o2 sensor NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 325 of 2898

12. A/T Does Not Perform Lock-up=NJAT0342SYMPTOM:

A/T does not perform lock-up at the specified speed.

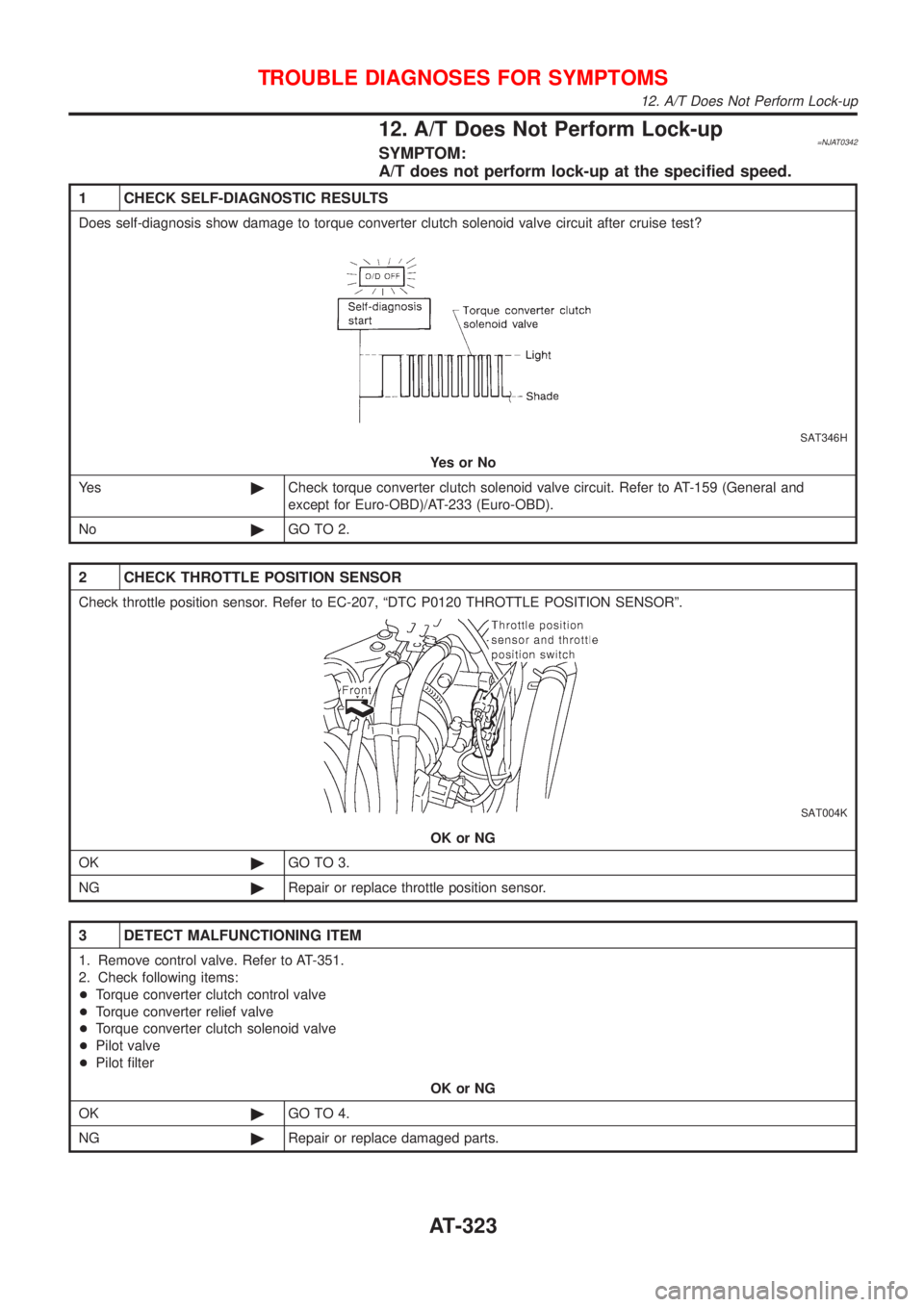

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to torque converter clutch solenoid valve circuit after cruise test?

SAT346H

YesorNo

Ye s©Check torque converter clutch solenoid valve circuit. Refer to AT-159 (General and

except for Euro-OBD)/AT-233 (Euro-OBD).

No©GO TO 2.

2 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-207, ªDTC P0120 THROTTLE POSITION SENSORº.

SAT004K

OK or NG

OK©GO TO 3.

NG©Repair or replace throttle position sensor.

3 DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-351.

2. Check following items:

+Torque converter clutch control valve

+Torque converter relief valve

+Torque converter clutch solenoid valve

+Pilot valve

+Pilot filter

OK or NG

OK©GO TO 4.

NG©Repair or replace damaged parts.

TROUBLE DIAGNOSES FOR SYMPTOMS

12. A/T Does Not Perform Lock-up

AT-323

Page 330 of 2898

15. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)=NJAT0345SYMPTOM:

+Engine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

+Vehicle does not decelerate by engine brake when turning

overdrive control switch OFF.

+Vehicle does not decelerate by engine brake when shifting

A/T from ªDº to ª2º position.

