oil NISSAN 300ZX 1984 Z31 Steering System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1984, Model line: 300ZX, Model: NISSAN 300ZX 1984 Z31Pages: 20, PDF Size: 0.7 MB

Page 1 of 20

STEERING SYSTEM

I---

SECTION ST

CONTENTS

STEERING SYSTEM . . . ... ..

STEERING COLUMN . . . .... ..

POWER STEERING SYSTEM -Checking - . ..

POWER STEERING GEAR AND LINKAGE

POWER STEERING

OIL PUMP . .. ... ..

SERVICE DATA AND SPECIFICATIONS (S D S ) . . . . . . . .

SPECIAL SERVICE TOOLS . .. .. ..

Refer to section MA for:

CHECKING WHEEL ALIGNMENT

Toe-in

Front wheel turning angle

BASIC MECHANICAL SYSTEM

Checking drive belts

. ST- 2

ST- 4

.. ST- 6

. . ST- 8

ST-14

. .. .. ST-17

. . . ST-20

Page 2 of 20

STEERING SYSTEM

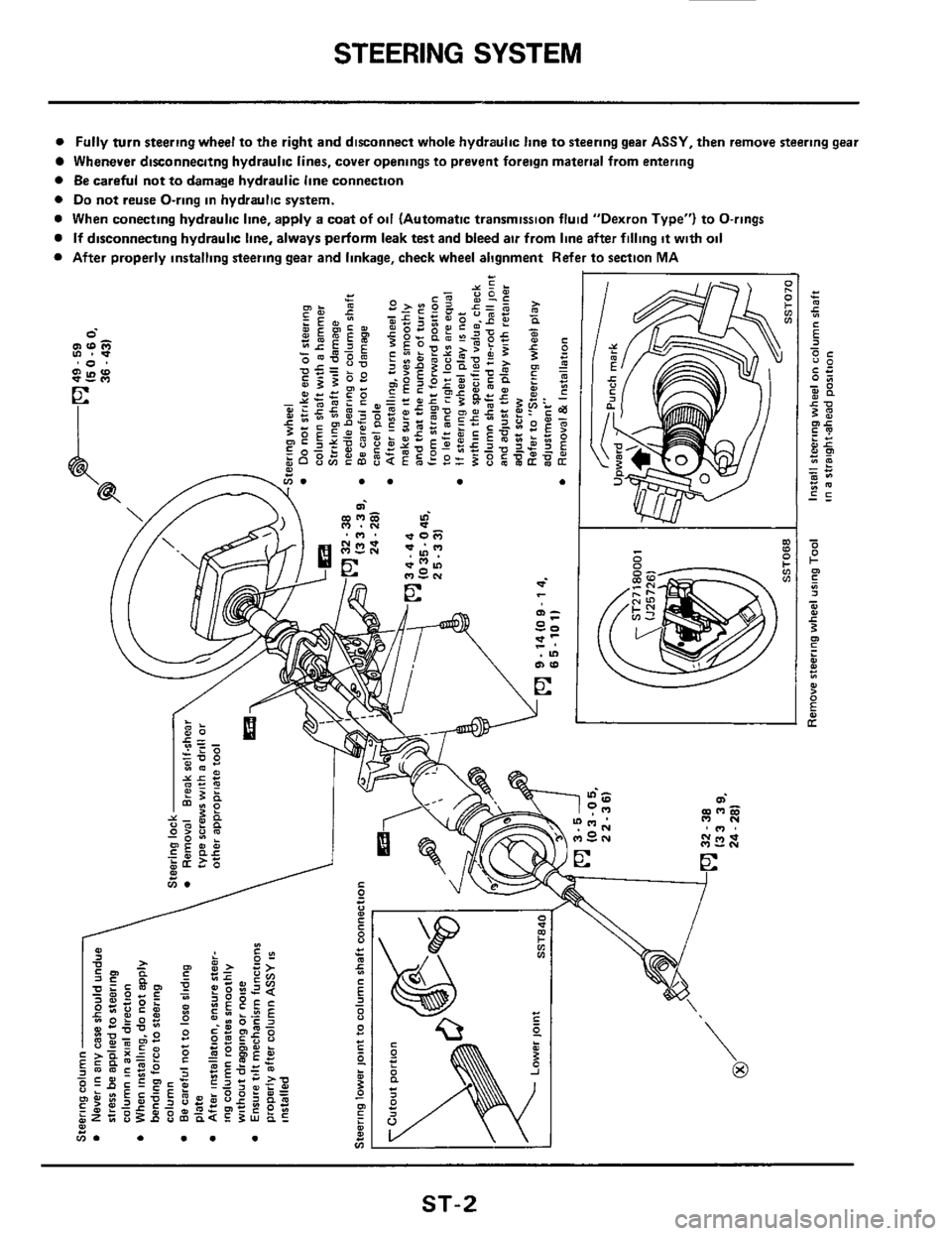

a Fully turn steering wheel to the right and disconnect whole hydraulic line to steering gear ASSY. then remove steering gear

Whenever dirconnecitng hydraulic lines, cover openings to prevent foreign material from entering

a Be careful not to damage hydraulic line connection

a Do not reuse O-ring in hydraulic system.

a When conecting hydraulic line, apply a coat of oil (Automatic transmission fluid "Dexron Type") to O-rings

If disconnecting hydraulic line. always perform leak test and bleed air from line after filling it with oil

a After properly installing steering gear and linkage, check wheel alignment Refer to section MA

ST-2

Page 6 of 20

POWER STEERING SYSTEM -Checking

Fluid Level Check

Check the fluid level when the fluid IS cold.

Refer to MA section

Power Steering Pump

Belt Tension

Refer to MA section

Fluid Leakage Check

1 Run engine at idle speed or 1,000 rpm

Make sure temperature of fluid

in tank rises to

60 to 80°C (140 to 176°F).

