run flat MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1655 of 2103

B R A K E S Y S T E M 7 .

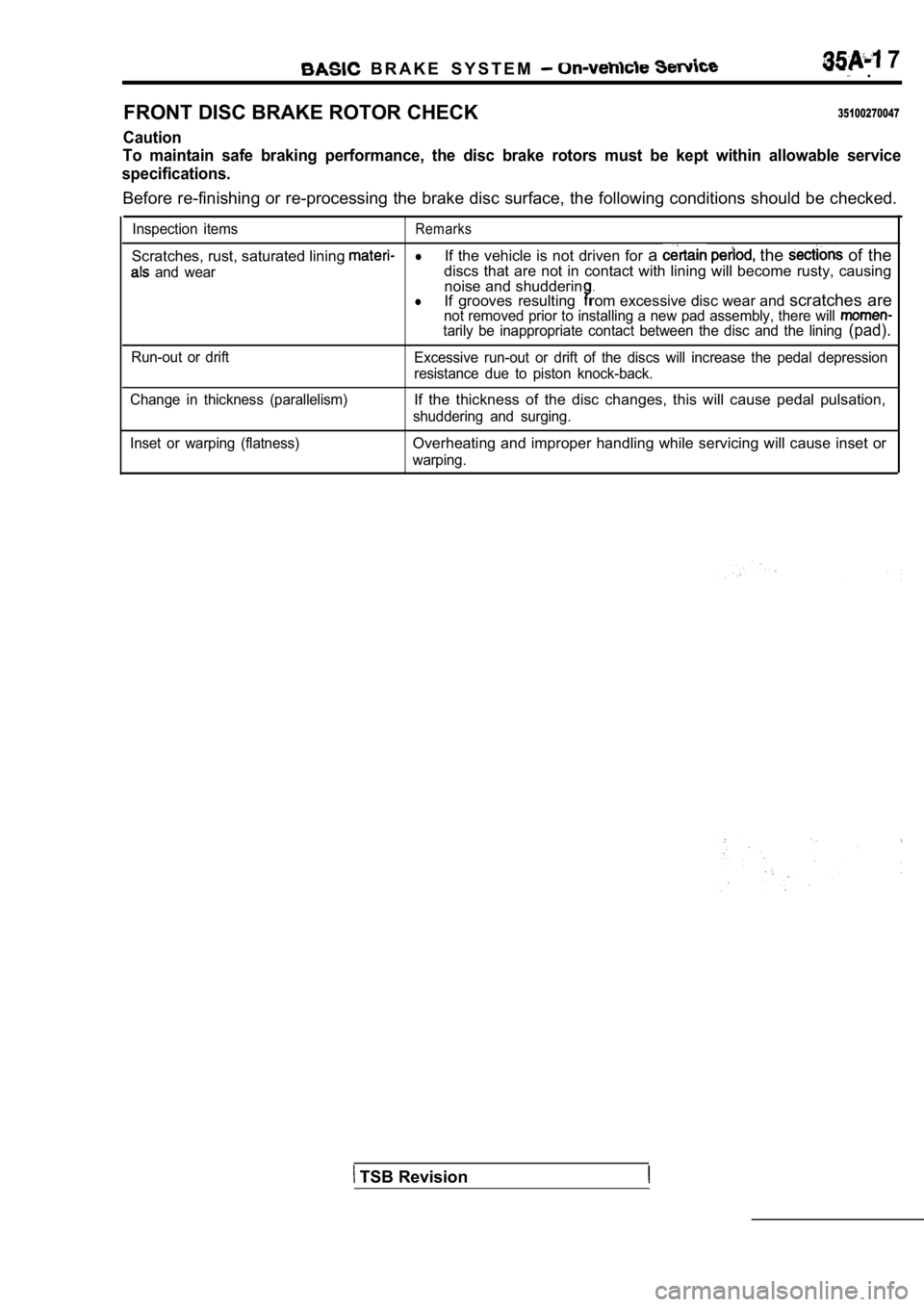

FRONT DISC BRAKE ROTOR CHECK

35100270047

Caution

To maintain safe braking performance, the disc brak e rotors must be kept within allowable service

specifications.

Before re-finishing or re-processing the brake disc surface, the following conditions should be checke d.

Inspection itemsRemarks

Scratches, rust, saturated lining lIf the vehicle is not driven for a the of the

and weardiscs that are not in contact with lining will beco me rusty, causing

noise and shudderin.lIf grooves resultingrom excessive disc wear and scratches arenot removed prior to installing a new pad assembly, there will tarily be inappropriate contact between the disc and the lining (pad).

Run-out or drift

Excessive run-out or drift of the discs will increa se the pedal depression

resistance due to piston knock-back.

