ignition MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 3 of 2103

CONTENTS

GENERAL DATA AND SPECIFICATIONS. .

HOW TO USE THIS MANUAL. . . . . . . . . . . . .3

Explanation of Manual Contents. . . . . . . . . . . . . .4

Model Indications

. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance, Repair and

Servicing Explanations. . . . . . . . . . . . . . . . . . . . . . .

3

Special Tool Note. . . . . . . . . . . . . . . . . . . . . . . . . . .3

Terms Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tightening Torque Indication. . . . . . . . . . . . . . . . .3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . . . . . . . . .6

Connector Inspection Service Points

. . . . . . . . . .10

Connector Measurement Service Points . . . . . . . .9

How to Cope with Intermittent Malfunctions . . .11

How to Use the Inspection Procedures

. . . . . . .

8

Inspection Service Points for a Blown Fuse . . .

12

Troubleshooting Contents. . . . . . . . . . . . . . . . . . . .6

LUBRICATION AND MAINTENANCE . . . . . . .33

MAIN SEALANT AND ADHESIVE TABLE

. .

MAINTENANCE SERVICE. . . . . . . . . . . . . . . . . .38

Air Cleaner Element. . . . . . . . . . . . . . . . . . . . . . . .39

Automatic Transaxle Fluid

. . . . . . . . . . . . . . . . . . .45

Ball Joint and Steering Linkage Seals

. . . . . . . .50

Brake Hoses.... . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Disc Brake Pads. . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Drive Belt (For Generator, Water Pump, Power

Steering Pump). . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Drive Shaft Boots

. . . . . . . . . . . . . . . . . . . . . . . . . . .50

Engine Coolant. . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Evaporative Emission Control System . . . . . . . . .

Exhaust System. . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Fuel Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Ignition Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

Manual Transaxle Oil . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . .

50

Rear Drum Brake Linings and

Rear Wheel Cylinders . . . . . . . . . . . . . . . . . . . . . . .

Spark Plugs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

SRS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Timing Belt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Transfer Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

PRECAUTIONS BEFORE SERVICE. . . . . . . .20

RECOMMENDED LUBRICANTS

LUBRICANT CAPACITIES TABLE. . . . . . . . . .34

SCHEDULED MAINTENANCE TABLE. . . . .

SPECIAL HANDLING INSTRUCTIONS FOR

AWD MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26

TIGHTENING TORQUE. . . . . . . . . . . . . . . . . . . .32

TOWING AND HOISTING . . . . . . . . . . . . . . . . . .22

VEHICLE IDENTIFICATION. . . . . . . . . . . . . . . . .13

Engine Model Stamping. . . . . . . . . . . . . . . . . . . . .15

Theft Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Vehicle Identification Code Chart Plate

. . . . . . .13

Vehicle Identification Number List. . . . . . . . . . . .14

Vehicle Identification Number Location. . . . . . . .13

Vehicle Information Code Plate.. . . . . . . . . . . . . .15

Vehicle Safety Certification Label

. . . . . . . . . . . . .15

Page 9 of 2103

GENERAL How to Use Troubleshooting/Inspection Service Points

4.After repair or replacement, recheck the voltmeter to confirm the repair

the problem.

Terminal Resistance and Continuity Checks

1. Turn the ignition switch to off.

2. Disconnect the ECU connector.

3.Measure the resistance and check for continuity bet ween the terminals of the ECU

connector while referring to the check chart.

NOTE

Checks don’t have to be carried out in the order gi ven in the chart.

Cautlon

If resistance and continuity checks are performed the wrong terminals, damage

vehicle wiring, sensors, ECU, and/or ohmmeter may o ccur.

Use care to prevent this!

4.If the ohmmeter shows any deviation from the Normal Condition value, check the corresponding

5.

sensor, actuator and related electrical wiring, then repair or replace.

After repair or replacement, recheck with the ohmme ter to confirm that the repair

the problem.

10. INSPECTION PROCEDURES USING AN OSCILLOSCOPE

When there are inspection procedures using an oscil loscope, these are listed here.

