Electric NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2396 of 2898

NJGI0011

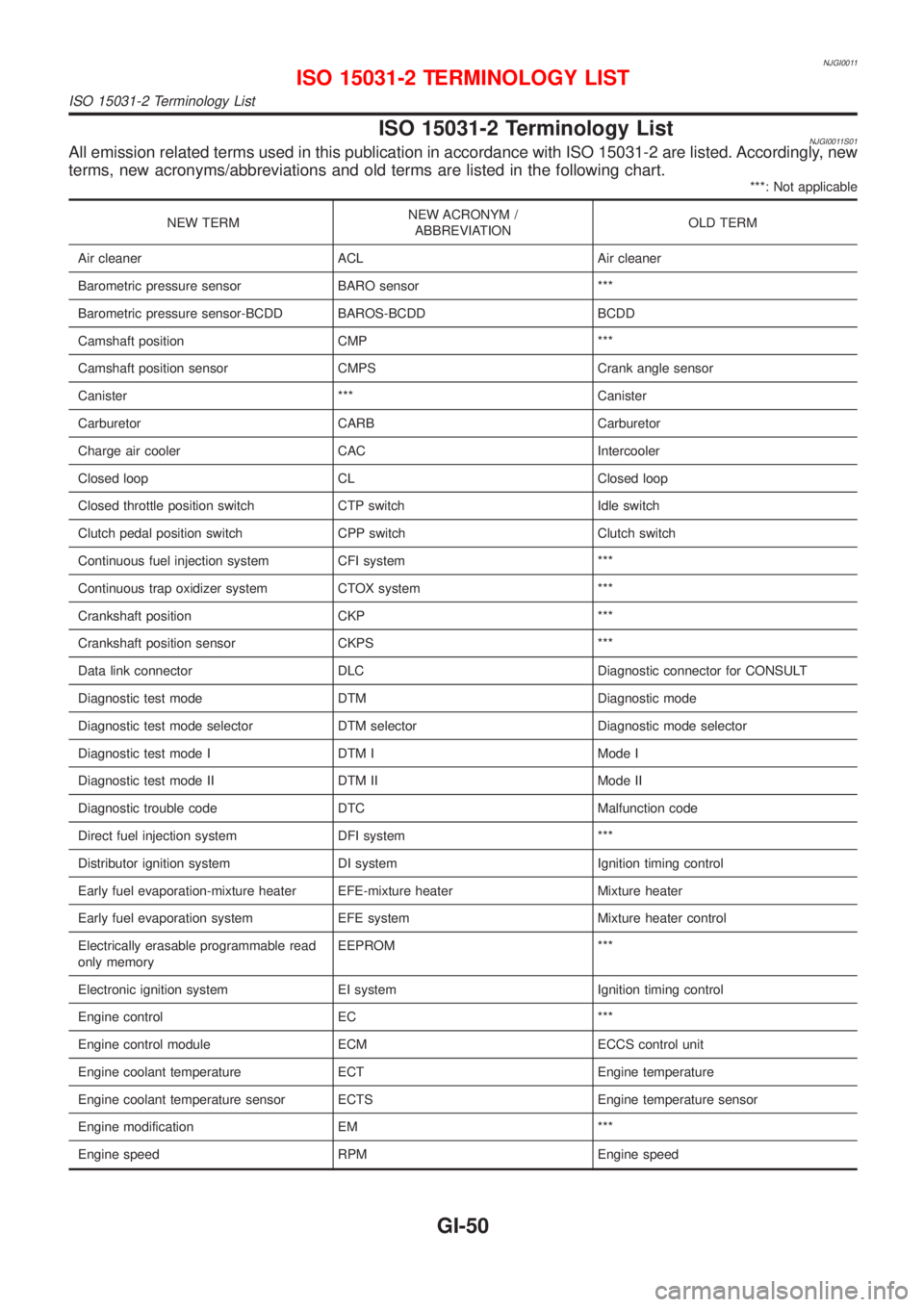

ISO 15031-2 Terminology ListNJGI0011S01All emission related terms used in this publication in accordance with ISO 15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure sensor BARO sensor ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List

