trunk MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 18 of 2103

GENERAL Vehicle Identification

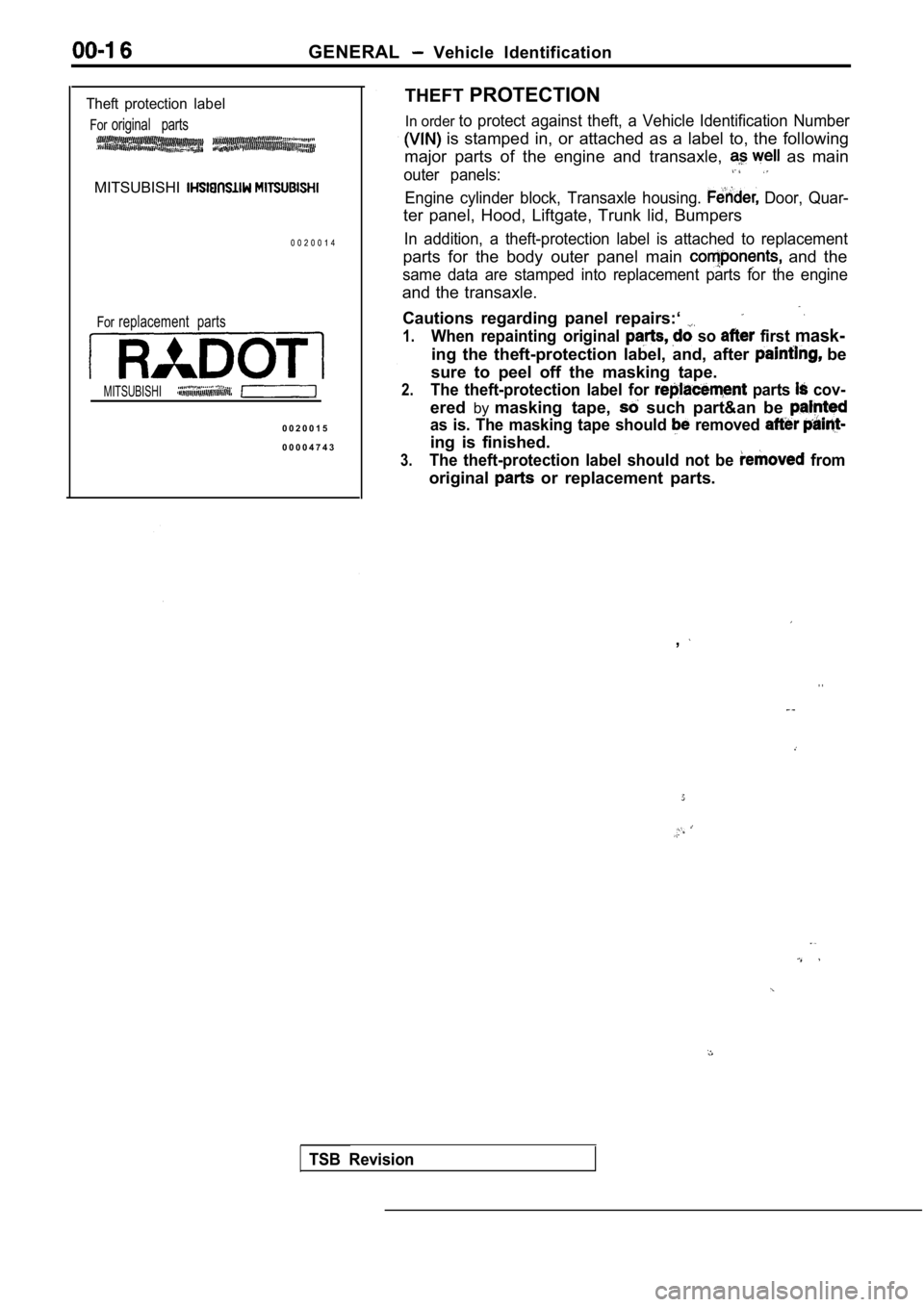

Theft protection label

Fororiginal parts

MITSUBISHI

0 0 2 0 0 1 4

Forreplacement parts

MITSUBISHI

0 0 2 0 0 1 5

0 0 0 0 4 7 4 3THEFT

PROTECTION

In order to protect against theft, a Vehicle Identification Number

is stamped in, or attached as a label to, the foll owing

major parts of the engine and transaxle,

as main

outer panels:

Engine cylinder block, Transaxle housing. Door, Quar-

ter panel, Hood, Liftgate, Trunk lid, Bumpers

In addition, a theft-protection label is attached t o replacement

parts for the body outer panel main and the

same data are stamped into replacement parts for th e engine

and the transaxle.

Cautions regarding panel repairs:‘

1.When repainting original so first mask-

ing the theft-protection label, and, after be

sure to peel off the masking tape.

2.The theft-protection label for parts cov-

ered bymasking tape, such part&an be

as is. The masking tape should removed

ing is finished.

3.The theft-protection label should not be from

original or replacement parts.

,

. .

