parking brake MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 24 of 2103

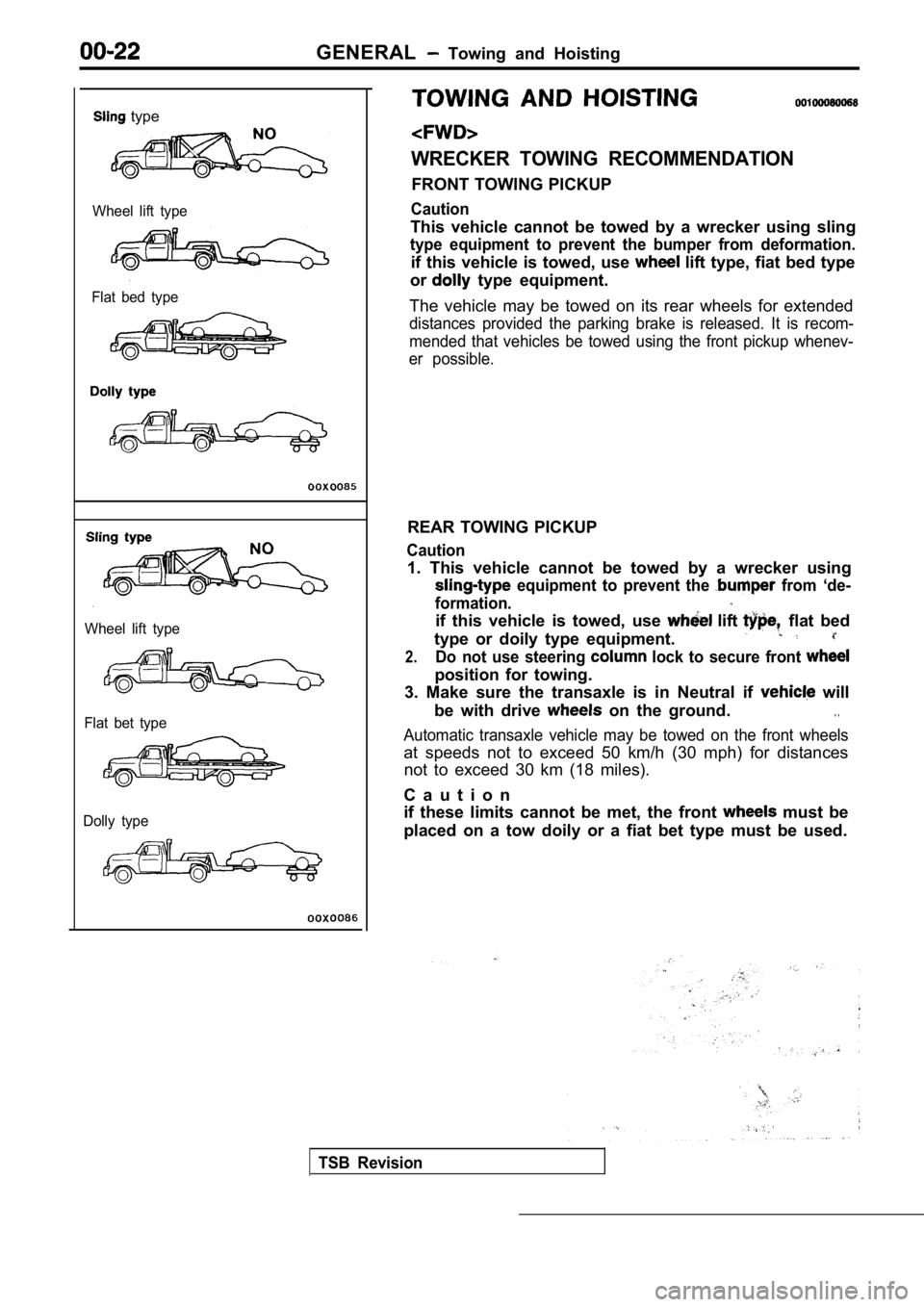

GENERAL Towing and Hoisting

type

Wheel lift type

Flat bed type

Wheel lift type

Flat bet type

Dolly type

WRECKER TOWING RECOMMENDATION

FRONT TOWING PICKUP

Caution

This vehicle cannot be towed by a wrecker using sli ng

type equipment to prevent the bumper from deformati on.

if this vehicle is towed, use lift type, fiat bed type

or

type equipment.

The vehicle may be towed on its rear wheels for ext ended

distances provided the parking brake is released. It is recom-

mended that vehicles be towed using the front picku p whenev-

er possible.

REAR TOWING PICKUP

Caution

1. This vehicle cannot be towed by a wrecker using

equipment to prevent the from ‘de-

formation.

if this vehicle is towed, use lift flat bed

type or doily type equipment.

2.Do not use steering lock to secure front

position for towing.

3. Make sure the transaxle is in Neutral if

will

be with drive

on the ground.. .

Automatic transaxle vehicle may be towed on the fro nt wheels

at speeds not to exceed 50 km/h (30 mph) for distan ces

not to exceed 30 km (18 miles).

C a u t i o n

if these limits cannot be met, the front

must be

placed on a tow doily or a fiat bet type must be us ed.

