wheel bolts MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 5 of 2103

GENERAL How to Use This

HOW TO USE THIS MANUAL

MAINTENANCE, REPAIR AND

SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning procedures for the inspection, maintenance, repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the model codes, or similar designati on

(engine type, transaxle type, etc.). A description

of these designations is covered in this manual

under “VEHICLE IDENTIFICATION”.

ON-VEHICLE SERVICE

“On-vehicle Service” are procedures for performing

inspections and adjustments of particularly impor-

tant locations with regard to the construction and

for maintenance and servicing, but other inspec-

tions (for looseness, play, cracking, damage, etc.

must also be performed.

SERVICE PROCEDURES

The service steps are arranged in numerical order

and attention must to be paid in performing vehicle

service are described in detail in SERVICE POINTS.

TERMS DEFINITION

STANDARD VALUE

Indicates the value used as the standard for judgin g

the quality of a part or assembly on inspection

or the value to which the part or assembly is cor-

rected and adjusted. It is given by tolerance.

LIMIT

Indicates a maximum or minimum value, the part

or assembly should be kept within, in order to be functional. This value is established outside the

standard value range.

REFERENCE VALUE

Indicates the adjustment value prior to starting th e

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTION

Indicates the presentation of information particula rly

vital to the worker during the performance of maint e-

nance and servicing procedures in order to avoid

the possibility of injury to the worker, or damage

to component parts, or a reduction of component

or vehicle function or performance, etc..

TIGHTENING TORQUE INDICATION

The tightening torque shown in this manual is a

basic value with a tolerance of

10% except the

following cases when the upper. and

of tightening torque are given. (1) The tolerance of the ‘basic value

10%.

(2) Special bolts or, the ‘like are

(3) Special tightening methods are used.

SPECIAL TOOL NOTE

When the MMC special tool is described, please

refer to the special tool

is located at the beginning of each group, for a

cross reference from the tool, number

to the special tool number that available in your

market..

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T

Indicates the manual transaxle, or models equipped with the manual transaxle.

A/T

Indicates the automatic transaxle, or models equip ped with the automatic transaxle.

MFI: Indicates the

fuel injection, or engines equipped with the fuel injection.

Turbo: Indicates the engine with turbocharger, or m odels equipped

such an

Non-turbo: Indicates the engine without turbocharger, or models equipped with, such anengine.

FWD: Indicates the front wheel drive vehicles.

AWD: Indicates the all wheel drive vehicles.

ABS: Indicates the anti-lock braking system or mode ls equipped with the

braking

Page 58 of 2103

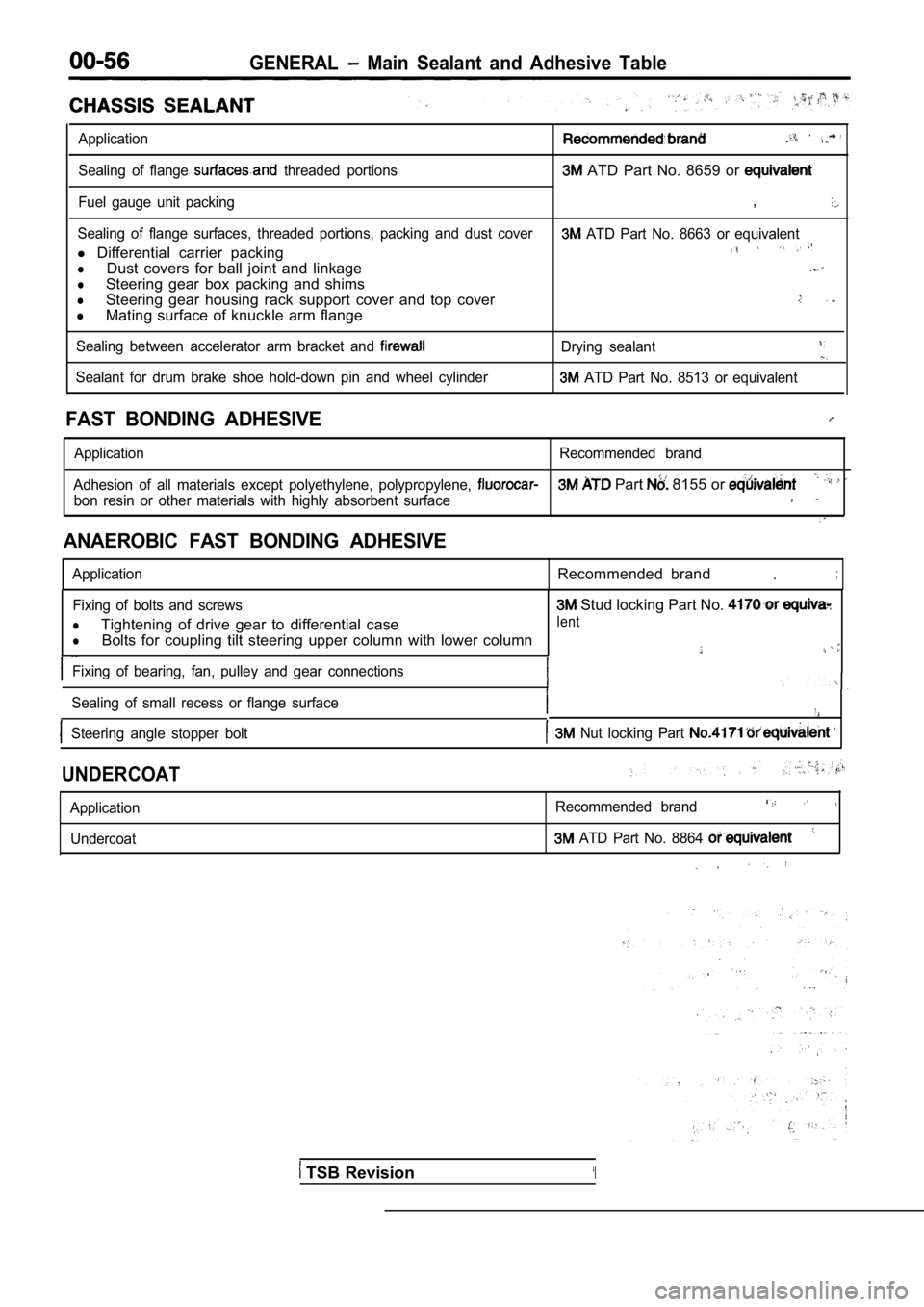

GENERAL Main Sealant and Adhesive Table

Application

Sealing of flange threaded portions ATD Part No. 8659 or

Fuel gauge unit packing,

Sealing of flange surfaces, threaded portions, packing and dust cover ATD Part No. 8663 or equivalent

