jack points MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 79 of 2103

ENGINE -‘Engine Assembly

COMPRESSOR

Disconnect the compressor connector and remove the

compressor from the compressor bracket

the hose

attached.

NOTE

Place the removed A/C compressor in a where it will

not be a hindrance when removing ‘and installing th e engine

assembly, and tie it with a cord:

Caution

Do not bend the joint the A/C hose and the

pipe by force.

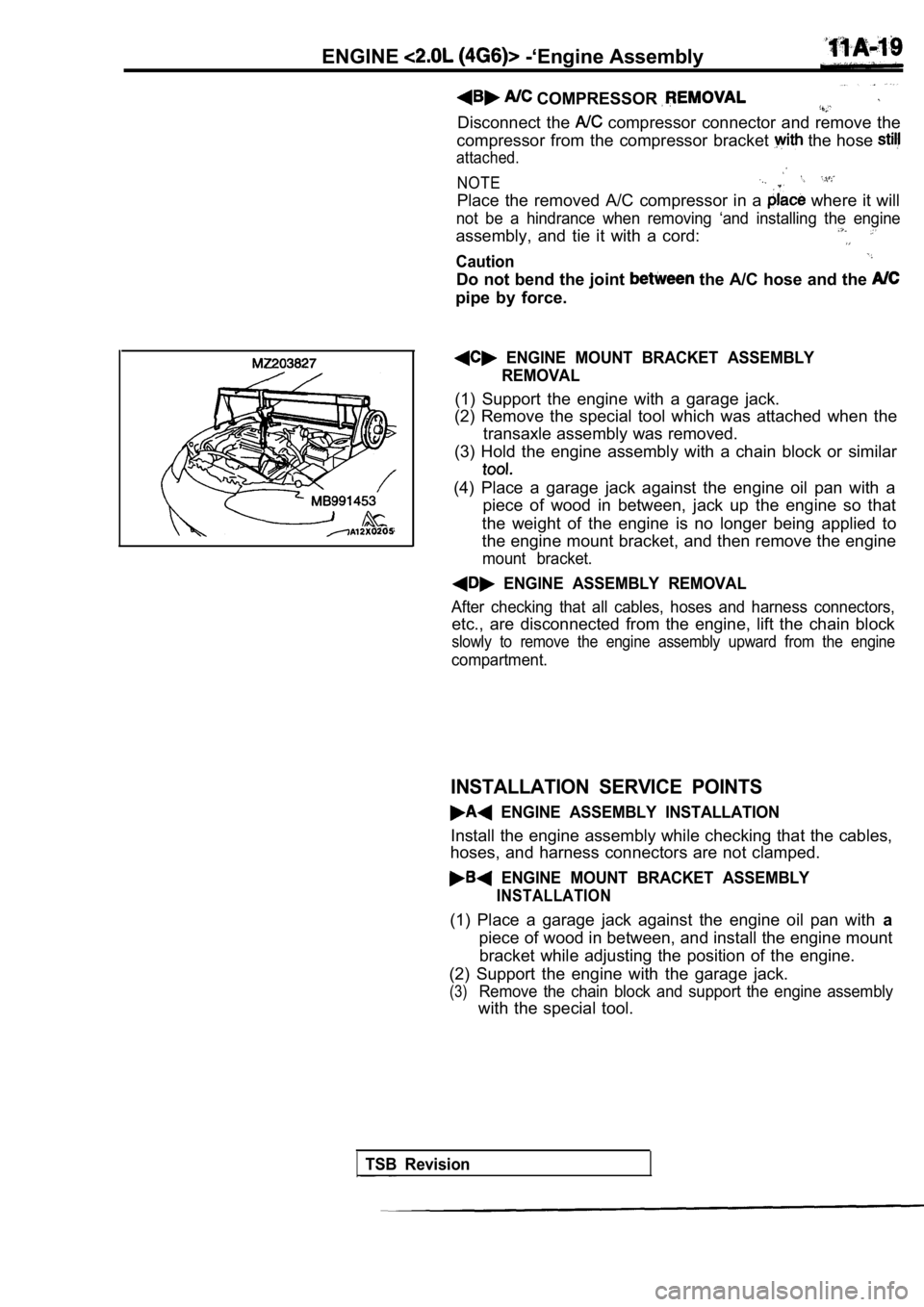

ENGINE MOUNT BRACKET ASSEMBLY

REMOVAL

(1) Support the engine with a garage jack.

(2) Remove the special tool which was attached when the

transaxle assembly was removed.

(3) Hold the engine assembly with a chain block or similar

(4) Place a garage jack against the engine oil pan with a

piece of wood in between, jack up the engine so tha t

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engin e

mount bracket.

ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from th e engine

compartment.

INSTALLATION SERVICE POINTS

ENGINE ASSEMBLY INSTALLATION

Install the engine assembly while checking that the cables,

hoses, and harness connectors are not clamped.

ENGINE MOUNT BRACKET ASSEMBLY

INSTALLATION

(1) Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mo unt

bracket while adjusting the position of the engine.

(2) Support the engine with the garage jack.

(3)Remove the chain block and support the engine assem bly

with the special tool.

TSB Revision

Page 188 of 2103

ENGINE Enaine

Engine side

bracketEngine

Notch

INSTALLATION SERVICE POINTS

ENGINE ASSEMBLY INSTALLATION

Install the engine assembly while checking that the cables,

hoses, and harness connectors are not clamped.

