oil pressure MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 23 of 2103

GENERAL Precautions before Service . .

Caution

1.Before connecting or disconnecting the negative

be sure to turn off the ignition and

the lighting switch.

(if this is not done, the possibility semi-

conductor parts being damaged.)

2.After completion of the work steps [when the bat-

tery’s negative terminal is connected], warm

up the engine and allow it for approximately

five minutes under the conditions be-

low, in order to stabilize the engine condi-

tions, and then check to be sure that idling’ is

satisfactory.

Engine temperature:

Lights, electric fans, accessories: OFF

Transaxle: Neutral position

(A/T models: “N” or “P”)

Steering

neutral (center) position

mm (in.)

Scan tool

ROM pack

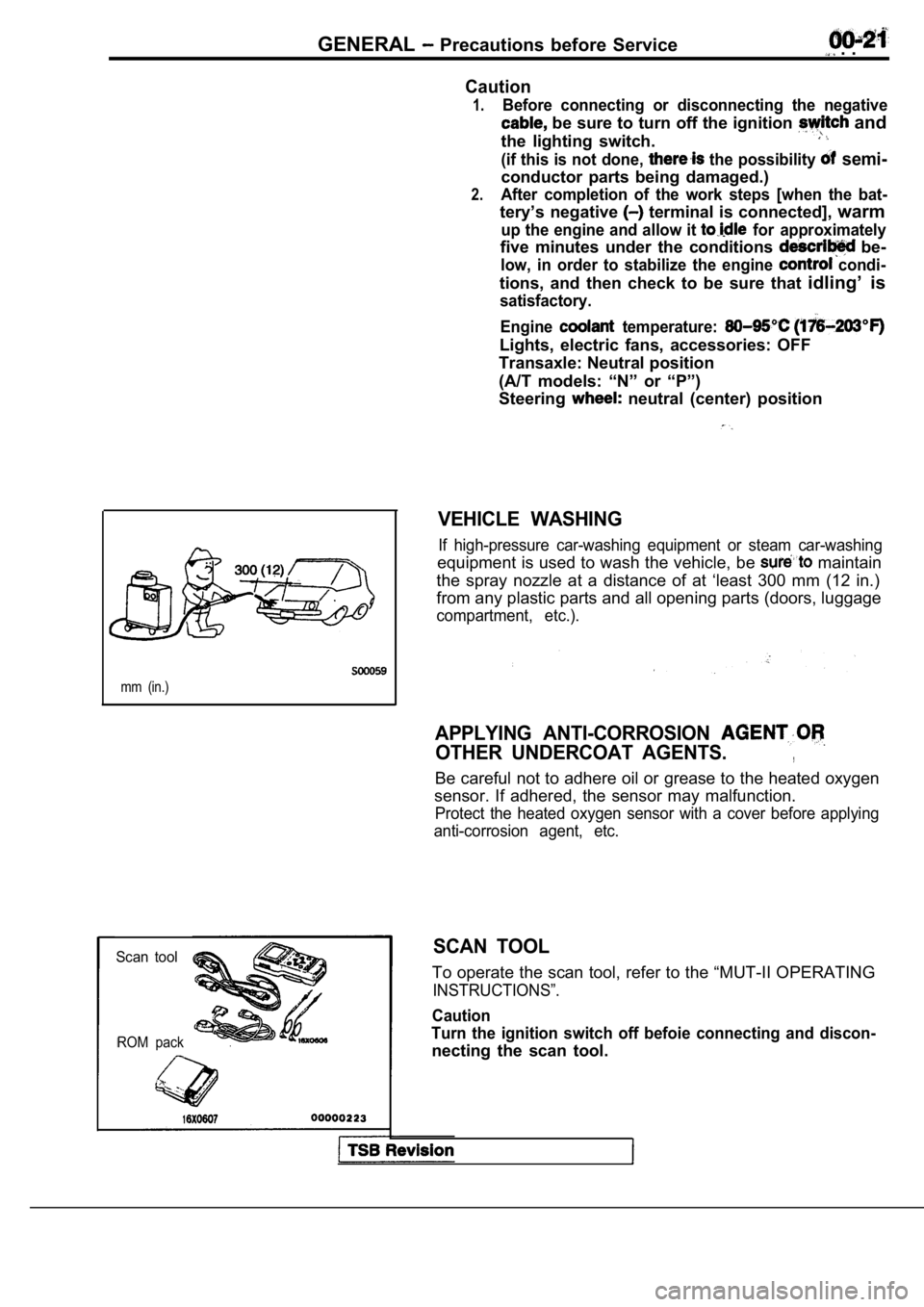

VEHICLE WASHING

If high-pressure car-washing equipment or steam car -washing

equipment is used to wash the vehicle, be maintain

the spray nozzle at a distance of at ‘least 300 mm (12 in.)

from any plastic parts and all opening parts (doors , luggage

compartment, etc.).

APPLYING ANTI-CORROSION

OTHER UNDERCOAT AGENTS.,

Be careful not to adhere oil or grease to the heate d oxygen

sensor. If adhered, the sensor may malfunction.

Protect the heated oxygen sensor with a cover befor e applying

anti-corrosion agent, etc.

SCAN TOOL

To operate the scan tool, refer to the “MUT-II OPER ATING

INSTRUCTIONS”.

Caution

Turn the ignition switch off befoie connecting and discon-

necting the scan tool.

