differential MITSUBISHI SPYDER 1990 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 904 of 2103

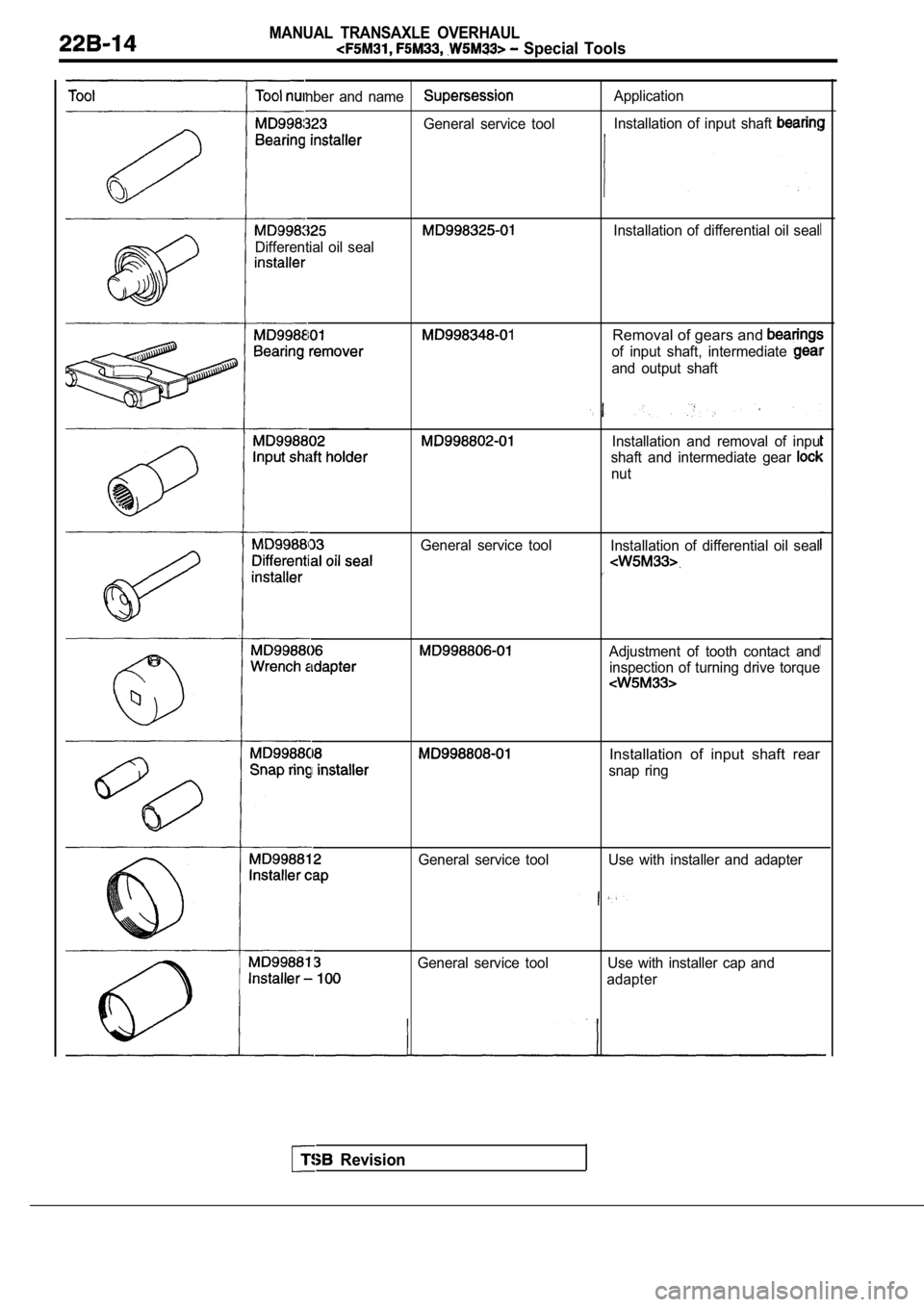

nber and nameApplication

General service tool Installation of input shaft

Differential oil seal

Installation of differential oil seal

Removal of gears and

of input shaft, intermediate

and output shaft

Installation and removal of inpu

shaft and intermediate gear

nut

General service tool Installation of differential oil seal

Adjustment of tooth contact and

inspection of turning drive torque

Installation of input shaft rear

snap ring

General service tool Use with installer and adapter

General service tool Use with installer cap and adapter

MANUAL TRANSAXLE OVERHAUL

Special Tools

I

Revision

Page 909 of 2103

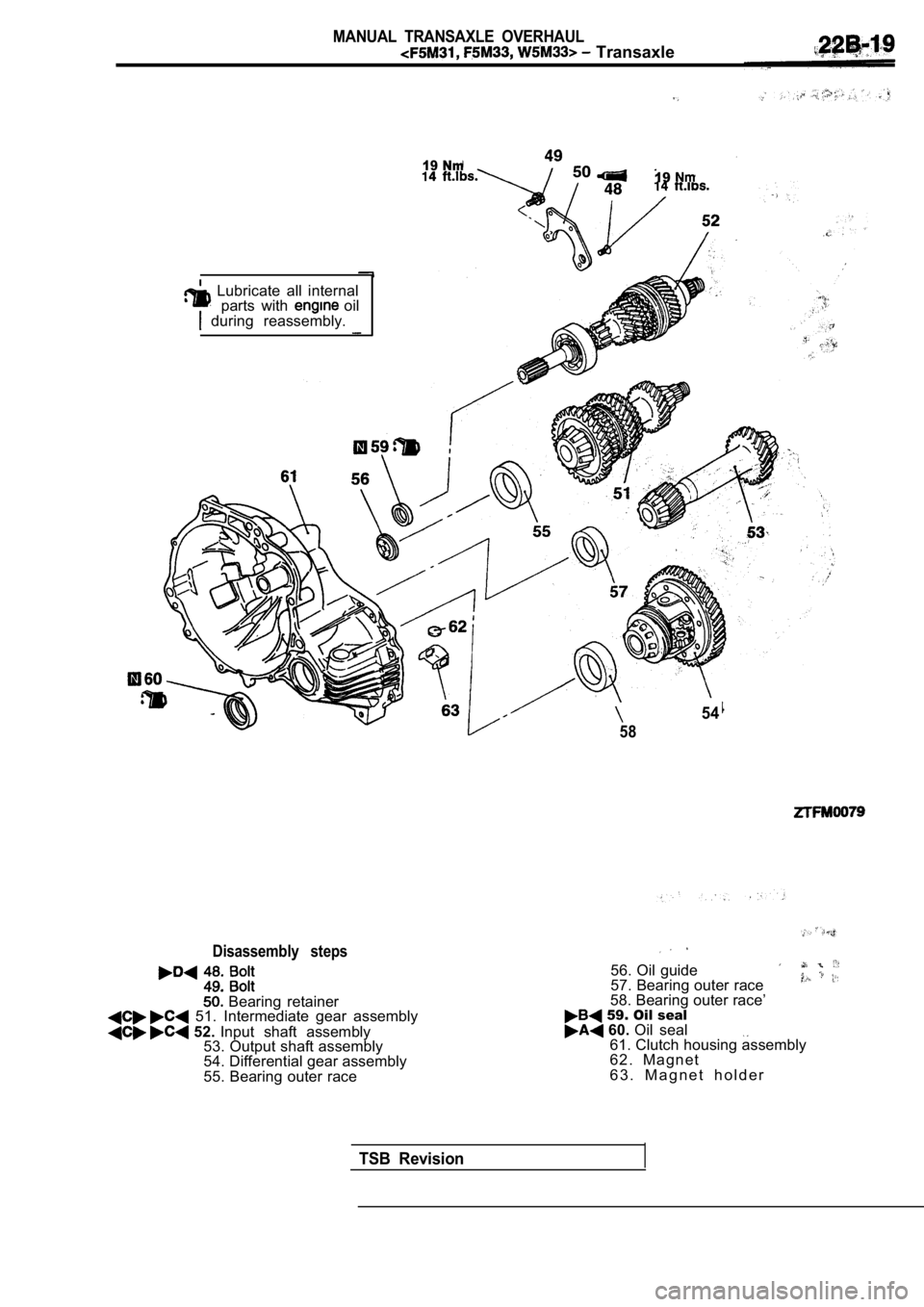

MANUAL TRANSAXLE OVERHAUL

Transaxle

Lubricate all internalparts with oil during reassembly.

