wiring MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 8 of 2103

G E N E R A L How to Use Troubleshooting/Inspection Service Points

Troubleshooting of electronic control systems for which the scan tool the basic outline

described below. Furthermore, even in systems for w hich the scan tool cannot be used, part of these

systems still follow this outline.

TROUBLESHOOTING CONTENTS

1. STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

The main procedures for diagnostic troubleshooting are shown.

2. SYSTEM OPERATION AND SYMPTOM VERIFICATION TESTS If verification of the trouble symptoms is difficul t, procedures for checking operation and verifying

trouble symptoms are shown.

3. DIAGNOSTIC FUNCTION The following diagnostic functions are shown.

l ,Method of reading diagnostic trouble codes

Method of erasing diagnostic trouble codes

lInput inspection service points

4. INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

5. INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODE S

Indicates the inspection procedures corresponding t o each diagnostic trouble code. (Refer to the

next page on how to use the inspection procedures.)

6. INSPECTION CHART FOR TROUBLE SYMPTOMS

If there are trouble symptoms, even though the scan tool displays no diagnostic inspection

procedures for each trouble symptom will be found b y means of this chart.

7. INSPECTION PROCEDURE FOR TROUBLE SYMPTOMS

Indicates the inspection procedures corresponding t o each trouble symptoms the Inspection

Chart for Trouble Symptoms. (Refer to the next page on how to use the inspection procedures.)

8. DATA LIST REFERENCE TABLE

Inspection items and normal judgement values have b een provided in this chart as reference

9. CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspection items and standard values have been provided

in this chart as reference information.

Terminal Voltage Checks

1. Connect a needle-nosed wire probe or paper clip to a voltmeter probe.

2.Insert the needle-nosed wire probe into each of the ECU connector from the wire side,

and measure the voltage while referring to the chec k chart.

NOTE

1. Measure voltage with the ECU connectors connecte d.

2. You may find it convenient to pull out the ECU t o make it easier to reach the connector

terminals.

3. Checks don’t have to be carried out in the order given in the chart.

Short-circuiting the positive probe between a connector damage

the vehicle wiring, the sensor, the ECU, or all thr ee.

Use care to prevent this

3. If voltage readings differ from Normal Condition values, related actuators, and

wiring, then replace or repair.

TSB Revision

Page 9 of 2103

GENERAL How to Use Troubleshooting/Inspection Service Points

4.After repair or replacement, recheck the voltmeter to confirm the repair

the problem.

Terminal Resistance and Continuity Checks

1. Turn the ignition switch to off.

2. Disconnect the ECU connector.

3.Measure the resistance and check for continuity bet ween the terminals of the ECU

connector while referring to the check chart.

NOTE

Checks don’t have to be carried out in the order gi ven in the chart.

Cautlon

If resistance and continuity checks are performed the wrong terminals, damage

vehicle wiring, sensors, ECU, and/or ohmmeter may o ccur.

Use care to prevent this!

4.If the ohmmeter shows any deviation from the Normal Condition value, check the corresponding

5.

sensor, actuator and related electrical wiring, then repair or replace.

After repair or replacement, recheck with the ohmme ter to confirm that the repair

the problem.

10. INSPECTION PROCEDURES USING AN OSCILLOSCOPE

When there are inspection procedures using an oscil loscope, these are listed here.

,

TSB Revision

Page 13 of 2103

G E N E R A L How to Use __

HOW TO COPE WITH INTERMITTENT

Most intermittent malfunctions occur under certain conditions. If those conditions can be identified, the

cause will be easier to find.

TO COPE WITH INTERMITTENT MALFUNCTION;1. Ask the customer about the malfunction

Ask what it feels

it sounds like, etc.

Then ask about

conditions; weather,

frequency of occurrence, and so on.

2.Determine the from the custom-

er’s responses

Typically, almost all intermittent malfunctions

occur from conditions like vibration, tempera-

ture and/or moisture change, poor connections.

From the customer’s replies, it should be rea-

soned which condition is influenced.

3. Use simulation test In the cases of vibration or poor connections,

use the simulation tests below to attempt to

duplicate the customer’s complaint. Determine

the most likely circuit(s) and perform

tion tests on the connectors and parts of that

circuit(s). Be sure to use the inspection proce-

dures provided for trouble codes

a n d t r o u b l e s y m p t o m s .

For temperature and/or moisture conditions re-

lated intermittent malfunctions, using common

sense, try to change the of

circuit components, then use

tion tests below,

4. Verify the intermittent malfunction is elimi-

nated

Repair the malfunctioning part and try to

the condition(s) again to verify the intermit-

tent malfunction has been eliminated.

