gas mileage MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 35 of 2103

GENERAL Lubrication arid Maintenance,

00100120067

Maintenance and lubrication service recommenda-

tions have been compiled to provide maximum

protection for the vehicle owner’s investment

against all reasonable types of driving conditions.

Since these conditions vary with the individual ve-

hicle owner’s driving habits, the area in which the

vehicle is operated and the type of to which

the vehicle is subjected, it is necessary to prescr ibe

lubrication and maintenance service on a time fre-

quency as well as mileage interval basis.

Oils, lubricants and greases are classified and

graded according to standards recommended by

the Society of Automotive Engineers (SAE), the

American Petroleum Institute (API) and the National

Lubricating Grease Institute (NLGI).

MAINTENANCE SCHEDULES

Information for service maintenance is provided

under “SCHEDULED MAINTENANCE TABLE”.

Three schedules are provided; one for “Required

Maintenance”, one for “General Maintenance” and

one for “Severe Usage Service”. Item numbers in the “SCHEDULED MAINTE-

NANCE TABLE” correspond to the item

in the “MAINTENANCE SERVICE” section.

SEVERE SERVICE

Vehicles operating under severe service conditions

will require more frequent service. Component service information is included in ap-

propriate units for vehicles operating under one

or more of the following conditions:

1. Police, taxi, or commercial type operation

2. Operation of Vehicle

(1) Short-trip operation at freezing temperature

(engine not thoroughly warmed up)

(2) More than 50% operation in heavy city traf-

fic during hot weather above

(3) Extensive idling

(4) Driving in sandy areas

(5) Driving in salty areas

(6) Driving in dusty conditions

ENGINE OIL

Either of the following engine oils should be used:

(1) Engine oil displaying EOLCS certification mark

(2) Engine oil conforming to the API classification SH

or ECII.

For further details, refer to “LUBRICANTS SELEC-

TION” section.

Caution

Test to EPA have shown

laboratory animals develop skin after

prolonged contact with used engine oil. Accord-

ingly, the potential exists for

to

a number:, of skin disorders, including

from such exposure to used

Care should be taken, when changing

engine oil, to minimize the

of exposure time to used your

skin. Protective clothing and that

be penetrated by worn.

should be thoroughly with soap

use waterless hand remove,

any used engine oil. Do not use gasoline, thin- ners, or solvents.

GEAR LUBRICANTS

The SAE grade number indicates

of Multi-purpose Gear Lubricants.

The API classification system

cants in terms of gear lubricants

conforming to API

or ‘with a

of SAE are recommended for

transaxle.

LUBRICANTS GREASES

Semi-solid lubricants bear the

designation

and are further classified as grades 0, 1, 2; 3 etc .

Whenever “Chassis Lubricant” is specified, Multi-

purpose Grease,

grade 2, should be used.

FUEL USAGE

Your car must use unleaded

This car has a fuel filler tube especially

to accept only the smaller-diameter unleaded gaso- line dispensing nozzle.

Caution

Using leaded gasoline in your car will damage

the catalytic converter and oxygen sensor, and

affect the warranty coverage validity.

Your car is designed to operate on premium

leaded gasoline having a minimum octane rating

of 91 or 95 RON (Research Octane

If premium unleaded gasoline is not

leaded gasoline having a octane rating of 87,

91 RON (Research Octane Number) may be used. In this case, the performance and fuel consumption

will suffer a little degradation.

Gasolines Containing Alcohol

Some gasolines sold at service stations contain

alcohol, although they may not be so identified.

