engine MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

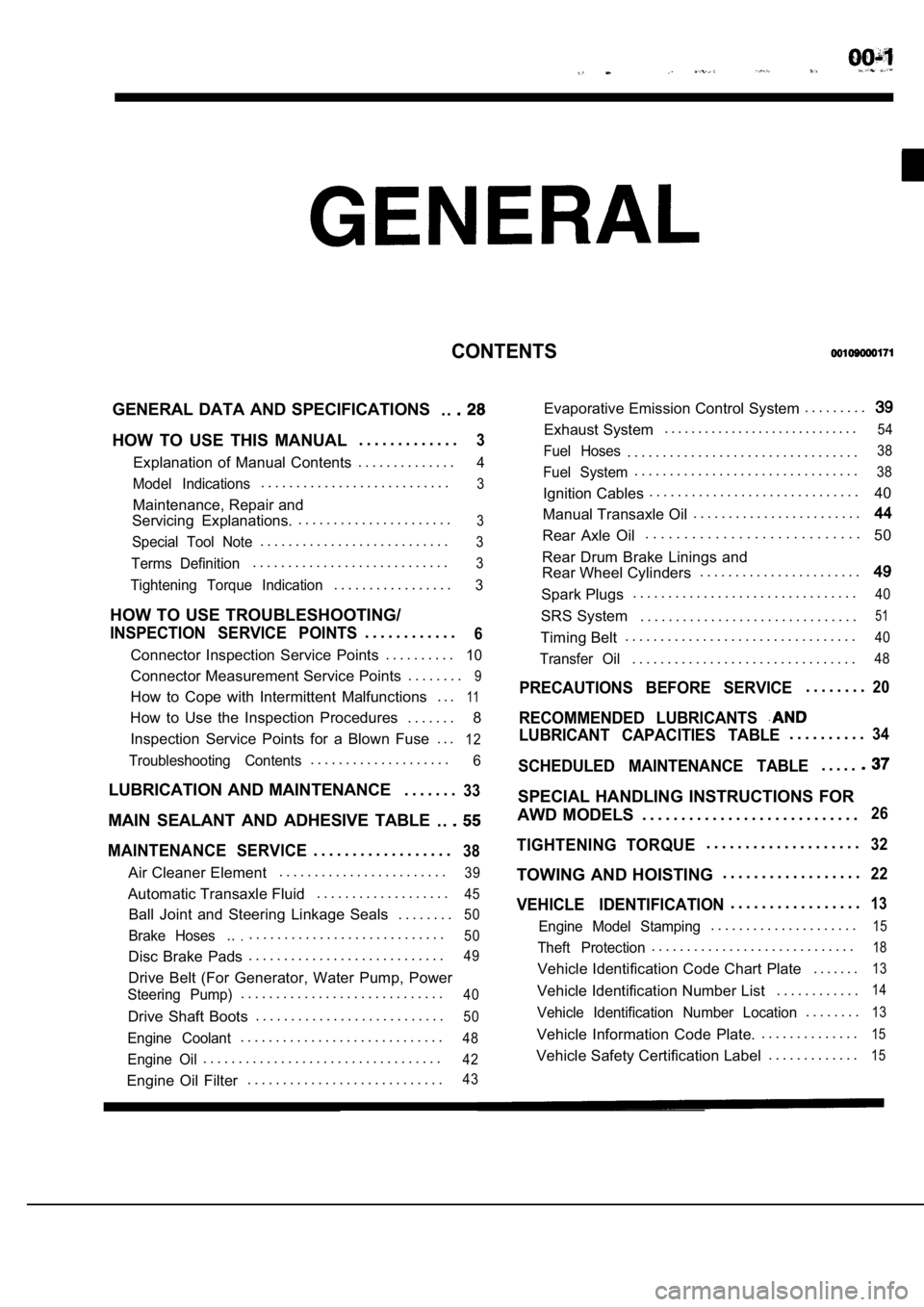

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 5 of 2103

GENERAL How to Use This

HOW TO USE THIS MANUAL

MAINTENANCE, REPAIR AND

SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the model codes, or similar designati on

(engine type, transaxle type, etc.). A description

of these designations is covered in this manual

under “VEHICLE IDENTIFICATION”.

ON-VEHICLE SERVICE

“On-vehicle Service” are procedures for performing

inspections and adjustments of particularly impor-

tant locations with regard to the construction and

for maintenance and servicing, but other inspec-

tions (for looseness, play, cracking, damage, etc.

must also be performed.