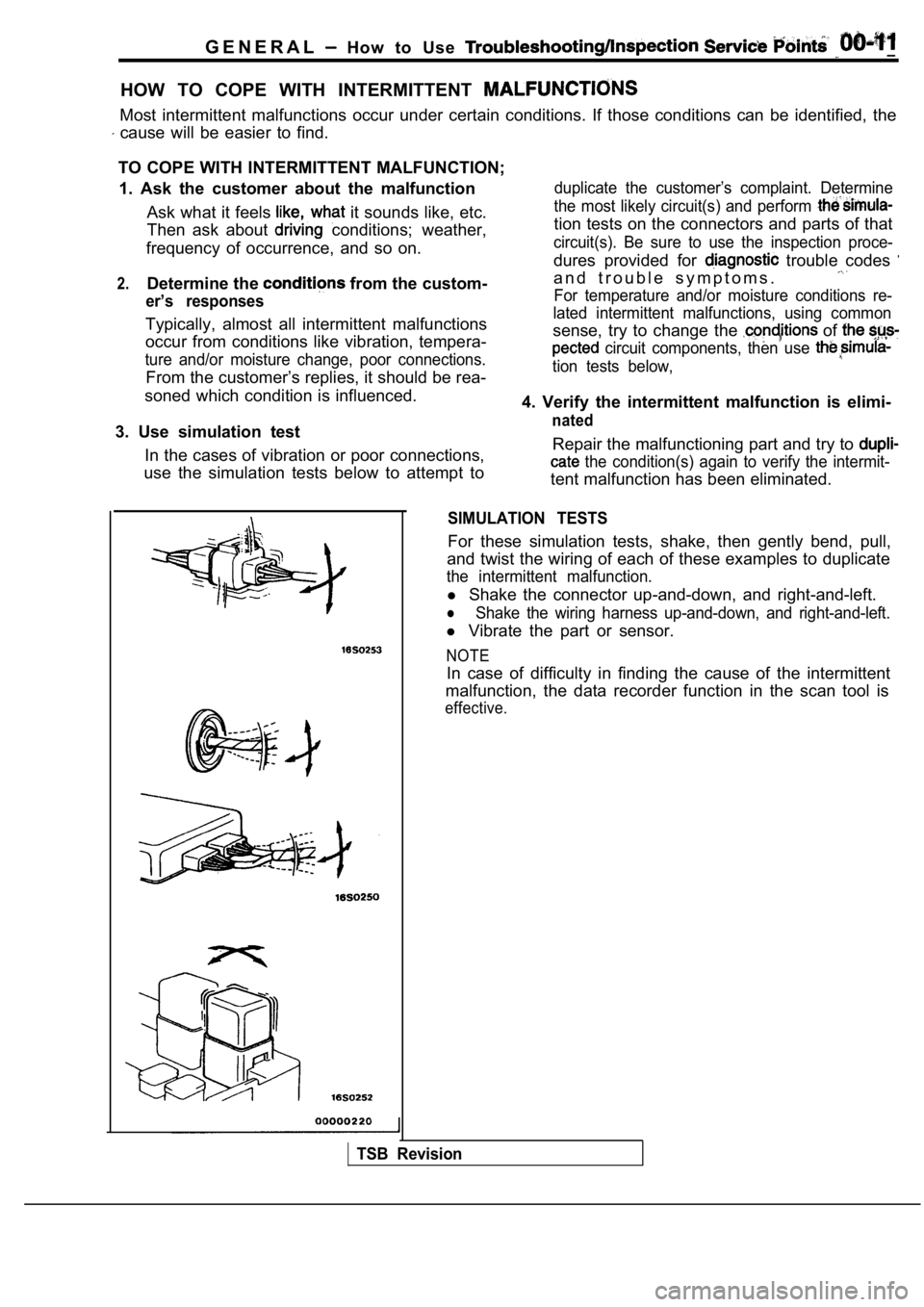

SIMULATION TESTS

For these simulation tests, shake, then gently bend , pull,

and twist the wiring of each of these examples to d uplicate

the intermittent malfunction.

l Shake the connector up-and-down, and right-and-left .

lShake the wiring harness up-and-down, and right-and -left.

l Vibrate the part or sensor.

NOTE

In case of difficulty in finding the cause of the i ntermittent

malfunction, the data recorder function in the scan tool is

effective.

TSB Revision

Page 22 of 2103

GENERAL before Service

PRECAUTIONS BEFORE SERVICE.

SUPPLEMENTAL RESTRAINT SYSTEM

1. to follow when servicing SRS

(1) Be sure to read GROUP Supplemental Restraint System

For safe operations, please follow the directions a nd heed all

(2) Always use the designated special tools and tes t equipment.

(3) Wait at least 60 seconds after disconnecting the battery cable before” further work;

The SRS system is designed to retain enough voltage to deploy the air bag even after the battery

has been disconnected. Serious injury may result from unintended air bag deployment if work

is done on the SRS system immediately after the bat tery cable is disconnected.

