o2 sensor NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 737 of 2898

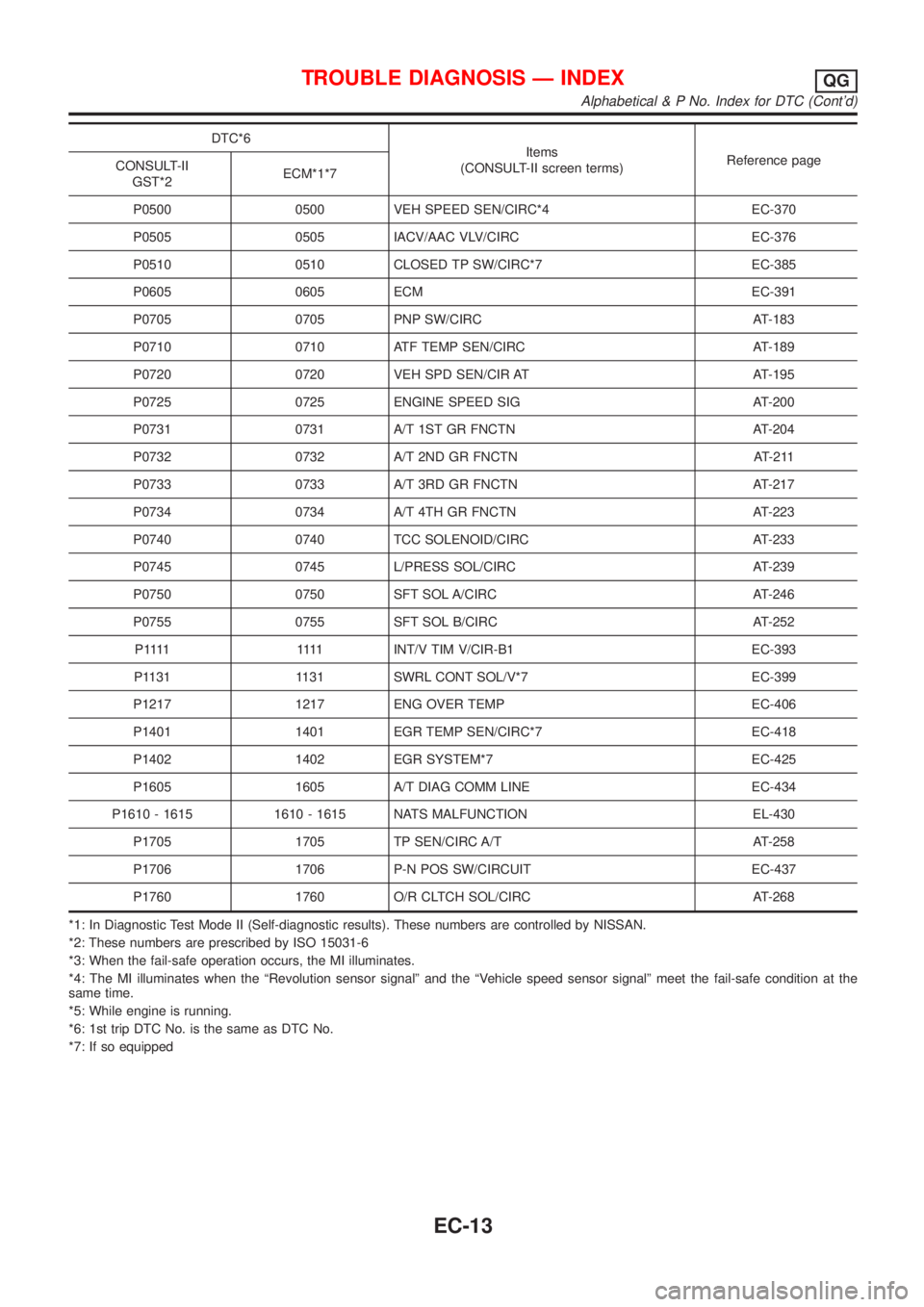

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1*7

P0500 0500 VEH SPEED SEN/CIRC*4 EC-370

P0505 0505 IACV/AAC VLV/CIRC EC-376

P0510 0510 CLOSED TP SW/CIRC*7 EC-385

P0605 0605 ECM EC-391

P0705 0705 PNP SW/CIRC AT-183

P0710 0710 ATF TEMP SEN/CIRC AT-189

P0720 0720 VEH SPD SEN/CIR AT AT-195

P0725 0725 ENGINE SPEED SIG AT-200

P0731 0731 A/T 1ST GR FNCTN AT-204

P0732 0732 A/T 2ND GR FNCTN AT-211

P0733 0733 A/T 3RD GR FNCTN AT-217

P0734 0734 A/T 4TH GR FNCTN AT-223

P0740 0740 TCC SOLENOID/CIRC AT-233

P0745 0745 L/PRESS SOL/CIRC AT-239

P0750 0750 SFT SOL A/CIRC AT-246

P0755 0755 SFT SOL B/CIRC AT-252

P 1111 1111INT/V TIM V/CIR-B1 EC-393

P1131 1131 SWRL CONT SOL/V*7 EC-399

P1217 1217 ENG OVER TEMP EC-406

P1401 1401 EGR TEMP SEN/CIRC*7 EC-418

P1402 1402 EGR SYSTEM*7 EC-425

P1605 1605 A/T DIAG COMM LINE EC-434

P1610 - 1615 1610 - 1615 NATS MALFUNCTION EL-430

P1705 1705 TP SEN/CIRC A/T AT-258

P1706 1706 P-N POS SW/CIRCUIT EC-437

P1760 1760 O/R CLTCH SOL/CIRC AT-268

*1: In Diagnostic Test Mode II (Self-diagnostic results). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6

*3: When the fail-safe operation occurs, the MI illuminates.