SERVICE PROCEDURES

The service steps are arranged in numerical order

and attention must to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

TERMS DEFINITION

STANDARD VALUE

Indicates the value used as the standard for judgin g

the quality of a part or assembly on inspection

or the value to which the part or assembly is cor-

rected and adjusted. It is given by tolerance.

LIMIT

Indicates a maximum or minimum value, the part

or assembly should be kept within, in order to be functional. This value is established outside the

standard value range.

REFERENCE VALUE

Indicates the adjustment value prior to starting th e

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTION

Indicates the presentation of information particula rly

vital to the worker during the performance of maint e-

nance and servicing procedures in order to avoid

the possibility of injury to the worker, or damage

to component parts, or a reduction of component

or vehicle function or performance, etc..

TIGHTENING TORQUE INDICATION

The tightening torque shown in this manual is a

basic value with a tolerance of

10% except the

following cases when the upper. and

of tightening torque are given. (1) The tolerance of the ‘basic value

10%.

(2) Special bolts or, the ‘like are

(3) Special tightening methods are used.

SPECIAL TOOL NOTE

When the MMC special tool is described, please

refer to the special tool

is located at the beginning of each group, for a

cross reference from the tool, number

to the special tool number that available in your

market..

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T

Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T

Indicates the automatic transaxle, or models equip ped with the automatic transaxle.

MFI: Indicates the

fuel injection, or engines equipped with the fuel injection.

Turbo: Indicates the engine with turbocharger, or m odels equipped

such an

Non-turbo: Indicates the engine without turbocharger, or models equipped with, such anengine.

FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles.