(4) Never attempt to disassemble or repair the SRS components (SRS-ECU air bag module and

clock spring). If faulty, replace it.

(5) Warning labels must be heeded when servicing or handling SRS components. Warning labels

are located in the following locations.

Sun visor

l Glove box

. S R S - E C U

l Steering wheel

l Air bag module

l Clock spring

l Steering gear and linkage clamp

(6) Store components removed from the SRS

a clean and dry place.

The air bag module should be stored on a flat surfa ce and placed so that the pad surface is’

facing upward.

Do not place anything on top of it.

(7) Be sure to deploy the air bag before disposing of the air bag’module or disposing of a vehicle

equipped with an air bag. (Refer to GROUP

Air Bag Module Disposal Procedures.)

(8) Whenever you finish servicing the

check the SRS warning light operation to make sure

that the system functions properly.

2.Observe the following when carrying out operations on places where SRS components are installed,’

.,

including operations not directly related to the SR S air bag.

(1) When removing or installing parts do not allow any impact or shock to the SRS components.

(2) SRS components should not be subjected to heat over so remove the SRS compo-

nents before drying or baking the vehicle after painting.

After re-installing them, check the SRS warning lig ht operation to make sure that the system

functions properly.

SERVICING THE ELECTRICAL SYSTEM

1. Note the following before proceeding with work o n the

electrical system.

Note that the following must never be done:

Unauthorized modifications of any electrical device or

wiring, because such modifications might lead to a vehicle

malfunction, over-capacity or short-circuit that co uld result

in a fire in the vehicle.

2.When servicing the electrical system, disconnect th e nega-

tive cable terminal from the battery.