GI-50

Page 2397 of 2898

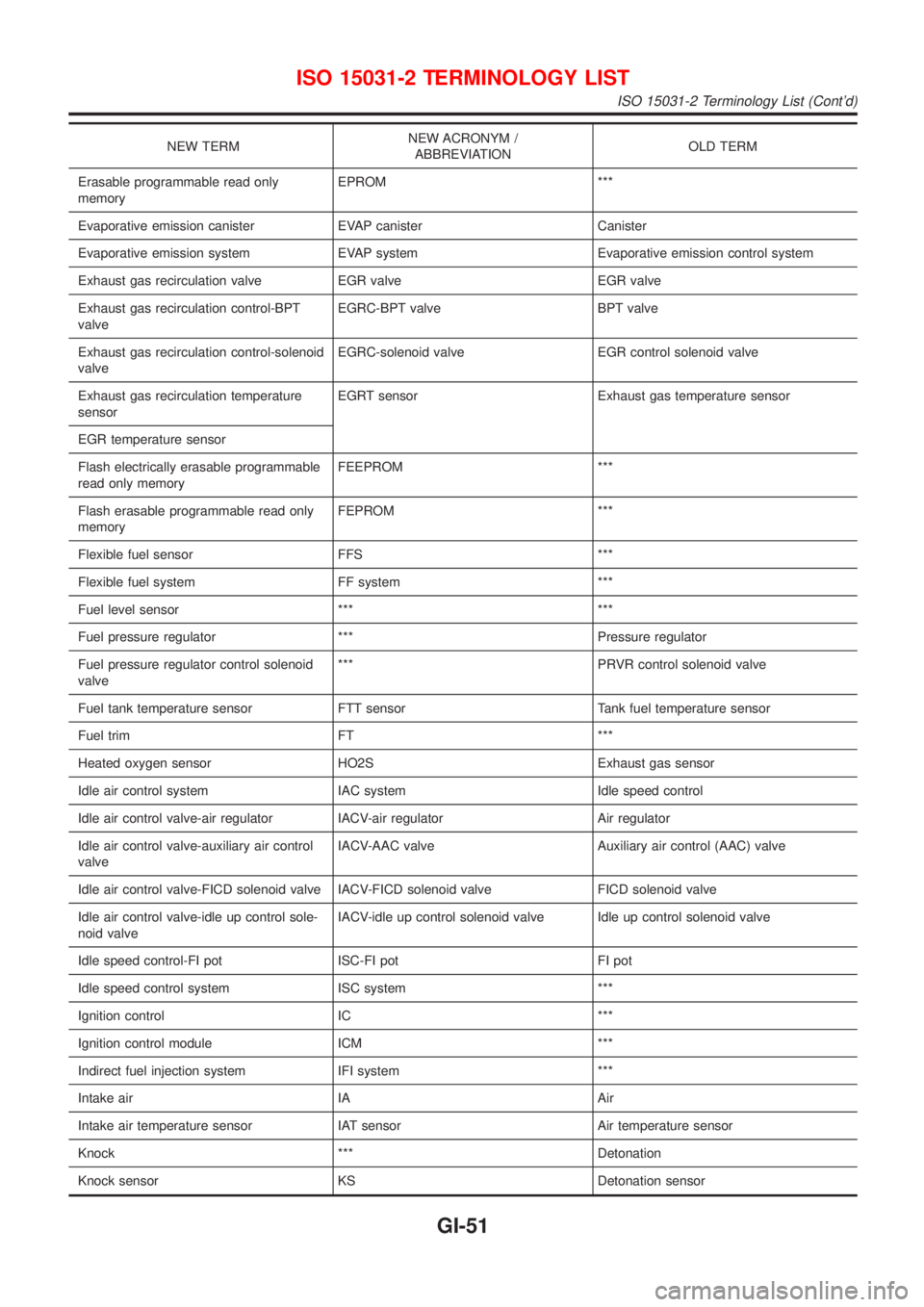

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Erasable programmable read only

memoryEPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Evaporative emission control system

Exhaust gas recirculation valve EGR valve EGR valve

Exhaust gas recirculation control-BPT

valveEGRC-BPT valve BPT valve

Exhaust gas recirculation control-solenoid

valveEGRC-solenoid valve EGR control solenoid valve

Exhaust gas recirculation temperature

sensorEGRT sensor Exhaust gas temperature sensor

EGR temperature sensor

Flash electrically erasable programmable

read only memoryFEEPROM ***

Flash erasable programmable read only

memoryFEPROM ***

Flexible fuel sensor FFS ***

Flexible fuel system FF system ***

Fuel level sensor *** ***

Fuel pressure regulator *** Pressure regulator

Fuel pressure regulator control solenoid

valve*** PRVR control solenoid valve

Fuel tank temperature sensor FTT sensor Tank fuel temperature sensor

Fuel trim FT ***

Heated oxygen sensor HO2S Exhaust gas sensor

Idle air control system IAC system Idle speed control

Idle air control valve-air regulator IACV-air regulator Air regulator

Idle air control valve-auxiliary air control

valveIACV-AAC valve Auxiliary air control (AAC) valve

Idle air control valve-FICD solenoid valve IACV-FICD solenoid valve FICD solenoid valve

Idle air control valve-idle up control sole-

noid valveIACV-idle up control solenoid valve Idle up control solenoid valve

Idle speed control-FI pot ISC-FI pot FI pot

Idle speed control system ISC system ***

Ignition control IC ***

Ignition control module ICM ***

Indirect fuel injection system IFI system ***

Intake air IA Air

Intake air temperature sensor IAT sensor Air temperature sensor

Knock *** Detonation

Knock sensor KS Detonation sensor

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-51

Page 2402 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJHA0190The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Working with HFC-134a

(R-134a)

NJHA0113WARNING:

+CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed, compressor fail-

ure is likely to occur.

+Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor failure is likely to occur.

+The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

a) When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

b) When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as pos-

sible to minimize the entry of moisture into system.

c) Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

d) Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Remove R-134a from the A/C system, using certified service equipment meeting

requirements of R-134a recycling equipment, or R-134a recovery equipment. If accidental system

discharge occurs, ventilate work area before resuming service. Additional health and safety

information may be obtained from refrigerant and lubricant manufacturers.

e) Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

General Refrigerant PrecautionsNJHA0114WARNING:

+Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

+Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

HA-2

Page 2411 of 2898

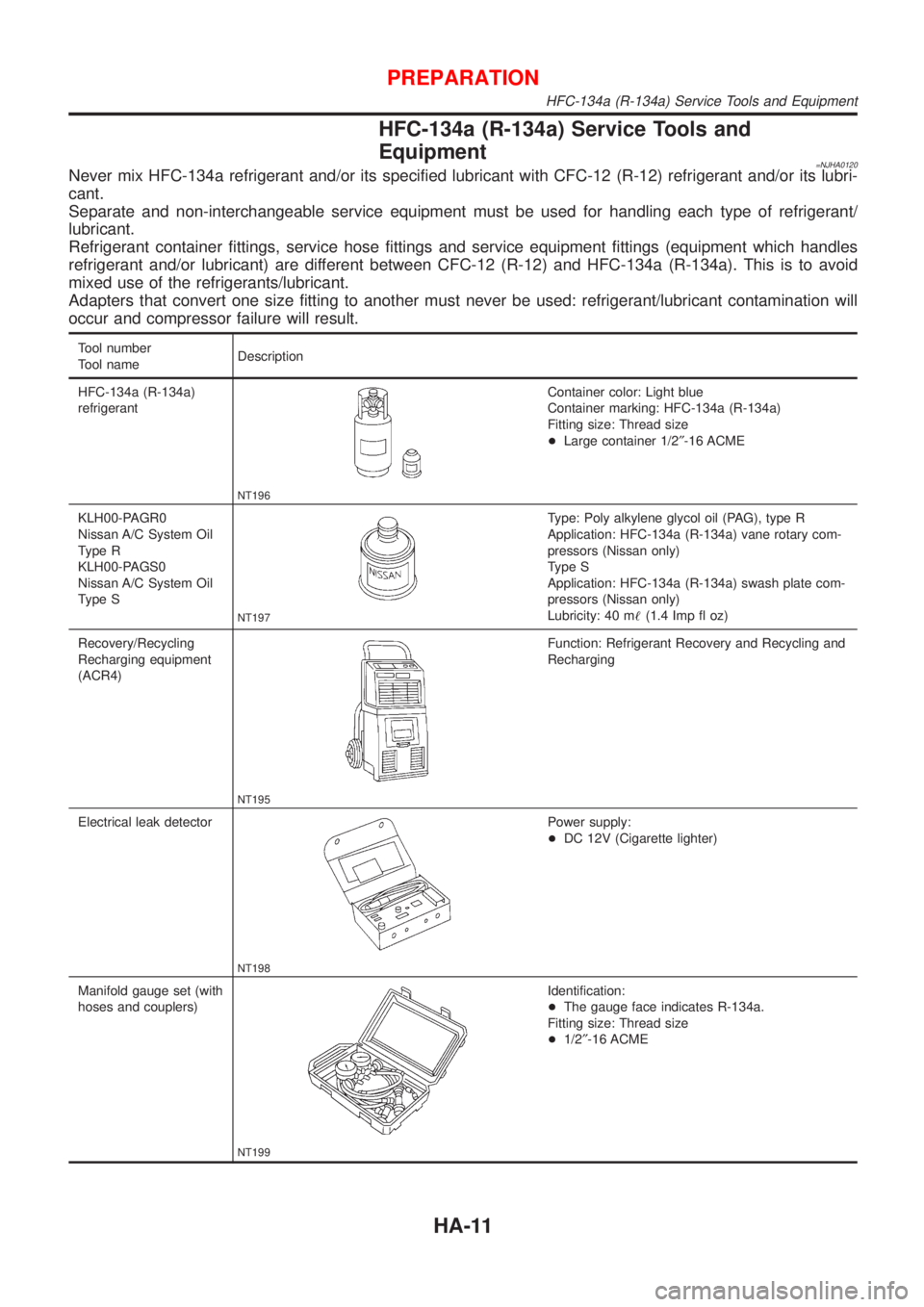

HFC-134a (R-134a) Service Tools and

Equipment

=NJHA0120Never mix HFC-134a refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or its lubri-

cant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor failure will result.

Tool number

Tool nameDescription

HFC-134a (R-134a)

refrigerant

NT196

Container color: Light blue

Container marking: HFC-134a (R-134a)

Fitting size: Thread size

+Large container 1/2²-16 ACME

KLH00-PAGR0

Nissan A/C System Oil

Type R

KLH00-PAGS0

Nissan A/C System Oil

Type S

NT197

Type: Poly alkylene glycol oil (PAG), type R

Application: HFC-134a (R-134a) vane rotary com-

pressors (Nissan only)

Type S

Application: HFC-134a (R-134a) swash plate com-

pressors (Nissan only)

Lubricity: 40 m!(1.4 Imp fl oz)

Recovery/Recycling

Recharging equipment

(ACR4)

NT195

Function: Refrigerant Recovery and Recycling and

Recharging

Electrical leak detector

NT198

Power supply:

+DC 12V (Cigarette lighter)

Manifold gauge set (with

hoses and couplers)

NT199

Identification:

+The gauge face indicates R-134a.

