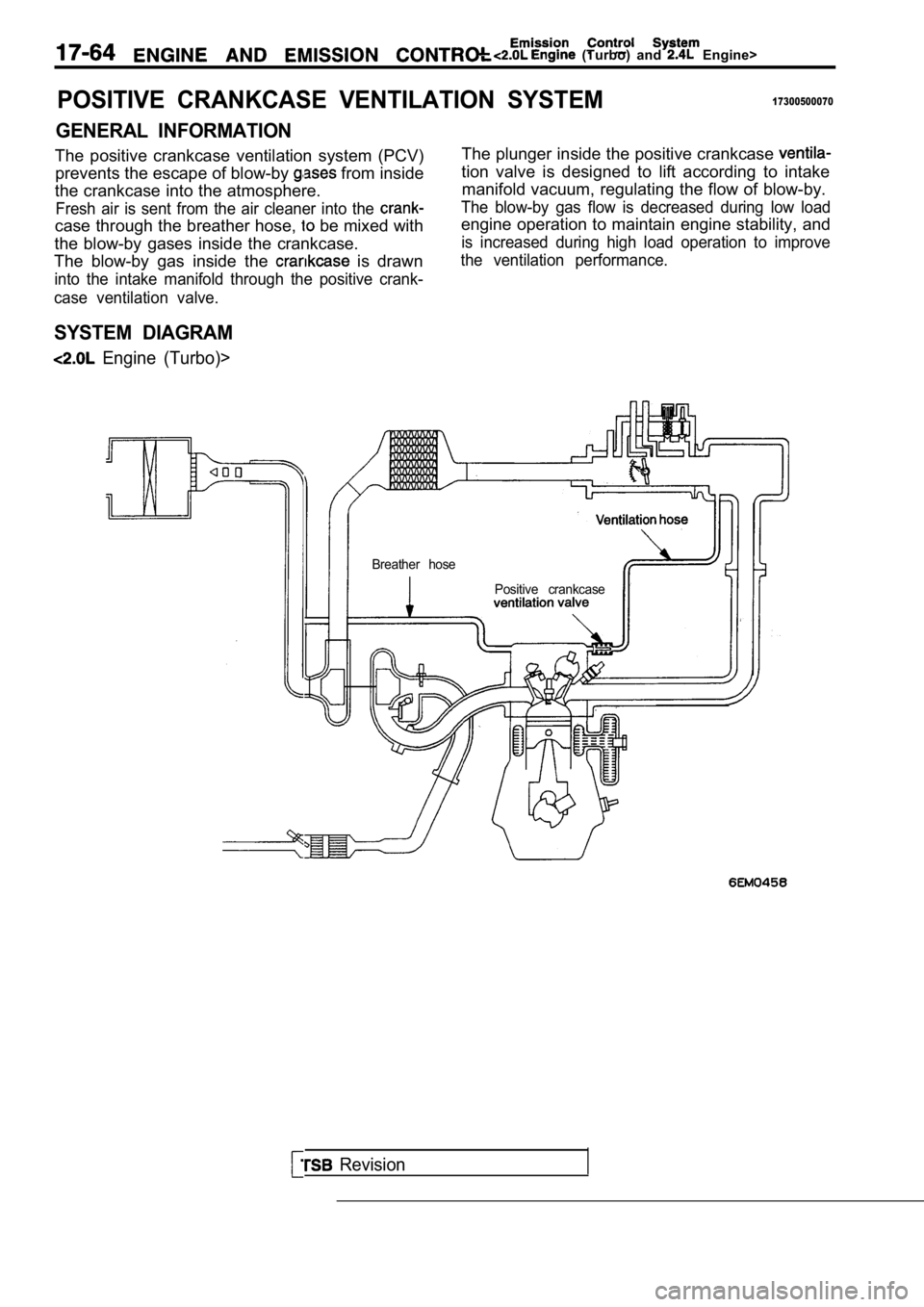

POSITIVE CRANKCASE VENTILATION SYSTEM17300500070

GENERAL INFORMATION

The positive crankcase ventilation system (PCV)prevents the escape of blow-by

from inside

the crankcase into the atmosphere.

Fresh air is sent from the air cleaner into the

case through the breather hose, be mixed with

the blow-by gases inside the crankcase.

The blow-by gas inside the

is drawn

into the intake manifold through the positive crank -

case ventilation valve.

The plunger inside the positive crankcase

tion valve is designed to lift according to intake manifold vacuum, regulating the flow of blow-by.

The blow-by gas flow is decreased during low load

engine operation to maintain engine stability, and

is increased during high load operation to improve

the ventilation performance.