TSB Revision

Page 21 of 2103

GENERAL Vehicle

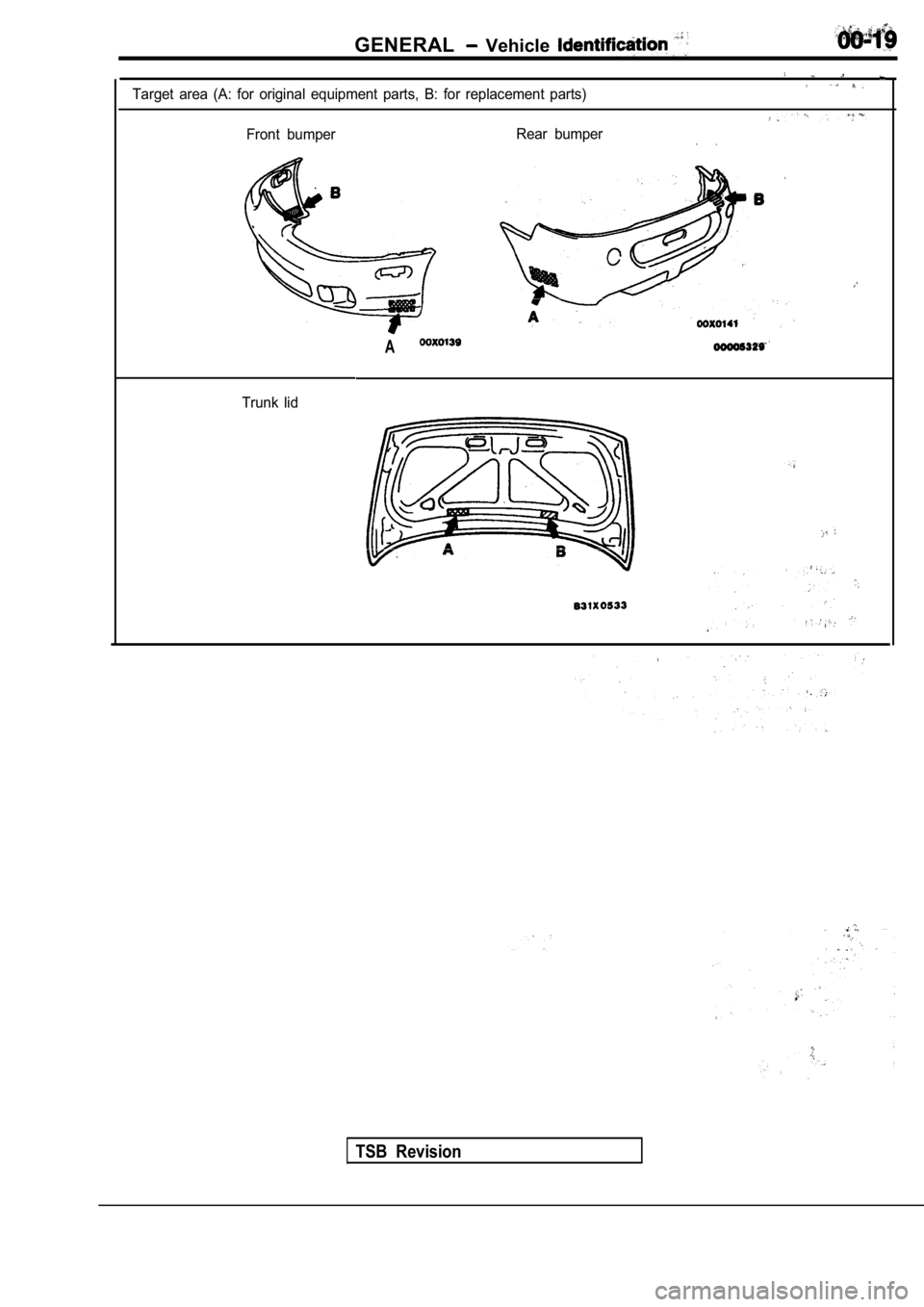

Target area (A: for original equipment parts, B: for replacement parts)