ABS: Indicates the anti-lock braking system or mode ls equipped with the

braking

Page 16 of 2103

G E N E R A L Vehicle

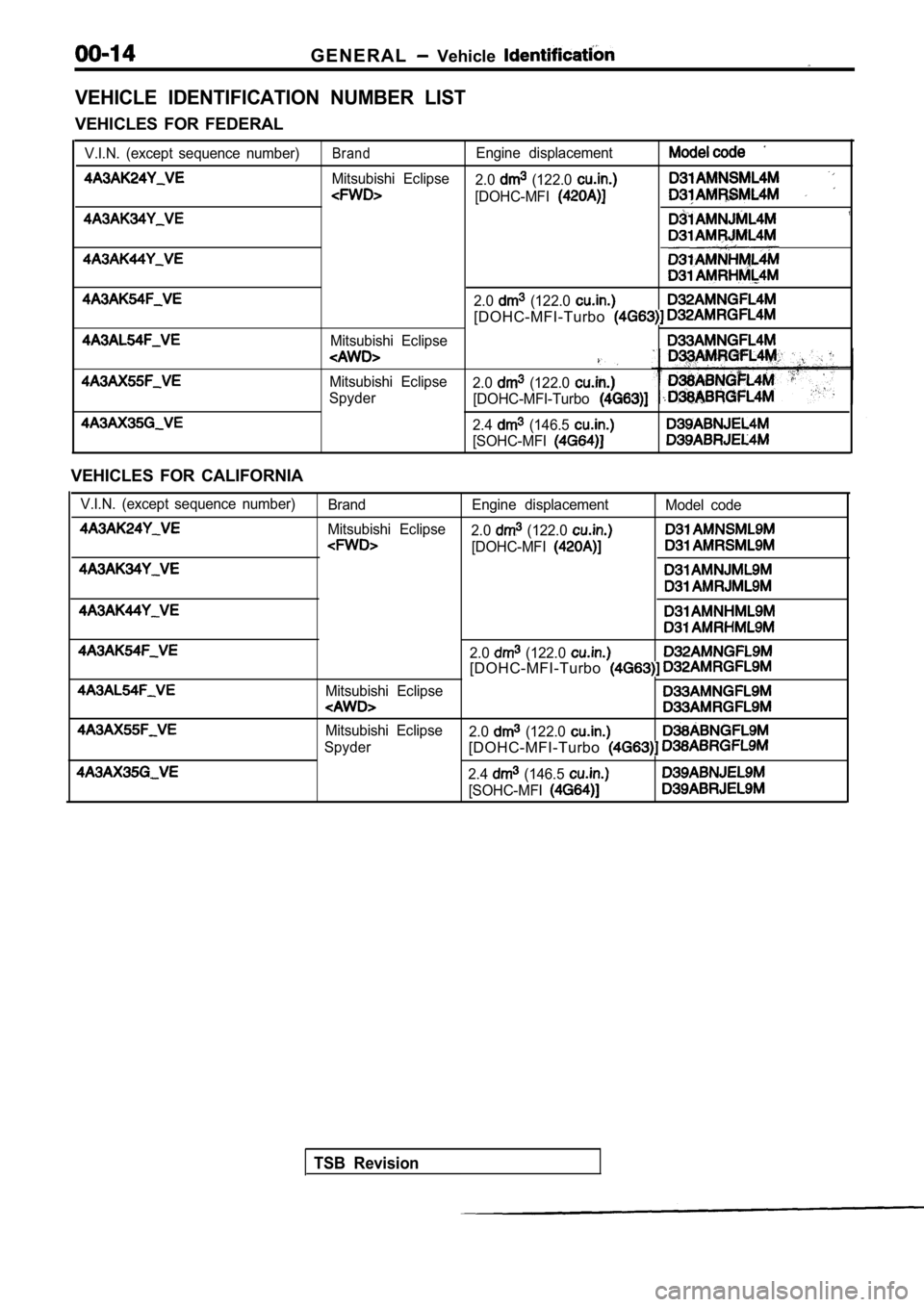

VEHICLE IDENTIFICATION NUMBER LIST

VEHICLES FOR FEDERAL

V.I.N. (except sequence number)BrandEngine displacement

Mitsubishi Eclipse2.0 (122.0

[DOHC-MFI

2.0 (122.0

[DOHC-MFI-Turbo

Mitsubishi Eclipse

Mitsubishi Eclipse2.0 (122.0 Spyder [DOHC-MFI-Turbo

2.4 (146.5

[SOHC-MFI

VEHICLES FOR CALIFORNIA

V.I.N. (except sequence number)Brand Engine displacement Model code

Mitsubishi Eclipse 2.0

(122.0

[DOHC-MFI

2.0 (122.0 [DOHC-MFI-Turbo

Mitsubishi Eclipse

Mitsubishi Eclipse 2.0 (122.0

Spyder[DOHC-MFI-Turbo

2.4 (146.5

[SOHC-MFI

TSB Revision

Page 17 of 2103

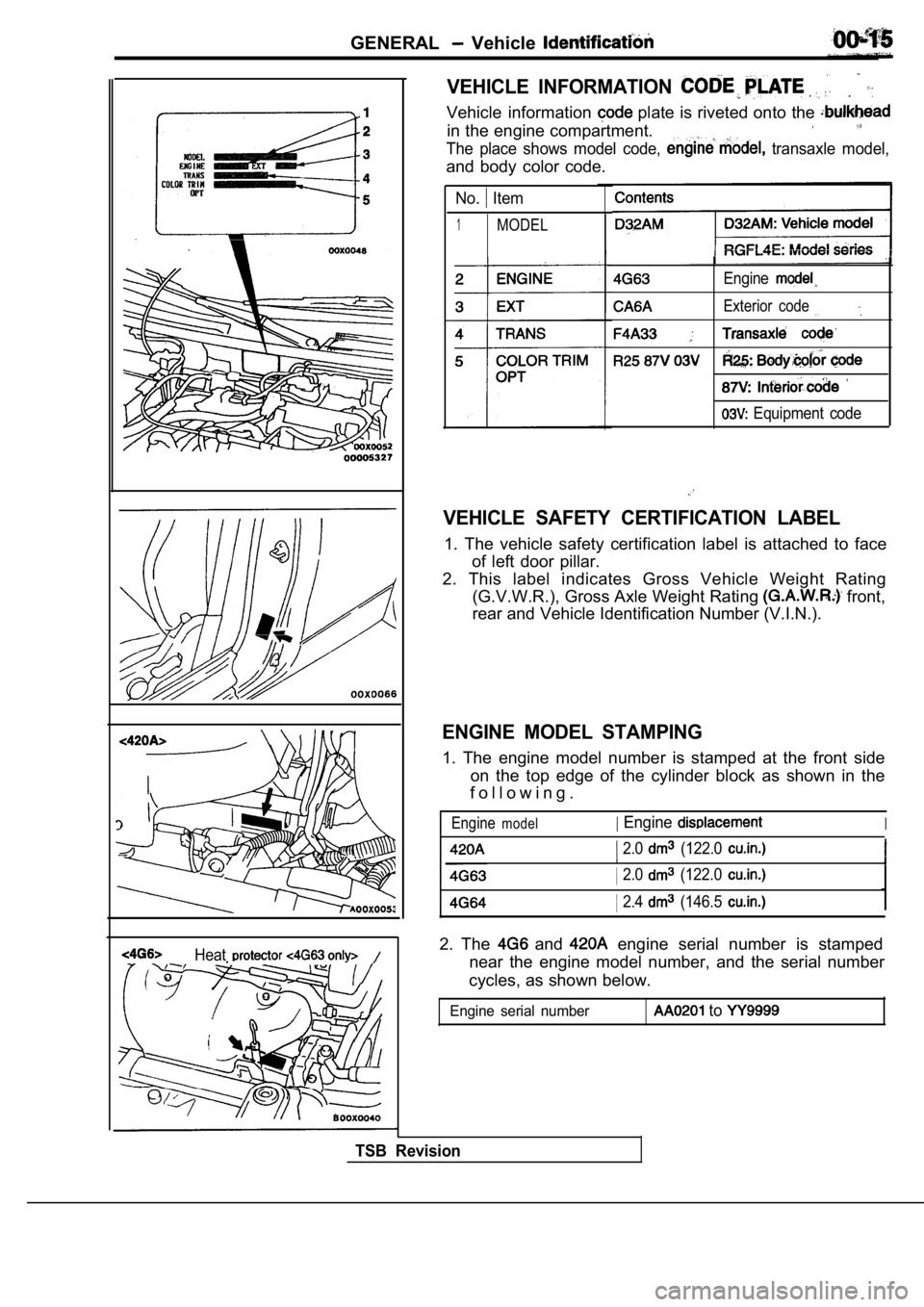

GENERAL Vehicle

Heat

VEHICLE INFORMATION

Vehicle information plate is riveted onto the

in the engine compartment.

The place shows model code, transaxle model,

and body color code.

No. Item

1MODEL

Engine

Exterior code

Equipment code

VEHICLE SAFETY CERTIFICATION LABEL

1. The vehicle safety certification label is attached to face

of left door pillar.

2. This label indicates Gross Vehicle Weight Rating (G.V.W.R.), Gross Axle Weight Rating

front,

rear and Vehicle Identification Number (V.I.N.).

ENGINE MODEL STAMPING

1. The engine model number is stamped at the front side