l Differential carrier packing

lDust covers for ball joint and linkage

lSteering gear box packing and shims

lSteering gear housing rack support cover and top co ver

lMating surface of knuckle arm flange

Sealing between accelerator arm bracket and Drying sealant

Sealant for drum brake shoe hold-down pin and wheel cylinder ATD Part No. 8513 or equivalent

FAST BONDING ADHESIVE

Application Recommended brand

Adhesion of all materials except polyethylene, poly propylene,

Part 8155 or

bon resin or other materials with highly absorbent surface,

ANAEROBIC FAST BONDING ADHESIVE

ApplicationRecommended brand.

Fixing of bolts and screws

lTightening of drive gear to differential case

lBolts for coupling tilt steering upper column with lower column

Fixing of bearing, fan, pulley and gear connections

Sealing of small recess or flange surface

Steering angle stopper bolt Nut locking Part

Stud locking Part No.

lent

UNDERCOAT

Application Undercoat Recommended brand

ATD Part No. 8864

TSB Revision‘I

Page 90 of 2103

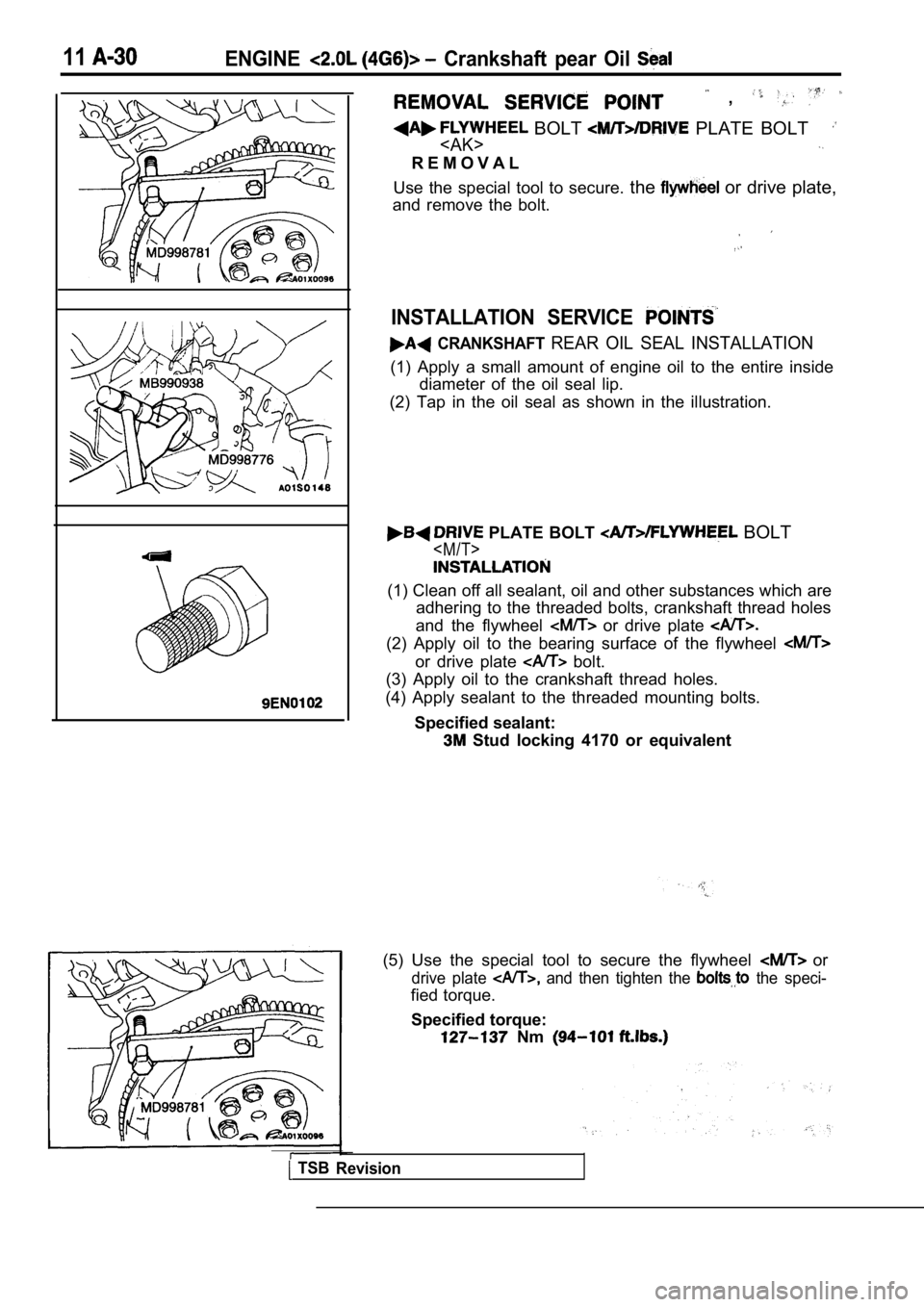

11ENGINE Crankshaft pear Oil

,

BOLT PLATE BOLT

R E M O V A L

Use the special tool to secure. the

or drive plate,

and remove the bolt.

INSTALLATION SERVICE

CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small amount of engine oil to the entir e inside

diameter of the oil seal lip.

(2) Tap in the oil seal as shown in the illustratio n.