19 Nm19

54

58

Disassembly steps

Bearing retainer 51. Intermediate gear assembly

52. Input shaft assembly

53. Output shaft assembly

54. Differential gear assembly

55. Bearing outer race

56. Oil guide

57. Bearing outer race

58. Bearing outer race’ 59. Oil seal 60. Oil seal61. Clutch housing assembly

6 2 . M a g n e t

6 3 . M a g n e t h o l d e r

TSB Revision

Page 912 of 2103

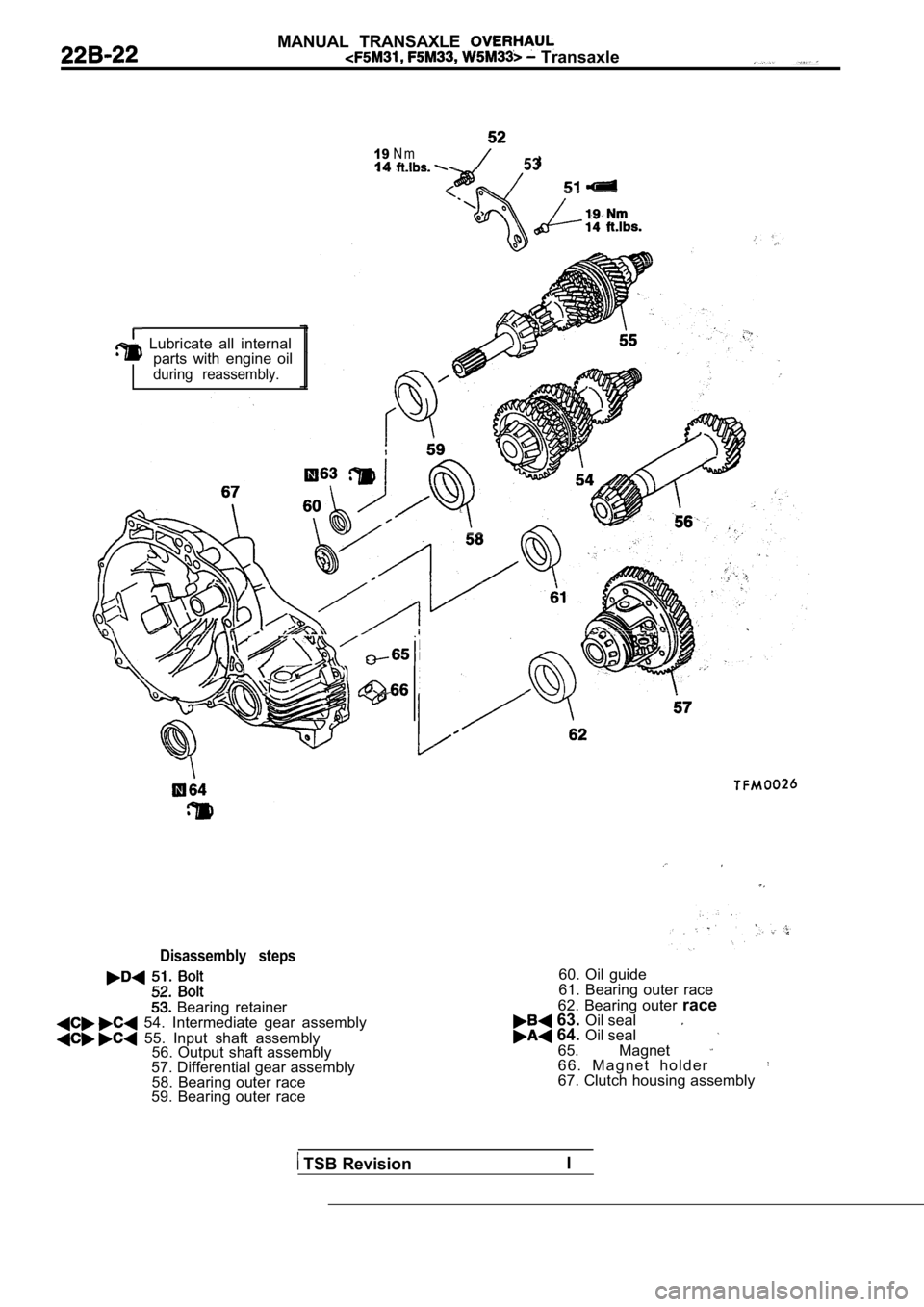

MANUAL TRANSAXLE Transaxle

19N m1453

Lubricate all internalparts with engine oil

during reassembly.

.