on the top edge of the cylinder block as shown in t he

f o l l o w i n g .

Enginemodel Engine

2.0 (122.0

I

I 2.0 (122.0

2.4 (146.5

2. The and engine serial number is stamped

near the engine model number, and the serial number

cycles, as shown below.

Engine serial number to

TSB Revision

Page 18 of 2103

GENERAL Vehicle Identification

Theft protection label

Fororiginal parts

MITSUBISHI

0 0 2 0 0 1 4

Forreplacement parts

MITSUBISHI

0 0 2 0 0 1 5

0 0 0 0 4 7 4 3THEFT

PROTECTION

In order to protect against theft, a Vehicle Identification Number

is stamped in, or attached as a label to, the foll owing

major parts of the engine and transaxle,

as main

outer panels:

Engine cylinder block, Transaxle housing. Door, Quar-

ter panel, Hood, Liftgate, Trunk lid, Bumpers

In addition, a theft-protection label is attached t o replacement

parts for the body outer panel main and the

same data are stamped into replacement parts for th e engine

and the transaxle.

Cautions regarding panel repairs:‘

1.When repainting original so first mask-

ing the theft-protection label, and, after be

sure to peel off the masking tape.

2.The theft-protection label for parts cov-

ered bymasking tape, such part&an be

as is. The masking tape should removed

ing is finished.

3.The theft-protection label should not be from

original or replacement parts.

,

. .