PLATE BOLT BOLT

(1) Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread h oles

and the flywheel

or drive plate

(2) Apply oil to the bearing surface of the flywhee l

or drive plate bolt.

(3) Apply oil to the crankshaft thread holes.

(4) Apply sealant to the threaded mounting bolts.

Specified sealant:

Stud locking 4170 or equivalent

TSB Revision

(5) Use the special tool to secure the flywheel or

drive plate and then tighten the the speci-

fied torque.

Specified torque:

Nm

Page 296 of 2103

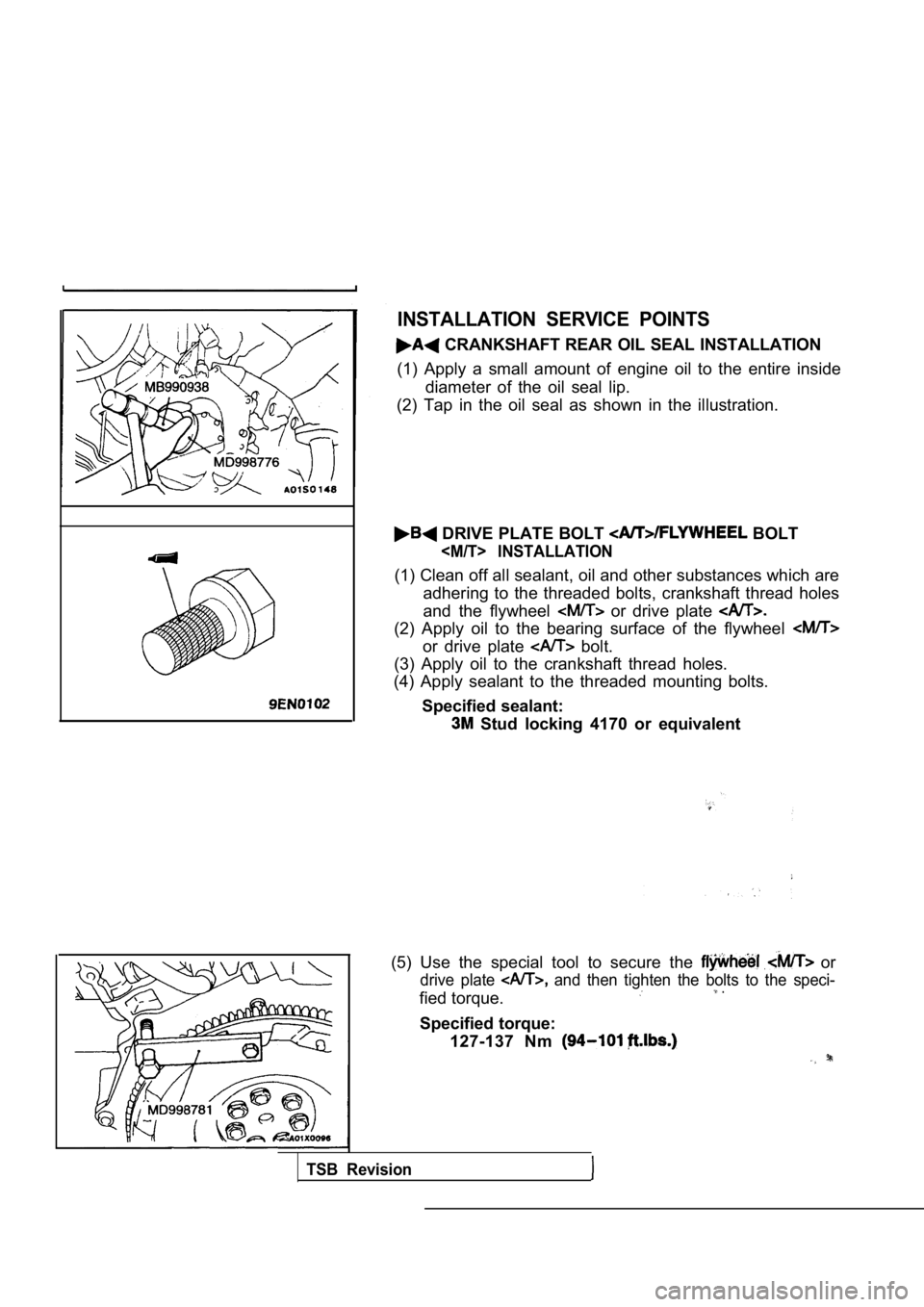

INSTALLATION SERVICE POINTS

CRANKSHAFT REAR OIL SEAL INSTALLATION

(1) Apply a small amount of engine oil to the entir e inside

diameter of the oil seal lip.

(2) Tap in the oil seal as shown in the illustratio n.

DRIVE PLATE BOLT BOLT

(1) Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread h oles

and the flywheel

or drive plate

(2) Apply oil to the bearing surface of the flywhee l

or drive plate bolt.

(3) Apply oil to the crankshaft thread holes.

(4) Apply sealant to the threaded mounting bolts.

Specified sealant:

Stud locking 4170 or equivalent

(5) Use the special tool to secure the

or

drive plate and then tighten the bolts to the speci-

fied torque. .