2 Turn steering wheel to right-to-left several

times

3 Hold steering wheel at each "lock" position for

five seconds

and carefully check for fluid

leakage

CAUTION :

0 Do not hold steering wheel at "lock" position

for more than 15 seconds at a time.

0 If fluid leaks at connectors, replace O-ring (if

equipped) Do not overtighten connector as

this can damage O-ring and connector.

- Bleeding Hydraulic System -

1. Raise front end of vehicle until wheels clear

ground

2 While adding fluid, quickly turn steering wheel

fully to right and

left and lightly touch steering

stoppers.

Repeat steering wheel operation until fluid

level no

longer decreases

Repeat step 2 above

3. Start engine.

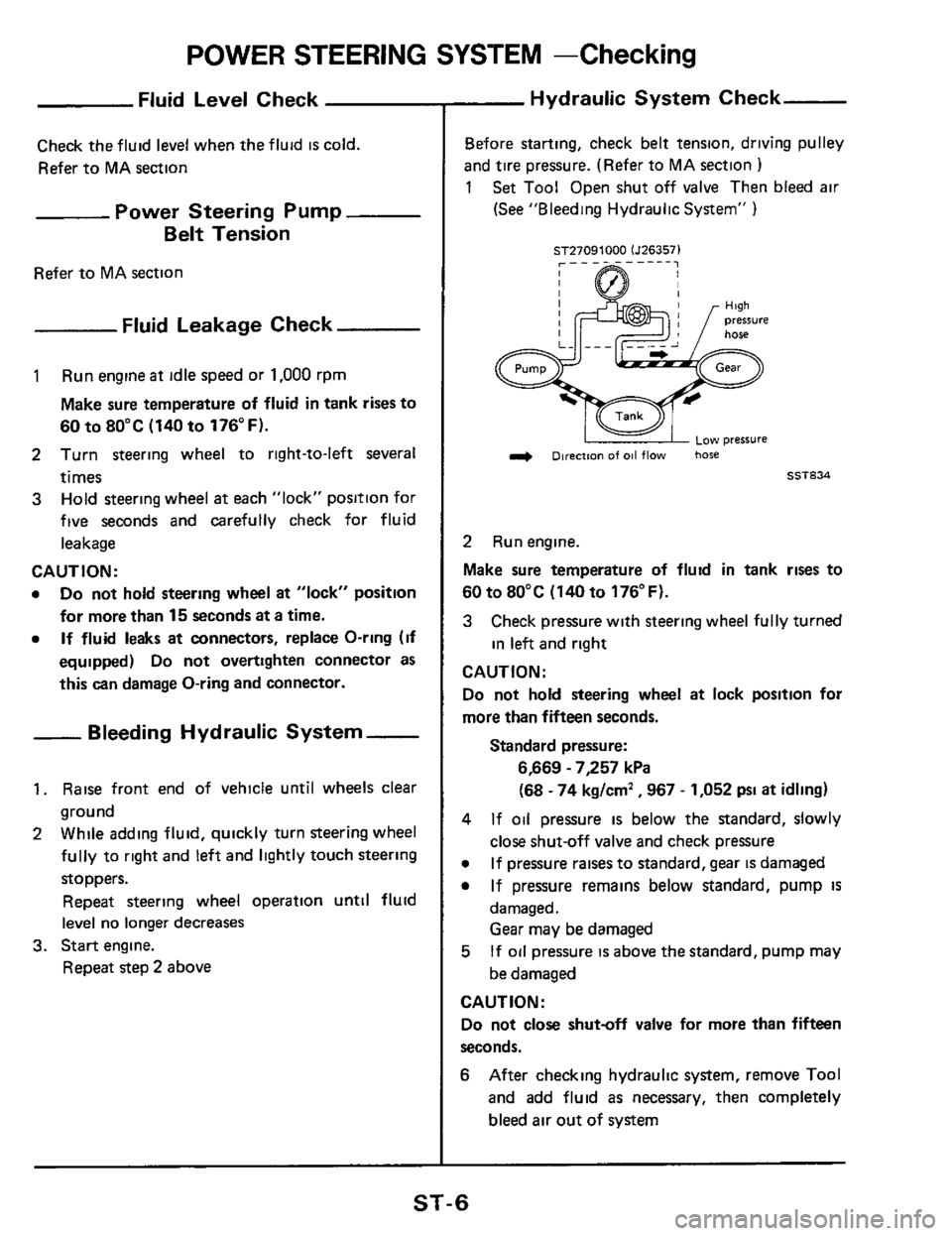

Hydraulic System Check

Before starting, check belt tension, driving pulley

and tire pressure. (Refer to MA section )

1 Set Tool Open shut off valve Then bled air

(See "Bleeding Hydraulic System" )

ST27091000 lJ263571

L 1 ow pressure

& Direction of 011 flow hose

ET834

2 Run engine.

Make sure temperature of fluid in tank rises to

60 to 80°C

(140 to 176°F).

3 Check pressure with steering wheel fully turned

in left and right

CAUTION:

Do not hold steering wheel at lock position for

more than fifteen seconds.

Standard pressure:

6,669 - 7,257 kPa

(68

- 74 kglcm' ,967 - 1,052 psi at idling)

4

0

0

If oil pressure is below the standard, slowly

close shut-off valve and check pressure

If pressure raises to standard, gear is damaged

If pressure remains below standard, pump

IS

damaged.

Gear may be damaged

If oil pressure is above the standard, pump may

be damaged 5

CAUTION:

Do not close shutoff valve for more than fifteen

seconds.

