NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: power steering fluid, wheelbase, jump start terminals, maintenance schedule, jacking, Front brakes, fuel pressure

Page 1031 of 2898

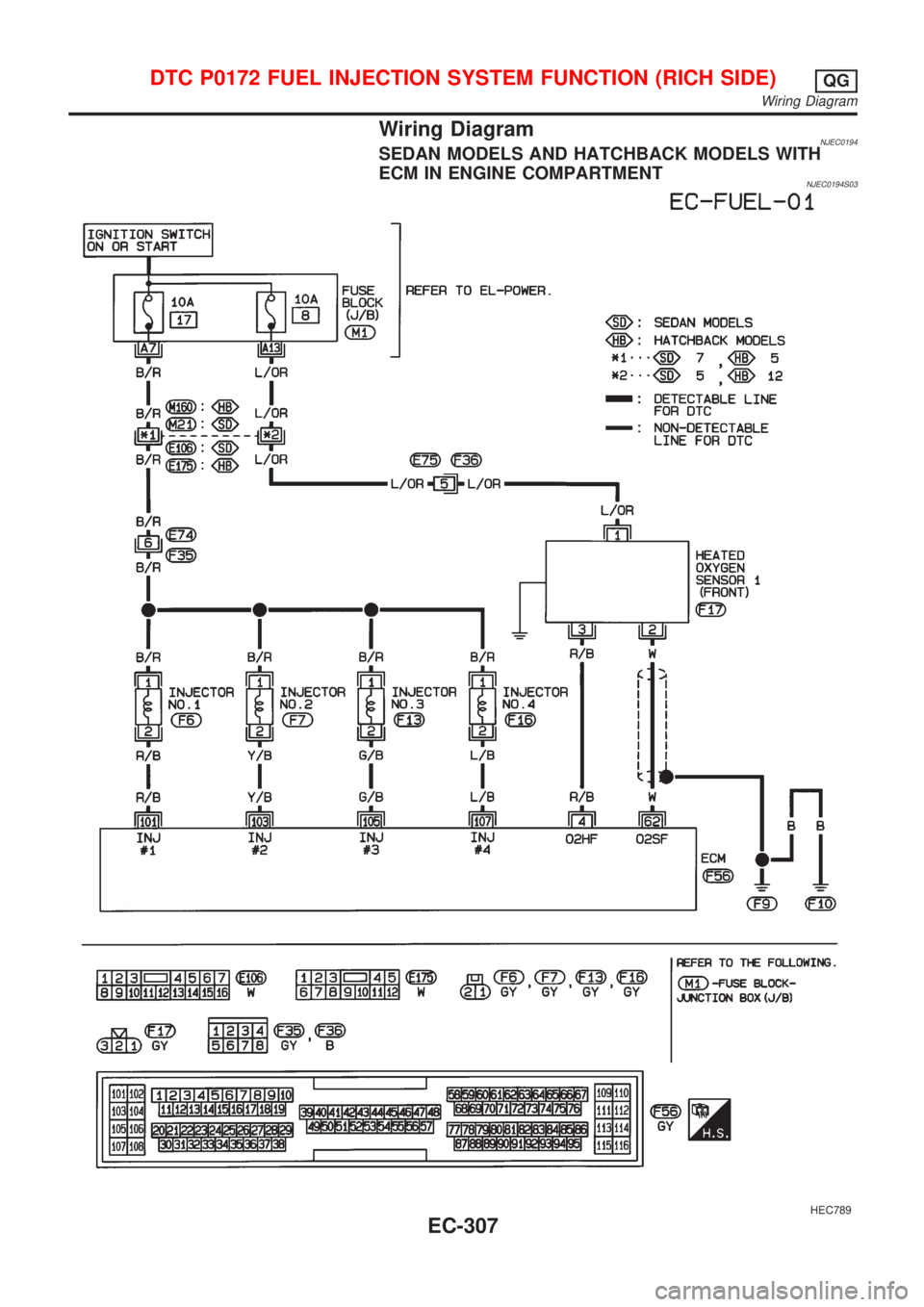

Wiring DiagramNJEC0194SEDAN MODELS AND HATCHBACK MODELS WITH

ECM IN ENGINE COMPARTMENT

NJEC0194S03

HEC789

DTC P0172 FUEL INJECTION SYSTEM FUNCTION (RICH SIDE)QG

Wiring Diagram

EC-307

Page 1032 of 2898

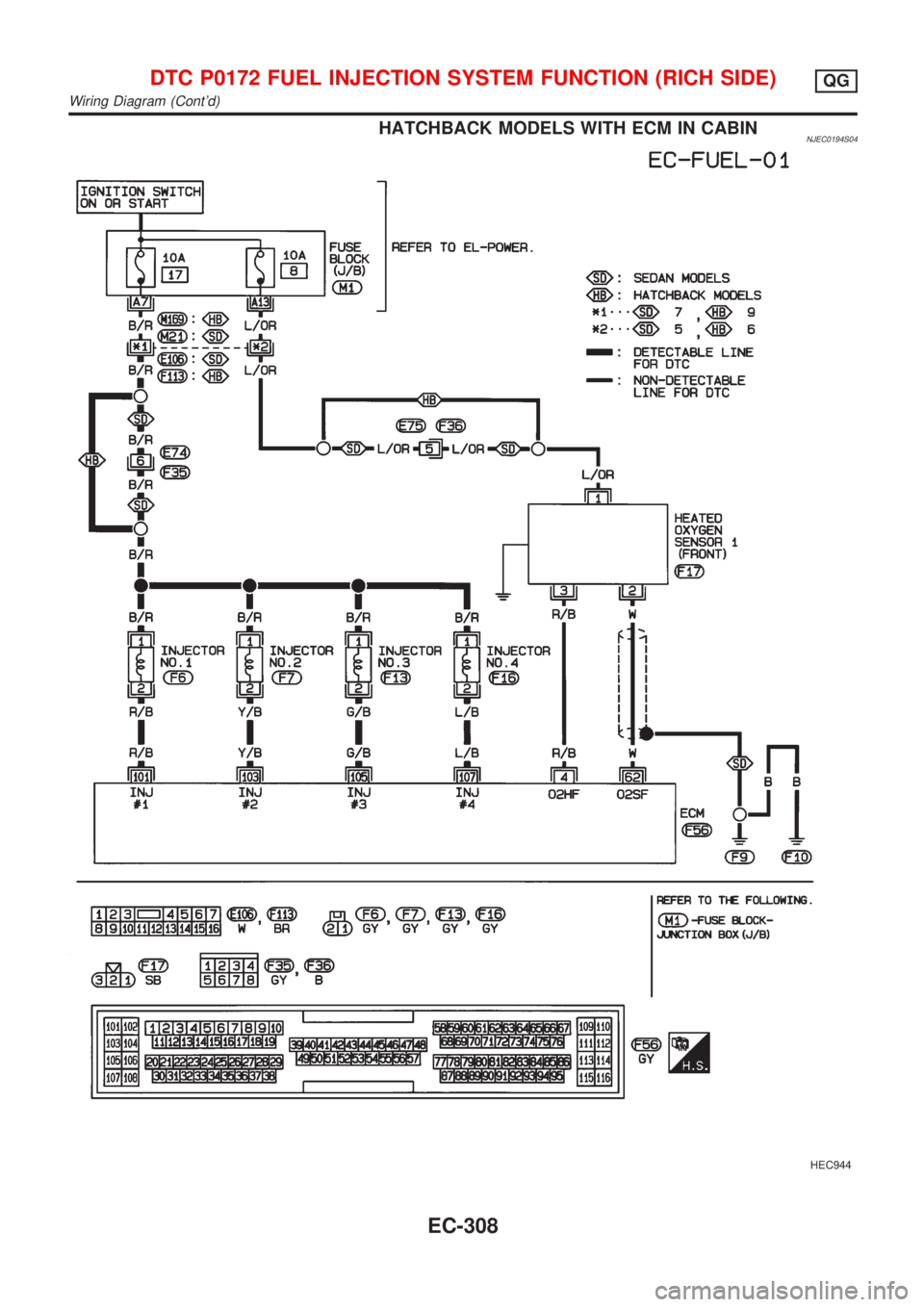

HATCHBACK MODELS WITH ECM IN CABINNJEC0194S04

HEC944

DTC P0172 FUEL INJECTION SYSTEM FUNCTION (RICH SIDE)QG

Wiring Diagram (Cont'd)