*4: The MI illuminates when the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the

same time.

*5: While engine is running.

*6: 1st trip DTC No. is the same as DTC No.

*7: If so equipped

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-13

Page 738 of 2898

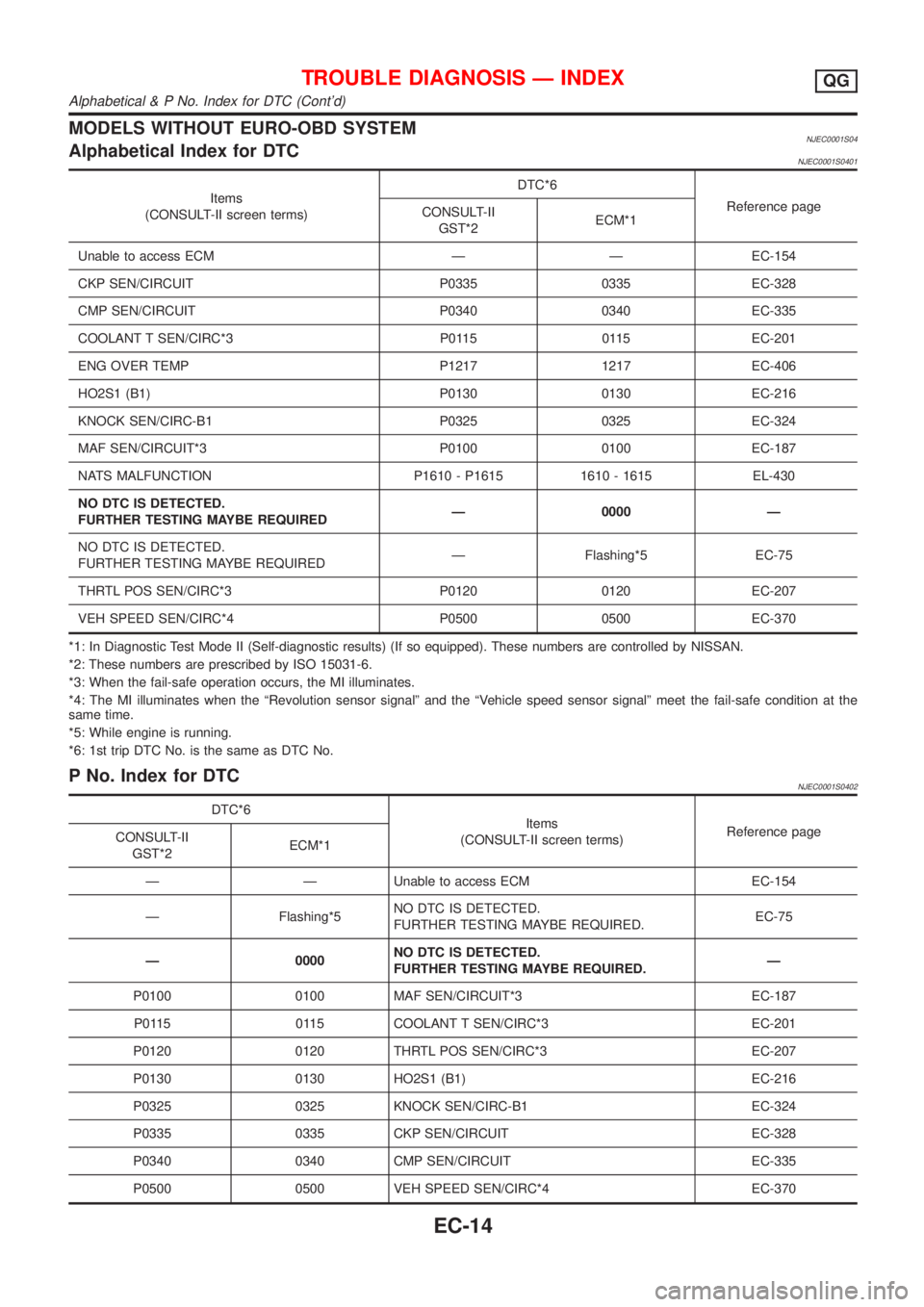

MODELS WITHOUT EURO-OBD SYSTEMNJEC0001S04Alphabetical Index for DTCNJEC0001S0401

Items

(CONSULT-II screen terms)DTC*6

Reference page

CONSULT-II

GST*2ECM*1

Unable to access ECM Ð Ð EC-154

CKP SEN/CIRCUIT P0335 0335 EC-328

CMP SEN/CIRCUIT P0340 0340 EC-335

COOLANT T SEN/CIRC*3 P0115 0115 EC-201

ENG OVER TEMP P1217 1217 EC-406

HO2S1 (B1) P0130 0130 EC-216

KNOCK SEN/CIRC-B1 P0325 0325 EC-324

MAF SEN/CIRCUIT*3 P0100 0100 EC-187

NATS MALFUNCTION P1610 - P1615 1610 - 1615 EL-430

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ 0000 Ð

NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIREDÐ Flashing*5 EC-75

THRTL POS SEN/CIRC*3 P0120 0120 EC-207

VEH SPEED SEN/CIRC*4 P0500 0500 EC-370

*1: In Diagnostic Test Mode II (Self-diagnostic results) (If so equipped). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6.