Front bumperRear bumper

Trunk lid

A

TSB Revision

Page 57 of 2103

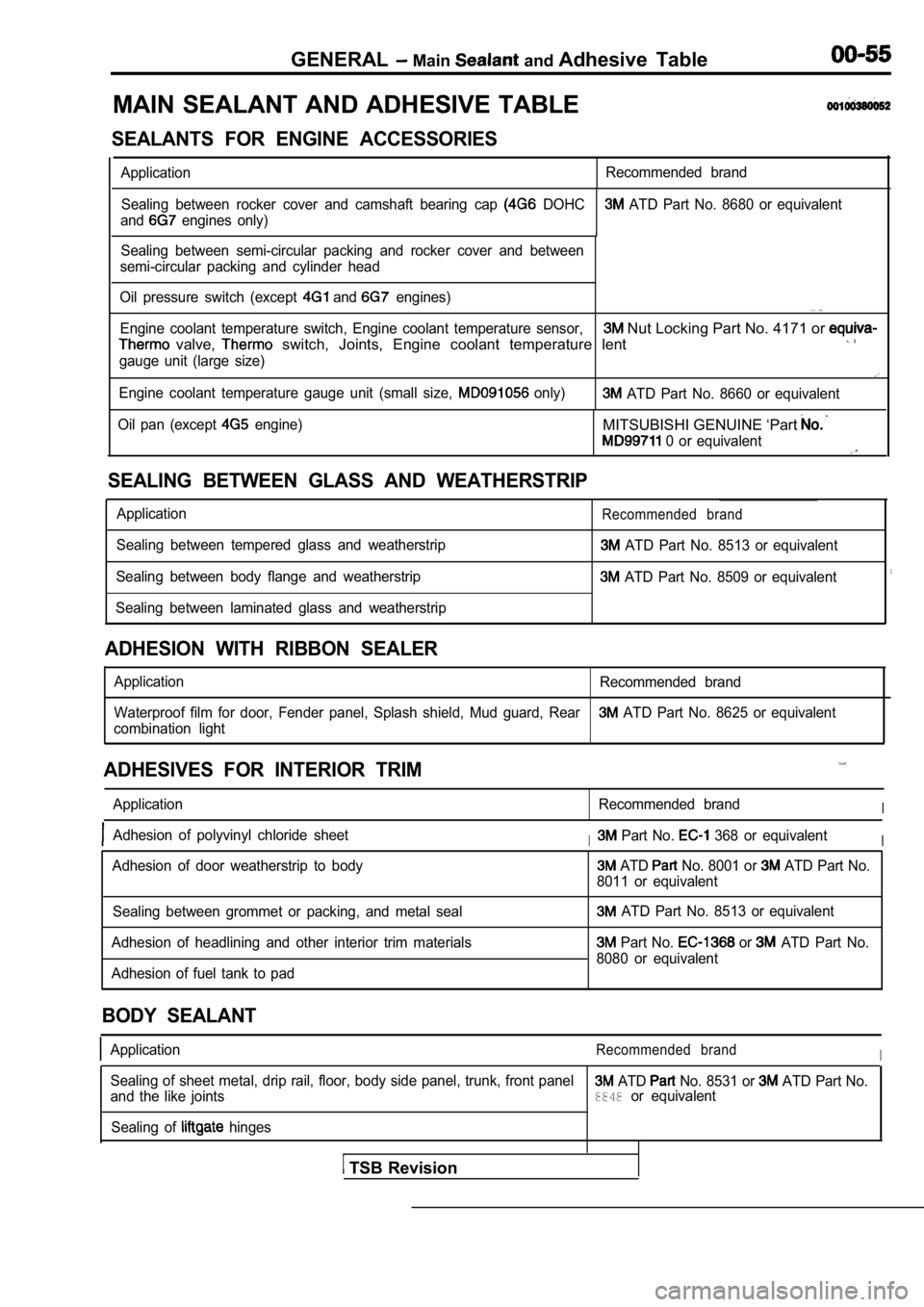

GENERAL Main and Adhesive Table

MAIN SEALANT AND ADHESIVE TABLE

SEALANTS FOR ENGINE ACCESSORIES

Application Recommended brand

Sealing between rocker cover and camshaft bearing c ap

DOHC ATD Part No. 8680 or equivalent

and

engines only)

1Sealing between semi-circular packing and rocker co ver and between

semi-circular packing and cylinder head

Oil pressure switch (except

and engines). . .

Engine coolant temperature switch, Engine coolant t emperature sensor, Nut Locking Part No. 4171 or

valve, switch, Joints, Engine coolant temperature lent

gauge unit (large size)

Engine coolant temperature gauge unit (small size, only) ATD Part No. 8660 or equivalent

Oil pan (except

engine)MITSUBISHI GENUINE ‘Part

0 or equivalent

SEALING BETWEEN GLASS AND WEATHERSTRIP

Application

Sealing between tempered glass and weatherstrip

Sealing between body flange and weatherstrip

Sealing between laminated glass and weatherstripRecommended brand

ATD Part No. 8513 or equivalent

ATD Part No. 8509 or equivalent

ADHESION WITH RIBBON SEALER

Application Recommended brand

Waterproof film for door, Fender panel, Splash shie ld, Mud guard, Rear

ATD Part No. 8625 or equivalent

combination light

ADHESIVES FOR INTERIOR TRIM

Application Recommended brandI

Adhesion of polyvinyl chloride sheetI Part No. 368 or equivalentI

Adhesion of door weatherstrip to body ATD No. 8001 or ATD Part No.

8011 or equivalent

Sealing between grommet or packing, and metal seal

Adhesion of headlining and other interior trim mate rials

Adhesion of fuel tank to pad

ATD Part No. 8513 or equivalent

Part No. or ATD Part No.