,

TSB Revision

Page 11 of 2103

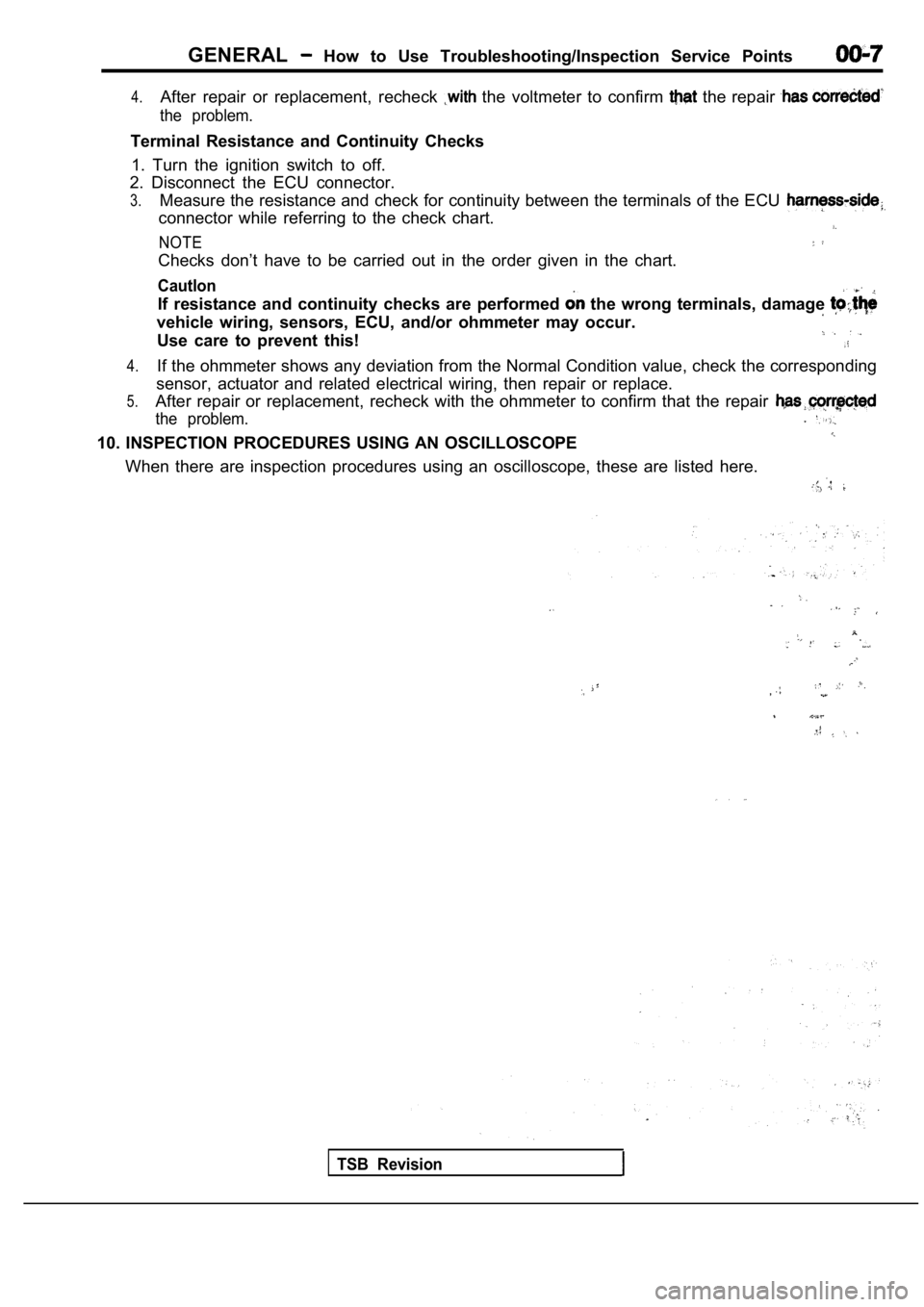

GENERAL How to Use Troubleshooting/Inspection Service ‘Points

CONNECTOR

Turn the ignition switch to when connecting and discon-

necting the connectors, and turn the ignition switch to ON

when measuring if there are no instructions to the contrary.

IF INSPECTING WITH THE CONNECTOR

CONNECTED

(WITH CIRCUIT IN A CONDITION OF

Waterproof Connectors

Be sure to use the special tool (harness connector) . Never

insert a test probe from the. harness side, because to do

so will reduce the waterproof performance and result in corro-

sion.

Ordinary (non-waterproof) Connectors

Check by inserting the test probe from’. the harness side.

Note that if the connector (control unit, etc.) is too small to

permit insertion of the test probe, it should not b e forced;

use a special tool (the extra-thin probe in the har ness set

for checking) for this purpose.

IF INSPECTING WITH THE CONNECTOR DISCONNECTED,

Use the special tool (inspection harness for

pin

contact pressure in the harness set, for ‘inspectio n).

The inspection harness for connector pin contact pr essure’

should be used. The test probe

be forcibly in-

serted, as it may cause a defective contact.

Caution. .

At time, be careful not to short the connector

with the test probes. To do so may damage the

inside the ECU.

Revision

Page 23 of 2103

GENERAL Precautions before Service . .

Caution

1.Before connecting or disconnecting the negative

be sure to turn off the ignition and

the lighting switch.

(if this is not done, the possibility semi-

conductor parts being damaged.)

2.After completion of the work steps [when the bat-

tery’s negative terminal is connected], warm

up the engine and allow it for approximately

five minutes under the conditions be-

low, in order to stabilize the engine condi-

tions, and then check to be sure that idling’ is

satisfactory.