TSB Revision

Page 25 of 2103

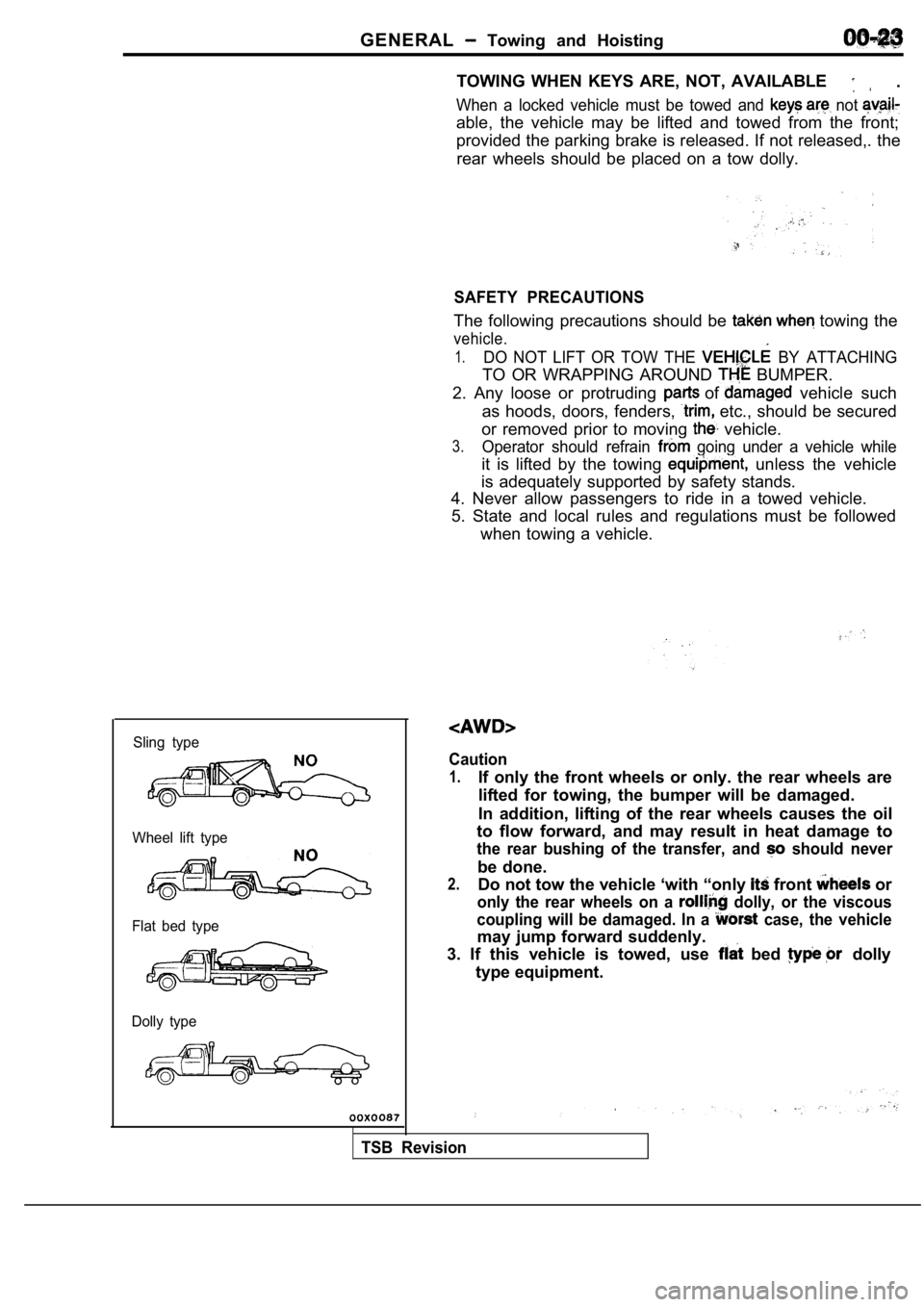

GENERAL Towing and Hoisting

Sling type

Wheel lift type

Flat bed type

Dolly type

TOWING WHEN KEYS ARE, NOT, AVAILABLE .

When a locked vehicle must be towed and not

able, the vehicle may be lifted and towed from the front;

provided the parking brake is released. If not rele ased,. the

rear wheels should be placed on a tow dolly.

SAFETY PRECAUTIONS

The following precautions should be towing the

vehicle.

1.DO NOT LIFT OR TOW THE BY ATTACHING

TO OR WRAPPING AROUND BUMPER.

2. Any loose or protruding

of vehicle such

as hoods, doors, fenders,

etc., should be secured

or removed prior to moving

vehicle.

3.Operator should refrain going under a vehicle while

it is lifted by the towing unless the vehicle

is adequately supported by safety stands.

4. Never allow passengers to ride in a towed vehicl e.

5. State and local rules and regulations must be fo llowed

when towing a vehicle.

Caution

1.If only the front wheels or only. the rear wheels a re

lifted for towing, the bumper will be damaged.

In addition, lifting of the rear wheels causes the oil

to flow forward, and may result in heat damage to

the rear bushing of the transfer, and should never

be done.

2.Do not tow the vehicle ‘with “only front or

only the rear wheels on a dolly, or the viscous

coupling will be damaged. In a

case, the vehicle

may jump forward suddenly.

3. If this vehicle is towed, use

bed dolly

type equipment.

