NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 1011 of 2898

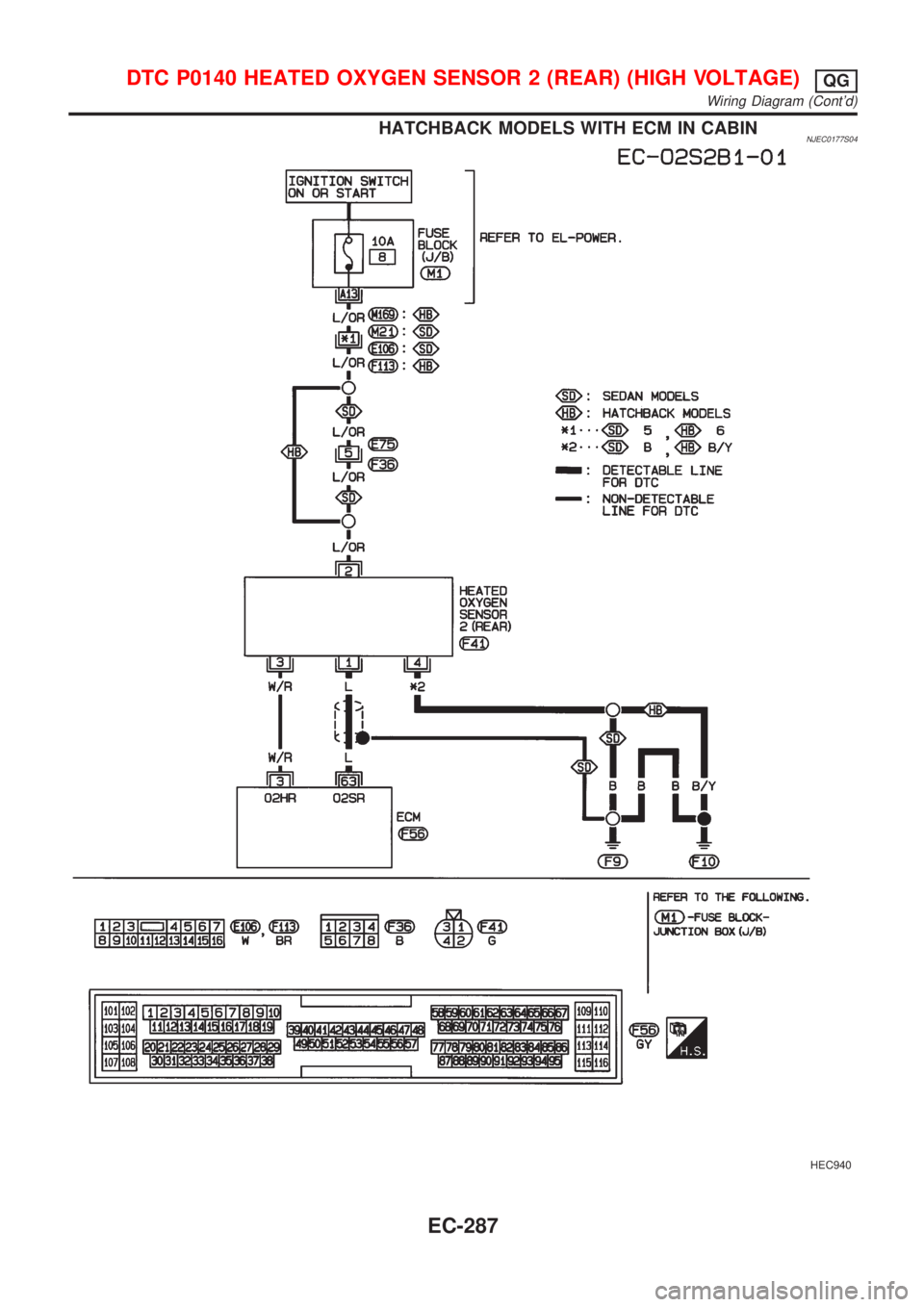

HATCHBACK MODELS WITH ECM IN CABINNJEC0177S04

HEC940

DTC P0140 HEATED OXYGEN SENSOR 2 (REAR) (HIGH VOLTAGE)QG

Wiring Diagram (Cont'd)