Fitting size: Thread size

+1/2²-16 ACME

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment

HA-11

Page 2439 of 2898

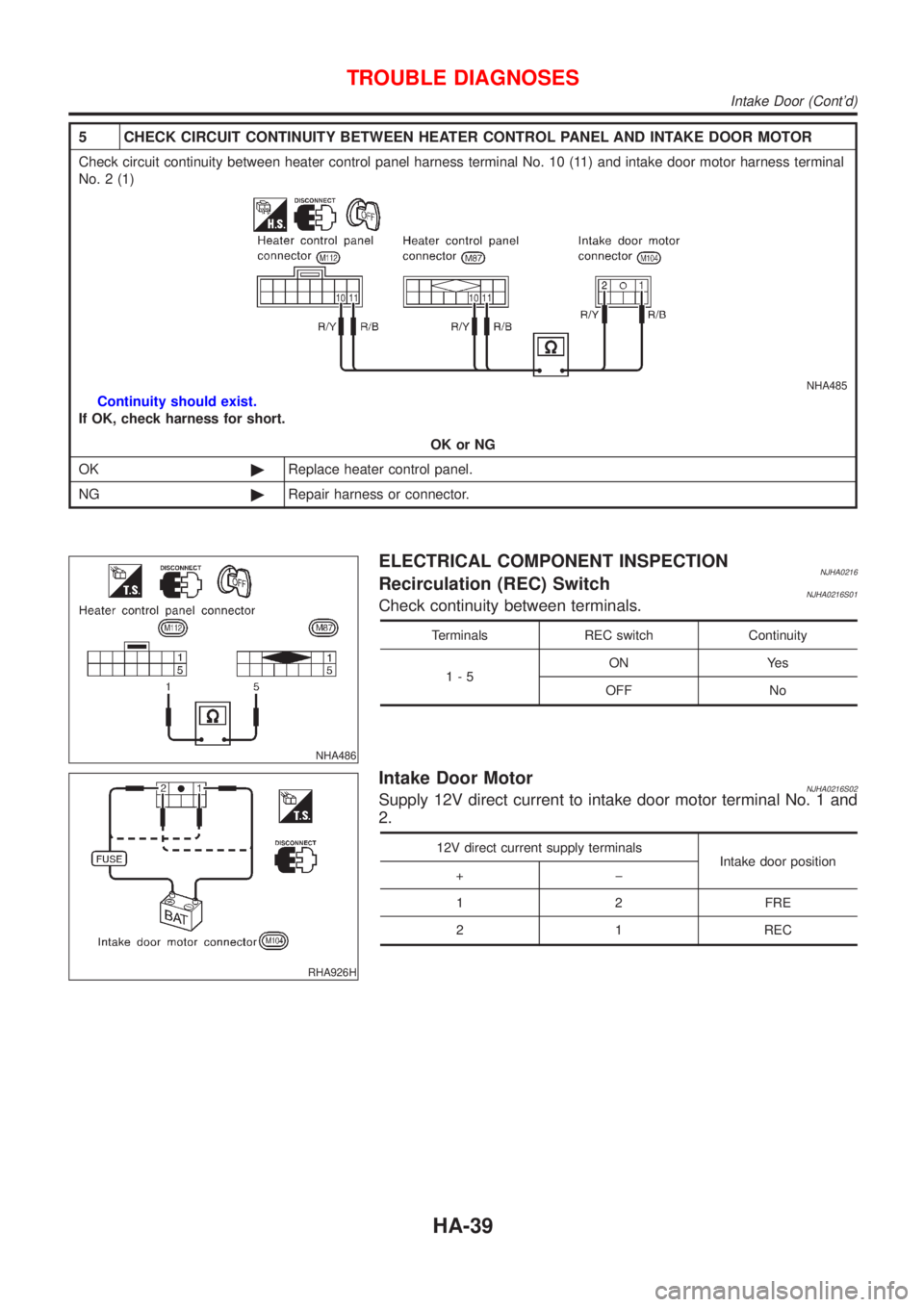

5 CHECK CIRCUIT CONTINUITY BETWEEN HEATER CONTROL PANEL AND INTAKE DOOR MOTOR

Check circuit continuity between heater control panel harness terminal No. 10 (11) and intake door motor harness terminal

No. 2 (1)

NHA485

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©Replace heater control panel.

NG©Repair harness or connector.

NHA486

ELECTRICAL COMPONENT INSPECTIONNJHA0216Recirculation (REC) SwitchNJHA0216S01Check continuity between terminals.

Terminals REC switch Continuity

1-5ON Yes

OFF No

RHA926H

Intake Door MotorNJHA0216S02Supply 12V direct current to intake door motor terminal No. 1 and

2.

12V direct current supply terminals

Intake door position

+þ

1 2 FRE

2 1 REC

TROUBLE DIAGNOSES

Intake Door (Cont'd)

