Electric NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2501 of 2898

C

CHARGE - Wiring diagram ....................... SC-27

CHIME - Wiring diagram ................. EL-199, 207

CIGAR - Wiring diagram ................. EL-236, 237

CKPS - Wiring diagram .......... EC-330, 485, 695

CMPS - Wiring diagram .......................... EC-337

CONSULT for ABS .................................... BR-65

CONSULT for engine ........................ EC-83, 632

COOL/F - Wiring diagram ............... EC-409, 730

Camshaft inspection ......................... EM-37, 123

Camshaft position sensor (CMPS) ......... EC-335

Camshaft position sensor (PHASE) ........ EC-335

Canister - See EVAP canister ................... EC-36

Charging system ....................................... SC-26

Cigarette lighter ....................................... EL-236

Circuit breaker ........................................... EL-38

Closed throttle position switch ....... EC-385, 520

Clutch cover .............................................. CL-22

Clutch disc ................................................. CL-22

Clutch master cylinder ............................... CL-11

Clutch operating cylinder ........................... CL-14

Clutch pedal .............................................. CL-10

Clutch release bearing ........................ CL-17, 20

Clutch release mechanism .................. CL-17, 20

Clutch withdrawal lever ....................... CL-17, 20

Coil spring (front) ........................................ SU-9

Coil spring (rear) ....................................... SU-21

Collision diagnosis .................................... RS-85

Combination lamp, rear, removal and

installation .............................................. BT-47

Combination meter removal and instal-

lation - See Instrument panel ................ BT-25

Combination meter .................................. EL-144

Combination switch ................................... EL-56

Compression pressure ............................. EM-83

Compressor clutch removal and

installation .............................................. HA-83

Compressor precaution ............................... HA-5

Compressor special service tool ................. HA-9

Connecting rod bearing clearance ... EM-60, 151

Connecting rod bushing clearance ... EM-61, 153

Connecting rod ................................. EM-57, 146

Console box - See Instrument panel ......... BT-25

Control lever (M/T) .................................... MT-29

Control valve (A/T) ................................... AT-388

Converter housing installation ................. AT-355

Coolant mixture ratio ................................ MA-18

Cooling circuit (engine) ....................... LC-12, 37

Cooling fan control system .................. LC-17, 43

Cooling fan control .......................... EC-406, 730

Cooling fan motor ................................... EC-417

Cooling fan relay ..................................... EC-416

Coupling sleeve (M/T) .................. MT-31, 55, 93

Crankcase emission control system -

See Positive crankcase ventilation ...... EC-39,

613

Crankcase ventilation system - See

Positive crankcase ventilation ....... EC-39, 613

Crankshaft position sensor (OBD) .. EC-328, 484Crankshaft position sensor (POS) .. EC-328, 484

