automatic transmission NISSAN 300ZX 1984 Z31 Automatic Transmission Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 99, PDF Size: 3.09 MB

Page 2 of 99

DESCRIPTION OF E4N71B

I

The Model E4N71B automatic transmission is the

latest addition to Niaan's lineup

of transmissions.

This transmission

is based on the model L4N71B

(mounted on the 1983 model 810), and can pro-

vide lockup of

all forward speeds (1st to 4th speed)

by electronic control.

By use of a microcomputer, the electronic-control-

led lockup system permits lockup of

all forward

speeds (1st to 4th speed)

Either shifting pattern ("standard" or "power")

is

automatically selected by programs set in the

lockup control unit depending on the speed

at

which the accelerator pedal is depressed These

programs are

set in response to the vehicle speed

and throttle position

rlnhibitor switch \Lockup control unit

/;?\I!

LPower Shift switch and mdtcator

Stop lamp rwlrch

\Kickdown switch

Downshift solenoid

Shift switch and low temperature sensor

Throttle valve rwitchl 0 indicator

Lockup solenoid 0 D cancel solenoid

SAT7M

AT-2

Page 4 of 99

GENERAL SERVICE NOTICE

Repai

Before proceeding with disassembly, thorough-

ly clean the outside of the transmission It IS

important to prevent the internal parts of the

transmission from becoming contaminated by

dirt or other foreign matter.

Disassembly should

be done in a clean work

area. Use

a nylon cloth or paper towel for wiping

parts clean. Common

shop rags can leave lint

that might interfere with the transmission's

operation.

When disassembling parts, be sure to place

them in order

in parts rack so they can be put

back in the unit

in their proper positions

All parts should be carefully cleaned with a

general purpose, non.flammable solvent before

inspection or reassembly.

Gaskets,

seals, and O-rings should be replaced.

It is also very important to perform functional

tests whenever it is designated.

The valve body contains many precision parts

Contri

CONTROL VALVE UPPER BODY

3rd4th shift valve7

Pressure I

Uotes

and requires extreme care when parts are

removed and serviced. Place removed parts on

a parts rack so they can be put back in the

valve body in the same positions and

se-

quences. Care will also prevent springs and

small parts from becoming scattered or

lost

Before assembly, apply a coat of recommended

A

T.F. to all parts Vaseline may be applied to

O-rings and

seals. Do not use any grease.

Care should be taken to avoid damaging

O-rings, seals and

gaskets when assembling

Abbreviations used throughout this section stand

for the following.

A.T.F. ... Automatic transmission fluid

D, ........ Drive range 1st gear

D, .... ... Drive range 2nd gear

D, . . ... Drive range 3rd gear

D4 ........ Drive range 4th gear

0.D . .... Overdrive

1, ....... . 1 range 2nd gear

1, . . .... 1 range lstgear

Valve

Vacuum throttle valve

f rThrottle back-up valve

1st 2nd shift valve

2nd3rd shift valve

Second lock valve -i

SAT742

AT-4

Page 7 of 99

GENERAL SERVICE NOTICE

I (Cont'd) Oil Cham

OIL CHANNELS IN DRUM SUPPORT OIL CHANNELS IN CONVERTER HOUSING

To lock-up ~ontrol valve

rDrain (E4N71Bl

clutch (Front)

Forward clutch

clutch pressure Front & 0 0 lubrmtmn

SAT706

3peration Mechanic:

In the E4N71B and 4N71B automatic transmission, each part operates as shown in the following table at

each gear select position

'arking

pawl

Htgh-

'everse

Front) Forward clutch (Rear) 0 D band servo Direct

clutch Range -

Release

ON ON

1 Reverse 1 ON 1 ION) ON

+-

ON I

I Neutral I ON I (ON) ON

T-

ON

-

ON

-

ON

ON

JT

I ION

'34

(0 D 1 ON I ON

Second I ON I (ON) ON

1 ON I (ON) 12

(Second) ON ON I ON

ON ord ON I I ON

The low & reverse brake IS applied In "1 I" range to prevent free wheeling when coasting and allows engine braking.