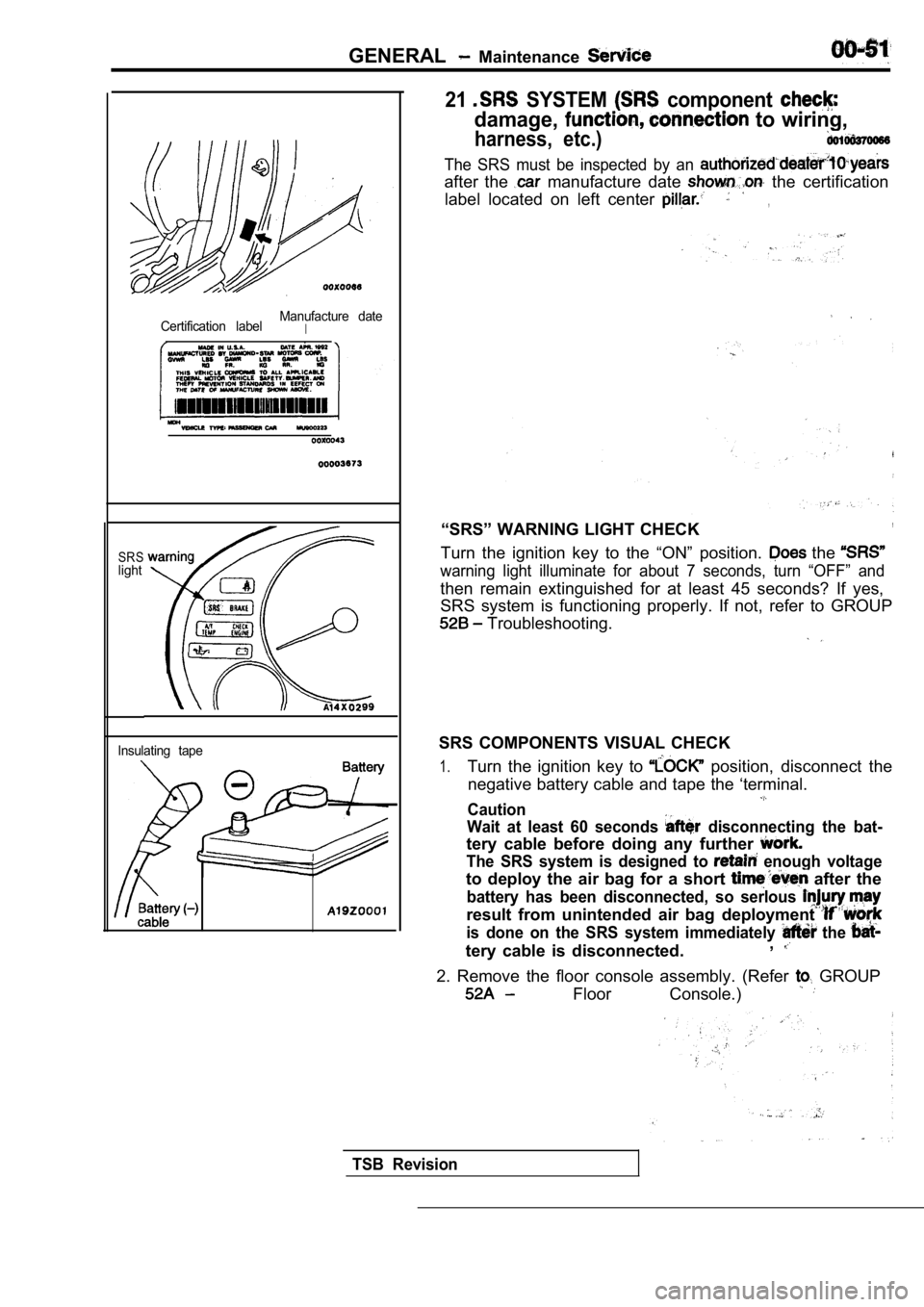

Page 53 of 2103

GENERAL Maintenance

21 SYSTEM component

damage, to wiring,

harness, etc.)

Certification labelManufacture dateI

SRSlight

Insulating tape

The SRS must be inspected by an

after the manufacture date the certification

label located on left center

,

“SRS” WARNING LIGHT CHECK,

Turn the ignition key to the “ON” position. the

warning light illuminate for about 7 seconds, turn “OFF” and

then remain extinguished for at least 45 seconds? I f yes,

SRS system is functioning properly. If not, refer t o GROUP

Troubleshooting.

SRS COMPONENTS VISUAL CHECK

1.Turn the ignition key to position, disconnect the

negative battery cable and tape the ‘terminal.

Caution

Wait at least 60 seconds

disconnecting the bat-

tery cable before doing any further

The SRS system is designed to enough voltage

to deploy the air bag for a short after the

battery has been disconnected, so serlous

result from unintended air bag deployment

is done on the SRS system immediately the

tery cable is disconnected. ,

2. Remove the floor console assembly. (Refer GROUP

Floor Console.)

