NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1051 of 2898

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

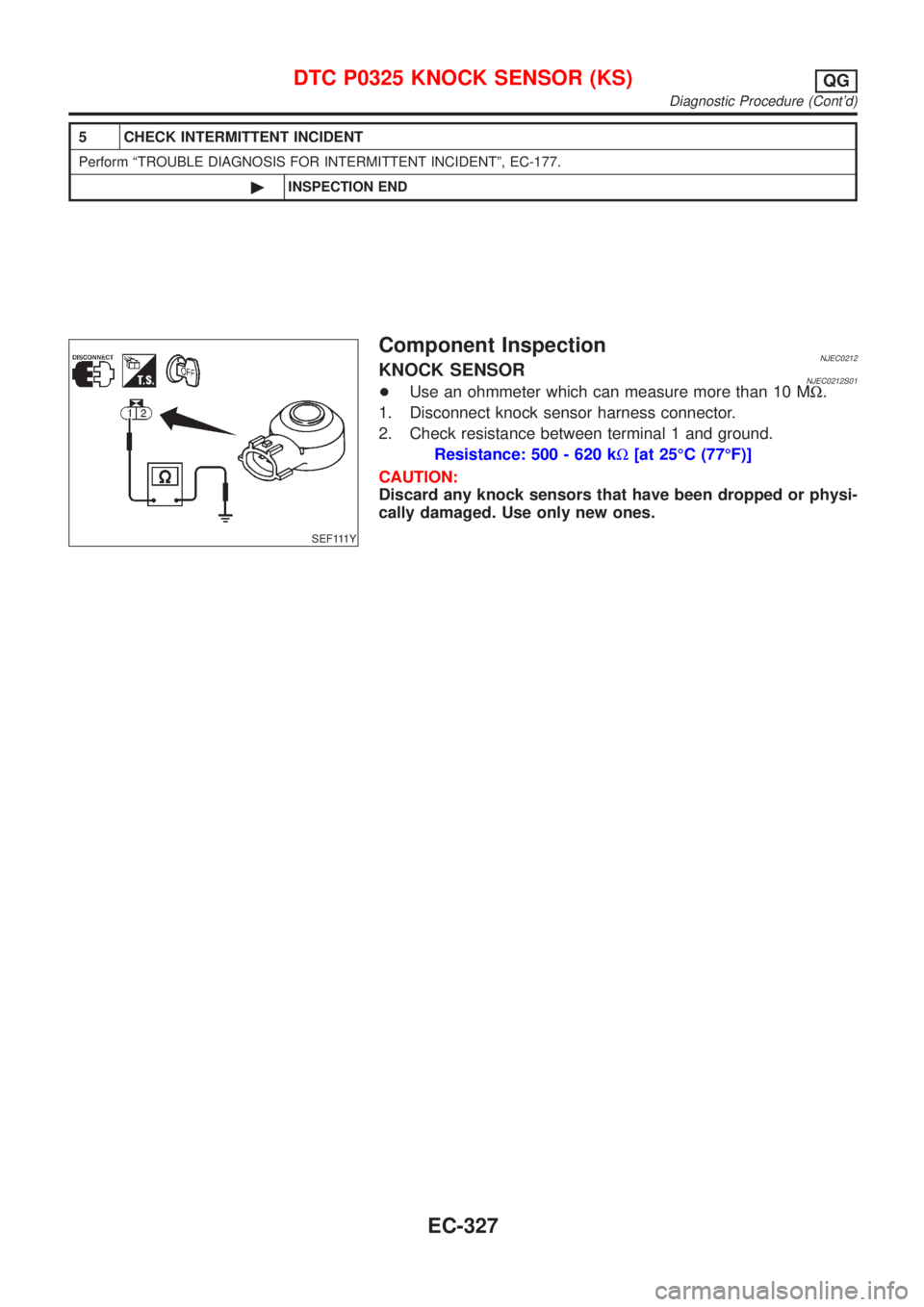

SEF111Y

Component InspectionNJEC0212KNOCK SENSORNJEC0212S01+Use an ohmmeter which can measure more than 10 MW.

1. Disconnect knock sensor harness connector.

2. Check resistance between terminal 1 and ground.

Resistance: 500 - 620 kW[at 25ÉC (77ÉF)]

CAUTION:

Discard any knock sensors that have been dropped or physi-

cally damaged. Use only new ones.