Crankshaft position sensor (TDC) .......... EC-695

Crankshaft ........................................ EM-59, 148

Cylinder block ................................... EM-54, 140

Cylinder head .................................... EM-34, 119

D

DEF - Wiring diagram ...................... EL-242, 250

DTC work support ..................................... EC-92

Data link connector for Consult ........ EC-40, 632

Daytime light system ................................. EL-67

Detonation sensor - See Knock

sensor .................................................. EC-324

Diagnosis sensor unit ............................... RS-26

Diagnostic trouble code (DTC) for

OBD system .................... EC-10, 72, 596, 627

Diagnostic trouble code (DTC) inspec-

tion priority chart .................................. EC-153

Differential gear (FF A/T) ......................... AT-442

Differential gear (FF M/T) ...... MT-31, 44, 55, 93,

107

Dimensions ................................................. GI-43

Dome light - See Interior lamp ................ EL-115

Door glass ................................................. BT-17

Door lock ................................................... BT-21

Door mirror ................................................ BT-75

Door trim .................................................... BT-39

Door, front .................................................. BT-16

Door, rear ................................................... BT-16

Drive plate runout ..................................... EM-62

Drive shaft (front) ...................................... AX-10

Dropping resistor (A/T) .................... AT-182, 245

Dual pressure switch ................................ HA-13

E

ECCS-D control module ........ EC-659, 714, 792,

794, 799, 801

ECM input/output signal ................. EC-164, 659

ECTS - Wiring diagram ................... EC-203, 680

EGR control valve ................................... EC-432

EGR temperature sensor ........................ EC-418

EGR volume control valve ...................... EC-815

EGR/TS - Wiring diagram ....................... EC-421

EGRC1 - Wiring diagram ....... EC-347, 429, 494,

817

EVAP canister purge volume control

solenoid valve ........................................ EC-37

EVAP canister purge volume control

valve ............................................ EC-364, 503

EVAP canister ........................................... EC-37

Electric sunroof ........................................ EL-292

Electrical diagnoses ................................... GI-21

Electrical ignition system .......................... EC-34

Electrical load signal circuit ..................... EC-578

Electrical unit ........................................... EL-581

Electrical units location ............................ EL-517

ALPHABETICAL INDEX

IDX-3

Page 2503 of 2898

Headlining - See Roof trim ........................ BT-43

Heated oxygen sensor (HO2S)