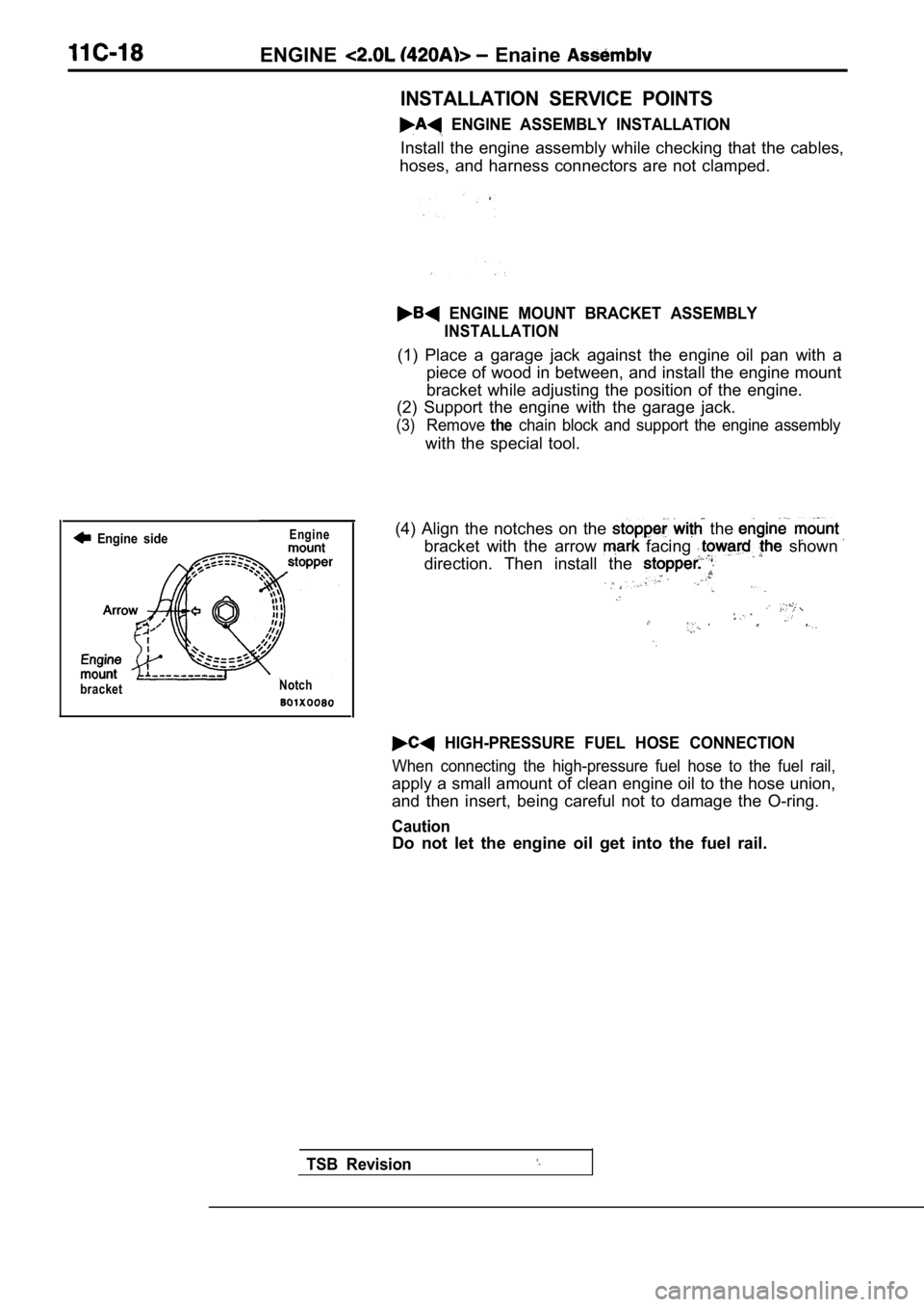

ENGINE MOUNT BRACKET ASSEMBLY

INSTALLATION

(1) Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mo unt

bracket while adjusting the position of the engine.

(2) Support the engine with the garage jack.

(3)Removethechain block and support the engine assembly

with the special tool.

(4) Align the notches on the

the

bracket with the arrow facing shown

direction. Then install the

HIGH-PRESSURE FUEL HOSE CONNECTION

When connecting the high-pressure fuel hose to the fuel rail,

apply a small amount of clean engine oil to the hose union,

and then insert, being careful not to damage the O- ring.

Caution

Do not let the engine oil get into the fuel rail.

TSB Revision

Page 192 of 2103

ENGINECamshaft and

554

.