1 CHECK SELF-DIAGNOSTIC RESULTS

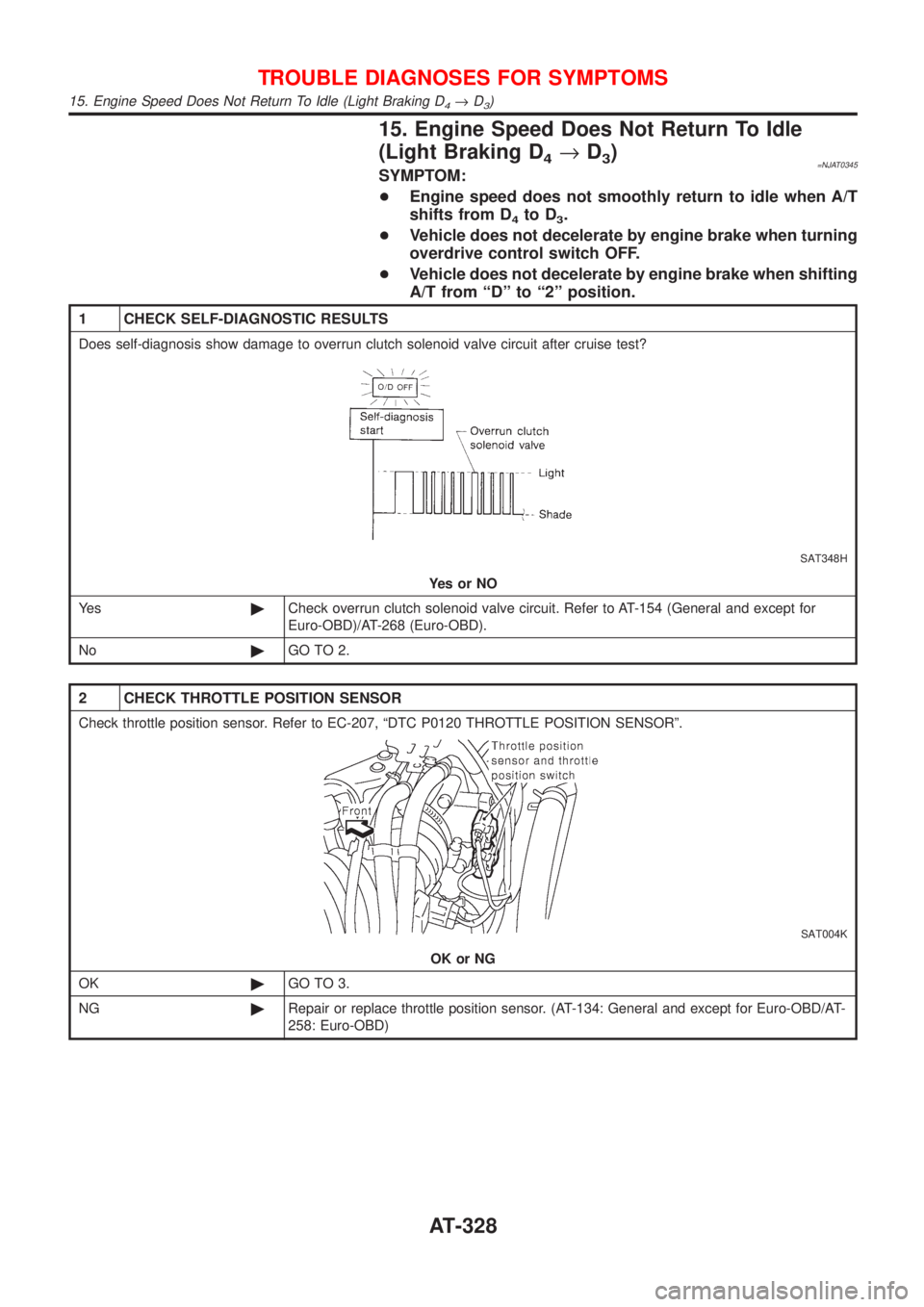

Does self-diagnosis show damage to overrun clutch solenoid valve circuit after cruise test?

SAT348H

YesorNO

Ye s©Check overrun clutch solenoid valve circuit. Refer to AT-154 (General and except for

Euro-OBD)/AT-268 (Euro-OBD).

No©GO TO 2.

2 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-207, ªDTC P0120 THROTTLE POSITION SENSORº.

SAT004K

OK or NG

OK©GO TO 3.

NG©Repair or replace throttle position sensor. (AT-134: General and except for Euro-OBD/AT-

258: Euro-OBD)

TROUBLE DIAGNOSES FOR SYMPTOMS

15. Engine Speed Does Not Return To Idle (Light Braking D4®D3)

AT-328

Page 332 of 2898

16. Vehicle Does Not Start From D1NJAT0346SYMPTOM:

Vehicle does not start from D

1on Cruise test Ð Part 2.