DTC P0325 KNOCK SENSOR (KS)QG

Diagnostic Procedure (Cont'd)

EC-327

Page 1052 of 2898

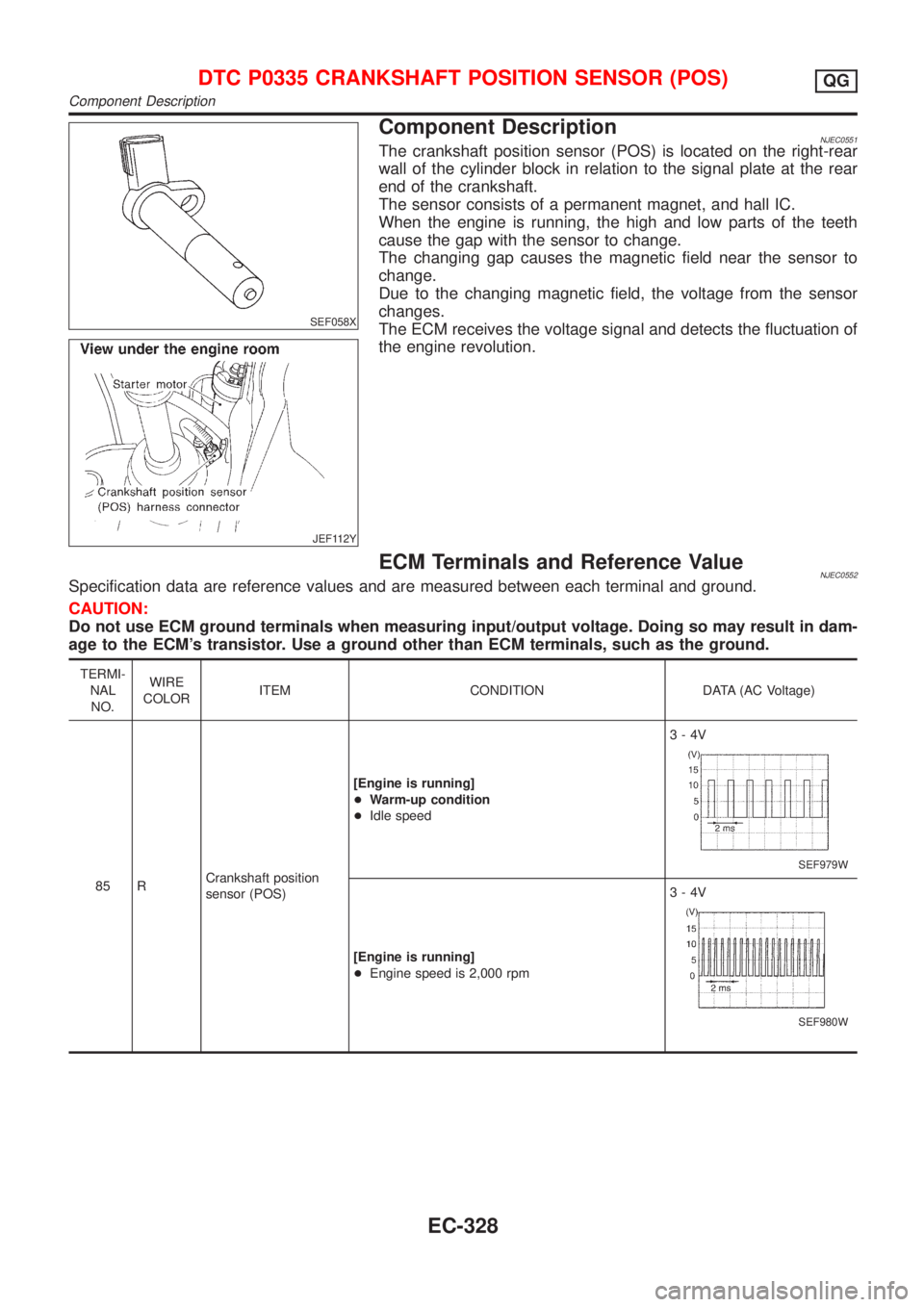

SEF058X

JEF112Y

Component DescriptionNJEC0551The crankshaft position sensor (POS) is located on the right-rear

wall of the cylinder block in relation to the signal plate at the rear

end of the crankshaft.

The sensor consists of a permanent magnet, and hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the fluctuation of

the engine revolution.