(front) .......... EC-216, 224, 230, 236, 245, 450

Heated oxygen sensor (HO2S) heater

(front) ........................................... EC-252, 457

Heated oxygen sensor (HO2S) heater

(rear) ............................................ EC-291, 469

Heated oxygen sensor (rear) ......... EC-258, 267,

275, 284, 462

Heated seat ............................................. EL-288

Height (Dimensions) ................................... GI-43

High clutch ............................................... AT-407

Hood ............................................................ BT-7

Horn ......................................................... EL-234

How to erase DTC for OBD system .. EC-70, 73,

627

I

IACV-AAC valve .............................. EC-376, 511

IATS - Wiring diagram .................... EC-196, 444

IGN/SG - Wiring diagram ........................ EC-548

ILL - Wiring diagram ................................ EL-112

INJECT - Wiring diagram ........................ EC-542

INT/L - Wiring diagram .................... EL-141, 143

IVC - Wiring diagram ...................... EC-395, 527

Identification plate ...................................... GI-40

Idle air control (IAC) system ........... EC-376, 511

Idle air control valve (IACV) ............ EC-376, 511

Idle speed ......................................... EC-43, 641

Ignition timing ............................................ EC-43

Illumination ............................................... EL-108

Injection nozzle ....................................... EC-614

Injector removal and installation ............... EC-41

Input shaft (FF M/T) ............... MT-36, 64, 93, 98

Instrument panel ........................................ BT-25

Intake air temperature sensor ......... EC-194, 442

Intake valve timing control solenoid

valve ............................................ EC-393, 526

Interior lamp on-off control .............. EL-116, 128

Interior lamp ............................................. EL-115

Interior ........................................................ BT-31

J

Jacking points ............................................ GI-45

Joint connector (J/C) ............................... EL-583

Junction box (J/B) .................................... EL-577

K

Keyless entry system - See Multi-remote control

system ..................................................... EL-392

Knock sensor (KS) .......................... EC-324, 325

Knuckle spindle ........................................... AX-5

L

LOAD - Wiring diagram .......................... EC-579

Length (Dimensions) .................................. GI-43

License lamp ............................................. EL-81

Lifting points ............................................... GI-46

Line pressure solenoid valve ................... AT-232

Line pressure test (A/T) ............................. AT-84

Liquid gasket application ...................... EM-4, 77

Location of electrical units ....................... EL-517

Lock, door .................................................. BT-21

Low and reverse brake ............................ AT-419

Lubricant (R134a) A/C .............................. HA-80

Lubricants ................................................. MA-16

Lubrication circuit (engine) .................... LC-4, 27

M

M/T major overhaul ....................... MT-30, 54, 92

M/T removal and installation ..................... MT-23

MAFS - Wiring diagram .................. EC-189, 673

MAIN - Wiring diagram ................... EC-178, 666

MAJOR OVERHALL ................................ AT-357

METER - Wiring diagram ........................ EL-151

MIL & Data link connectors circuit .......... EC-591

MIL/DL - Wiring diagram ................. EC-591, 831

MIRROR - Wiring diagram .............. EL-294, 295

Magnet clutch ............................................ HA-83

Mainshaft (M/T) .................... MT-39, 69, 93, 103

Malfunction indicator lamp (MIL) ...... EC-74, 628

Manual air conditioner - Wiring

diagram .................................................. HA-27

Manual transaxle number .......................... GI-42

Mass air flow sensor (MAFS) ......... EC-187, 673

Master cylinder (brake) ............................. BR-14

Master cylinder (clutch) ............................. CL-11

Meter ........................................................ EL-144

Mirror defogger ........................................ EL-240

Mirror, door ................................................ BT-75

Misfire ...................................................... EC-318

Mode door control linkage

adjustment ............................................. HA-41

Model variation ........................................... GI-38

Molding - See Exterior ............................... BT-47

Multi-remote control system .................... EL-392

Multiport fuel injection (MFI) system ......... EC-32

Multiport fuel injection precautions ............... GI-6

N

NATS (Nissan Anti-theft System)

precautions ................................................... GI-3

NATS (Nissan Anti-theft System) ............ EL-422

NATS - Wiring diagram ................... EL-425, 427

NVH troubleshooting (AX) ........................... AX-3

NVH troubleshooting (BR) .......................... BR-7

NVH troubleshooting (MT) ........................ MT-13

NVH troubleshooting (ST) ........................... ST-5

ALPHABETICAL INDEX

IDX-5

Page 2505 of 2898

Seat, rear ................................................... BT-60

Self-diagnostic results ....................... EC-74, 628

Shift control components (M/T) .... MT-32, 56, 94

Shift fork (M/T) .............................. MT-32, 56, 94

Shift lever .................................................. MT-29

Shift lock system ...................................... AT-343

Shift schedule .......................................... AT-470

Shift solenoid valve A (A/T) ..... AT-204, 209, 222

Shift solenoid valve B (A/T) ............. AT-204, 209

Shock absorber (front) .............................. SU-10

Shock absorber (rear) ............................... SU-21

Side air bag ........................................ RS-36, 38

Side trim .................................................... BT-31

Spare tire size ............................................ GI-43

Speedometer ........................................... EL-144

Spiral cable ............................................... RS-29

Spot lamp ................................................ EL-141

Spring (Wheelarch) height .......................... SU-6

Stabilizer bar (front) ................................... SU-11

Stall test (A/T) ............................................ AT-80

Standardized relay ....................................... EL-8

Start signal ...................................... EC-557, 823

Starter ....................................................... SC-18

Starting system ......................................... SC-13

Steering linkage ......................................... ST-16

Steering switch .......................................... EL-59

Steering wheel and column ....................... ST-11

Steering wheel play ..................................... ST-6

Steering wheel turning force ....................... ST-8

Stop lamp .................................................. EL-85

Striking rod (M/T) .......................... MT-32, 56, 94

Strut (front) .................................................. SU-9

Strut (rear) ................................................. SU-20

Sub-gear (M/T) ................................... MT-31, 55

Sunroof, electric ....................................... EL-292

Sunroof ...................................................... BT-63

Super lock ................................................ EL-349

Supplemental Restraint System ............... RS-20

Supplemental restraint system - Wiring

diagram .................................................. RS-53

Swirl control valve control solenoid

valve ............................................ EC-399, 475

Symbols and abbreviations ........................ GI-10

Symptom matrix chart ..................... EC-155, 646

Synchronizer (M/T) ....................... MT-31, 55, 93

System readiness test (SRT) code ........... EC-62

T

TCM circuit diagram ................................... AT-17

TCM inspection table ............................... AT-119

TFTS - Wiring diagram ........................... EC-315

TP/SW - Wiring diagram ................. EC-387, 521

TPS - Wiring diagram ............................. EC-210

TURN - Wiring diagram ........................... EL-103

Tachometer .............................................. EL-144

Tail lamp .................................................... EL-81

Tank fuel temperature sensor ................. EC-313

Thermostat .......................................... LC-15, 41Three way catalyst precautions ................... GI-6