EC-287

Page 1012 of 2898

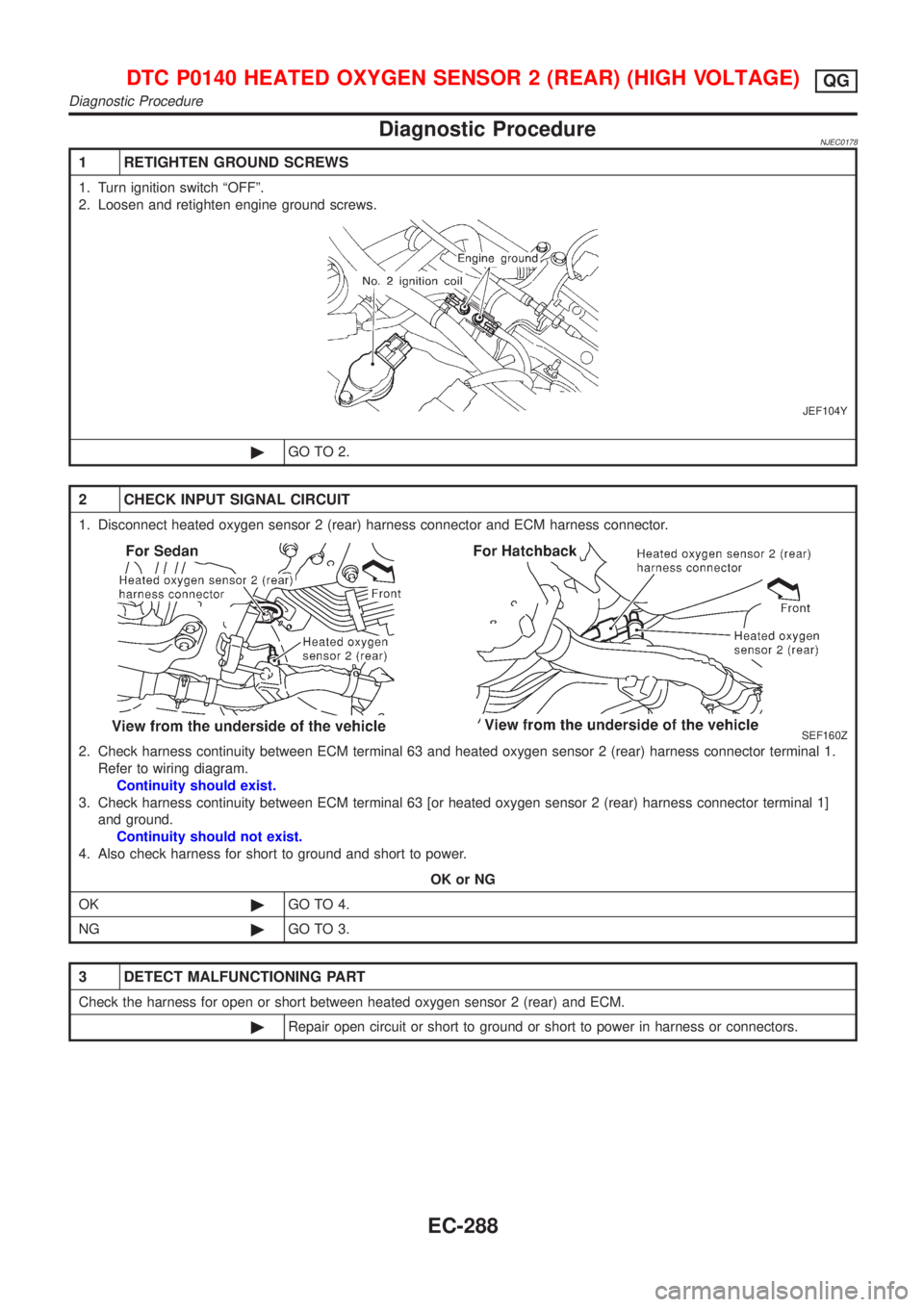

Diagnostic ProcedureNJEC0178

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

©GO TO 2.

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect heated oxygen sensor 2 (rear) harness connector and ECM harness connector.

SEF160Z

2. Check harness continuity between ECM terminal 63 and heated oxygen sensor 2 (rear) harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 63 [or heated oxygen sensor 2 (rear) harness connector terminal 1]

and ground.

Continuity should not exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0140 HEATED OXYGEN SENSOR 2 (REAR) (HIGH VOLTAGE)QG