Specified torque: 127-137 Nm

TSB Revision

Page 369 of 2103

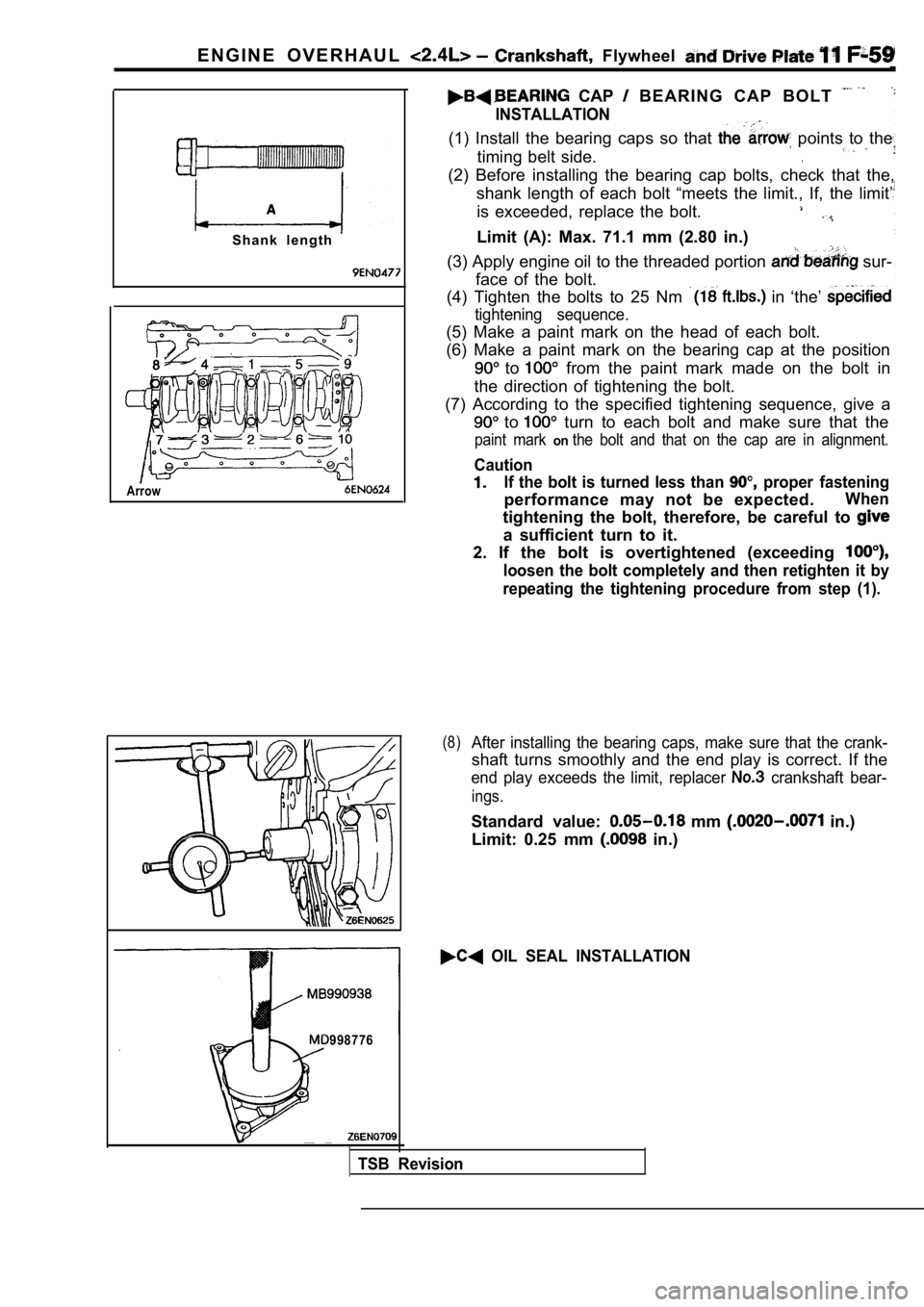

E N G I N E O V E R H A U L Flywheel

S h a n k l e n g t h

Arrow

CAP B E A R I N G C A P B O L T

INSTALLATION

(1) Install the bearing caps so that points to the

timing belt side.

(2) Before installing the bearing cap bolts, check that the,

shank length of each bolt “meets the limit., If, th e limit’

is exceeded, replace the bolt.

Limit (A): Max. 71.1 mm (2.80 in.)

(3) Apply engine oil to the threaded portion

sur-

face of the bolt.

(4) Tighten the bolts to 25 Nm

in ‘the’

tightening sequence.

(5) Make a paint mark on the head of each bolt.

(6) Make a paint mark on the bearing cap at the pos ition

to from the paint mark made on the bolt in

the direction of tightening the bolt.

(7) According to the specified tightening sequence, give a

to turn to each bolt and make sure that the

paint mark onthe bolt and that on the cap are in alignment.

Caution

If the bolt is turned less than proper fastening

performance may not be expected.When

tightening the bolt, therefore, be careful to

a sufficient turn to it.

2. If the bolt is overtightened (exceeding

loosen the bolt completely and then retighten it by

repeating the tightening procedure from step (1).

(8)After installing the bearing caps, make sure that t he crank-

shaft turns smoothly and the end play is correct. I f the

end play exceeds the limit, replacer crankshaft bear-

ings.

Standard value: mm in.)

Limit: 0.25 mm

in.)