Change in thickness (parallelism)

If the thickness of the disc changes, this will cau se pedal pulsation,

shuddering and surging.

Inset or warping (flatness)

Overheating and improper handling while servicing w ill cause inset or

warping.

TSB Revision

Page 1782 of 2103

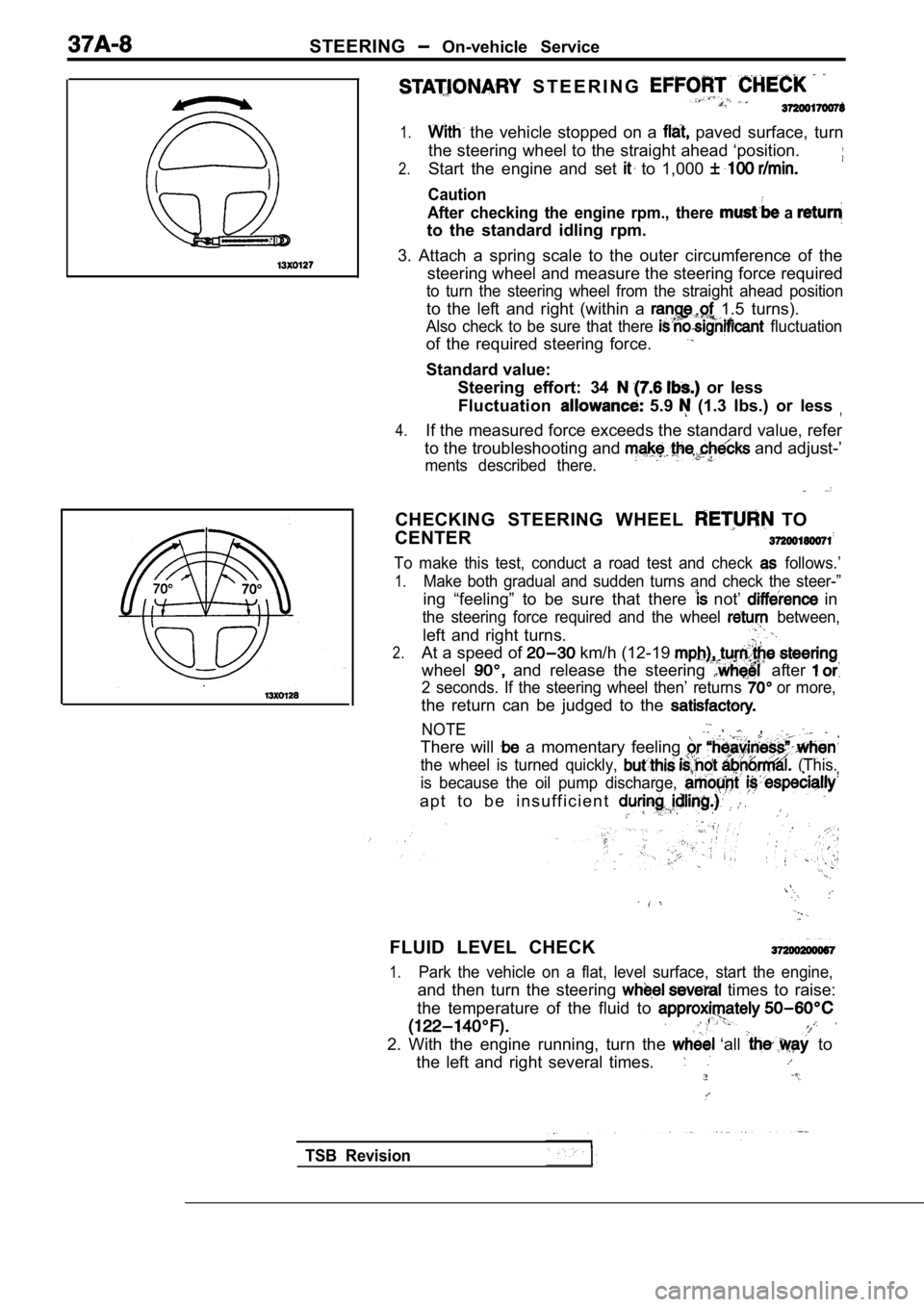

STEERING On-vehicle Service

S T E E R I N G

1. the vehicle stopped on a paved surface, turn

the steering wheel to the straight ahead ‘position.

2.Start the engine and set to 1,000

Caution

After checking the engine rpm., there

a

to the standard idling rpm.

3. Attach a spring scale to the outer circumference of the

steering wheel and measure the steering force requi red

to turn the steering wheel from the straight ahead position

to the left and right (within a 1.5 turns).

Also check to be sure that there fluctuation

of the required steering force.