Three way catalyst .................................. EC-359

Throttle position sensor (TPS) ................ EC-207

Throttle position sensor

adjustment ................................... EC-100, 128

Throttle position switch ........... AT-141, 267, 341,

EC-385, 520

Throwout bearing - See Clutch release

bearing ............................................. CL-17, 20

Tie-rod ball joints ....................................... ST-20

Tie-rod ........................................................ ST-16

Tightening torque of standard bolts ........... GI-49

Timing chain ....................................... EM-23, 94

Tire size ...................................................... GI-43

Torque converter installation .................... AT-355

Tow truck towing ........................................ GI-47

Transmission case (M/T) .............. MT-30, 54, 92

Tread-FR&RR (Dimensions) ...................... GI-43

Trim ............................................................ BT-31

Trouble diagnoses ...................................... GI-31

Trunk lid finisher ........................................ BT-45

Trunk lid opener - See Trunk lid ................ BT-10

Trunk lid trim .............................................. BT-45

Trunk lid ..................................................... BT-10

Trunk room lamp ..................................... EL-141

Trunk room trim ......................................... BT-45

Turn signal lamp ........................................ EL-96

Two trip detection logic ............................. EC-59

Two-pole lift ................................................ GI-46

U

Under body ................................................ BT-80

V

VSS - Wiring diagram ..................... EC-372, 701

Vacuum hose (brake system) ................... BR-22

Vacuum hose drawing (Engine control) .... EC-30

Vacuum pump ........................................... BR-23

Valve clearance ................................ EM-44, 133

Valve guide ....................................... EM-39, 124

Valve lifter ................................................. EM-43

Valve seat ......................................... EM-41, 126

Valve spring ...................................... EM-42, 128

Vehicle speed sensor (VSS) ........... EC-370, 701

Viscosity number (SAE) ............................ MA-17

Viscous coupling (FF M/T) ........................ MT-93

W

WARN - Wiring diagram .......................... EL-190

WIP/R - Wiring diagram .................. EL-225, 227

WIPER - Wiring diagram ................. EL-217, 220

Warning chime ......................................... EL-197

Warning lamps ......................................... EL-184

Washer, front ........................................... EL-215

ALPHABETICAL INDEX

IDX-7

Page 2711 of 2898

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NJRS0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL N16 is as follows (The composition

varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTION FOR SEAT BELT SERVICENJRS0002CAUTION:

+Before removing the seat belt pre-tensioner assembly, turn the ignition switch off, disconnect both

battery cables and wait at least 3 minutes.

+Do not use electrical test equipment for seat belt pre-tensioner connector.

+After replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner connector, check the system function. Refer to ªSRS Operation Checkº for details. (RS-59)

+Do not use disassemble buckle or seat belt assembly.

+Replace anchor bolts if they are deformed or worn out.

+Never oil tongue and buckle.

+If any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

+If webbing is cut, frayed, or damaged, replace seat belt assembly.

+When replacing seat belt assembly, use a genuine seat belt assembly.

After A CollisionNJRS0002S01WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

+The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

+The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

+The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for dam-

age or distortion and repair as necessary before installing a new seat belt assembly.

+Anchor bolts are deformed or worn out.

+The seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

SEAT BELTS

Precautions

RS-3

Page 2728 of 2898

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NJRS0006The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL N16 is as follows (The composition

varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICENJRS0007+Do not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

+Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

+Diagnosis sensor unit must always be installed with their arrow marks ªÜº pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

+The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

+Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module standing with stud bolt side setting bottom.

+Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

+After air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSISNJRS0008When you read wiring diagrams, refer to the following:

+GI-11, ªHOW TO READ WIRING DIAGRAMSº

+EL-10, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

+GI-32, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

+GI-21, ªHOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Precautions

RS-20

Page 2733 of 2898

SRS797-A

Maintenance ItemsNJRS0012CAUTION:

Do not use electrical test equipment to check SRS circuit.

1. Check operation of ªAIR BAGº warning lamp.

After turning ignition key to ªONº position, ªAIR BAGº warning

lamp illuminates. The ªAIR BAGº warning lamp will go off after

about 7 seconds if no malfunction is detected. If any of the fol-

lowing ªAIR BAGº warning lamp conditions occur, immediately

check the air bag system. Refer to RS-59 for details.

+The ªAIR BAGº warning lamp does not illuminate when the

ignition switch is turned ªONº.

+The ªAIR BAGº warning lamp does not go off about 7 seconds

after the ignition switch is turned ªONº.

+The ªAIR BAGº warning lamp blinks after about 7 seconds after

the ignition switch is turned ªONº.