*3: When the fail-safe operation occurs, the MI illuminates.

*4: The MI illuminates when the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the

same time.

*5: While engine is running.

*6: 1st trip DTC No. is the same as DTC No.

P No. Index for DTCNJEC0001S0402

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1

Ð Ð Unable to access ECM EC-154

Ð Flashing*5NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.EC-75

Ð 0000NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.Ð

P0100 0100 MAF SEN/CIRCUIT*3 EC-187

P0115 0115 COOLANT T SEN/CIRC*3 EC-201

P0120 0120 THRTL POS SEN/CIRC*3 EC-207

P0130 0130 HO2S1 (B1) EC-216

P0325 0325 KNOCK SEN/CIRC-B1 EC-324

P0335 0335 CKP SEN/CIRCUIT EC-328

P0340 0340 CMP SEN/CIRCUIT EC-335

P0500 0500 VEH SPEED SEN/CIRC*4 EC-370

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-14

Page 739 of 2898

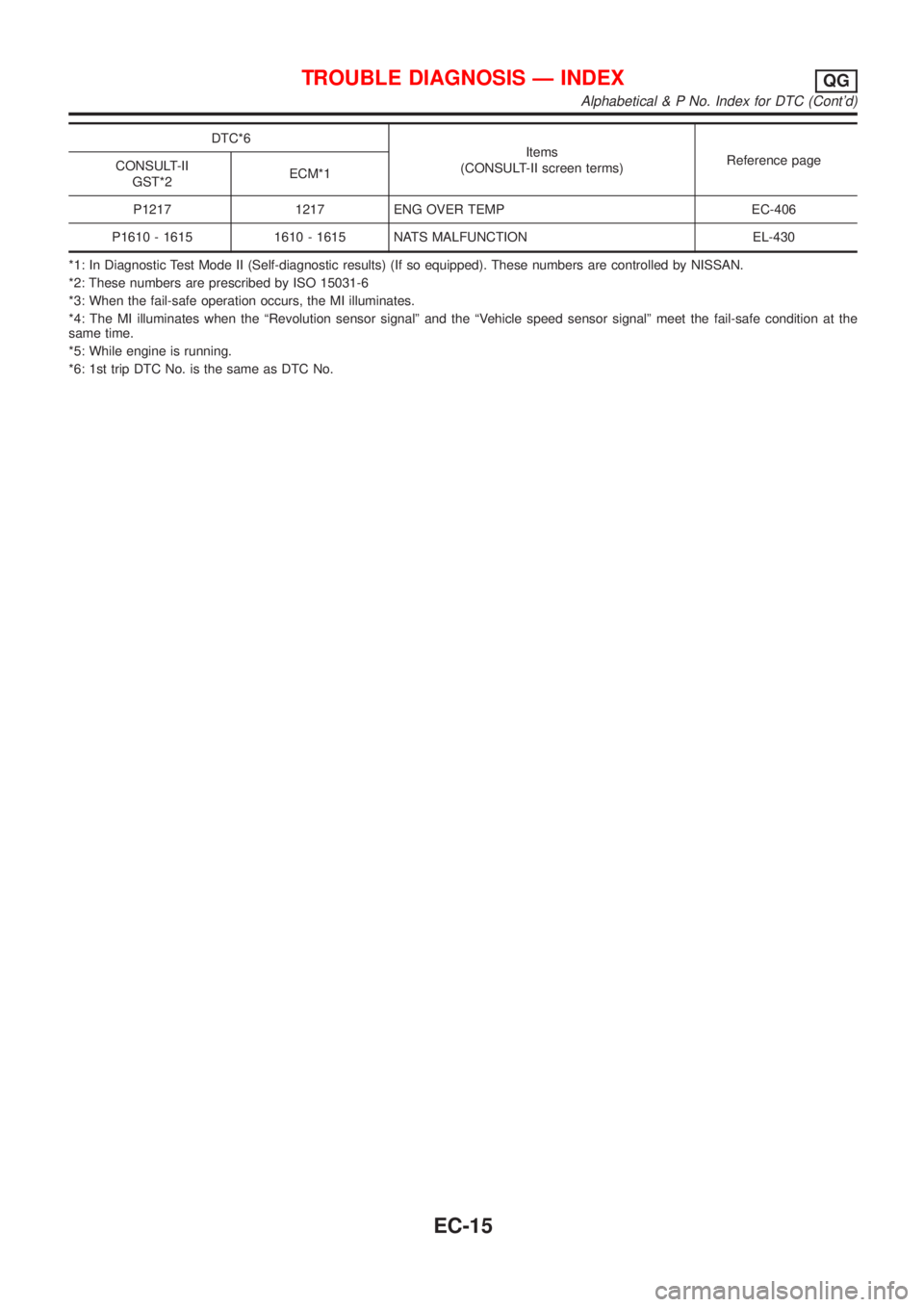

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1

P1217 1217 ENG OVER TEMP EC-406

P1610 - 1615 1610 - 1615 NATS MALFUNCTION EL-430

*1: In Diagnostic Test Mode II (Self-diagnostic results) (If so equipped). These numbers are controlled by NISSAN.