OIL SEAL INSTALLATION

998776

TSB Revision

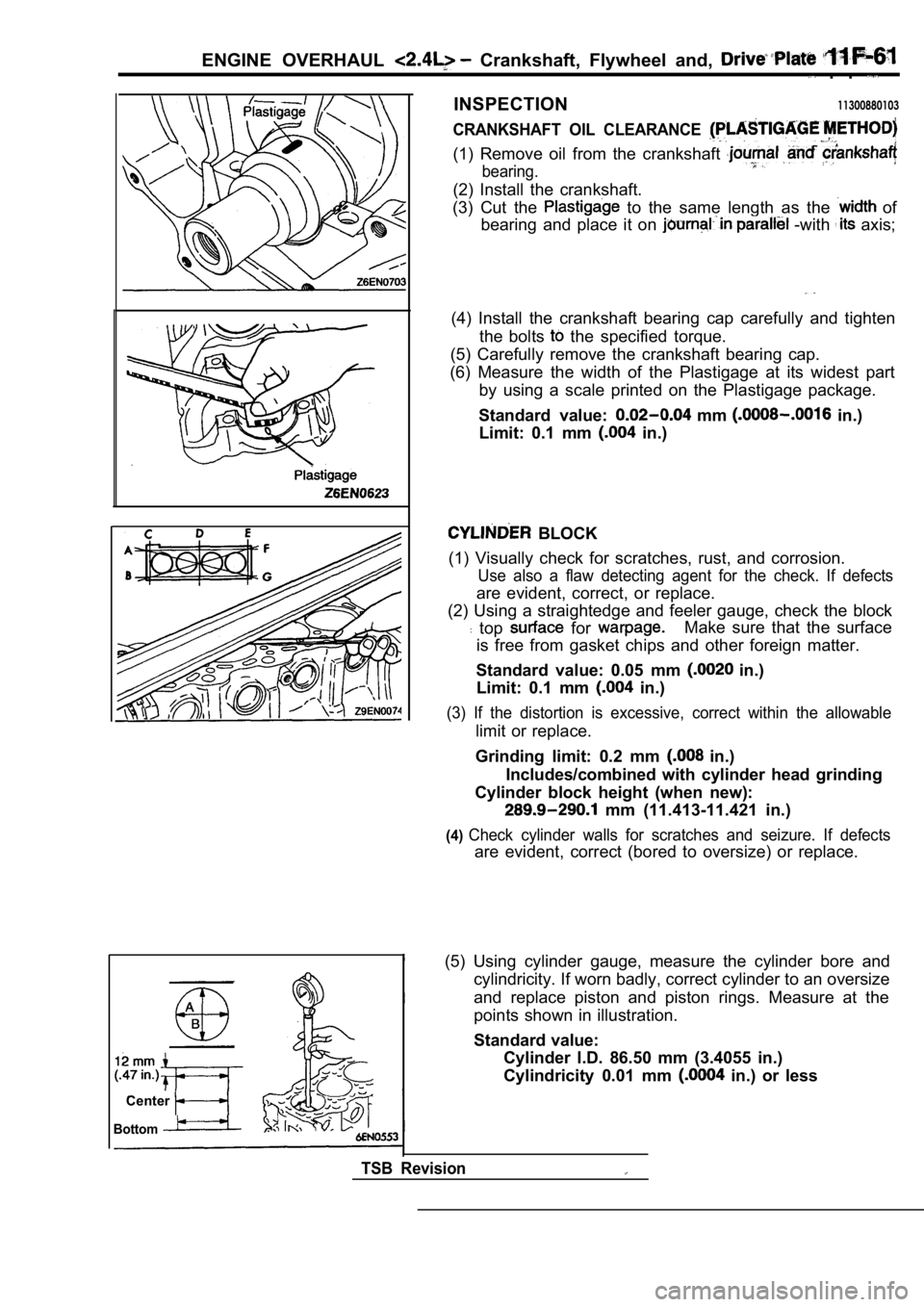

Page 371 of 2103

ENGINE OVERHAUL Crankshaft, Flywheel and, . .

INSPECTION11300880103

CRANKSHAFT OIL CLEARANCE

(1) Remove oil from the crankshaft

bearing.

(2) Install the crankshaft.

(3) Cut the

to the same length as the of

bearing and place it on

-with axis;

(4) Install the crankshaft bearing cap carefully an d tighten

the bolts

the specified torque.

(5) Carefully remove the crankshaft bearing cap.

(6) Measure the width of the Plastigage at its wide st part

by using a scale printed on the Plastigage package.

Standard value:

mm in.)

Limit: 0.1 mm

in.)

BLOCK

(1) Visually check for scratches, rust, and corrosi on.

Use also a flaw detecting agent for the check. If d efects

are evident, correct, or replace.

(2) Using a straightedge and feeler gauge, check th e block

top for Make sure that the surface

is free from gasket chips and other foreign matter.

Standard value: 0.05 mm

in.)

Limit: 0.1 mm

in.)

(3) If the distortion is excessive, correct within the allowable

limit or replace.

Grinding limit: 0.2 mm

in.)

Includes/combined with cylinder head grinding

Cylinder block height (when new):

mm (11.413-11.421 in.)

(4)Check cylinder walls for scratches and seizure. If defects

are evident, correct (bored to oversize) or replace.

Center

Bottom

TSB Revision

(5) Using cylinder gauge, measure the cylinder bore and

cylindricity. If worn badly, correct cylinder to an oversize

and replace piston and piston rings. Measure at the

points shown in illustration.

Standard value: Cylinder I.D. 86.50 mm (3.4055 in.)