TSB Revision

Page 29 of 2103

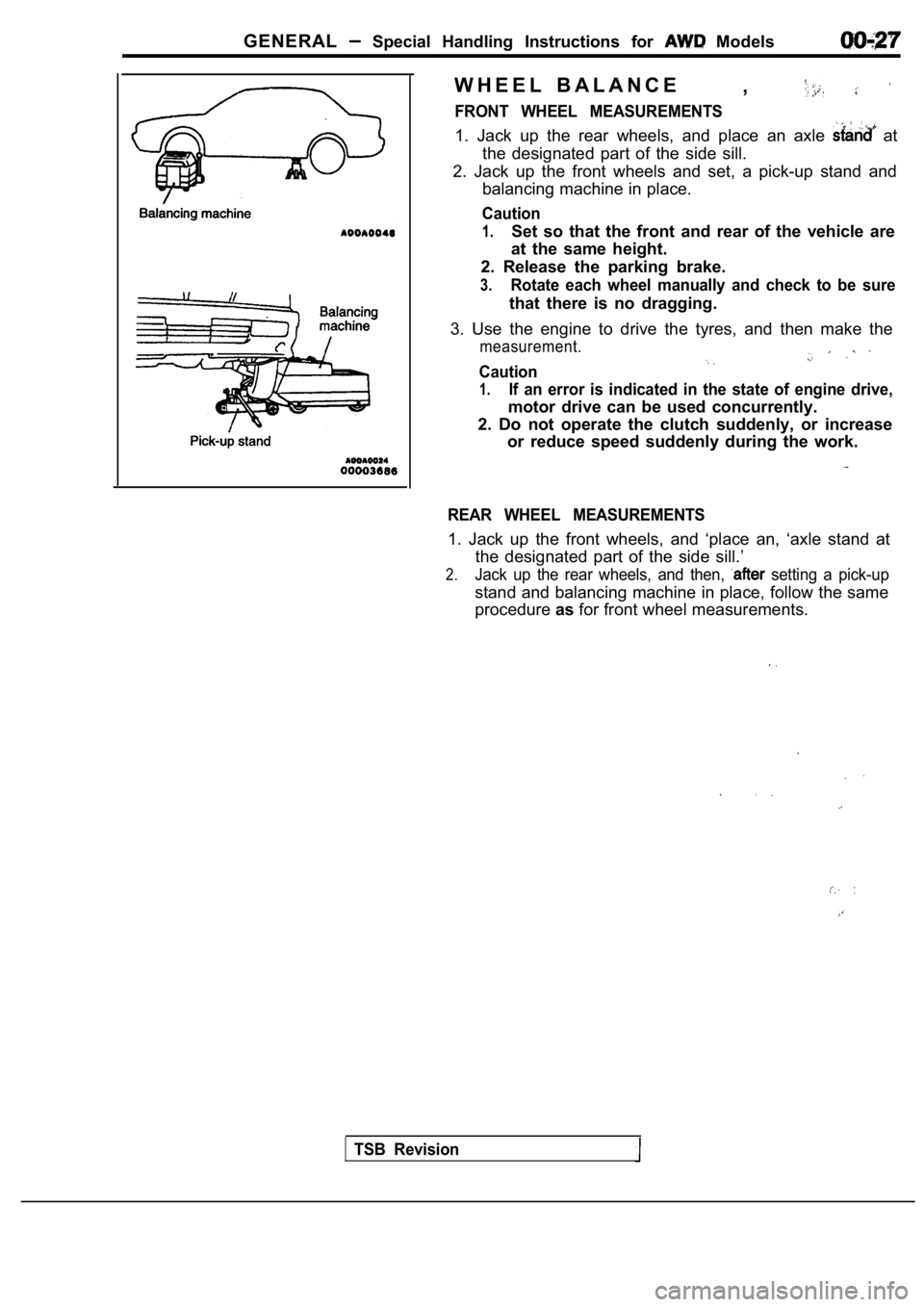

GENERAL Special Handling Instructions for Models

W H E E L B A L A N C E,

FRONT WHEEL MEASUREMENTS

1. Jack up the rear wheels, and place an axle at

the designated part of the side sill.

2. Jack up the front wheels and set, a pick-up stan d and

balancing machine in place.

Caution

1.Set so that the front and rear of the vehicle are

at the same height.

2. Release the parking brake.

3.Rotate each wheel manually and check to be sure

that there is no dragging.

3. Use the engine to drive the tyres, and then make the

measurement.

Caution

1.If an error is indicated in the state of engine drive,

motor drive can be used concurrently.

2. Do not operate the clutch suddenly, or increase or reduce speed suddenly during the work.

REAR WHEEL MEASUREMENTS

1. Jack up the front wheels, and ‘place an, ‘axle s tand at

the designated part of the side sill.’

2.Jack up the rear wheels, and then, setting a pick-up

stand and balancing machine in place, follow the sa me

procedure asfor front wheel measurements.