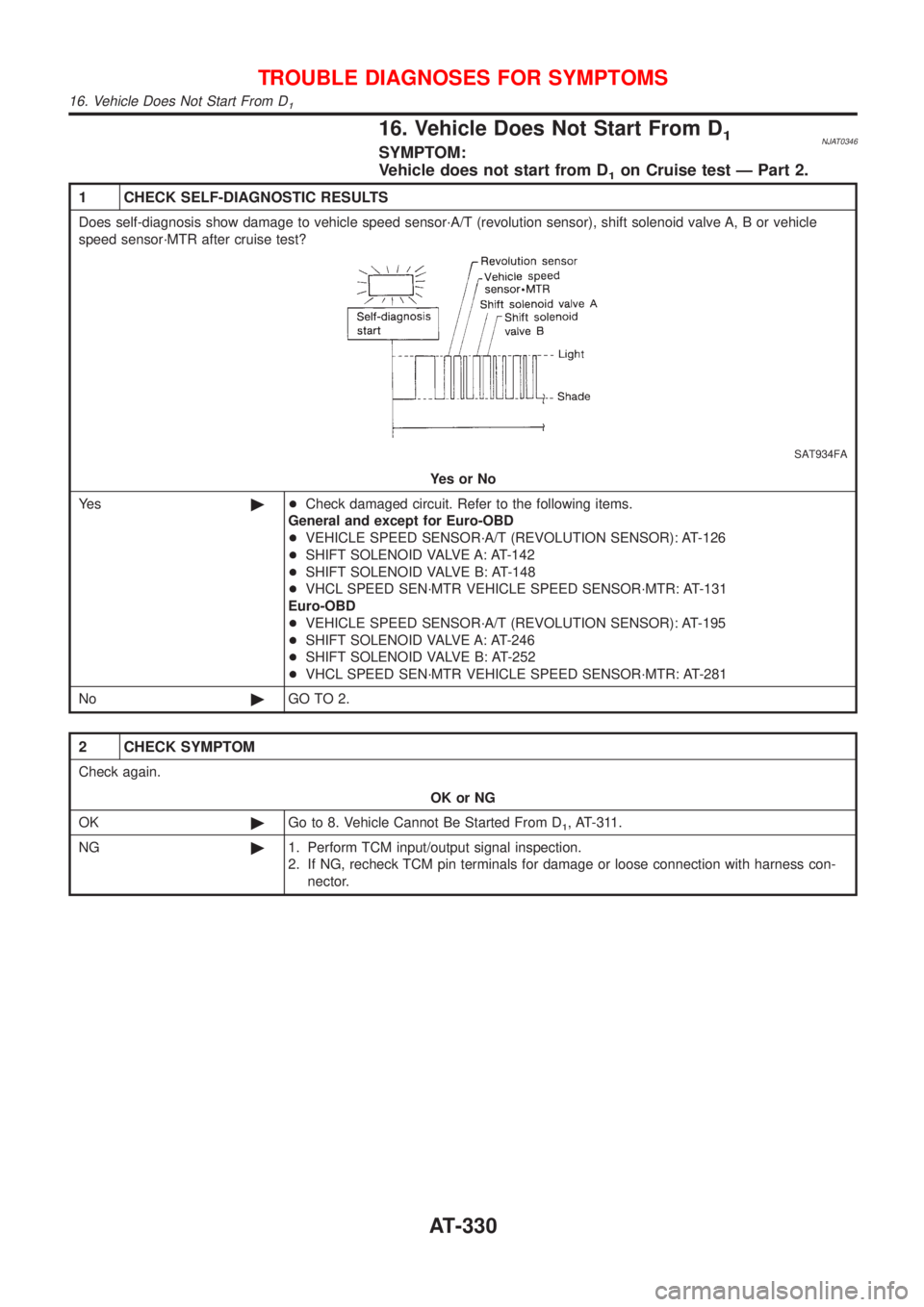

1 CHECK SELF-DIAGNOSTIC RESULTS

Does self-diagnosis show damage to vehicle speed sensor´A/T (revolution sensor), shift solenoid valve A, B or vehicle

speed sensor´MTR after cruise test?

SAT934FA

YesorNo

Ye s©+Check damaged circuit. Refer to the following items.

General and except for Euro-OBD

+VEHICLE SPEED SENSOR´A/T (REVOLUTION SENSOR): AT-126

+SHIFT SOLENOID VALVE A: AT-142

+SHIFT SOLENOID VALVE B: AT-148

+VHCL SPEED SEN´MTR VEHICLE SPEED SENSOR´MTR: AT-131

Euro-OBD

+VEHICLE SPEED SENSOR´A/T (REVOLUTION SENSOR): AT-195

+SHIFT SOLENOID VALVE A: AT-246

+SHIFT SOLENOID VALVE B: AT-252

+VHCL SPEED SEN´MTR VEHICLE SPEED SENSOR´MTR: AT-281

No©GO TO 2.

2 CHECK SYMPTOM

Check again.

OK or NG

OK©Go to 8. Vehicle Cannot Be Started From D

1, AT-311.

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

16. Vehicle Does Not Start From D1

AT-330

Page 355 of 2898

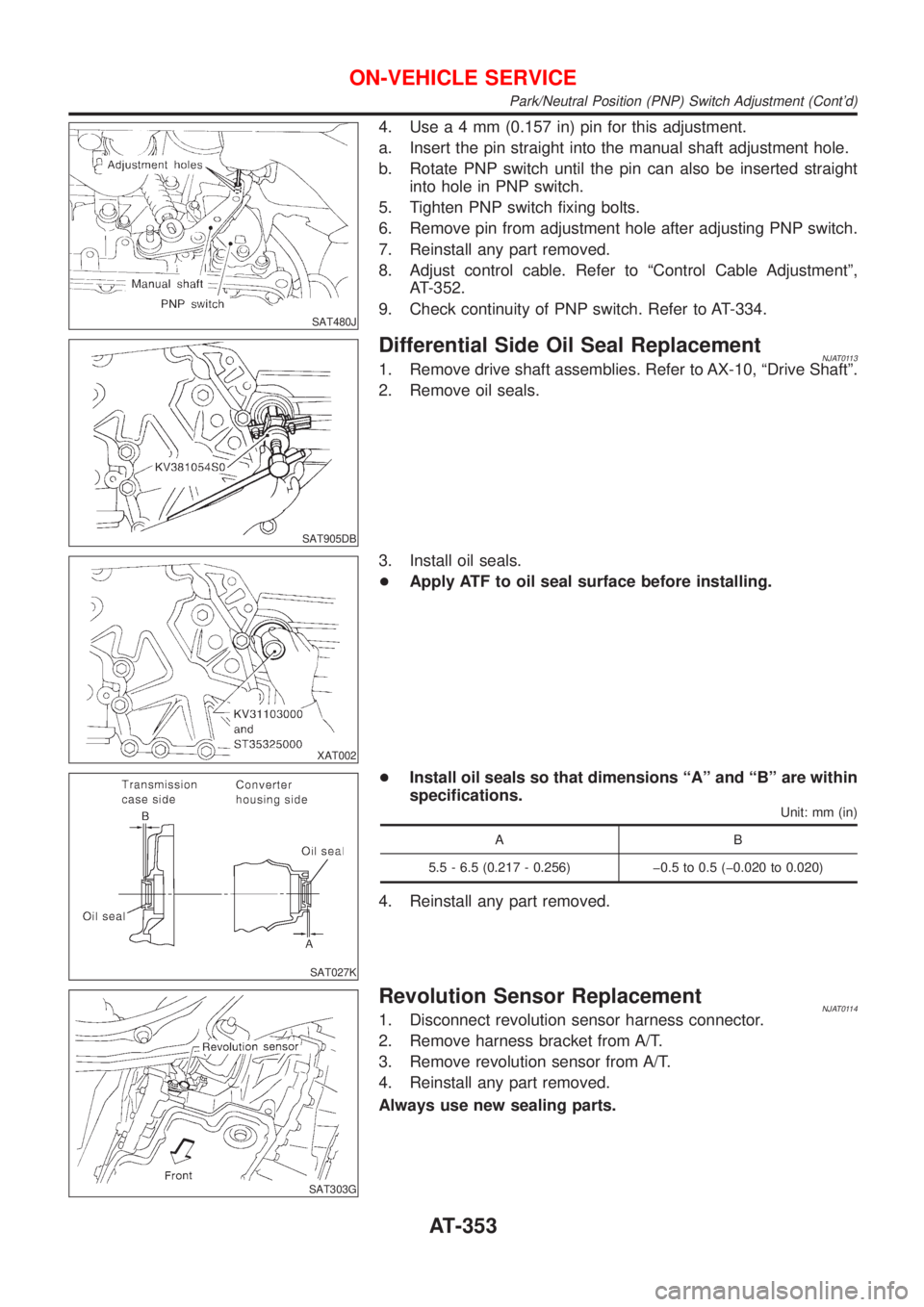

SAT480J

4. Usea4mm(0.157 in) pin for this adjustment.

a. Insert the pin straight into the manual shaft adjustment hole.

b. Rotate PNP switch until the pin can also be inserted straight

into hole in PNP switch.

