Engine NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 341 of 2898

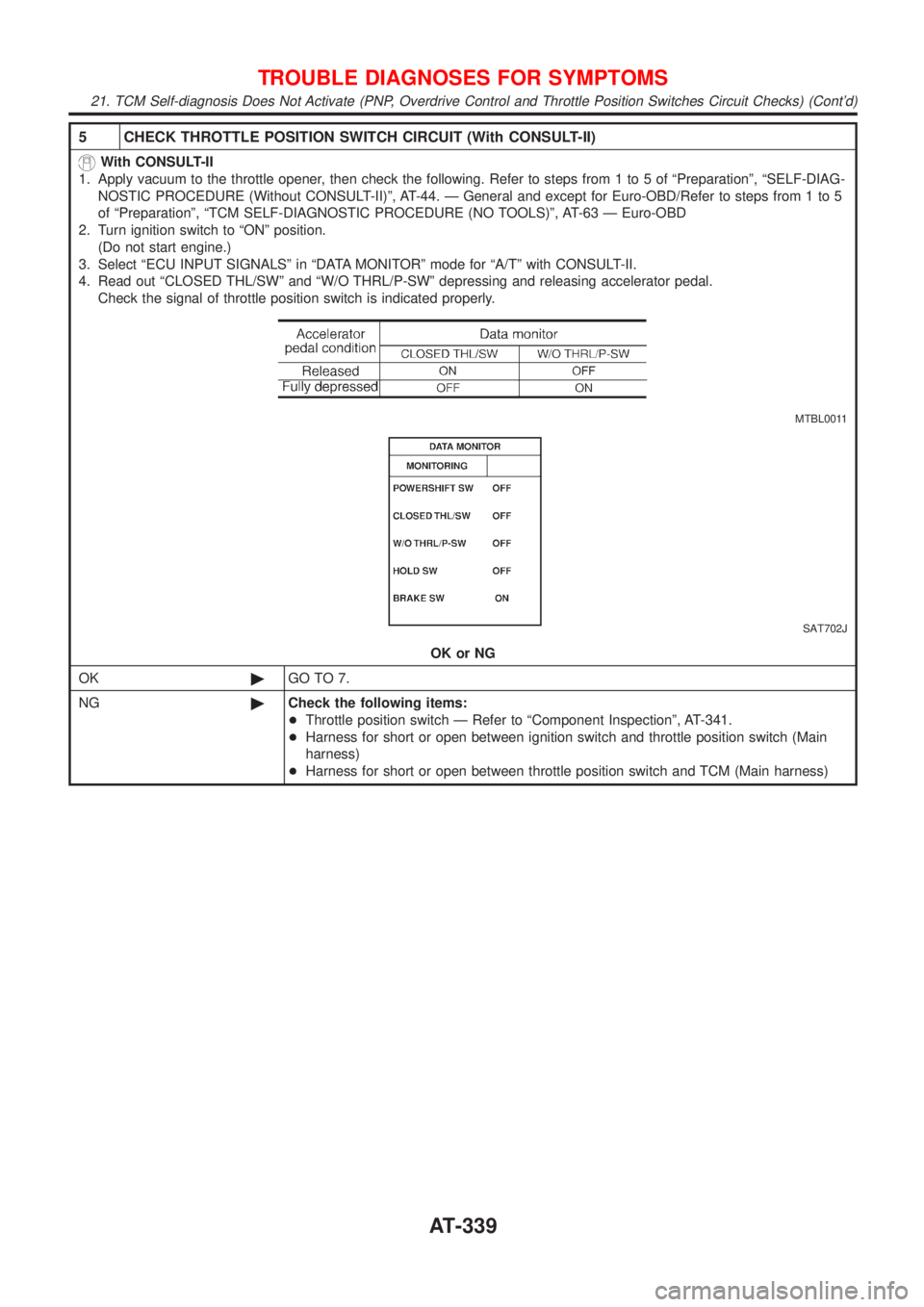

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps from 1 to 5 of ªPreparationº, ªSELF-DIAG-

NOSTIC PROCEDURE (Without CONSULT-II)º, AT-44. Ð General and except for Euro-OBD/Refer to steps from 1 to 5

of ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)º, AT-63 Ð Euro-OBD

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT702J

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponent Inspectionº, AT-341.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-339