Diagnostic Procedure

EC-288

Page 1013 of 2898

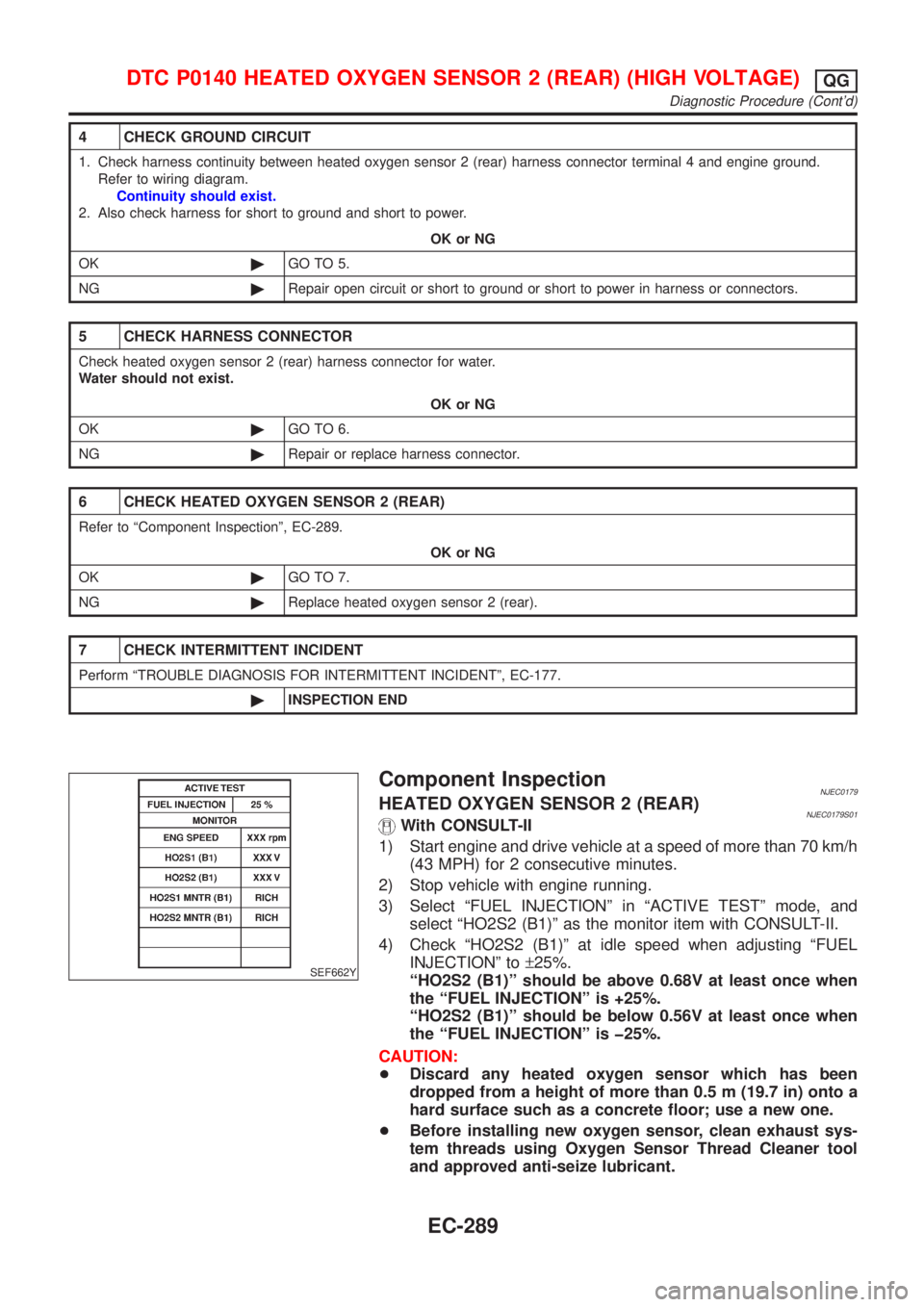

4 CHECK GROUND CIRCUIT

1. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 4 and engine ground.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK HARNESS CONNECTOR

Check heated oxygen sensor 2 (rear) harness connector for water.

Water should not exist.

OK or NG

OK©GO TO 6.

NG©Repair or replace harness connector.

6 CHECK HEATED OXYGEN SENSOR 2 (REAR)

Refer to ªComponent Inspectionº, EC-289.

OK or NG

OK©GO TO 7.

NG©Replace heated oxygen sensor 2 (rear).

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

SEF662Y

Component InspectionNJEC0179HEATED OXYGEN SENSOR 2 (REAR)NJEC0179S01With CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Select ªFUEL INJECTIONº in ªACTIVE TESTº mode, and

select ªHO2S2 (B1)º as the monitor item with CONSULT-II.

4) Check ªHO2S2 (B1)º at idle speed when adjusting ªFUEL

INJECTIONº to±25%.

ªHO2S2 (B1)º should be above 0.68V at least once when

the ªFUEL INJECTIONº is +25%.

ªHO2S2 (B1)º should be below 0.56V at least once when

the ªFUEL INJECTIONº is þ25%.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0140 HEATED OXYGEN SENSOR 2 (REAR) (HIGH VOLTAGE)QG

Diagnostic Procedure (Cont'd)

EC-289

Page 1014 of 2898

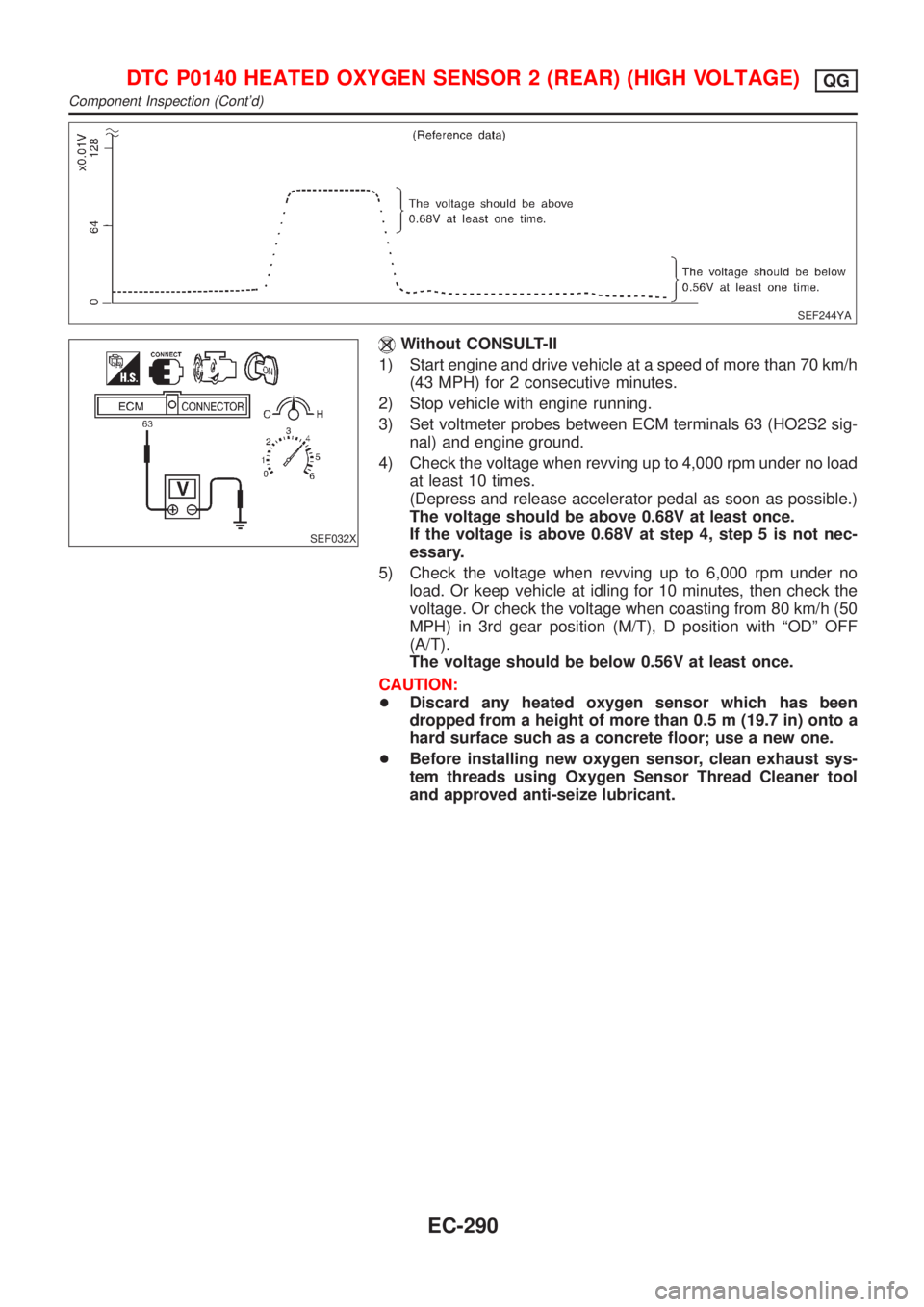

SEF244YA

SEF032X

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeter probes between ECM terminals 63 (HO2S2 sig-

nal) and engine ground.

4) Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.68V at least once.

If the voltage is above 0.68V at step 4, step 5 is not nec-

essary.

5) Check the voltage when revving up to 6,000 rpm under no

load. Or keep vehicle at idling for 10 minutes, then check the

voltage. Or check the voltage when coasting from 80 km/h (50

MPH) in 3rd gear position (M/T), D position with ªODº OFF

(A/T).

The voltage should be below 0.56V at least once.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0140 HEATED OXYGEN SENSOR 2 (REAR) (HIGH VOLTAGE)QG

Component Inspection (Cont'd)

EC-290

Page 1015 of 2898

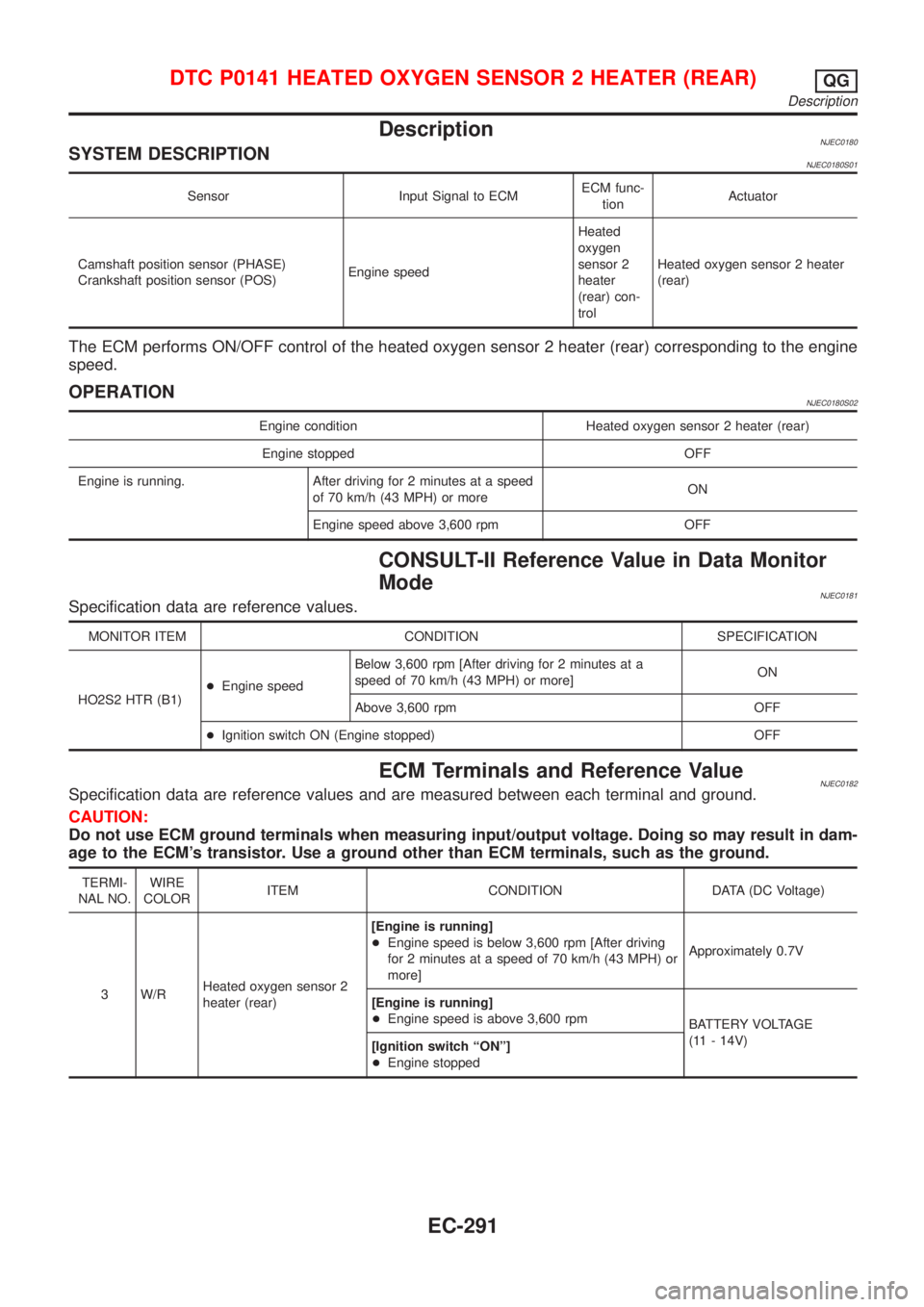

DescriptionNJEC0180SYSTEM DESCRIPTIONNJEC0180S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor (PHASE)

Crankshaft position sensor (POS)Engine speedHeated

oxygen

sensor 2

heater

(rear) con-

trolHeated oxygen sensor 2 heater

(rear)

The ECM performs ON/OFF control of the heated oxygen sensor 2 heater (rear) corresponding to the engine

speed.