ECM Terminals and Reference ValueNJEC0552Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (AC Voltage)

85 RCrankshaft position

sensor (POS)[Engine is running]

+Warm-up condition

+Idle speed3-4V

SEF979W

[Engine is running]

+Engine speed is 2,000 rpm3-4V

SEF980W

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

Component Description

EC-328

Page 1053 of 2898

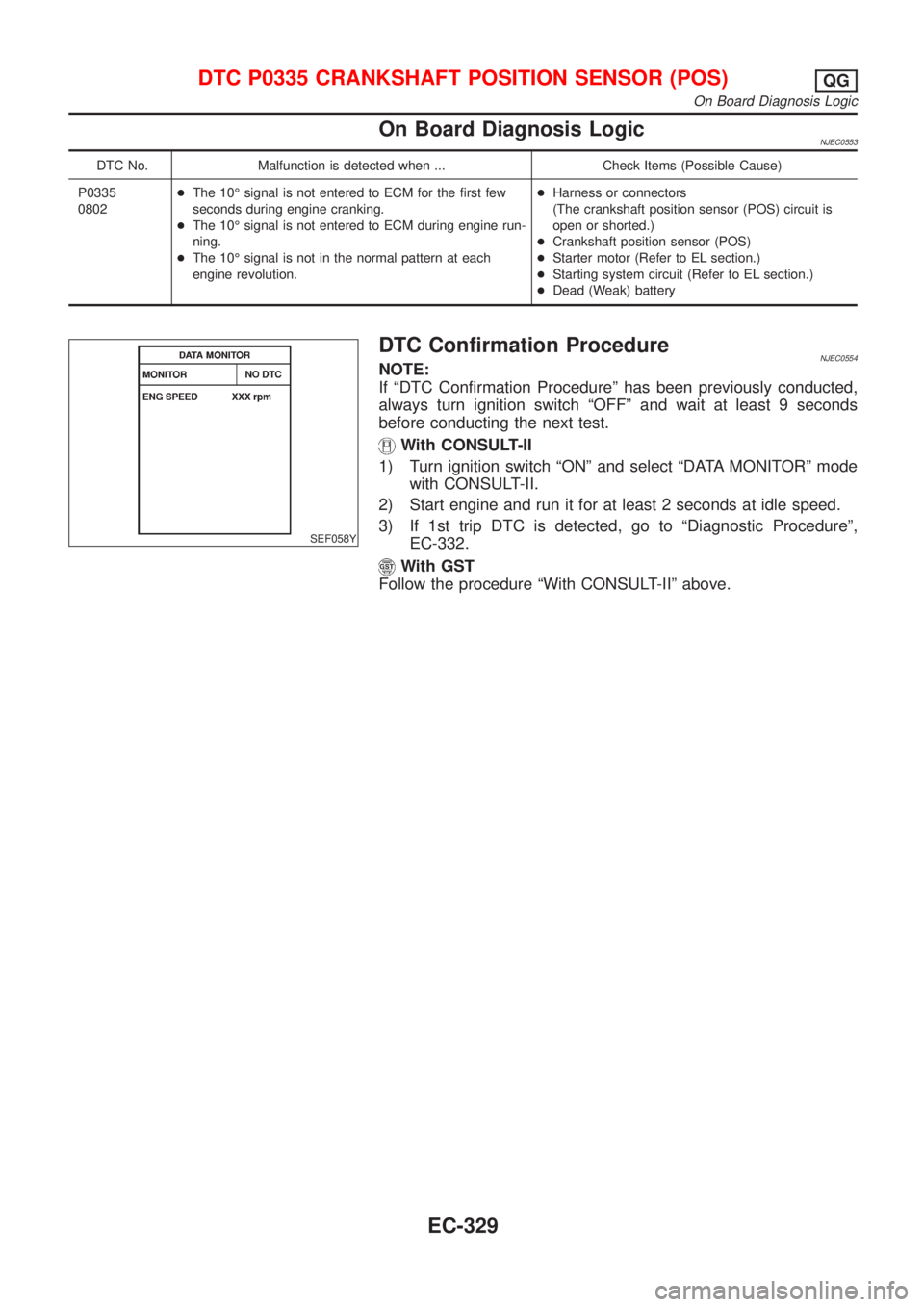

On Board Diagnosis LogicNJEC0553

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0335

0802+The 10É signal is not entered to ECM for the first few

seconds during engine cranking.

+The 10É signal is not entered to ECM during engine run-

ning.

+The 10É signal is not in the normal pattern at each

engine revolution.+Harness or connectors

(The crankshaft position sensor (POS) circuit is

open or shorted.)

+Crankshaft position sensor (POS)

+Starter motor (Refer to EL section.)

+Starting system circuit (Refer to EL section.)