Page 342 of 2898

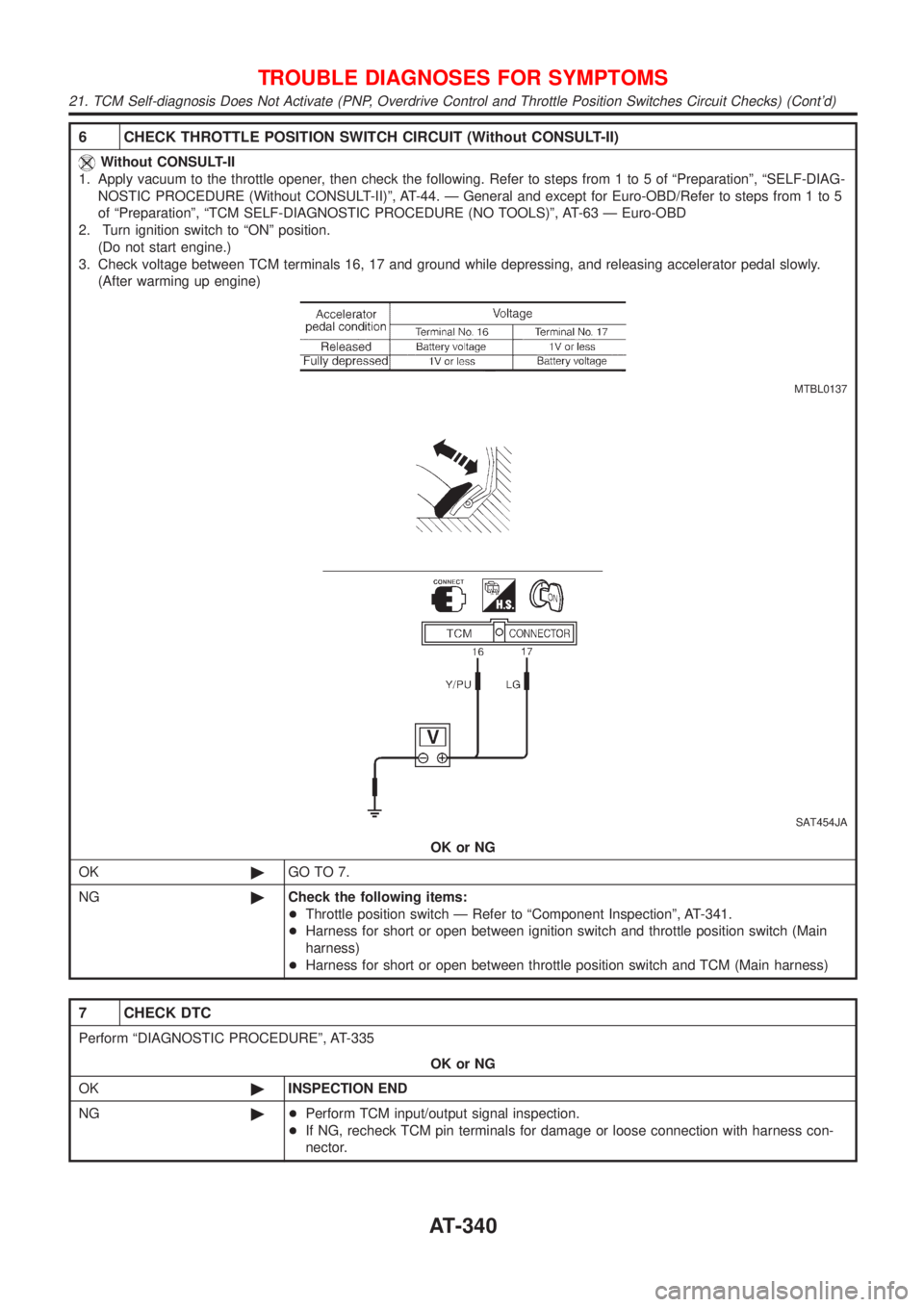

6 CHECK THROTTLE POSITION SWITCH CIRCUIT (Without CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps from 1 to 5 of ªPreparationº, ªSELF-DIAG-

NOSTIC PROCEDURE (Without CONSULT-II)º, AT-44. Ð General and except for Euro-OBD/Refer to steps from 1 to 5

of ªPreparationº, ªTCM SELF-DIAGNOSTIC PROCEDURE (NO TOOLS)º, AT-63 Ð Euro-OBD

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(After warming up engine)

MTBL0137

SAT454JA

OK or NG

OK©GO TO 7.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponent Inspectionº, AT-341.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

7 CHECK DTC

Perform ªDIAGNOSTIC PROCEDUREº, AT-335

OK or NG

OK©INSPECTION END

NG©+Perform TCM input/output signal inspection.