OPERATIONNJEC0180S02

Engine condition Heated oxygen sensor 2 heater (rear)

Engine stopped OFF

Engine is running. After driving for 2 minutes at a speed

of 70 km/h (43 MPH) or moreON

Engine speed above 3,600 rpm OFF

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0181Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 HTR (B1)+Engine speedBelow 3,600 rpm [After driving for 2 minutes at a

speed of 70 km/h (43 MPH) or more]ON

Above 3,600 rpm OFF

+Ignition switch ON (Engine stopped) OFF

ECM Terminals and Reference ValueNJEC0182Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

3 W/RHeated oxygen sensor 2

heater (rear)[Engine is running]

+Engine speed is below 3,600 rpm [After driving

for 2 minutes at a speed of 70 km/h (43 MPH) or

more]Approximately 0.7V

[Engine is running]

+Engine speed is above 3,600 rpm

BATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Engine stopped

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Description

EC-291

Page 1016 of 2898

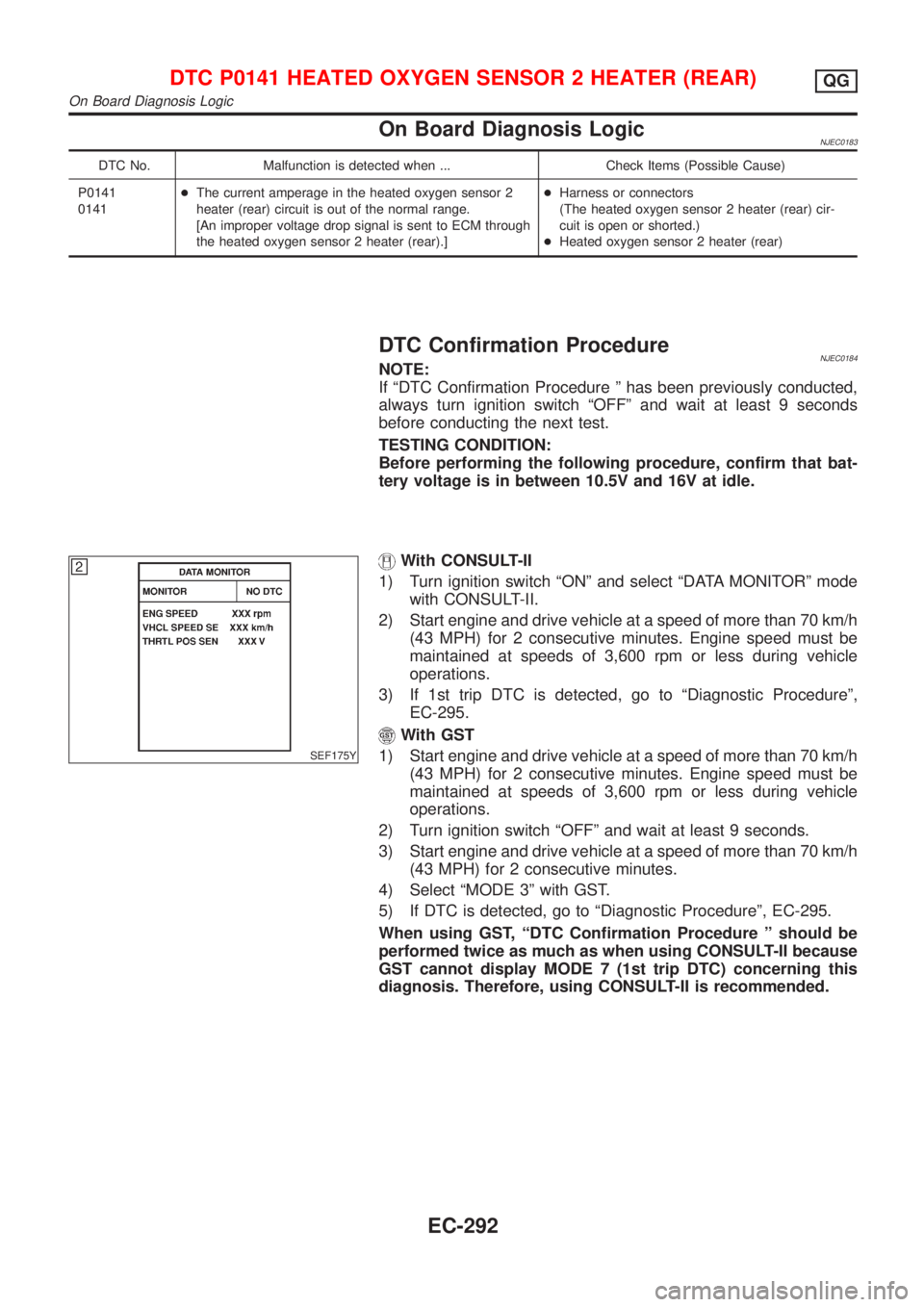

On Board Diagnosis LogicNJEC0183

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0141

0141+The current amperage in the heated oxygen sensor 2

heater (rear) circuit is out of the normal range.

[An improper voltage drop signal is sent to ECM through

the heated oxygen sensor 2 heater (rear).]+Harness or connectors

(The heated oxygen sensor 2 heater (rear) cir-

cuit is open or shorted.)

+Heated oxygen sensor 2 heater (rear)

DTC Confirmation ProcedureNJEC0184NOTE:

If ªDTC Confirmation Procedure º has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is in between 10.5V and 16V at idle.

SEF175Y

With CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes. Engine speed must be

maintained at speeds of 3,600 rpm or less during vehicle

operations.

3) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-295.

With GST

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes. Engine speed must be

maintained at speeds of 3,600 rpm or less during vehicle

operations.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

4) Select ªMODE 3º with GST.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-295.