8080 or equivalent

BODY SEALANT

ApplicationRecommended brandI

Sealing of sheet metal, drip rail, floor, body side panel, trunk, front panel ATD No. 8531 or ATD Part No.

and the like joints8848or equivalent

Sealing of

hinges

TSB Revision

Page 1825 of 2103

CONTENTS

DOOR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Door Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Door Glass and Regulator . . . . . . . . . . . . . . . . . . .56

Door Handle and Latch. . . . . . . . . . . . . . . . . . . . .59

Door Opening Weatherstrip. . . . . . . . . . . . . . . . . .63

Door Trim and Waterproof Film . . . . . . . . . . . . . .54

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .48

Sealant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Service Specifications. . . . . . . . . . . . . . . . . . . . . . .33

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

ELECTRIC CONVERTIBLE TOP. . . . . . . . . . . .91

Balance Link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Convertible Top Assembly. . . . . . . . . . . . . . . . . . .94

Convertible Top Bypass Switch . . . . . . . . . . . . . .104

Convertible Top Control Module. . . . . . . . . . . . .105

Convertible Top Switch. . . . . . . . . . . . . . . . . . . . .103

Front Roof Weatherstrip. . . . . . . . . . . . . . . . . . . .100

Headliner. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .94

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Drive Motor. . . . . . . . . . . . . . . . . . . . . . . .99

Driven Gear . . . . . . . . . . . . . . . . . . . . . . .96

Rail Weatherstrip and

Top Cover Retainer . . . . . . . . . . . . . . . . . . . . . . . .

101

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

FENDER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fender. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Sealants

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUEL FILLER DOOR . . . . . . . . . . . . . . . . . . . . . . .6

HOOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

ENTRY SYSTEM . . . . . . . . . . . . . . . .72

Entry System

. . . . . . . . . . . . . . . . . . . . . . .77

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Troubleshooting

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

SUNROOF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

On-vehicle Service. . . . . . . . . . . . . . . . . . . . . . . . . .82

Sealant and Adhesive . . . . . . . . . . . . . . . . . . . . . . .82

Sunroof. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

UNDER COVER. . . . . . . . . . . . . . . . . . . . . . . . . . .81

WINDSHIELD AND WINDOW GLASS . . . . . . . .

7

Glass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

On-vehicle Service

. . . . . . . . . . . . . . . . . . . . . . . . . .10

Quarter Window Glass . . . . . . . . . . . . . . . . . . . . . .22

Quarter Window Glass and

Regulator Assembly. . . . . . . . . . . . . . . . . . . . . . . . .26

Sealant and Adhesive. . . . . . . . . . . . . . . . . . . . . . . .7

Service Specifications. . . . . . . . . . . . . . . . . . . . . . . .7

Special Tool

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Windshield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Windshield and Window Glass . . . . . . . . . . . . . . .15

TRUNK LID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Trunk Lid

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

TRUNK LID LOCK RELEASE HANDLE AND

CABLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Page 1892 of 2103

TRUNK LID

B O D Y Trunk Lid

TROUBLESHOOTING

Improper closure Striker and latch not properly aligned

Adjust the alignment

Difficult locking and unlocking.

Uneven body clearance Incorrectly installed trunk lid

Adjust the installation of trunk lid

Uneven height Incorrect trunk lid bumper height Adjust the trunk lid bumper height