Engine temperature:

Lights, electric fans, accessories: OFF

Transaxle: Neutral position

(A/T models: “N” or “P”)

Steering

neutral (center) position

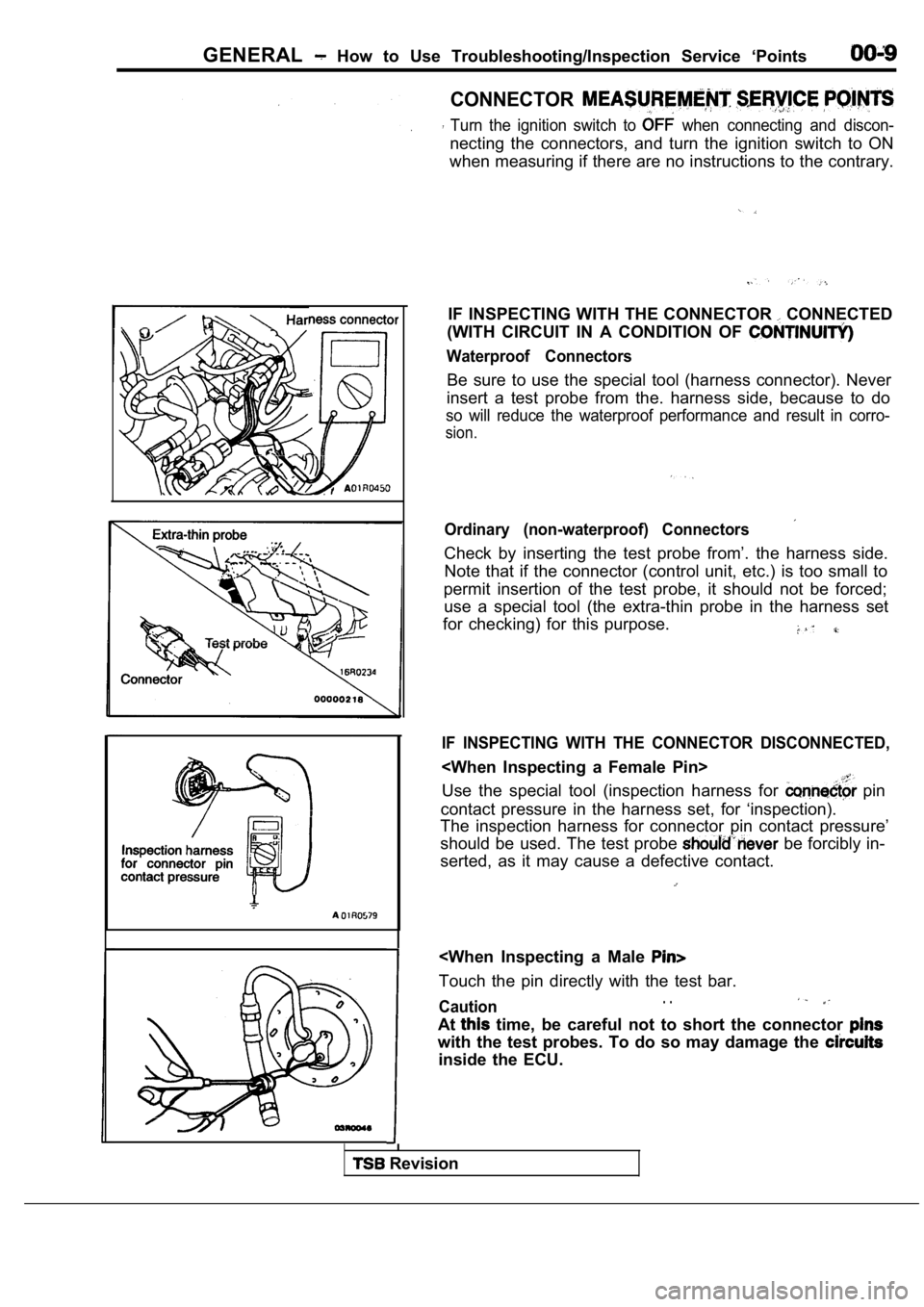

mm (in.)

Scan tool

ROM pack

VEHICLE WASHING

If high-pressure car-washing equipment or steam car -washing

equipment is used to wash the vehicle, be maintain

the spray nozzle at a distance of at ‘least 300 mm (12 in.)

from any plastic parts and all opening parts (doors , luggage

compartment, etc.).

APPLYING ANTI-CORROSION

OTHER UNDERCOAT AGENTS.,

Be careful not to adhere oil or grease to the heate d oxygen

sensor. If adhered, the sensor may malfunction.

Protect the heated oxygen sensor with a cover befor e applying

anti-corrosion agent, etc.

SCAN TOOL

To operate the scan tool, refer to the “MUT-II OPER ATING

INSTRUCTIONS”.

Caution

Turn the ignition switch off befoie connecting and discon-

necting the scan tool.