EC-308

Page 1033 of 2898

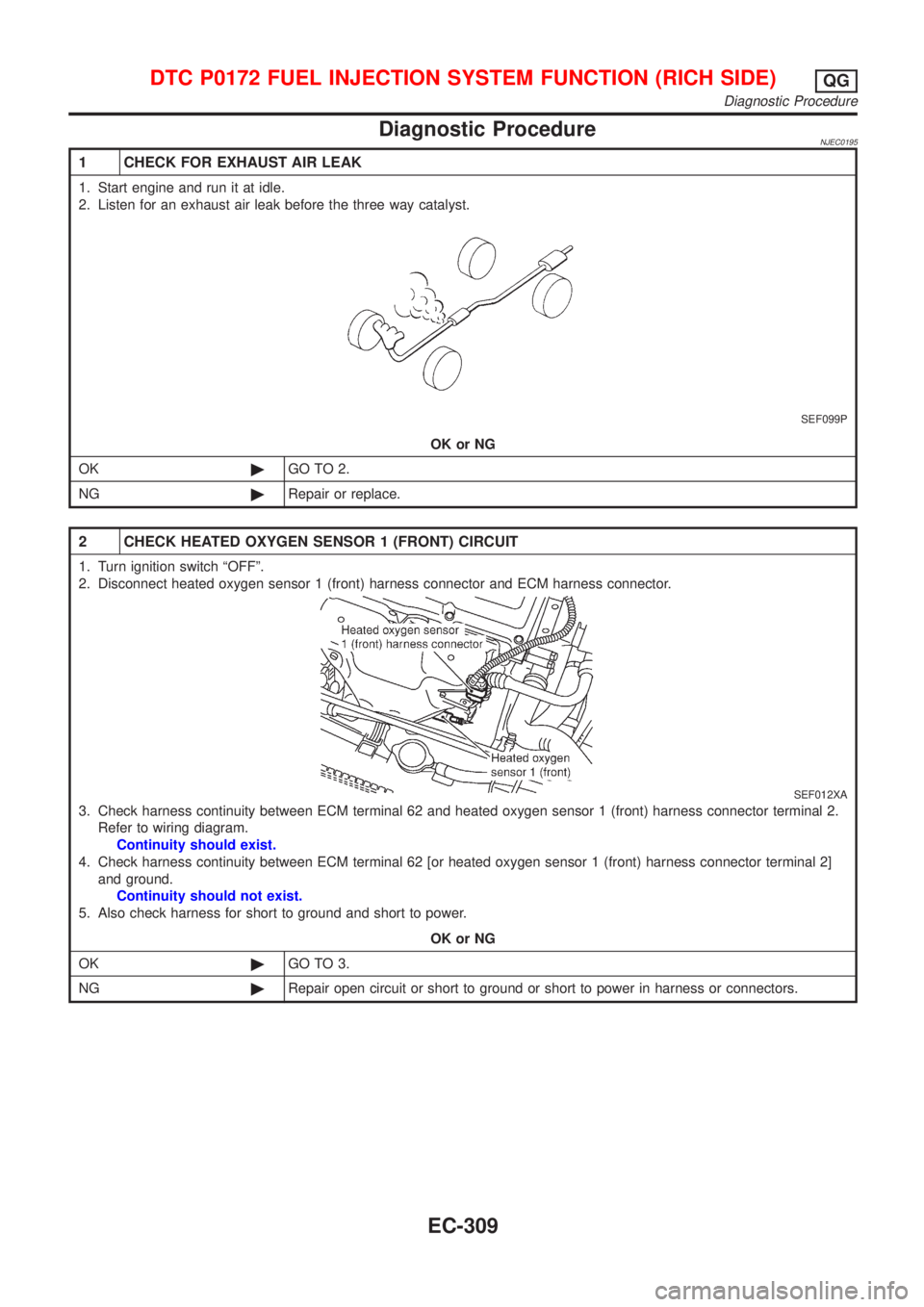

Diagnostic ProcedureNJEC0195

1 CHECK FOR EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before the three way catalyst.

SEF099P

OK or NG

OK©GO TO 2.

NG©Repair or replace.

2 CHECK HEATED OXYGEN SENSOR 1 (FRONT) CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF012XA

3. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between ECM terminal 62 [or heated oxygen sensor 1 (front) harness connector terminal 2]

and ground.

Continuity should not exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0172 FUEL INJECTION SYSTEM FUNCTION (RICH SIDE)QG