5. Tighten PNP switch fixing bolts.

6. Remove pin from adjustment hole after adjusting PNP switch.

7. Reinstall any part removed.

8. Adjust control cable. Refer to ªControl Cable Adjustmentº,

AT-352.

9. Check continuity of PNP switch. Refer to AT-334.

SAT905DB

Differential Side Oil Seal ReplacementNJAT01131. Remove drive shaft assemblies. Refer to AX-10, ªDrive Shaftº.

2. Remove oil seals.

XAT002

3. Install oil seals.

+Apply ATF to oil seal surface before installing.

SAT027K

+Install oil seals so that dimensions ªAº and ªBº are within

specifications.

Unit: mm (in)

AB

5.5 - 6.5 (0.217 - 0.256) þ0.5 to 0.5 (þ0.020 to 0.020)

4. Reinstall any part removed.

SAT303G

Revolution Sensor ReplacementNJAT01141. Disconnect revolution sensor harness connector.

2. Remove harness bracket from A/T.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

Always use new sealing parts.

ON-VEHICLE SERVICE

Park/Neutral Position (PNP) Switch Adjustment (Cont'd)

AT-353

Page 356 of 2898

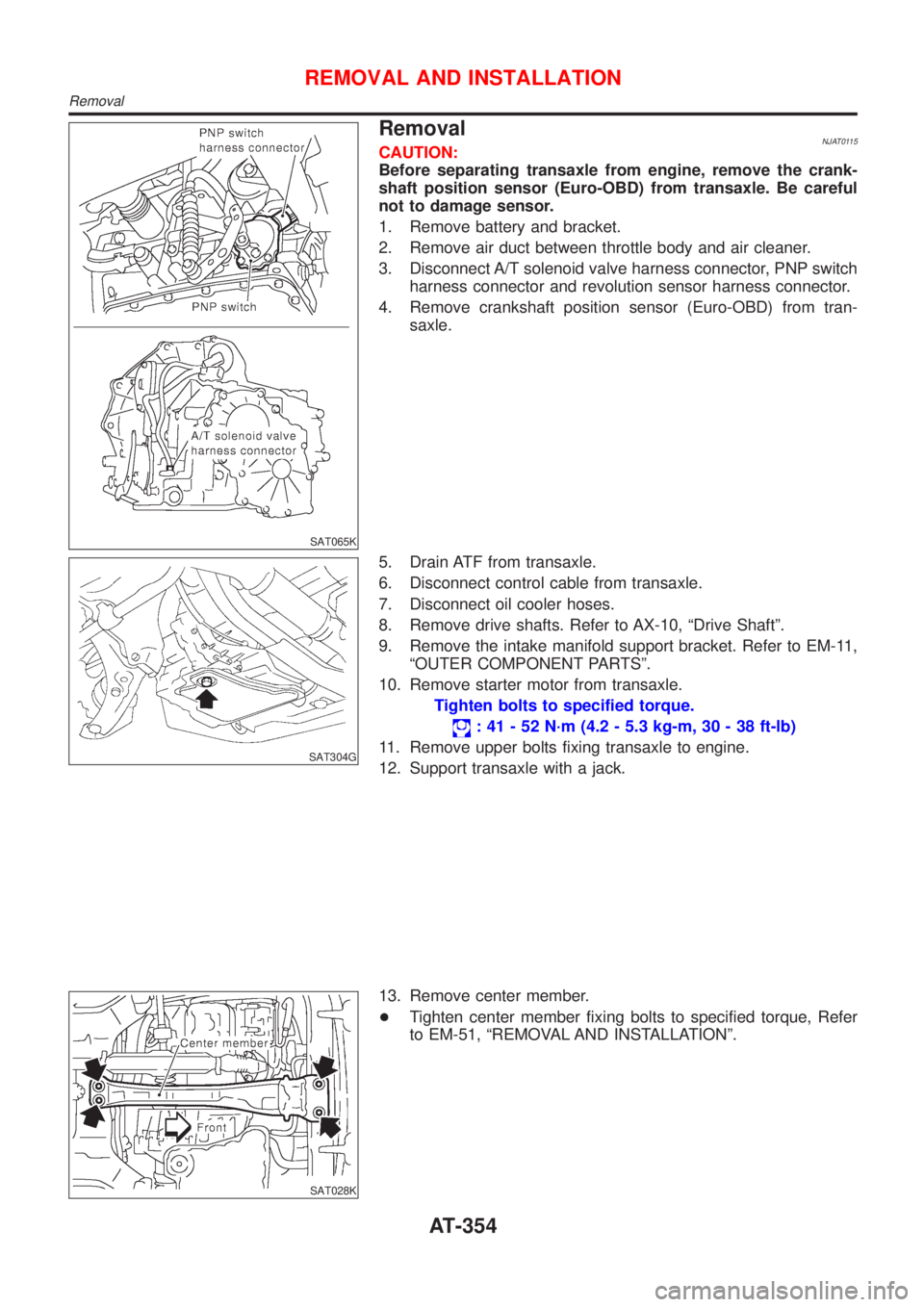

SAT065K

RemovalNJAT0115CAUTION:

Before separating transaxle from engine, remove the crank-

shaft position sensor (Euro-OBD) from transaxle. Be careful

not to damage sensor.