Standard value:

Steering effort: 34

or less

Fluctuation

5.9 (1.3 Ibs.) or less

4.If the measured force exceeds the standard value, r efer

to the troubleshooting and

and adjust-’

ments described there.

CHECKING STEERING WHEEL TO

CENTER

To make this test, conduct a road test and check follows.’

1.Make both gradual and sudden turns and check the st eer-”

ing “feeling” to be sure that there not’ in

the steering force required and the wheel between,

left and right turns.

2.At a speed of km/h (12-19

wheel and release the steering after

2 seconds. If the steering wheel then’ returns or more,

the return can be judged to the

NOTE ,

There will a momentary feeling

the wheel is turned quickly, (This.

is because the oil pump discharge,

a p t t o b e i n s u f f i c i e n t

FLUID LEVEL CHECK

1.Park the vehicle on a flat, level surface, start th e engine,

and then turn the steering times to raise:

the temperature of the fluid to

2. With the engine running, turn the ‘all to

the left and right several times.

TSB Revision

Page 1894 of 2103

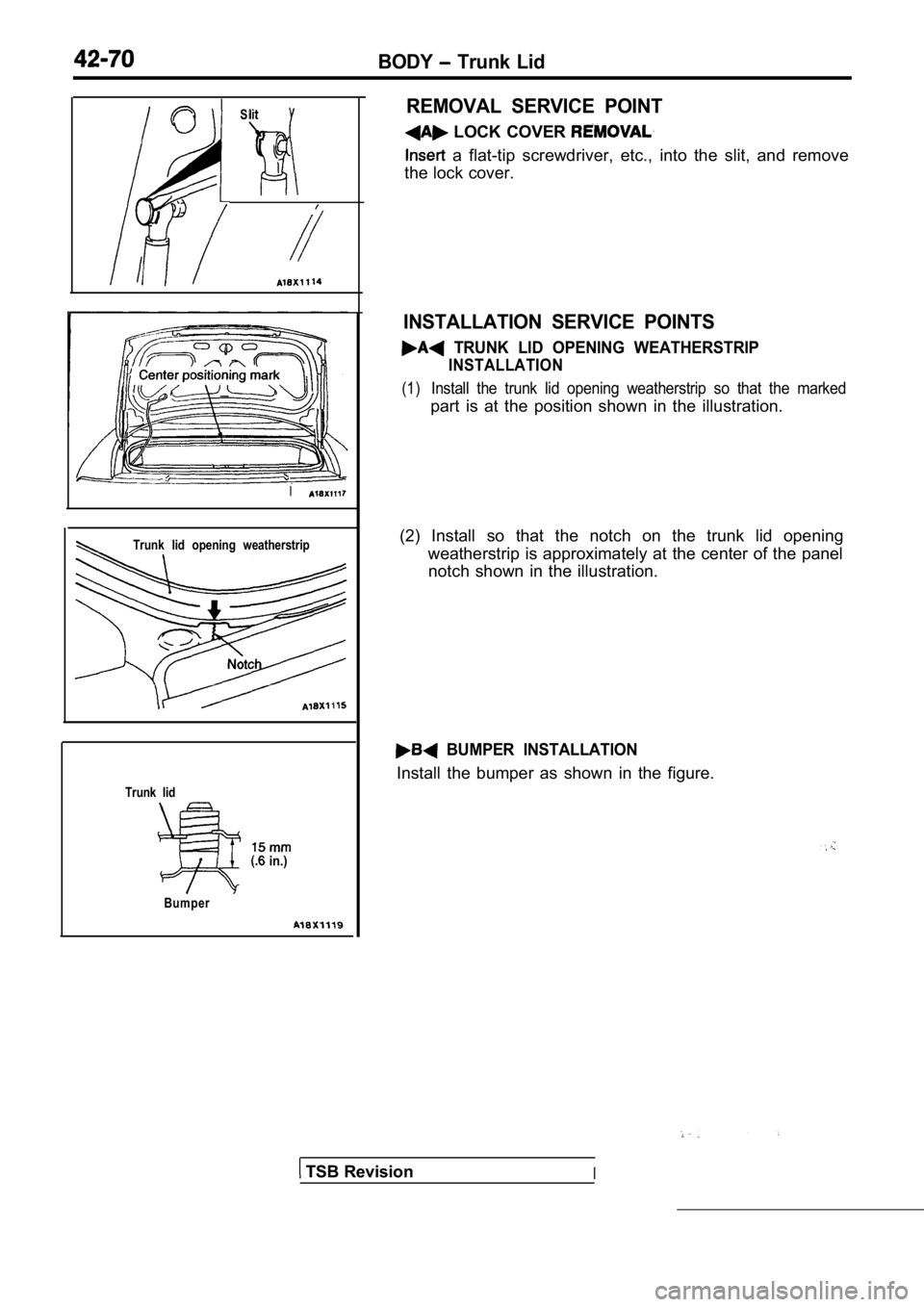

BODY Trunk Lid

Slit

I

I

Trunk lid opening weatherstrip

Trunk lid

in.)

