clock MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 22 of 2103

GENERAL before Service

PRECAUTIONS BEFORE SERVICE.

SUPPLEMENTAL RESTRAINT SYSTEM

1. to follow when servicing SRS

(1) Be sure to read GROUP Supplemental Restraint System

For safe operations, please follow the directions a nd heed all

(2) Always use the designated special tools and tes t equipment.

(3) Wait at least 60 seconds after disconnecting the battery cable before” further work;

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the bat tery cable is disconnected.

(4) Never attempt to disassemble or repair the SRS components (SRS-ECU air bag module and

clock spring). If faulty, replace it.

(5) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

Sun visor

l Glove box

. S R S - E C U

l Steering wheel

l Air bag module

l Clock spring

l Steering gear and linkage clamp

(6) Store components removed from the SRS

a clean and dry place.

The air bag module should be stored on a flat surfa ce and placed so that the pad surface is’

facing upward.

Do not place anything on top of it.

(7) Be sure to deploy the air bag before disposing of the air bag’module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP

Air Bag Module Disposal Procedures.)

(8) Whenever you finish servicing the

check the SRS warning light operation to make sure

that the system functions properly.

2.Observe the following when carrying out operations on places where SRS components are installed,’

.,

including operations not directly related to the SR S air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat over so remove the SRS compo-

nents before drying or baking the vehicle after painting.

After re-installing them, check the SRS warning lig ht operation to make sure that the system

functions properly.

SERVICING THE ELECTRICAL SYSTEM

1. Note the following before proceeding with work o n the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that co uld result

in a fire in the vehicle.

2.When servicing the electrical system, disconnect th e nega-

tive cable terminal from the battery.

Page 54 of 2103

GENERAL Maintenance Service

0 0 0 0 0 1 6 7

Inflator case

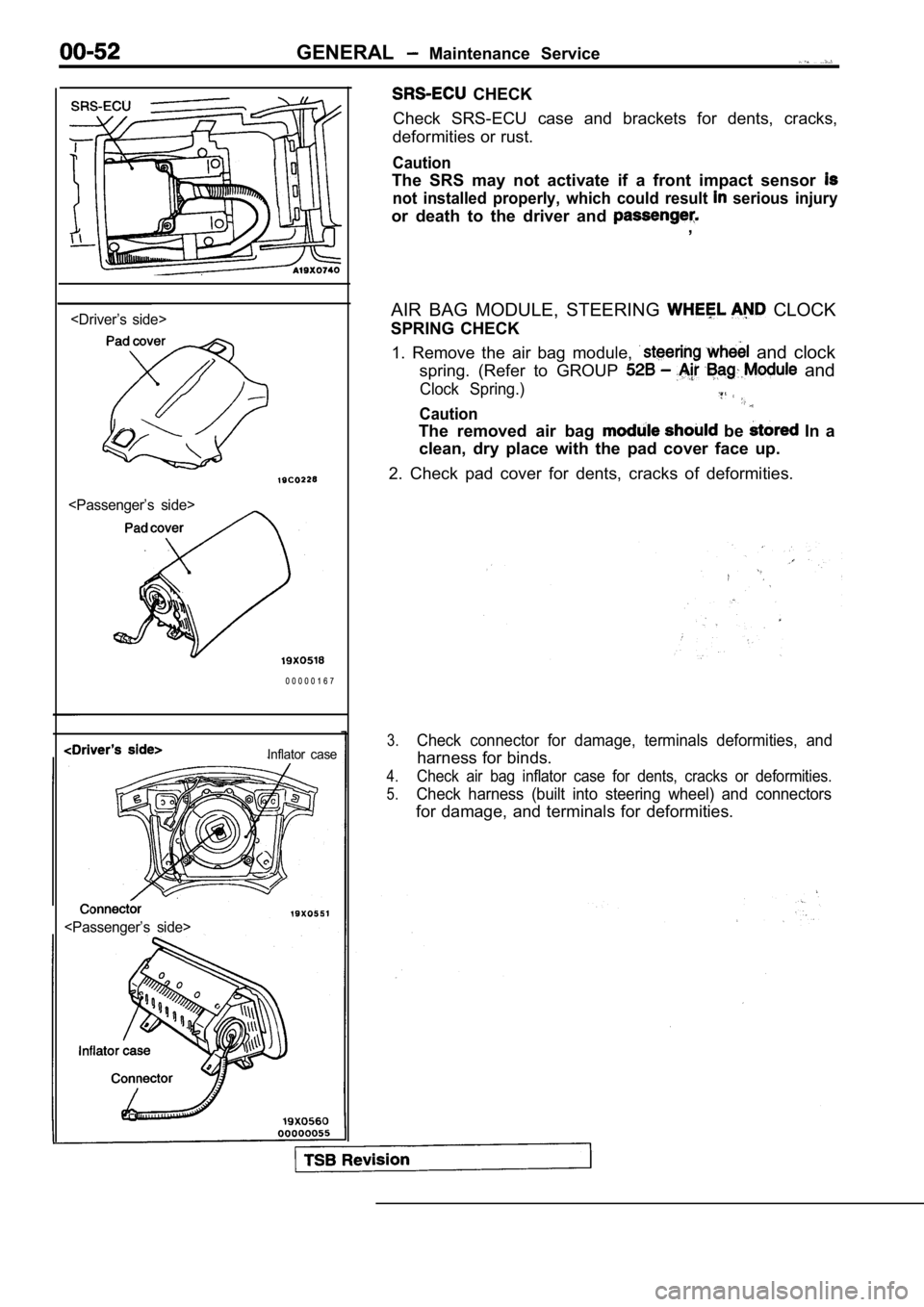

CHECK

Check SRS-ECU case and brackets for dents, cracks,

deformities or rust.

Caution

The SRS may not activate if a front impact sensor

not installed properly, which could result serious injury

or death to the driver and ,

AIR BAG MODULE, STEERING

CLOCK

SPRING CHECK

1. Remove the air bag module,

and clock

spring. (Refer to GROUP

and

Clock Spring.)