Diagnostic Procedure

EC-309

Page 1034 of 2898

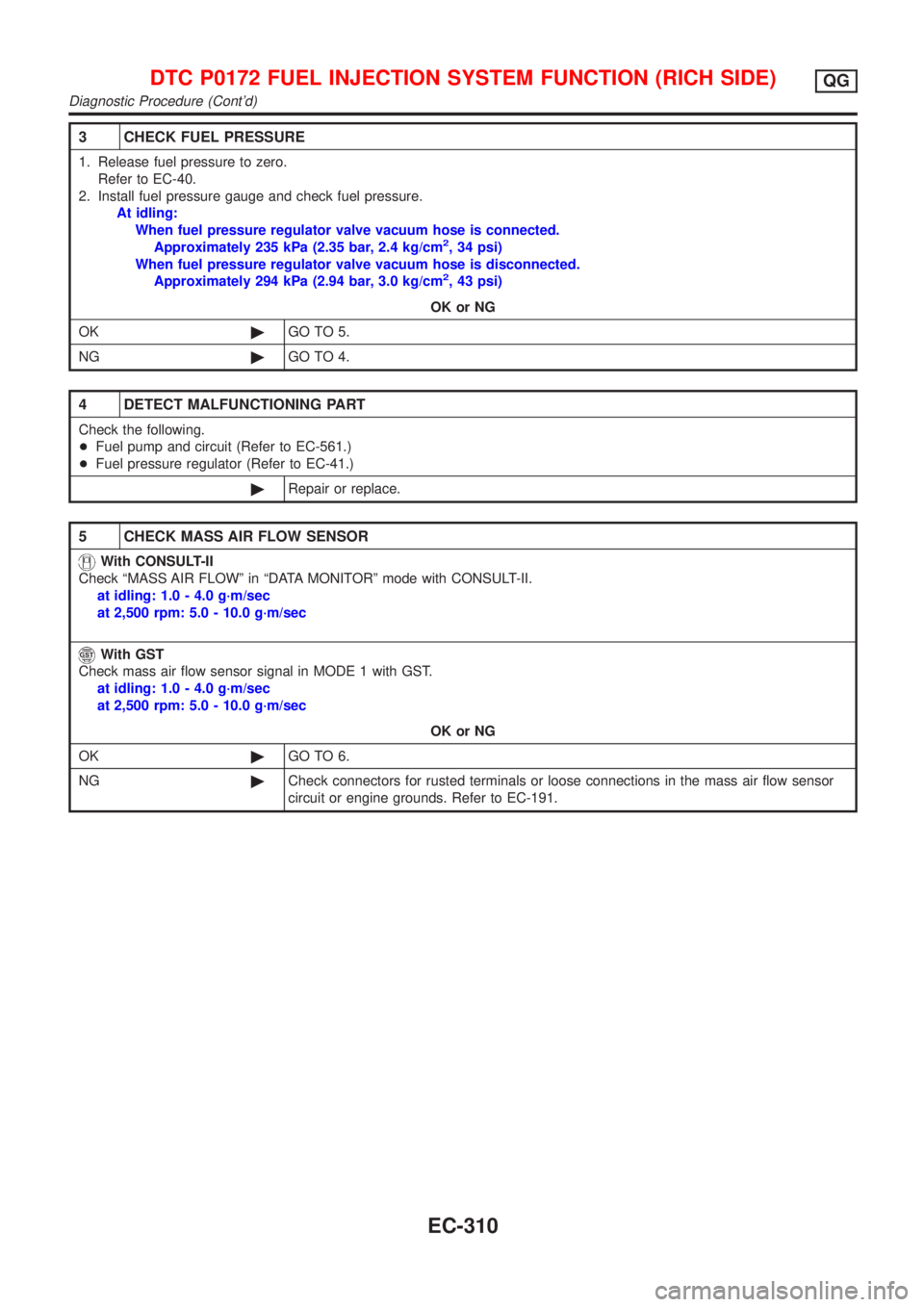

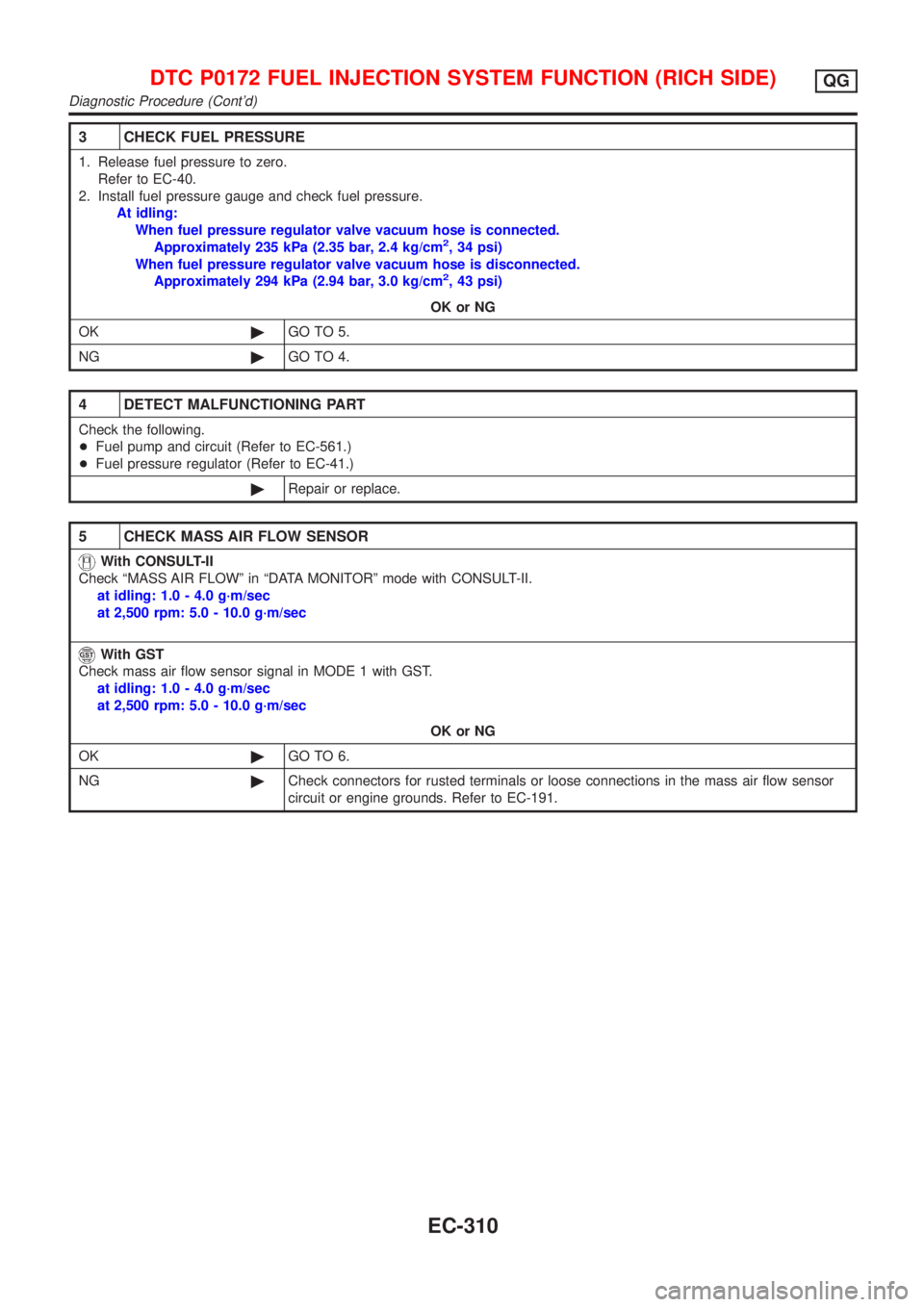

3 CHECK FUEL PRESSURE

1. Release fuel pressure to zero.

Refer to EC-40.

2. Install fuel pressure gauge and check fuel pressure.

At idling:

When fuel pressure regulator valve vacuum hose is connected.

Approximately 235 kPa (2.35 bar, 2.4 kg/cm

2, 34 psi)

When fuel pressure regulator valve vacuum hose is disconnected.

Approximately 294 kPa (2.94 bar, 3.0 kg/cm

2, 43 psi)

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Fuel pump and circuit (Refer to EC-561.)

+Fuel pressure regulator (Refer to EC-41.)

©Repair or replace.

5 CHECK MASS AIR FLOW SENSOR

With CONSULT-II

Check ªMASS AIR FLOWº in ªDATA MONITORº mode with CONSULT-II.

at idling: 1.0 - 4.0 g´m/sec

at 2,500 rpm: 5.0 - 10.0 g´m/sec

With GST

Check mass air flow sensor signal in MODE 1 with GST.

at idling: 1.0 - 4.0 g´m/sec

at 2,500 rpm: 5.0 - 10.0 g´m/sec

OK or NG

OK©GO TO 6.

NG©Check connectors for rusted terminals or loose connections in the mass air flow sensor

circuit or engine grounds. Refer to EC-191.