1. Remove battery and bracket.

2. Remove air duct between throttle body and air cleaner.

3. Disconnect A/T solenoid valve harness connector, PNP switch

harness connector and revolution sensor harness connector.

4. Remove crankshaft position sensor (Euro-OBD) from tran-

saxle.

SAT304G

5. Drain ATF from transaxle.

6. Disconnect control cable from transaxle.

7. Disconnect oil cooler hoses.

8. Remove drive shafts. Refer to AX-10, ªDrive Shaftº.

9. Remove the intake manifold support bracket. Refer to EM-11,

ªOUTER COMPONENT PARTSº.

10. Remove starter motor from transaxle.

Tighten bolts to specified torque.

: 41 - 52 N´m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

11. Remove upper bolts fixing transaxle to engine.

12. Support transaxle with a jack.

SAT028K

13. Remove center member.

+Tighten center member fixing bolts to specified torque, Refer

to EM-51, ªREMOVAL AND INSTALLATIONº.

REMOVAL AND INSTALLATION

Removal

AT-354

Page 382 of 2898

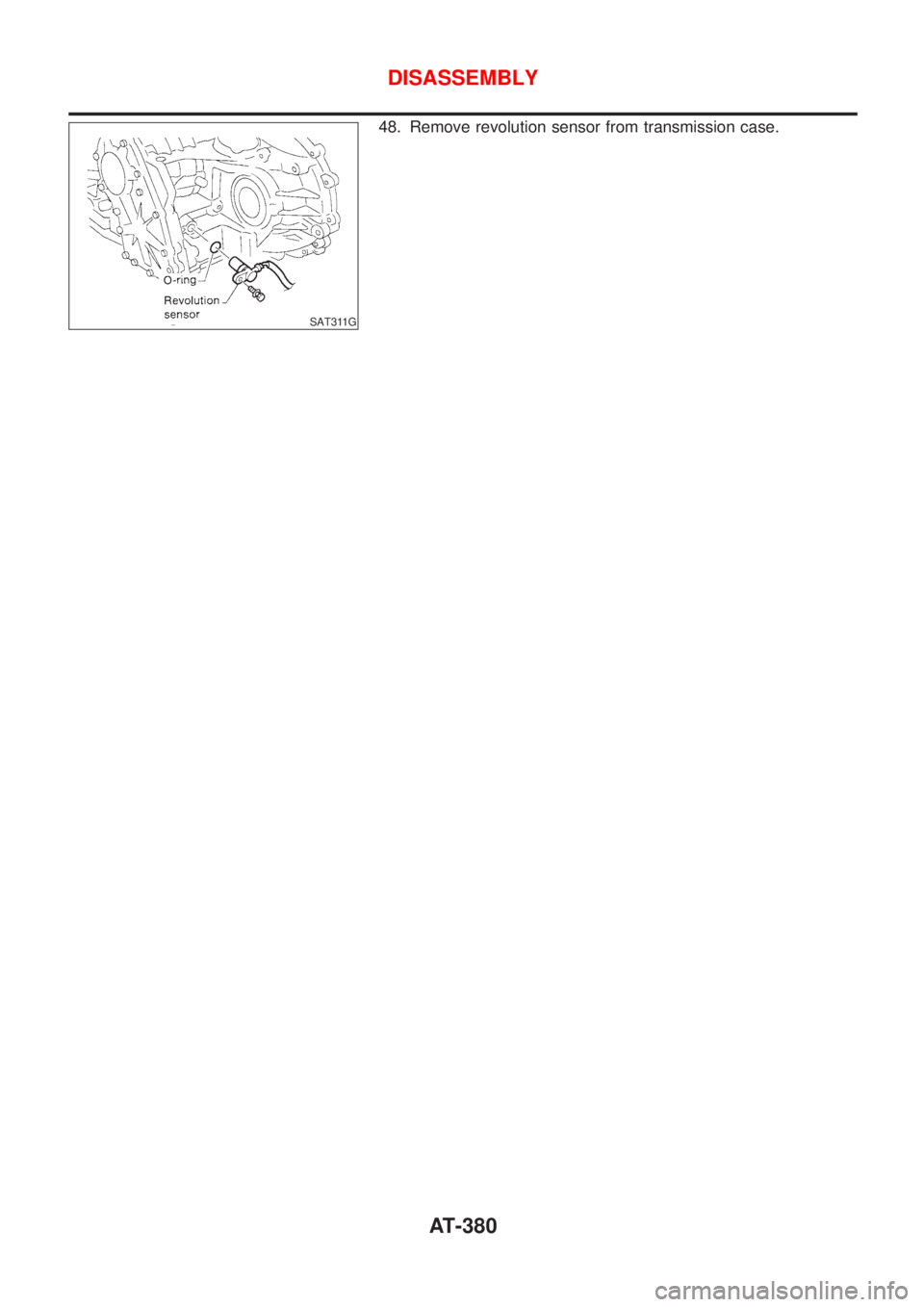

SAT311G

48. Remove revolution sensor from transmission case.

DISASSEMBLY

AT-380

Page 448 of 2898

SAT311G

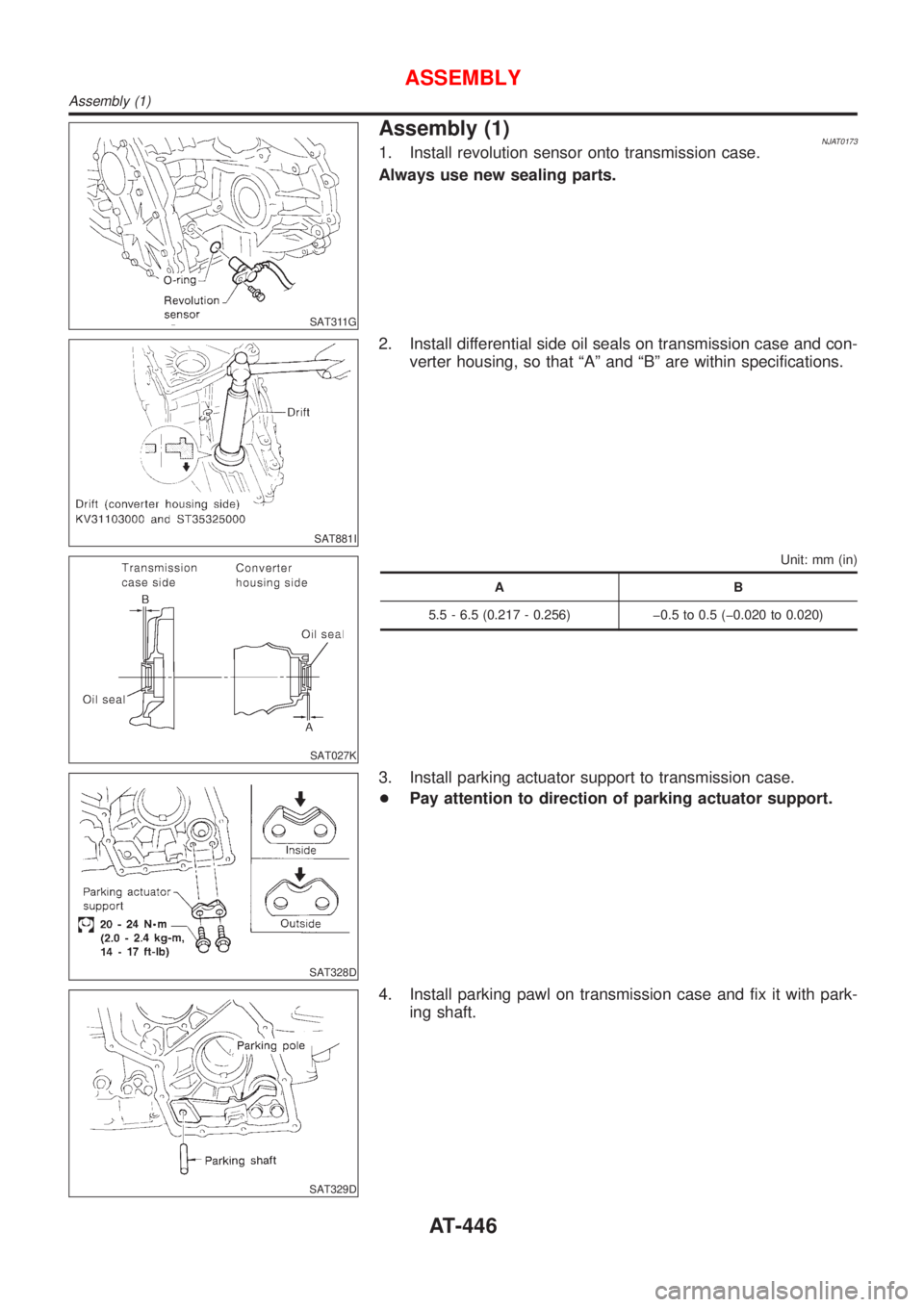

Assembly (1)NJAT01731. Install revolution sensor onto transmission case.

Always use new sealing parts.

SAT881I

2. Install differential side oil seals on transmission case and con-

verter housing, so that ªAº and ªBº are within specifications.

SAT027K

Unit: mm (in)

AB

5.5 - 6.5 (0.217 - 0.256) þ0.5 to 0.5 (þ0.020 to 0.020)

SAT328D

3. Install parking actuator support to transmission case.

+Pay attention to direction of parking actuator support.

SAT329D

4. Install parking pawl on transmission case and fix it with park-

ing shaft.

ASSEMBLY

Assembly (1)