Caution

The removed air bag be In a

clean, dry place with the pad cover face up.

2. Check pad cover for dents, cracks of deformities .

3.Check connector for damage, terminals deformities, and

harness for binds.

4.Check air bag inflator case for dents, cracks or deformities.

5.Check harness (built into steering wheel) and conne ctors

for damage, and terminals for deformities.

Page 55 of 2103

G E N E R A L Maintenance

Protective tube

harness

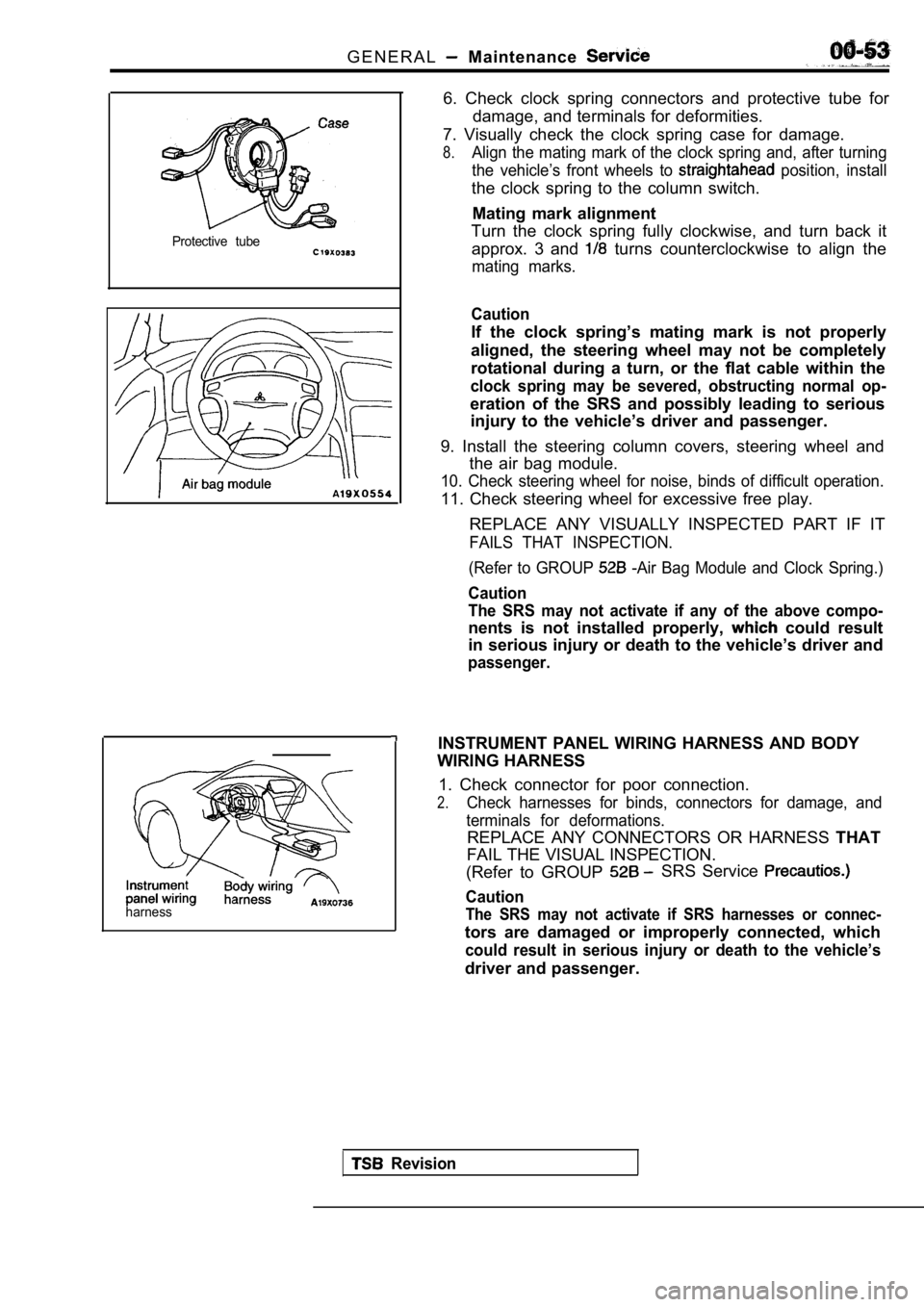

6. Check clock spring connectors and protective tube for

damage, and terminals for deformities.

7. Visually check the clock spring case for damage.

8.Align the mating mark of the clock spring and, afte r turning

the vehicle’s front wheels to

position, install

the clock spring to the column switch.

Mating mark alignment

Turn the clock spring fully clockwise, and turn bac k it

approx. 3 and

turns counterclockwise to align the

mating marks.

Caution

If the clock spring’s mating mark is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal op-

eration of the SRS and possibly leading to serious

injury to the vehicle’s driver and passenger.

9. Install the steering column covers, steering whe el and

the air bag module.

10. Check steering wheel for noise, binds of diffic ult operation.

11. Check steering wheel for excessive free play.

REPLACE ANY VISUALLY INSPECTED PART IF IT

FAILS THAT INSPECTION.

(Refer to GROUP

-Air Bag Module and Clock Spring.)

Caution

The SRS may not activate if any of the above compo-

nents is not installed properly, could result

in serious injury or death to the vehicle’s driver and

passenger.

INSTRUMENT PANEL WIRING HARNESS AND BODY

WIRING HARNESS

1. Check connector for poor connection.

2.Check harnesses for binds, connectors for damage, a nd

terminals for deformations.

REPLACE ANY CONNECTORS OR HARNESS THAT

FAIL THE VISUAL INSPECTION.

(Refer to GROUP

SRS Service

Caution

The SRS may not activate if SRS harnesses or connec -

tors are damaged or improperly connected, which

could result in serious injury or death to the vehicle’s

driver and passenger.