TSB Revision

Page 19 of 2103

GENERAL Vehicle

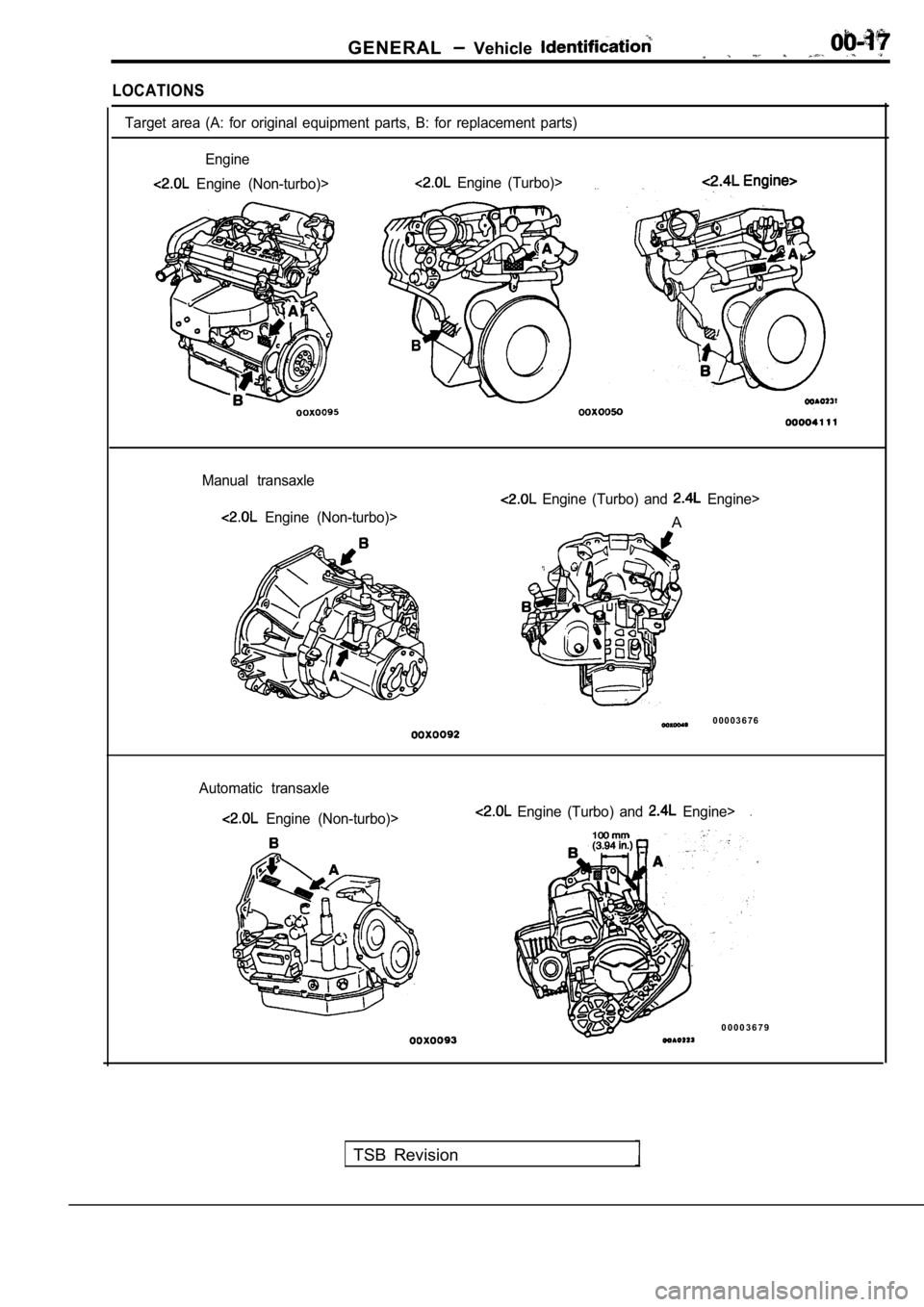

LOCATIONS

Target area (A: for original equipment parts, B: for replacement parts)

Engine

Engine (Non-turbo)> Engine (Turbo)>

Manual transaxle

Engine (Non-turbo)>

Engine (Turbo) and Engine>

A

0 0 0 0 3 6 7 6

Automatic transaxle

Engine (Non-turbo)> Engine (Turbo) and Engine>.

0 0 0 0 3 6 7 9

TSB Revision

Page 23 of 2103

GENERAL Precautions before Service . .

Caution

1.Before connecting or disconnecting the negative

be sure to turn off the ignition and

the lighting switch.

(if this is not done, the possibility semi-

conductor parts being damaged.)

2.After completion of the work steps [when the bat-

tery’s negative terminal is connected], warm

up the engine and allow it for approximately

five minutes under the conditions be-

low, in order to stabilize the engine condi-

tions, and then check to be sure that idling’ is

satisfactory.