TSB Revision

Page 49 of 2103

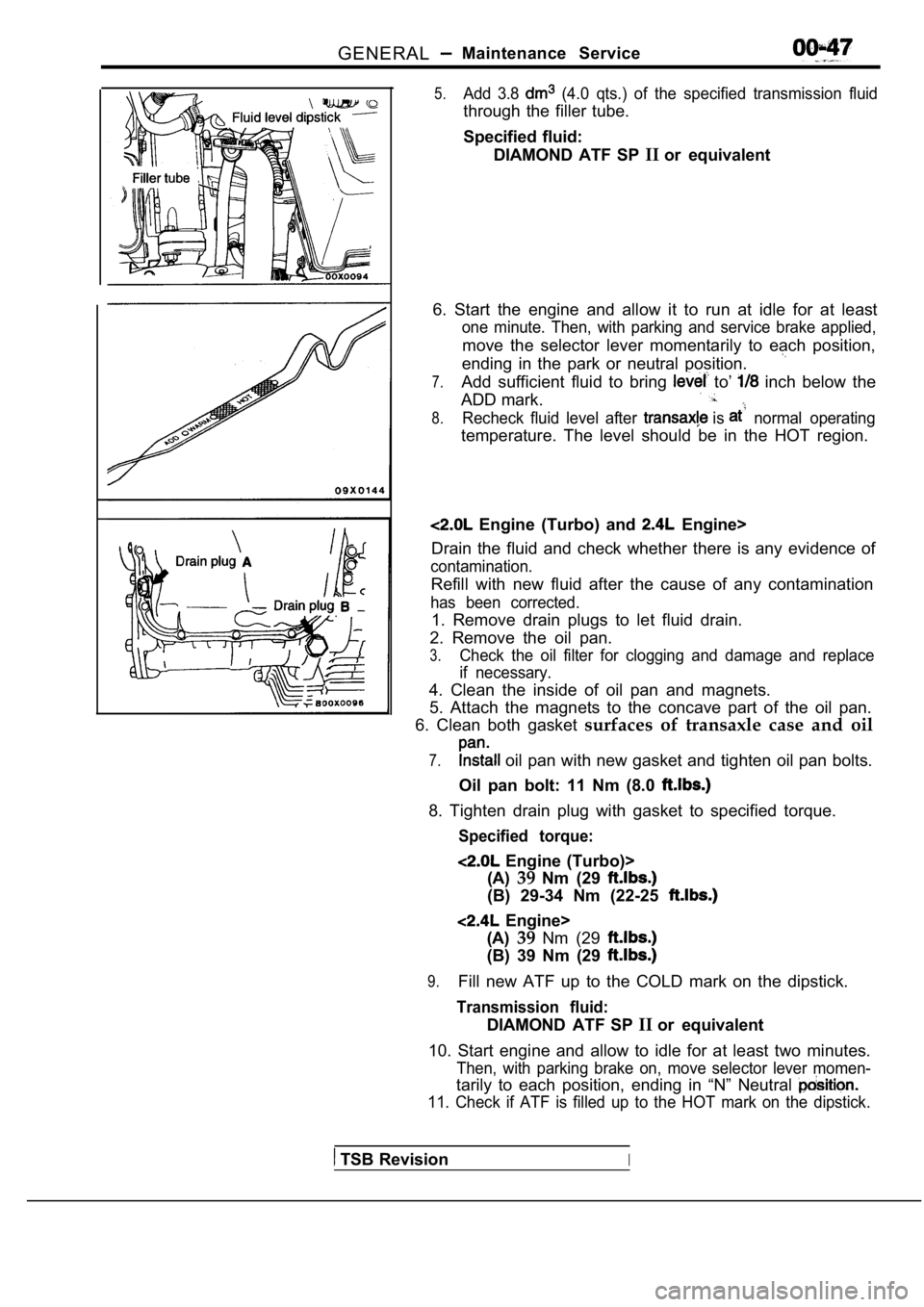

GENERALMaintenance Service

5.Add 3.8 (4.0 qts.) of the specified transmission fluid

through the filler tube.

Specified fluid:DIAMOND ATF SP IIor equivalent

6. Start the engine and allow it to run at idle for at least

one minute. Then, with parking and service brake ap plied,

move the selector lever momentarily to each positio n,

ending in the park or neutral position.

7.Add sufficient fluid to bring to’ inch below the

ADD mark.

8.Recheck fluid level after is normal operating

temperature. The level should be in the HOT region.

Engine (Turbo) and Engine>

Drain the fluid and check whether there is any evid ence of

contamination.

Refill with new fluid after the cause of any contam ination

has been corrected.

1. Remove drain plugs to let fluid drain.

2. Remove the oil pan.

3.Check the oil filter for clogging and damage and re place

if necessary.

4. Clean the inside of oil pan and magnets.

5. Attach the magnets to the concave part of the oi l pan.

6. Clean both gasket surfaces of transaxle case and oil

7. oil pan with new gasket and tighten oil pan bolts.

Oil pan bolt: 11 Nm (8.0

8. Tighten drain plug with gasket to specified torq ue.

Specified torque:

Engine (Turbo)>

(A) 39Nm (29

(B) 29-34 Nm (22-25

Engine>

(A) 39Nm (29

(B) 39 Nm (29

9.Fill new ATF up to the COLD mark on the dipstick.

Transmission fluid:

DIAMOND ATF SP IIor equivalent

10. Start engine and allow to idle for at least two minutes.

Then, with parking brake on, move selector lever mo men-

tarily to each position, ending in “N” Neutral

11. Check if ATF is filled up to the HOT mark on the dipstick.

TSB RevisionI

Page 836 of 2103

CLUTCH On-vehicle Service

Interlock switch

Revision

INTERLOCK SWITCH OPERATING CHECK

1.

2.

Lock the front wheels, apply the parking brake and put

the shift lever in the

gear.

After normally adjusting the clutch pedal, check th e inter-

lock switch operation as follows:

(1) The engine should not start even if the ignition switch

is turned to “START” position with the clutch pedal

not depressed. If the engine should start, check th e

interlock switch

harness.

(2) The engine should start after the clutch has be en

disconnected while the clutch pedal is depressed with

the ignition switch turned to “START” position.

If the engine should start before the clutch pedal

is disconnected or the engine does not start even

if the clutch pedal is depressed, adjust the interl ock

switch.