TSB Revision

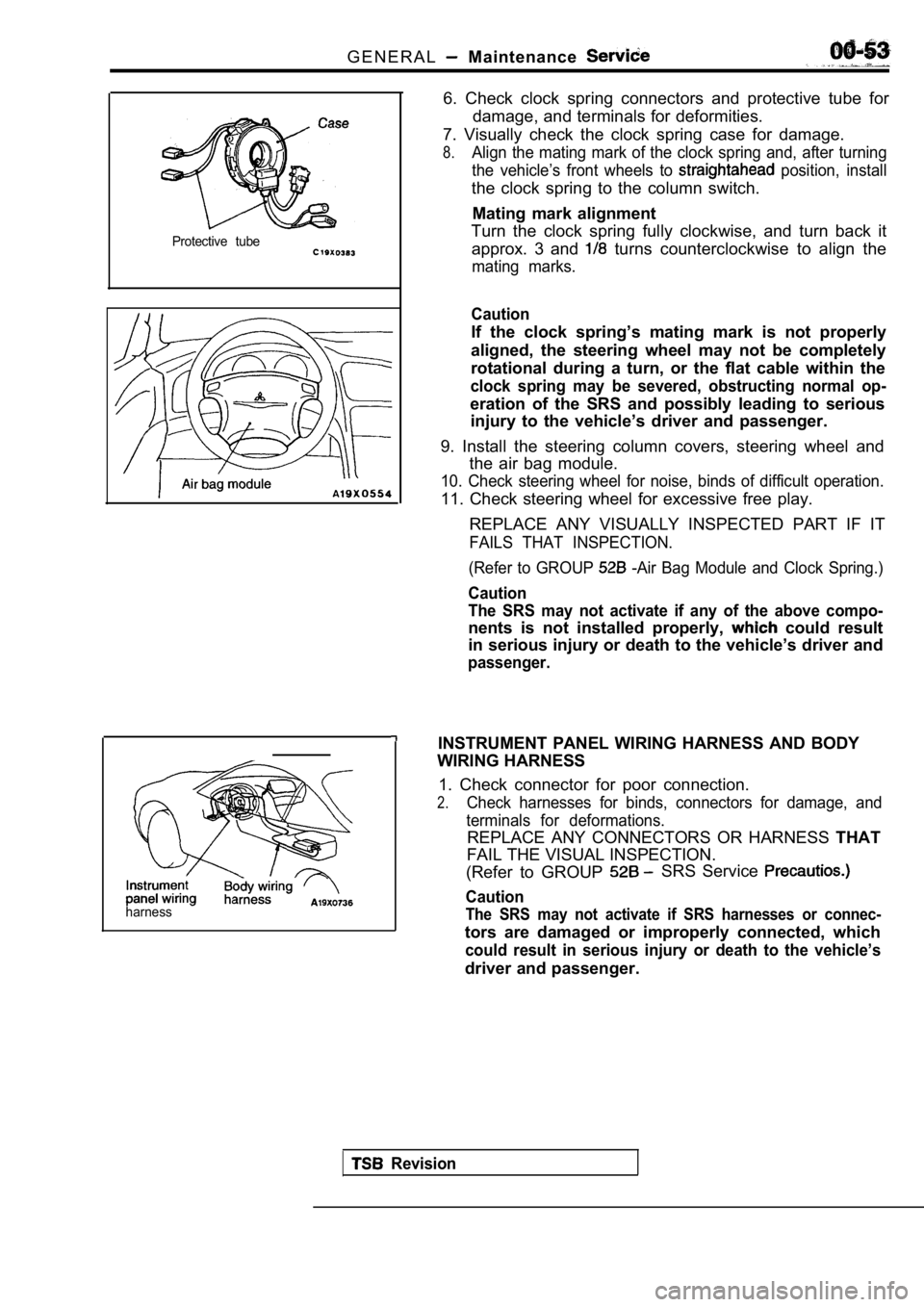

Page 55 of 2103

G E N E R A L Maintenance

Protective tube

harness

6. Check clock spring connectors and protective tube for

damage, and terminals for deformities.

7. Visually check the clock spring case for damage.

8.Align the mating mark of the clock spring and, afte r turning

the vehicle’s front wheels to

position, install

the clock spring to the column switch.

Mating mark alignment

Turn the clock spring fully clockwise, and turn bac k it

approx. 3 and

turns counterclockwise to align the

mating marks.

Caution

If the clock spring’s mating mark is not properly

aligned, the steering wheel may not be completely

rotational during a turn, or the flat cable within the

clock spring may be severed, obstructing normal op-

eration of the SRS and possibly leading to serious

injury to the vehicle’s driver and passenger.

9. Install the steering column covers, steering whe el and

the air bag module.

10. Check steering wheel for noise, binds of diffic ult operation.

11. Check steering wheel for excessive free play.

REPLACE ANY VISUALLY INSPECTED PART IF IT

FAILS THAT INSPECTION.

(Refer to GROUP

-Air Bag Module and Clock Spring.)

Caution

The SRS may not activate if any of the above compo-

nents is not installed properly, could result

in serious injury or death to the vehicle’s driver and

passenger.

INSTRUMENT PANEL WIRING HARNESS AND BODY

WIRING HARNESS

1. Check connector for poor connection.

2.Check harnesses for binds, connectors for damage, a nd

terminals for deformations.

REPLACE ANY CONNECTORS OR HARNESS THAT

FAIL THE VISUAL INSPECTION.

(Refer to GROUP

SRS Service

Caution

The SRS may not activate if SRS harnesses or connec -

tors are damaged or improperly connected, which

could result in serious injury or death to the vehicle’s

driver and passenger.