Engine temperature:

Lights, electric fans, accessories: OFF

Transaxle: Neutral position

(A/T models: “N” or “P”)

Steering

neutral (center) position

mm (in.)

Scan tool

ROM pack

VEHICLE WASHING

If high-pressure car-washing equipment or steam car -washing

equipment is used to wash the vehicle, be maintain

the spray nozzle at a distance of at ‘least 300 mm (12 in.)

from any plastic parts and all opening parts (doors , luggage

compartment, etc.).

APPLYING ANTI-CORROSION

OTHER UNDERCOAT AGENTS.,

Be careful not to adhere oil or grease to the heate d oxygen

sensor. If adhered, the sensor may malfunction.

Protect the heated oxygen sensor with a cover befor e applying

anti-corrosion agent, etc.

SCAN TOOL

To operate the scan tool, refer to the “MUT-II OPER ATING

INSTRUCTIONS”.

Caution

Turn the ignition switch off befoie connecting and discon-

necting the scan tool.

Page 29 of 2103

GENERAL Special Handling Instructions for Models

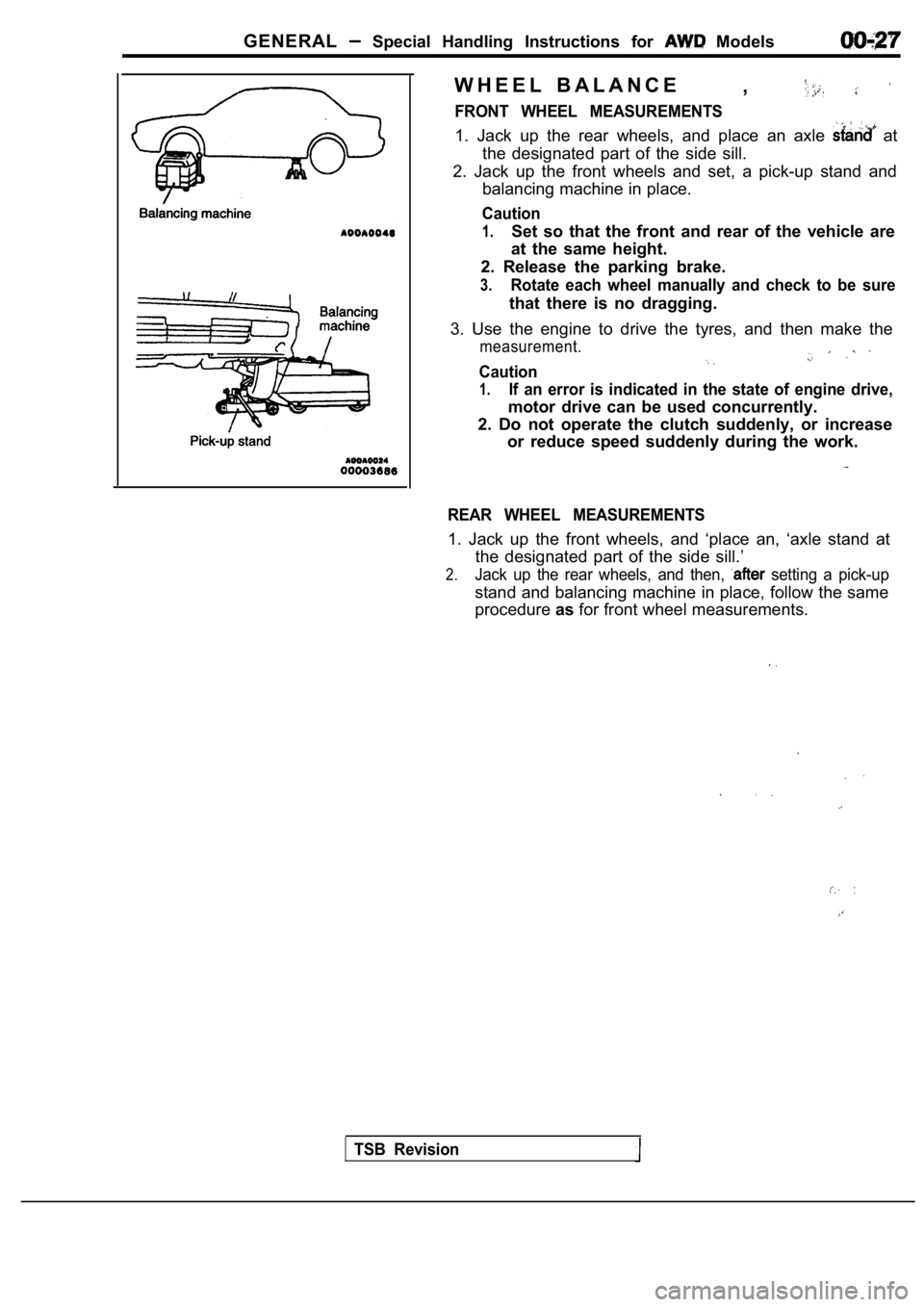

W H E E L B A L A N C E,

FRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle at

the designated part of the side sill.