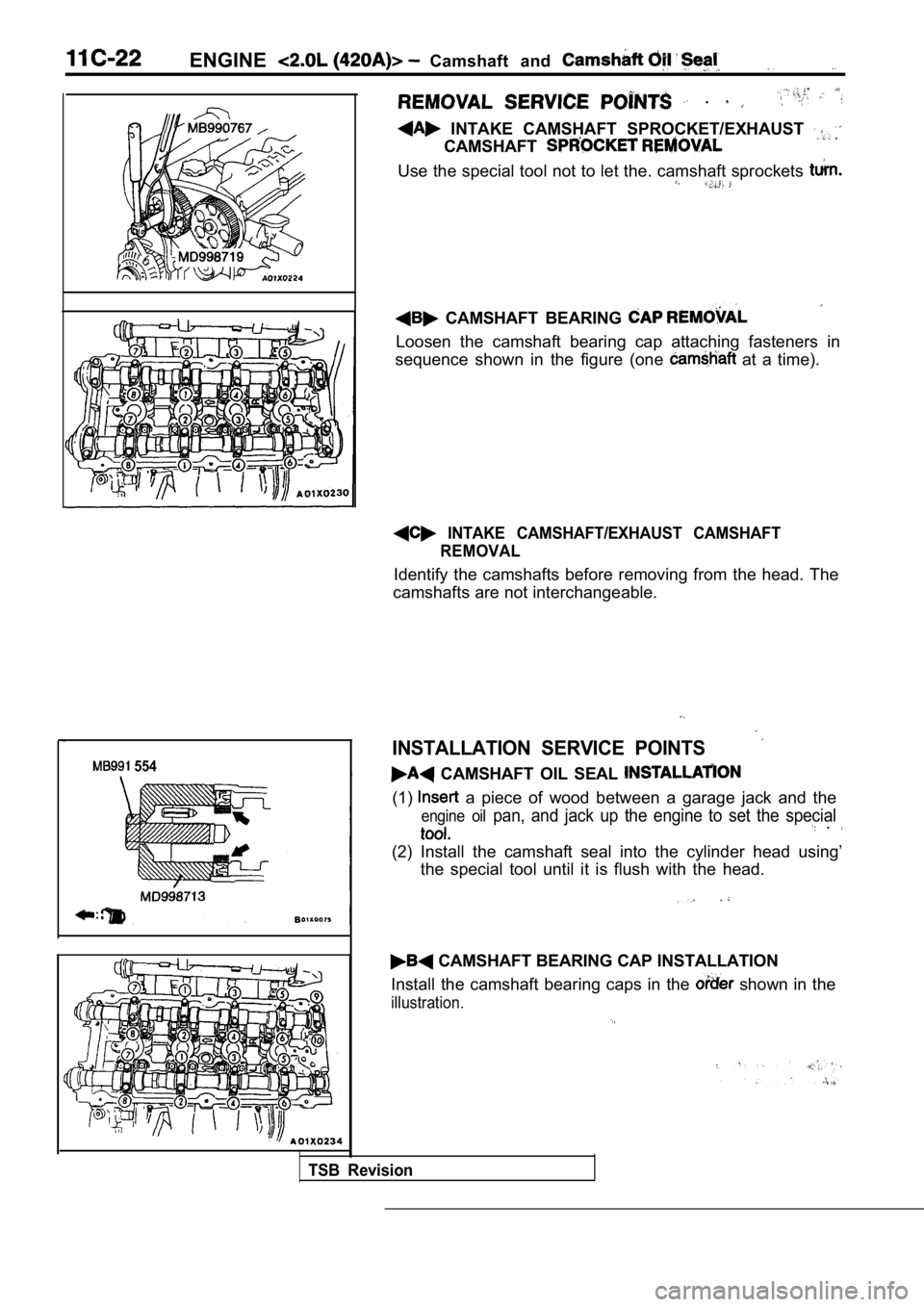

INTAKE CAMSHAFT SPROCKET/EXHAUST

CAMSHAFT

Use the special tool not to let the. camshaft sprockets

CAMSHAFT BEARING

Loosen the camshaft bearing cap attaching fasteners in

sequence shown in the figure (one

at a time).

INTAKE CAMSHAFT/EXHAUST CAMSHAFT REMOVAL

Identify the camshafts before removing from the hea d. The

camshafts are not interchangeable.

INSTALLATION SERVICE POINTS

CAMSHAFT OIL SEAL

(1) a piece of wood between a garage jack and the

engine oil pan, and jack up the engine to set the special .

(2) Install the camshaft seal into the cylinder hea d using’

the special tool until it is flush with the head.

CAMSHAFT BEARING CAP INSTALLATION

Install the camshaft bearing caps in the

shown in the

illustration.

TSB Revision

Page 205 of 2103

ENGINE Timing Belt

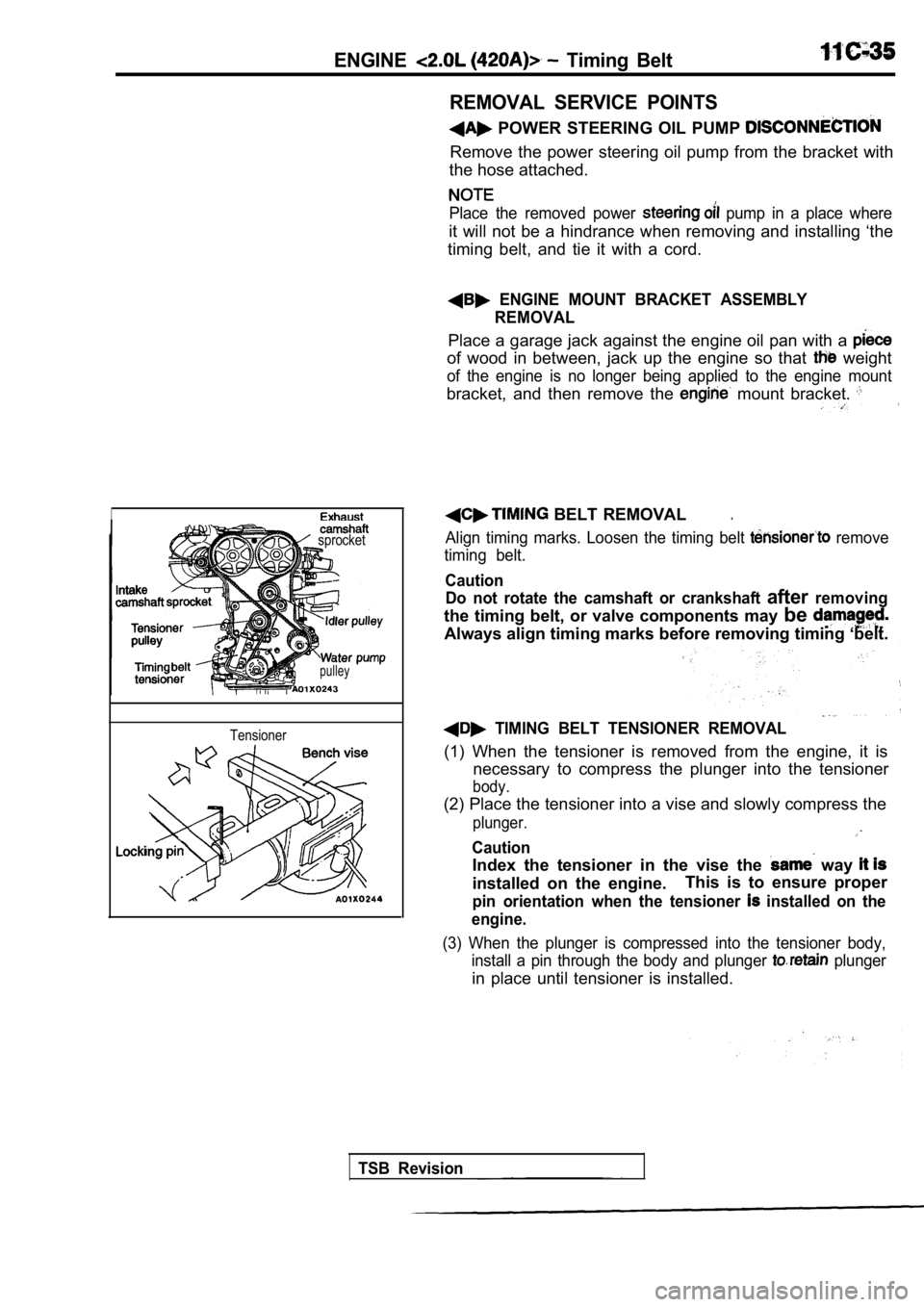

REMOVAL SERVICE POINTS

POWER STEERING OIL PUMP

Remove the power steering oil pump from the bracket with

the hose attached.