Disassembly steps

Bearing retainer 54. Intermediate gear assembly

55. Input shaft assembly 56. Output shaft assembly

57. Differential gear assembly 58. Bearing outer race

59. Bearing outer race 60. Oil guide

61. Bearing outer race

62. Bearing outer race

63. Oil seal 64. Oil seal65. Magnet 6 6 . M a g n e t h o l d e r67. Clutch housing assembly

TSB Revision I

Page 914 of 2103

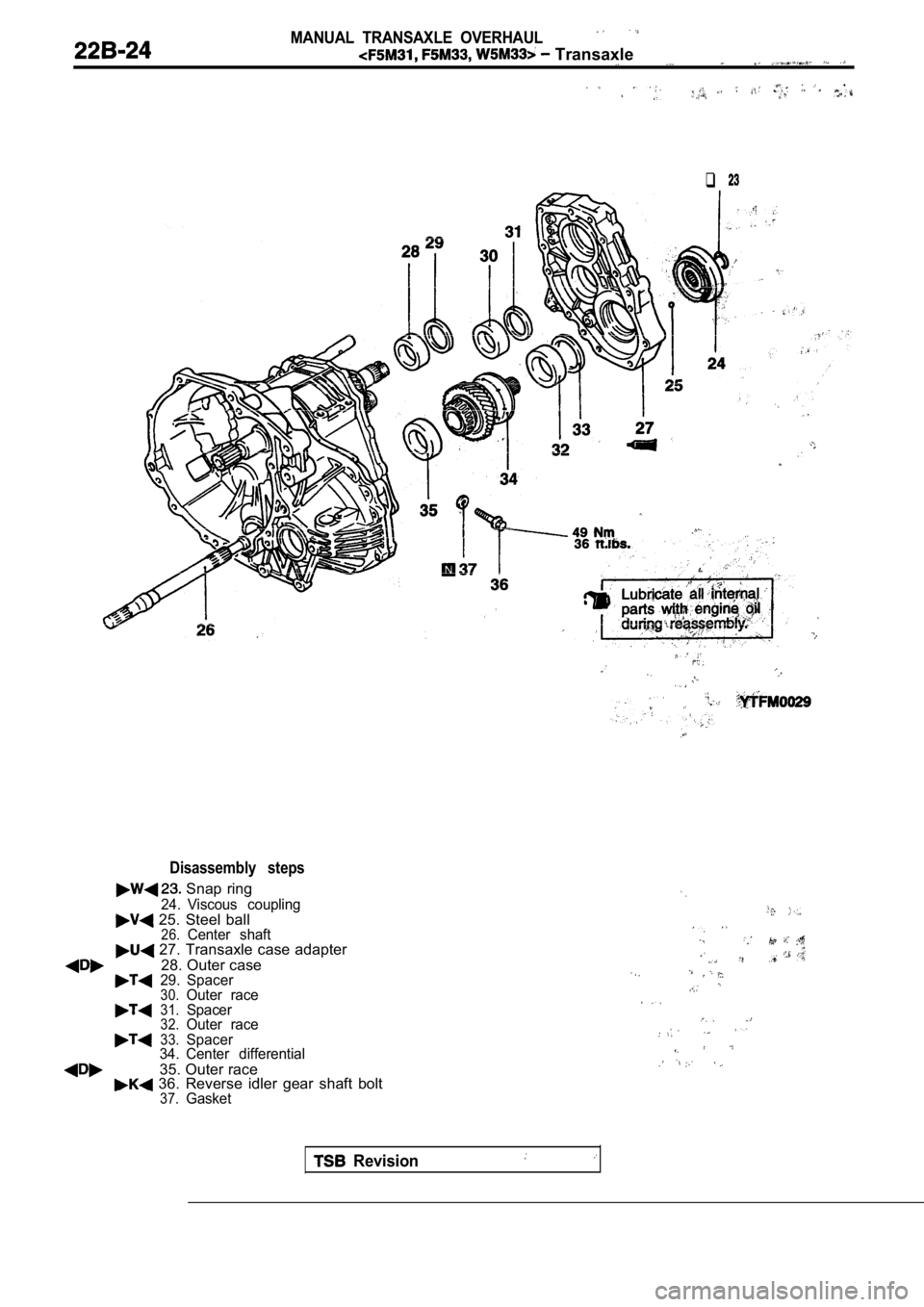

MANUAL TRANSAXLE OVERHAUL

Transaxle

q

Disassembly steps

Snap ring

24. Viscous coupling 25. Steel ball26.Center shaft 27. Transaxle case adapter

28. Outer case29. Spacer30.Outer race31.Spacer32.Outer race33.Spacer

34. Center differential

35. Outer race 36. Reverse idler gear shaft bolt37.Gasket

Revision

Page 920 of 2103

MANUAL Transaxle

SolderSolder