2. Jack up the front wheels and set, a pick-up stan d and

balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are

at the same height.

2. Release the parking brake.

3.Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tyres, and then make the

measurement.

Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2. Do not operate the clutch suddenly, or increase or reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and ‘place an, ‘axle s tand at

the designated part of the side sill.’

2.Jack up the rear wheels, and then, setting a pick-up

stand and balancing machine in place, follow the sa me

procedure asfor front wheel measurements.

TSB Revision

Page 32 of 2103

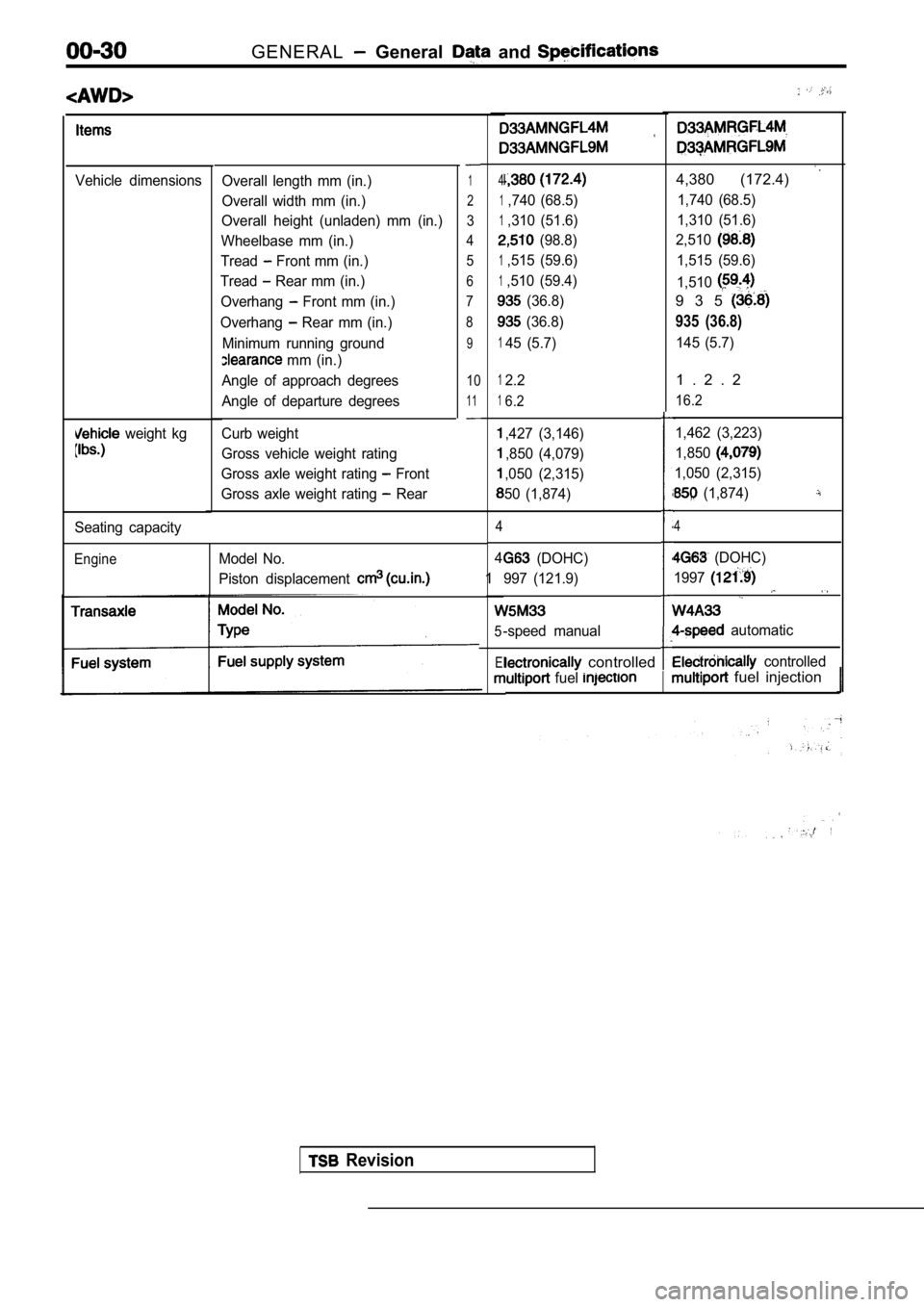

GENERAL General and

Vehicle dimensions

weight kg

Overall length mm (in.)

Overall width mm (in.)

Overall height (unladen) mm (in.)

Wheelbase mm (in.)

Tread

Front mm (in.)

Tread

Rear mm (in.)

Overhang

Front mm (in.)

Overhang

Rear mm (in.)

Minimum running ground

mm (in.)

Angle of approach degrees

Angle of departure degrees

Curb weight

Gross vehicle weight rating

Gross axle weight rating

Front

Gross axle weight rating

Rear

1

2

3

4 5

6

7

8

9

10

11

Seating capacity

EngineModel No.

Piston displacement

4

1,740 (68.5)

1,310 (51.6)

(98.8)

1,515 (59.6)

1,510 (59.4)

(36.8)

(36.8)

145 (5.7)

4,380 (172.4)

1,740 (68.5)

1,310 (51.6)

2,510

1,515 (59.6)

1,510

9 3 5

935 (36.8)

145 (5.7)

12.2

16.2

,427 (3,146)

,850 (4,079)

,050 (2,315)

50 (1,874)

4

4

1

5

El

1 . 2 . 2

16.2

1,462 (3,223)

1,850

1,050 (2,315)

(1,874)

4

(DOHC)

997 (121.9)

-speed manual

(DOHC)

1997

automatic

controlled controlled

fuel fuel injection

Revision

Page 35 of 2103

GENERAL Lubrication arid Maintenance,

00100120067

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual ve-

hicle owner’s driving habits, the area in which the

vehicle is operated and the type of to which

the vehicle is subjected, it is necessary to prescr ibe

lubrication and maintenance service on a time fre-

quency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by

the Society of Automotive Engineers (SAE), the

American Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”. Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item