Revision

Page 100 of 2103

E N G I N E Belt

Auto tensioner

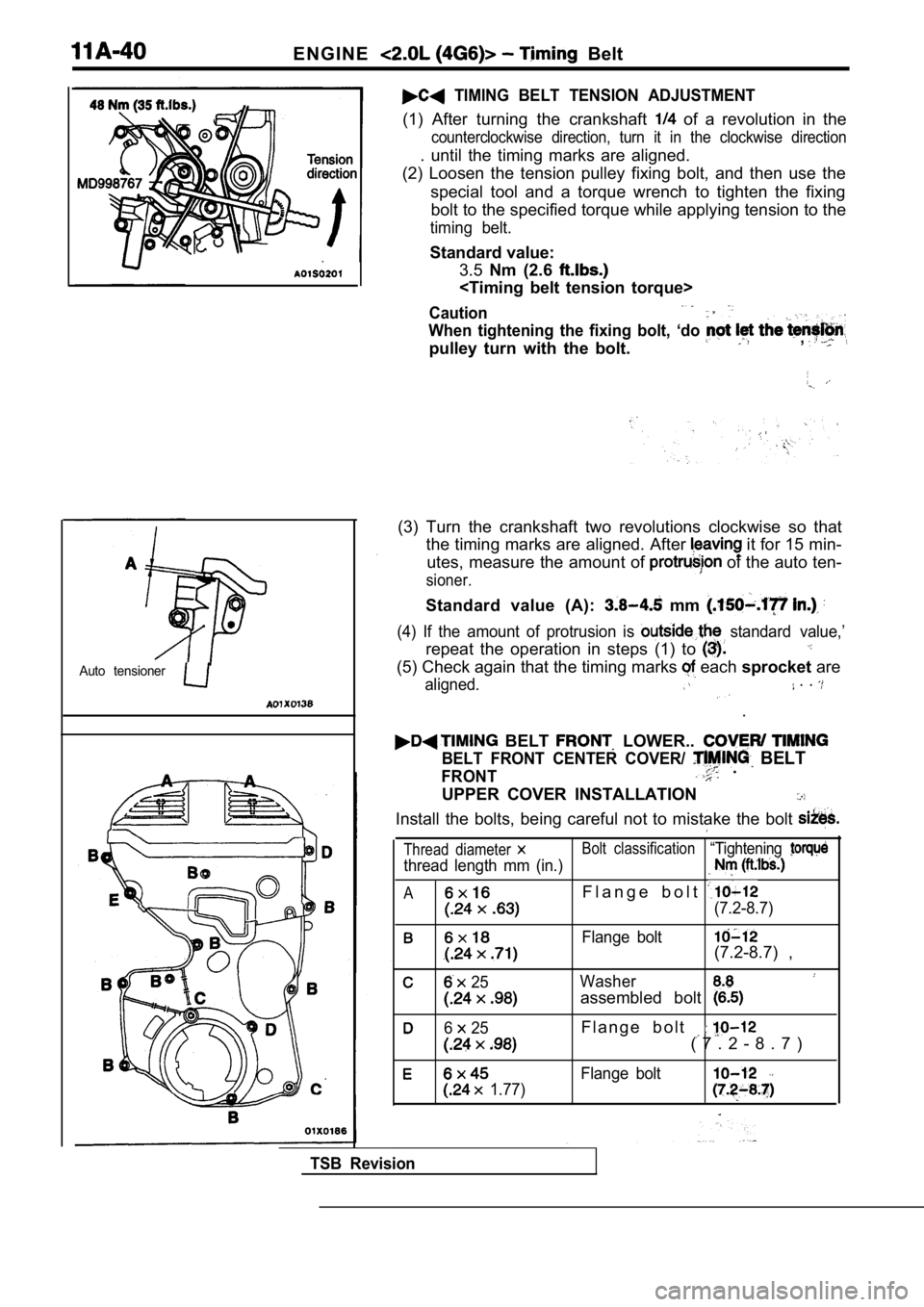

TIMING BELT TENSION ADJUSTMENT

(1) After turning the crankshaft of a revolution in the

counterclockwise direction, turn it in the clockwise direction

. until the timing marks are aligned.

(2) Loosen the tension pulley fixing bolt, and then use the

special tool and a torque wrench to tighten the fix ing

bolt to the specified torque while applying tension to the

timing belt.

Standard value:

3.5 Nm (2.6

Caution

When tightening the fixing bolt, ‘do

pulley turn with the bolt.,

(3) Turn the crankshaft two revolutions clockwise s o that

the timing marks are aligned. After

it for 15 min-

utes, measure the amount of

of the auto ten-

sioner.

Standard value (A): mm

(4) If the amount of protrusion is standard value,’

repeat the operation in steps (1) to

(5) Check again that the timing marks each sprocket are

aligned. . .

.

BELT LOWER..

BELT FRONT CENTER COVER/ BELT

FRONT .

UPPER COVER INSTALLATION

Install the bolts, being careful not to mistake the bolt

Thread diameter Bolt classification“Tightening

thread length mm (in.)

AF l a n g e b o l t

(7.2-8.7)

Flange bolt(7.2-8.7) ,

25Washer

assembled bolt

6 25F l a n g e b o l t

( 7 . 2 - 8 . 7 )

Flange bolt

1.77)