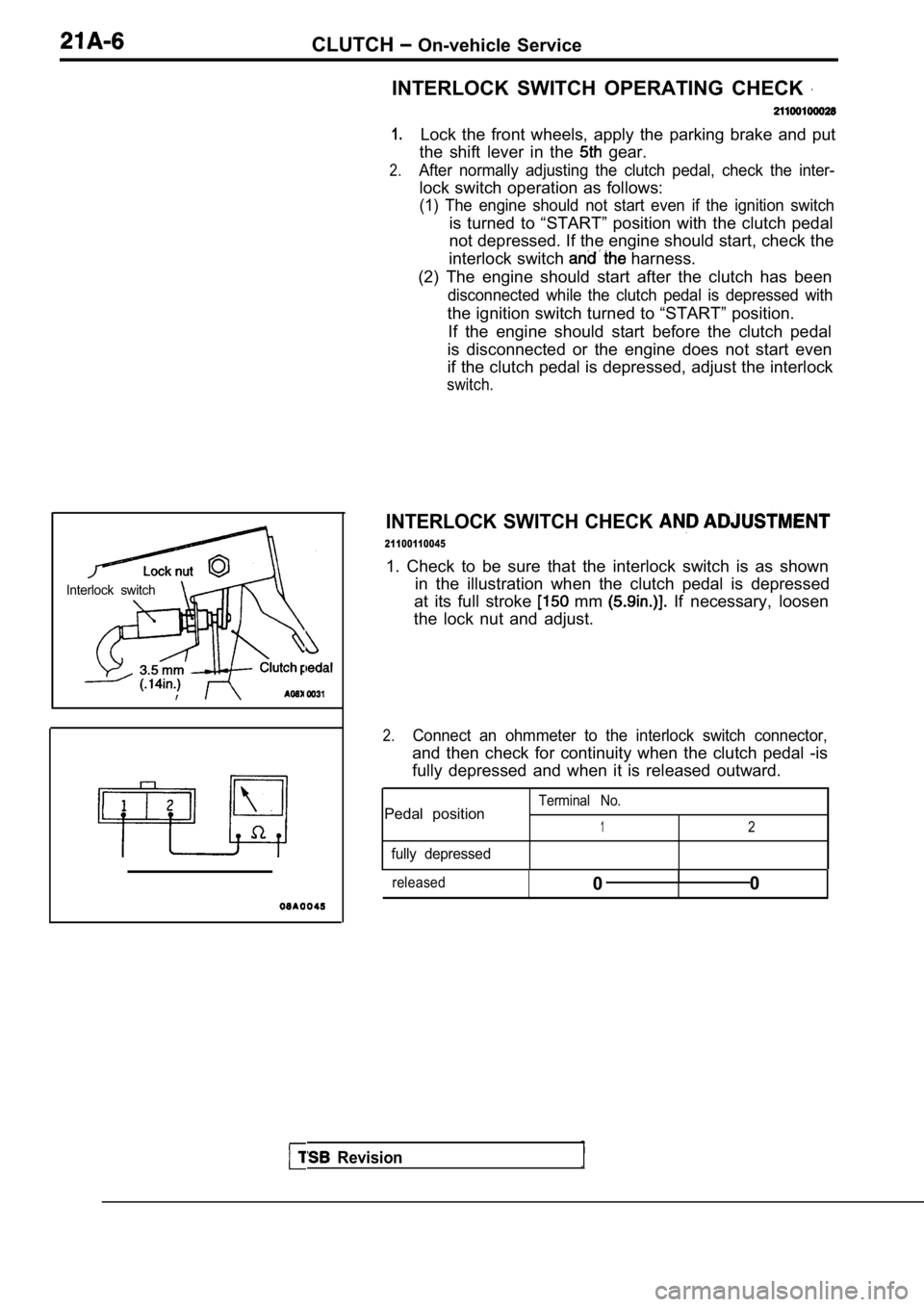

INTERLOCK SWITCH CHECK

21100110045

1. Check to be sure that the interlock switch is as shown

in the illustration when the clutch pedal is depres sed

at its full stroke

mm If necessary, loosen

the lock nut and adjust.

2.Connect an ohmmeter to the interlock switch connect or,

and then check for continuity when the clutch pedal -is

fully depressed and when it is released outward.

Terminal No.Pedal position12

fully depressed

released0I0

Page 1072 of 2103

AUTOMATIC TRANSAXLE

ENGINE (TURBO) AND On-vehicle Service

Stall test consists of determining maximum engine speed

obtained at full throttle in positions. This test

checks torque converter overrunning clutch operation,

and holding ability of transmission clutches and

brake.

Caution

During this test, make sure no stands in front

of, or behind, vehicle.

1.Check the transmission fluid level, fluid temperatu re and

coolant temperature.

lFluid level: At “HOT” position on dipstick

l Fluid temperature:

lEngine coolant temperature:

2. Apply chocks to both rear wheels.

3.

engine tachometer.

4. Apply parking and service brakes fully.

5 . S t a r t e n g i n e .

6. With selector lever in position, depress accelerator

pedal fully to read engine

rpm. Do not hold

throttle wide open any longer than is necessary to obtain

maximum engine rpm reading, and never longer

5 seconds at a time. If more than one stall test is required,

operate at approximately 1,000 in neutral

for 2 minutes to cool transmission fluid between te sts.

Standard value:

TSB Revision

2,100 2,600

3 , 3 0 0 3 , 6 0 0

7.Place selector lever to position and perform test

by the same procedures above.

Stall Speed Above Specification in

If stall speed is higher than Specification, rear c lutch or overrun-

ning clutch is slipping. In this case, perform hydrau-

lic test to locate cause of slippage.

Stall Above Specification in “R”

If stall speed is higher than front clutch of trans-

axle or low-reverse brake is In this perform

hydraulic test to locate cause of slippage.

Stall Speed Above Specification and “R”

If stall speed is lower than insufficient engine

output or faulty torque converter is Check for en-

gine misfiring, ignition timing, valve clearance etc. If these

are good, torque converter is faulty..