+Dead (Weak) battery

SEF058Y

DTC Confirmation ProcedureNJEC0554NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and run it for at least 2 seconds at idle speed.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-332.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

On Board Diagnosis Logic

EC-329

Page 1054 of 2898

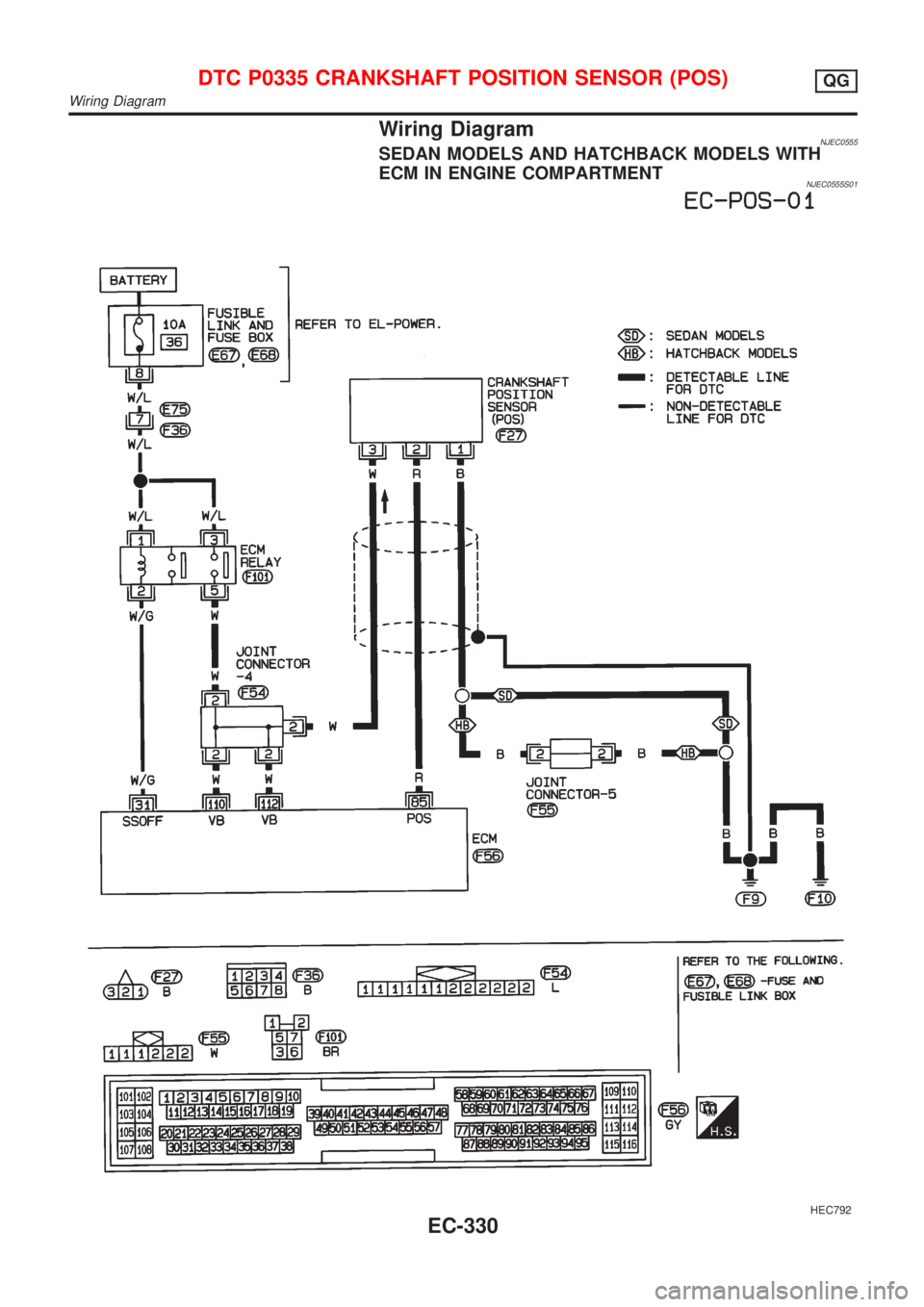