Place the removed power pump in a place where

it will not be a hindrance when removing and instal ling ‘the

timing belt, and tie it with a cord.

ENGINE MOUNT BRACKET ASSEMBLY REMOVAL

I

sprocket

pulley

Place a garage jack against the engine oil pan with a

of wood in between, jack up the engine so that weight

of the engine is no longer being applied to the eng ine mount

bracket, and then remove the mount bracket.

BELT REMOVAL.

Align timing marks. Loosen the timing belt remove

timing belt.

Caution Do not rotate the camshaft or crankshaft

afterremoving

the timing belt, or valve components may be

Always align timing marks before removing timing ‘b elt.

TIMING BELT TENSIONER REMOVAL

(1) When the tensioner is removed from the engine, it is

necessary to compress the plunger into the tensione r

body.

(2) Place the tensioner into a vise and slowly compress the

plunger.

Caution

Index the tensioner in the vise the way

installed on the engine.This is to ensure proper

pin orientation when the tensioner installed on the

engine.

(3) When the plunger is compressed into the tension er body,

install a pin through the body and plunger

plunger

in place until tensioner is installed.

Tensioner

TSB Revision

Page 286 of 2103

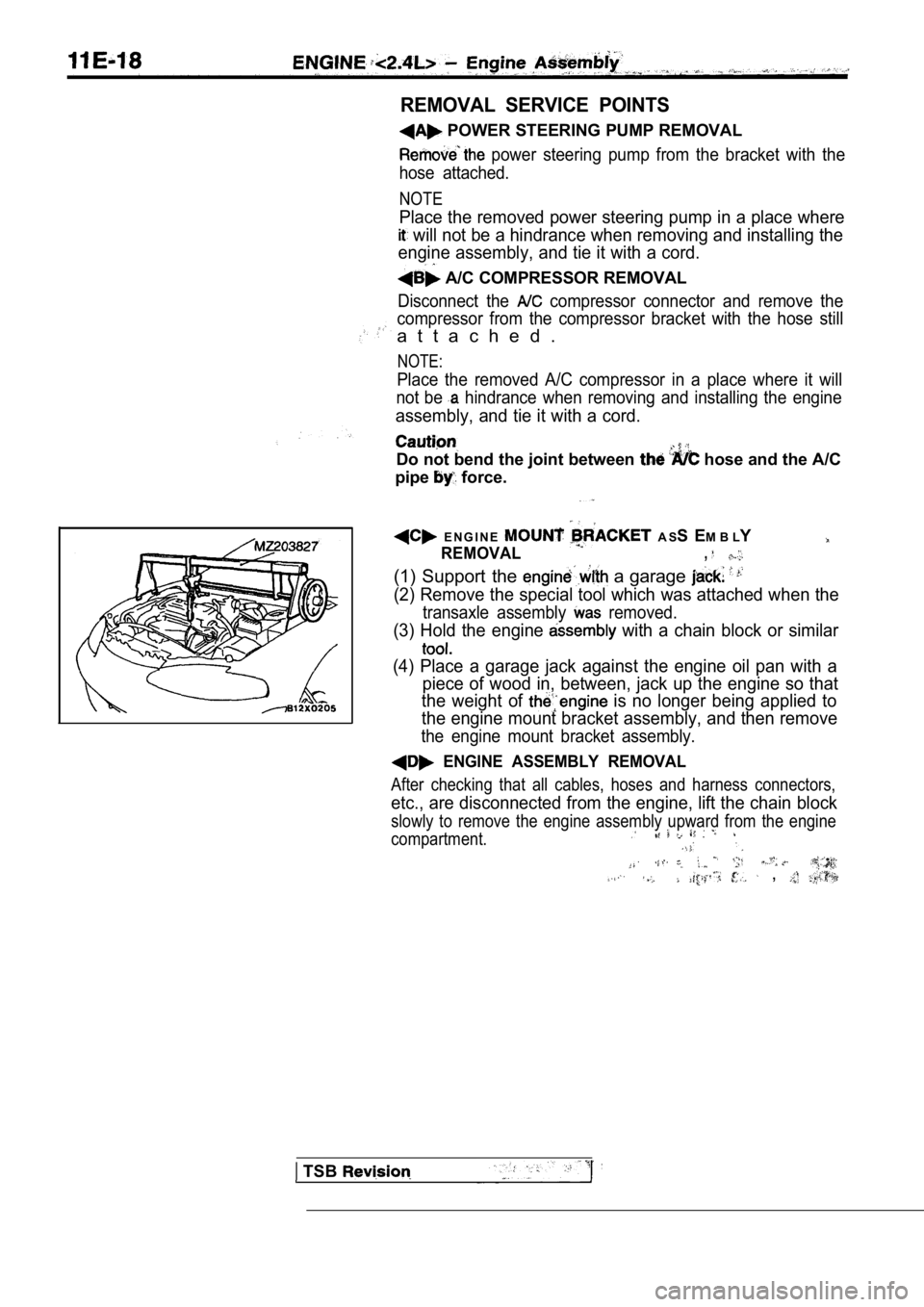

REMOVAL SERVICE POINTS

POWER STEERING PUMP REMOVAL

power steering pump from the bracket with the

hose attached.

NOTE

Place the removed power steering pump in a place wh ere

will not be a hindrance when removing and installing the

engine assembly, and tie it with a cord.

A/C COMPRESSOR REMOVAL

Disconnect the compressor connector and remove the

compressor from the compressor bracket with the hos e still

a t t a c h e d .

NOTE:

Place the removed A/C compressor in a place where i t will

not be

hindrance when removing and installing the engine

assembly, and tie it with a cord.

Do not bend the joint between hose and the A/C

pipe

force.

E N G I N E A S S E M B L Y

REMOVAL,

(1) Support the a garage

(2) Remove the special tool which was attached when the

transaxle assembly removed.

(3) Hold the engine with a chain block or similar

(4) Place a garage jack against the engine oil pan with a

piece of wood in, between, jack up the engine so th at

the weight of

is no longer being applied to

the engine mount bracket assembly, and then remove

the engine mount bracket assembly.