Page 45 of 2103

GENERAL Maintenance Service

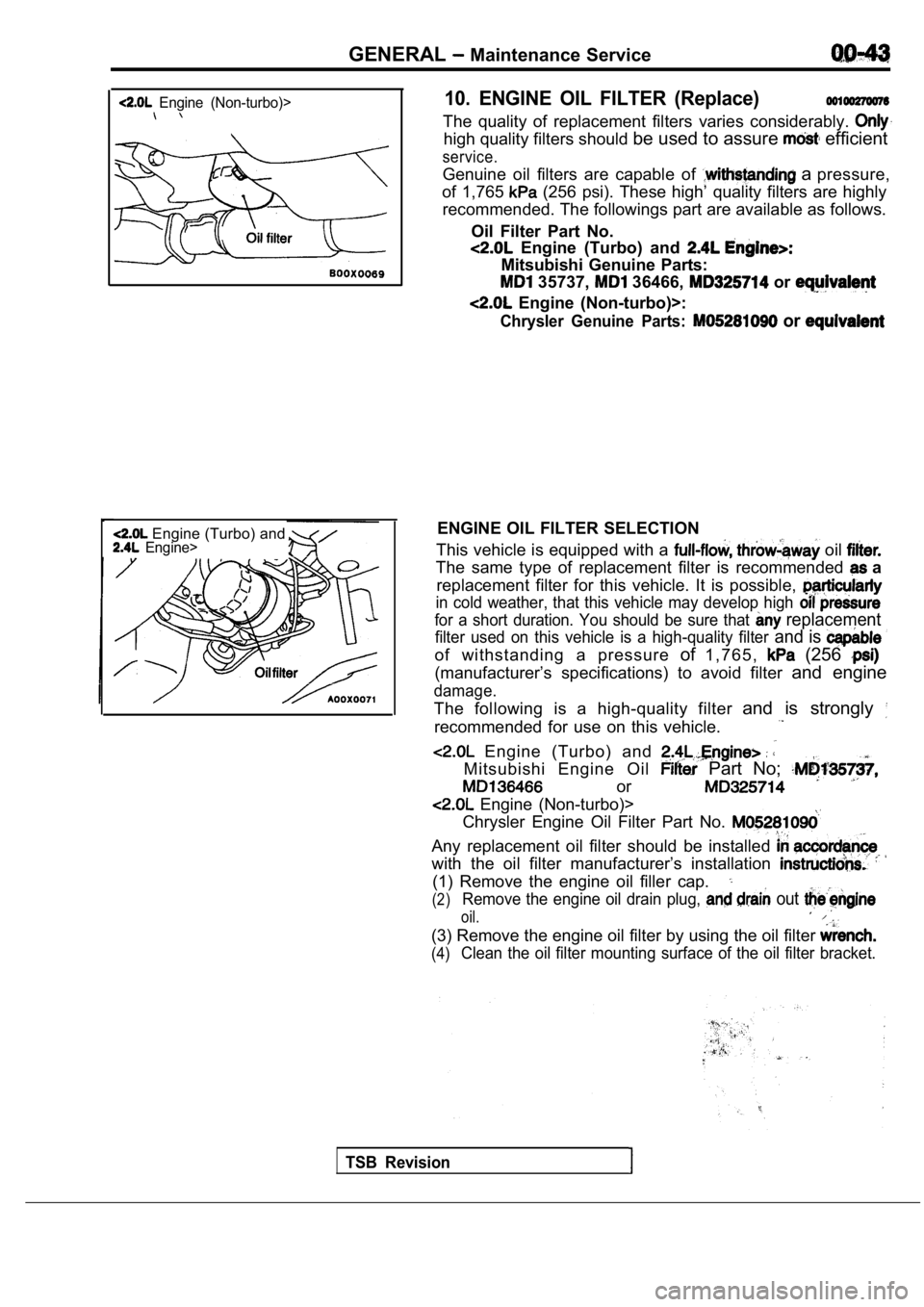

Engine (Non-turbo)>

Engine (Turbo) and Engine>

10. ENGINE OIL FILTER (Replace)

The quality of replacement filters varies considerably.

high quality filters should be used to assure efficient

service.

Genuine oil filters are capable of a pressure,

of 1,765

(256 psi). These high’ quality filters are highly

recommended. The followings part are available as f ollows.

Oil Filter Part No.

Engine (Turbo) and

Mitsubishi Genuine Parts:

35737, 36466, or

Engine (Non-turbo)>:

Chrysler Genuine Parts: or

ENGINE OIL FILTER SELECTION

This vehicle is equipped with a

oil

The same type of replacement filter is recommended a

replacement filter for this vehicle. It is possible ,

in cold weather, that this vehicle may develop high

for a short duration. You should be sure that replacement

filter used on this vehicle is a high-quality filter and is

of withstanding a pressure of1 , 7 6 5 , (256

(manufacturer’s specifications) to avoid filter and engine

damage.

The following is a high-quality filter and is strongly

recommended for use on this vehicle.

Engine (Turbo) and

Mitsubishi Engine Oil Part No;

or

Engine (Non-turbo)>

Chrysler Engine Oil Filter Part No.

Any replacement oil filter should be installed

with the oil filter manufacturer’s installation

(1) Remove the engine oil filler cap.

(2)Remove the engine oil drain plug, out

oil.

(3) Remove the engine oil filter by using the oil f ilter

(4)Clean the oil filter mounting surface of the oil filter bracket.