*2: These numbers are prescribed by ISO 15031-6

*3: When the fail-safe operation occurs, the MI illuminates.

*4: The MI illuminates when the ªRevolution sensor signalº and the ªVehicle speed sensor signalº meet the fail-safe condition at the

same time.

*5: While engine is running.

*6: 1st trip DTC No. is the same as DTC No.

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-15

Page 740 of 2898

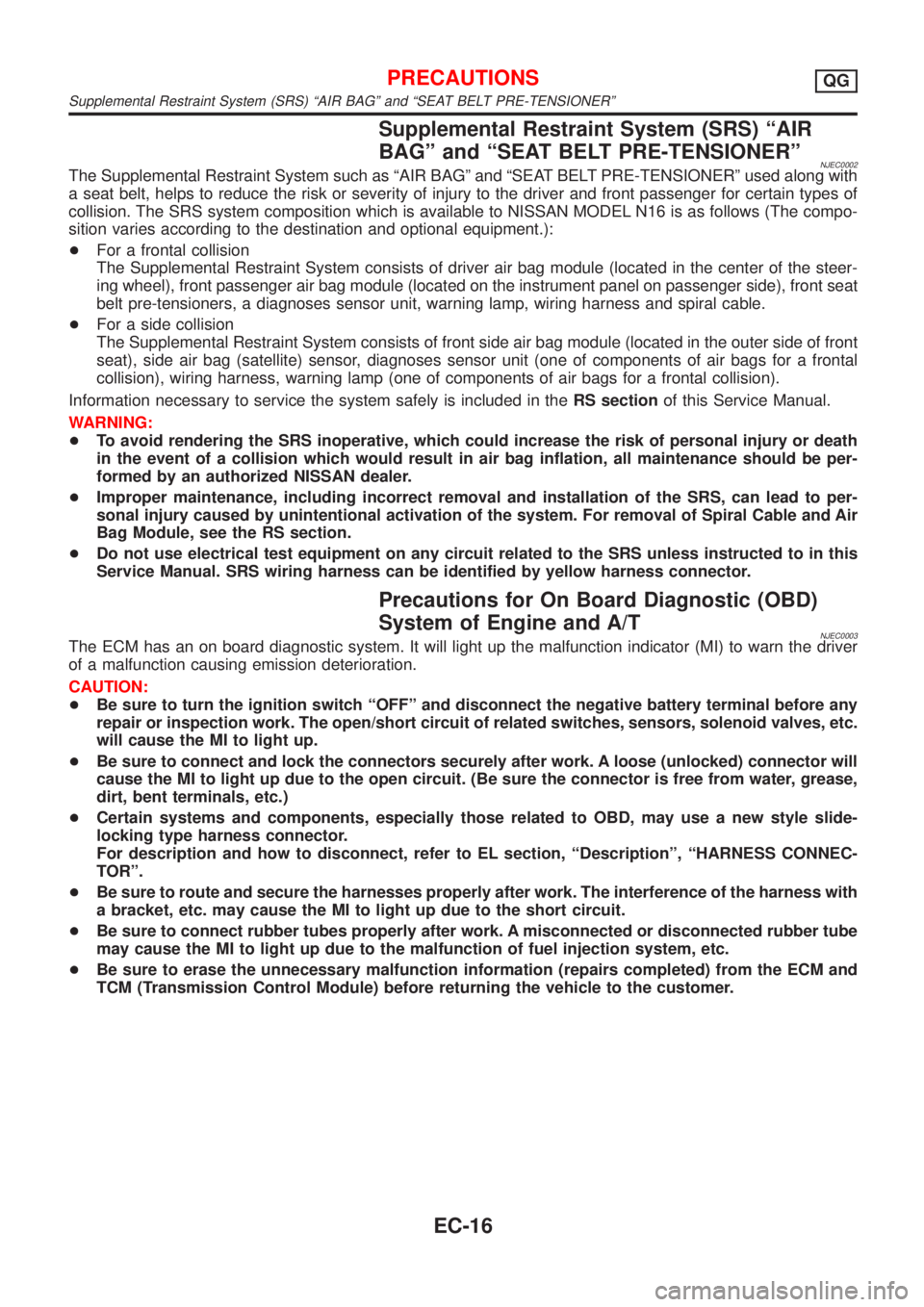

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJEC0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnoses sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnoses sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harness can be identified by yellow harness connector.

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T

NJEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission Control Module) before returning the vehicle to the customer.

PRECAUTIONSQG

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-16

Page 742 of 2898

MEF040D

+Handle mass air flow sensor carefully to avoid damage.

+Do not disassemble mass air flow sensor.

+Do not clean mass air flow sensor with any type of deter-

gent.

+Do not disassemble IAC valve-AAC valve.

+Even a slight leak in the air intake system can cause seri-

ous problems.

+Do not shock or jar the camshaft position sensor and

crankshaft position sensor.

+Before replacing ECM, perform refer to ªECM Terminals

and Reference Valueº inspection and make sure ECM

functions properly, EC-164.