HA-39

Page 2450 of 2898

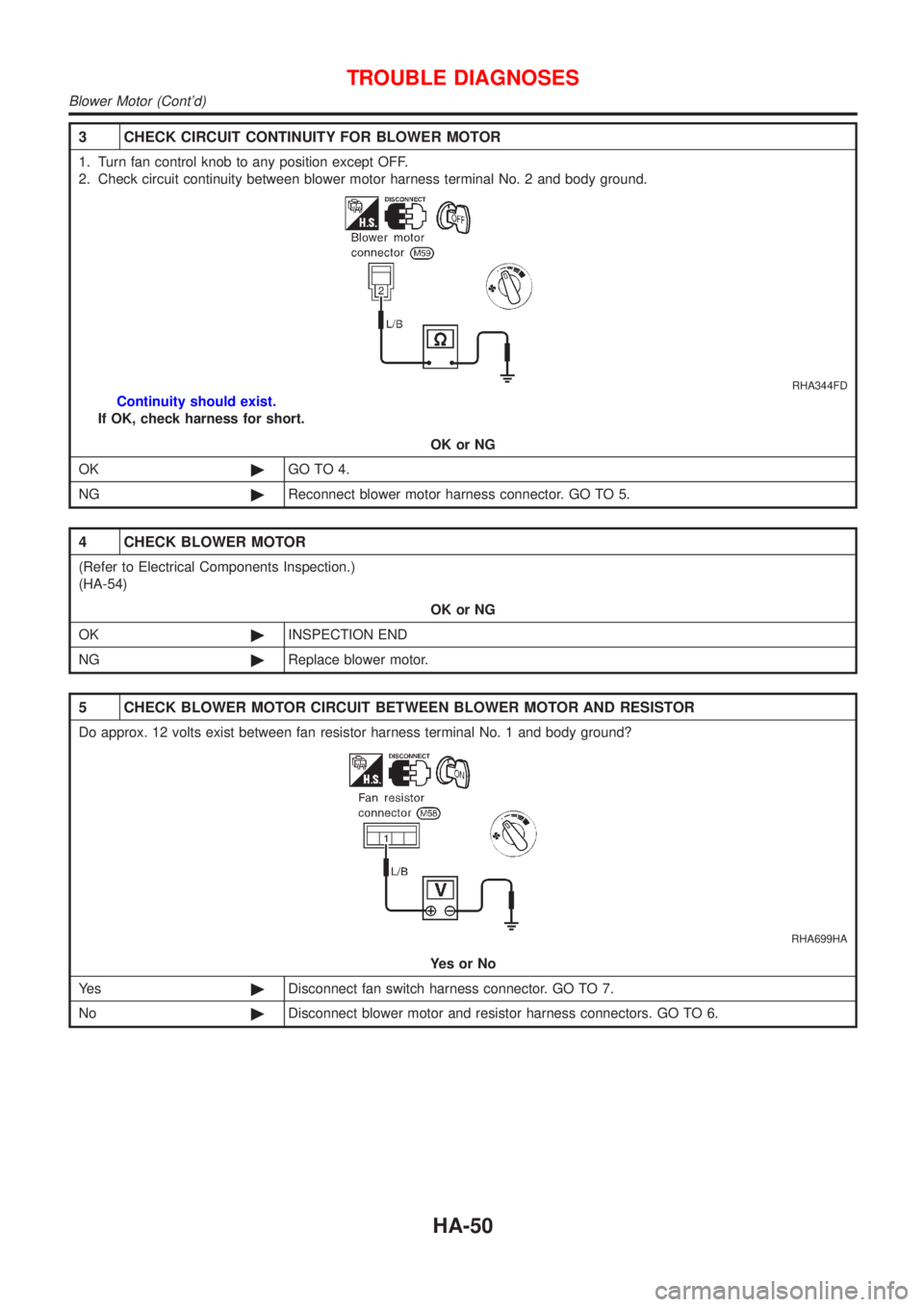

3 CHECK CIRCUIT CONTINUITY FOR BLOWER MOTOR

1. Turn fan control knob to any position except OFF.

2. Check circuit continuity between blower motor harness terminal No. 2 and body ground.

RHA344FD

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©GO TO 4.

NG©Reconnect blower motor harness connector. GO TO 5.

4 CHECK BLOWER MOTOR

(Refer to Electrical Components Inspection.)

(HA-54)

OK or NG

OK©INSPECTION END

NG©Replace blower motor.

5 CHECK BLOWER MOTOR CIRCUIT BETWEEN BLOWER MOTOR AND RESISTOR

Do approx. 12 volts exist between fan resistor harness terminal No. 1 and body ground?

RHA699HA

YesorNo

Ye s©Disconnect fan switch harness connector. GO TO 7.

No©Disconnect blower motor and resistor harness connectors. GO TO 6.

TROUBLE DIAGNOSES

Blower Motor (Cont'd)