Cylindricity 0.01 mm

in.) or less

Page 734 of 2103

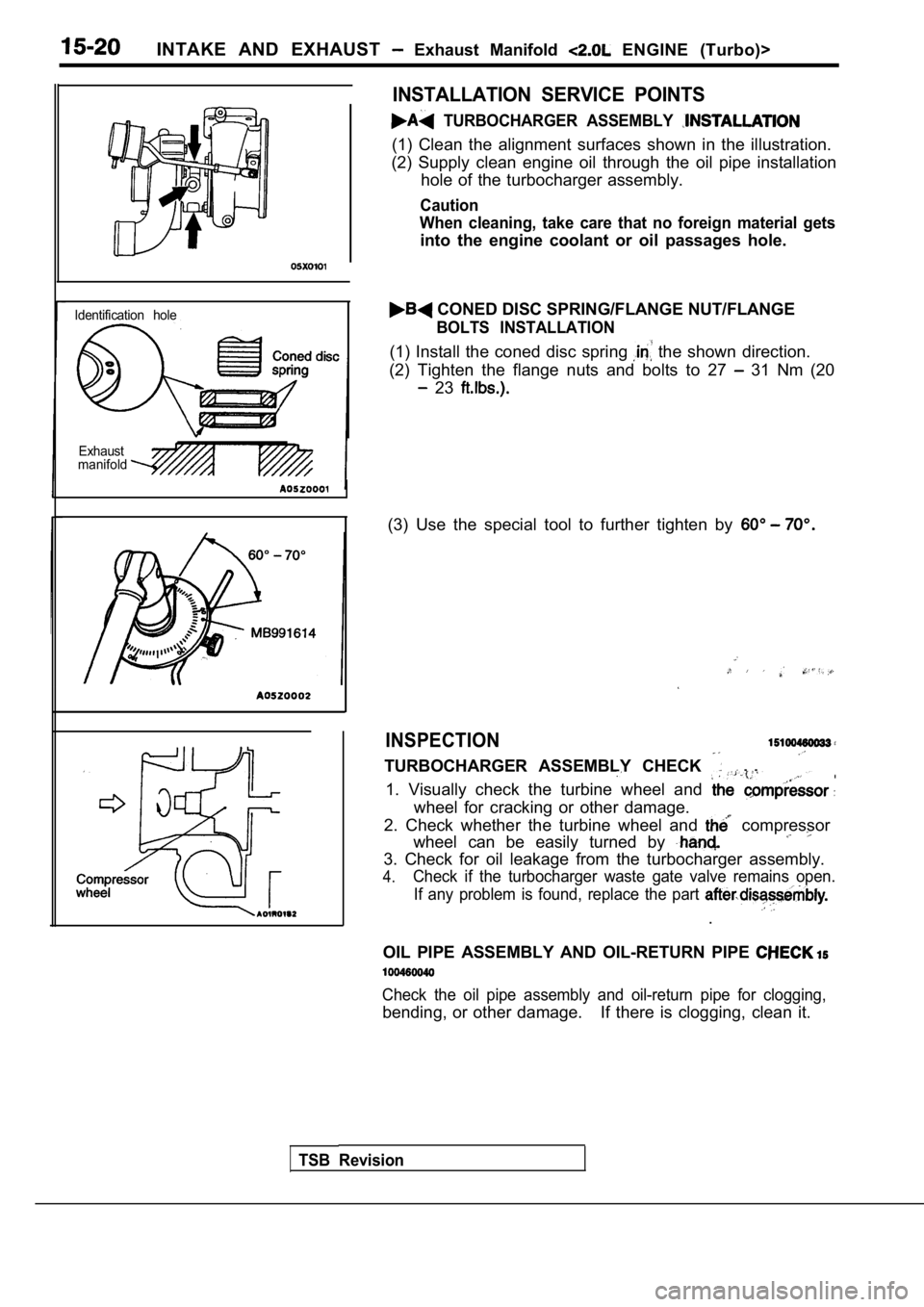

INTAKE AND EXHAUST Exhaust Manifold ENGINE (Turbo)>

Identification holeExhaust

manifold

INSTALLATION SERVICE POINTS

TURBOCHARGER ASSEMBLY

(1) Clean the alignment surfaces shown in the illus tration.

(2) Supply clean engine oil through the oil pipe in stallation

hole of the turbocharger assembly.

Caution

When cleaning, take care that no foreign material g ets

into the engine coolant or oil passages hole.

CONED DISC SPRING/FLANGE NUT/FLANGE

BOLTS INSTALLATION

(1) Install the coned disc spring the shown direction.

(2) Tighten the flange nuts and bolts to 27

31 Nm (20

23

(3) Use the special tool to further tighten by

INSPECTION

TURBOCHARGER ASSEMBLY CHECK . .

1. Visually check the turbine wheel and

wheel for cracking or other damage.

2. Check whether the turbine wheel and

compressor

wheel can be easily turned by

3. Check for oil leakage from the turbocharger asse mbly.

4.Check if the turbocharger waste gate valve remains open.

If any problem is found, replace the part

.

OIL PIPE ASSEMBLY AND OIL-RETURN PIPE

Check the oil pipe assembly and oil-return pipe for clogging,

bending, or other damage. If there is clogging, clea n it.