Page 1174 of 2103

AUTOMATIC TRANSAXLE

ENGINE (NON-TURBO)> On-vehicle Service

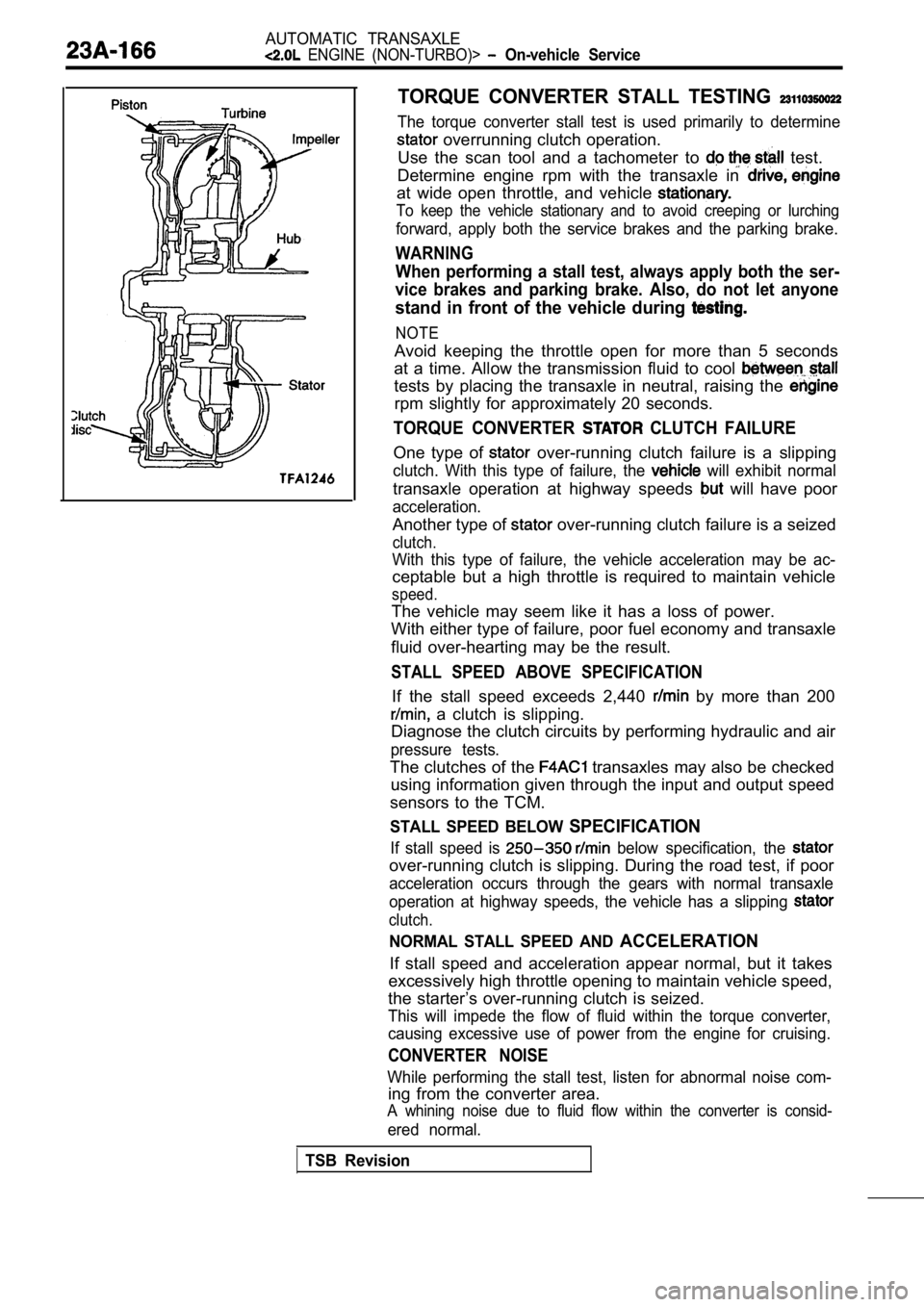

TORQUE CONVERTER STALL TESTING

The torque converter stall test is used primarily to determine

overrunning clutch operation.

Use the scan tool and a tachometer to

test.

Determine engine rpm with the transaxle in

at wide open throttle, and vehicle

To keep the vehicle stationary and to avoid creepin g or lurching

forward, apply both the service brakes and the parking brake.

WARNING

When performing a stall test, always apply both the ser-

vice brakes and parking brake. Also, do not let any one

stand in front of the vehicle during

NOTE

Avoid keeping the throttle open for more than 5 seconds

at a time. Allow the transmission fluid to cool

tests by placing the transaxle in neutral, raising the

rpm slightly for approximately 20 seconds.

TORQUE CONVERTER CLUTCH FAILURE

One type of over-running clutch failure is a slipping

clutch. With this type of failure, the will exhibit normal

transaxle operation at highway speeds will have poor

acceleration.

Another type of over-running clutch failure is a seized

clutch.

With this type of failure, the vehicle acceleration may be ac-

ceptable but a high throttle is required to maintai n vehicle

speed.

The vehicle may seem like it has a loss of power.

With either type of failure, poor fuel economy and transaxle

fluid over-hearting may be the result.

STALL SPEED ABOVE SPECIFICATION

If the stall speed exceeds 2,440 by more than 200

a clutch is slipping.

Diagnose the clutch circuits by performing hydrauli c and air

pressure tests.

The clutches of the transaxles may also be checked

using information given through the input and outpu t speed

sensors to the TCM.

STALL SPEED BELOW SPECIFICATION

If stall speed is below specification, the

over-running clutch is slipping. During the road te st, if poor

acceleration occurs through the gears with normal t ransaxle

operation at highway speeds, the vehicle has a slip ping

clutch.

NORMAL STALL SPEED AND ACCELERATION

If stall speed and acceleration appear normal, but it takes

excessively high throttle opening to maintain vehic le speed,

the starter’s over-running clutch is seized.

This will impede the flow of fluid within the torqu e converter,

causing excessive use of power from the engine for cruising.

CONVERTER NOISE

While performing the stall test, listen for abnormal noise com-

ing from the converter area.

A whining noise due to fluid flow within the conver ter is consid-

ered normal.

TSB Revision

Page 1537 of 2103

REAR AXLE . .