HA-50

Page 2451 of 2898

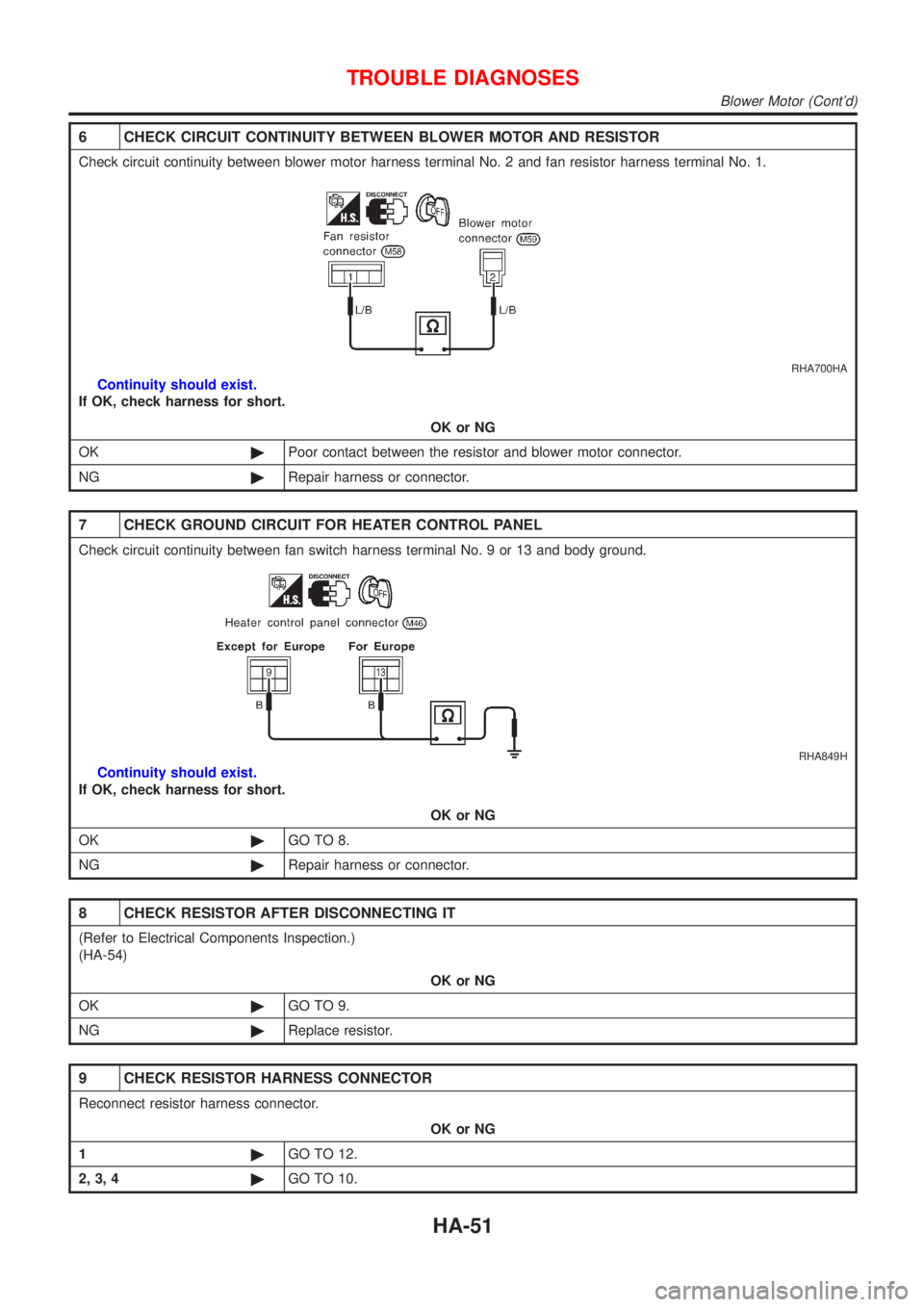

6 CHECK CIRCUIT CONTINUITY BETWEEN BLOWER MOTOR AND RESISTOR

Check circuit continuity between blower motor harness terminal No. 2 and fan resistor harness terminal No. 1.

RHA700HA

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©Poor contact between the resistor and blower motor connector.

NG©Repair harness or connector.

7 CHECK GROUND CIRCUIT FOR HEATER CONTROL PANEL

Check circuit continuity between fan switch harness terminal No. 9 or 13 and body ground.

RHA849H

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©GO TO 8.

NG©Repair harness or connector.

8 CHECK RESISTOR AFTER DISCONNECTING IT

(Refer to Electrical Components Inspection.)

(HA-54)

OK or NG

OK©GO TO 9.

NG©Replace resistor.

9 CHECK RESISTOR HARNESS CONNECTOR

Reconnect resistor harness connector.

OK or NG

1©GO TO 12.

2, 3, 4©GO TO 10.

TROUBLE DIAGNOSES

Blower Motor (Cont'd)