TSB Revision

Page 48 of 2103

GENERAL Maintenance

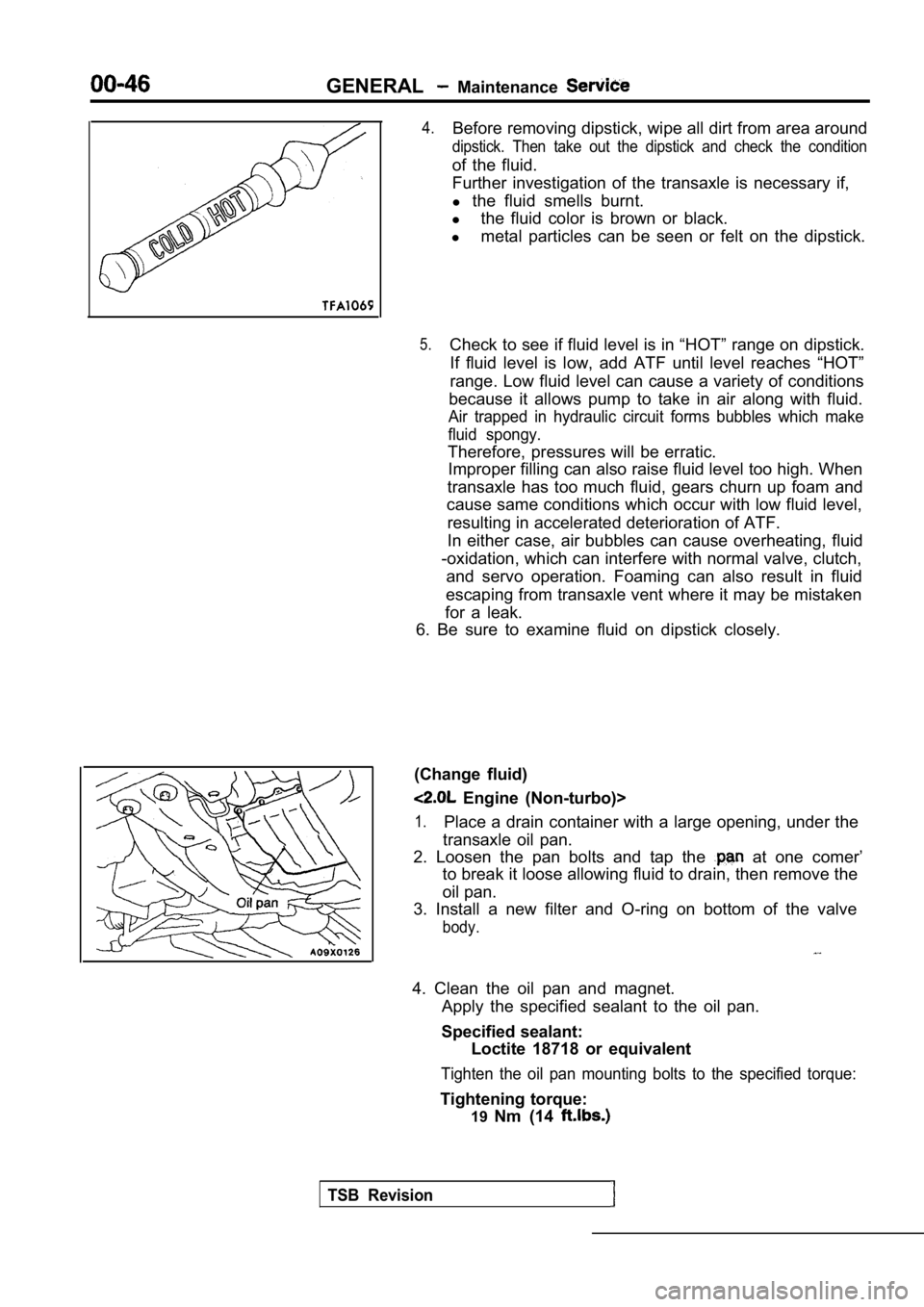

4.Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the condition

of the fluid.

Further investigation of the transaxle is necessary if,

l the fluid smells burnt.

l the fluid color is brown or black.

l metal particles can be seen or felt on the dipstick .

5.Check to see if fluid level is in “HOT” range on dipstick.

If fluid level is low, add ATF until level reaches “HOT”

range. Low fluid level can cause a variety of condi tions

because it allows pump to take in air along with fl uid.

Air trapped in hydraulic circuit forms bubbles which make

fluid spongy.

Therefore, pressures will be erratic. Improper filling can also raise fluid level too hig h. When

transaxle has too much fluid, gears churn up foam a nd

cause same conditions which occur with low fluid le vel,

resulting in accelerated deterioration of ATF.

In either case, air bubbles can cause overheating, fluid

-oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in flu id

escaping from transaxle vent where it may be mistak en

for a leak.

6. Be sure to examine fluid on dipstick closely.

(Change fluid)

Engine (Non-turbo)>

1.Place a drain container with a large opening, under the

transaxle oil pan.

2. Loosen the pan bolts and tap the

at one comer’

to break it loose allowing fluid to drain, then rem ove the

oil pan.

3. Install a new filter and O-ring on bottom of the valve

body.

4. Clean the oil pan and magnet.

Apply the specified sealant to the oil pan.

Specified sealant: Loctite 18718 or equivalent

Tighten the oil pan mounting bolts to the specified torque:

Tightening torque:

19Nm (14

TSB Revision

Page 57 of 2103

GENERAL Main and Adhesive Table

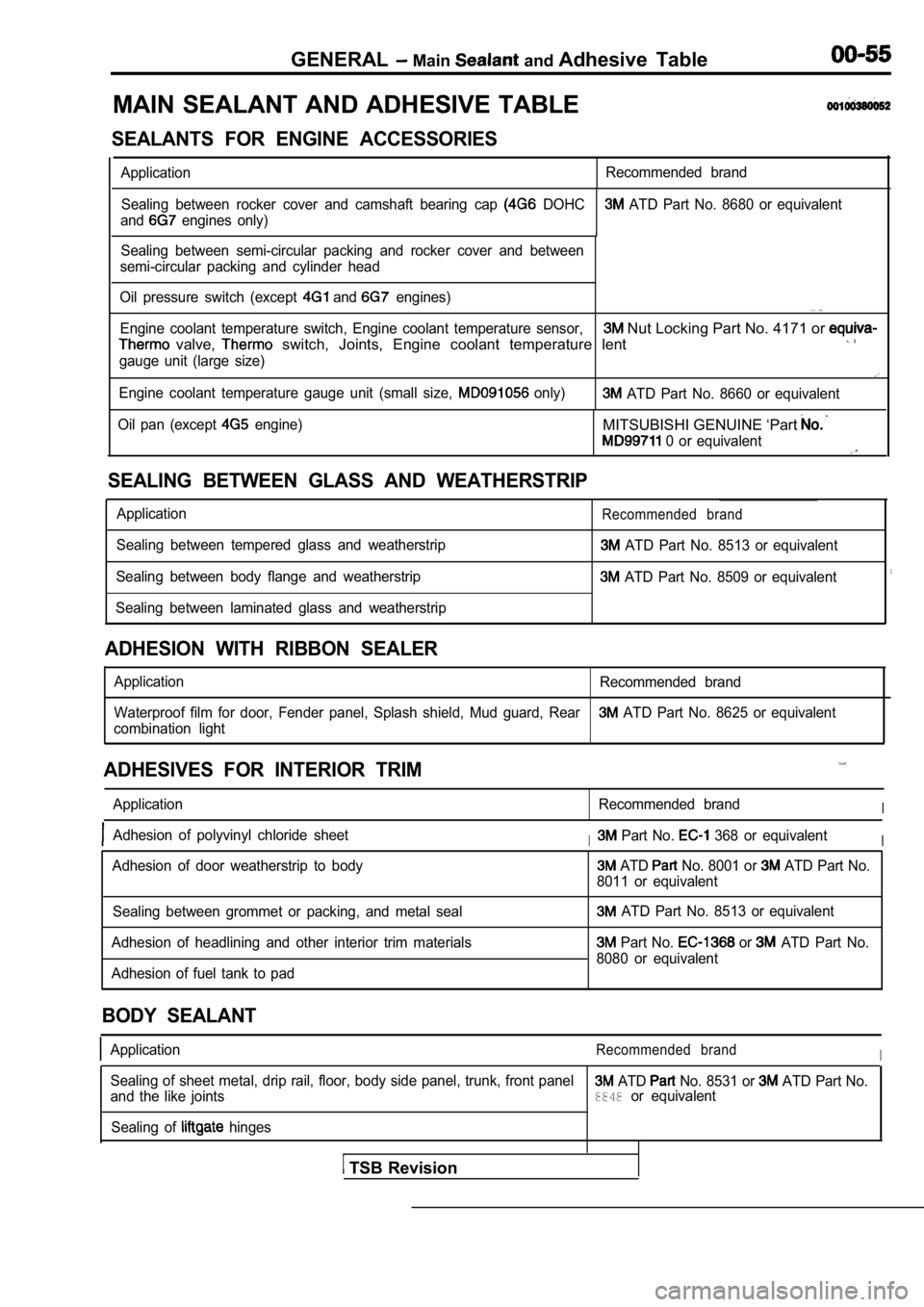

MAIN SEALANT AND ADHESIVE TABLE

SEALANTS FOR ENGINE ACCESSORIES

Application Recommended brand

Sealing between rocker cover and camshaft bearing c ap

DOHC ATD Part No. 8680 or equivalent

and

engines only)

1Sealing between semi-circular packing and rocker co ver and between

semi-circular packing and cylinder head

Oil pressure switch (except

and engines). . .

Engine coolant temperature switch, Engine coolant t emperature sensor, Nut Locking Part No. 4171 or

valve, switch, Joints, Engine coolant temperature lent

gauge unit (large size)

Engine coolant temperature gauge unit (small size, only) ATD Part No. 8660 or equivalent

Oil pan (except

engine)MITSUBISHI GENUINE ‘Part

0 or equivalent

SEALING BETWEEN GLASS AND WEATHERSTRIP

Application

Sealing between tempered glass and weatherstrip

Sealing between body flange and weatherstrip

Sealing between laminated glass and weatherstripRecommended brand

ATD Part No. 8513 or equivalent

ATD Part No. 8509 or equivalent

ADHESION WITH RIBBON SEALER

Application Recommended brand

Waterproof film for door, Fender panel, Splash shie ld, Mud guard, Rear

ATD Part No. 8625 or equivalent

combination light

ADHESIVES FOR INTERIOR TRIM

Application Recommended brandI

Adhesion of polyvinyl chloride sheetI Part No. 368 or equivalentI

Adhesion of door weatherstrip to body ATD No. 8001 or ATD Part No.

8011 or equivalent

Sealing between grommet or packing, and metal seal

Adhesion of headlining and other interior trim mate rials

Adhesion of fuel tank to pad

ATD Part No. 8513 or equivalent

Part No. or ATD Part No.

8080 or equivalent

BODY SEALANT

ApplicationRecommended brandI

Sealing of sheet metal, drip rail, floor, body side panel, trunk, front panel ATD No. 8531 or ATD Part No.

and the like joints8848or equivalent

Sealing of

hinges

TSB Revision

Page 61 of 2103

ENGINE

CONTENTS

CAMSHAFT AND CAMSHAFT OIL

SEAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

CRANKSHAFT FRONT OIL SEAL . . . . . . . 28

CRANKSHAFT PULLEY . . . . . . . . . . . . . . . . . 21

CRANKSHAFT REAR OIL SEAL. . . . . . . .29

Curb Speed Check. . . . . . . . . . . . . . . . . .10

Drive Belt Tension Check and

Adjustment . , . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mixture Check . . . . . . . . . . . . . . . . . .

. . . . .10

Ignition Timing Check. . . . . . . . . . . .. . . . . . . . .

Lash Adjuster Check . . . . . . . . . . . . . . . .

CYLINDER HEAD GASKET . . . . . . . . . . . . .31

ENGINE ASSEMBLY. . . . . . . . . . . . . . . . . . . .16

GENERAL INFORMATION. . . . . . . . . . . . . . . .2

OIL PAN AND OIL SCREEN . . . . . . . . . . . .26

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . .7

Basic Idle Speed Adjustment

. . . . . . . . . . . . . . . . . . . . . . Refer to GROUP

Lash Adjuster Replacement. . . . . . . .. . . .15

Manifold Vacuum Check. . . . . . . . . . . . . . . ....13

SEALANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE SPECIFICATIONS. . . . . . . . . . . . . .3

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . .4

BELT. . . . . . . . . . . . . . . . . . . . . . . . . . .36

TIMING BELT . . . . . . . . . . . . . . . . . . . . . . . .41

Compression Pressure Check . . . . . . . . . . . .