TSB Revision

Page 124 of 2103

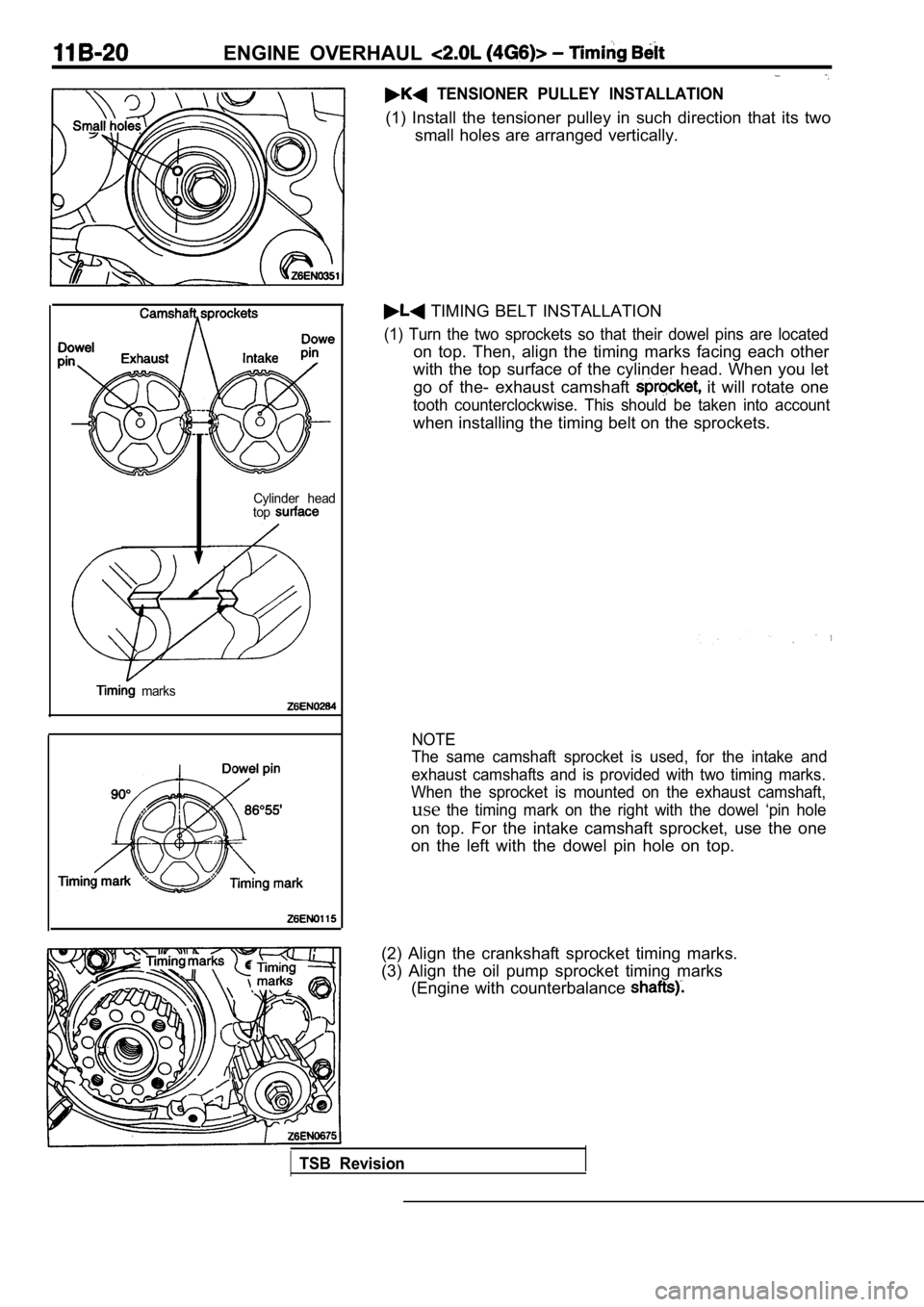

ENGINE OVERHAUL

TENSIONER PULLEY INSTALLATION

(1) Install the tensioner pulley in such direction that its two

small holes are arranged vertically.

Cylinder head

top

marks

TIMING BELT INSTALLATION

(1) Turn the two sprockets so that their dowel pins are located

on top. Then, align the timing marks facing each ot her

with the top surface of the cylinder head. When you let

go of the- exhaust camshaft

it will rotate one

tooth counterclockwise. This should be taken into a ccount

when installing the timing belt on the sprockets.

NOTE

The same camshaft sprocket is used, for the intake and

exhaust camshafts and is provided with two timing m arks.

When the sprocket is mounted on the exhaust camshaf t,

usethe timing mark on the right with the dowel ‘pin hole

on top. For the intake camshaft sprocket, use the o ne

on the left with the dowel pin hole on top.

(2) Align the crankshaft sprocket timing marks.