HA-51

Page 2453 of 2898

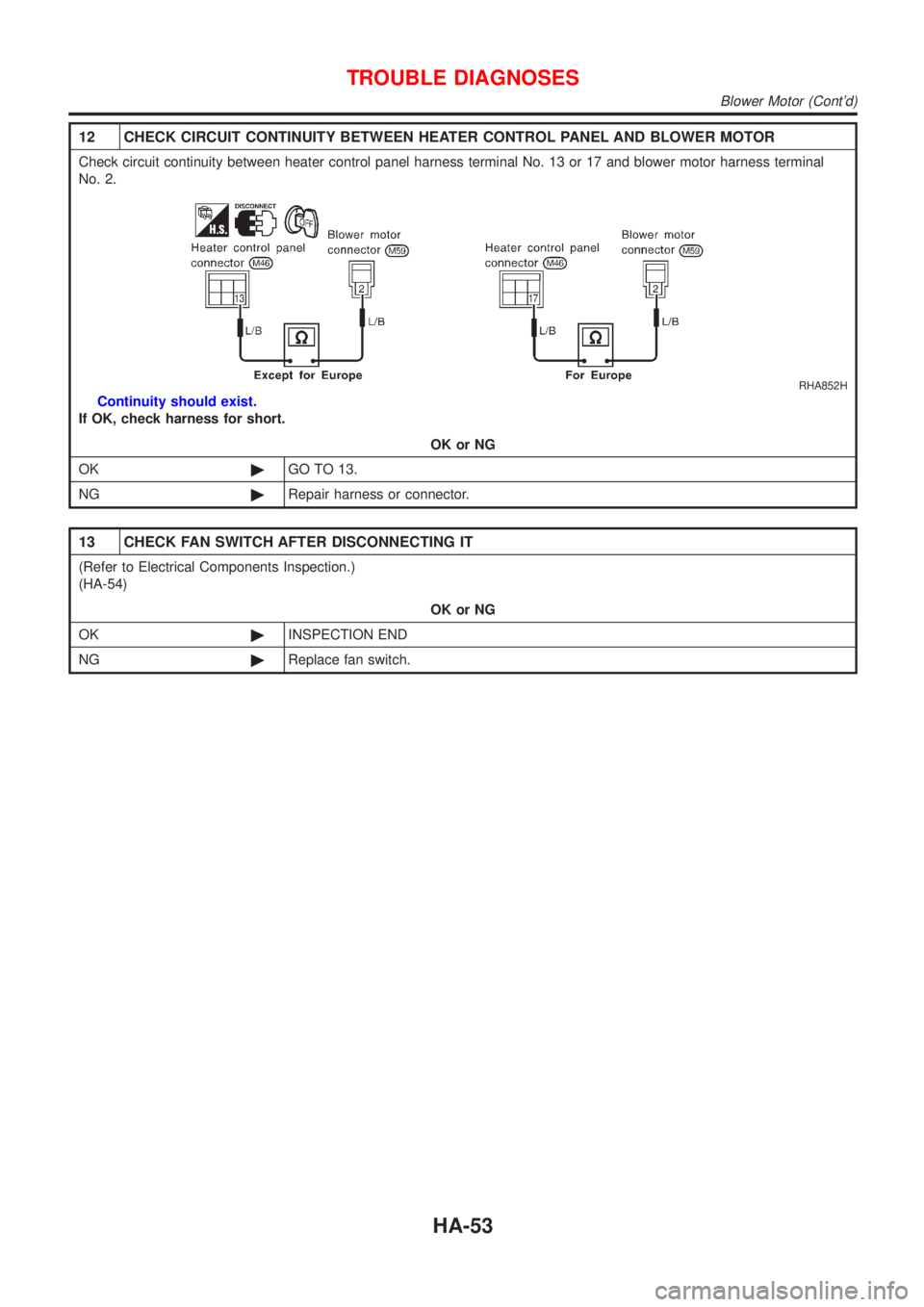

12 CHECK CIRCUIT CONTINUITY BETWEEN HEATER CONTROL PANEL AND BLOWER MOTOR

Check circuit continuity between heater control panel harness terminal No. 13 or 17 and blower motor harness terminal

No. 2.

RHA852H

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©GO TO 13.

NG©Repair harness or connector.

13 CHECK FAN SWITCH AFTER DISCONNECTING IT

(Refer to Electrical Components Inspection.)

(HA-54)

OK or NG

OK©INSPECTION END

NG©Replace fan switch.

TROUBLE DIAGNOSES

Blower Motor (Cont'd)

HA-53

Page 2454 of 2898

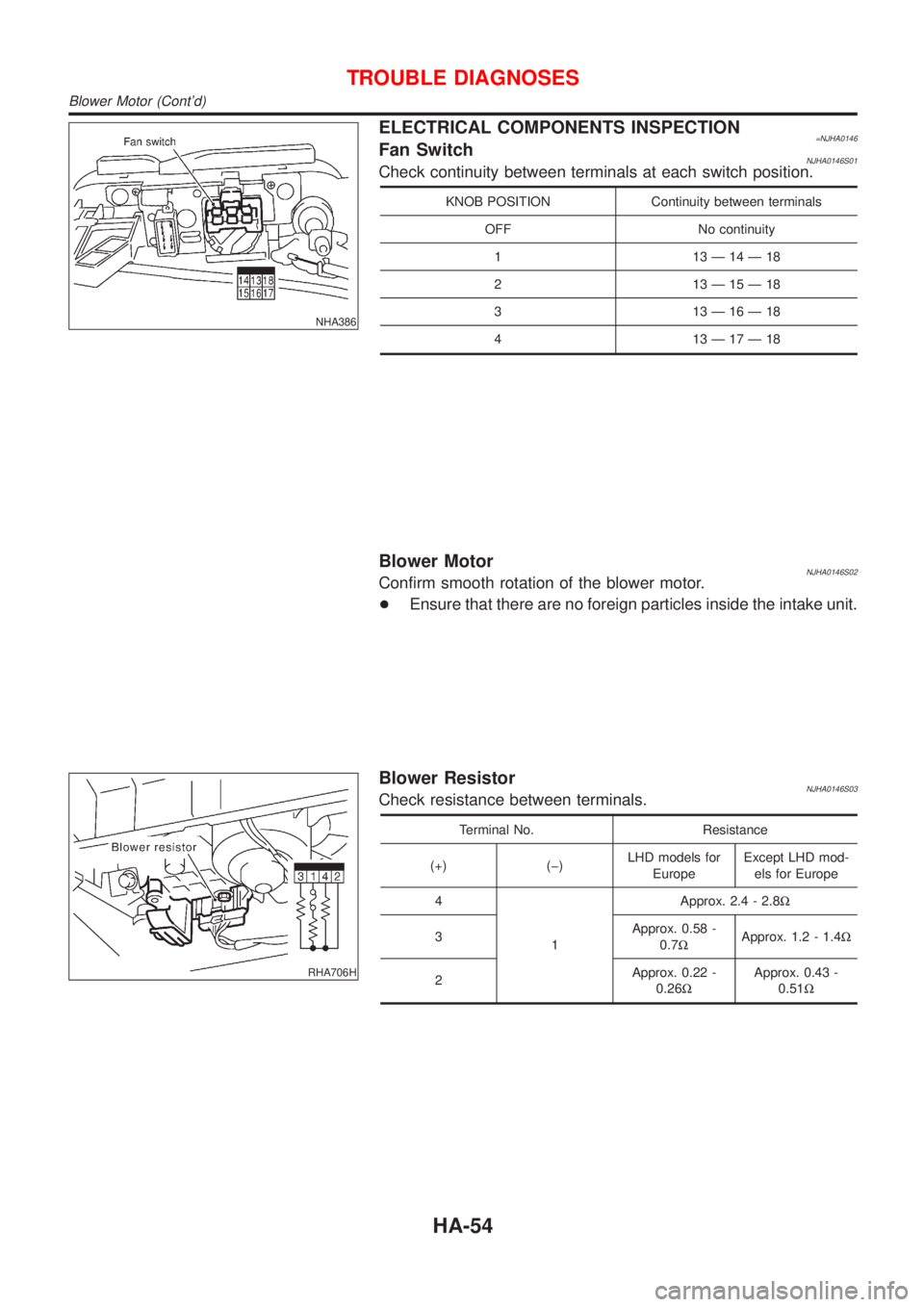

NHA386

ELECTRICAL COMPONENTS INSPECTION=NJHA0146Fan SwitchNJHA0146S01Check continuity between terminals at each switch position.