. . 11TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . 6

Page 62 of 2103

ENGINE General Information

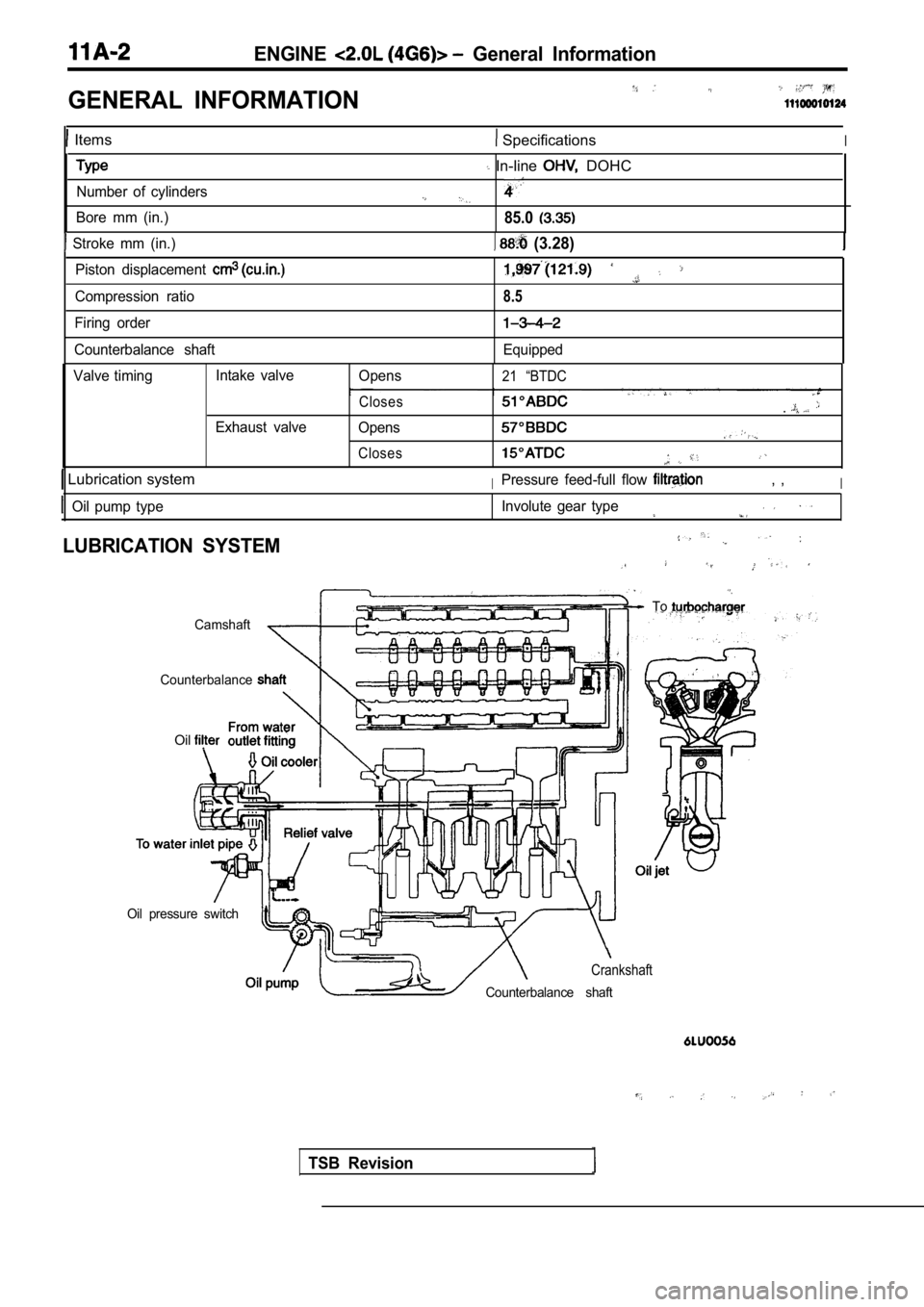

GENERAL INFORMATION

Items SpecificationsI

Number of cylinders

Bore mm (in.)

Stroke mm (in.)

In-line DOHC

85.0

(3.28)

Piston displacement

Compression ratio

Firing order

Counterbalance shaft8.5

Equipped

Valve timing Intake valve

Exhaust valve Opens

Closes

Opens

Closes 21 “BTDC

.