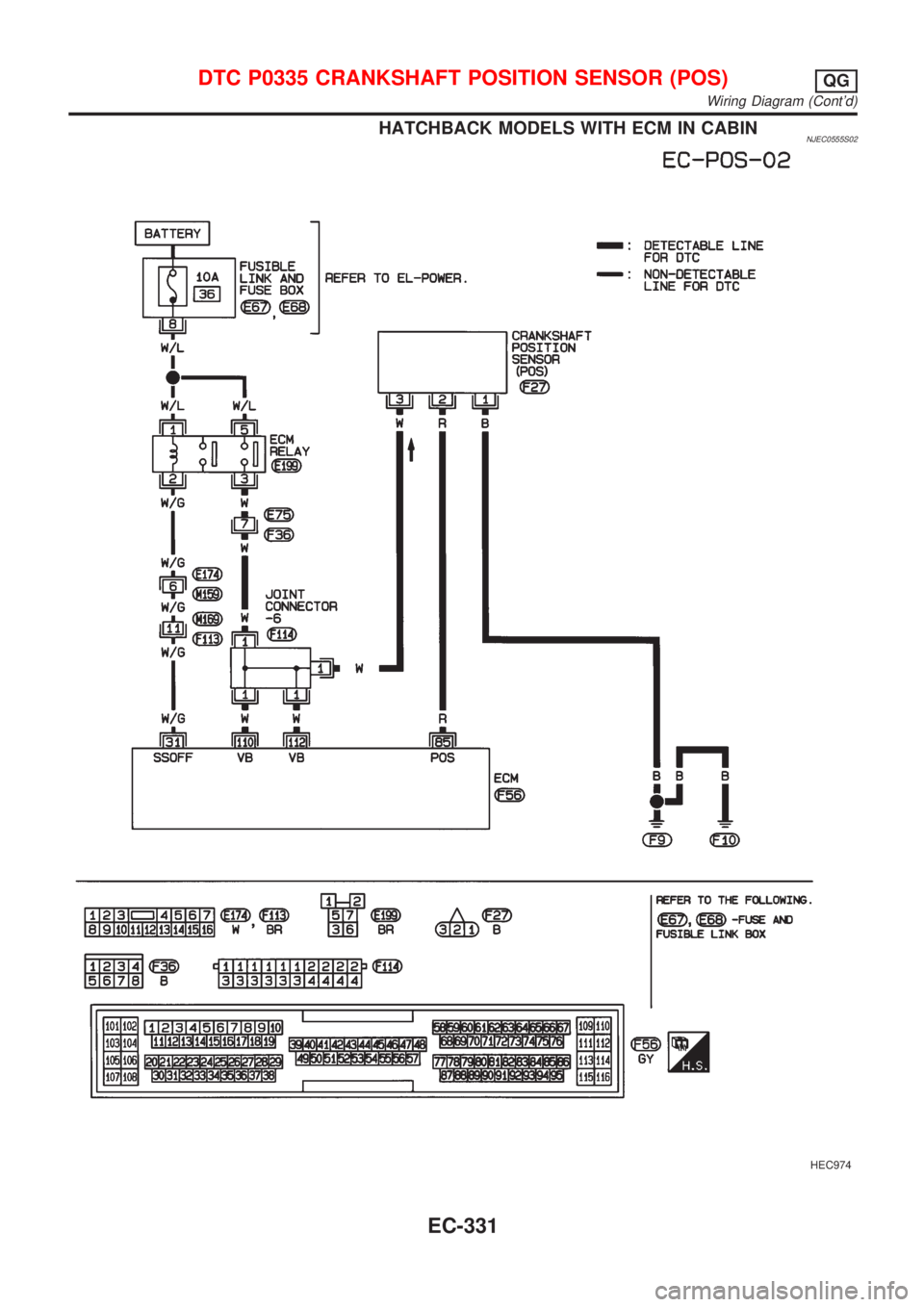

Wiring DiagramNJEC0555SEDAN MODELS AND HATCHBACK MODELS WITH

ECM IN ENGINE COMPARTMENT

NJEC0555S01

HEC792

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

Wiring Diagram

EC-330

Page 1055 of 2898

HATCHBACK MODELS WITH ECM IN CABINNJEC0555S02

HEC974

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

Wiring Diagram (Cont'd)