2. Visually check SRS components.

1) Diagnosis sensor unit

+Check diagnosis sensor unit and bracket for dents, cracks and

deformities.

+Check connectors for damage, and terminals for deformities.

2) Air bag module and steering wheel

+Remove air bag module from steering wheel, instrument panel

or seatback. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

+Install driver air bag module to steering wheel to check fit or

alignment with the wheel.

+Check steering wheel for excessive free play.

+Install front passenger air bag module to instrument panel to

check fit or alignment with the instrument panel.

+Install front side air bag module to seatback to check fit and

alignment with the seat.

3) Spiral cable

+Check spiral cable for dents, cracks, or deformities.

+Check connectors and protective tape for damage.

+Check steering wheel for noise, binding or heavy operation.

4) Main harness, body harness, side air bag module sub-harness

+Check connectors for poor connections, damage, and termi-

nals for deformities.

+Check harnesses for binding, chafing or cut.

5) Front seat belt pre-tensioner

+Check harness cover and connectors for damage, terminals

for deformities, and harness for binding.

+Check belts for damage and anchors for loose mounting.

+Check retractor for smooth operation.

+Perform self-diagnosis for seat belt pre-tensioner using ªAIR

BAGº warning lamp or CONSULT-II.

Refer to ªSRS Operation Checkº for details. (RS-59)

6) Side air bag (satellite) sensor

+Check side air bag (satellite) sensor (including bracket portion)

for dents, cracks or deformities.

+Check connectors for damage, and terminals for deformities.

CAUTION:

Replace previously used special bolts, hex bolts and ground

bolt with new ones.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Maintenance Items