in the “MAINTENANCE SERVICE” section.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information is included in ap-

propriate units for vehicles operating under one

or more of the following conditions:

1. Police, taxi, or commercial type operation

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traf-

fic during hot weather above

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

Either of the following engine oils should be used:

(1) Engine oil displaying EOLCS certification mark

(2) Engine oil conforming to the API classification SH

or ECII.

For further details, refer to “LUBRICANTS SELEC-

TION” section.

Caution

Test to EPA have shown

laboratory animals develop skin after

prolonged contact with used engine oil. Accord-

ingly, the potential exists for

to

a number:, of skin disorders, including

from such exposure to used

Care should be taken, when changing

engine oil, to minimize the

of exposure time to used your

skin. Protective clothing and that

be penetrated by worn.

should be thoroughly with soap

use waterless hand remove,

any used engine oil. Do not use gasoline, thin- ners, or solvents.

GEAR LUBRICANTS

The SAE grade number indicates

of Multi-purpose Gear Lubricants.

The API classification system

cants in terms of gear lubricants

conforming to API

or ‘with a

of SAE are recommended for

transaxle.

LUBRICANTS GREASES

Semi-solid lubricants bear the

designation

and are further classified as grades 0, 1, 2; 3 etc .

Whenever “Chassis Lubricant” is specified, Multi-

purpose Grease,

grade 2, should be used.

FUEL USAGE

Your car must use unleaded

This car has a fuel filler tube especially

to accept only the smaller-diameter unleaded gaso- line dispensing nozzle.

Caution

Using leaded gasoline in your car will damage

the catalytic converter and oxygen sensor, and

affect the warranty coverage validity.

Your car is designed to operate on premium

leaded gasoline having a minimum octane rating

of 91 or 95 RON (Research Octane

If premium unleaded gasoline is not

leaded gasoline having a octane rating of 87,

91 RON (Research Octane Number) may be used. In this case, the performance and fuel consumption

will suffer a little degradation.

Gasolines Containing Alcohol

Some gasolines sold at service stations contain

alcohol, although they may not be so identified.

TSB Revision