SAT652J

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ªDTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

SEF348N

+When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

+Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

PRECAUTIONSQG

Engine Fuel & Emission Control System (Cont'd)

EC-18

Page 744 of 2898

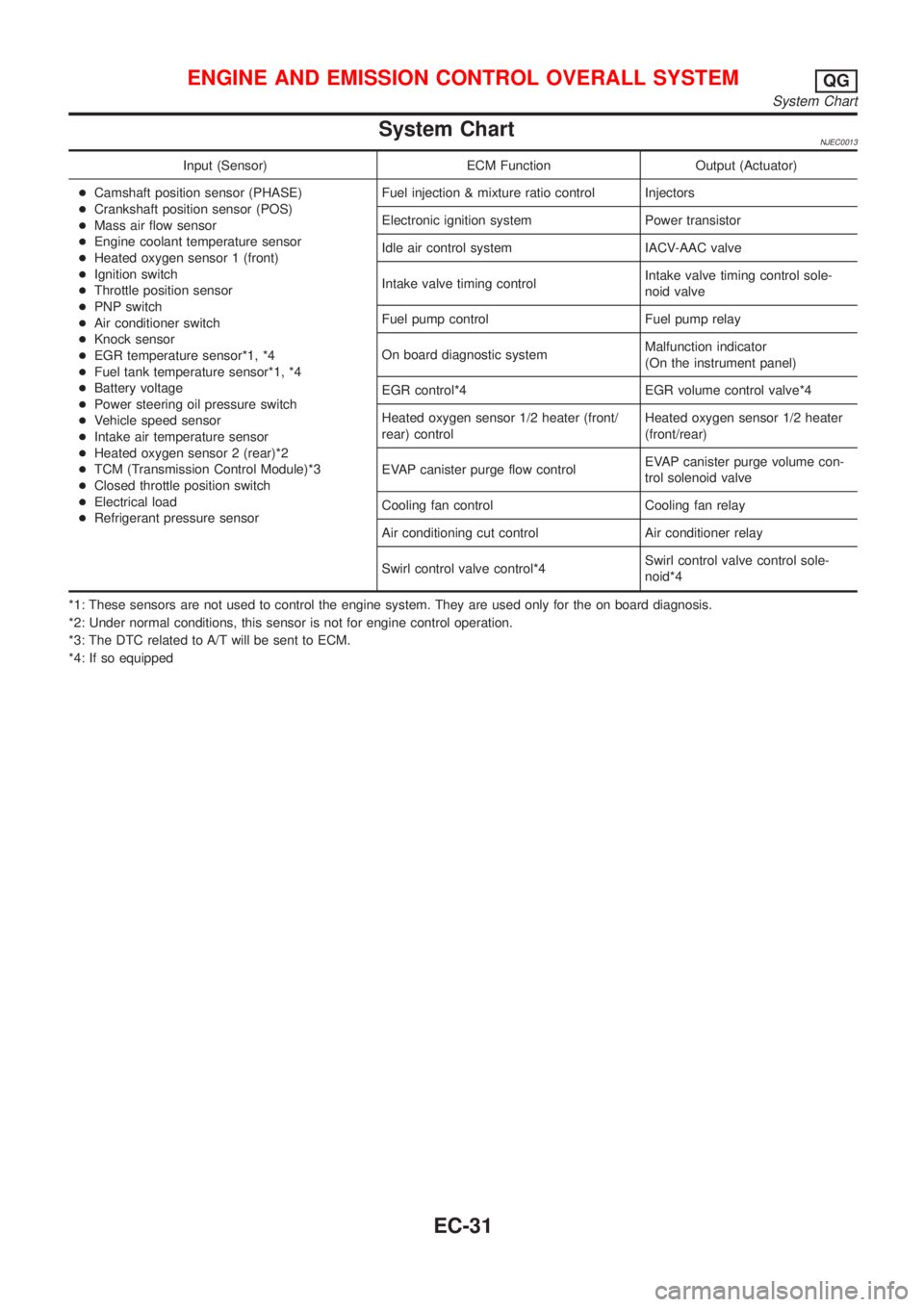

Special Service ToolsNJEC0007

Tool number

Tool nameDescription

KV10117100

Heated oxygen sensor

wrench

NT379

Loosening or tightening heated oxygen sensor 1

(front) with 22 mm hexagon nut

KV10114400

Heated oxygen sensor

wrench

NT636

Loosening or tightening heated oxygen sensor 2

(rear)

a: 22 mm

Commercial Service ToolsNJEC0008

Tool name Description

Fuel filler cap adapter

NT653

Checking fuel tank vacuum relief valve opening

pressure

Oxygen sensor thread

cleaner

NT778

Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm dia. with pitch 1.5 mm, for Zirconia

Oxygen Sensor

b: 12 mm dia. with pitch 1.25 mm, for Titania

Oxygen Sensor

Anti-seize lubricant (Per-

matex

TM133AR or

equivalent meeting MIL

specification MIL-A-907)