(3) Align the oil pump sprocket timing marks (Engine with counterbalance

TSB Revision

Page 126 of 2103

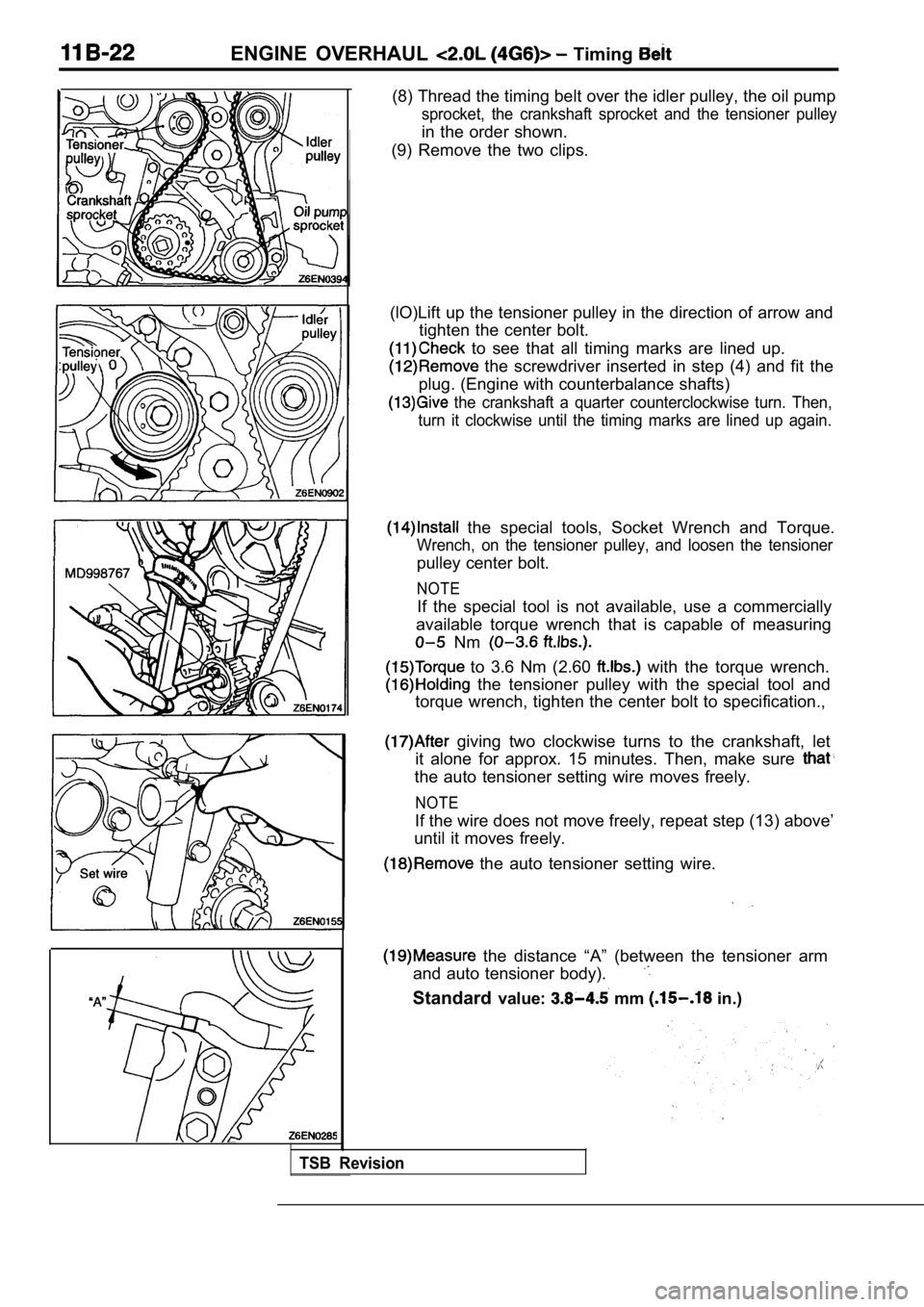

ENGINE OVERHAUL Timing

(8) Thread the timing belt over the idler pulley, the oil pump

sprocket, the crankshaft sprocket and the tensioner pulley

in the order shown.

(9) Remove the two clips.

(lO)Lift up the tensioner pulley in the direction o f arrow and

tighten the center bolt.

to see that all timing marks are lined up.

the screwdriver inserted in step (4) and fit the

plug. (Engine with counterbalance shafts)

the crankshaft a quarter counterclockwise turn. Th en,

turn it clockwise until the timing marks are lined up again.

the special tools, Socket Wrench and Torque.

Wrench, on the tensioner pulley, and loosen the ten sioner

pulley center bolt.

NOTE

If the special tool is not available, use a commercially

available torque wrench that is capable of measurin g

Nm

to 3.6 Nm (2.60 with the torque wrench.

the tensioner pulley with the special tool and

torque wrench, tighten the center bolt to specifica tion.,

giving two clockwise turns to the crankshaft, let

it alone for approx. 15 minutes. Then, make sure

the auto tensioner setting wire moves freely.

NOTE

If the wire does not move freely, repeat step (13) above’

until it moves freely.

the auto tensioner setting wire.

the distance “A” (between the tensioner arm

and auto tensioner body).

Standard value: mm in.)