EC-331

Page 1056 of 2898

Diagnostic ProcedureNJEC0556

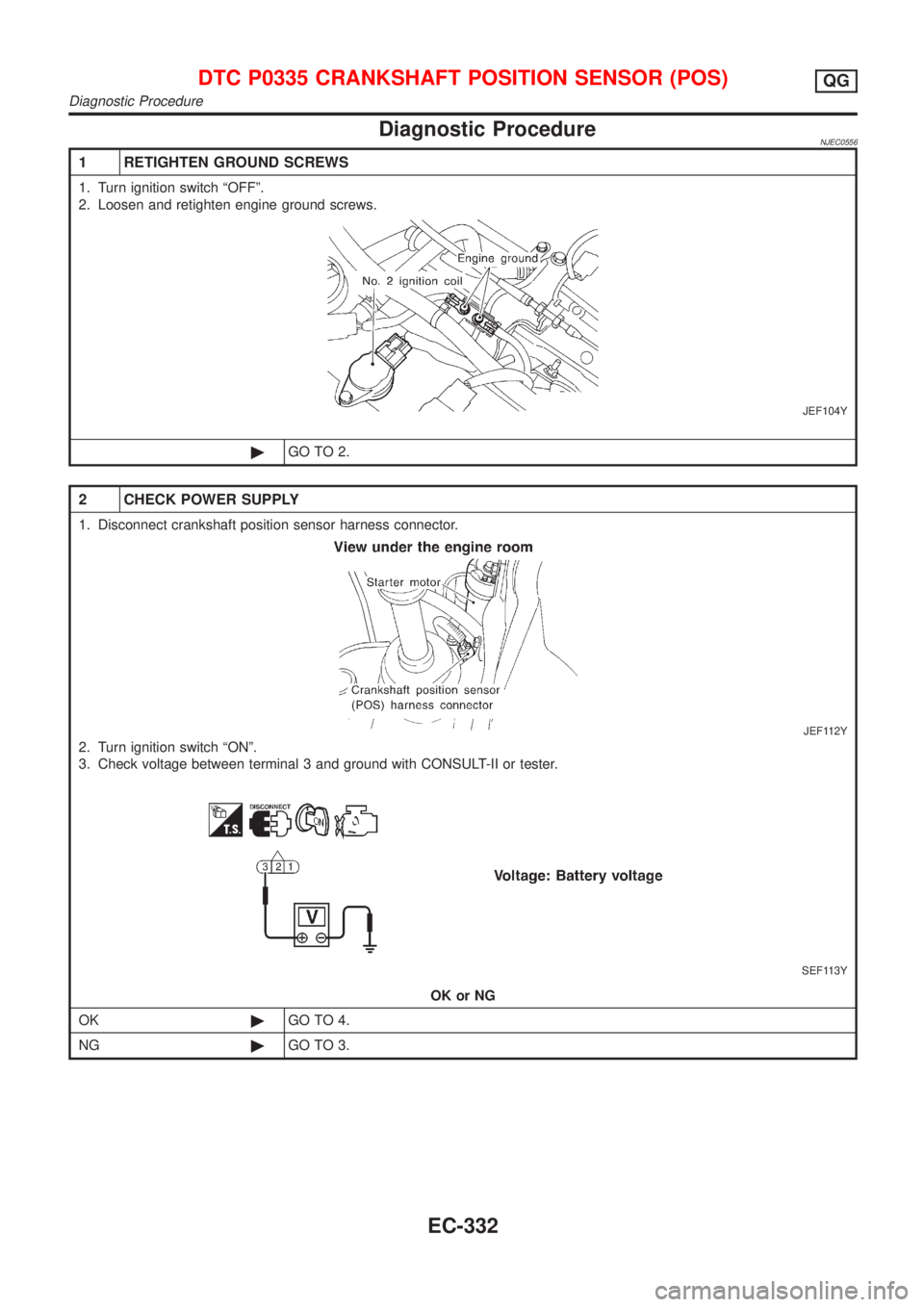

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

©GO TO 2.