DTC P0172 FUEL INJECTION SYSTEM FUNCTION (RICH SIDE)QG

Diagnostic Procedure (Cont'd)

EC-310

Page 1035 of 2898

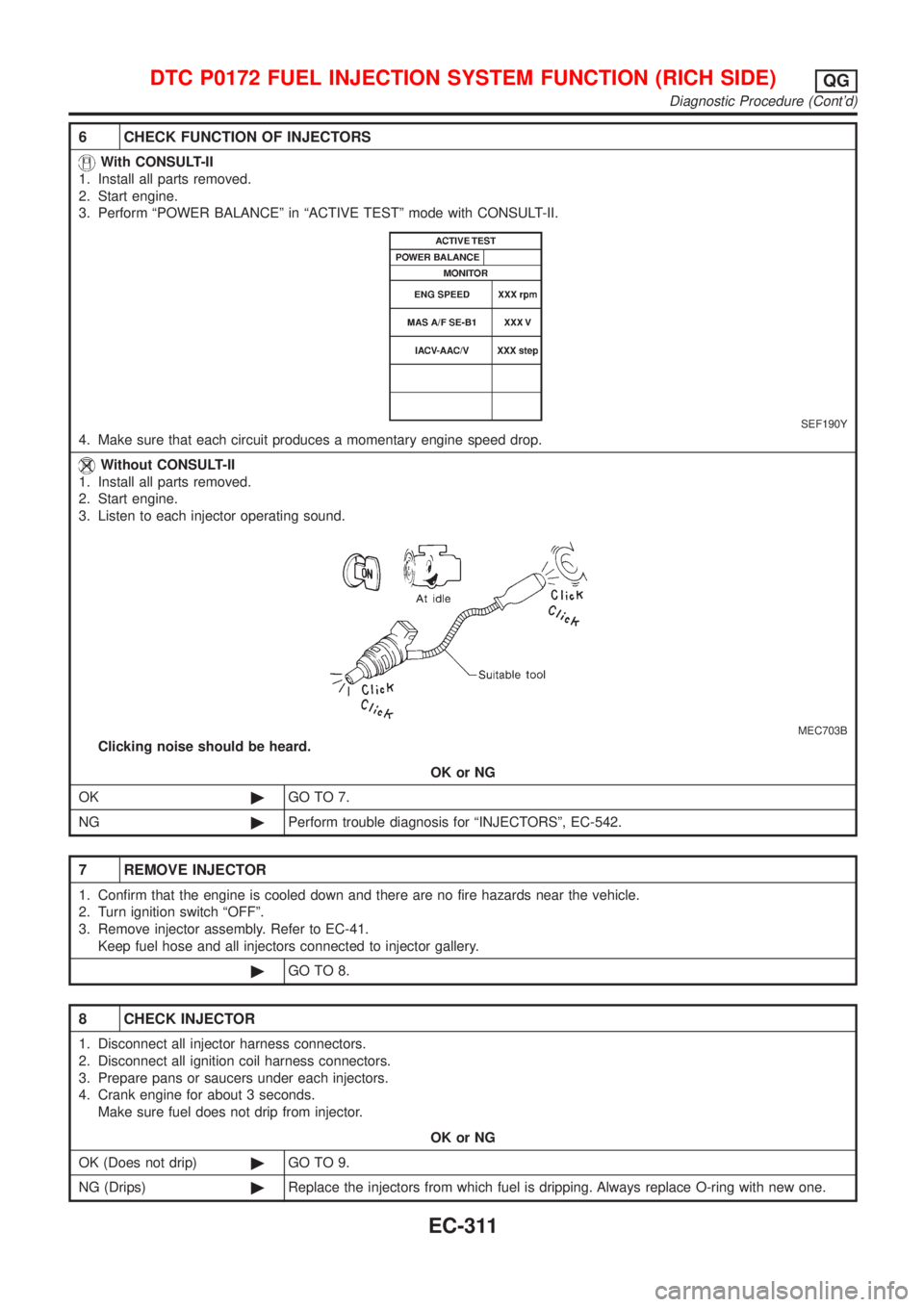

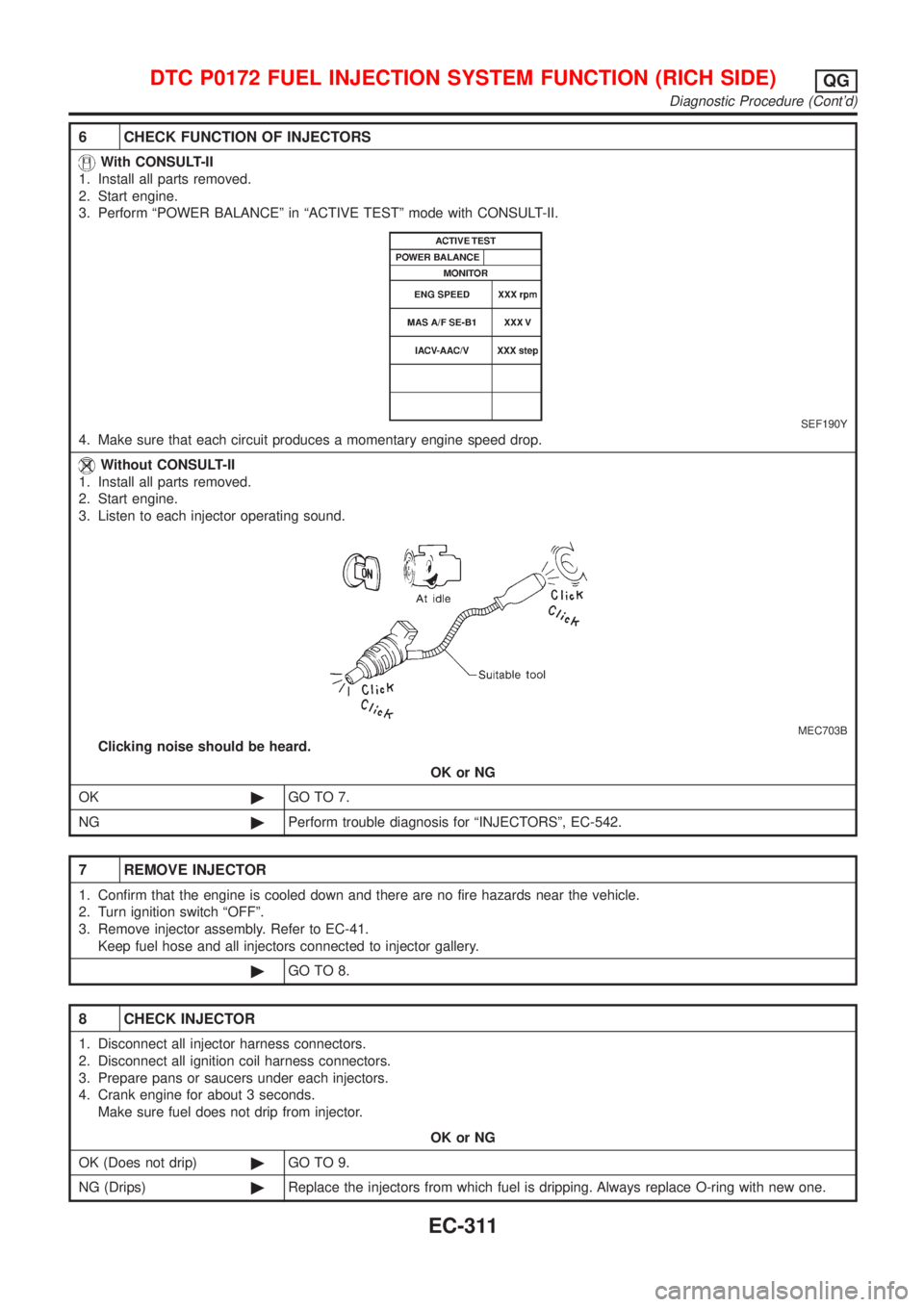

6 CHECK FUNCTION OF INJECTORS

With CONSULT-II

1. Install all parts removed.

2. Start engine.

3. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

SEF190Y

4. Make sure that each circuit produces a momentary engine speed drop.

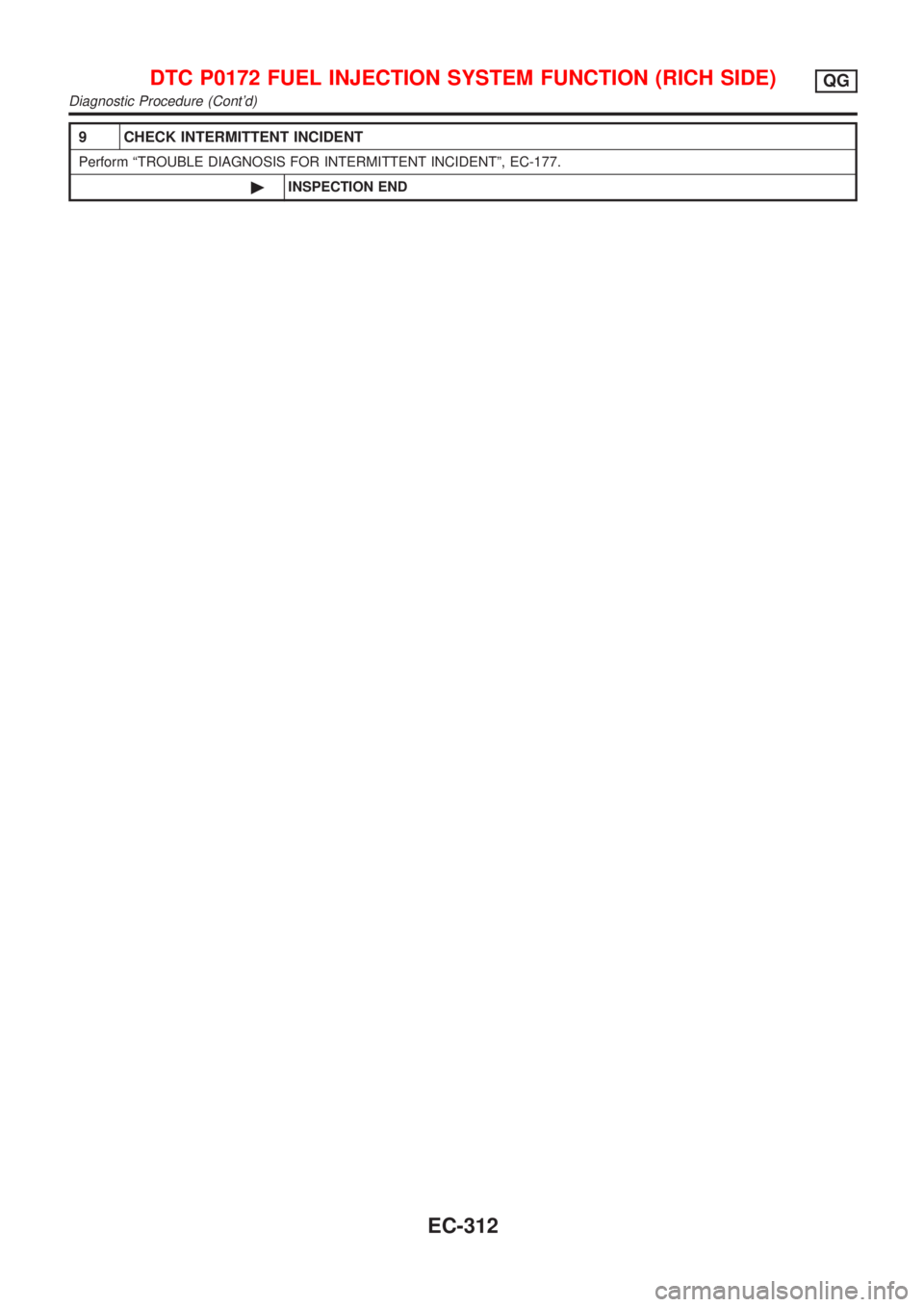

Without CONSULT-II

1. Install all parts removed.

2. Start engine.

3. Listen to each injector operating sound.

MEC703B

Clicking noise should be heard.

OK or NG

OK©GO TO 7.

NG©Perform trouble diagnosis for ªINJECTORSº, EC-542.

7 REMOVE INJECTOR

1. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

2. Turn ignition switch ªOFFº.

3. Remove injector assembly. Refer to EC-41.

Keep fuel hose and all injectors connected to injector gallery.

©GO TO 8.

8 CHECK INJECTOR

1. Disconnect all injector harness connectors.

2. Disconnect all ignition coil harness connectors.

3. Prepare pans or saucers under each injectors.

4. Crank engine for about 3 seconds.

Make sure fuel does not drip from injector.

OK or NG

OK (Does not drip)©GO TO 9.

NG (Drips)©Replace the injectors from which fuel is dripping. Always replace O-ring with new one.

DTC P0172 FUEL INJECTION SYSTEM FUNCTION (RICH SIDE)QG

Diagnostic Procedure (Cont'd)

EC-311

Page 1036 of 2898

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

DTC P0172 FUEL INJECTION SYSTEM FUNCTION (RICH SIDE)QG

Diagnostic Procedure (Cont'd)