6 After checking hydraulic system, remove Tool

and add fluid as necessary, then completely

bleed

air out of system

ST-6

Page 8 of 20

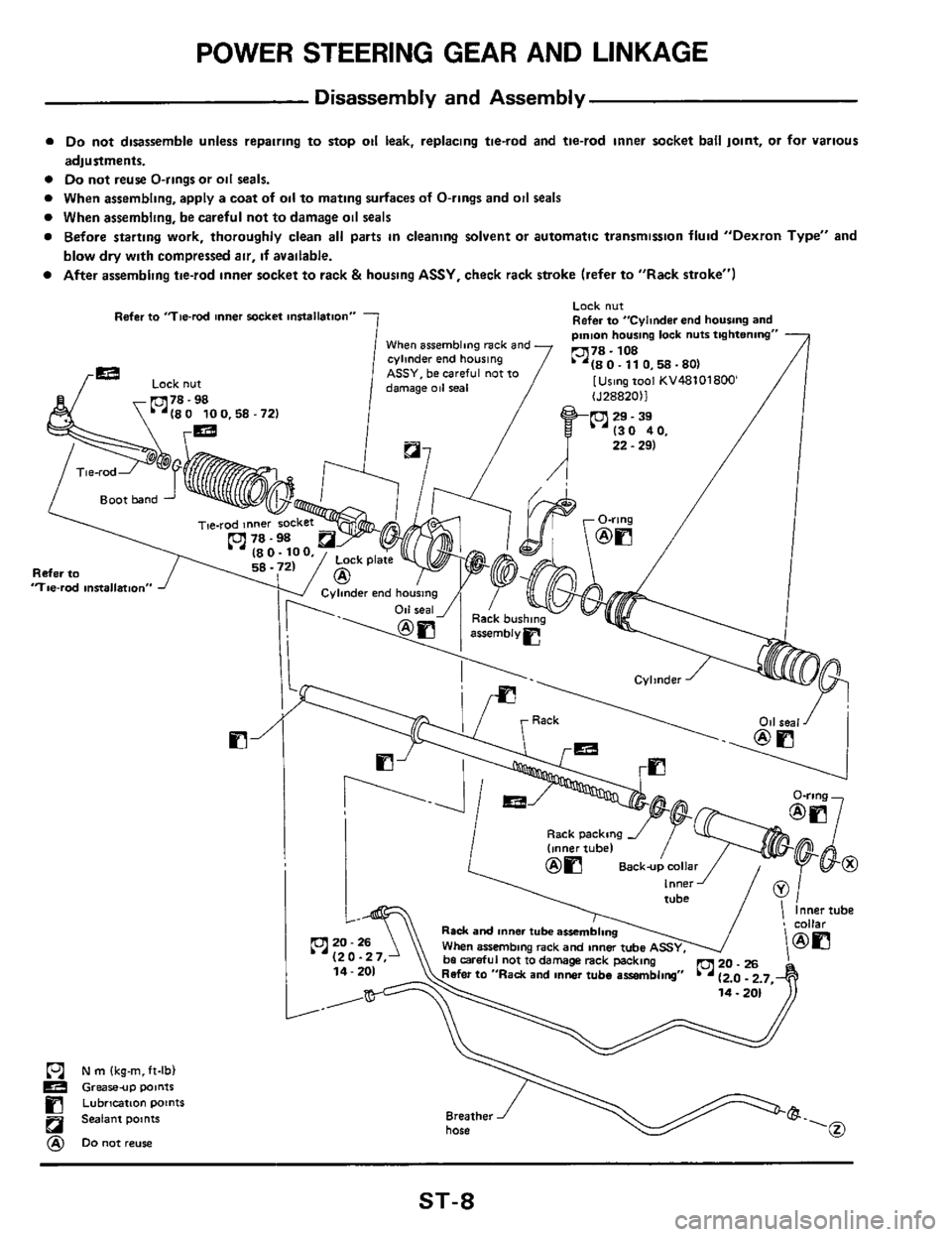

POWER STEERING GEAR AND LINKAGE

Disassembly and Assembly

0 Do not disassemble unless repairing to stop oil leak, replacing tie-rod and tie-rod inner rocket ball joint, or for various

adjustments.

0 Do not reuse O-rings or oil seals.

0 When assembling, apply a coat of oil to mating surfaces of O-rings and 011 seals

0 When assembling, be careful not to damage oil seals

0 Before starting work, thoroughly clean all parts in cleaning solvent or automatic transmission fluid "Dexron Type" and

blow dry with compressed air, if available.

0 After assembling tie-rod inner socket to rack & housing ASSY, check rack stroke (refer to "Rack stroke")

Lock nut

Refer to "Cylinder end housing and Refer to 'Tie-md inner Locket mtallation"

7 .... . . , . pmon housing lock nuts tight !e","." -

&?; '(80 100.58-72)

78.108

[Using tool KV48101800

when assembling ram ana cylinder end housing ASSY, becareful not to damage 011 seal

"18 0.11 0,58.80)

e]'

/ I

Refer to

'Tne-rod ,"stallatlo""

, collar

' @,e3

14.20)

be careful not to damage rack packing inner tube anernblong" (91 (2.0.2.7.

I.