When using GST, ªDTC Confirmation Procedure º should be

performed twice as much as when using CONSULT-II because

GST cannot display MODE 7 (1st trip DTC) concerning this

diagnosis. Therefore, using CONSULT-II is recommended.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

On Board Diagnosis Logic

EC-292

Page 1017 of 2898

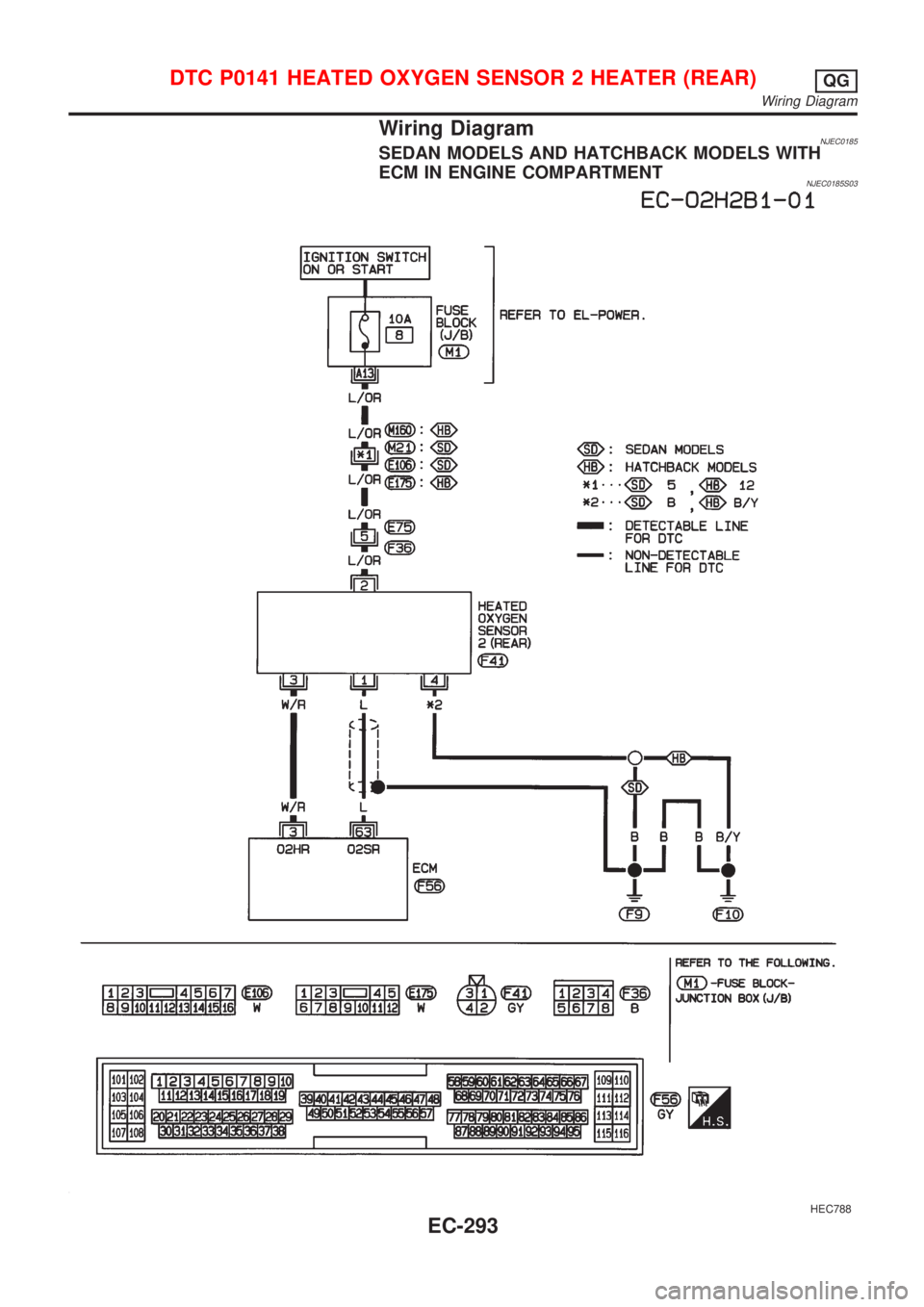

Wiring DiagramNJEC0185SEDAN MODELS AND HATCHBACK MODELS WITH

ECM IN ENGINE COMPARTMENT