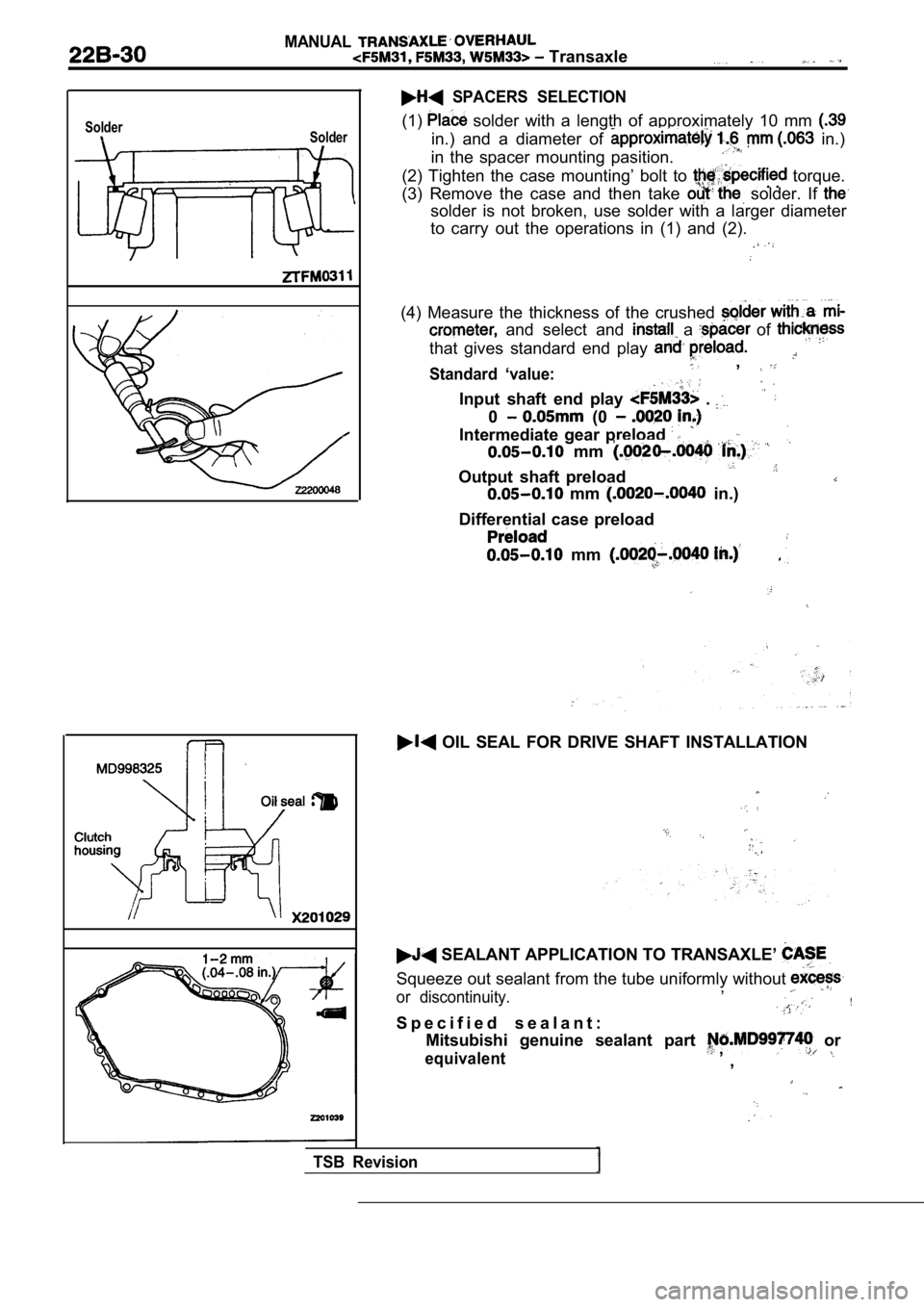

SPACERS SELECTION

(1) solder with a length of approximately 10 mm

in.) and a diameter of in.)

in the spacer mounting pasition.

(2) Tighten the case mounting’ bolt to

torque.

(3) Remove the case and then take

solder. If

solder is not broken, use solder with a larger diam eter

to carry out the operations in (1) and (2).

(4) Measure the thickness of the crushed

and select and a of

that gives standard end play

Standard ‘value: ,

Input shaft end play .

0 (0

Intermediate gear preload

mm

Output shaft preload

mm in.)

Differential case preload

mm

OIL SEAL FOR DRIVE SHAFT INSTALLATION

SEALANT APPLICATION TO TRANSAXLE’

Squeeze out sealant from the tube uniformly without

or discontinuity.,

S p e c i f i e d s e a l a n t :