EC-312

Page 1037 of 2898

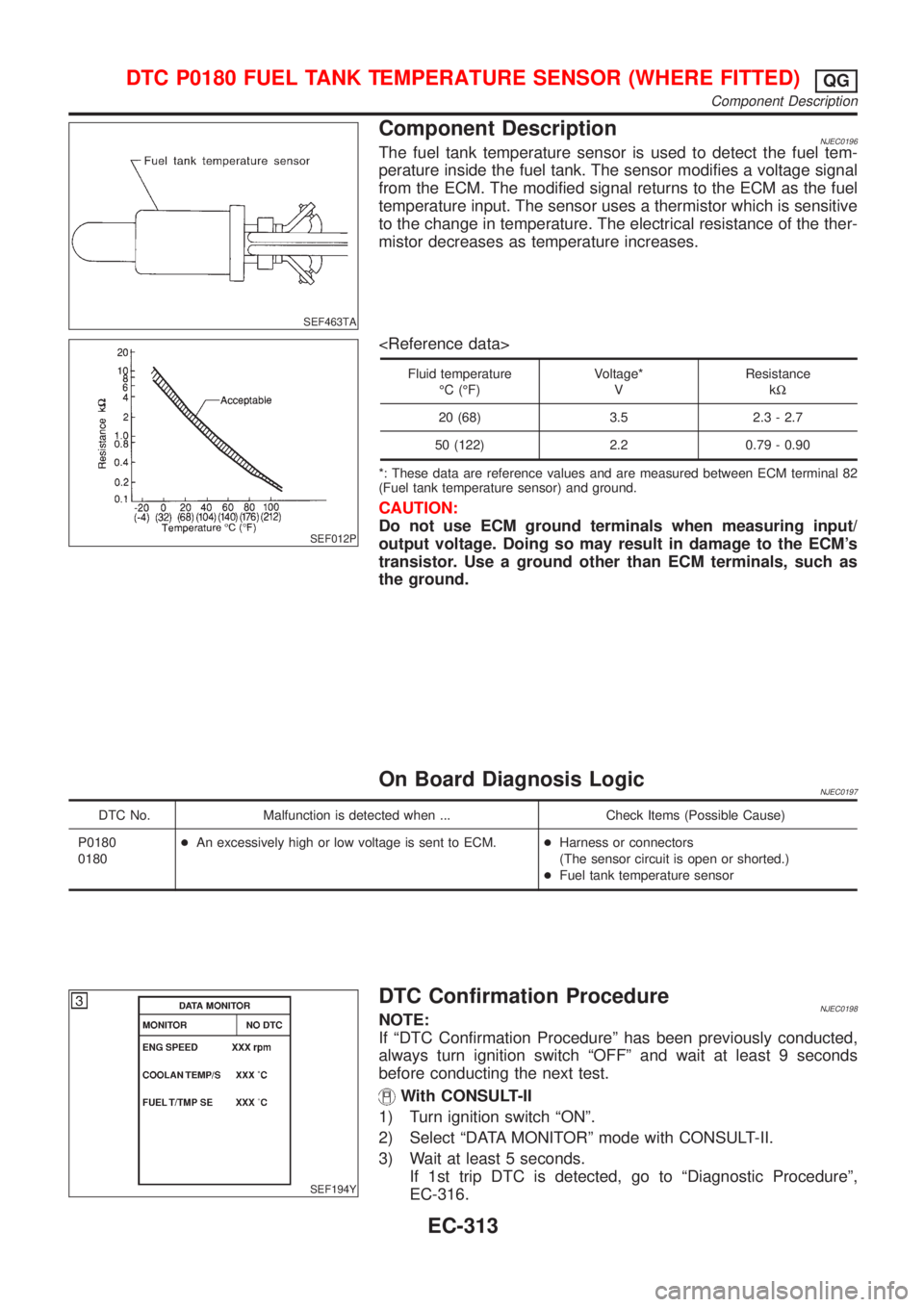

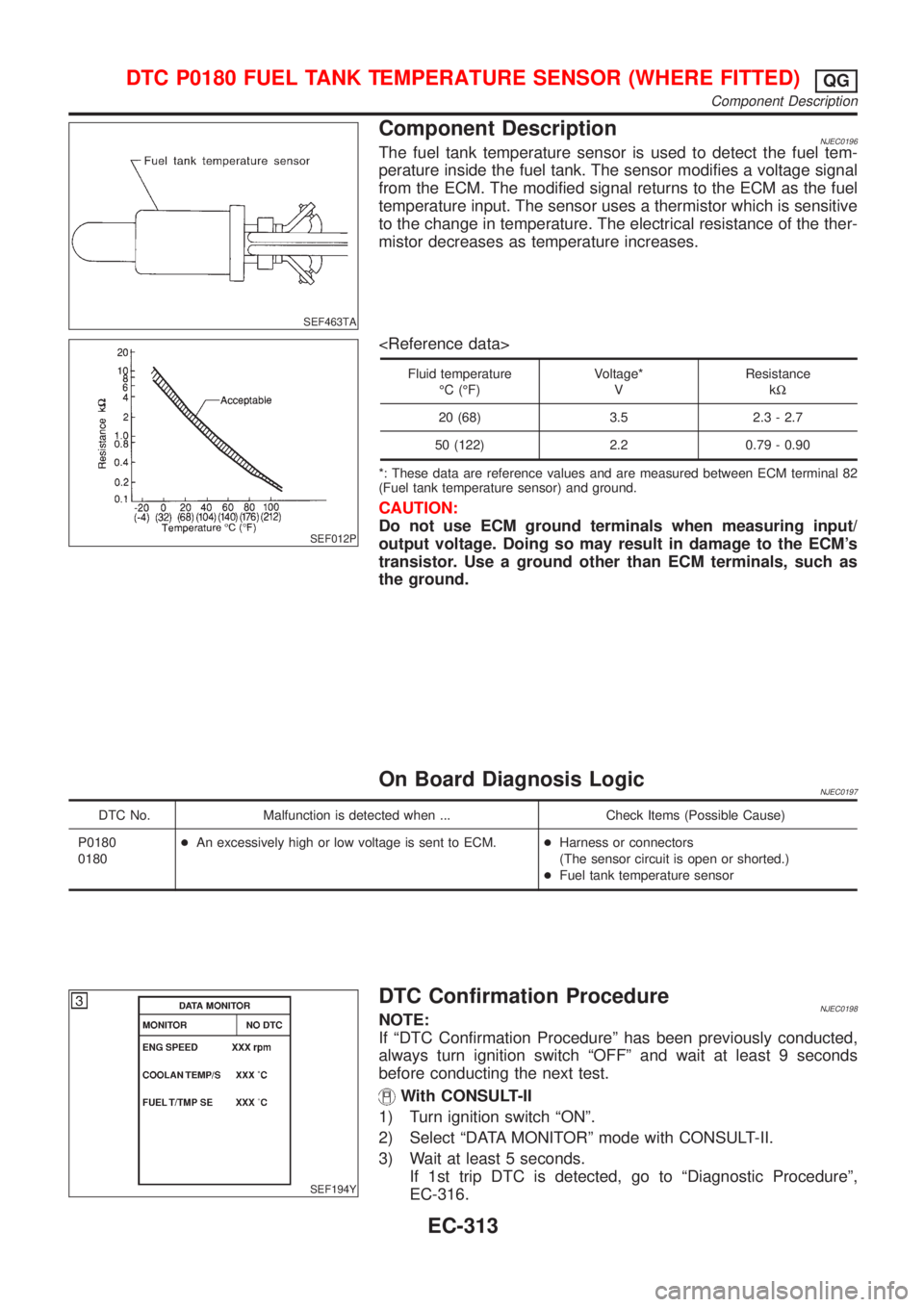

SEF463TA

Component DescriptionNJEC0196The fuel tank temperature sensor is used to detect the fuel tem-

perature inside the fuel tank. The sensor modifies a voltage signal

from the ECM. The modified signal returns to the ECM as the fuel

temperature input. The sensor uses a thermistor which is sensitive

to the change in temperature. The electrical resistance of the ther-

mistor decreases as temperature increases.

SEF012P

Fluid temperature

ÉC (ÉF)Voltage*

VResistance

kW

20 (68) 3.5 2.3 - 2.7

50 (122) 2.2 0.79 - 0.90

*: These data are reference values and are measured between ECM terminal 82

(Fuel tank temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

On Board Diagnosis LogicNJEC0197

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0180

0180+An excessively high or low voltage is sent to ECM.+Harness or connectors

(The sensor circuit is open or shorted.)