NT779

Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

PREPARATIONQG

Special Service Tools

EC-20

Page 755 of 2898

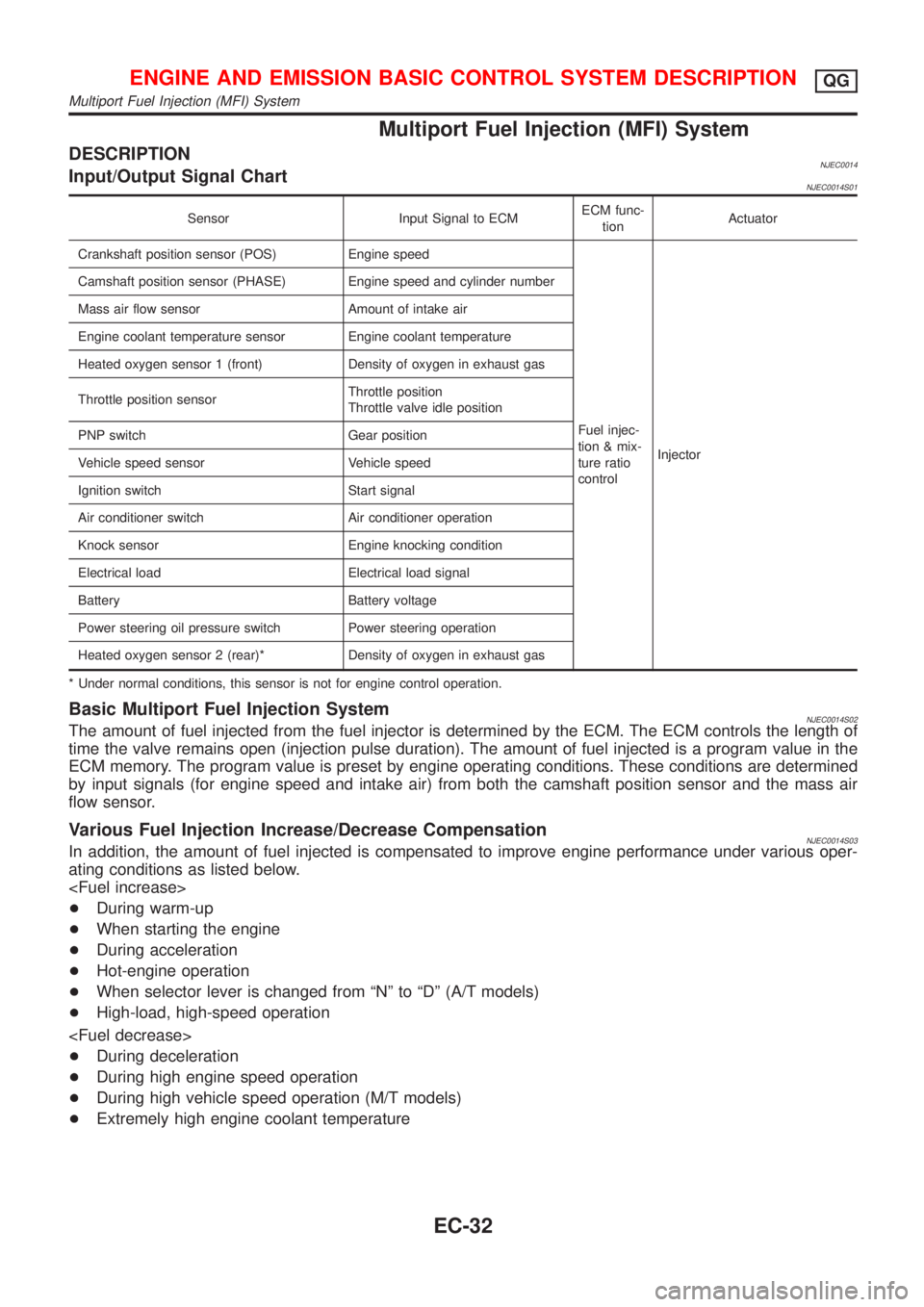

System ChartNJEC0013

Input (Sensor) ECM Function Output (Actuator)

+Camshaft position sensor (PHASE)

+Crankshaft position sensor (POS)

+Mass air flow sensor

+Engine coolant temperature sensor

+Heated oxygen sensor 1 (front)

+Ignition switch

+Throttle position sensor

+PNP switch

+Air conditioner switch

+Knock sensor

+EGR temperature sensor*1, *4

+Fuel tank temperature sensor*1, *4

+Battery voltage

+Power steering oil pressure switch

+Vehicle speed sensor

+Intake air temperature sensor

+Heated oxygen sensor 2 (rear)*2

+TCM (Transmission Control Module)*3

+Closed throttle position switch

+Electrical load

+Refrigerant pressure sensorFuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Intake valve timing controlIntake valve timing control sole-

noid valve

Fuel pump control Fuel pump relay

On board diagnostic systemMalfunction indicator

(On the instrument panel)

EGR control*4 EGR volume control valve*4

Heated oxygen sensor 1/2 heater (front/

rear) controlHeated oxygen sensor 1/2 heater

(front/rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Swirl control valve control*4Swirl control valve control sole-

noid*4

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: Under normal conditions, this sensor is not for engine control operation.

*3: The DTC related to A/T will be sent to ECM.

*4: If so equipped

ENGINE AND EMISSION CONTROL OVERALL SYSTEMQG

System Chart

EC-31

Page 756 of 2898

Multiport Fuel Injection (MFI) System

DESCRIPTIONNJEC0014Input/Output Signal ChartNJEC0014S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Fuel injec-

tion & mix-

ture ratio

controlInjector Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 (front) Density of oxygen in exhaust gas

Throttle position sensorThrottle position

Throttle valve idle position

PNP switch Gear position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Air conditioner switch Air conditioner operation

Knock sensor Engine knocking condition

Electrical load Electrical load signal

Battery Battery voltage

Power steering oil pressure switch Power steering operation

Heated oxygen sensor 2 (rear)* Density of oxygen in exhaust gas

* Under normal conditions, this sensor is not for engine control operation.

Basic Multiport Fuel Injection SystemNJEC0014S02The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the camshaft position sensor and the mass air

flow sensor.