+If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

TROUBLE DIAGNOSES FOR SYMPTOMS

21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit Checks) (Cont'd)

AT-340

Page 347 of 2898

Diagnostic ProcedureNJAT0105SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-349.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-352.

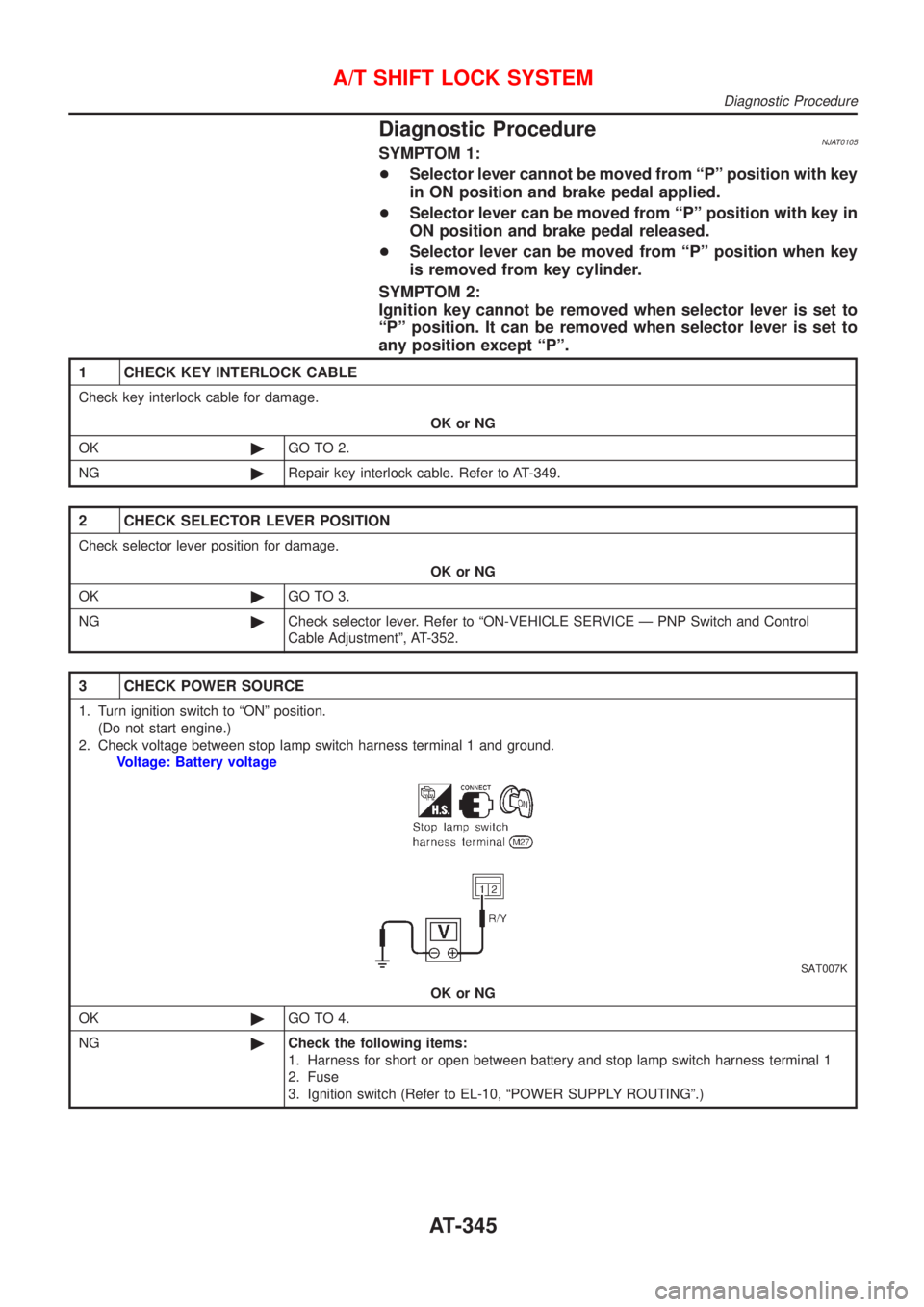

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT007K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL-10, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-345