TSB Revision

Page 785 of 2103

Emission

ENGINE AND EMISSION CONTROL

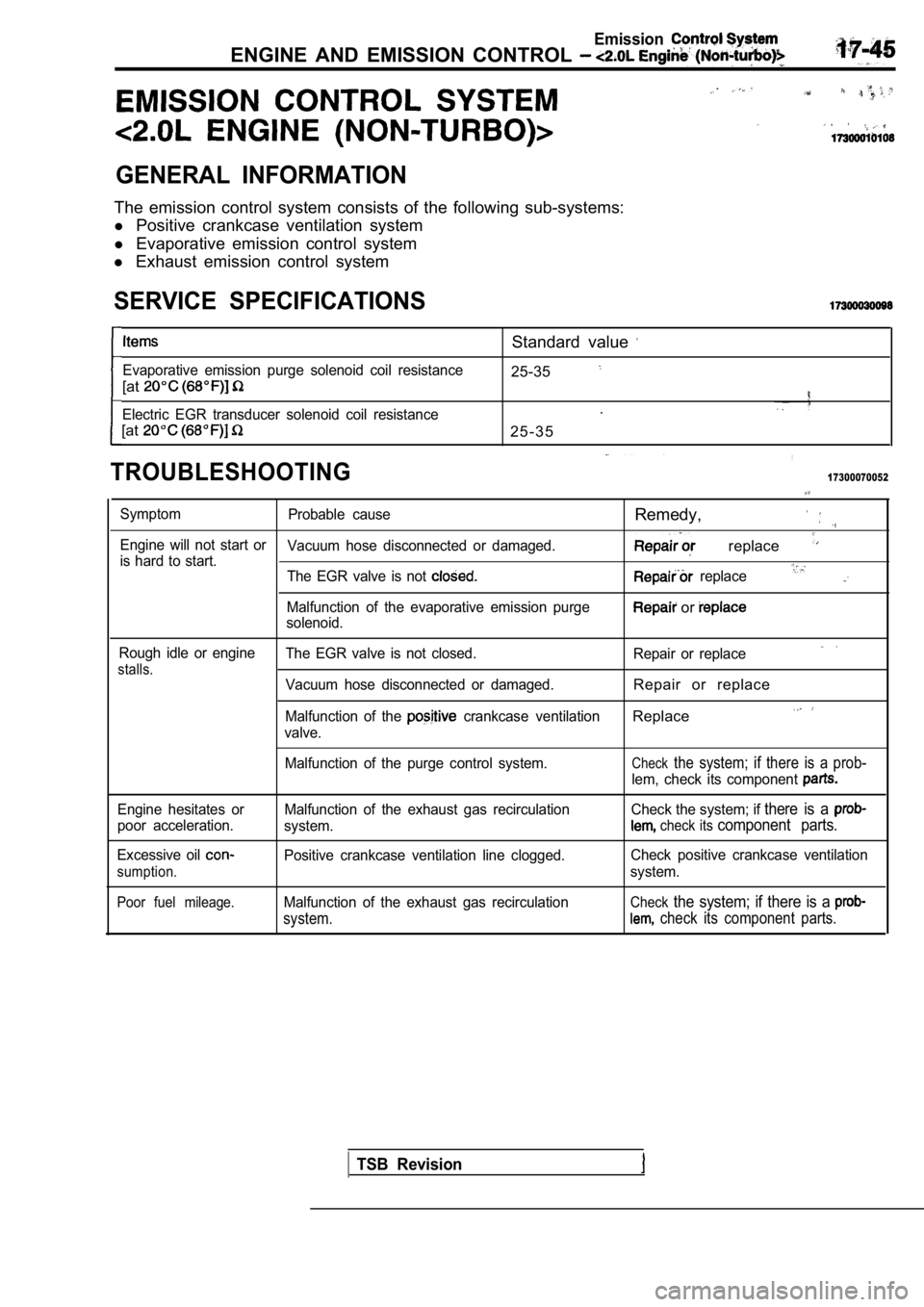

GENERAL INFORMATION

The emission control system consists of the following sub-systems:

l Positive crankcase ventilation system

l Evaporative emission control system

l Exhaust emission control system

SERVICE SPECIFICATIONS

Evaporative emission purge solenoid coil resistance

[at

Electric EGR transducer solenoid coil resistance

[at

Standard value

25-35

.

2 5 - 3 5

TROUBLESHOOTING17300070052

Symptom Probable causeRemedy,

Engine will not start or

Vacuum hose disconnected or damaged. replace is hard to start.

The EGR valve is not replace

Malfunction of the evaporative emission purge or solenoid.

Rough idle or engineThe EGR valve is not closed. Repair or replace

stalls.Vacuum hose disconnected or damaged.Repair or replace

Malfunction of the crankcase ventilationReplace

valve.

Malfunction of the purge control system.

Checkthe system; if there is a prob-

lem, check its component

Engine hesitates or

poor acceleration.

Excessive oil

sumption.

Poor fuel mileage.

Malfunction of the exhaust gas recirculation

system.

Positive crankcase ventilation line clogged.

Malfunction of the exhaust gas recirculation

system.

Check the system; if there is a

check its component parts.

Check positive crankcase ventilation

system.

Checkthe system; if there is a

check its component parts.