Mitsubishi genuine sealant part

or

equivalent ,,

TSB Revision

Page 923 of 2103

MANUAL OVERHAUL

Transaxle

Oil seal

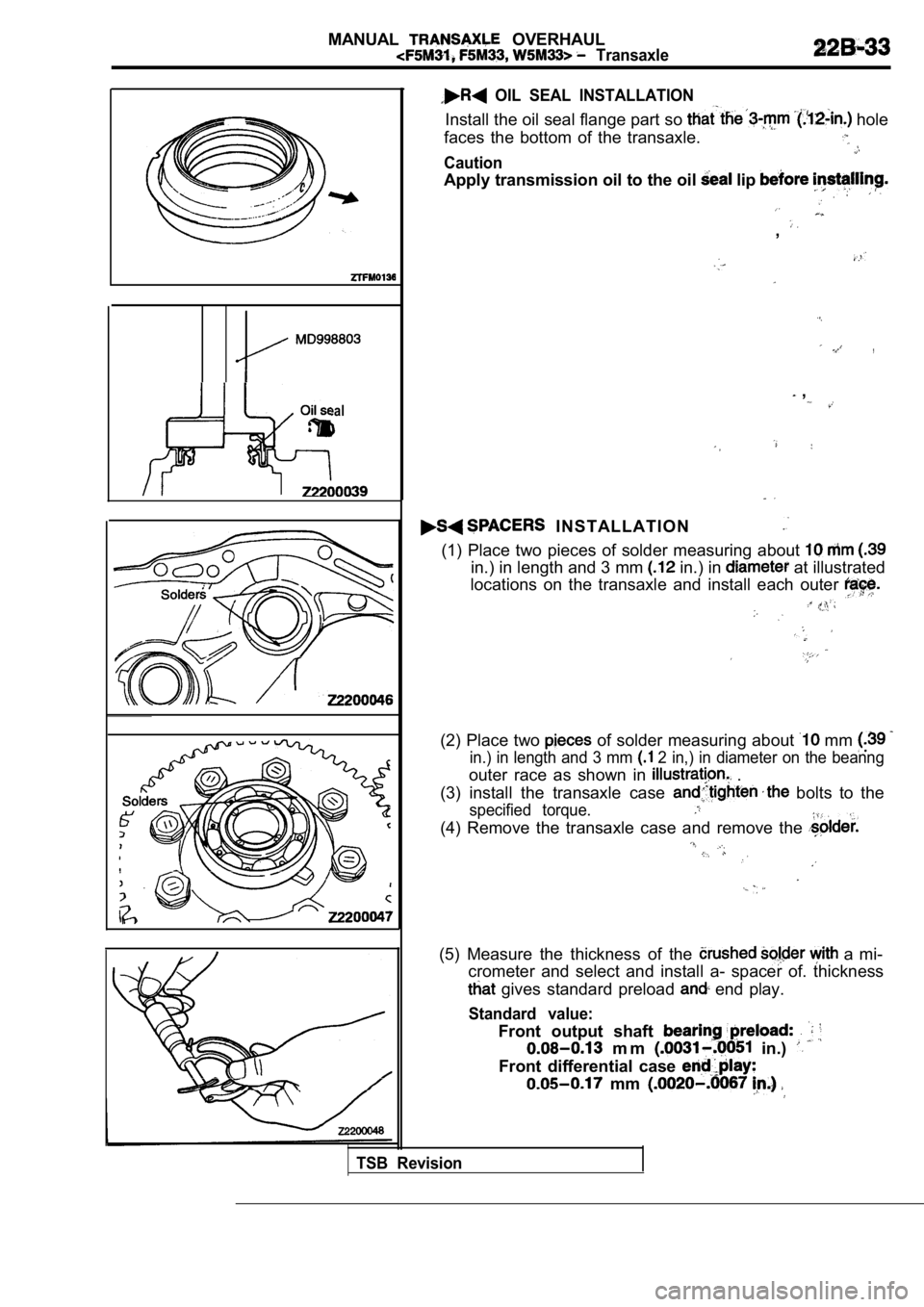

OIL SEAL INSTALLATION

Install the oil seal flange part so hole

faces the bottom of the transaxle.

Caution

Apply transmission oil to the oil lip

,

,

,

I N S T A L L A T I O N

(1) Place two pieces of solder measuring about

in.) in length and 3 mm in.) in at illustrated

locations on the transaxle and install each outer

(2) Place two of solder measuring about mm

in.) in length and 3 mm 2 in,) in diameter on the beanng

outer race as shown in .

(3) install the transaxle case

bolts to the

specified torque.

(4) Remove the transaxle case and remove the

(5) Measure the thickness of the a mi-

crometer and select and install a- spacer of. thick ness

gives standard preload end play.

Standard value:

Front output shaft

m m in.)