ENGINE ASSEMBLY REMOVAL

After checking that all cables, hoses and harness c onnectors,

etc., are disconnected from the engine, lift the chain block

slowly to remove the engine assembly upward from th e engine

compartment.

,

TSB

Page 872 of 2103

MANUAL TRANSAXLE

ENGINE AND ENGINE> Transaxle Assembly

I

Nut

ITransaxle

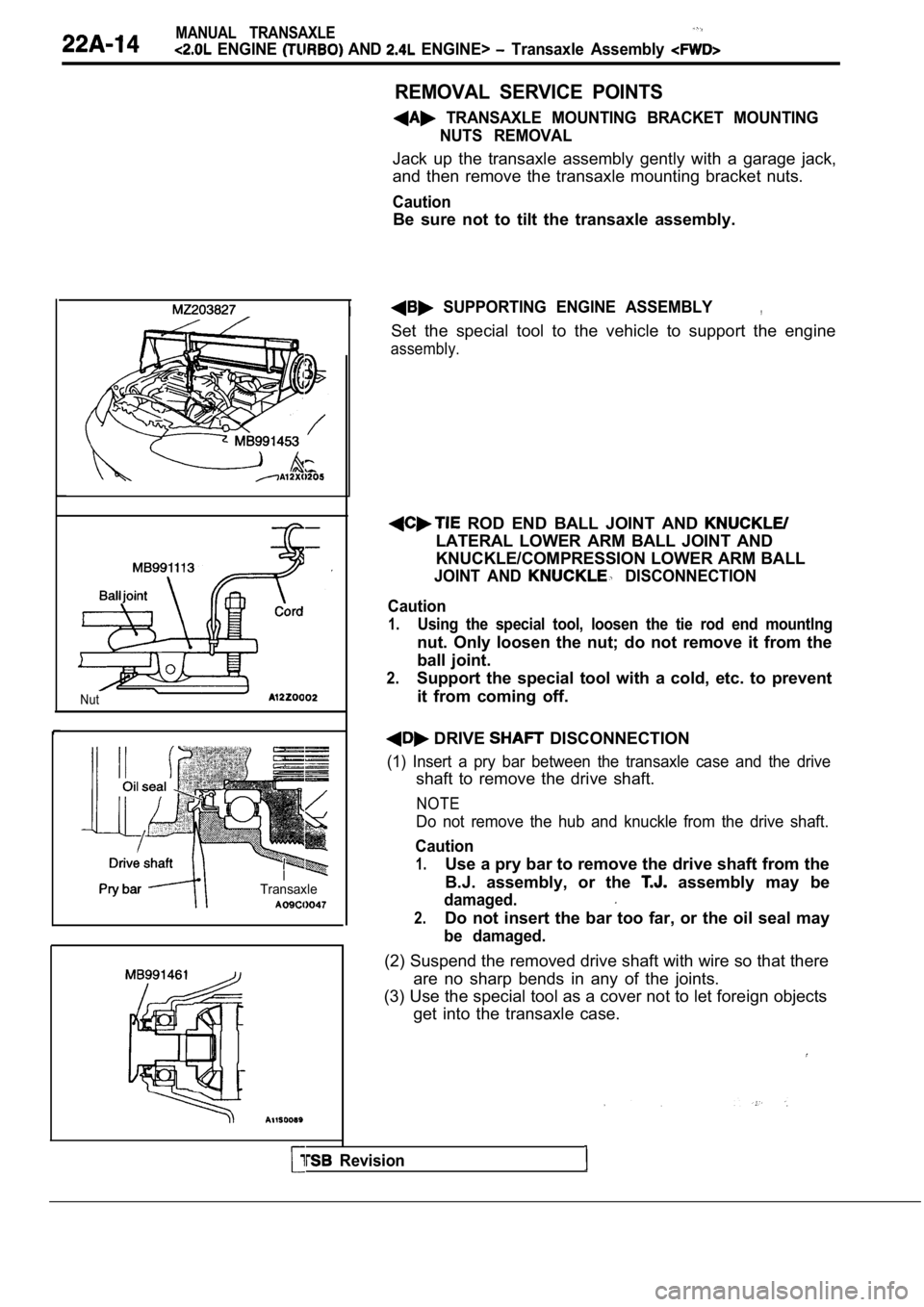

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket nuts .

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY,

Set the special tool to the vehicle to support the engine

assembly.

ROD END BALL JOINT AND

LATERAL LOWER ARM BALL JOINT AND

KNUCKLE/COMPRESSION LOWER ARM BALL

JOINT AND DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun tlng

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cold, etc. to prevent

it from coming off.

DRIVE DISCONNECTION

(1) Insert a pry bar between the transaxle case and the drive

shaft to remove the drive shaft.

NOTE

Do not remove the hub and knuckle from the drive sh aft.

Caution

1.Use a pry bar to remove the drive shaft from the

B.J. assembly, or the

assembly may be

damaged.

2.Do not insert the bar too far, or the oil seal may

be damaged.

(2) Suspend the removed drive shaft with wire so that there

are no sharp bends in any of the joints.

(3) Use the special tool as a cover not to let fore ign objects

get into the transaxle case.