RS-25

Page 2755 of 2898

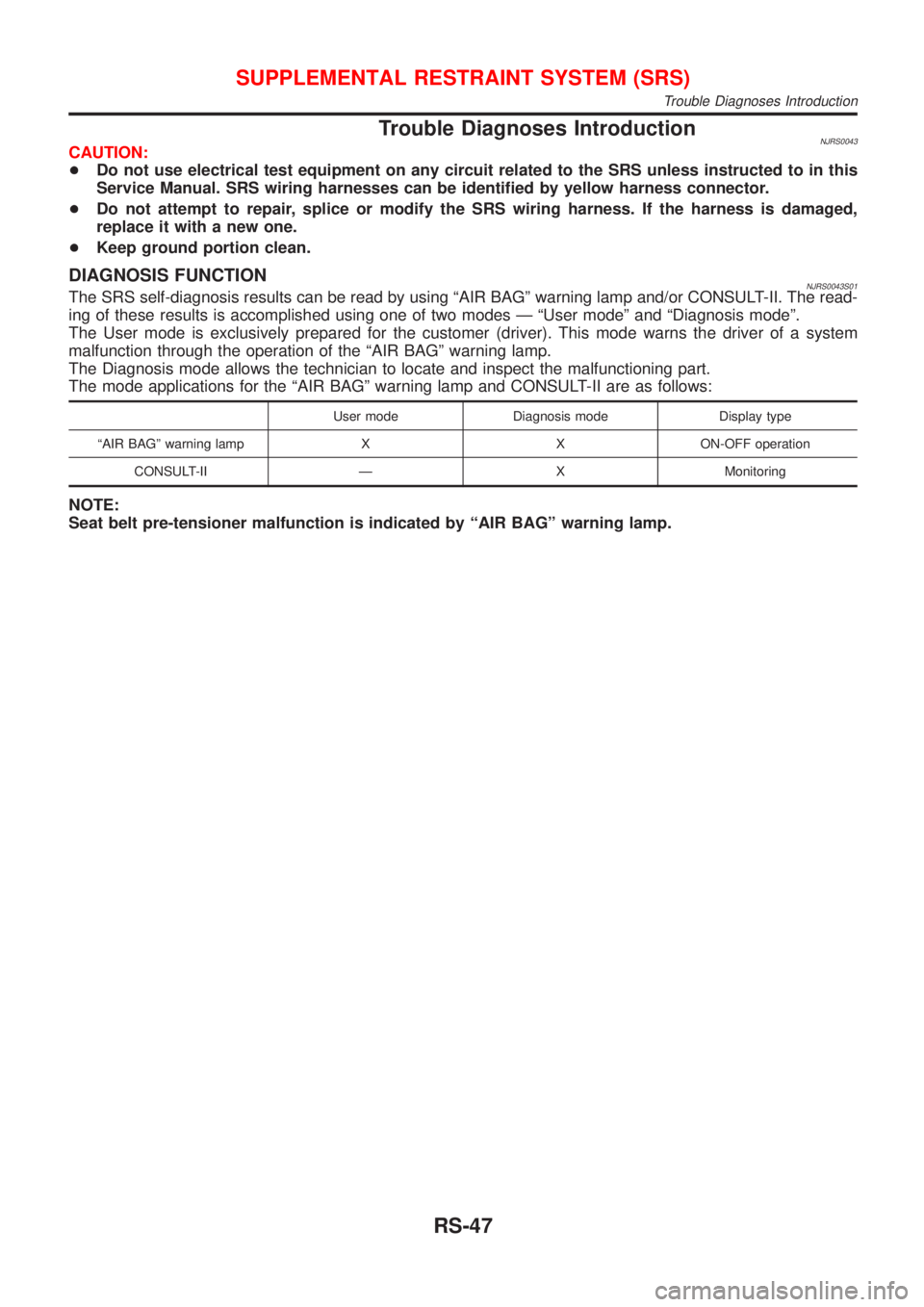

Trouble Diagnoses IntroductionNJRS0043CAUTION:

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

+Do not attempt to repair, splice or modify the SRS wiring harness. If the harness is damaged,

replace it with a new one.

+Keep ground portion clean.

DIAGNOSIS FUNCTIONNJRS0043S01The SRS self-diagnosis results can be read by using ªAIR BAGº warning lamp and/or CONSULT-II. The read-

ing of these results is accomplished using one of two modes Ð ªUser modeº and ªDiagnosis modeº.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system

malfunction through the operation of the ªAIR BAGº warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the ªAIR BAGº warning lamp and CONSULT-II are as follows:

User mode Diagnosis mode Display type

ªAIR BAGº warning lamp X X ON-OFF operation

CONSULT-II Ð X Monitoring

NOTE:

Seat belt pre-tensioner malfunction is indicated by ªAIR BAGº warning lamp.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses Introduction

RS-47

Page 2798 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJSC0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Wiring Diagrams and Trouble DiagnosesNJSC0002When you read wiring diagrams, refer to the following:

+GI-11, ªHOW TO READ WIRING DIAGRAMSº

+EL-10, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnoses, refer to the following:

+GI-32, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

+GI-21, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

SC-2

Page 2822 of 2898

System DescriptionNJSC0009SEDANNJSC0009S01The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (A/T models with QG13DE engine and M/T models with gasoline engine) or 100A (A/T models

except QG13DE engine and diesel engine models) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 17 (Models with tachometer) or 22 (Models without tachometer) for the

charge warning lamp.

Ground is supplied to terminal 62 (Models with tachometer) or 61 (Models without tachometer) of the combi-

nation meter through terminal 3 (L) of the alternator. With power and ground supplied, the charge warning lamp

will illuminate. When the alternator is providing sufficient voltage with the engine running, the ground is opened

and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

HATCHBACKNJSC0009S02The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (Gasoline engine models without daytime light system) or 100A (A/T models, diesel engine mod-

els and gasoline engine models with daytime light system) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 40 or 1

Ground is supplied to terminal 1 or 28 of the combination meter through terminal 3 (L) of the alternator. With

power and ground supplied, the charge warning lamp will illuminate. When the alternator is providing suffi-

cient voltage with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

CHARGING SYSTEM

System Description

SC-26

Page 2838 of 2898

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJST0044The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses (except ªSEAT BELT PRE-TENSIONERº connector) can be

identified by yellow harness connector.

Precautions for Steering SystemNJST0003+Before disassembly, thoroughly clean the outside of the unit.

+Disassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

+Place disassembled parts in order, on a parts rack, for easier and proper assembly.

+Use nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

+Before inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

+Before assembly, apply a coat of recommended power steering fluid* to hydraulic parts. Vaseline

may be applied to O-rings and seals. Do not use any grease.

+Replace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: DEXRON

TMIII or equivalent. Refer to MA-16, ªFluids and Lubricantsº.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

ST-2