Symptom

Abnormal

Probable cause

Loose wheel nuts

Damaged or worn wheel

Bentordistorted brake discs

Remedy

Tighten Replace

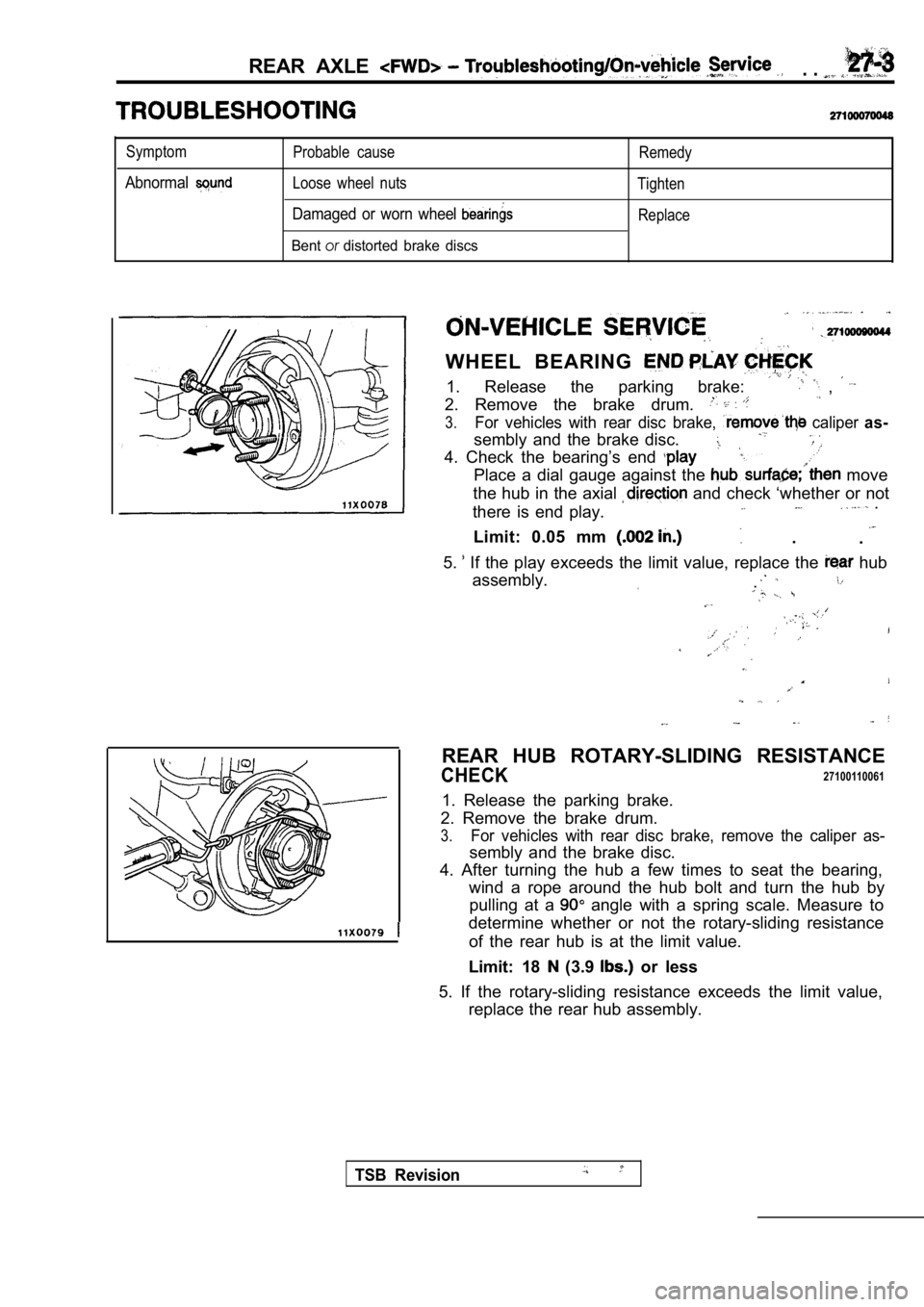

WHEEL BEARING

1. Release the parking brake: ,

2. Remove the brake drum.

3.For vehicles with rear disc brake, caliper as-

sembly and the brake disc.

4. Check the bearing’s end

Place a dial gauge against the move

the hub in the axial

and check ‘whether or not

there is end play. .

.

Limit: 0.05 mm .

5.

If the play exceeds the limit value, replace the hub

assembly.

.

REAR HUB ROTARY-SLIDING RESISTANCE

CHECK27100110061

1. Release the parking brake.

2. Remove the brake drum.

3.For vehicles with rear disc brake, remove the calip er as-

sembly and the brake disc.

4. After turning the hub a few times to seat the be aring,

wind a rope around the hub bolt and turn the hub by pulling at a

angle with a spring scale. Measure to

determine whether or not the rotary-sliding resista nce

of the rear hub is at the limit value.

Limit: 18

(3.9 or less

5. If the rotary-sliding resistance exceeds the lim it value,

replace the rear hub assembly.