TSB Revision

Page 799 of 2103

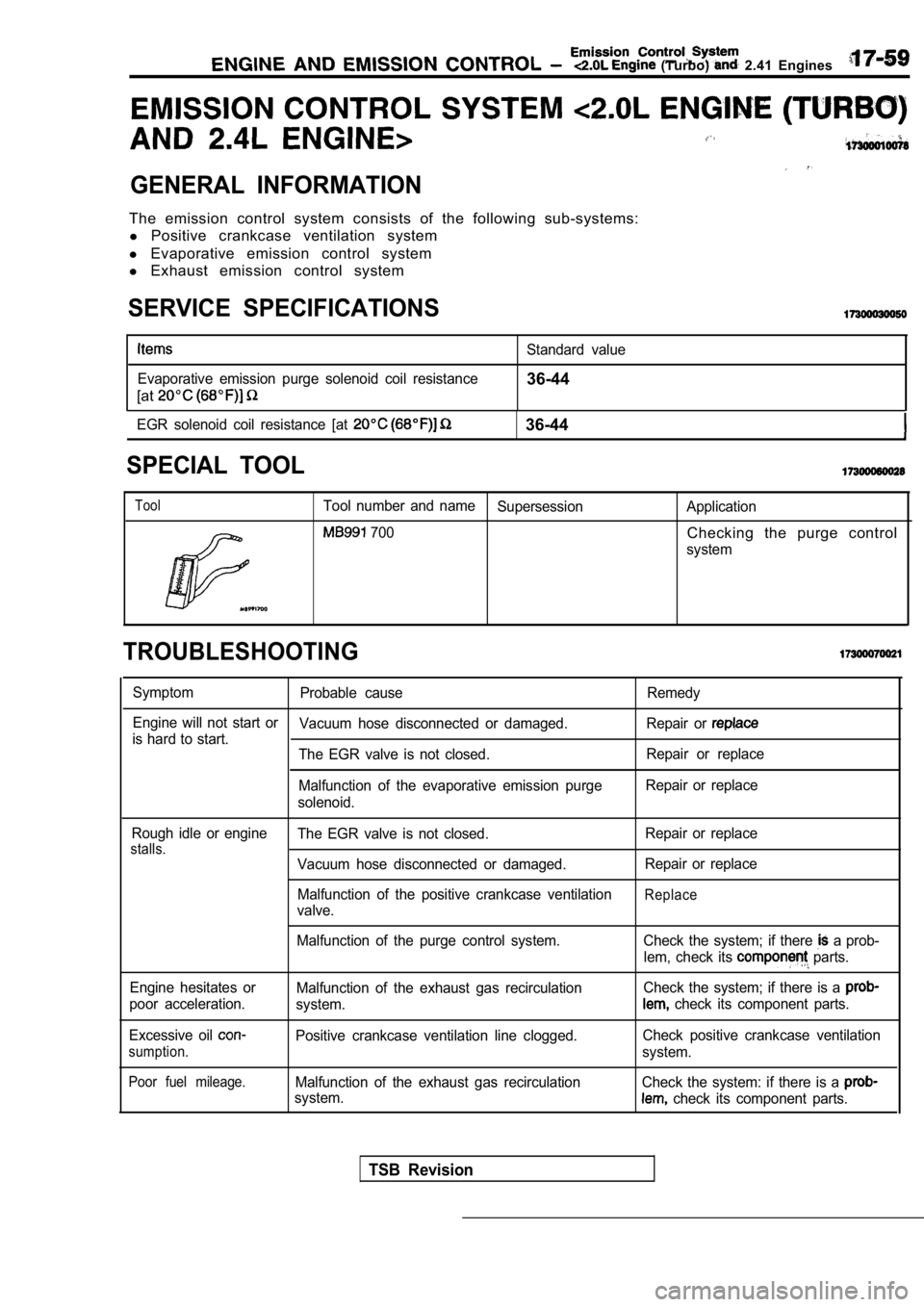

(Turbo) 2.41 Engines

GENERAL INFORMATION

The emission control system consists of the following sub-systems:

l Positive crankcase ventilation system

l Evaporative emission control system

l Exhaust emission control system

SERVICE SPECIFICATIONS

Evaporative emission purge solenoid coil resistance

[at

Standard value

36-44

EGR solenoid coil resistance [at 36-44

SPECIAL TOOL

ToolTool number and name

Supersession Application

700Checking the purge control

system

TROUBLESHOOTING

SymptomProbable cause Remedy

Engine will not start or Vacuum hose disconnected or damaged. Repair or

is hard to start.

The EGR valve is not closed. Repair or replace

Malfunction of the evaporative emission purge Repair or replace

solenoid.

Rough idle or engine

stalls.The EGR valve is not closed.

Vacuum hose disconnected or damaged.

Malfunction of the positive crankcase ventilation

valve. Repair or replace

Repair or replace

Replace

Malfunction of the purge control system.

Engine hesitates or

poor acceleration.

Excessive oil

sumption.

Poor fuel mileage.

Malfunction of the exhaust gas recirculation

system.

Positive crankcase ventilation line clogged.

Malfunction of the exhaust gas recirculation

system. Check the system; if there

a prob-

lem, check its

parts.

Check the system; if there is a

check its component parts.

Check positive crankcase ventilation

system.

Check the system: if there is a

check its component parts.

TSB Revision