TSB Revision

Page 1893 of 2103

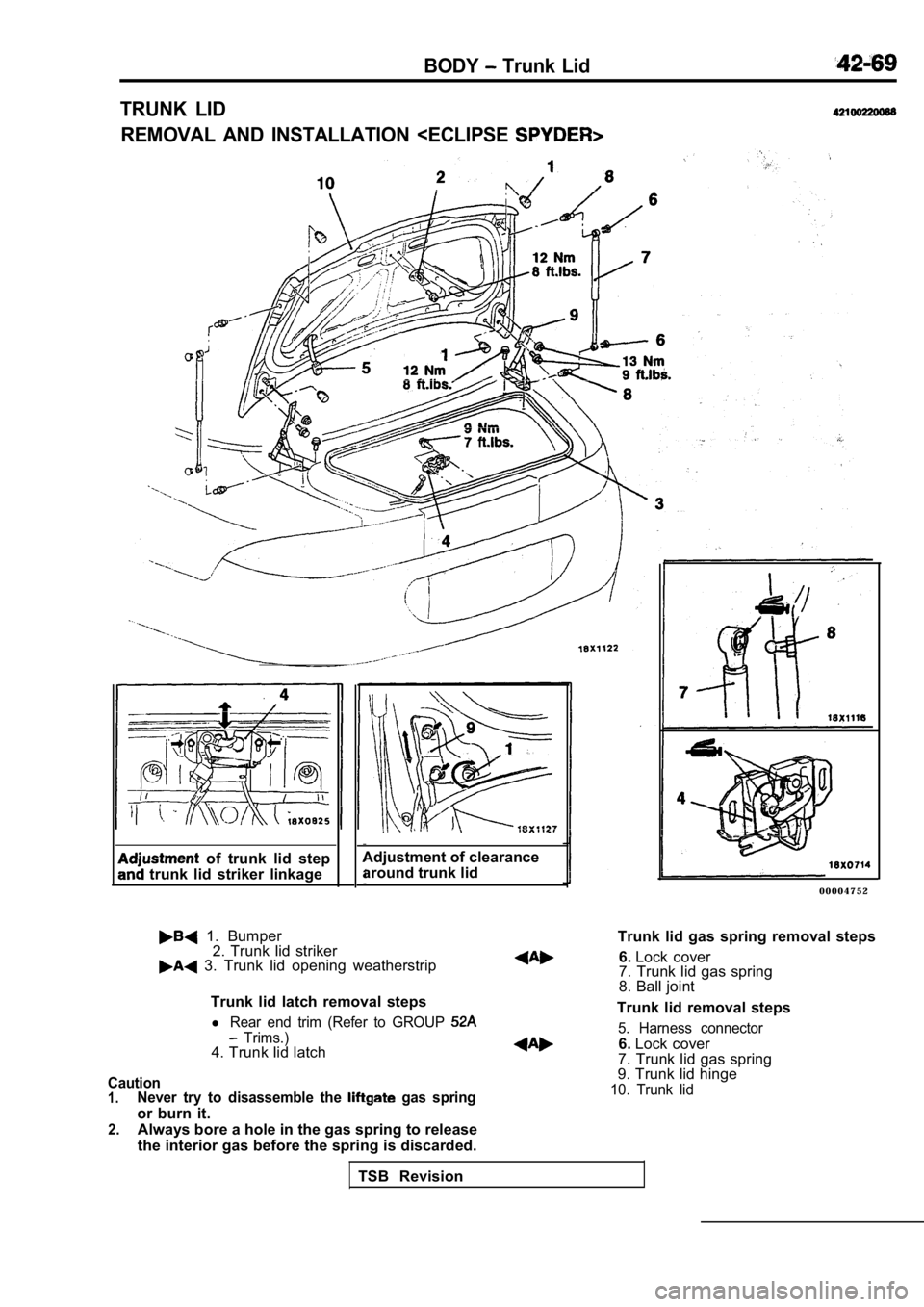

BODY Trunk Lid

TRUNK LID

REMOVAL AND INSTALLATION

trunk lid striker linkageAdjustment of clearance

around trunk lid

1. Bumper

2. Trunk lid striker

3. Trunk lid opening weatherstrip

Trunk lid latch removal steps

l Rear end trim (Refer to GROUP

Trims.)4. Trunk lid latch

Caution1.Never try to disassemble the gas spring

or burn it.

2.Always bore a hole in the gas spring to release

the interior gas before the spring is discarded.