TSB Revision

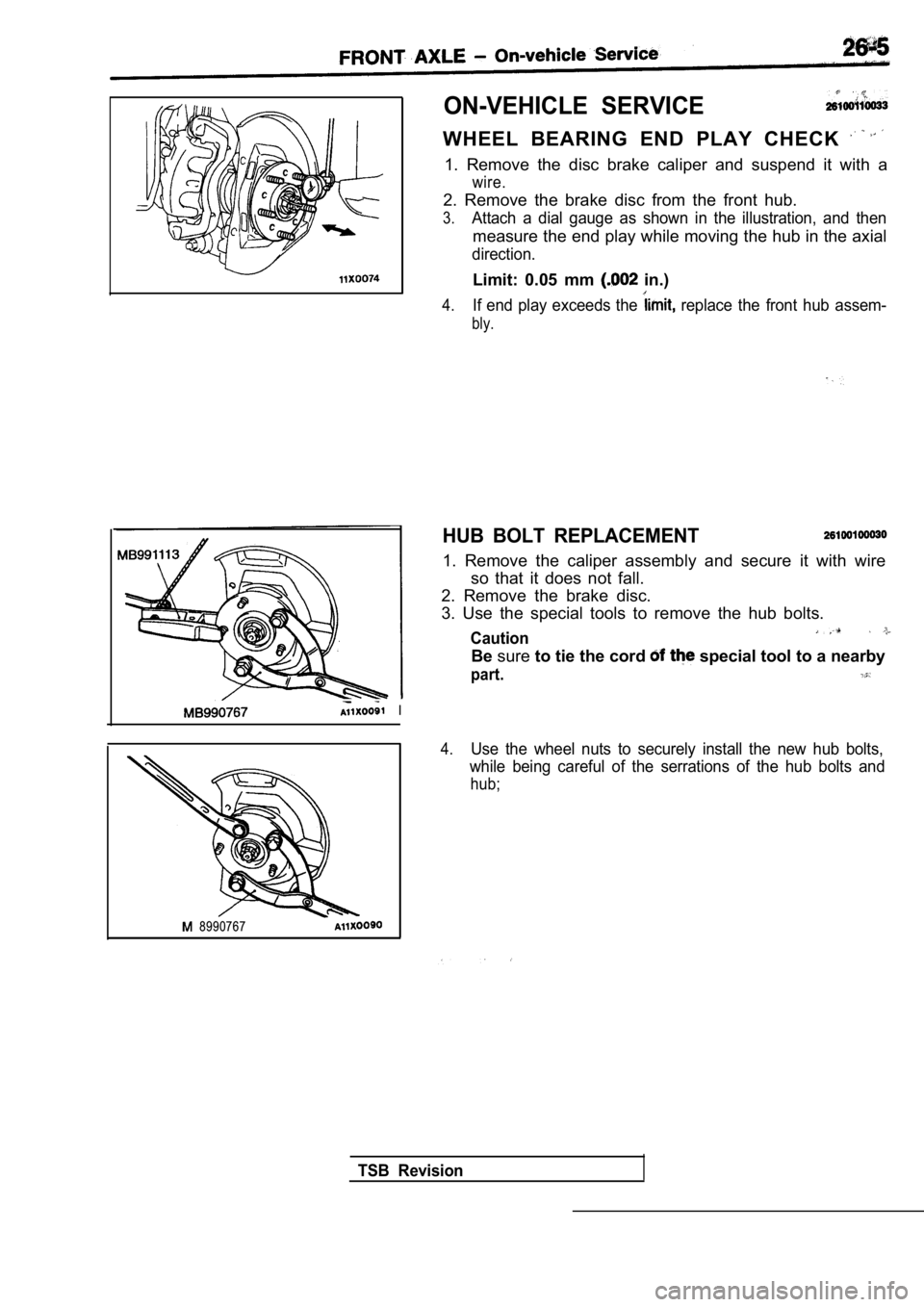

Page 1509 of 2103

I

8990767

ON-VEHICLE SERVICE

WHEEL BEARING END PLAY CHECK

1. Remove the disc brake caliper and suspend it with a

wire.

2. Remove the brake disc from the front hub.

3.Attach a dial gauge as shown in the illustration, and then

measure the end play while moving the hub in the ax ial

direction.

Limit: 0.05 mm in.)

4.If end play exceeds the replace the front hub assem-

bly.

HUB BOLT REPLACEMENT

1. Remove the caliper assembly and secure it with w ire

so that it does not fall.

2. Remove the brake disc.

3. Use the special tools to remove the hub bolts.

Caution

Be sure to tie the cord special tool to a nearby

part.

4.Use the wheel nuts to securely install the new hub bolts,

while being careful of the serrations of the hub bo lts and

hub;

TSB Revision

Page 1511 of 2103

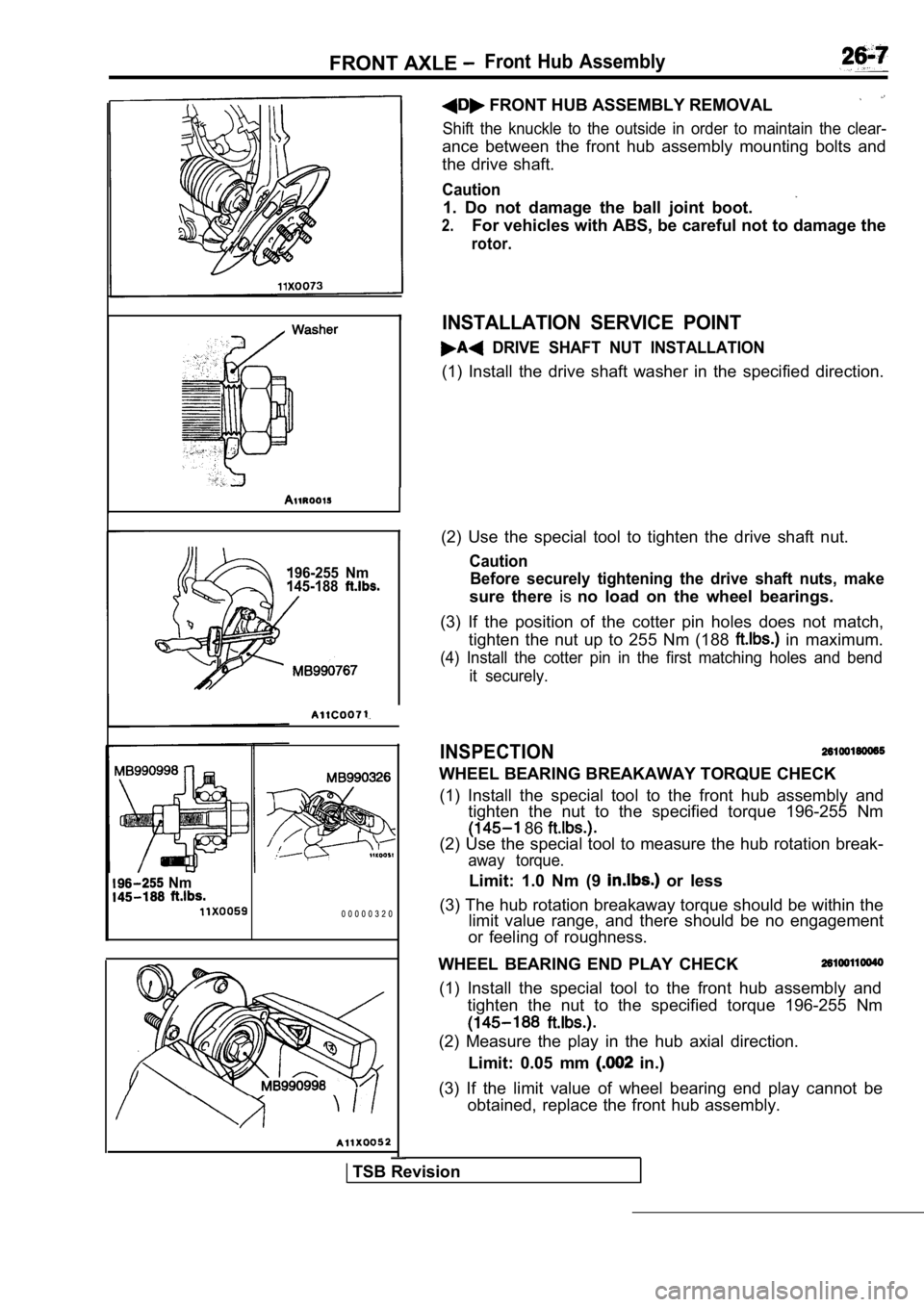

FRONT AXLE Front Hub Assembly

196-255 Nm

145-188

I(2) Use the special tool to tighten the drive shaft nut.