Front differential case

mm

TSB Revision

Page 924 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle.,

22200056

0123

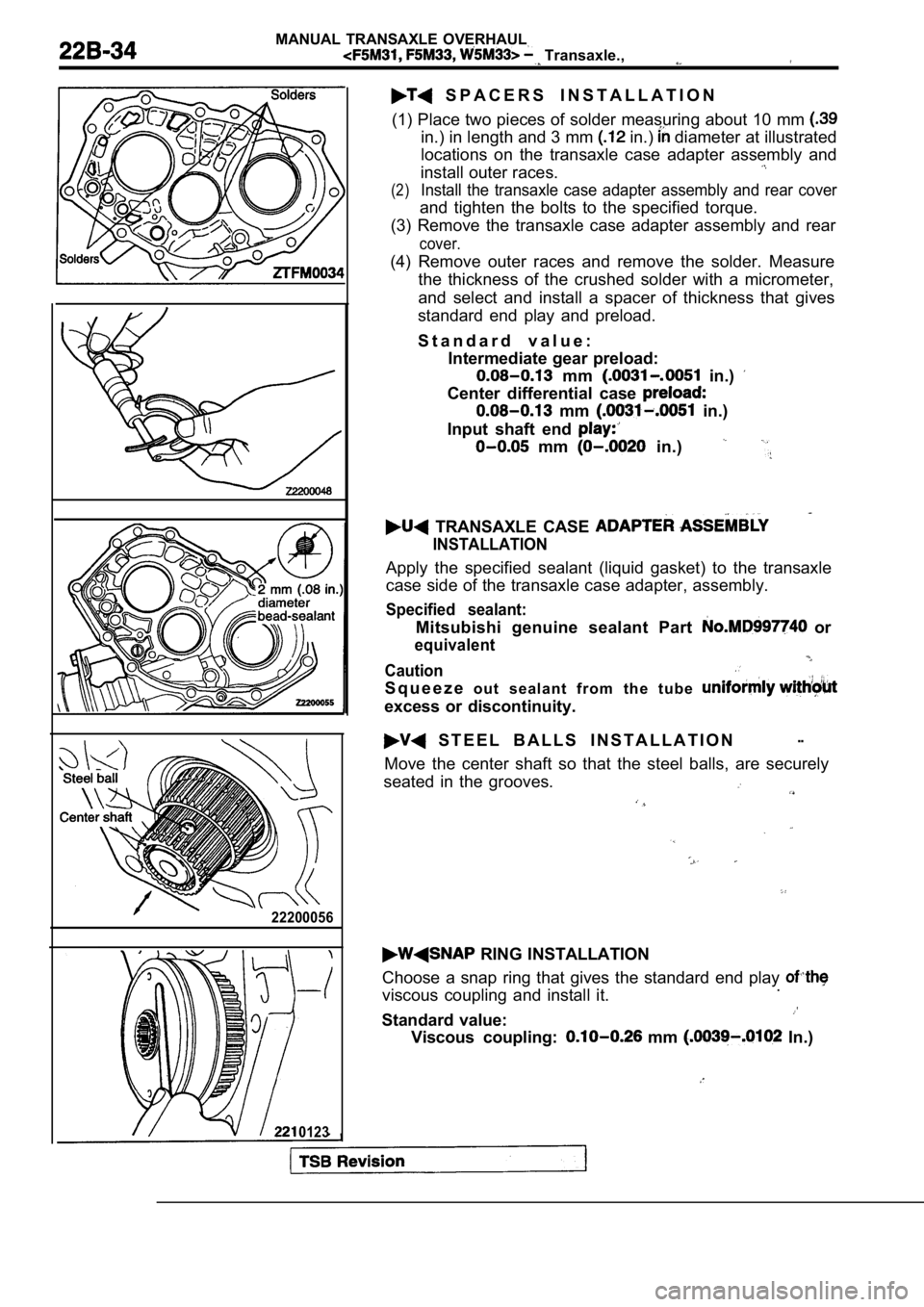

S P A C E R S I N S T A L L A T I O N

(1) Place two pieces of solder measuring about 10 m m

in.) in length and 3 mm in.) diameter at illustrated

locations on the transaxle case adapter assembly an d

install outer races.

(2)Install the transaxle case adapter assembly and rea r cover

and tighten the bolts to the specified torque.

(3) Remove the transaxle case adapter assembly and rear

cover.

(4) Remove outer races and remove the solder. Measu re

the thickness of the crushed solder with a micromet er,

and select and install a spacer of thickness that g ives

standard end play and preload.

S t a n d a r d v a l u e : Intermediate gear preload:

mm in.)

Center differential case

mm in.)

Input shaft end

mm in.)

TRANSAXLE CASE

INSTALLATION

Apply the specified sealant (liquid gasket) to the transaxle

case side of the transaxle case adapter, assembly.

Specified sealant:

Mitsubishi genuine sealant Part or

equivalent

Caution

S q u e e z e o u t s e a l a n t f r o m t h e t u b e

excess or discontinuity.

S T E E L B A L L S I N S T A L L A T I O N--

Move the center shaft so that the steel balls, are securely

seated in the grooves.

RING INSTALLATION

Choose a snap ring that gives the standard end play

viscous coupling and install it..

Standard value:

Viscous coupling: mm In.)