Various Fuel Injection Increase/Decrease CompensationNJEC0014S03In addition, the amount of fuel injected is compensated to improve engine performance under various oper-

ating conditions as listed below.

+During warm-up

+When starting the engine

+During acceleration

+Hot-engine operation

+When selector lever is changed from ªNº to ªDº (A/T models)

+High-load, high-speed operation

+During deceleration

+During high engine speed operation

+During high vehicle speed operation (M/T models)

+Extremely high engine coolant temperature

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONQG

Multiport Fuel Injection (MFI) System

EC-32

Page 757 of 2898

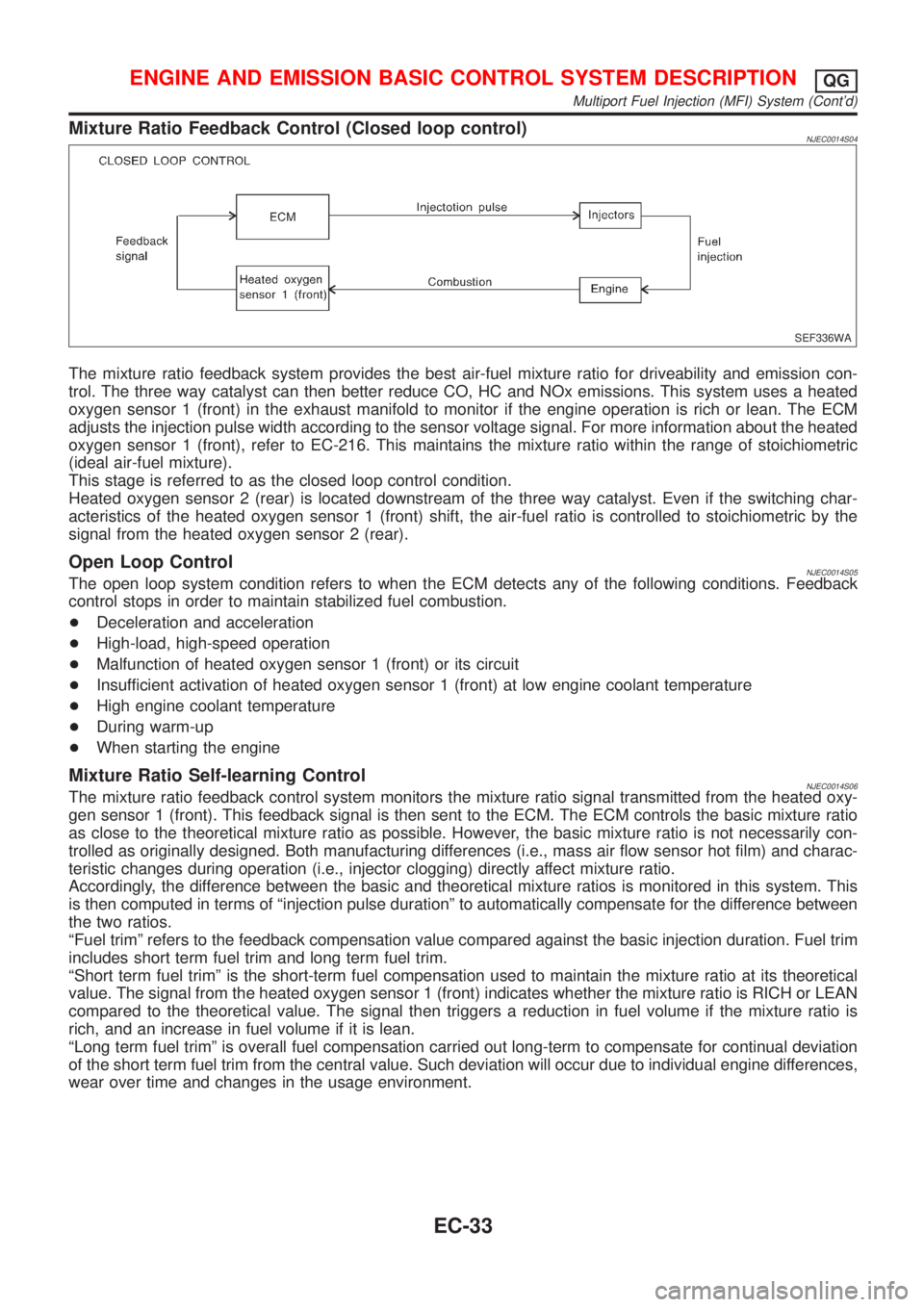

Mixture Ratio Feedback Control (Closed loop control)NJEC0014S04

SEF336WA

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission con-

trol. The three way catalyst can then better reduce CO, HC and NOx emissions. This system uses a heated

oxygen sensor 1 (front) in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about the heated

oxygen sensor 1 (front), refer to EC-216. This maintains the mixture ratio within the range of stoichiometric

(ideal air-fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 (rear) is located downstream of the three way catalyst. Even if the switching char-

acteristics of the heated oxygen sensor 1 (front) shift, the air-fuel ratio is controlled to stoichiometric by the

signal from the heated oxygen sensor 2 (rear).