Caution

Before securely tightening the drive shaft nuts, ma ke

sure there isno load on the wheel bearings.

(3) If the position of the cotter pin holes does no t match,

tighten the nut up to 255 Nm (188

in maximum.

(4) Install the cotter pin in the first matching ho les and bend

it securely.

INSPECTION

WHEEL BEARING BREAKAWAY TORQUE CHECK

(1) Install the special tool to the front hub assem bly and

tighten the nut to the specified torque 196-255 Nm

86

(2) Use the special tool to measure the hub rotatio n break-

away torque.

Limit: 1.0 Nm (9 or less

(3) The hub rotation breakaway torque should be wit hin the

limit value range, and there should be no engagemen t

or feeling of roughness. Nm

0 0 0 0 0 3 2 0

FRONT HUB ASSEMBLY REMOVAL

Shift the knuckle to the outside in order to mainta in the clear-

ance between the front hub assembly mounting bolts and

the drive shaft.

Caution

1. Do not damage the ball joint boot.

2.For vehicles with ABS, be careful not to damage the

rotor.

INSTALLATION SERVICE POINT

DRIVE SHAFT NUT INSTALLATION

(1) Install the drive shaft washer in the specified direction.

WHEEL BEARING END PLAY CHECK

(1) Install the special tool to the front hub assem bly and

tighten the nut to the specified torque 196-255 Nm

(2) Measure the play in the hub axial direction.

Limit: 0.05 mm

in.)

(3) If the limit value of wheel bearing end play ca nnot be

obtained, replace the front hub assembly.

TSB Revision

Page 1538 of 2103

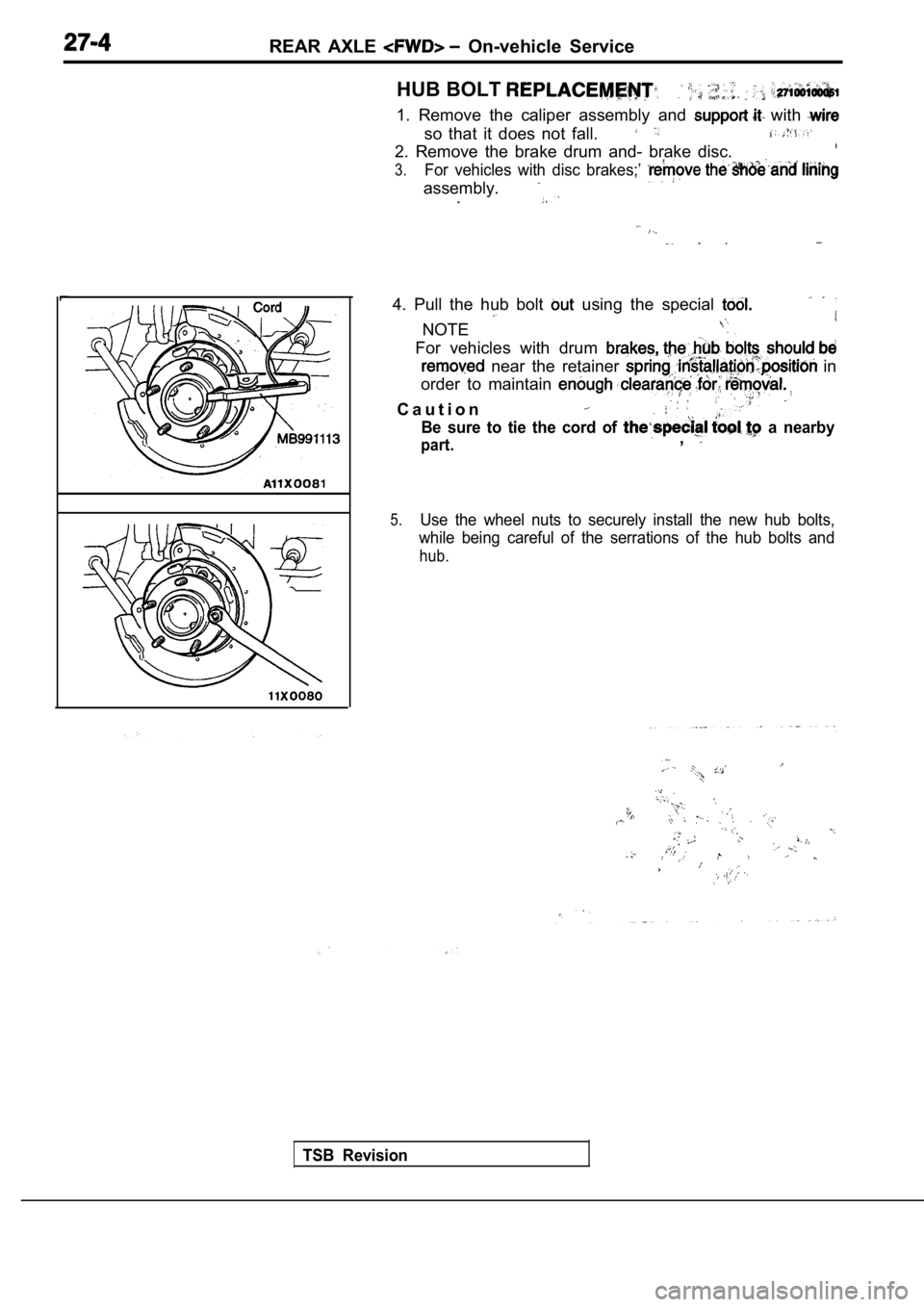

REAR AXLE On-vehicle Service

HUB BOLT

1. Remove the caliper assembly and with

so that it does not fall.

2. Remove the brake drum and- brake disc.

3.For vehicles with disc brakes;’

assembly..

4. Pull the hub bolt using the special

NOTE

For vehicles with drum

near the retainer in

order to maintain

C a u t i o n

Be sure to tie the cord of a nearby

part.,

5.Use the wheel nuts to securely install the new hub bolts,

while being careful of the serrations of the hub bo lts and

hub.

TSB Revision

.

,

,

,