Page 947 of 2103

MANUAL TRANSAXLE OVERHAUL

Differential

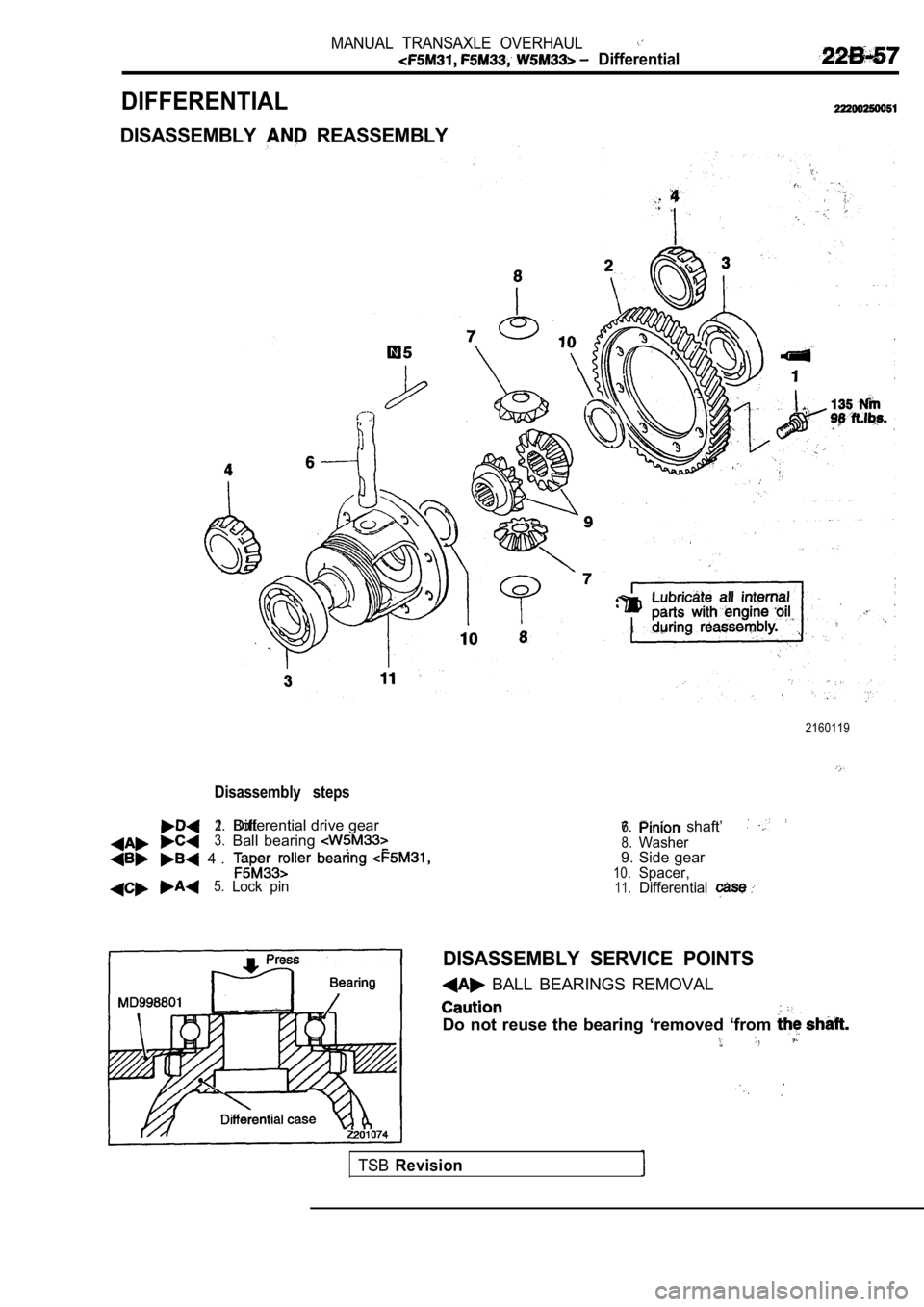

DIFFERENTIAL

DISASSEMBLY REASSEMBLY

2160119

Disassembly steps

1.Bolt2.Differential drive gear3.Ball bearing

4 .

5.Lock pin

6.Pinion shaft’7.

8.Washer9. Side gear10.Spacer,11.Differential

Do not reuse the bearing ‘removed ‘from

DISASSEMBLY SERVICE POINTS

BALL BEARINGS REMOVAL

TSBRevision

Page 948 of 2103

MANUAL TRANSAXLE OVERHAUL

D i f f e r e n t i a l , , .

Bearing

Differential case Lock pin

Lock pinDifferential case

Pinion shaft

ILock pin end with

larger chamferingat three places onpin outside

9

9 Bearing

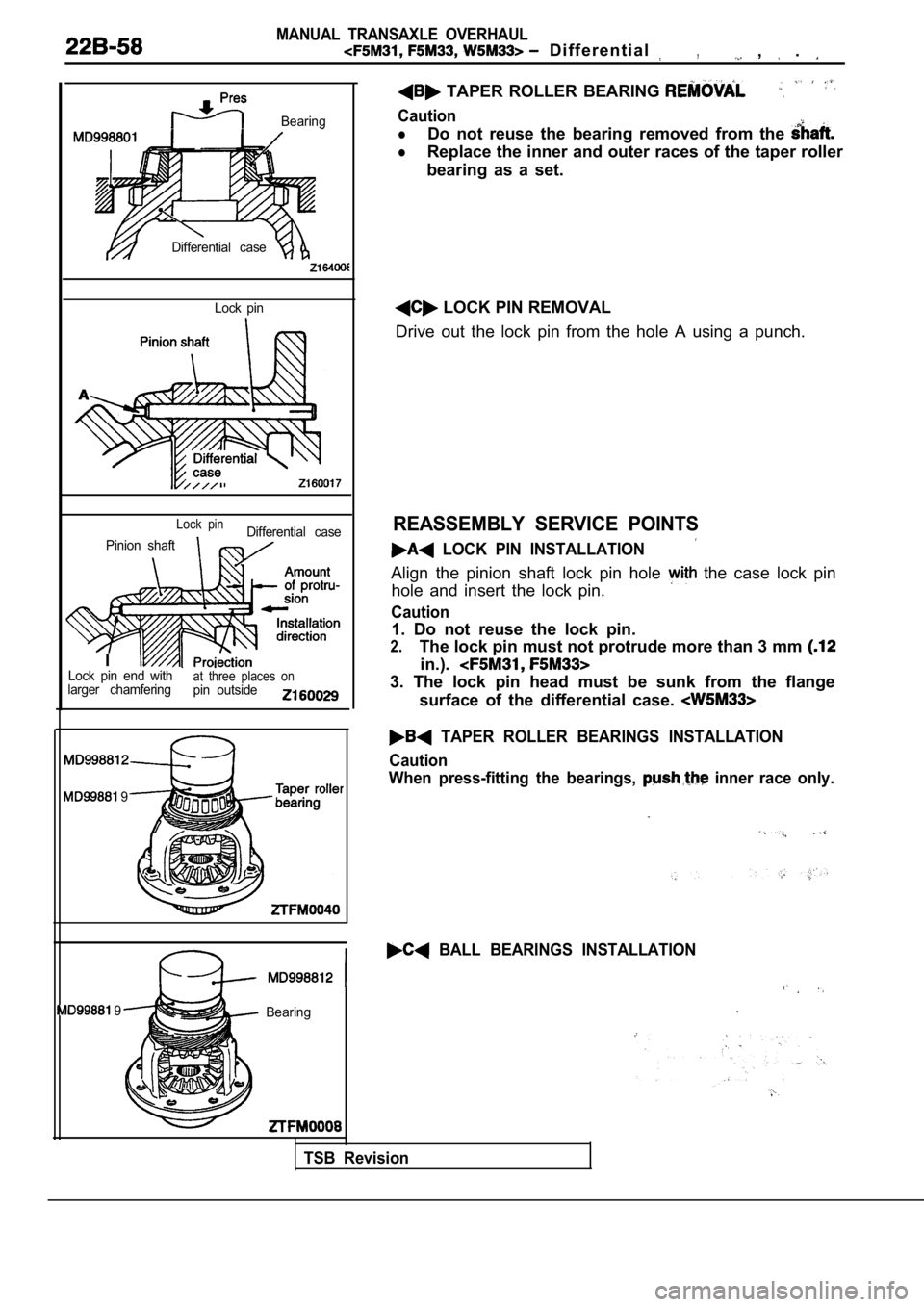

TAPER ROLLER BEARING

Caution

lDo not reuse the bearing removed from the

lReplace the inner and outer races of the taper roll er

bearing as a set.