Lubrication systemIPressure feed-full flow , ,I

Oil pump type

LUBRICATION SYSTEM

Involute gear type

To

Camshaft

Counterbalance

TSB Revision

Oil

Oil pressure switch

Crankshaft

Counterbalance shaft

Page 66 of 2103

ENGINE,

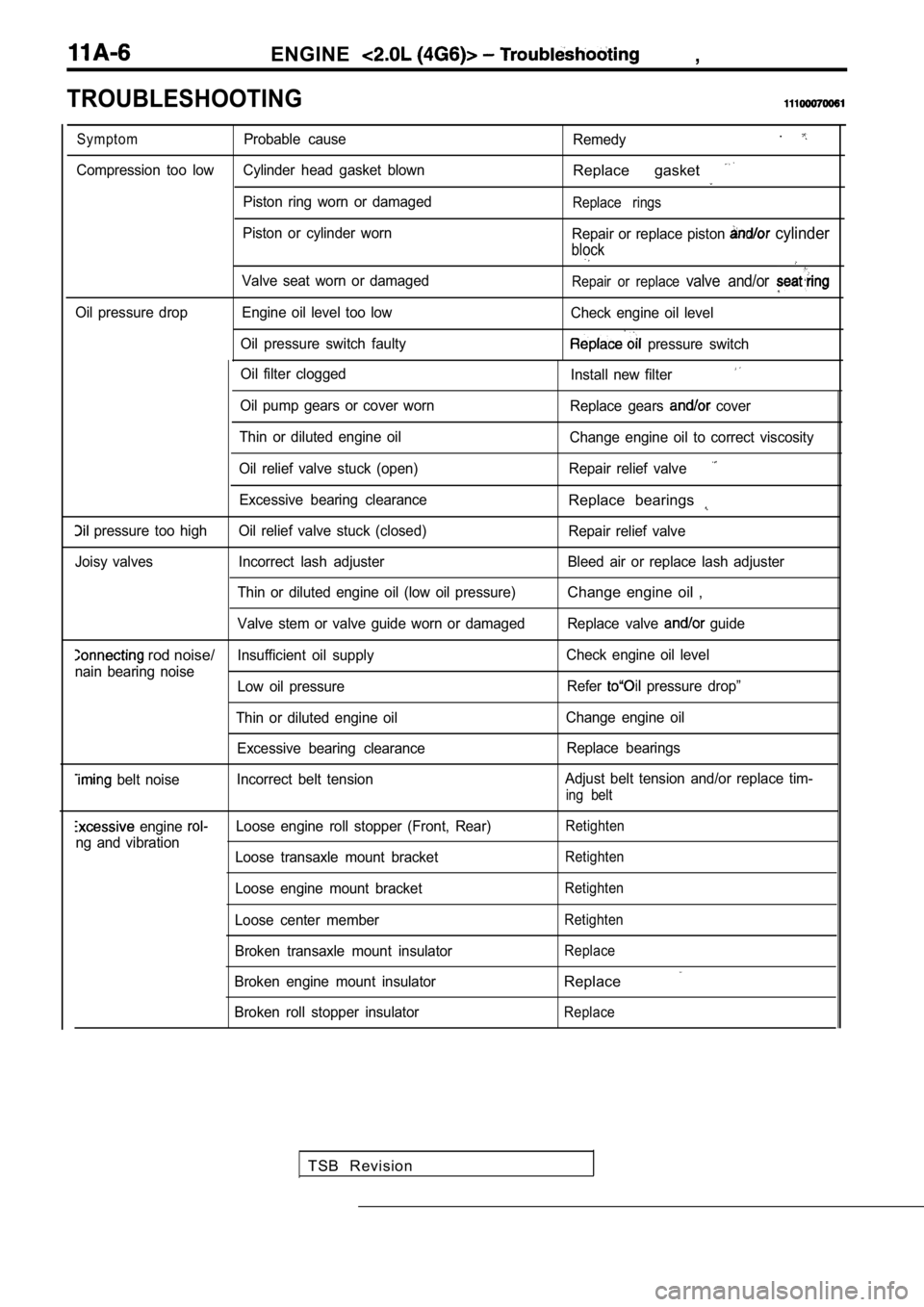

TROUBLESHOOTING

Oil filter cloggedInstall new filter

Oil pump gears or cover wornReplace gears cover

Thin or diluted engine oil Change engine oil to correct viscosity

Oil relief valve stuck (open) Repair relief valve

Excessive bearing clearanceReplace bearings

pressure too high Oil relief valve stuck (closed) Repair relief valve

Joisy valves Incorrect lash adjuster Bleed air or rep lace lash adjuster

Thin or diluted engine oil (low oil pressure)

Change engine oil ,

Valve stem or valve guide worn or damaged Replace va lve guide

rod noise/Insufficient oil supplyCheck engine oil level

nain bearing noise Low oil pressure Refer

pressure drop”

Thin or diluted engine oil Change engine oil

Excessive bearing clearance Replace bearings

belt noiseIncorrect belt tension Adjust belt tension and/or replace tim-ing belt

engine Loose engine roll stopper (Front, Rear)Retighten

ng and vibration

Loose transaxle mount bracketRetighten

Loose engine mount bracketRetighten

Loose center memberRetighten

Broken transaxle mount insulatorReplace

Broken engine mount insulatorReplace

Broken roll stopper insulatorReplace

Symptom

Probable cause

Remedy.

Compression too low Cylinder head gasket blownReplace gasket

Piston ring worn or damagedReplace rings

Piston or cylinder worn

Repair or replace piston cylinder

block

Valve seat worn or damagedRepair or replace valve and/or

Oil pressure drop Engine oil level too low Check engine oil level

Oil pressure switch faulty

pressure switch

TSB Revision

Page 71 of 2103

ENGINE On-vehicle

8. If the standard value is exceeded, check the following

items:

l Diagnostic output

l Closed-loop control (When the closed-loop control

is carried out normally, the output signal of the h eated

oxygen sensor repeats between and

,000 at idle.)

l Fuel pressure

I n j e c t o r

lIgnition coil, spark plug cable, spark plug

lEGR system and the EGR valve leak

l Evaporative emission control system

Compression pressure

NOTE

Replace the catalyst whenever the

HC contents do not remain inside the standard value .

(even though the result of the inspection is

all items.).