+Fuel tank temperature sensor

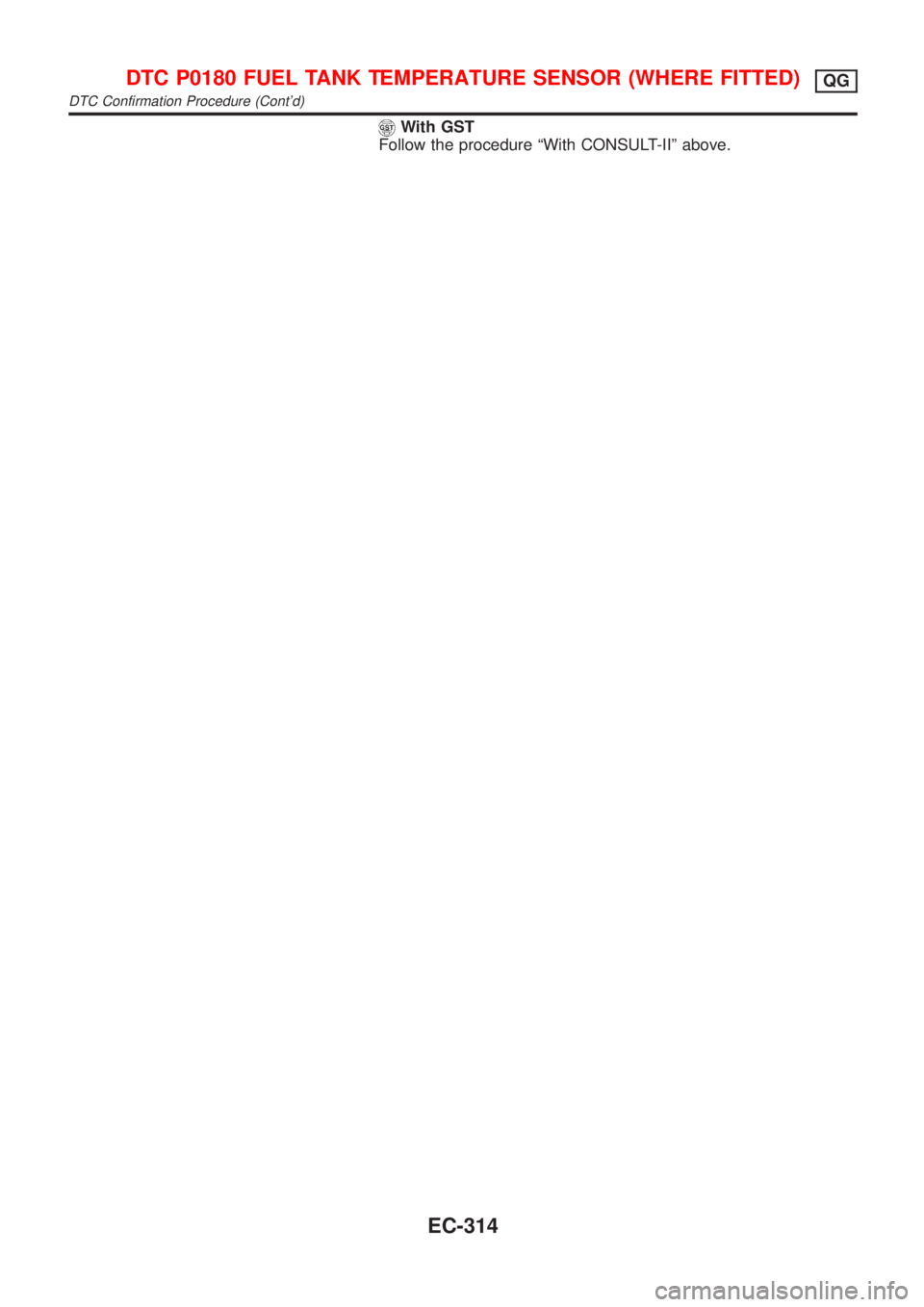

SEF194Y

DTC Confirmation ProcedureNJEC0198NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Wait at least 5 seconds.

If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-316.

DTC P0180 FUEL TANK TEMPERATURE SENSOR (WHERE FITTED)QG

Component Description

EC-313

Page 1038 of 2898

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0180 FUEL TANK TEMPERATURE SENSOR (WHERE FITTED)QG

DTC Confirmation Procedure (Cont'd)