NJEC0185S03

HEC788

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Wiring Diagram

EC-293

Page 1018 of 2898

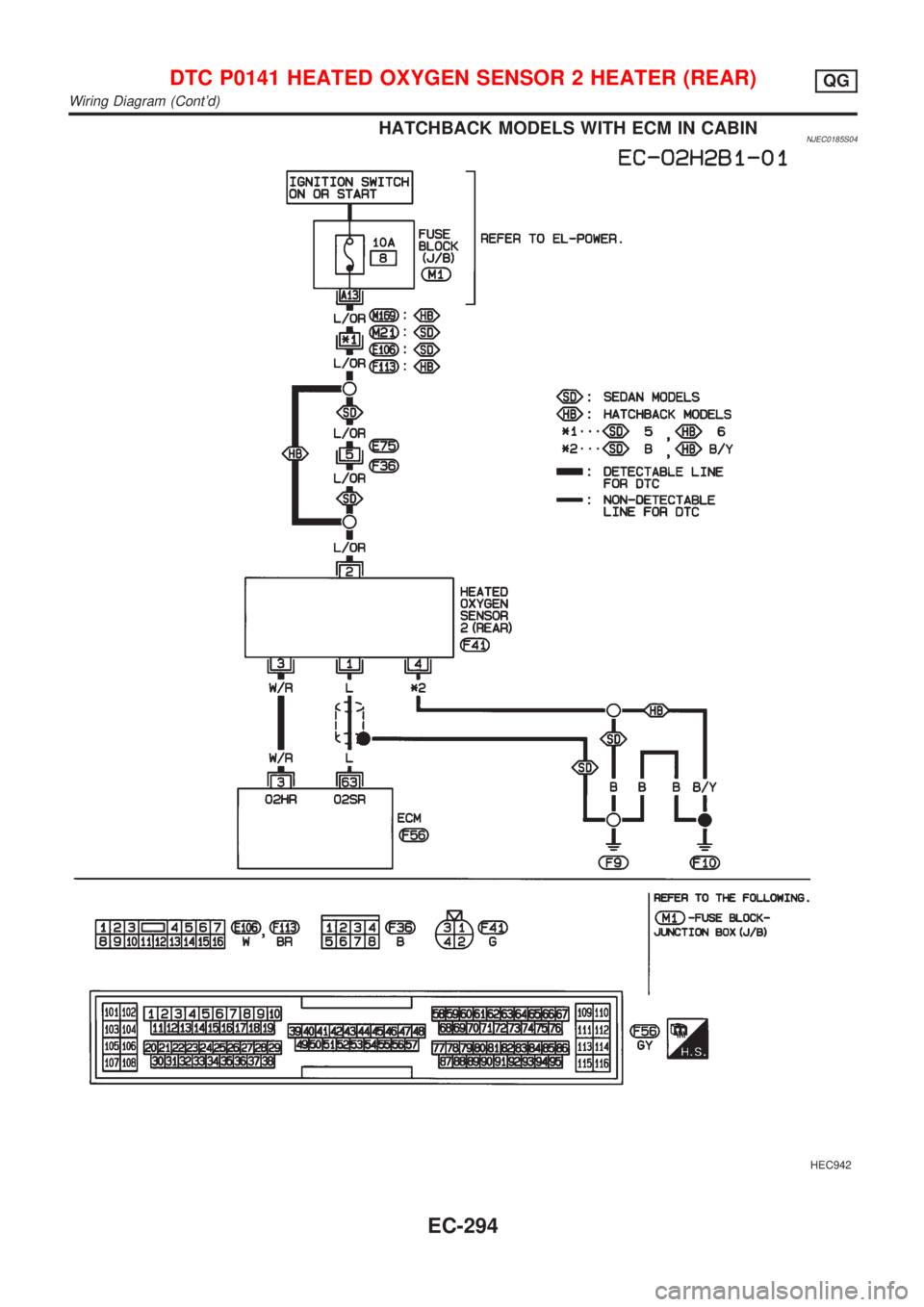

HATCHBACK MODELS WITH ECM IN CABINNJEC0185S04

HEC942

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Wiring Diagram (Cont'd)

EC-294

Page 1019 of 2898

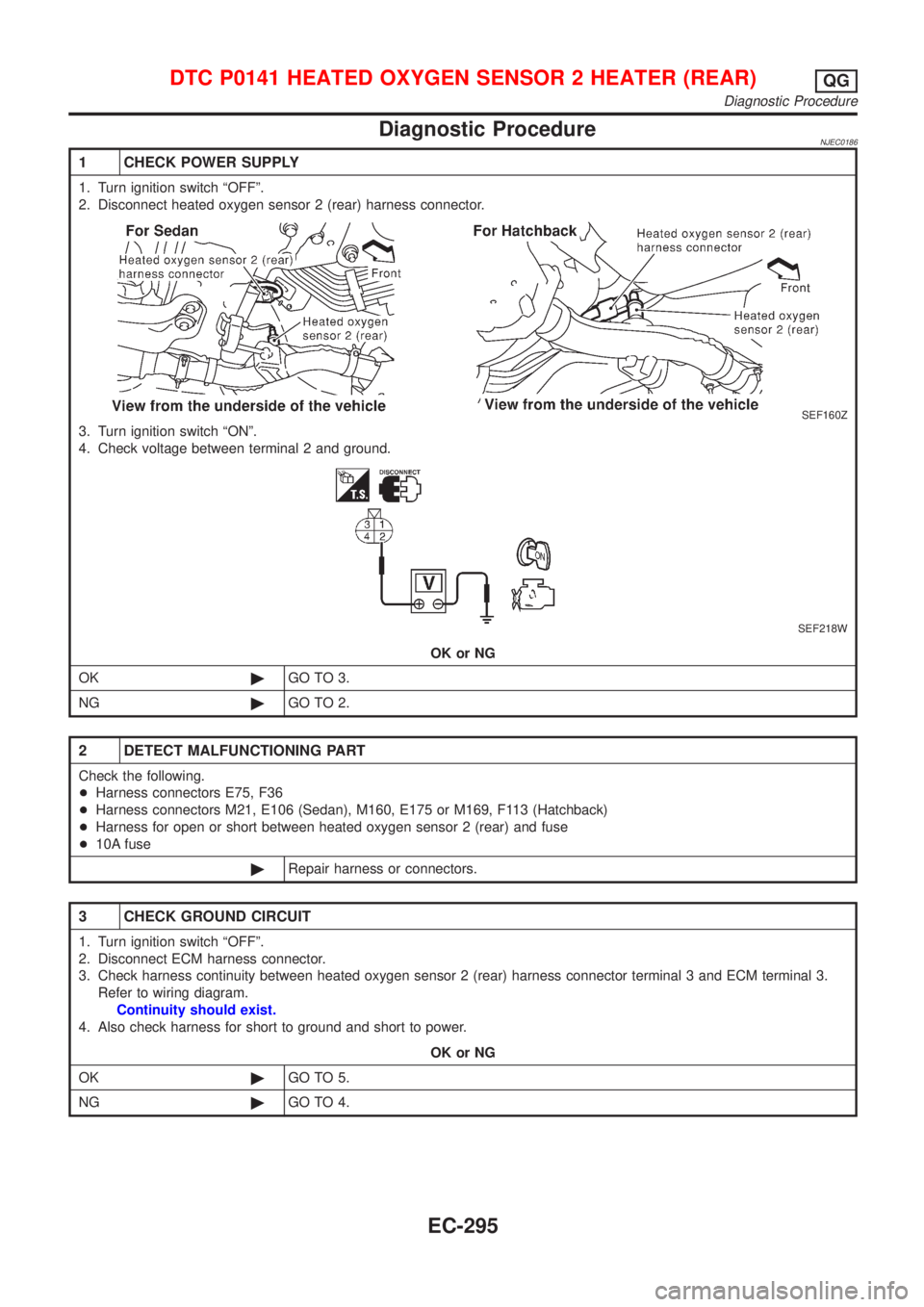

Diagnostic ProcedureNJEC0186

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector.