Open Loop ControlNJEC0014S05The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

+Deceleration and acceleration

+High-load, high-speed operation

+Malfunction of heated oxygen sensor 1 (front) or its circuit

+Insufficient activation of heated oxygen sensor 1 (front) at low engine coolant temperature

+High engine coolant temperature

+During warm-up

+When starting the engine

Mixture Ratio Self-learning ControlNJEC0014S06The mixture ratio feedback control system monitors the mixture ratio signal transmitted from the heated oxy-

gen sensor 1 (front). This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio

as close to the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily con-

trolled as originally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and charac-

teristic changes during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This

is then computed in terms of ªinjection pulse durationº to automatically compensate for the difference between

the two ratios.

ªFuel trimº refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

ªShort term fuel trimº is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from the heated oxygen sensor 1 (front) indicates whether the mixture ratio is RICH or LEAN

compared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is

rich, and an increase in fuel volume if it is lean.

ªLong term fuel trimº is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONQG

Multiport Fuel Injection (MFI) System (Cont'd)

EC-33

Page 758 of 2898

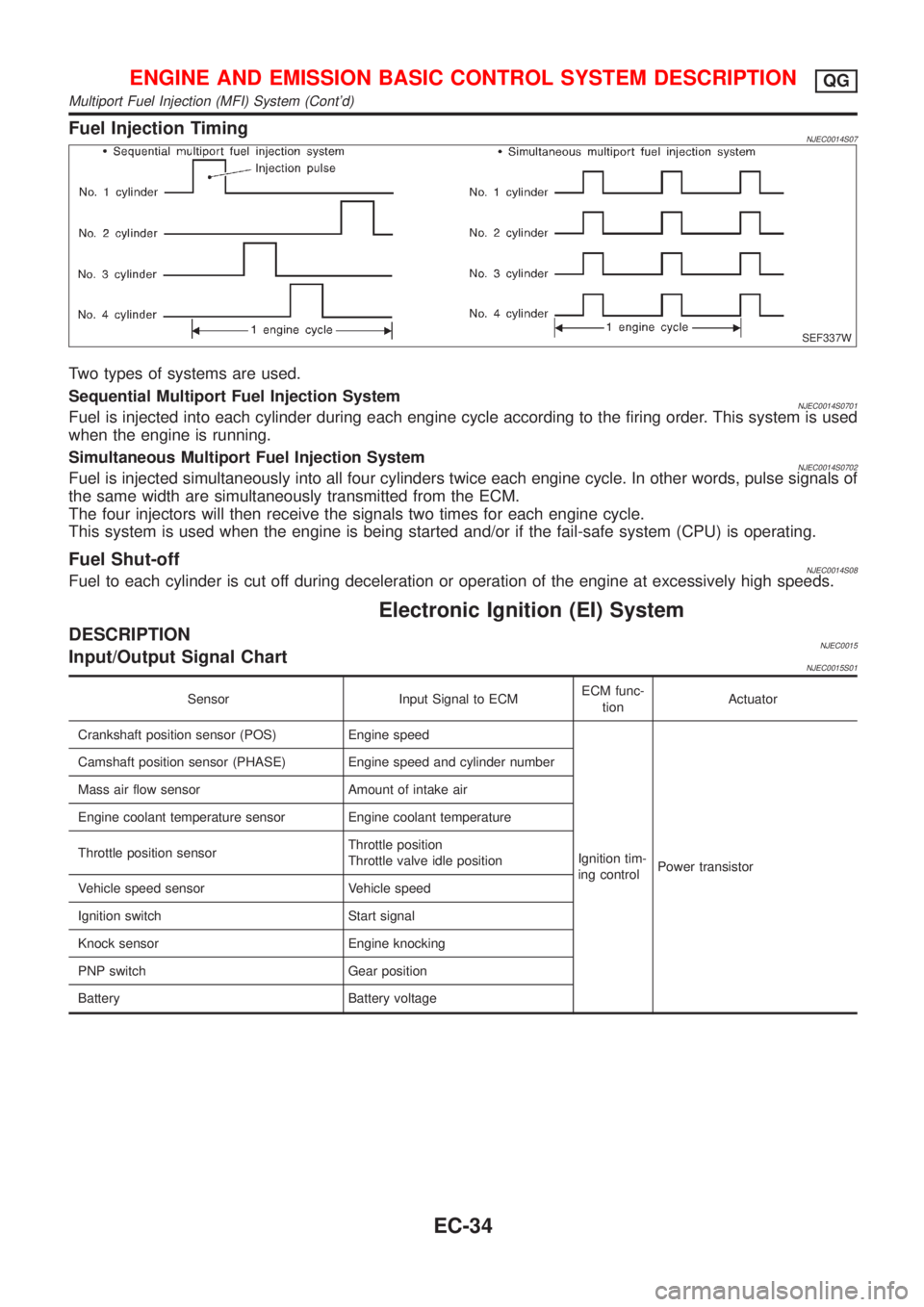

Fuel Injection TimingNJEC0014S07

SEF337W

Two types of systems are used.

Sequential Multiport Fuel Injection System

NJEC0014S0701Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

NJEC0014S0702Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

Fuel Shut-offNJEC0014S08Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Electronic Ignition (EI) System

DESCRIPTIONNJEC0015Input/Output Signal ChartNJEC0015S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

Ignition tim-

ing controlPower transistor Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensorThrottle position

Throttle valve idle position

Vehicle speed sensor Vehicle speed

Ignition switch Start signal

Knock sensor Engine knocking

PNP switch Gear position

Battery Battery voltage

ENGINE AND EMISSION BASIC CONTROL SYSTEM DESCRIPTIONQG

Multiport Fuel Injection (MFI) System (Cont'd)

EC-34