Revision

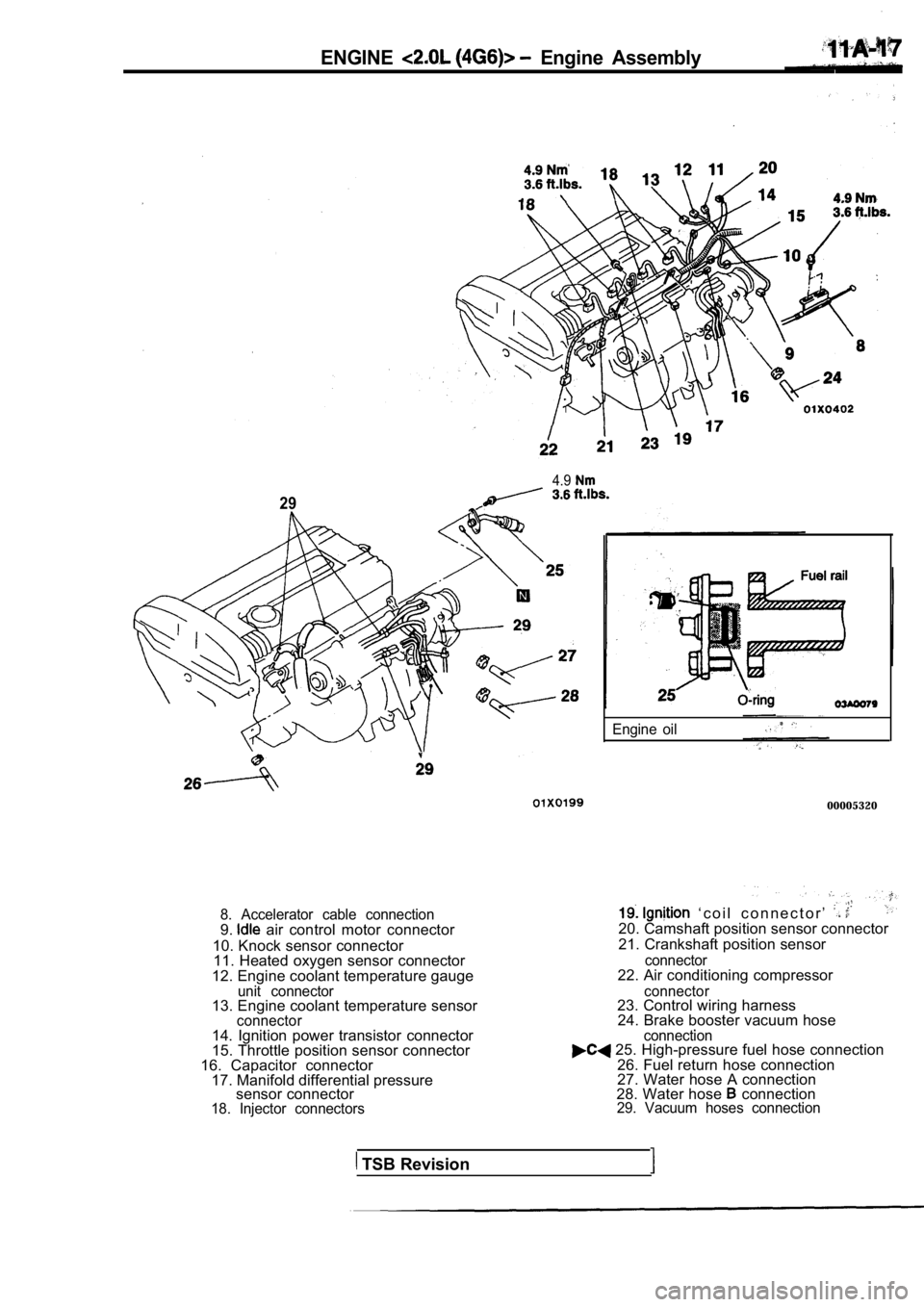

Page 77 of 2103

ENGINE Engine Assembly

4.9

29

8. Accelerator cable connection9. air control motor connector

10. Knock sensor connector 11. Heated oxygen sensor connector

12. Engine coolant temperature gauge

unit connector13. Engine coolant temperature sensorconnector

Engine oil

00005320

‘ c o i l c o n n e c t o r ’ 20. Camshaft position sensor connector

21. Crankshaft position sensor

connector22. Air conditioning compressor

connector23. Control wiring harness 24. Brake booster vacuum hose .