Page 348 of 2898

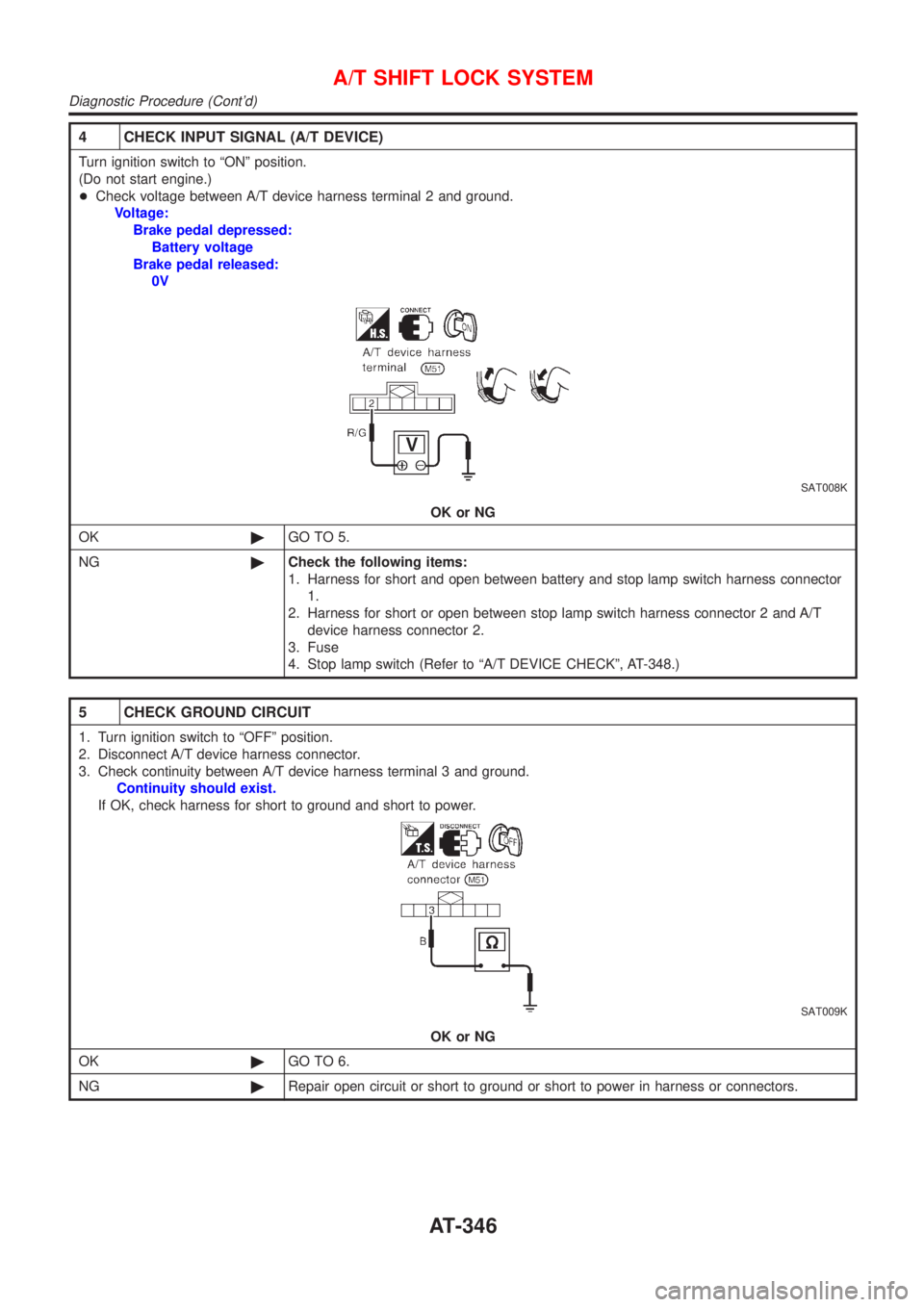

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 2 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT008K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 2.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-348.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 3 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT009K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-346