Rad. and inner tubearrrnblmg

pjl N m (kgm. ft-lb)

Greaseup winti

e] Lubrication points

@ Donot reuse a

ST-8

Page 10 of 20

POWER STEERING GEAR AND LINKAGE

Disassembly and Assembly (Cont'd)

0 Refer to "Tie-rod inner socket installation",

"Tie-rod installation", and "Rack stroke"

-

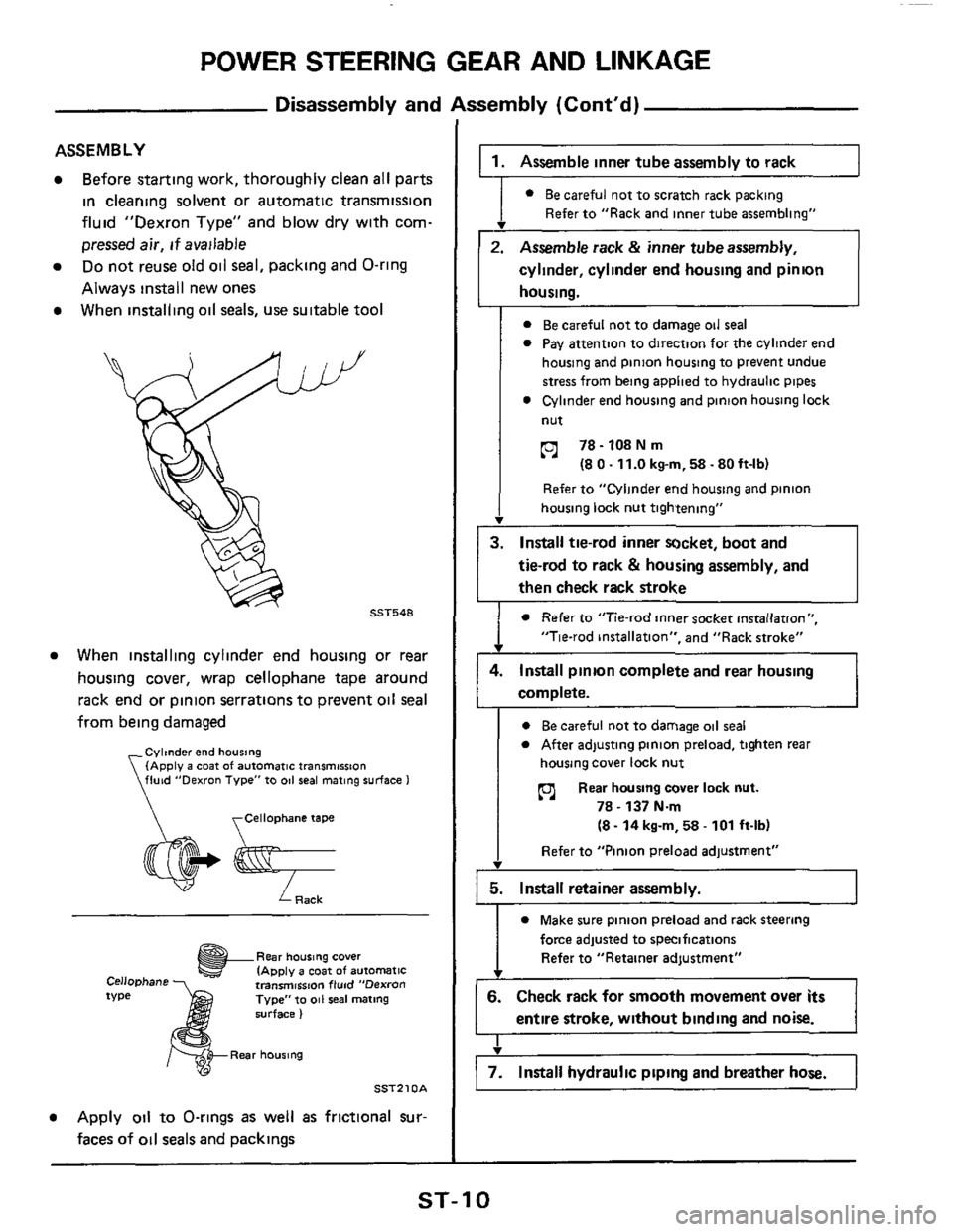

ASSEMBLY

Before starting work, thoroughly clean all parts

in cleaning solvent or automatic transmission

fluid "Dexron Type" and blow dry with com-

pressed air,

if available

Do not reuse old oil seal, packing and O-ring

Always

install new ones

When installing oil

seals, use suitable tool

SST548

When installing cylinder end housing or rear

housing cover, wrap cellophane tape around

rack end

or pinion serrations to prevent oil seal

from being damaged

Cylmder end housing (Apply a coat of automatrc transmission fluid "Oexron Type" to 081 seal mating surface I

rCellophane tape

a- - Rack

Rear housng cover IA~ply a coat of automatic transmission fluid "Dexron Type" to 011 seal mating

SSTZlOA

Apply oil to O-rings as well as frictional sur.

faces of oil

seals and packings

Refer to "Rack and inner tube assembling" v

2. Assemble rack & inner tube assembly,

cylinder, cylinder end housing and pinion

housina.

I 0 Be careful not to damage oil seal

0 Pay attention to dlrection for the cylinder end

housing and pinion housing to prevent undue

stress from being applied to hydraulic pipes

0 Cylinder end housing and pinion housing lock

nut

p1 78-108Nm

(8 0 . 11.0 kg-m, 58 - 80 ft-lb)

Refer to "Cylinder end housing and pinion

housing lock nut tightening"

4. Install pinion complete and rear housing

complete.

I

0 Be careful not to damage oil seal

0 After adjusting pinion preload, tighten real

housing cover lock nut

p1 78 - 137 N.m

(8 - 14 kg-m, 58. 101 ft-lbl

Rear housing cover lock nut.