Page 42 of 2103

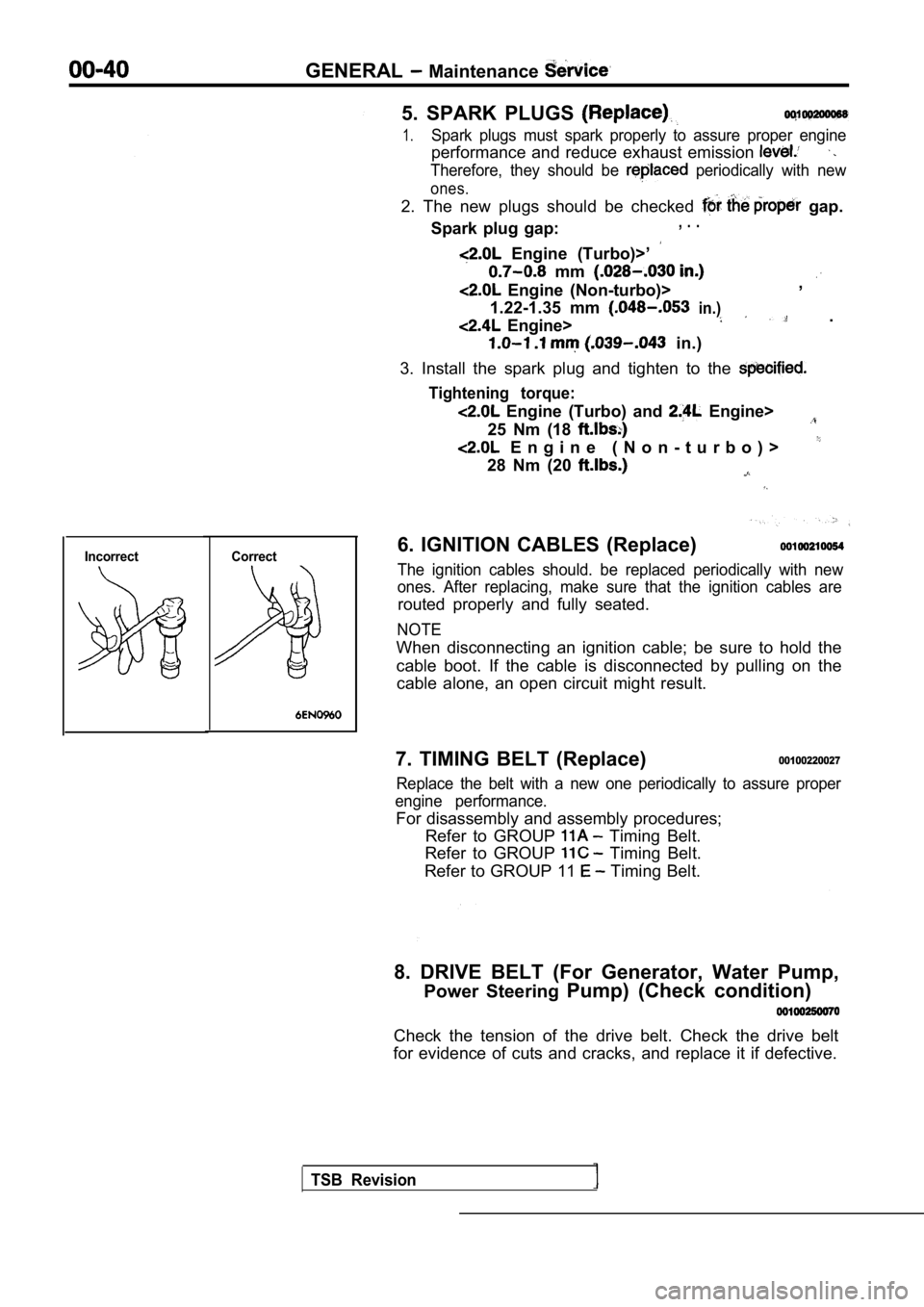

GENERAL Maintenance

Incorrect Correct

5. SPARK PLUGS

1.Spark plugs must spark properly to assure proper engine

performance and reduce exhaust emission

Therefore, they should be periodically with new

ones.

2. The new plugs should be checked gap.

Spark plug gap:, . .

Engine (Turbo)>’

mm

Engine (Non-turbo)> ,

1.22-1.35 mm

in.)

Engine> .

in.)

3. Install the spark plug and tighten to the

Tightening torque:

Engine (Turbo) and Engine>

25 Nm (18

E n g i n e ( N o n - t u r b o ) >

28 Nm (20

6. IGNITION CABLES (Replace)

The ignition cables should. be replaced periodicall y with new

ones. After replacing, make sure that the ignition cables are

routed properly and fully seated.

NOTE

When disconnecting an ignition cable; be sure to ho ld the

cable boot. If the cable is disconnected by pulling on the

cable alone, an open circuit might result.