0 0 0 0 4 7 5 2

Trunk lid gas spring removal steps 6. Lock cover

7. Trunk lid gas spring

8. Ball joint

Trunk lid removal steps

5. Harness connector

6. Lock cover

7. Trunk lid gas spring

9. Trunk lid hinge

10. Trunk lid

TSB Revision

Page 1894 of 2103

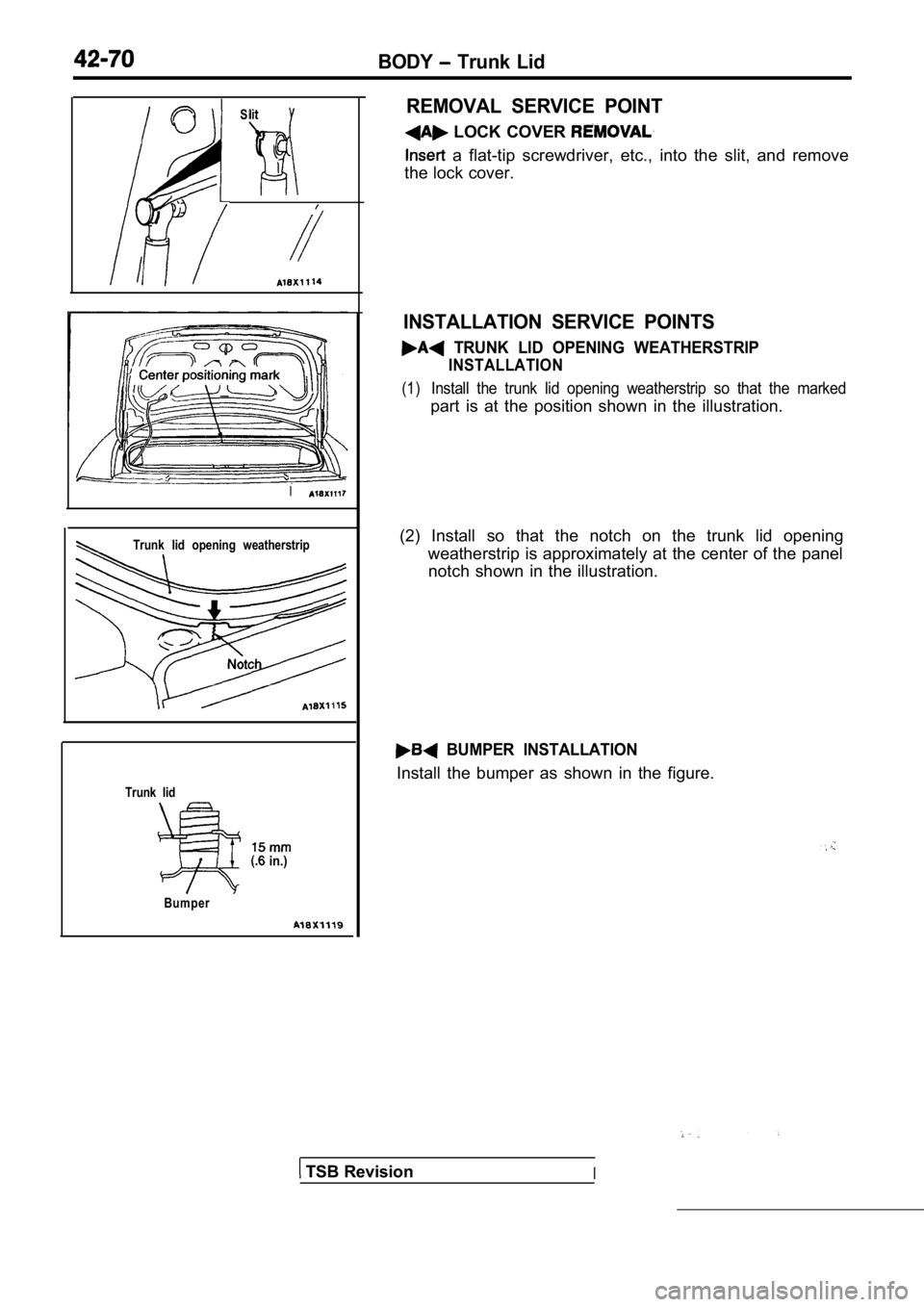

BODY Trunk Lid

Slit

I

I

Trunk lid opening weatherstrip

Trunk lid

in.)

Bumper

REMOVAL SERVICE POINT

LOCK COVER

a flat-tip screwdriver, etc., into the slit, and r emove

the lock cover.

INSTALLATION SERVICE POINTS

TRUNK LID OPENING WEATHERSTRIP

INSTALLATION

(1)Install the trunk lid opening weatherstrip so that the marked

part is at the position shown in the illustration.

(2) Install so that the notch on the trunk lid open ing

weatherstrip is approximately at the center of the panel

notch shown in the illustration.

BUMPER INSTALLATION

Install the bumper as shown in the figure.

TSB RevisionI

Page 1895 of 2103

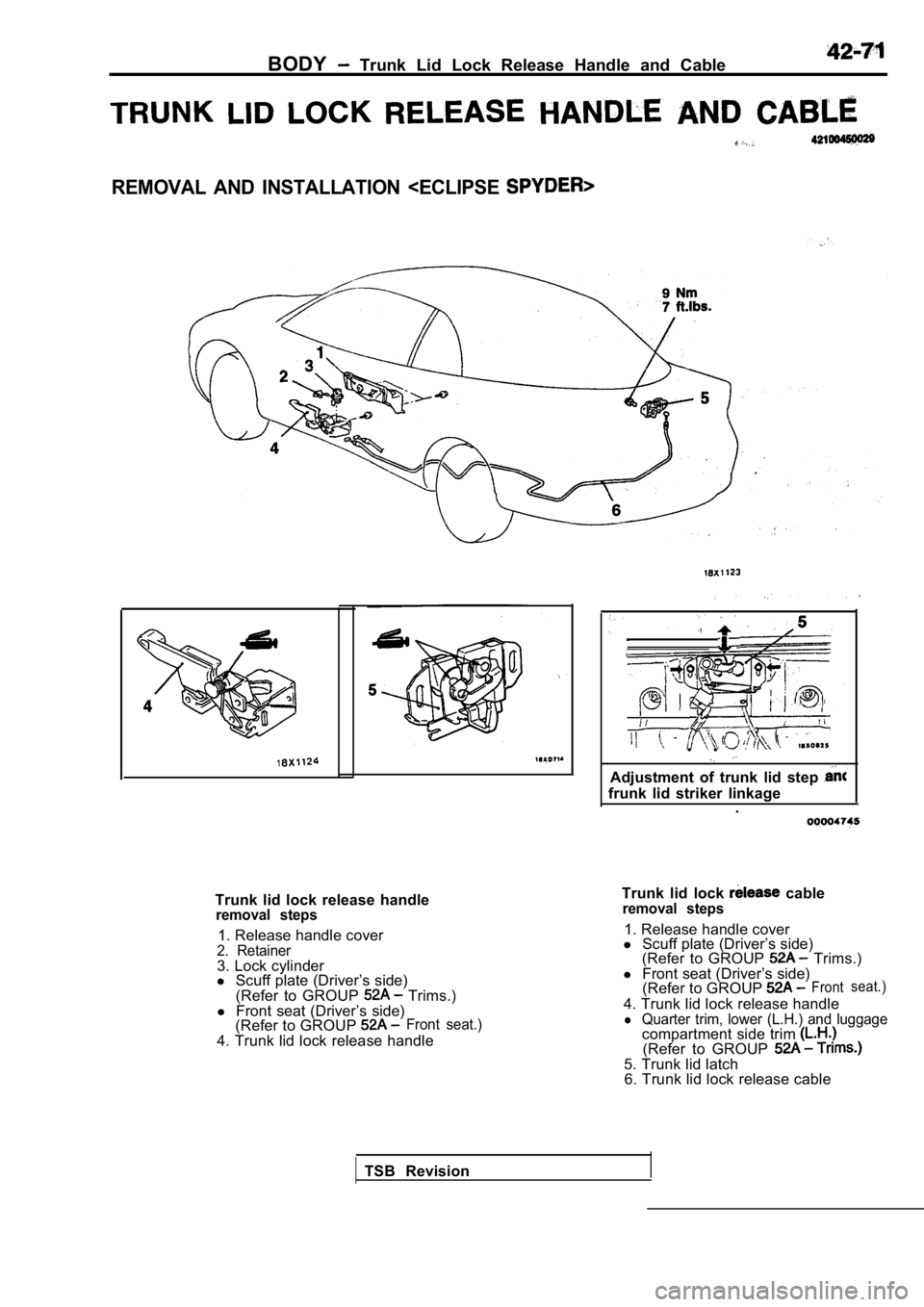

BODY Trunk Lid Lock Release Handle and Cable

REMOVAL AND INSTALLATION

1. Release handle cover2. Retainer3. Lock cylinder

l Scuff plate (Driver’s side)