Refer to "Pinion preload adjustment"

5. Install retainer assembly.

force adjusted to specifications

Refer to "Retainer adjustment"

6. Check rack for smooth movement over its

entire stroke, without binding and noise. I

7. Install hydraulic piping and breather hose.

ST- 1 0

Page 14 of 20

![NISSAN 300ZX 1984 Z31 Steering System Workshop Manual POWER STEERING OIL PUMP

Connector Ispool cover1 Flexible hose

69-78

38.52 mi70-8051 1 A Washe2 Connector bolt

7 . I 0 9- 12 (09.12.65 -871 13 9.5 3,28 - 381

s,,rr,nn ",no.... I

36-51] --I ..I NISSAN 300ZX 1984 Z31 Steering System Workshop Manual POWER STEERING OIL PUMP

Connector Ispool cover1 Flexible hose

69-78

38.52 mi70-8051 1 A Washe2 Connector bolt

7 . I 0 9- 12 (09.12.65 -871 13 9.5 3,28 - 381

s,,rr,nn ",no.... I

36-51] --I ..I](/img/5/578/w960_578-13.png)

POWER STEERING OIL PUMP

Connector Ispool cover1 Flexible hose

69-78

38.52 mi7'0-80'51 1 A Washe2 Connector bolt

7 . I 0 9- 12 (09.12.65 -871 13 9.5 3,28 - 381

s,,rr,nn ",no.... I

36-51] --I ..I.. r,r_

re switch (Non-turbocharged model)

Htgh-pressure ride

hydraultc

line pressure

1,961

- 2,942 kPa

(20.30 kg/cm' ,

Decreasing to aPProx

Turn ON

981 -2,942 kPa

(10 - 30 kg/cm' ,

142-427~511 1

42 I3 2 -43.23- 31)

L Pulley shaft (When assembling pulley shaft. be careful

not to damage oil seal lip1 seal

am

(41 31 -42 13.2 - 4.3, 23 - 311 (41 N m (kg-m. ft-lb)

fl Lubricatzon points (with automatic transmission fluid "Dexron Type") @ ~onotreu~

- Pre-disassembly Inspection

The power steering oil pump should be disassem-

bled only

d any of the following conditions are

ObSWVed.

Oil leak at the following points

SST126A

Deformed or damaged pulley

SST220A

Oil Pump Installation

mounting bracket

steering pump

(41 N m (kgm, ft-lbl

SST221A

m16-21 (1.6-21,

12.15)

After installing oil pump, adjust belt tension.

Refer to MA section.

ST-1 4

Page 15 of 20

POWER STEERING OIL PUMP

Diassernbl y

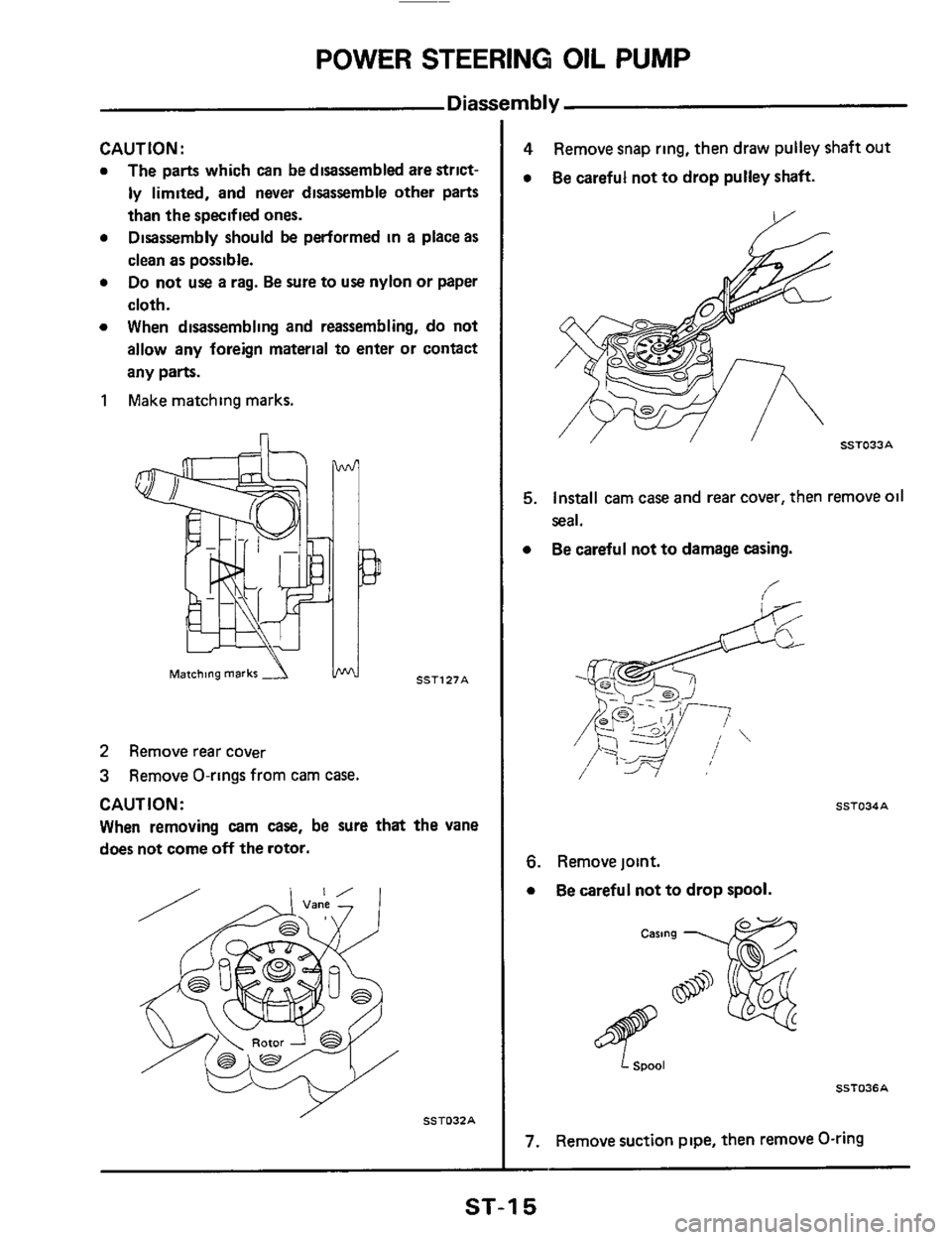

CAUTION:

a The parts which can be disassembled are strict-

ly limited, and never disassemble other parts

than the specified ones.

Disassembly should be performed in

a place as

clean as possible.