7. TIMING BELT (Replace)

00100220027

Replace the belt with a new one periodically to ass ure proper

engine performance.

For disassembly and assembly procedures; Refer to GROUP

Timing Belt.

Refer to GROUP

Timing Belt.

Refer to GROUP 11

Timing Belt.

8. DRIVE BELT (For Generator, Water Pump, Power Steering Pump) (Check condition)

Check the tension of the drive belt. Check the driv e belt

for evidence of cuts and cracks, and replace it if defective.

TSB Revision

Page 53 of 2103

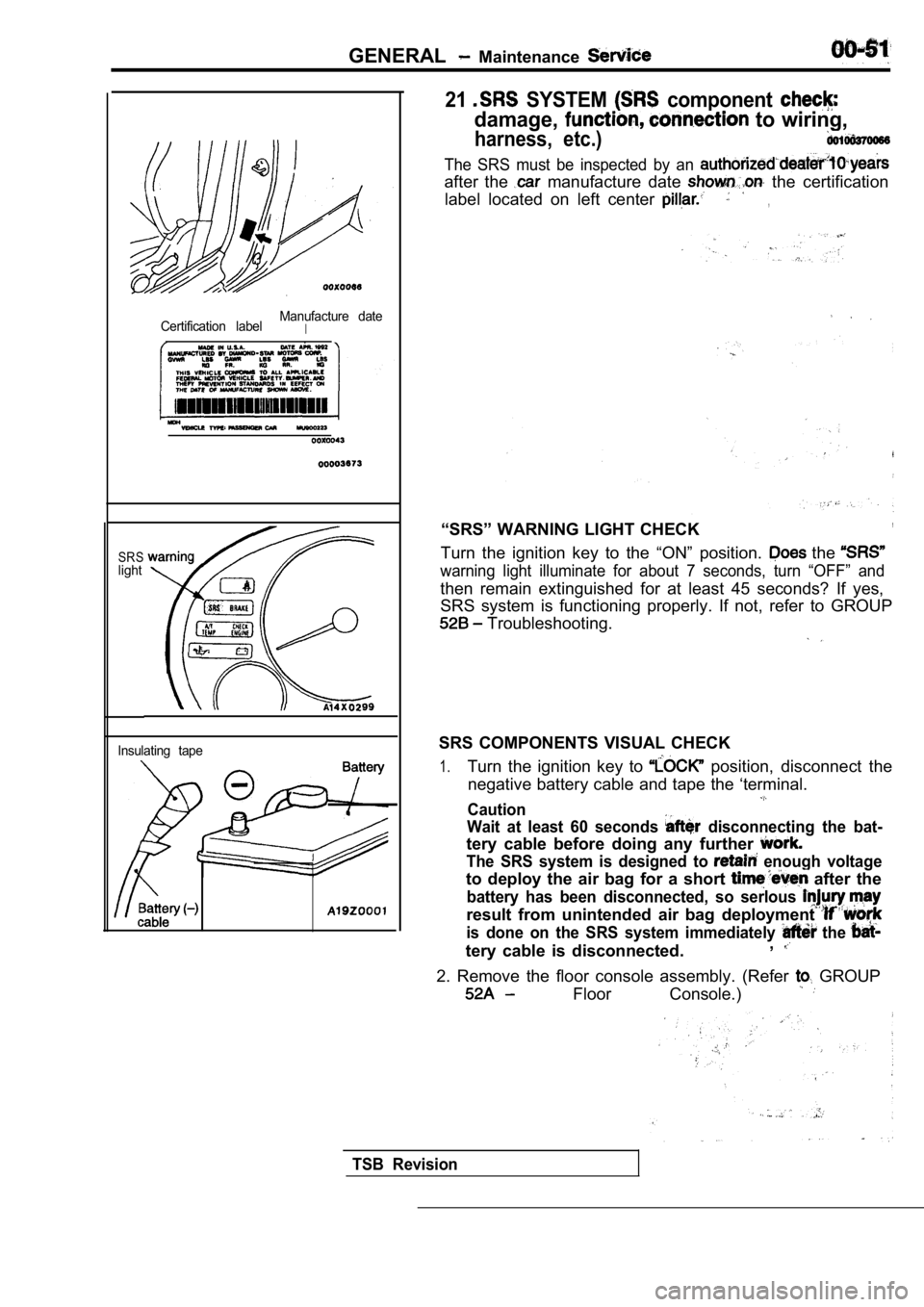

GENERAL Maintenance

21 SYSTEM component

damage, to wiring,

harness, etc.)

Certification labelManufacture dateI

SRSlight

Insulating tape

The SRS must be inspected by an

after the manufacture date the certification

label located on left center

,

“SRS” WARNING LIGHT CHECK,

Turn the ignition key to the “ON” position. the

warning light illuminate for about 7 seconds, turn “OFF” and

then remain extinguished for at least 45 seconds? I f yes,

SRS system is functioning properly. If not, refer t o GROUP

Troubleshooting.