Revision

Page 876 of 2103

MANUAL TRANSAXLE

ENGINE AND ENGINE> Transaxle Assembly

I -

Cord

I’ --

Nut

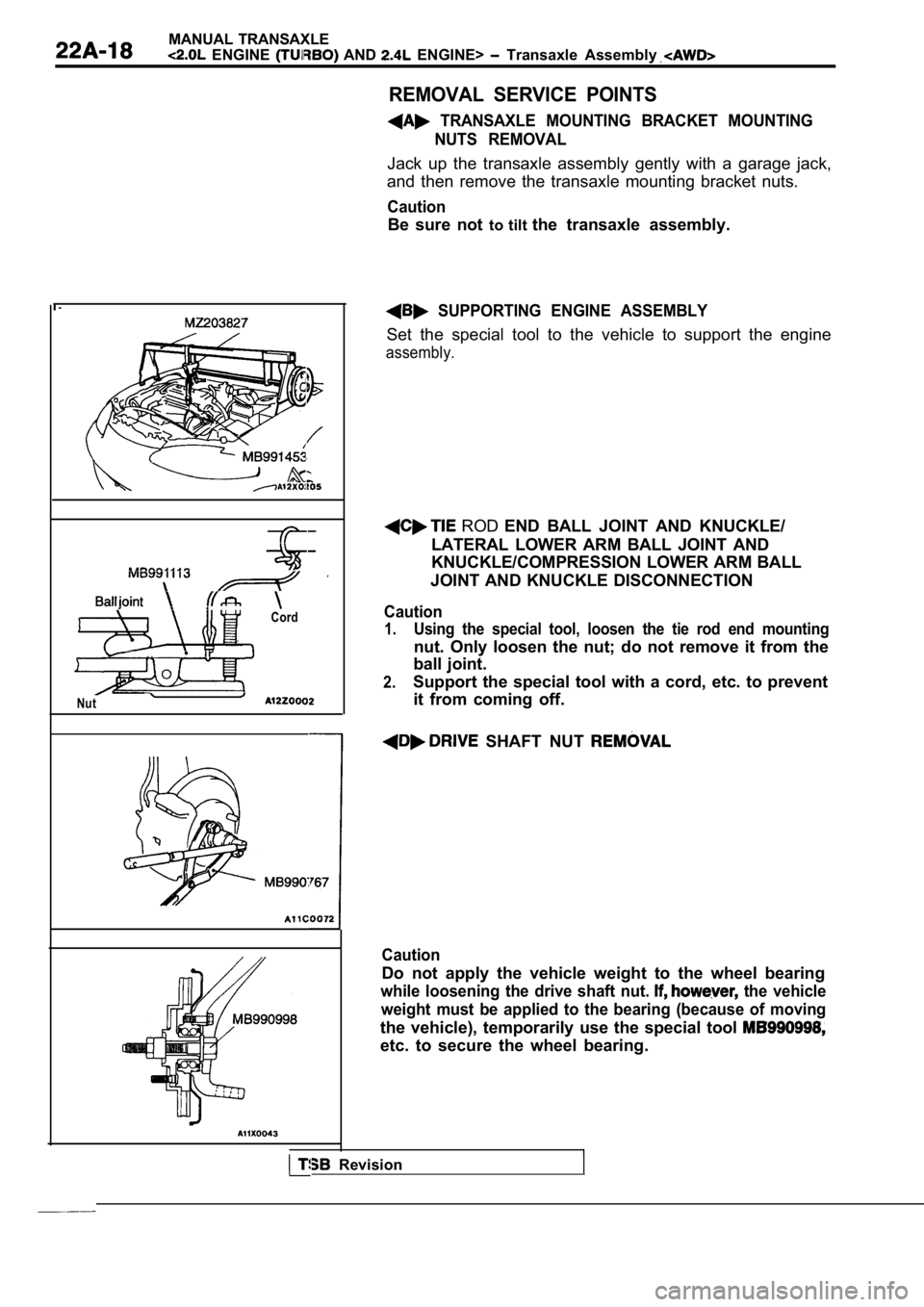

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket nuts .

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine

assembly.

ROD END BALL JOINT AND KNUCKLE/

LATERAL LOWER ARM BALL JOINT AND

KNUCKLE/COMPRESSION LOWER ARM BALL

JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun ting

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

SHAFT NUT

Caution

Do not apply the vehicle weight to the wheel bearin g

while loosening the drive shaft nut. the vehicle

weight must be applied to the bearing (because of m oving

the vehicle), temporarily use the special tool

etc. to secure the wheel bearing.