Do not use a rag. Be sure to use nylon or paper

cloth.

When disassembling and reassembling, do not

allow any foreign material to enter

or contact

any parts.

a

a

a

1 Make matching marks.

Matchmg marks 4 SSTl27A

2 Remove rear cover

3

CAUTION :

When removing cam case, be sure that the vane

does not come

off the rotor.

Remove O-rings from cam case.

SSTO32A ,

4

a

Remove snap ring, then draw pulley shaft out

Be careful not

to drop pulley shaft.

SST033A

5. Install cam case and rear cover, then remove 011

seal.

Be careful not to damage casing.

0

f

SST034A

6. Remove joint.

0 Be careful not to drop spool.

L spool

SSTOJSA

7. Remove suction pipe, then remove O-ring

ST-1 5

Page 16 of 20

POWER STEERlNG OIL PUMP

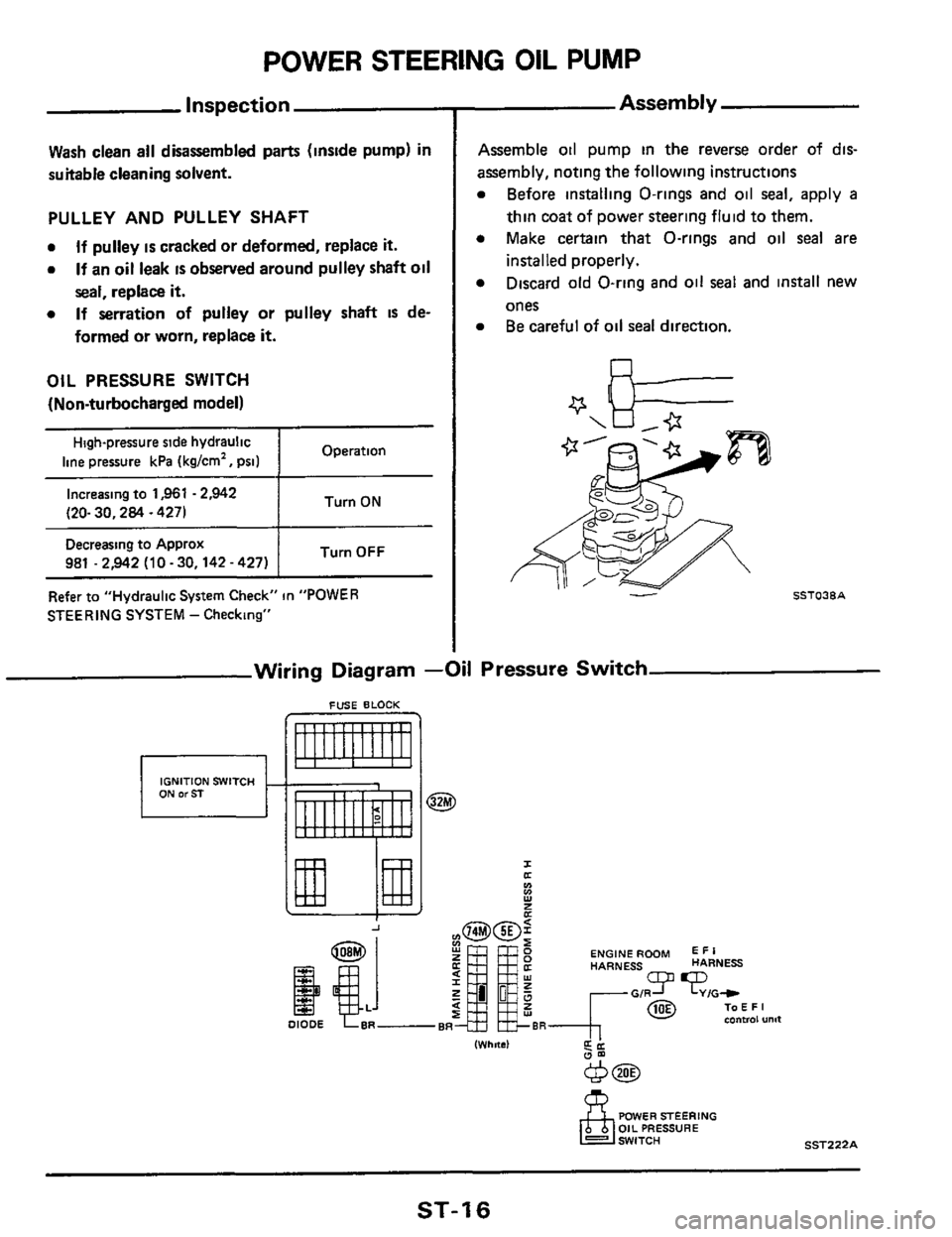

Inspection

Wash clean all disassembled parts (inside pump) in

suitable cleaning solvent.

PULLEY AND PULLEY SHAFT

0

0

If pulley is cracked or deformed, replace it.

If an oil leak IS observed around pulley shaft oil

seal, replace it.

If serration of pulley or pulley shaft IS de-

formed

or worn, replace it.

0

OIL PRESSURE SWITCH

(Non-turbocharged model)

Operation High-pressure side hydraulic

line pressure kPa (kglcm', psi) ~~

I Turn ON Increasing to 1,961 - 2,942

(20- 30,284 ~ 4271

Turn OFF Decreasing to Approx

981 .2,942 (10 - 30,142 - 427)

Refer to "Hydraulic

System Check" in "POWER

STEERING SYSTEM

- Checking"

Assembly

Assemble 011 pump in the reverse order of dts-

assembly, noting the following instructions

Before installing O-rings and oil seal, apply a

thin coat of power steering fluid to them.

Make certain that O-rings and oil

seal are

installed properly.

Discard old O-ring and oil

seal and install new

ones Be careful of

oil seal direction.