SRS COMPONENTS VISUAL CHECK

1.Turn the ignition key to position, disconnect the

negative battery cable and tape the ‘terminal.

Caution

Wait at least 60 seconds

disconnecting the bat-

tery cable before doing any further

The SRS system is designed to enough voltage

to deploy the air bag for a short after the

battery has been disconnected, so serlous

result from unintended air bag deployment

is done on the SRS system immediately the

tery cable is disconnected. ,

2. Remove the floor console assembly. (Refer GROUP

Floor Console.)

TSB Revision

Page 61 of 2103

ENGINE

CONTENTS

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

CRANKSHAFT FRONT OIL SEAL . . . . . . . 28

CRANKSHAFT PULLEY . . . . . . . . . . . . . . . . . 21

CRANKSHAFT REAR OIL SEAL. . . . . . . .29

Curb Speed Check. . . . . . . . . . . . . . . . . .10

Drive Belt Tension Check and

Adjustment . , . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mixture Check . . . . . . . . . . . . . . . . . .

. . . . .10

Ignition Timing Check. . . . . . . . . . . .. . . . . . . . .

Lash Adjuster Check . . . . . . . . . . . . . . . .

CYLINDER HEAD GASKET . . . . . . . . . . . . .31

ENGINE ASSEMBLY. . . . . . . . . . . . . . . . . . . .16

GENERAL INFORMATION. . . . . . . . . . . . . . . .2

OIL PAN AND OIL SCREEN . . . . . . . . . . . .26

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . .7

Basic Idle Speed Adjustment

. . . . . . . . . . . . . . . . . . . . . . Refer to GROUP

Lash Adjuster Replacement. . . . . . . .. . . .15

Manifold Vacuum Check. . . . . . . . . . . . . . . ....13

SEALANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS. . . . . . . . . . . . . .3

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . .4

BELT. . . . . . . . . . . . . . . . . . . . . . . . . . .36

TIMING BELT . . . . . . . . . . . . . . . . . . . . . . . .41

Compression Pressure Check . . . . . . . . . . . .