SYSTEM DIAGRAM

Engine (Turbo)>

Breather hose

Positive crankcase

Revision

Page 808 of 2103

17-68ENGINEAND EMISSION CONTROL (Turbo) and

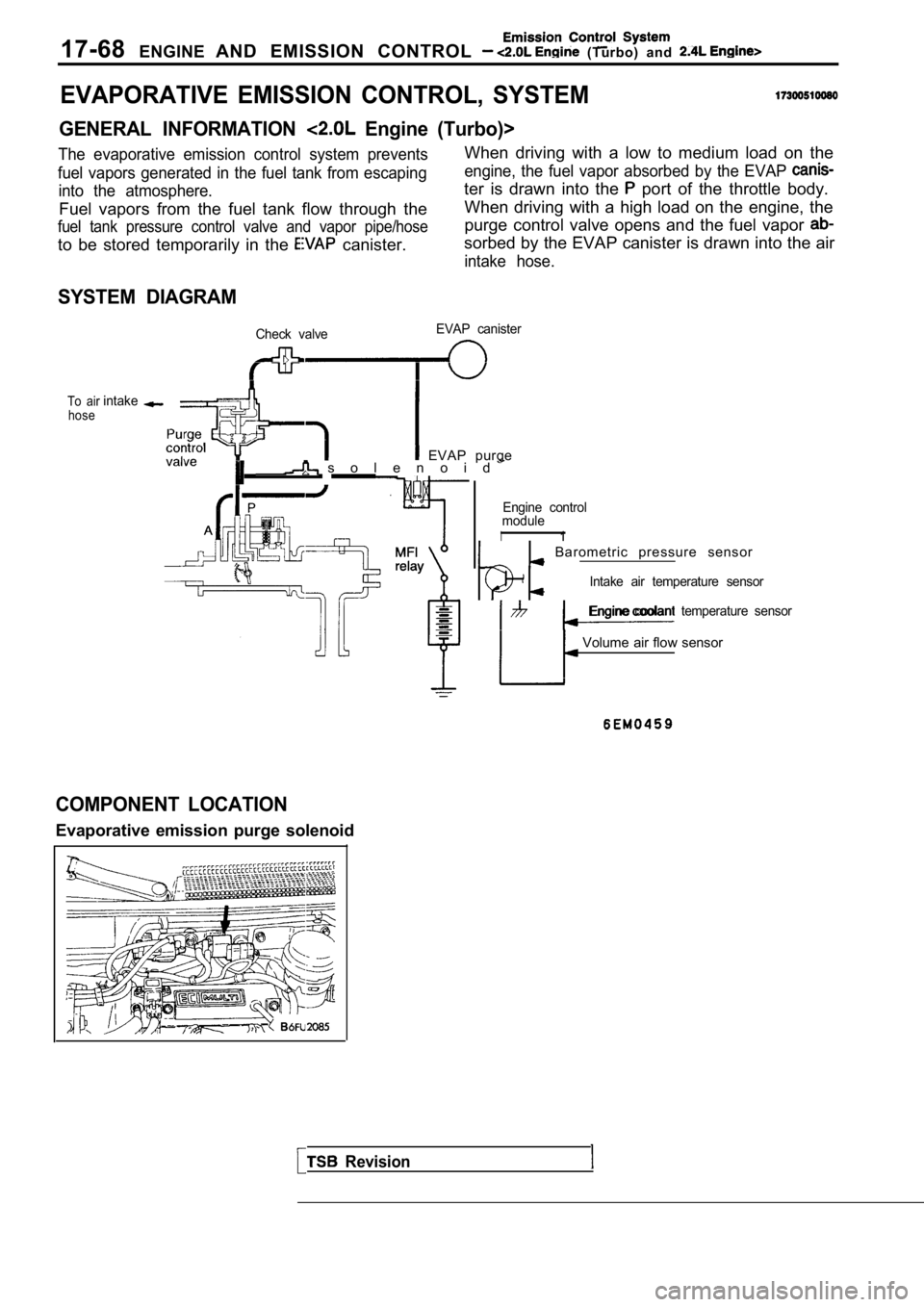

EVAPORATIVE EMISSION CONTROL, SYSTEM

GENERAL INFORMATION Engine (Turbo)>

The evaporative emission control system preventsWhen driving with a low to medium load on the

fuel vapors generated in the fuel tank from escapin gengine, the fuel vapor absorbed by the EVAP

into the atmosphere.ter is drawn into the port of the throttle body.

Fuel vapors from the fuel tank flow through the When driving with a high load on the engine, the

fuel tank pressure control valve and vapor pipe/hos

epurge control valve opens and the fuel vapor

to be stored temporarily in the canister.sorbed by the EVAP canister is drawn into the air

intake hose.

SYSTEM DIAGRAM

Check valve EVAP canister

To air

hoseintake

EVAP purge s o l e n o i d

Revision

Engine control

module

I1

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature sensor

Volume air flow sensor

COMPONENT LOCATION

Evaporative emission purge solenoid