Wiring Diagram -Oil Pressure Switch

FUSE BLOCK

IGNITION SWITCH

I a

Y

Ln v)

E

ENGINE ROOM E I R HARNESS HARNESS

IWhnsl d'

POWER STEERING OIL PRESSURE

SST222A

ST-1 6

Page 18 of 20

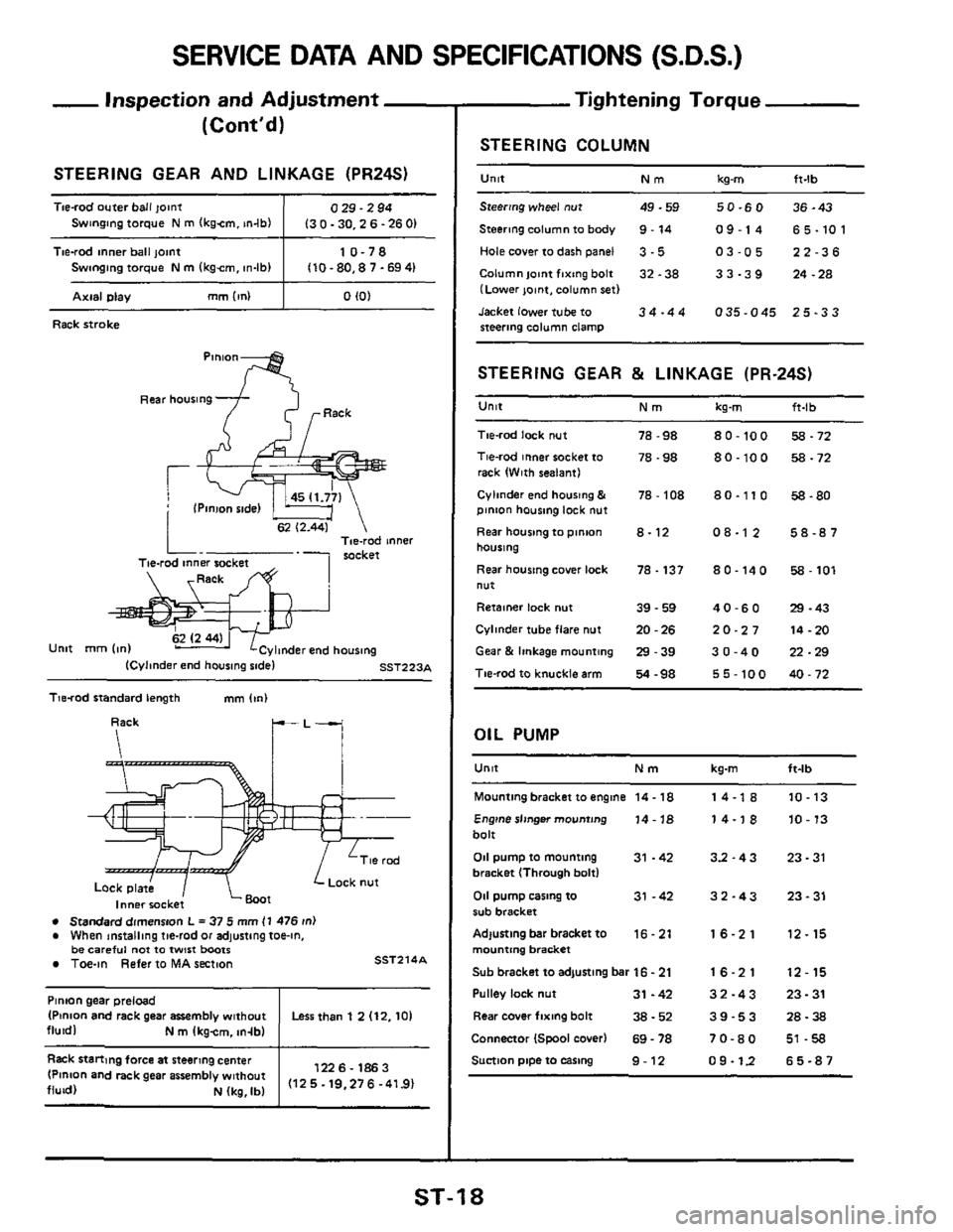

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

Tie-rod outer ball joint

Swinging torque N m (kgim. m4b)

- Inspection and Adjustment

(Cont'd)

0 29.2 94

I3 0.30,2 6.26

01 ~~~

Pinion gear

preload

(Ptnlon and rack gear assembly without

fluid1 N m Ikgcm, tn-lbl

Tie-rod inner ball joint 10-78 Swinging torque N m (kgem, in-lb) 110 - 80.8 7 .69 41

__~ ~

Less than 1 2 (12.10)

Axial Dlay mm (in) I 0 IO)

Rack stroke

Pinion

I' ? Pack

Rear housing

Tne-rod innel rocket Tie-rod inner socket

& .l

Unit mm Ion) linder end housina - ICyImder end hourmg sadel SST223A

Tie-rod standard length mm (In)

Inner rocket

8 Standard dimensnn L = 37 5 mm I1 476 ln) e When installing tie-rod or adjusting toe-in, be careful not Io twist boots Toe-in Refer to MA seCtion SST214A

1226- 1863

(12 5.19.276 -41.9) Rack stanmg force at steering center (Pinion and rack gear assembly without

fluid) N (kg. Ib)

Tightening Torque

STEERING COLUMN ~~~~

U"lt Nm kg-m ft-lb

Steering wheel nut 49-59 50-60 36-43

Steering column to

body 9 - 14 09-14 65-101

Hole cover to dash panel 3 .5 03-05 22-36

Columnlaintfixingbolt 32-38 33-39 24.28 (Lower joint, column set)

Jacket lower tube to

34-44 035-045 25-33 steering column clamp

STEERING GEAR & LINKAGE (PR-24s)