(Refer to GROUP

Trims.)

l Front seat (Driver’s side)

(Refer to GROUP

Front seat.)

4. Trunk lid lock release handle

. .

Adjustment of trunk lid step

frunk lid striker linkage .

Trunk lid lock cableremoval steps

1. Release handle cover

l Scuff plate (Driver’s side)

(Refer to GROUP

Trims.)

l Front seat (Driver’s side)

(Refer to GROUP

Front seat.)

4. Trunk lid lock release handlel Quarter trim, lower (L.H.) and luggagecompartment side trim (Refer to GROUP 5. Trunk lid latch

6. Trunk lid lock release cable

TSB Revision

Page 1920 of 2103

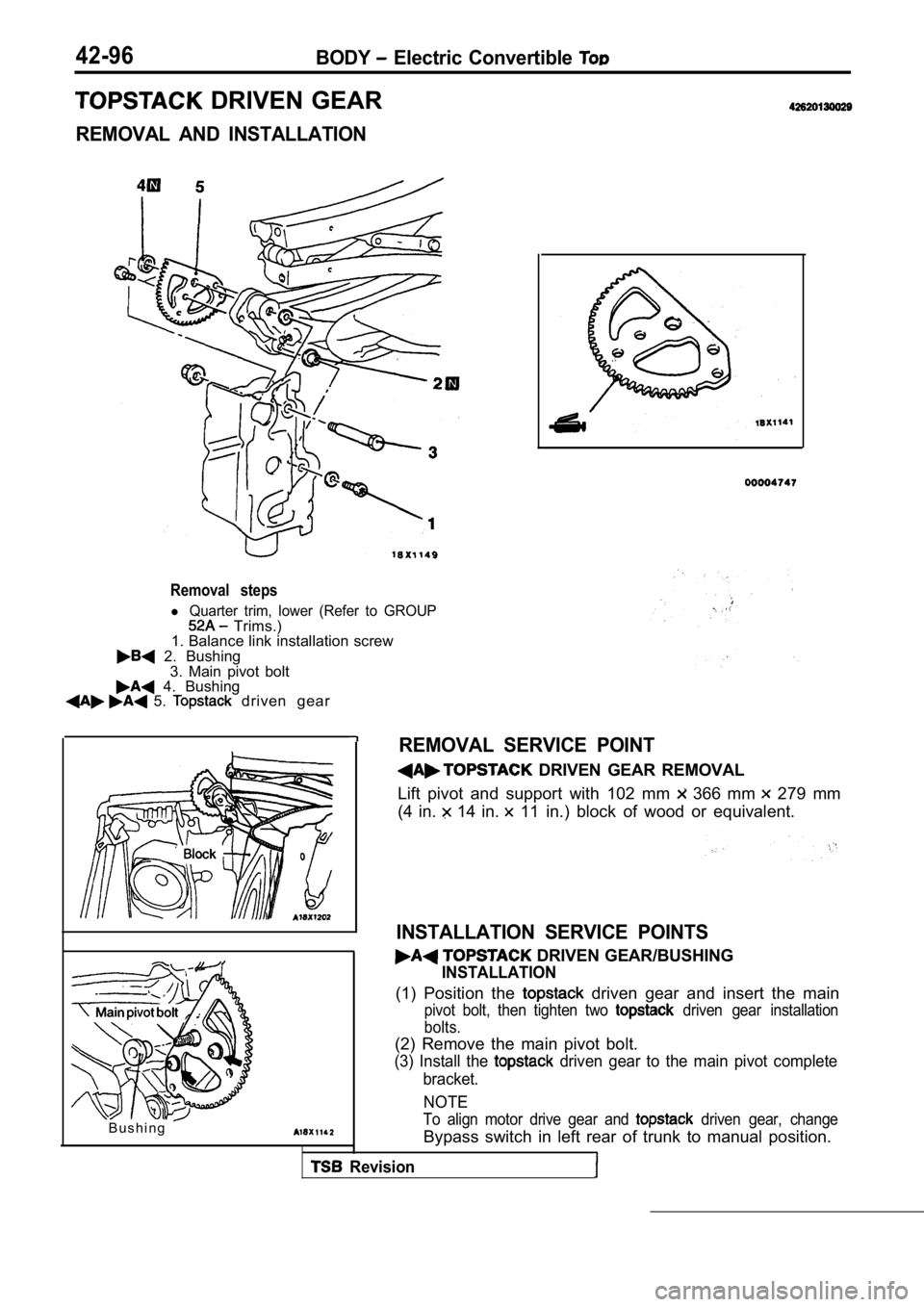

42-96BODY Electric Convertible

DRIVEN GEAR

REMOVAL AND INSTALLATION

Removal steps

l Quarter trim, lower (Refer to GROUP Trims.)