TSB Revision

Page 179 of 2103

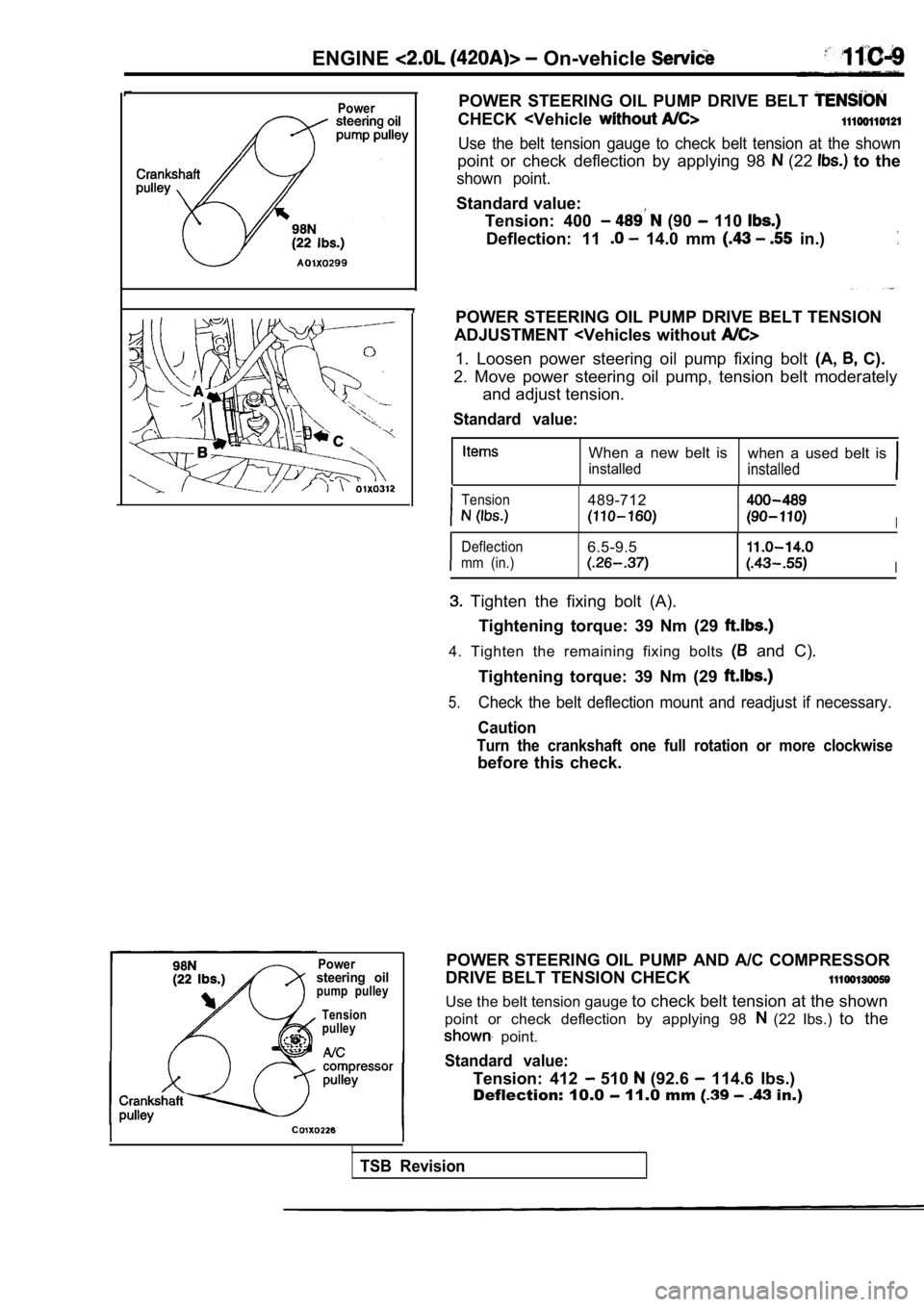

ENGINE On-vehicle

Power

Powersteering oilpump pulleyTension

pulley

POWER STEERING OIL PUMP DRIVE BELT

CHECK

point or check deflection by applying 98 (22 to the

shown point.

Standard value:

Tension: 400

(90 110

Deflection: 11 14.0 mm in.)

POWER STEERING OIL PUMP DRIVE BELT TENSION

ADJUSTMENT

2. Move power steering oil pump, tension belt moder ately

and adjust tension.

Standard value:

When a new belt is when a used belt is

installedinstalled

Tension489-712

I

Deflection6.5-9.5

mm (in.)I

Tighten the fixing bolt (A).

Tightening torque: 39 Nm (29

4. Tighten the remaining fixing bolts and C).

Tightening torque: 39 Nm (29

5.Check the belt deflection mount and readjust if nec essary.

Caution

Turn the crankshaft one full rotation or more clock wise

before this check.

POWER STEERING OIL PUMP AND A/C COMPRESSOR

DRIVE BELT TENSION CHECK

Use the belt tension gauge to check belt tension at the shown

point or check deflection by applying 98

(22 Ibs.) to the

point.

Standard value:

Tension: 412 510 (92.6 114.6 Ibs.)

Deflection: 10.0

11.0 mm in.)

TSB Revision

Page 282 of 2103

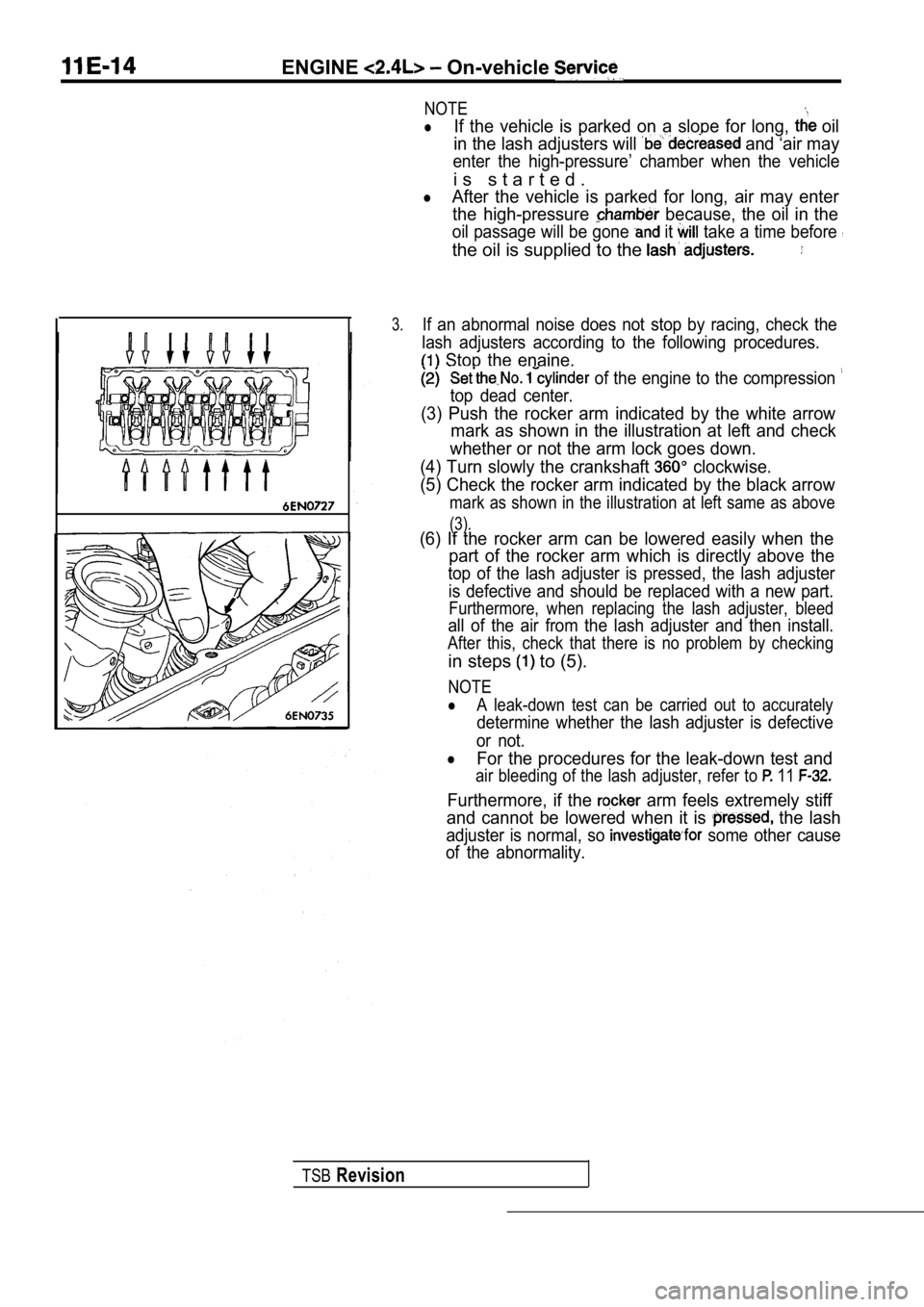

ENGINE On-vehicle

NOTE

lIf the vehicle is parked on a slope for long, oil

in the lash adjusters will

and ‘air may

enter the high-pressure’ chamber when the vehicle

i s s t a r t e d .

lAfter the vehicle is parked for long, air may enter the high-pressure

because, the oil in the

oil passage will be gone it take a time before

the oil is supplied to the

3.If an abnormal noise does not stop by racing, check the

lash adjusters according to the following procedure s.