14. Ignition power transistor connector

15. Throttle position sensor connector

16. Capacitor connector 17. Manifold differential pressure sensor connector

18. Injector connectors connection

25. High-pressure fuel hose connection

26. Fuel return hose connection

27. Water hose A connection

28. Water hose

connection29. Vacuum hoses connection

TSB Revision

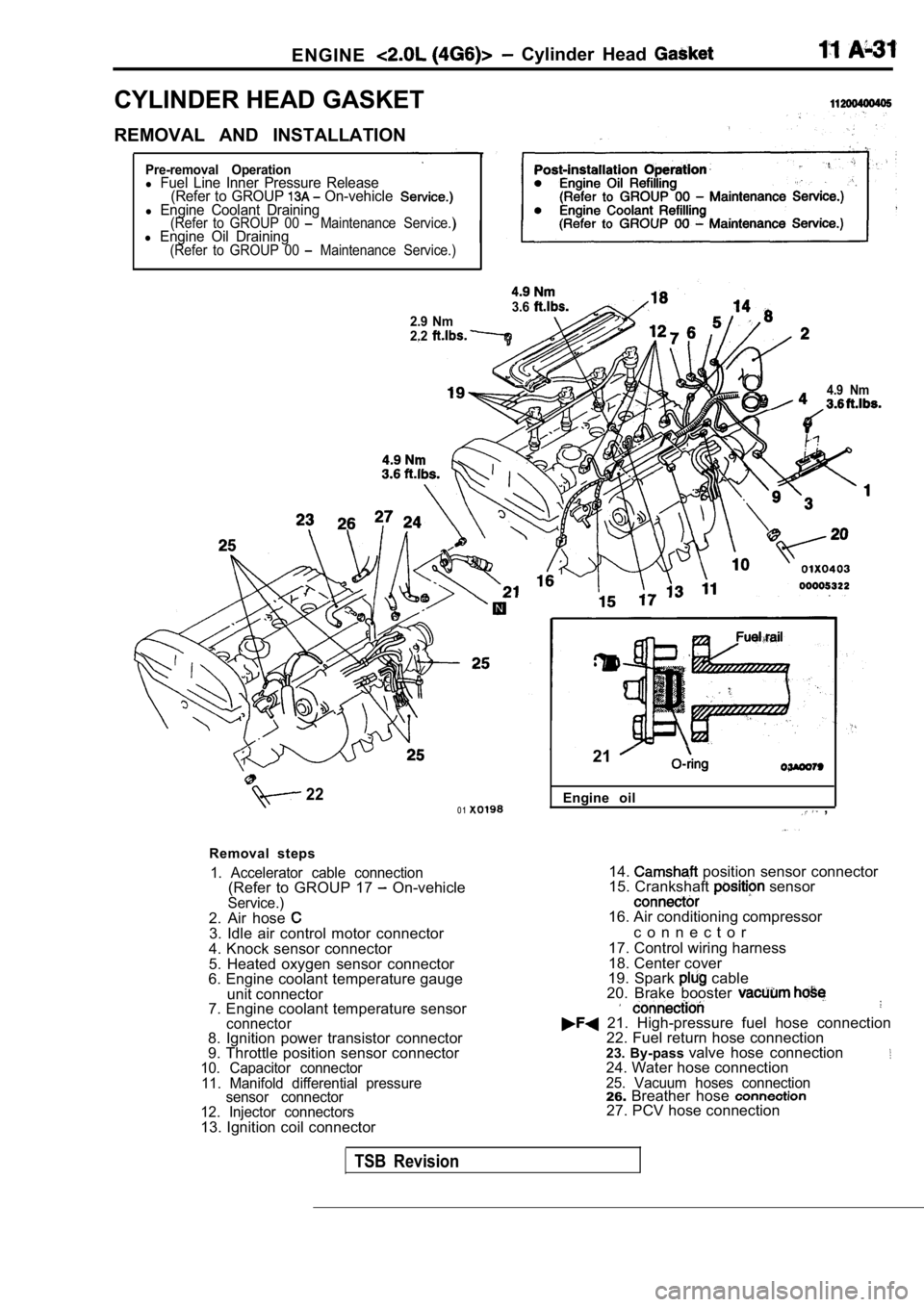

Page 91 of 2103

ENGINE Cylinder Head

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal Operationl Fuel Line Inner Pressure Release(Refer to GROUP On-vehiclel Engine Coolant Draining(Refer to GROUP 00 Maintenance Service.)l Engine Oil Draining(Refer to GROUP 00 Maintenance Service.)

3.62.9 Nm

2.2

4.9 Nm

220 1

Removal steps

1. Accelerator cable connection(Refer to GROUP 17 On-vehicleService.)2. Air hose 3. Idle air control motor connector

4. Knock sensor connector

5. Heated oxygen sensor connector

6. Engine coolant temperature gauge

unit connector

7. Engine coolant temperature sensor

connector8. Ignition power transistor connector

9. Throttle position sensor connector

10. Capacitor connector

11. Manifold differential pressure sensor connector

12. Injector connectors

13. Ignition coil connector Engine oil

,

21

14. position sensor connector

15. Crankshaft sensor

16. Air conditioning compressor

c o n n e c t o r

17. Control wiring harness

18. Center cover

19. Spark

cable

20. Brake booster

21. High-pressure fuel hose connection 22. Fuel return hose connection

23. By-pass valve hose connection

24. Water hose connection25. Vacuum hoses connection26.Breather hose 27. PCV hose connection

TSB Revision

Page 284 of 2103

.