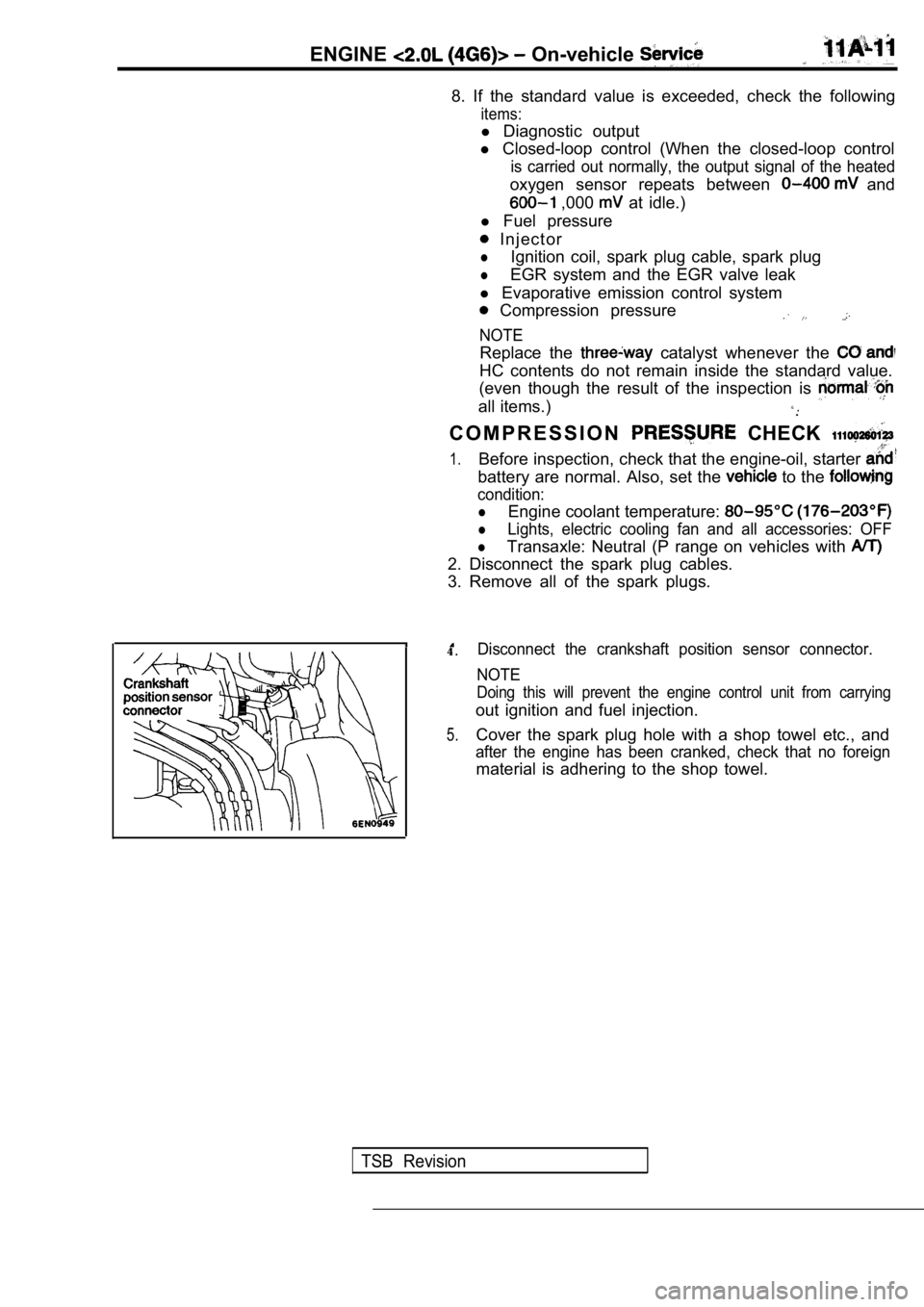

C O M P R E S S I O N

CHECK

1.Before inspection, check that the engine-oil, start er

battery are normal. Also, set the to the

condition:

lEngine coolant temperature:

lLights, electric cooling fan and all accessories: O FF

lTransaxle: Neutral (P range on vehicles with

2. Disconnect the spark plug cables.

3. Remove all of the spark plugs.

4.

5.

Disconnect the crankshaft position sensor connector .

NOTE

Doing this will prevent the engine control unit fro m carrying

out ignition and fuel injection.

Cover the spark plug hole with a shop towel etc., a nd

after the engine has been cranked, check that no fo reign

material is adhering to the shop towel.

TSB Revision

Page 72 of 2103

ENGINE On-vehicle

Caution

1.Keep away from the spark plug hole when crank-

ing.

2. If compression is measured with water, oil, fuel,

etc., that has come from cracks inside the cylinder ,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

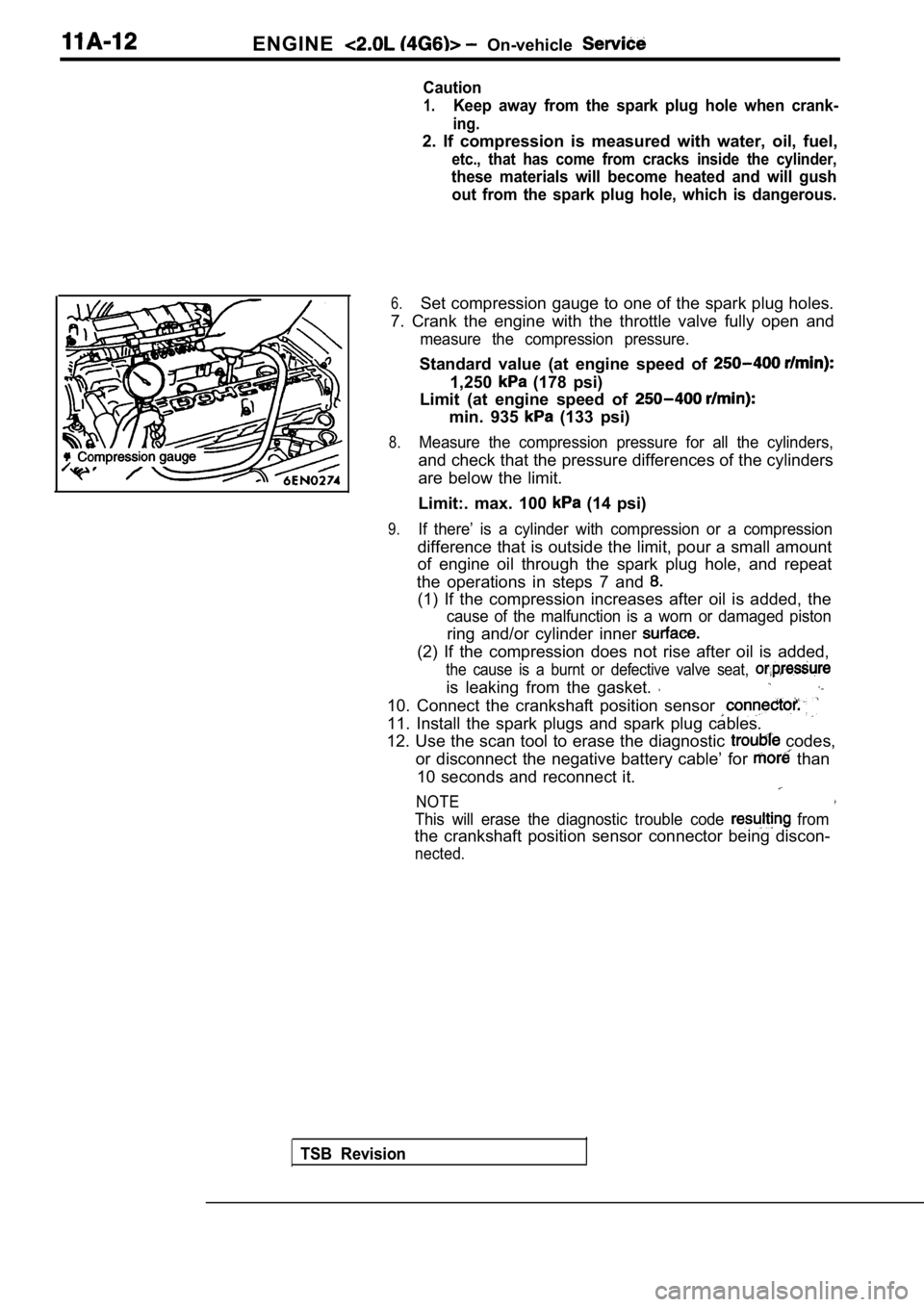

6.Set compression gauge to one of the spark plug hole s.

7. Crank the engine with the throttle valve fully o pen and

measure the compression pressure.

Standard value (at engine speed of

1,250 (178 psi)

Limit (at engine speed of

min. 935 (133 psi)

8.Measure the compression pressure for all the cylind ers,

and check that the pressure differences of the cylinders

are below the limit.

Limit:. max. 100

(14 psi)

9.If there’ is a cylinder with compression or a compr ession

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repe at

the operations in steps 7 and

(1) If the compression increases after oil is added , the

cause of the malfunction is a worn or damaged pisto n

ring and/or cylinder inner

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat,

is leaking from the gasket.