SEF160Z

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground.

SEF218W

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E75, F36

+Harness connectors M21, E106 (Sedan), M160, E175 or M169, F113 (Hatchback)

+Harness for open or short between heated oxygen sensor 2 (rear) and fuse

+10A fuse

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 3 and ECM terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Diagnostic Procedure

EC-295

Page 1020 of 2898

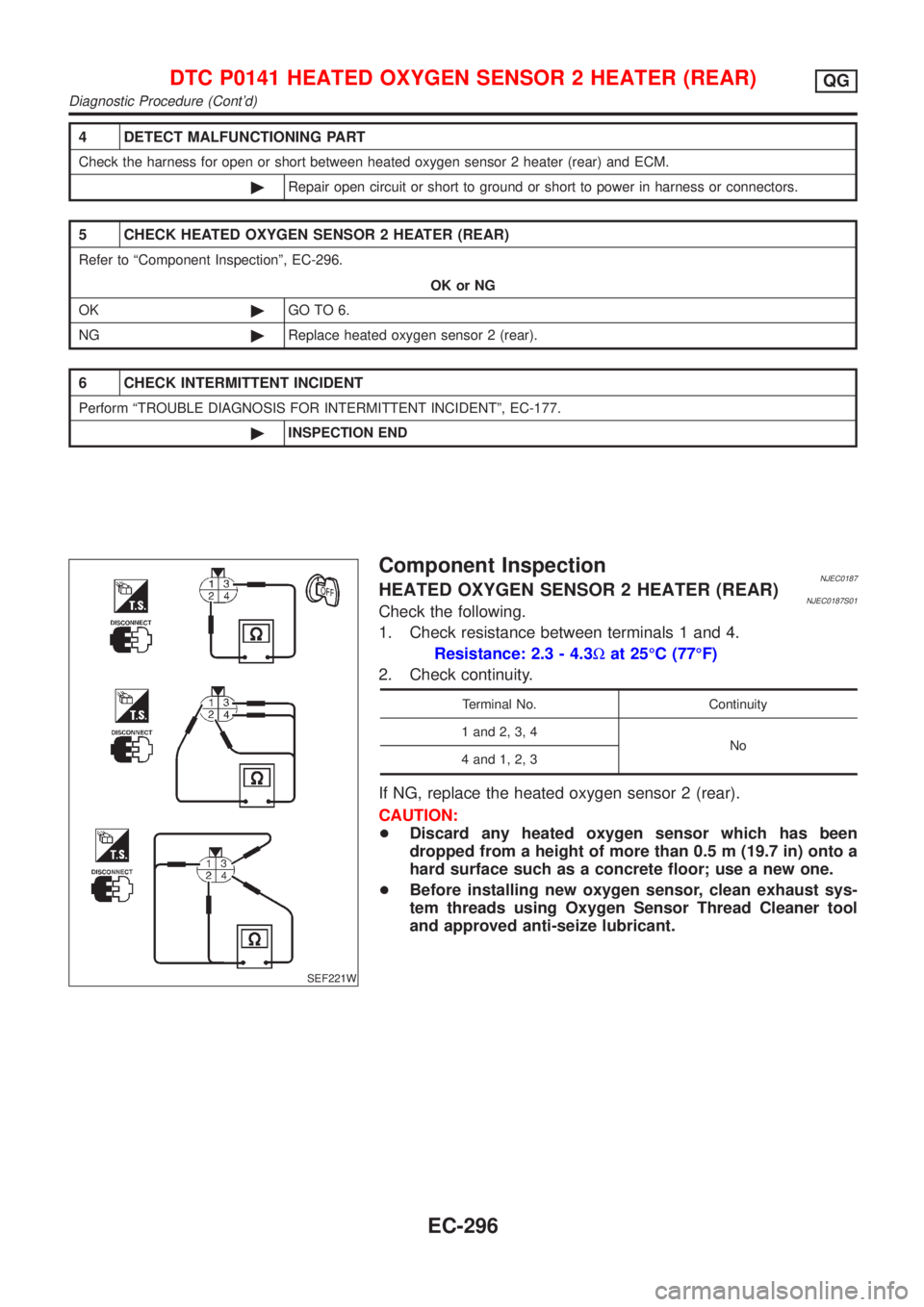

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 heater (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK HEATED OXYGEN SENSOR 2 HEATER (REAR)

Refer to ªComponent Inspectionº, EC-296.

OK or NG

OK©GO TO 6.

NG©Replace heated oxygen sensor 2 (rear).

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

©INSPECTION END

SEF221W

Component InspectionNJEC0187HEATED OXYGEN SENSOR 2 HEATER (REAR)NJEC0187S01Check the following.

1. Check resistance between terminals 1 and 4.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

2. Check continuity.

Terminal No. Continuity

1 and 2, 3, 4

No

4 and 1, 2, 3

If NG, replace the heated oxygen sensor 2 (rear).

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Diagnostic Procedure (Cont'd)

EC-296