4 . 9 N m

\ / X L - -3.6

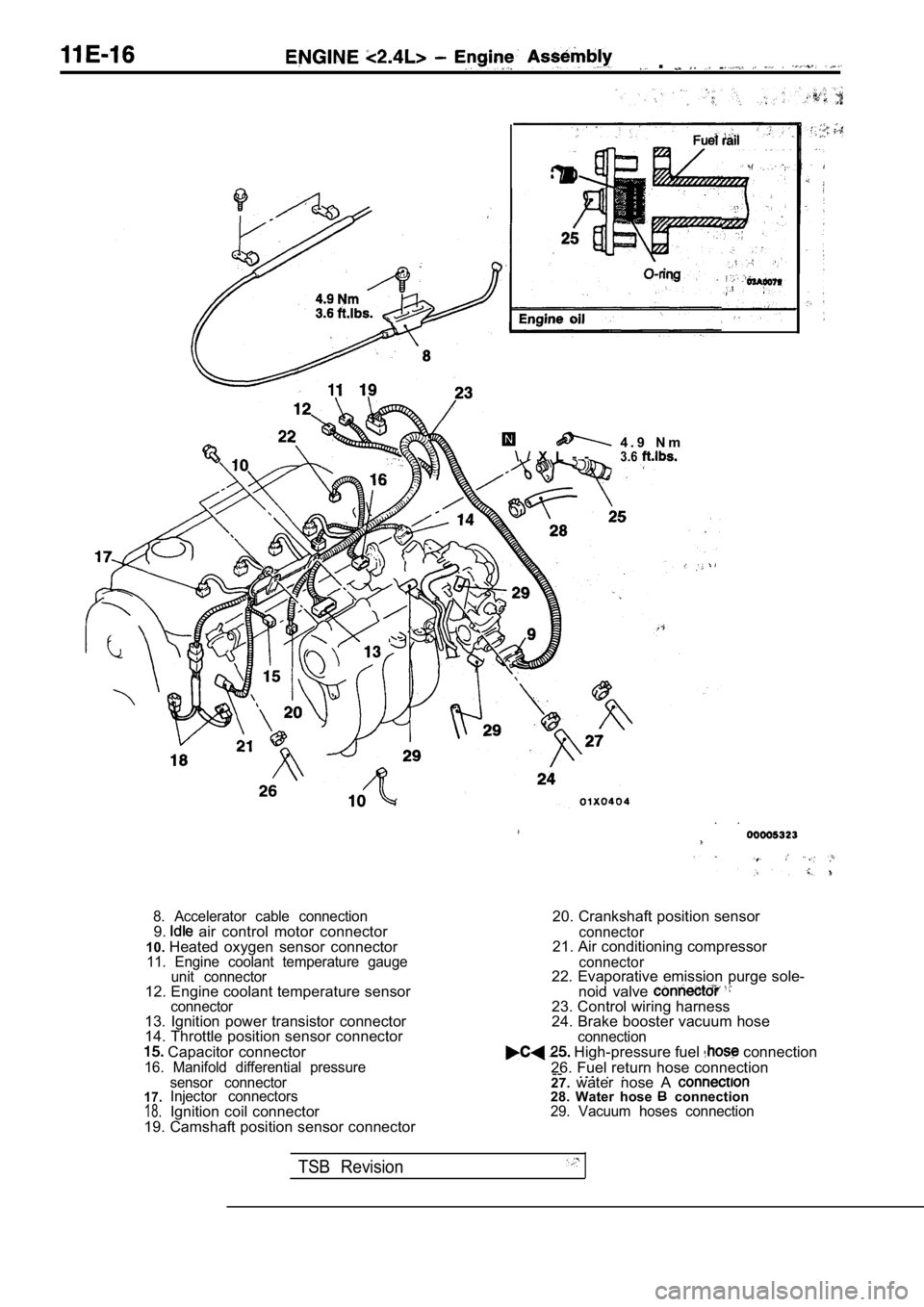

. .

8. Accelerator cable connection9. air control motor connector

10. Heated oxygen sensor connector

11. Engine coolant temperature gauge

unit connector

12. Engine coolant temperature sensorconnector13. Ignition power transistor connector

14. Throttle position sensor connector

Capacitor connector16. Manifold differential pressure

20. Crankshaft position sensor

connector21. Air conditioning compressor

connector22. Evaporative emission purge sole-

noid valve

23. Control wiring harness

24. Brake booster vacuum hose

connection High-pressure fuel connection

26. Fuel return hose connection --

. .. .

17.18.

sensor connector

Injector connectors

Ignition coil connector

19. Camshaft position sensor connector 27.

water nose A 28. Water hose connection29. Vacuum hoses connection

TSB Revision

Page 425 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 42

Code General scan tool

No.Ignition Coil CircuitP r o b a b l e

43

[Comment]

BackgroundlIgnition coil wiring harness or connectorfailedl The PCM MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (NON-TURBO)>

Scan tool 42

Code General scan tool

No.Ignition Coil CircuitP r o b a b l e

43

[Comment]

BackgroundlIgnition coil wiring harness or connectorfailedl The PCM](/img/19/57345/w960_57345-424.png)

ENGINE (NON-TURBO)>

Scan tool 42

Code General scan tool

No.Ignition Coil CircuitP r o b a b l e

43

[Comment]

BackgroundlIgnition coil wiring harness or connectorfailedl The PCM provides the ground control circuit for the side of ignition coil. Open circuit in coill Battery voltage is through the relay (ASD relay). P C M Range of Checkl Battery voltage: 13 or more (engine is running)

l relay (ASD relay): ON

l Engine: 3000 or lessl Engine speed and ignition timing are always stable.

Set Condition

lThe primary circuit is not achieving peak current w ith maximum dwell for 3 seconds.

SCAN TOOL Actuator test 10

relay (ASD relay)

OK: ooeratina sound can be heard.

NG Repair relay (ASD relay) related

OK

Measure at the ignition coil connector lDisconnect the connector, and measure at the harnes s side.

SCAN TOOL Actuator test 10

relay (ASD relay) relay (ASD relay) is turned on and off 1.4 seconds.

l Voltage between 2 and ground

[Measure with

relay (ASD relay) on.]

OK: Battery positive voltage Check the harness wire the (ASD-relay) and

the ignition coil connector. Repair,’ necessary.

NGMeasure at the PCM connector Check the following connector: lDisconnect the connector and measure at the harness side.lDisconnect PCM connector and short terminal (67) of

the harness-side connector to ground.

Voltage between 3 and ground OK: Battery positive voltage

OK

Check the harness wire between PCM and the ignition connector. Repair, if necessary.

Check the following connector:

OK

NG Repair

Check trouble symptom.

Replace the PCM.

N G

TSB Revision