. . 11TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . 6

Page 63 of 2103

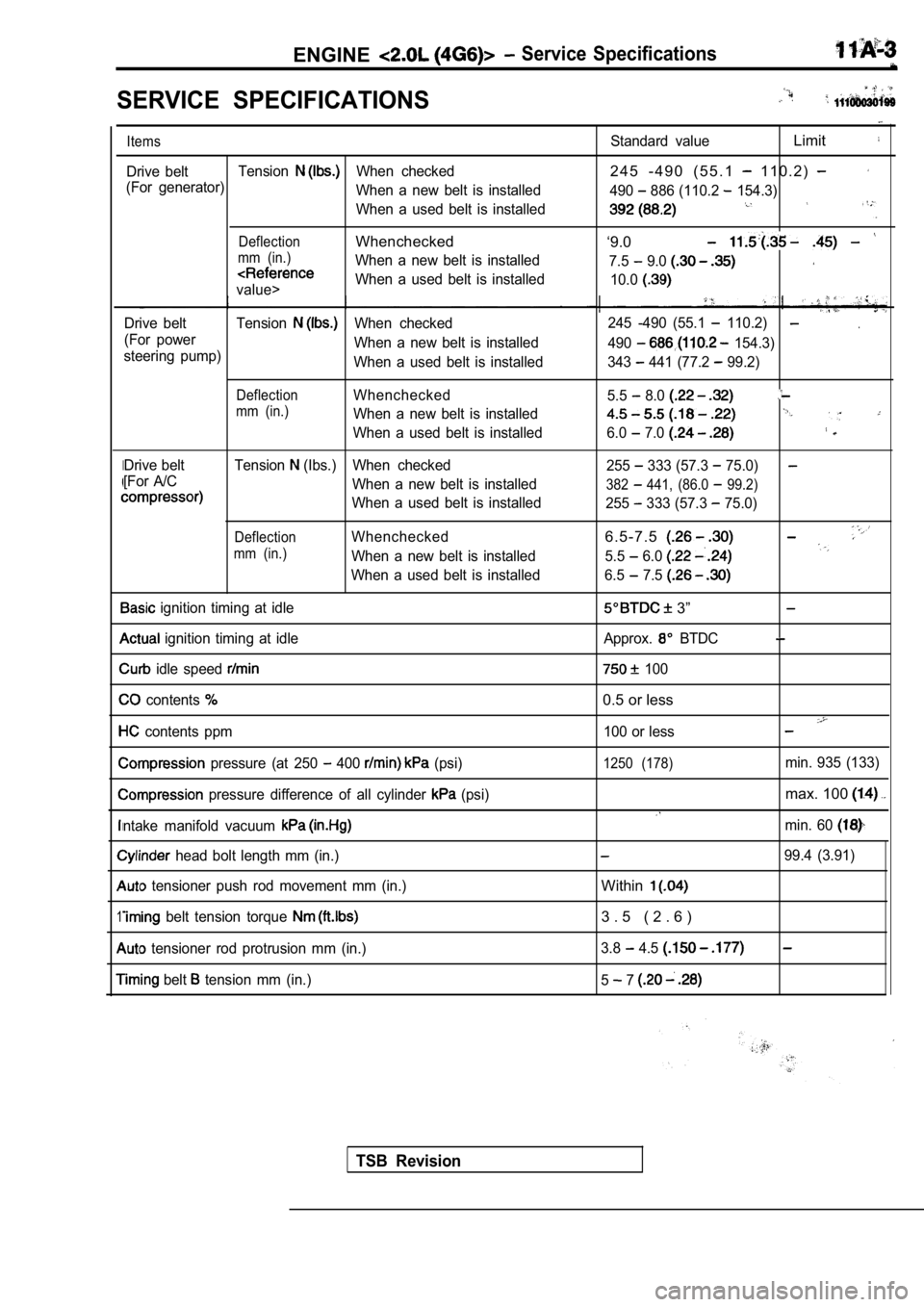

ENGINE Service Specifications

SERVICE SPECIFICATIONS

I

1

Items

Drive beltTensionWhen checked

(For generator) When a new belt is installed

When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

value>When a used belt is installed

Drive belt Tension

When checked

(For power When a new belt is installed

steering pump) When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

When a used belt is installed

Drive belt Tension

(Ibs.) When checked

[For A/C When a new belt is installed

When a used belt is installed

DeflectionWhenchecked

mm (in.)When a new belt is installed

When a used belt is installed

ignition timing at idle

ignition timing at idle

idle speed

contents

contents ppm

pressure (at 250 400 (psi)

pressure difference of all cylinder (psi)

ntake manifold vacuum

head bolt length mm (in.)

tensioner push rod movement mm (in.)

belt tension torque

tensioner rod protrusion mm (in.)

belt tension mm (in.)

Standard valueLimit

2 4 5 - 4 9 0 ( 5 5 . 1 1 1 0 . 2 )

490 886 (110.2 154.3)

‘9.0

7.5 9.0

10.0

.245 -490 (55.1 110.2)

490 154.3)

343

441 (77.2 99.2)

5.5

8.0

6.0 7.0

255 333 (57.3 75.0)

382 441, (86.0 99.2)

255 333 (57.3 75.0)

6 . 5 - 7 . 5

5.5 6.0

6.5 7.5

3”

Approx. BTDC

100

0.5 or less

100 or less

1250 (178)min. 935 (133)

max. 100

min. 60

99.4 (3.91)

Within

3 . 5 ( 2 . 6 )

3.8 4.5

5 7

TSB Revision

Page 69 of 2103

ENGINE On-vehicle

A/C COMPRESSOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen tension pulley fixing bolt A.

2. Adjust belt tension with adjusting bolt B.

Standard value:

Items

Tension

(Ibs.)

Deflection

When a new belt isWhen a used belt is

installedinstalled

382-411255-333

6.5-7.5

3. Tighten fixing nut A.

Tightening torque: 23-26 Nm

4.Check the belt deflection and readjust if neces-

sary.

Caution

This check should be carried out after turning the

crankshaft one full rotation or more in the forward

direction (to the right).