AT-446

Page 487 of 2898

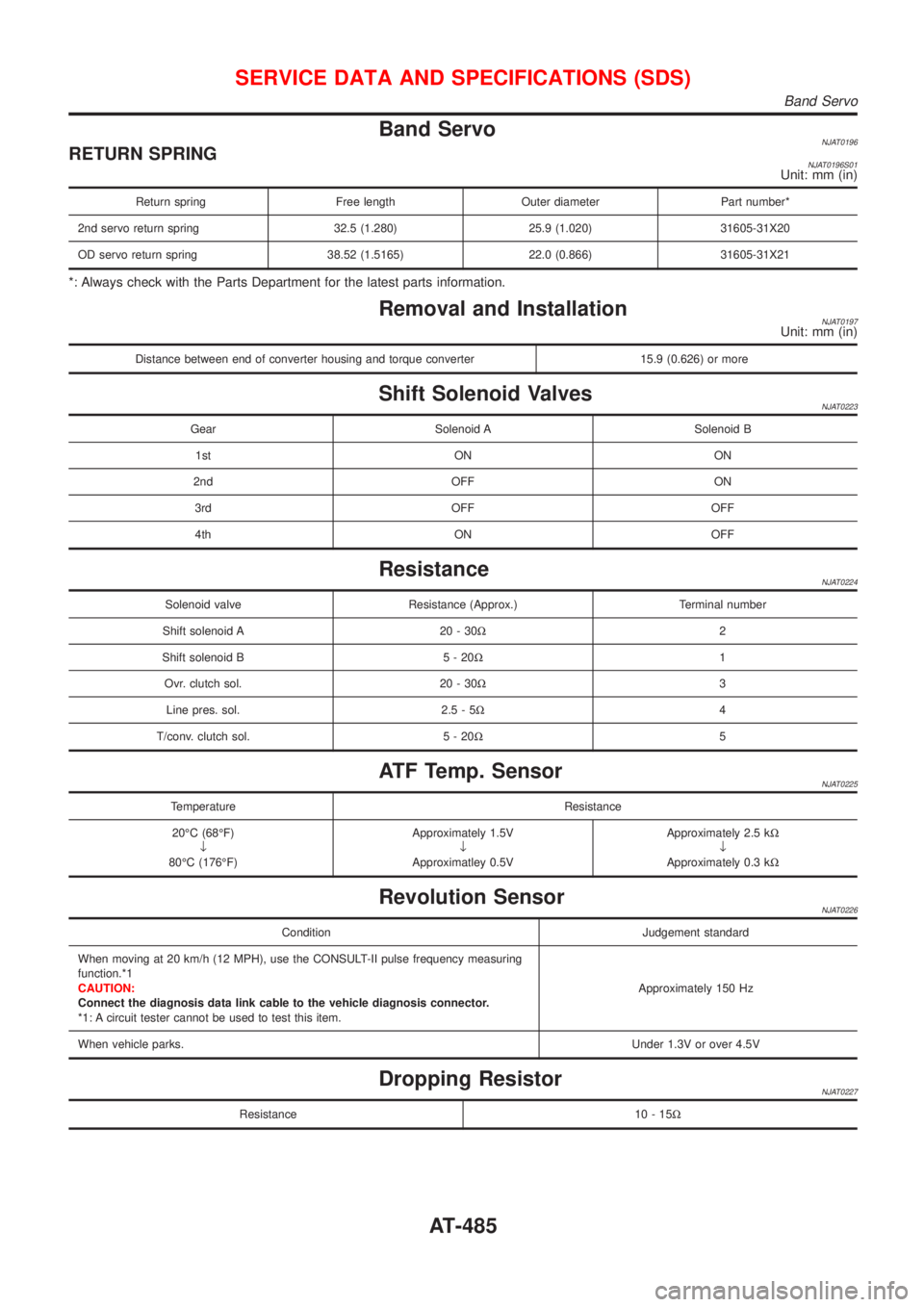

Band ServoNJAT0196RETURN SPRINGNJAT0196S01Unit: mm (in)

Return spring Free length Outer diameter Part number*

2nd servo return spring 32.5 (1.280) 25.9 (1.020) 31605-31X20

OD servo return spring 38.52 (1.5165) 22.0 (0.866) 31605-31X21

*: Always check with the Parts Department for the latest parts information.

Removal and InstallationNJAT0197Unit: mm (in)

Distance between end of converter housing and torque converter 15.9 (0.626) or more

Shift Solenoid ValvesNJAT0223

Gear Solenoid A Solenoid B

1st ON ON

2nd OFF ON

3rd OFF OFF

4th ON OFF

ResistanceNJAT0224

Solenoid valve Resistance (Approx.) Terminal number

Shift solenoid A 20 - 30W2

Shift solenoid B 5 - 20W1

Ovr. clutch sol. 20 - 30W3

Line pres. sol. 2.5 - 5W4

T/conv. clutch sol. 5 - 20W5

ATF Temp. SensorNJAT0225

Temperature Resistance

20ÉC (68ÉF)

¯

80ÉC (176ÉF)Approximately 1.5V

¯

Approximatley 0.5VApproximately 2.5 kW

¯

Approximately 0.3 kW

Revolution SensorNJAT0226

Condition Judgement standard

When moving at 20 km/h (12 MPH), use the CONSULT-II pulse frequency measuring

function.*1

CAUTION:

Connect the diagnosis data link cable to the vehicle diagnosis connector.

*1: A circuit tester cannot be used to test this item.Approximately 150 Hz

When vehicle parks.Under 1.3V or over 4.5V

Dropping ResistorNJAT0227

Resistance 10 - 15W

SERVICE DATA AND SPECIFICATIONS (SDS)