10. Connect the crankshaft position sensor

11. Install the spark plugs and spark plug cables.

12. Use the scan tool to erase the diagnostic

codes,

or disconnect the negative battery cable’ for

than

10 seconds and reconnect it.

NOTE

This will erase the diagnostic trouble code from

the crankshaft position sensor connector being disc on-

nected.

TSB Revision

Page 73 of 2103

ENGINE On-vehicle Service

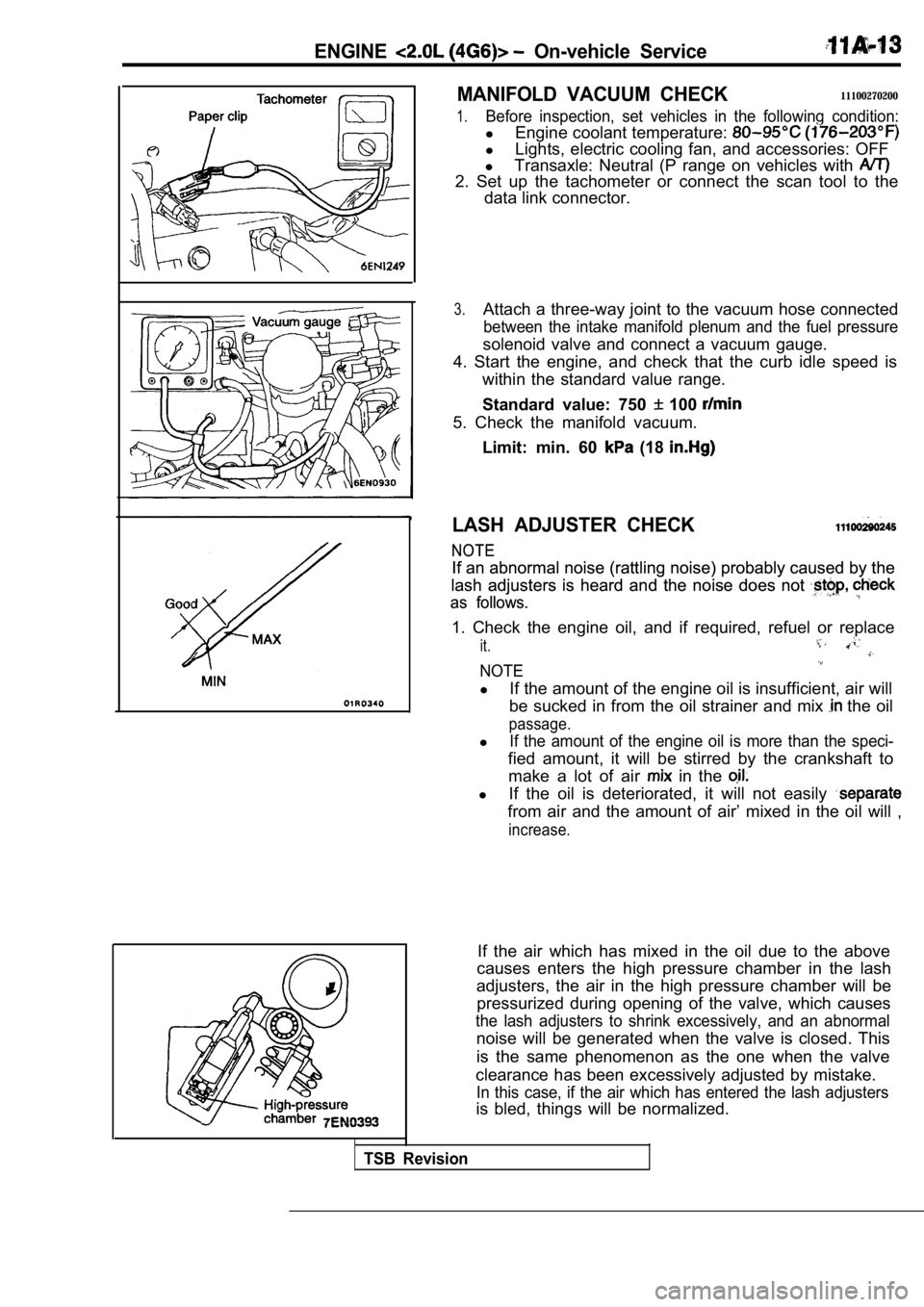

MANIFOLD VACUUM CHECK11100270200

1.Before inspection, set vehicles in the following condition:

lEngine coolant temperature:

lLights, electric cooling fan, and accessories: OFF

l Transaxle: Neutral (P range on vehicles with

2. Set up the tachometer or connect the scan tool t o the

data link connector.

3.Attach a three-way joint to the vacuum hose connect ed

between the intake manifold plenum and the fuel pressure

solenoid valve and connect a vacuum gauge.

4. Start the engine, and check that the curb idle s peed is

within the standard value range.

Standard value: 750

100

5. Check the manifold vacuum.

Limit: min. 60

(18

LASH ADJUSTER CHECK

NOTE

NOTE

If an abnormal noise (rattling noise) probably caus ed by the

If an abnormal noise (rattling noise) probably caus ed by the

lash adjusters is heard and the noise does not

lash adjusters is heard and the noise does not

as follows.

as follows.

1. Check the engine oil, and if required, refuel or replace

it.

NOTE

lIf the amount of the engine oil is insufficient, ai r will

be sucked in from the oil strainer and mix

the oil

passage.

lIf the amount of the engine oil is more than the sp eci-

fied amount, it will be stirred by the crankshaft to

make a lot of air

in the

l If the oil is deteriorated, it will not easily

from air and the amount of air’ mixed in the oil wi ll ,

increase.

If the air which has mixed in the oil due to the ab ove

causes enters the high pressure chamber in the lash

adjusters, the air in the high pressure chamber wil l be

pressurized during opening of the valve, which caus es

the lash adjusters to shrink excessively, and an abnormal

noise will be generated when the valve is closed. T his

is the same phenomenon as the one when the valve

clearance has been excessively adjusted by mistake.

In this case, if the air which has entered the lash adjusters

is bled, things will be normalized.

TSB Revision