1. Balance link installation screw

2. Bushing

3. Main pivot bolt

4. Bushing 5. driven gear

B u s h i n g

REMOVAL SERVICE POINT

DRIVEN GEAR REMOVAL

Lift pivot and support with 102 mm

366 mm 279 mm

(4 in.

14 in. 11 in.) block of wood or equivalent.

INSTALLATION SERVICE POINTS

DRIVEN GEAR/BUSHING

INSTALLATION

(1) Position the driven gear and insert the main

pivot bolt, then tighten two driven gear installation

bolts.

(2) Remove the main pivot bolt.

(3) Install the driven gear to the main pivot complete

bracket.

NOTE

To align motor drive gear and driven gear, change

Bypass switch in left rear of trunk to manual posit ion.

Revision

Page 2102 of 2103

ALPHABETICAL INDEX

TENSIONDrive Belt, Check and Adjustment . . . . . . . .11. . . . . . . .. . . . . . . . . . . .

TENSION PULLEY ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE>.. . . . . . . . .TEST EQUIPMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .THEFT-ALARM SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . . . .T H E R M O S T A T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .THICKNESS

Front Brake Disc, Check. . . . . . . . . . . . . . . . . . . . . . . . . . .Rear Brake Disc, Check. . . . . . . . . . . . . . . . . . . . . . . . . . .

THROTTLE BODY

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . .THROTTLE BODY MINIMUM AIR FLOW, Check. . . . . . .THROTTLE BODY (THROTTLE VALVE AREA) ENGINE (TURBO) AND ENGINE>, Cleaning .

THROTTLE POSITION SENSORAdjustment

ENGINE (TURBO) AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . .On-vehicle ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . .

ENGINE (TURBO) AND . . .TIE ROD END BALL JOINT, Breakaway Torque Check. . . .TIMING BELT

. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TIMING BELT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TIMING BELT, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . .TIRE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TIRE INFLATION PRESSURE, Check. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOE CONTROL ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TORQUE CONVERTER STALLTesting

ENGINE (NON-TURBO)>. . . . . . . . . . . ENGINE (TURBO) AND ENGINE>TOTAL BACKLASH Rear Axle, Check. . . . . . . . . . . .TRAILING ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSAXLE ENGINE (NON-TURBO)>. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ENGINE (TURBO) AND . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and . . . . . . . . . . . . . . . . . . . . . ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . .M/T ENGINE (TURBO) AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .M/T ENGINE (TURBO) AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .TRANSAXLECASEDisassembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . .Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSAXLE CONTROL

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE>. . . .A/T ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . ENGINE (TURBO) AND . . .

TRANSAXLE FLUID

Automatic, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement ENGINE (NON-TURBO)> . . . . . . . . . . . . .

ENGINE (TURBO) . . . TRANSAXLE FLUID LEVELCheck ENGINE (NON-TURBO)> . . . . . . . . . . . . . . . . ENGINE (TURBO) AND ENGINE>. . . . .

TRANSAXLE MOUNTING . . . . . . . . . . . . . . . . . . . . . . . , . . TRANSAXLE OIL

Manual, Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement ENGINE . . . . . . . . . . . . . .

. . . . . .

TRANSAXLE OIL COOLER

ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>.. . . . . .

TRANSAXLE OIL LEVEL

Check

ENGINE (NON-TURBO)>.. . . . . . . . . . . . .

ENGINE (TURBO) AND ENGINE>..

TRANSAXLE RANGE SENSOR, Continuity Check ENGINE (NON-TURBO)>. . . . . . . . . . . . . . . . . . . . . .TRANSFER

ENGINE (TURBO) AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSFER CASE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSFER CASE ADAPTER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER DRIVEN GEAR . . . . . . . . . . . . . . . . .TRANSFER OIL, Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER OIL, Replacement ENGINE AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER OIL LEVEL

ENGINE AND ENGINE>. . . . . . . . . . - -

. . . . . . . . . . .

TRANSFER OIL, Replacement ENGINE (TURBO) AND ENGINE>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRANSFER SHAFT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRIM, Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRIMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TRUNK LID LOCK RELEASE CABLE. . . . . . . . . . . . . . . . . . . .

TRUNK LID LOOK RELEASE HANDLE. . . . . . . . . . . . . . . . . .TUBING AND FITTINGS, Handling. . . . . . . . . . . . . . . . . . . . . .TURBOCHARGER BYPASS VALVE, CHECK. . . . . . . . . .. . .

TURBOCHARGER WASTE GATE SOLENOID

Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .On-vehicle Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . .

UNDER COVER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . .UPPER ARM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Suspension>. . . . . . . . . . . . . . . . . . . . ... . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . .. .

VACUUM

EGR Port, Check ENGINE ENGINE (TURBO) AND . . . . . . Manifold, Check . . . . . . . . . . . . . . . . . . . . 11 C-l

. . . . . . . . . . . . . . . . . . . . . .