2 CHECK POWER SUPPLY

1. Disconnect crankshaft position sensor harness connector.

JEF112Y

2. Turn ignition switch ªONº.

3. Check voltage between terminal 3 and ground with CONSULT-II or tester.

SEF113Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

Diagnostic Procedure

EC-332

Page 1057 of 2898

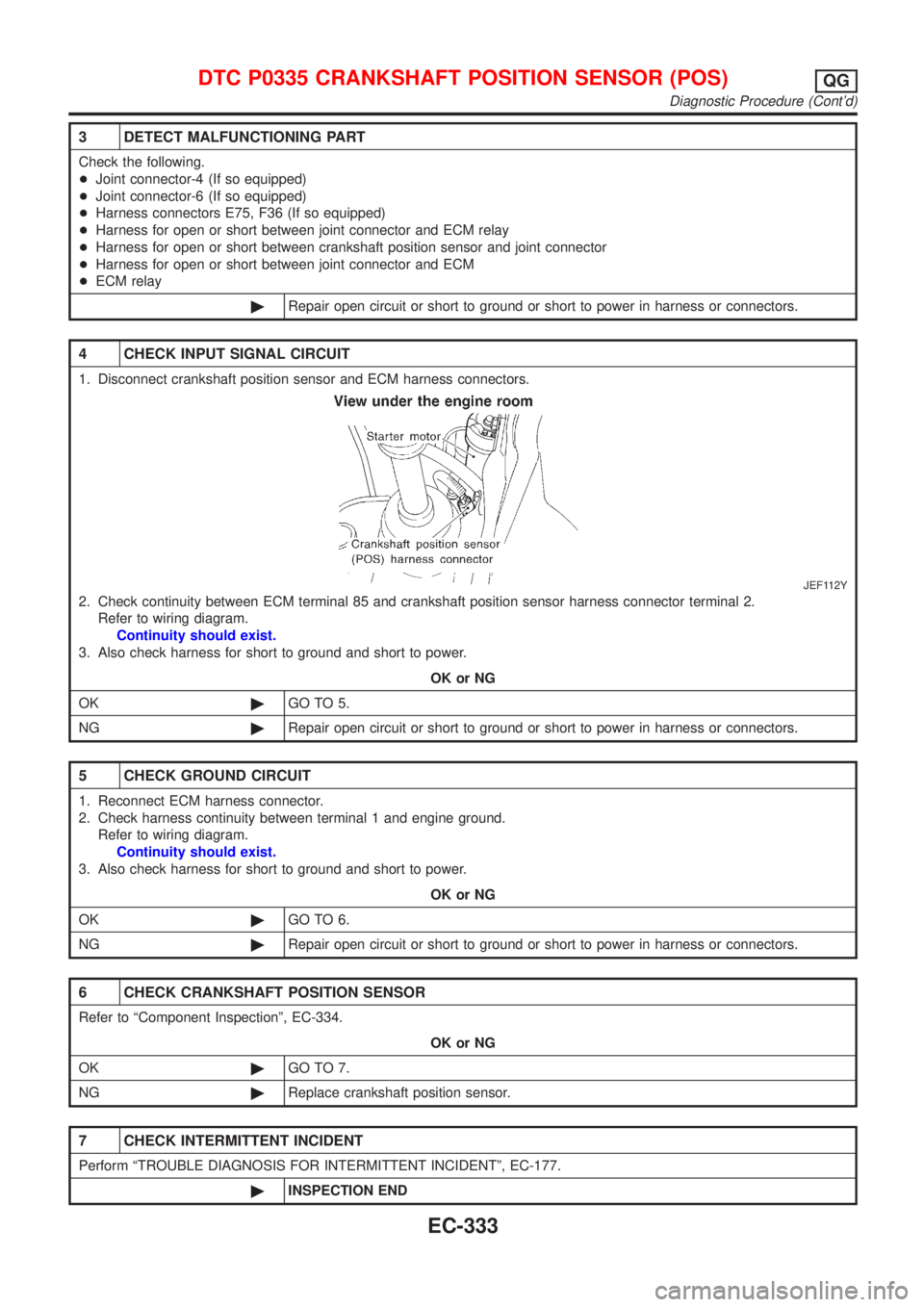

3 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-4 (If so equipped)

+Joint connector-6 (If so equipped)

+Harness connectors E75, F36 (If so equipped)

+Harness for open or short between joint connector and ECM relay

+Harness for open or short between crankshaft position sensor and joint connector

+Harness for open or short between joint connector and ECM

+ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect crankshaft position sensor and ECM harness connectors.

JEF112Y

2. Check continuity between ECM terminal 85 and crankshaft position sensor harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connector.

2. Check harness continuity between terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK CRANKSHAFT POSITION SENSOR

Refer to ªComponent Inspectionº, EC-334.

OK or NG

OK©GO TO 7.

NG©Replace crankshaft position sensor.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

Diagnostic Procedure (Cont'd)