Stop the enaine.

of the engine to the compression

top dead center.

(3) Push the rocker arm indicated by the white arrow

mark as shown in the illustration at left and check

whether or not the arm lock goes down.

(4) Turn slowly the crankshaft

clockwise.

(5) Check the rocker arm indicated by the black arr ow

mark as shown in the illustration at left same as above

(3).(6) If the rocker arm can be lowered easily when th e

part of the rocker arm which is directly above the

top of the lash adjuster is pressed, the lash adjus ter

is defective and should be replaced with a new part .

Furthermore, when replacing the lash adjuster, blee d

all of the air from the lash adjuster and then install.

After this, check that there is no problem by check ing

in steps to (5).

NOTE

lA leak-down test can be carried out to accurately

determine whether the lash adjuster is defective

or not.

lFor the procedures for the leak-down test and

air bleeding of the lash adjuster, refer to 11

Furthermore, if the arm feels extremely stiff

and cannot be lowered when it is

the lash

adjuster is normal, so some other cause

of the abnormality.

TSBRevision

Page 304 of 2103

ENGINE

marks

(22-44

Auto tensioner

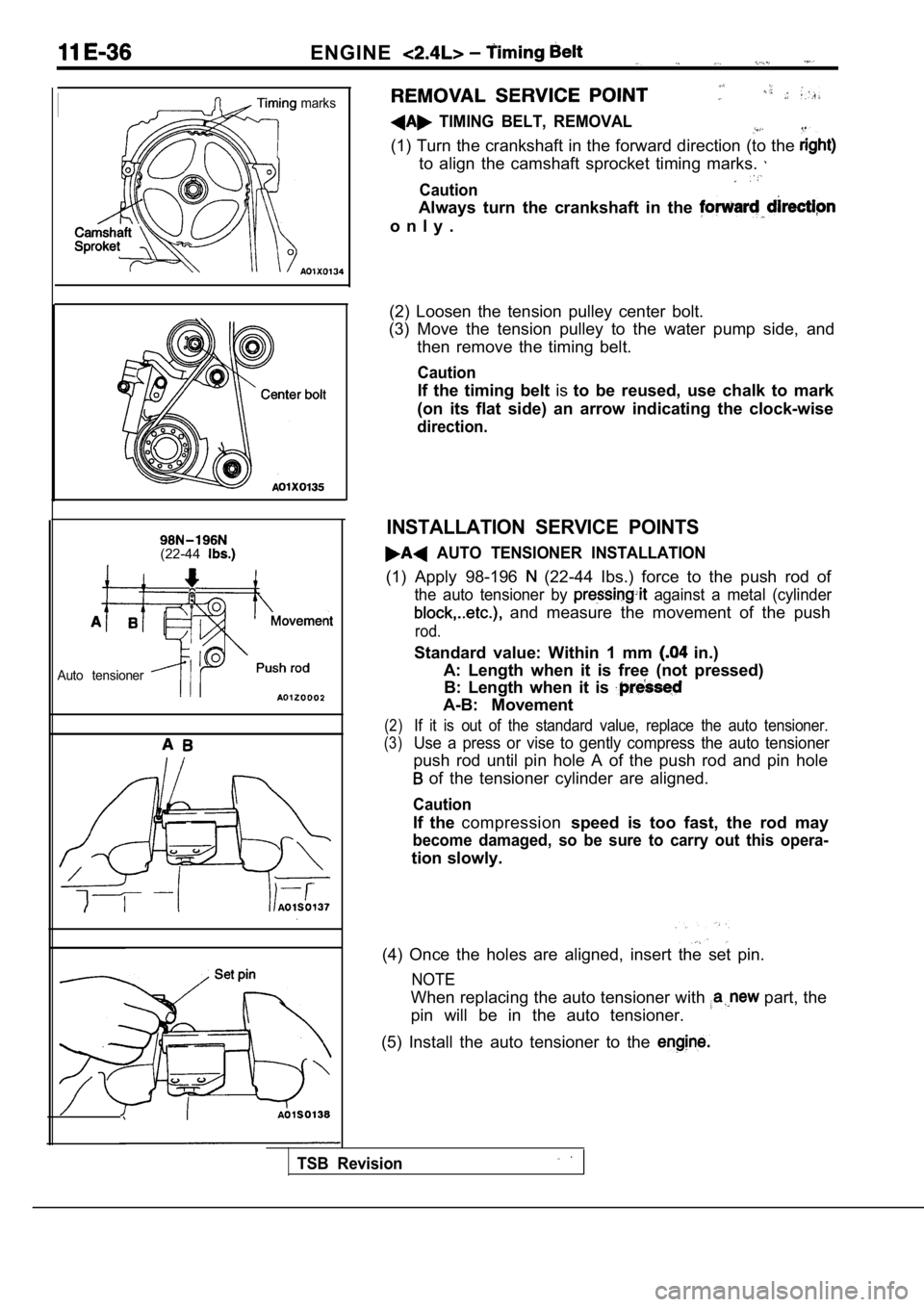

TIMING BELT, REMOVAL

(1) Turn the crankshaft in the forward direction (to the

to align the camshaft sprocket timing marks.

Caution

Always turn the crankshaft in the

o n l y .

(2) Loosen the tension pulley center bolt.

(3) Move the tension pulley to the water pump side, and

then remove the timing belt.

Caution

If the timing belt isto be reused, use chalk to mark

(on its flat side) an arrow indicating the clock-wi se

direction.