LOCK PIN REMOVAL

Drive out the lock pin from the hole A using a punc h.

REASSEMBLY SERVICE POINTS

LOCK PIN INSTALLATION

Align the pinion shaft lock pin hole the case lock pin

hole and insert the lock pin.

Caution

1. Do not reuse the lock pin.

2.The lock pin must not protrude more than 3 mm

in.).

3. The lock pin head must be sunk from the flange

surface of the differential case.

TAPER ROLLER BEARINGS INSTALLATION

Caution

When press-fitting the bearings,

inner race only.

BALL BEARINGS INSTALLATION

TSB Revision

Page 949 of 2103

MANUAL TRANSAXLE OVERHAUL Differential

160030I

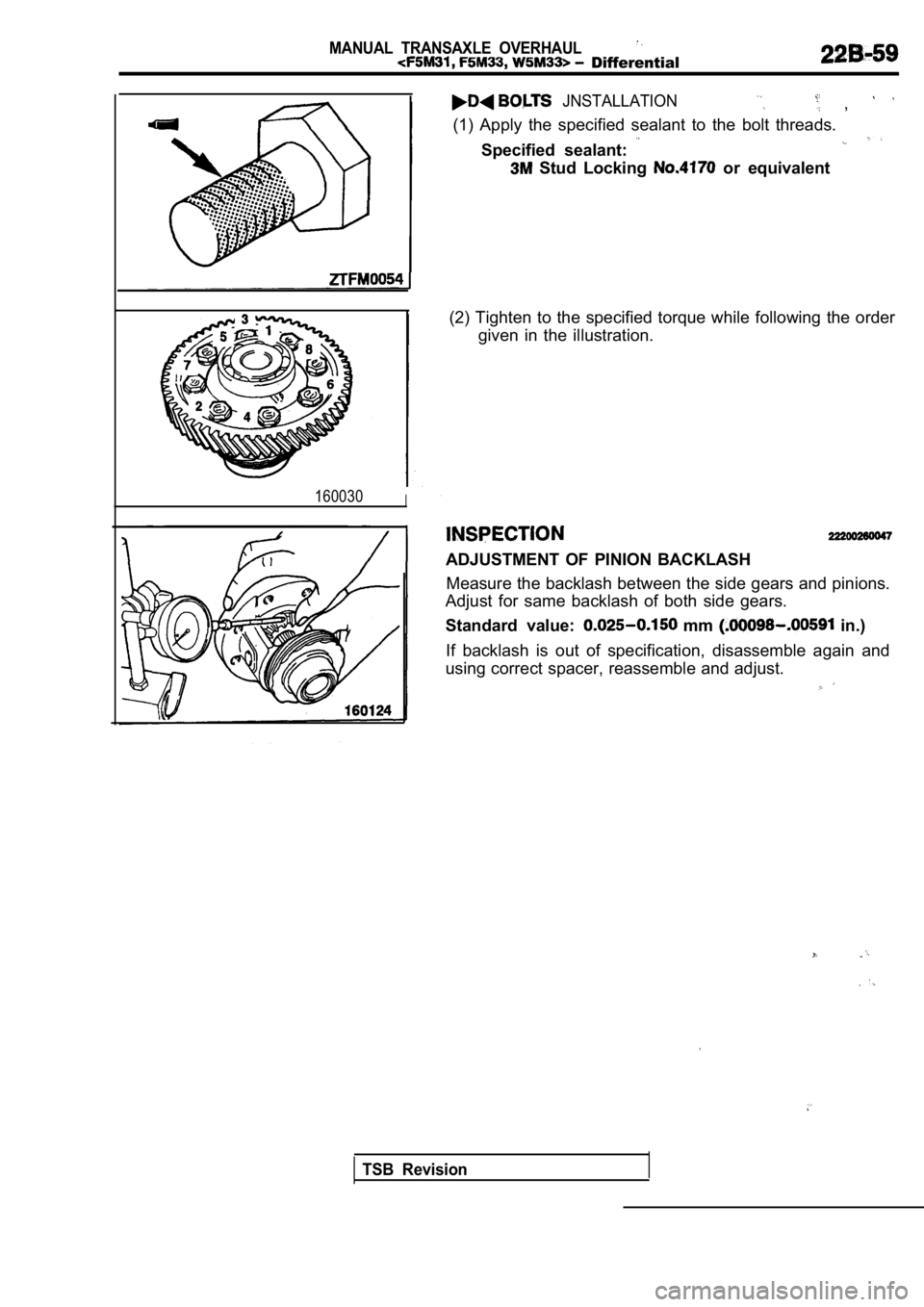

JNSTALLATION ,

(1) Apply the specified sealant to the bolt threads.

Specified sealant:

Stud Locking or equivalent

(2) Tighten to the specified torque while following the order

given in the illustration.

ADJUSTMENT OF PINION BACKLASH

Measure the backlash between the side gears and pin ions.

Adjust for same backlash of both side gears.

Standard value:

mm in.)

If backlash is out of specification, disassemble ag ain and

using correct spacer, reassemble and adjust.

TSB Revision