EC-333

Page 1058 of 2898

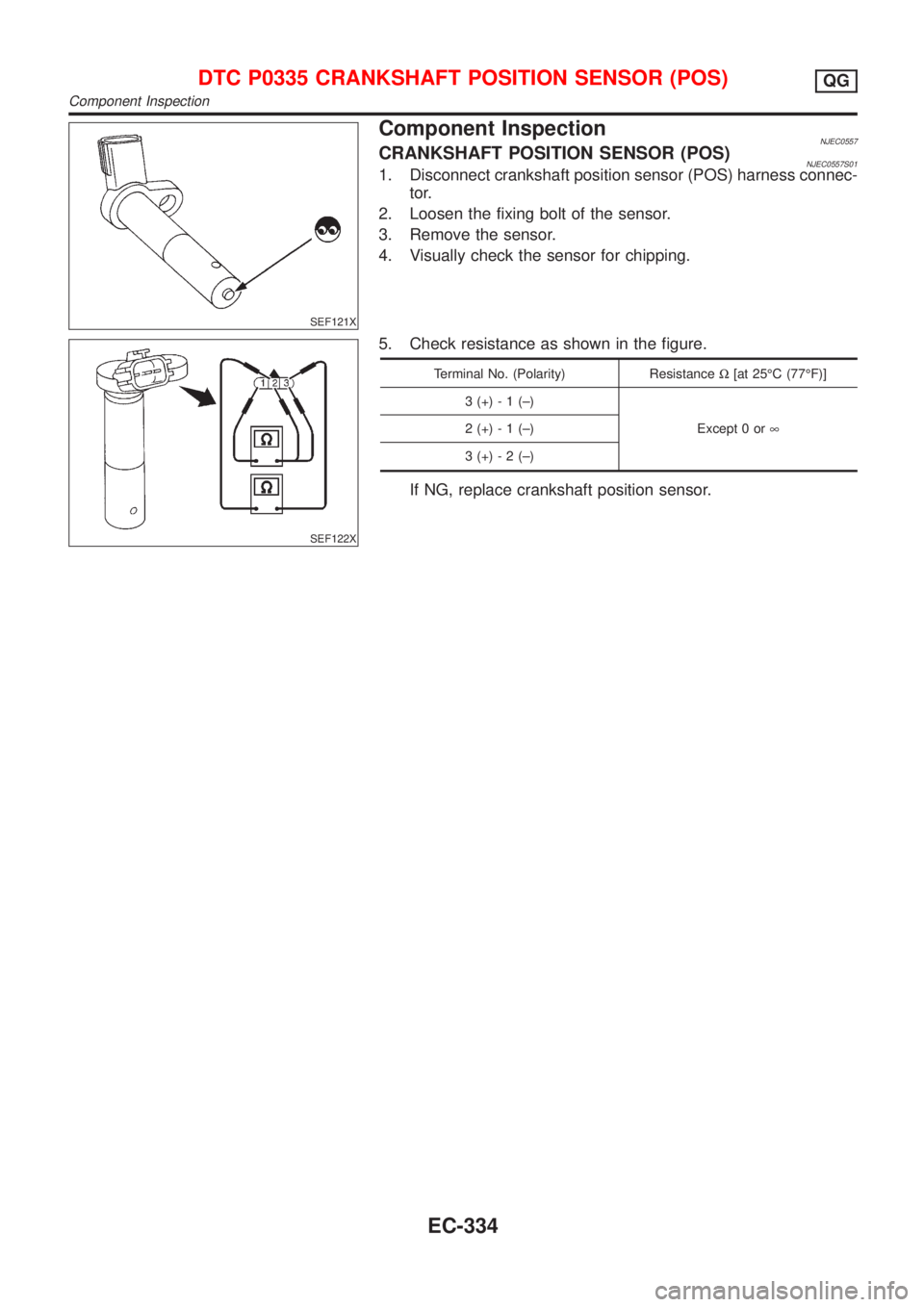

SEF121X

Component InspectionNJEC0557CRANKSHAFT POSITION SENSOR (POS)NJEC0557S011. Disconnect crankshaft position sensor (POS) harness connec-

tor.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

SEF122X

5. Check resistance as shown in the figure.

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (±)

Except 0 or¥ 2 (+) - 1 (±)

3 (+) - 2 (±)

If NG, replace crankshaft position sensor.

DTC P0335 CRANKSHAFT POSITION SENSOR (POS)QG

Component Inspection

EC-334

Page 1059 of 2898

SEF058X

Component DescriptionNJEC0220The camshaft position sensor (PHASE) senses the protrusion pro-

vided with exhaust valve cam sprocket to identify a particular cyl-

inder. The crankshaft position sensor senses the piston position.

The sensor consists of a permanent magnet and hall IC.

When the engine is running, the high and low parts of the teeth

cause the gap with the sensor to change.

The changing gap causes the magnetic field near the sensor to

change.

Due to the changing magnetic field, the voltage from the sensor

changes.

The ECM receives the voltage signal and detects the cylinder num-

ber signal.

ECM Terminals and Reference ValueNJEC0221Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

66

75R

RCamshaft position sen-

sor (PHASE)[Engine is running]

+Warm-up condition

+Idle speed3-4V

SEF977W

[Engine is running]

+Engine speed is 2,000 rpm3-4V

SEF978W

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)QG

Component Description

EC-335

Page 1060 of 2898

On Board Diagnosis LogicNJEC0222

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0340

0340+The cylinder No. signal is not entered to ECM for the first

few seconds during engine cranking.

+The cylinder No. signal is not entered to ECM during

engine running.

+The cylinder No. signal is not in the normal pattern dur-

ing engine running.+Harness or connectors

(The camshaft position sensor (PHASE) circuit is

open or shorted.)

+Camshaft position sensor (PHASE)

+Starter motor (Refer to EL section.)

+Starting system circuit (Refer to EL section.)

DTC Confirmation ProcedureNJEC0223NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V.

SEF013Y

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Crank engine for at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-339.

With GST

Follow the procedure ªWith CONSULT-IIº above.

DTC P0340 CAMSHAFT POSITION SENSOR (CMPS) (PHASE)QG

On Board Diagnosis Logic

EC-336