KNOB POSITION Continuity between terminals

OFF No continuity

1 13Ð14Ð18

2 13Ð15Ð18

3 13Ð16Ð18

4 13Ð17Ð18

Blower MotorNJHA0146S02Confirm smooth rotation of the blower motor.

+Ensure that there are no foreign particles inside the intake unit.

RHA706H

Blower ResistorNJHA0146S03Check resistance between terminals.

Terminal No. Resistance

(+) (þ)LHD models for

EuropeExcept LHD mod-

els for Europe

4

1Approx. 2.4 - 2.8W

3Approx. 0.58 -

0.7WApprox. 1.2 - 1.4W

2Approx. 0.22 -

0.26WApprox. 0.43 -

0.51W

TROUBLE DIAGNOSES

Blower Motor (Cont'd)

HA-54

Page 2466 of 2898

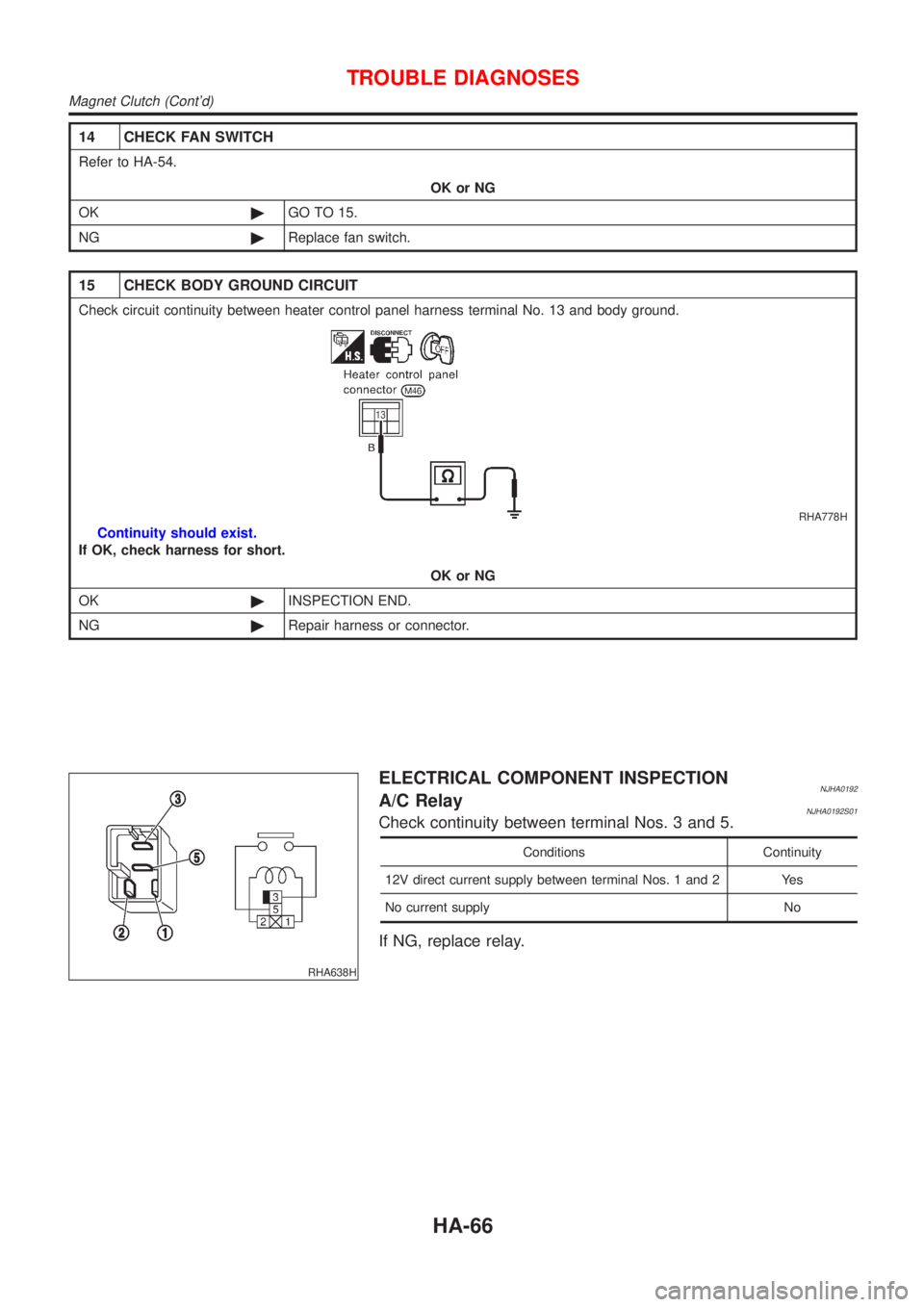

14 CHECK FAN SWITCH

Refer to HA-54.

OK or NG

OK©GO TO 15.

NG©Replace fan switch.

15 CHECK BODY GROUND CIRCUIT

Check circuit continuity between heater control panel harness terminal No. 13 and body ground.

RHA778H

Continuity should exist.

If OK, check harness for short.

OK or NG

OK©INSPECTION END.

NG©Repair harness or connector.

RHA638H

ELECTRICAL COMPONENT INSPECTIONNJHA0192A/C RelayNJHA0192S01Check continuity between terminal Nos. 3 and 5.

Conditions Continuity

12V direct current supply between terminal Nos. 1 and 2 Yes

No current supply No

If NG, replace relay.

TROUBLE DIAGNOSES

Magnet Clutch (Cont'd)

HA-66