Bumper

REMOVAL SERVICE POINT

LOCK COVER

a flat-tip screwdriver, etc., into the slit, and r emove

the lock cover.

INSTALLATION SERVICE POINTS

TRUNK LID OPENING WEATHERSTRIP

INSTALLATION

(1)Install the trunk lid opening weatherstrip so that the marked

part is at the position shown in the illustration.

(2) Install so that the notch on the trunk lid open ing

weatherstrip is approximately at the center of the panel

notch shown in the illustration.

BUMPER INSTALLATION

Install the bumper as shown in the figure.

TSB RevisionI

Page 2102 of 2103

ALPHABETICAL INDEX

TENSIONDrive Belt, Check and Adjustment . . . . . . . .11. . . . . . . .. . . . . . . . . . . .

TENSION PULLEY ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE>.. . . . . . . . .TEST EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .THEFT-ALARM SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . .T H E R M O S T A T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .THICKNESS

Front Brake Disc, Check. . . . . . . . . . . . . . . . . . . . . . . . . . .Rear Brake Disc, Check. . . . . . . . . . . . . . . . . . . . . . . . . . .

THROTTLE BODY

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . .THROTTLE BODY MINIMUM AIR FLOW, Check. . . . . . .THROTTLE BODY (THROTTLE VALVE AREA) ENGINE (TURBO) AND ENGINE>, Cleaning .

THROTTLE POSITION SENSORAdjustment

ENGINE (TURBO) AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . .On-vehicle ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . .TIE ROD END BALL JOINT, Breakaway Torque Check. . . .TIMING BELT

. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TIMING BELT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TIMING BELT, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .TIRE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIRE INFLATION PRESSURE, Check. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOE CONTROL ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TORQUE CONVERTER STALLTesting

ENGINE (NON-TURBO)>. . . . . . . . . . . ENGINE (TURBO) AND ENGINE>TOTAL BACKLASH Rear Axle, Check. . . . . . . . . . . .TRAILING ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSAXLE ENGINE (NON-TURBO)>. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ENGINE (TURBO) AND . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and . . . . . . . . . . . . . . . . . . . . . ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . .M/T ENGINE (TURBO) AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M/T ENGINE (TURBO) AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .TRANSAXLECASEDisassembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . .Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSAXLE CONTROL

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE>. . . .A/T ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . ENGINE (TURBO) AND . . .

TRANSAXLE FLUID

Automatic, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement ENGINE (NON-TURBO)> . . . . . . . . . . . . .

ENGINE (TURBO) . . . TRANSAXLE FLUID LEVELCheck ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE>. . . . .

TRANSAXLE MOUNTING . . . . . . . . . . . . . . . . . . . . . . . , . . TRANSAXLE OIL

Manual, Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement ENGINE . . . . . . . . . . . . . .

. . . . . .

TRANSAXLE OIL COOLER

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . .

TRANSAXLE OIL LEVEL

Check

ENGINE (NON-TURBO)>.. . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>..

TRANSAXLE RANGE SENSOR, Continuity Check ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . .TRANSFER

ENGINE (TURBO) AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSFER CASE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSFER CASE ADAPTER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER DRIVEN GEAR . . . . . . . . . . . . . . . . .TRANSFER OIL, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER OIL, Replacement ENGINE AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER OIL LEVEL

ENGINE AND ENGINE>. . . . . . . . . . - -

. . . . . . . . . . .

TRANSFER OIL, Replacement ENGINE (TURBO) AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER SHAFT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRIM, Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRIMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRUNK LID LOCK RELEASE CABLE. . . . . . . . . . . . . . . . . . . .

TRUNK LID LOOK RELEASE HANDLE. . . . . . . . . . . . . . . . . .TUBING AND FITTINGS, Handling. . . . . . . . . . . . . . . . . . . . . .TURBOCHARGER BYPASS VALVE, CHECK. . . . . . . . . .. . .

TURBOCHARGER WASTE GATE SOLENOID

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .On-vehicle Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDER COVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . .UPPER ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Suspension>. . . . . . . . . . . . . . . . . . . . ... . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .. .

VACUUM

EGR Port, Check ENGINE ENGINE (TURBO) AND . . . . . . Manifold, Check . . . . . . . . . . . . . . . . . . . . 11 C-l

. . . . . . . . . . . . . . . . . . . . . .