INSTALLATION SERVICE POINTS

AUTO TENSIONER INSTALLATION

(1) Apply 98-196 (22-44 Ibs.) force to the push rod of

the auto tensioner by against a metal (cylinder

and measure the movement of the push

rod.

Standard value: Within 1 mm in.)

A: Length when it is free (not pressed) B: Length when it is

A-B: Movement

(2)If it is out of the standard value, replace the aut o tensioner.

(3)Use a press or vise to gently compress the auto ten sioner

push rod until pin hole A of the push rod and pin hole

of the tensioner cylinder are aligned.

Caution

If the compression speed is too fast, the rod may

become damaged, so be sure to carry out this opera-

tion slowly.

(4) Once the holes are aligned, insert the set pin.

NOTE

When replacing the auto tensioner with part, the

pin will be in the auto tensioner.

(5) Install the auto tensioner to the

TSB Revision

Page 305 of 2103

E N G I N E Timing Belt

Timing marks

sprocket

mm

(2.36 in.)

or more .

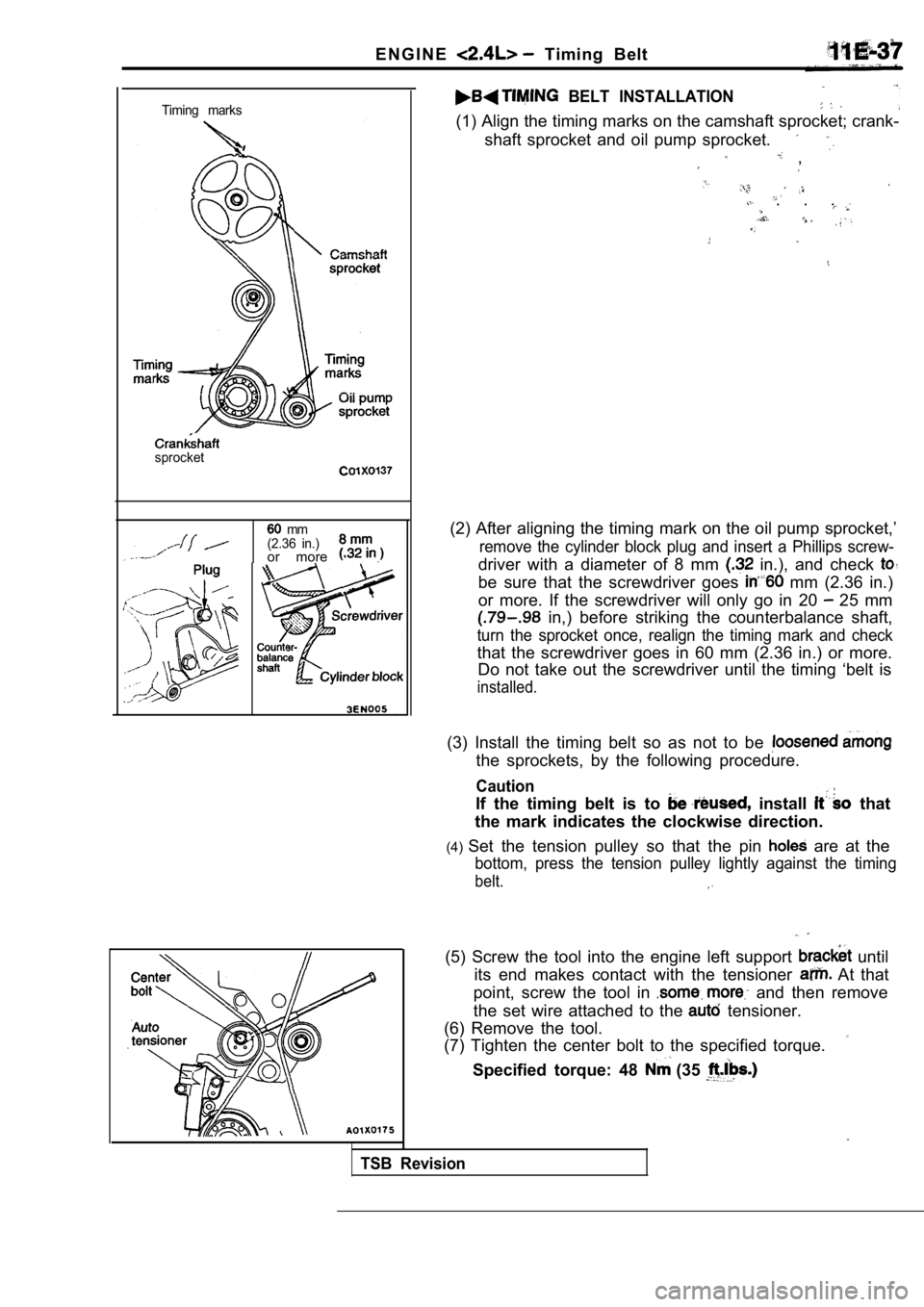

BELT INSTALLATION

(1) Align the timing marks on the camshaft sprocket ; crank-

shaft sprocket and oil pump sprocket.

,

. . .

(2) After aligning the timing mark on the oil pump sprocket,’

remove the cylinder block plug and insert a Phillips screw-

driver with a diameter of 8 mm in.), and check

be sure that the screwdriver goes mm (2.36 in.)

or more. If the screwdriver will only go in 20

25 mm

in,) before striking the counterbalance shaft,

turn the sprocket once, realign the timing mark and check

that the screwdriver goes in 60 mm (2.36 in.) or mo re.

Do not take out the screwdriver until the timing ‘b elt is

installed.

(3) Install the timing belt so as not to be

the sprockets, by the following procedure.

Caution

If the timing belt is to install that

the mark indicates the clockwise direction.

(4) Set the tension pulley so that the pin

are at the

bottom, press the tension pulley lightly against th e timing

belt.

TSB Revision

(5) Screw the tool into the engine left support until

its end makes contact with the tensioner

At that

point, screw the tool in

and then remove

the set wire attached to the

tensioner.

(6) Remove the tool.

(7) Tighten the center bolt to the specified torque .

Specified torque: 48 (35