I Revision

Page 888 of 2103

MANUAL TRANSAXLE

(NON-TURBO)> Transaxle Control

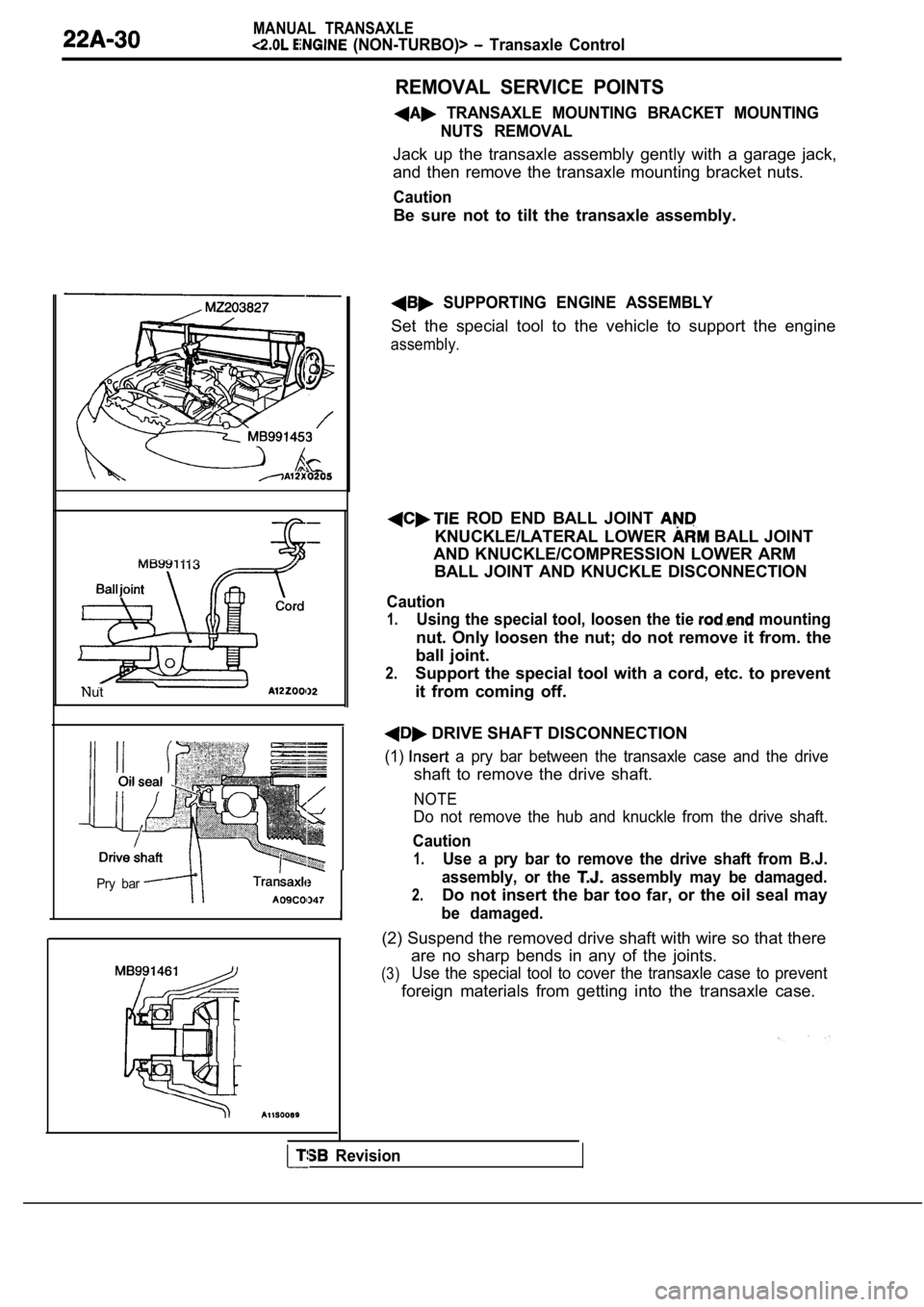

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket nuts .

Caution

Be sure not to tilt the transaxle assembly.

Nut

Pry bar

I

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine

assembly.

ROD END BALL JOINT

KNUCKLE/LATERAL LOWER BALL JOINT

AND KNUCKLE/COMPRESSION LOWER ARM BALL JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie mounting

nut. Only loosen the nut; do not remove it from. th e

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

DRIVE SHAFT DISCONNECTION

(1) a pry bar between the transaxle case and the drive

shaft to remove the drive shaft.

NOTE

Do not remove the hub and knuckle from the drive sh aft.

Caution

1.Use a pry bar to remove the drive shaft from B.J.

2.

assembly, or the assembly may be damaged.

Do not insert the bar too far, or the oil seal may

be damaged.

(2) Suspend the removed drive shaft with wire so that there

(3)

are no sharp bends in any of the joints.

Use the special tool to cover the transaxle case to prevent

foreign materials from getting into the transaxle c ase.

Revision

Page 1112 of 2103

AUTOMATIC TRANSAXLE

ENGINE AND ENGINE> Transaxle Assemblv

,

Nut

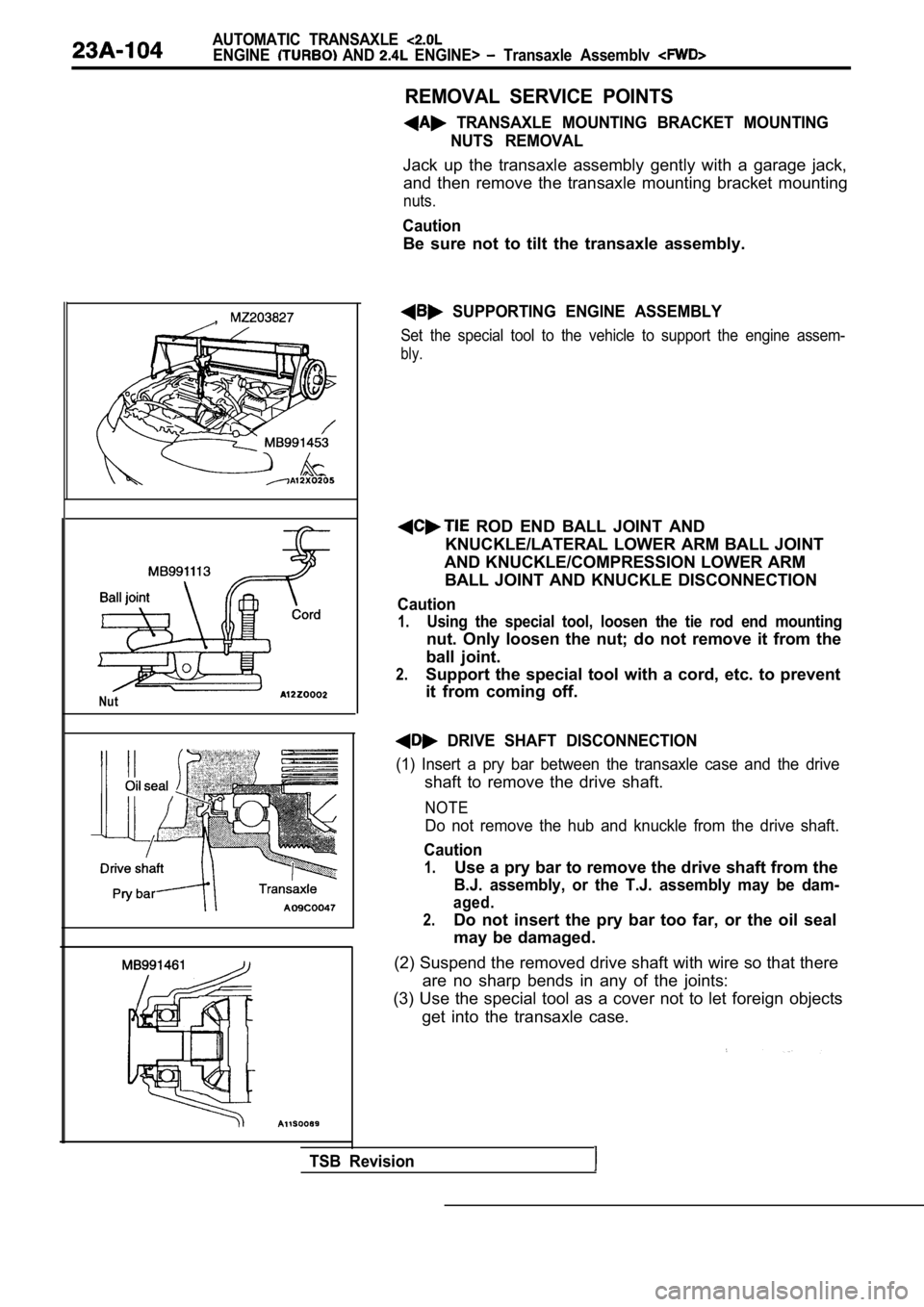

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the transaxle assembly gently with a garage jack,

and then remove the transaxle mounting bracket moun ting

nuts.