AT-7

Page 61 of 99

ASSEMBLY

290 (1 142)

29 5 (1 161)

30 0 (1 1811

30 5 (1 201)

31 0 (1 220)

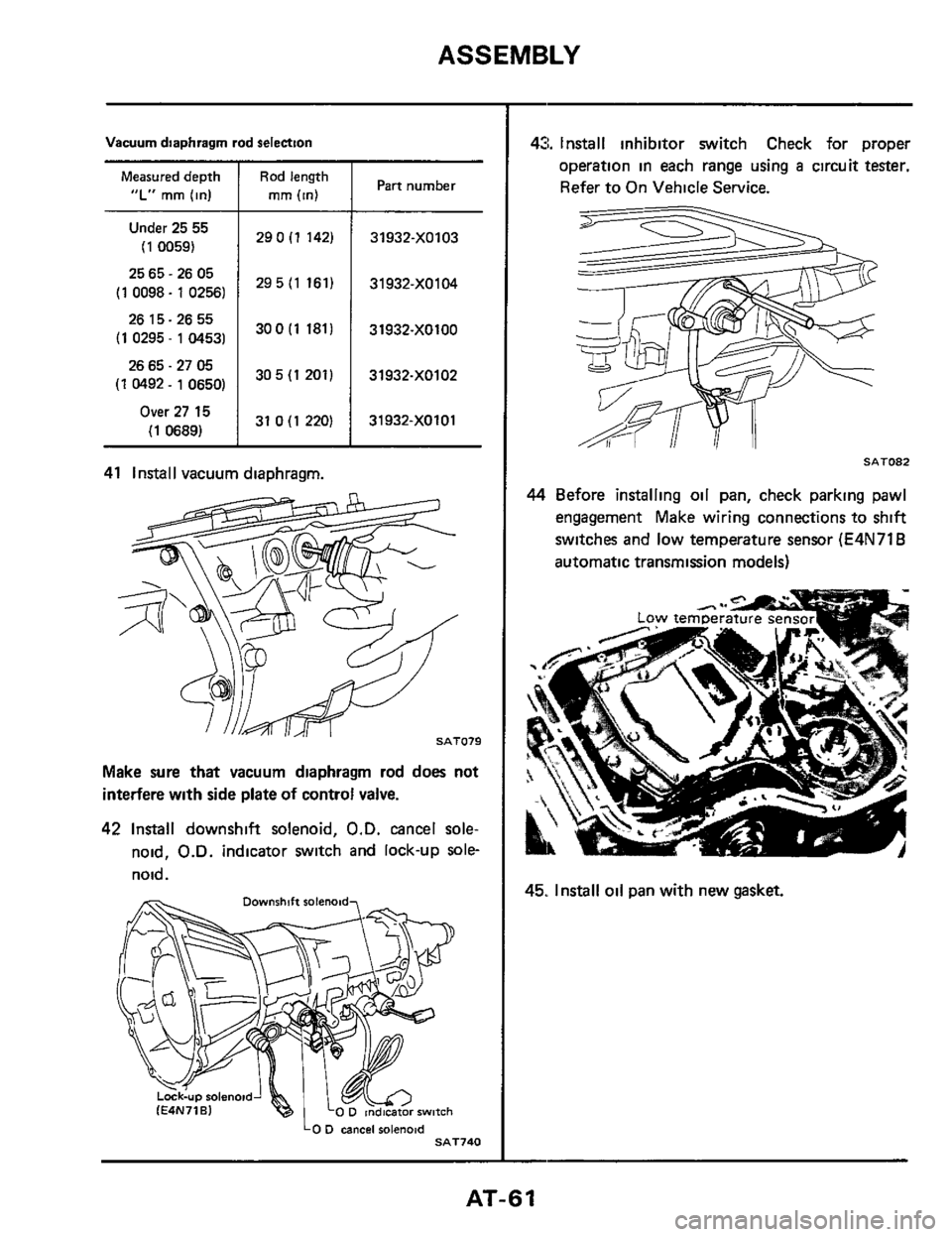

Vacuum diaphragm rod selection

31932-XO103

31932-X0104

31932-XOlOO

31932-X0102

31932-XOlOl

Measured depth

“L” mm (in)

Under 25 55

(1 0059)

25 65

- 26 05

(1

0098 - 1 02561

2615-2655

(1 0295 - 1 04531

26 65.27 05

(1 0492

- 1 0650)

Over 27 15

(1 0689)

Rod length

mm (in) Part number

41 Install vacuum diaphragm.

Make sure that vacuum diaphragm rod does not

interfere with side plate

of control valve.

42 Install downshift solenoid, O.D. cancel sole-

noid, O.D. indicator switch and lock-up sole-

noid.

LO D csncei rolenoid SAT740

43. Install inhibitor switch Check for proper

operation in each range using

a circuit tester.

Refer to On Vehicle Service.

Y li

SAT082

44 Before installing oil pan, check parking pawl

engagement Make wiring connections to shift

switches and low temperature sensor

(E4N71B

automatic transmission models)

45. Install oil pan with new gasket.

-

AT-61