TSB Revision

Page 1539 of 2103

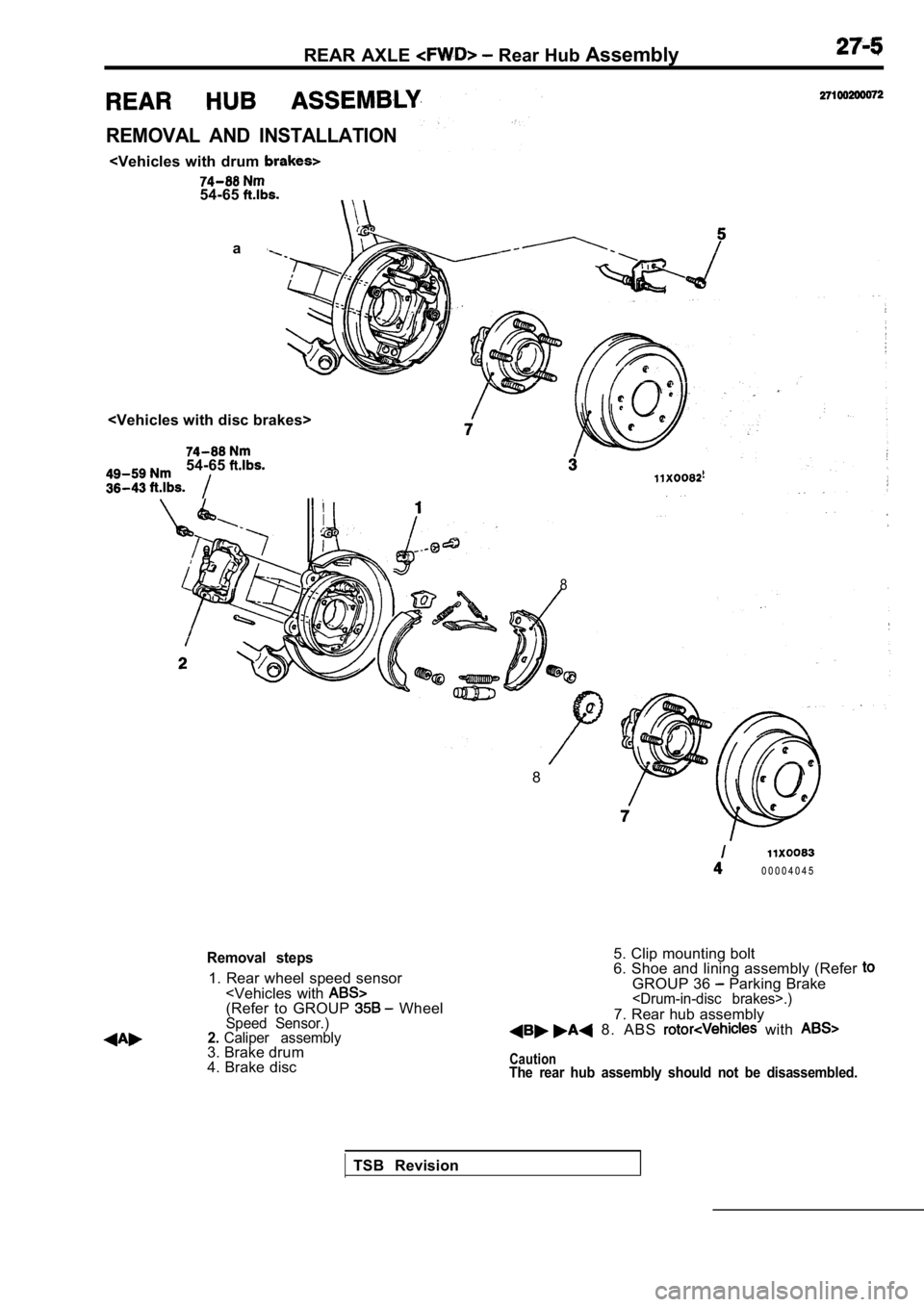

REAR AXLE Rear Hub Assembly

REMOVAL AND INSTALLATION

a

54-65

8

8

0 0 0 0 4 0 4 5

Removal steps

1. Rear wheel speed sensor

4. Brake disc 5. Clip mounting bolt

6. Shoe and lining assembly (Refer

GROUP 36 Parking Brake

7. Rear hub assembly 8. ABS with

CautionThe rear hub assembly should not be disassembled.

TSB Revision

Page 1550 of 2103

6REAR AXLE Service

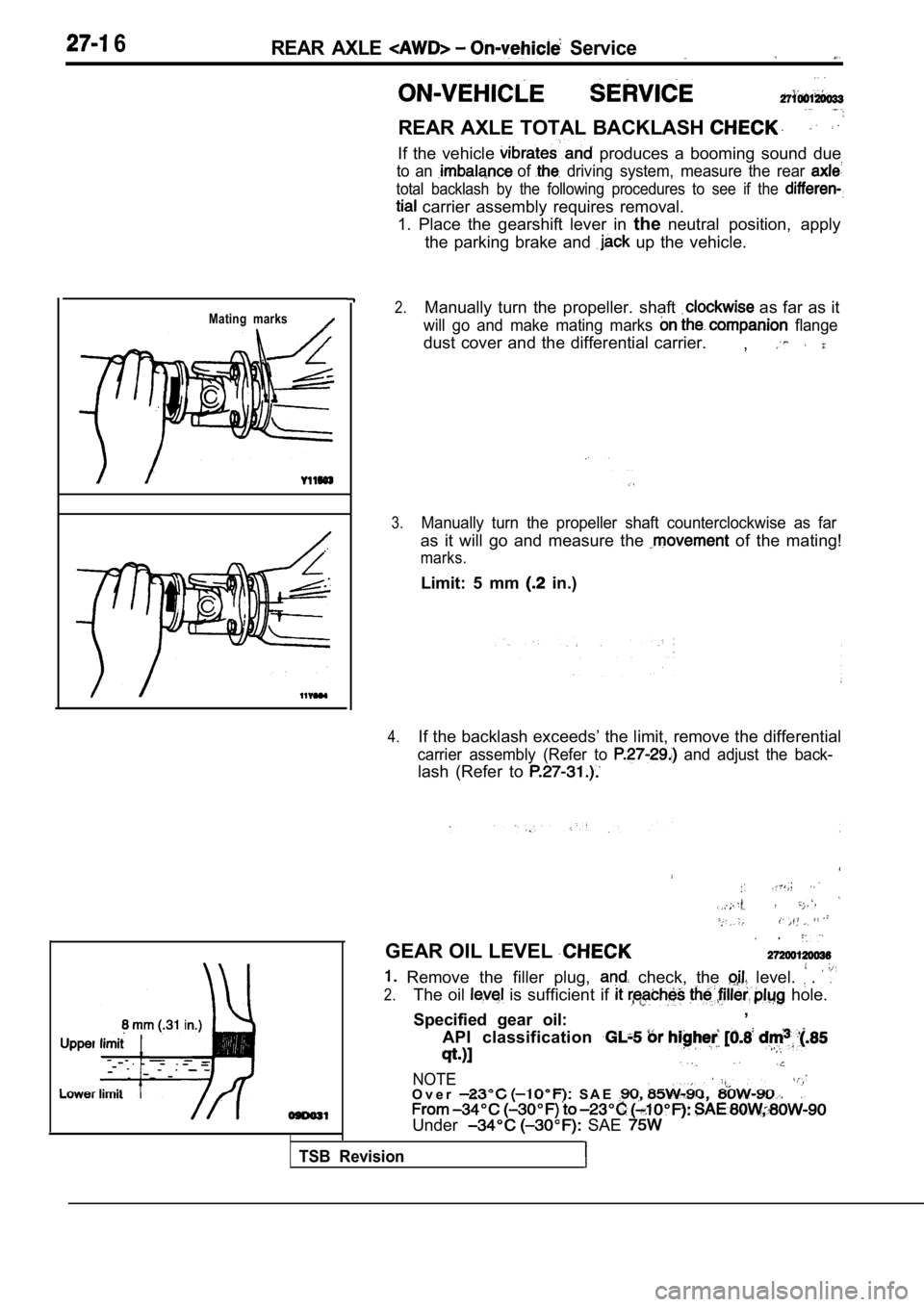

REAR AXLE TOTAL BACKLASH

If the vehicle produces a booming sound due

to an of driving system, measure the rear

total backlash by the following procedures to see if the

carrier assembly requires removal.

1. Place the gearshift lever in theneutral position, apply

the parking brake and

up the vehicle.

Mating marks2.Manually turn the propeller. shaft as far as it

will go and make mating marks flange

dust cover and the differential carrier. ,

3.Manually turn the propeller shaft counterclockwise as far

as it will go and measure the of the mating!

marks.

Limit: 5 mm in.)

4.If the backlash exceeds’ the limit, remove the differential

carrier assembly (Refer to and adjust the back-

lash (Refer to

TSB Revision

GEAR OIL LEVEL

Remove the filler plug, check, the level. .

2.The oil is sufficient if hole.

Specified gear oil: ,

API classification

NOTEO v e r S A E

Under SAE