EC-314

Page 1039 of 2898

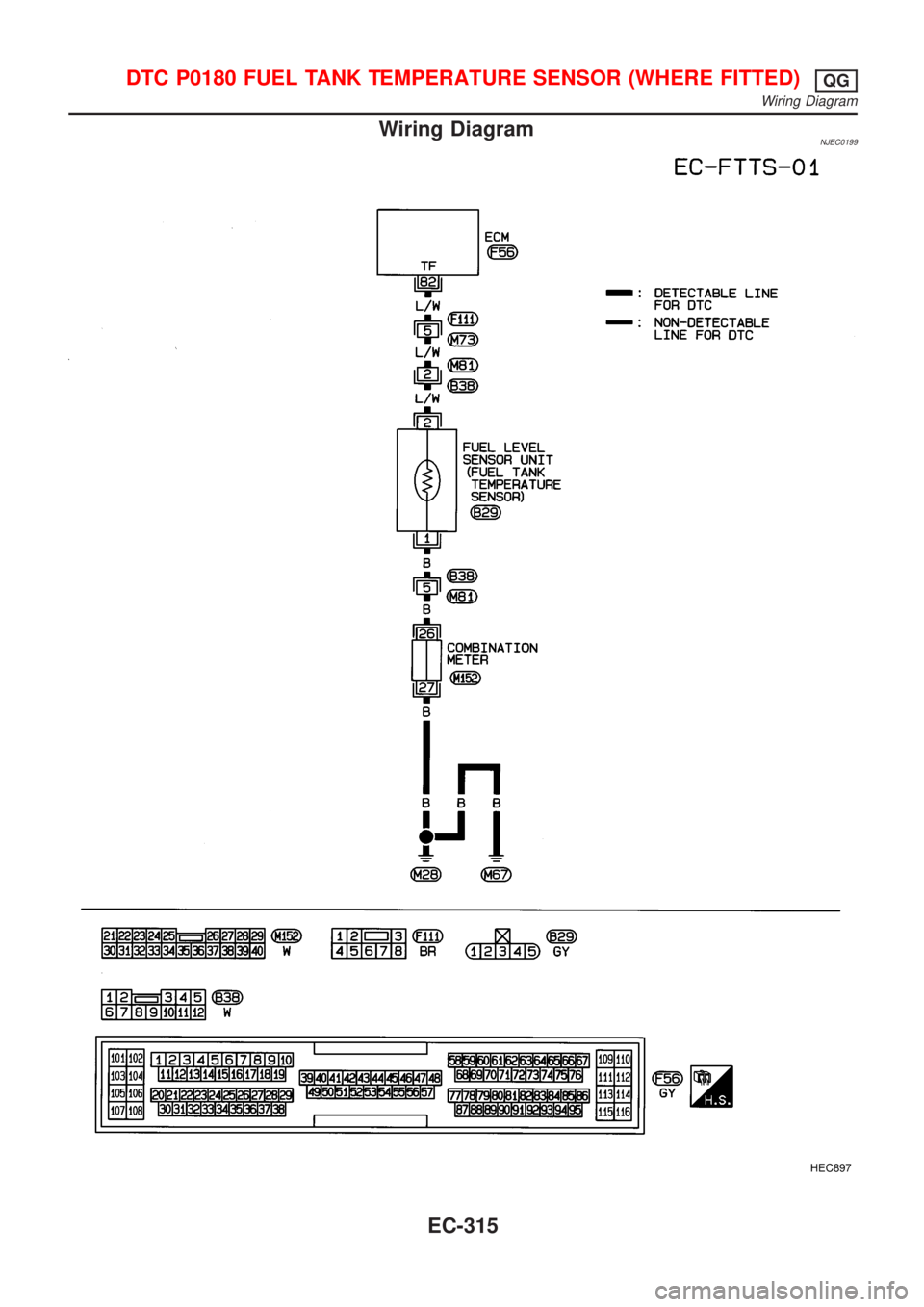

Wiring DiagramNJEC0199

HEC897

DTC P0180 FUEL TANK TEMPERATURE SENSOR (WHERE FITTED)QG

Wiring Diagram

EC-315

Page 1040 of 2898

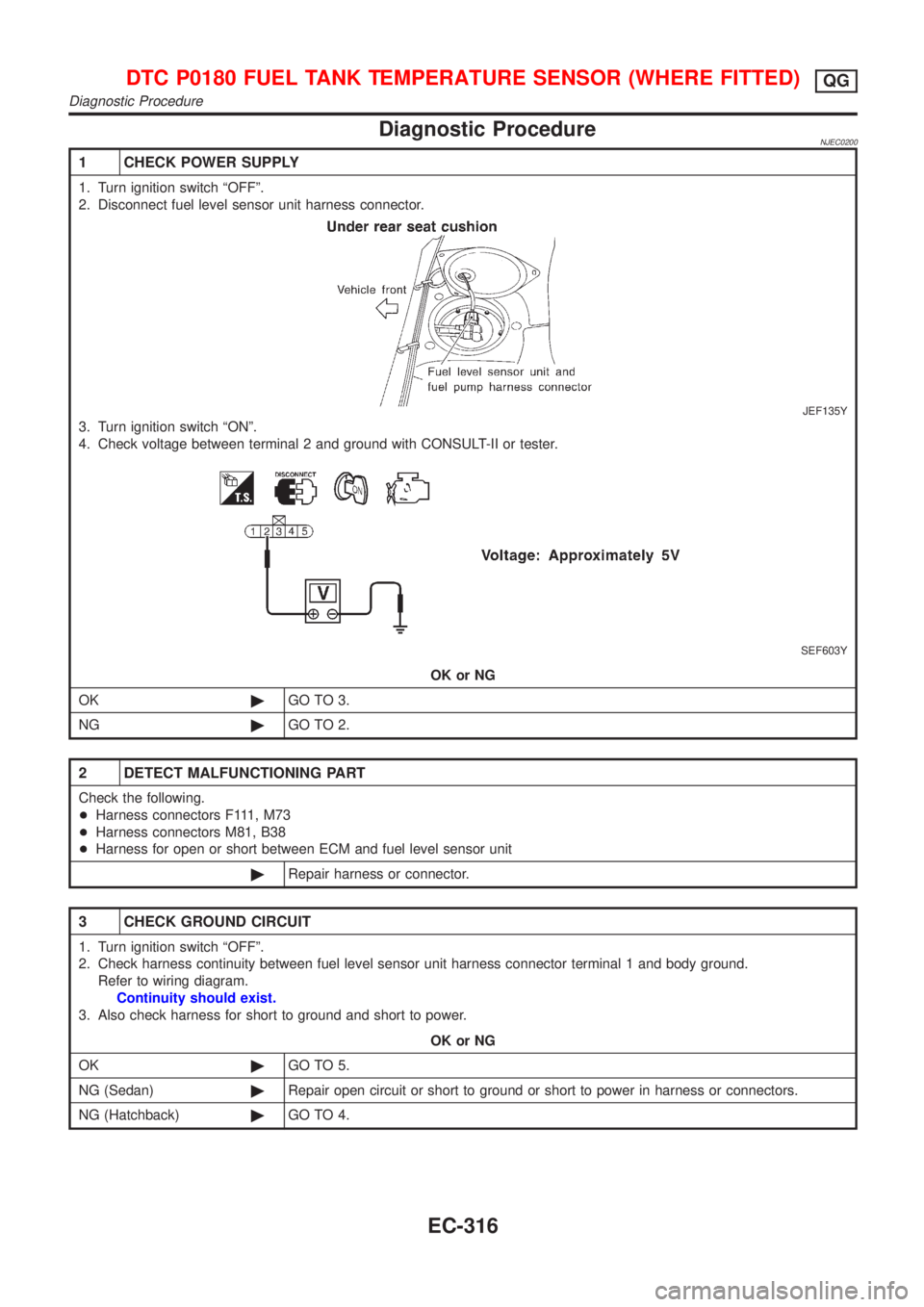

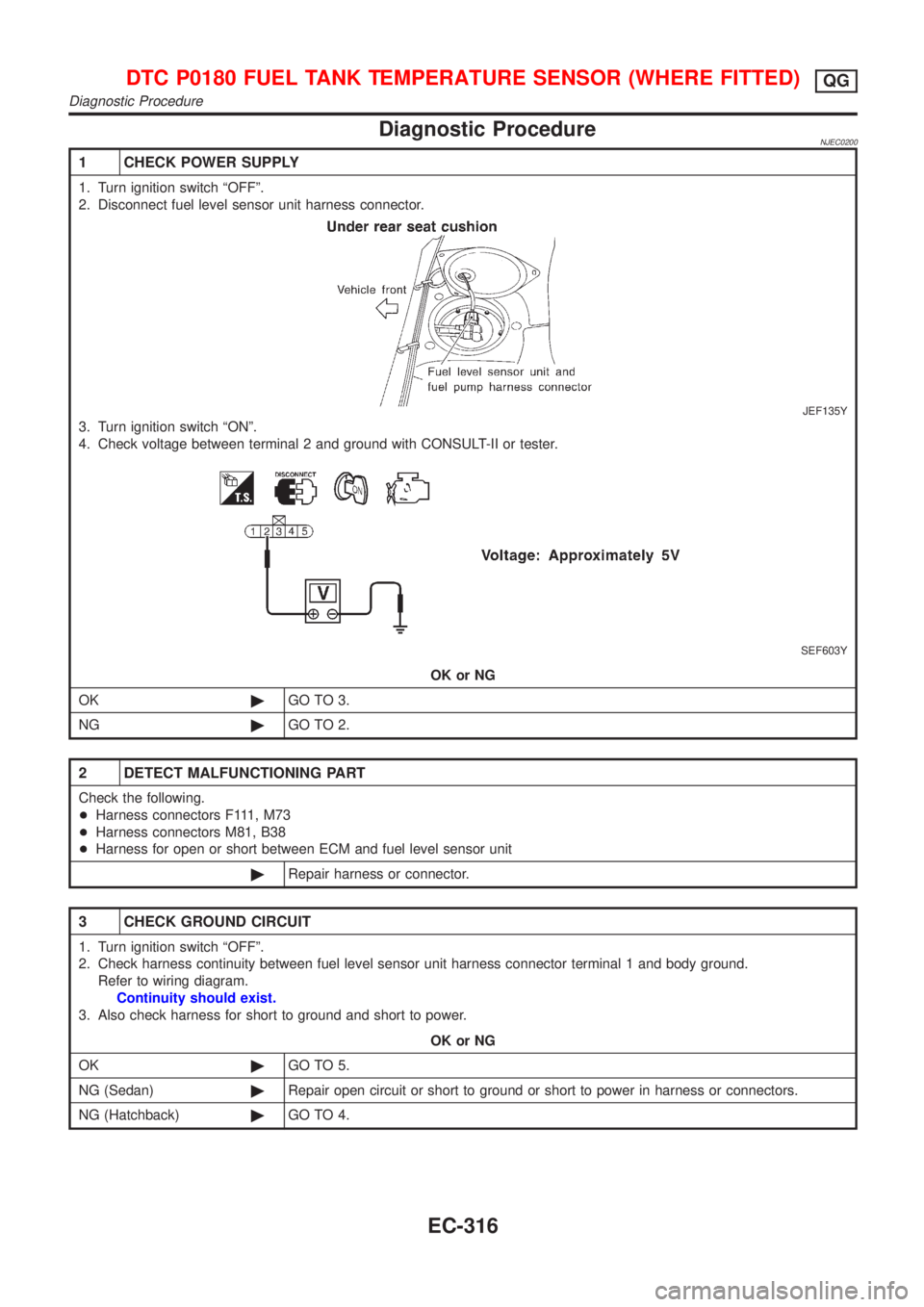

Diagnostic ProcedureNJEC0200

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect fuel level sensor unit harness connector.

JEF135Y

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground with CONSULT-II or tester.

SEF603Y

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F111, M73

+Harness connectors M81, B38

+Harness for open or short between ECM and fuel level sensor unit

©Repair harness or connector.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between fuel level sensor unit harness connector terminal 1 and body ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG (Sedan)©Repair open circuit or short to ground or short to power in harness or connectors.

NG (Hatchback)©GO TO 4.

DTC P0180 FUEL TANK TEMPERATURE SENSOR (WHERE FITTED)QG

Diagnostic Procedure

EC-316

Trending: AUX, catalytic converter, turn signal bulb, low beam, wheelbase, immobilizer, clock reset