Band Servo

AT-485

Page 493 of 2898

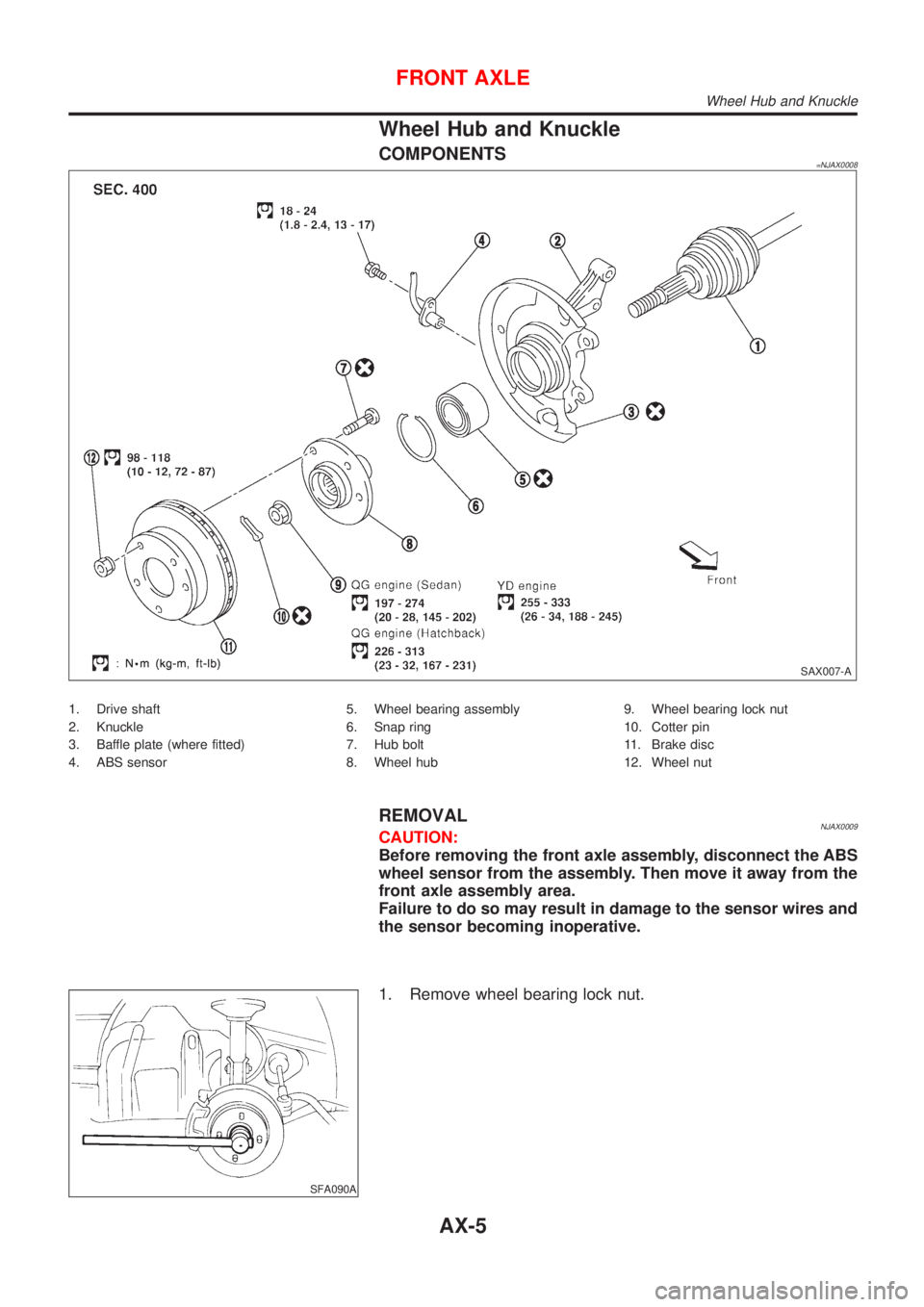

Wheel Hub and Knuckle

COMPONENTS=NJAX0008

SAX007-A

1. Drive shaft

2. Knuckle

3. Baffle plate (where fitted)

4. ABS sensor5. Wheel bearing assembly

6. Snap ring

7. Hub bolt

8. Wheel hub9. Wheel bearing lock nut

10. Cotter pin

11. Brake disc

12. Wheel nut

REMOVALNJAX0009CAUTION:

Before removing the front axle assembly, disconnect the ABS

wheel sensor from the assembly. Then move it away from the

front axle assembly area.

Failure to do so may result in damage to the sensor wires and

the sensor becoming inoperative.

SFA090A

1. Remove wheel bearing lock nut.

FRONT AXLE

Wheel Hub and Knuckle

AX-5

Page 510 of 2898

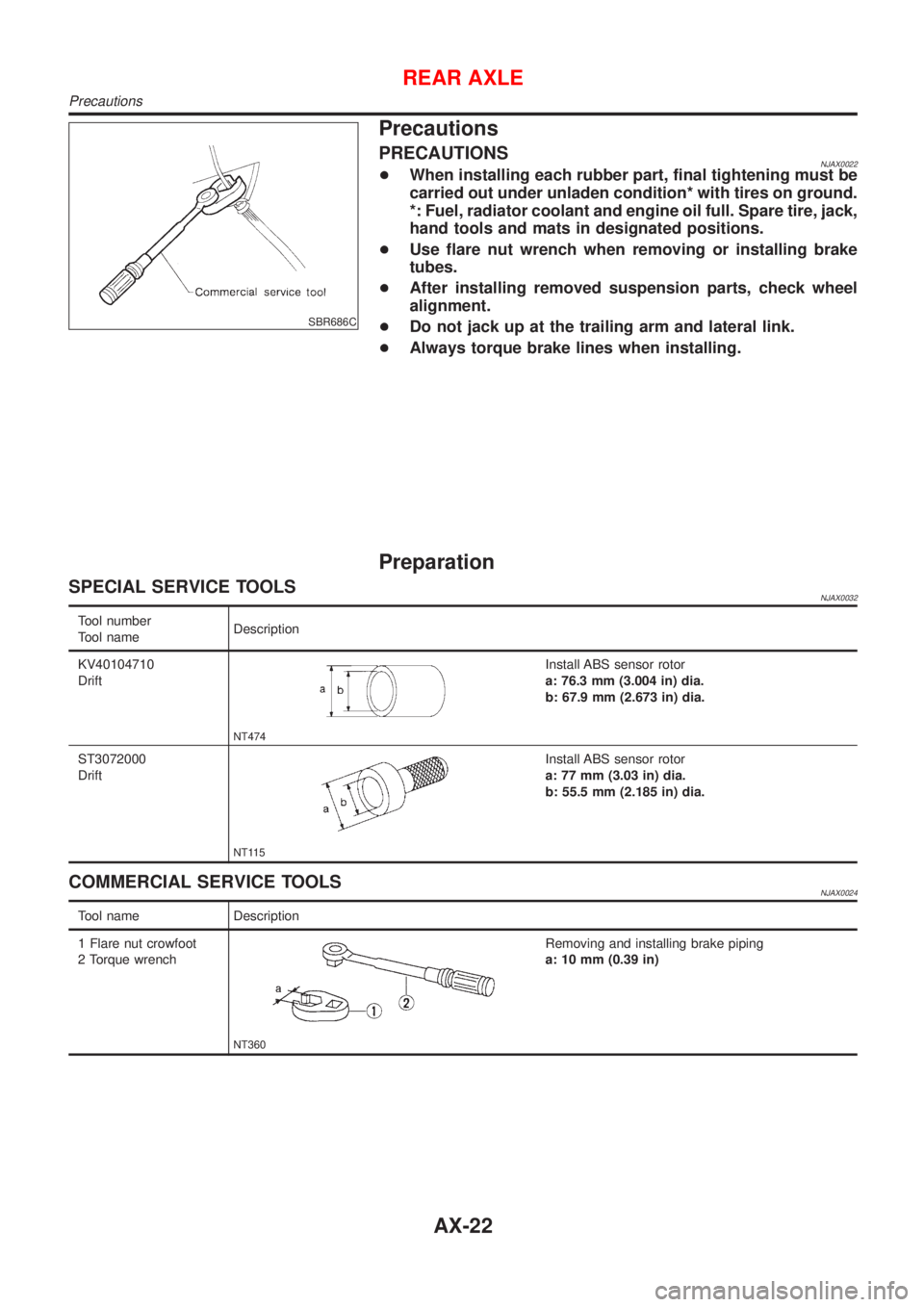

SBR686C

Precautions

PRECAUTIONSNJAX0022+When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+Use flare nut wrench when removing or installing brake

tubes.

+After installing removed suspension parts, check wheel

alignment.

+Do not jack up at the trailing arm and lateral link.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0032

Tool number

Tool nameDescription

KV40104710

Drift

NT474

Install ABS sensor rotor

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST3072000

Drift

NT115

Install ABS sensor rotor

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

COMMERCIAL SERVICE TOOLSNJAX0024

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

REAR AXLE

Precautions

AX-22