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine assem-

bly.

ROD END BALL JOINT AND

KNUCKLE/LATERAL LOWER ARM BALL JOINT

AND KNUCKLE/COMPRESSION LOWER ARM BALL JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun ting

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

DRIVE SHAFT DISCONNECTION

(1) Insert a pry bar between the transaxle case and the drive

shaft to remove the drive shaft.

NOTE

Do not remove the hub and knuckle from the drive sh aft.

Caution

1.Use a pry bar to remove the drive shaft from the

B.J. assembly, or the T.J. assembly may be dam-

aged.

2.Do not insert the pry bar too far, or the oil seal

may be damaged.

(2) Suspend the removed drive shaft with wire so th at there

are no sharp bends in any of the joints:

(3) Use the special tool as a cover not to let fore ign objects

get into the transaxle case.

TSB Revision

Page 1116 of 2103

.AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND ENGINE> Transaxle Assembly

,

Cord

N i t

TSB Revision

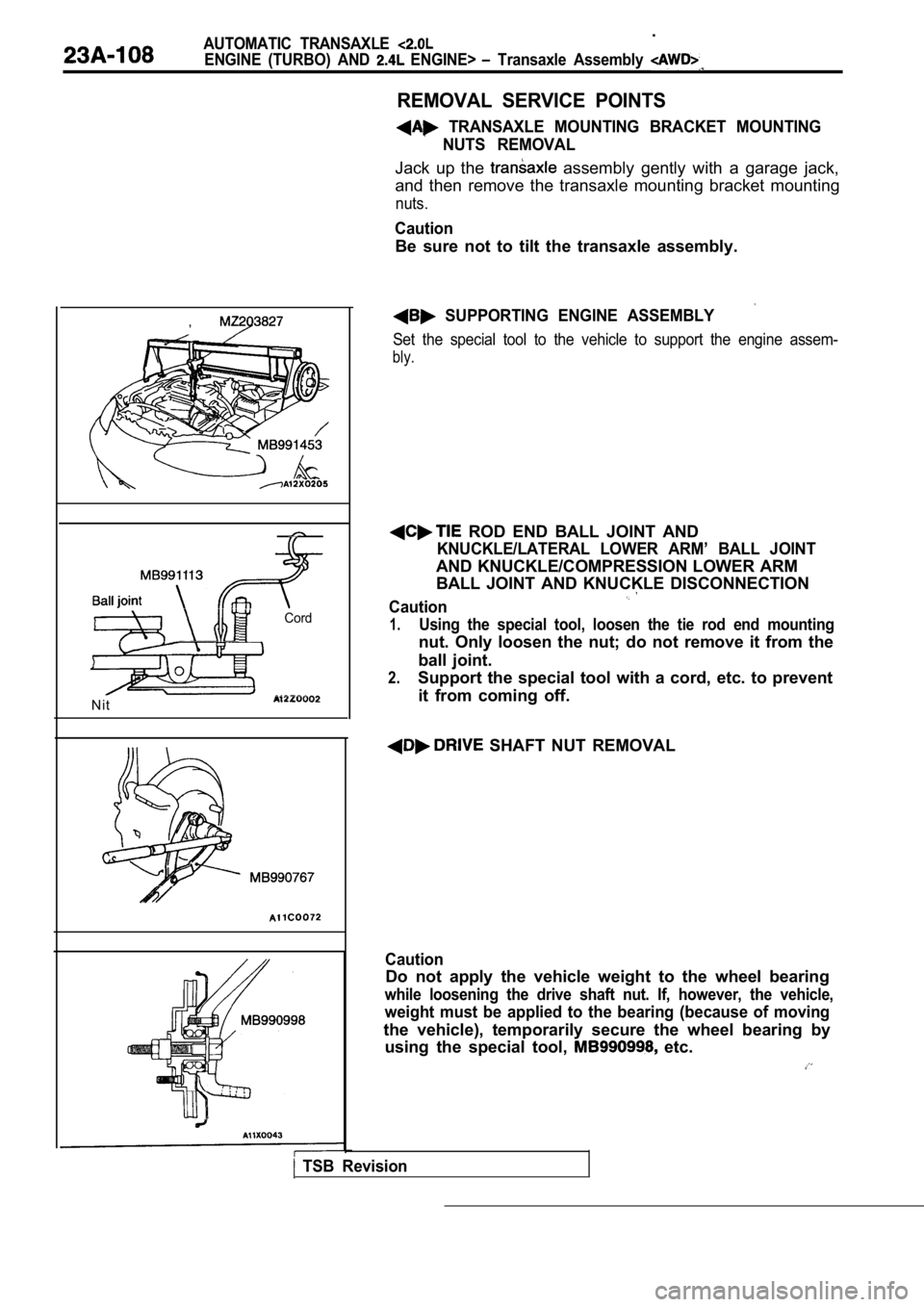

REMOVAL SERVICE POINTS

TRANSAXLE MOUNTING BRACKET MOUNTINGNUTS REMOVAL

Jack up the assembly gently with a garage jack,

and then remove the transaxle mounting bracket moun ting

nuts.

Caution

Be sure not to tilt the transaxle assembly.

SUPPORTING ENGINE ASSEMBLY

Set the special tool to the vehicle to support the engine assem-

bly.

ROD END BALL JOINT AND

KNUCKLE/LATERAL LOWER ARM’ BALL JOINT

AND KNUCKLE/COMPRESSION LOWER ARM

BALL JOINT AND KNUCKLE DISCONNECTION

Caution

1.Using the special tool, loosen the tie rod end moun ting

nut. Only loosen the nut; do not remove it from the

ball joint.

2.Support the special tool with a cord, etc. to preve nt

it from coming off.

SHAFT NUT REMOVAL

Caution

Do not apply the vehicle weight to the wheel bearin g

while loosening the drive shaft nut. If, however, the vehicle,

weight must be applied to the bearing (because of m oving

the vehicle), temporarily secure the wheel bearing by

using the special tool,

etc.