Unit Nm kg-m ft-lb

Tie-rod lock nut

Tie-rod inner socket to

rack (With sealant)

Cylinder end housmg

& pinion housmg lock nut

Rear housmg to pman

housing

Rear housing

cover lack

nut

Retainer lock nut

Cylinder tube flare nut

Gear & linkage mounting

Tie-rod

to knuckle arm

78 -98

78 -98

78 - 108

8-12

78.137

39 - 59

20

- 26

29-39

54 -98

80-100

80.100

80.110

08-1 2

80-140

40-60

20-27

30-40

55-100

58.72

58-72

58-80

58-87

Ea - 101

29 -43

14-20

22-29

40 - 72

OIL PUMP

U"lt Nm kg-m ft-lb

Mounting bracket to engine 14. 18

Engine sllnger mounting 14 - 18 bolt

011 pump to mounting 31 .42 bracket (Through bolt)

011 pump casing to 31 -42 rub bracket

Adlusting bar bracket

to 16.21 mounting bracket

Sub bracket to adjusting bar

16 - 21

Pulley lock nut 31 -42

Rear cover fixing bolt 38 - 52

Connector (Spool cover) 69 - 78

Suction piDe to easing 9-12

14-1 8

14-18

33-43

32-43

16-21

16-21

32-43

39-53

70-80

09-12

10-13

10

- 13

23 - 31

23 - 31

12-15

12-15

23.31

28-38

51

-58

65-87

ST-1 8

Page 19 of 20

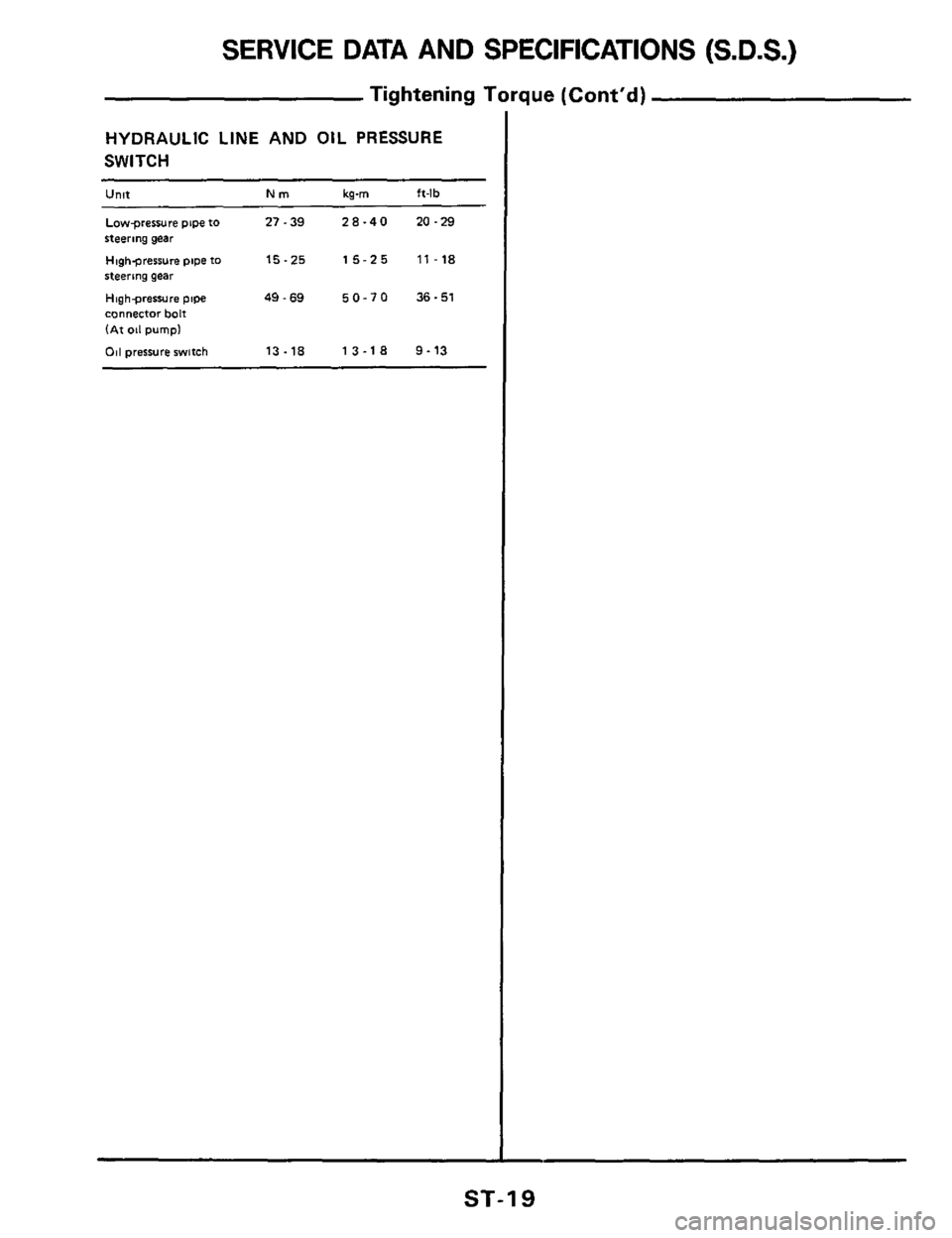

SERVICE DATA AND SPECIFICATIONS (S.D.S.)

Tightening Torque (Cont'd)

HYDRAULIC LINE AND OIL PRESSURE

SWITCH

U"lt Nm kg-m ft-lb

Lowpressure pipe to 27-39 28-40 20-29

Steering gear

Highpressure pipe to

15-25 15-25 11-18

steering gear

H ig hprerw re pipe 49 - 69 50-70 36-51

connector bolt

(At

011 pump1

011 pressure switch 13.18 13-18 9-13

ST-19