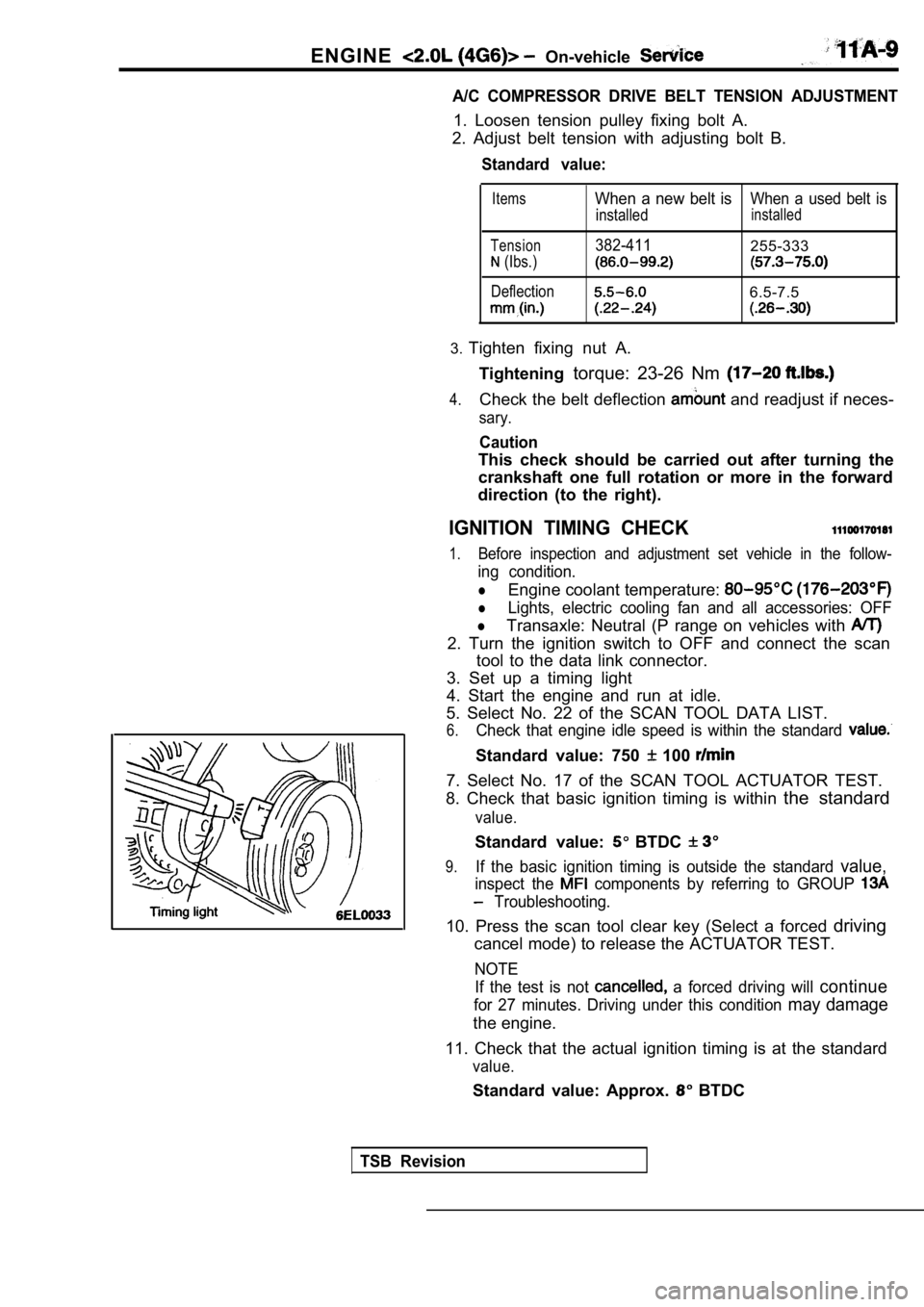

IGNITION TIMING CHECK

1.Before inspection and adjustment set vehicle in the follow-

ing condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Set up a timing light

4. Start the engine and run at idle.

5. Select No. 22 of the SCAN TOOL DATA LIST.

6.Check that engine idle speed is within the standard

Standard value: 750 100

7. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

8. Check that basic ignition timing is within the standard

value.

Standard value: BTDC

9.If the basic ignition timing is outside the standar d value,

inspect the components by referring to GROUP

Troubleshooting.

10. Press the scan tool clear key (Select a forced driving

cancel mode) to release the ACTUATOR TEST.

NOTE

If the test is not

a forced driving will continue

for 27 minutes. Driving under this condition may damage

the engine.

11. Check that the actual ignition timing is at the standard

value.

Standard value: Approx. BTDC

TSB Revision

Page 70 of 2103

ENGINE On-vehicle Service

NOTE

1.Ignition timing is variable within about even under

operating.

2. And it is automatically further advanced by abou t

from BTDC at higher altitudes.

CURB IDLE SPEED CHECK

1. Before inspection and adjustment, set vehicles in the

following condition.

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: OFF

lTransaxle: Neutral (P range on vehicles with

2. Turn the ignition switch to OFF and connect the scan

tool to the data link connector.

3. Select No. 17 of the SCAN TOOL ACTUATOR TEST.

4. Check the basic ignition timing.

Standard

BTDC

5. Run the engine at idle for 2 minutes.

6. Select No. 22 of the SCAN TOOL DATA LIST.

7. Check the curb idle speed.

Standard value: 750

100

NOTE

The idle speed is controlled automatically by the i dle air

control system.

8. If the idle speed is outside the standard value, inspect

the components by referring to GROUP Trou-

bleshooting.

IDLE MIXTURE CHECK .

1.Before inspection, set in following

lEngine coolant temperature:

lLights, electric cooling fan all

lTransaxle: Neutral (P range on

2. Turn the ignition switch to OFF and, connect the scan

tool to the data link ,

3. Select No. 17 of the SCAN TOOL

4.Check that the basic ignition

value.

Standard value: BTDC

5. Run the engine 2,500 for 2 minutes.

6. Set the CO, HC tester.

7. Check the CO contents and the HC contents, at id le.

Standard value: CO contents: 0.5% or less

HC contents: 100 rpm or less

Revision