Page 349 of 2898

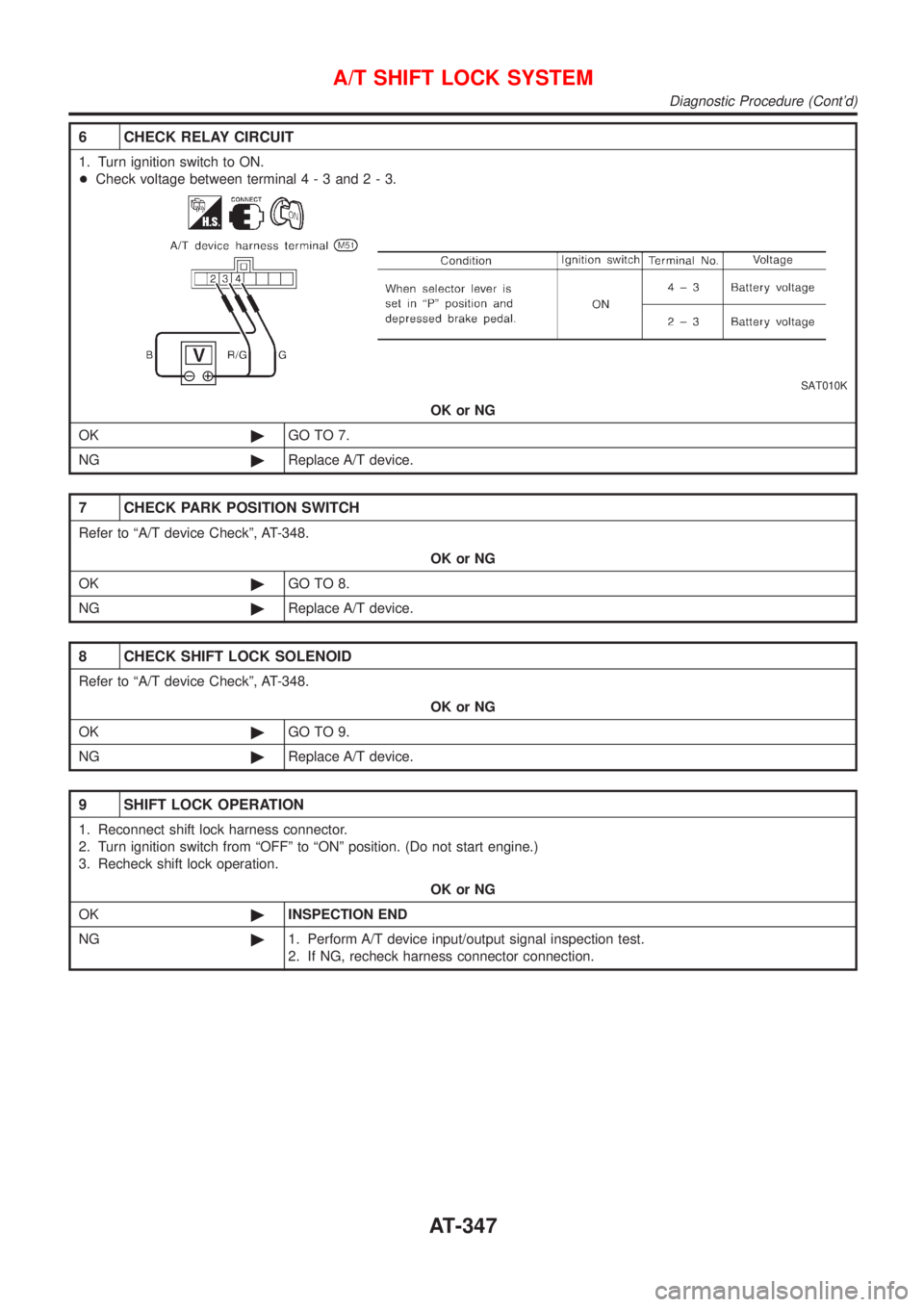

6 CHECK RELAY CIRCUIT

1. Turn ignition switch to ON.

+Check voltage between terminal4-3and2-3.

SAT010K

OK or NG

OK©GO TO 7.

NG©Replace A/T device.

7 CHECK PARK POSITION SWITCH

Refer to ªA/T device Checkº, AT-348.

OK or NG

OK©GO TO 8.

NG©Replace A/T device.

8 CHECK SHIFT LOCK SOLENOID

Refer to ªA/T device Checkº, AT-348.

OK or NG

OK©GO TO 9.

NG©Replace A/T device.

9 SHIFT LOCK OPERATION

1. Reconnect shift lock harness connector.

2. Turn ignition switch from ªOFFº to ªONº position. (Do not start engine.)

3. Recheck shift lock operation.

OK or NG

OK©INSPECTION END

NG©1. Perform A/T device input/output signal inspection test.

2. If NG, recheck harness connector connection.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-347

Page 356 of 2898

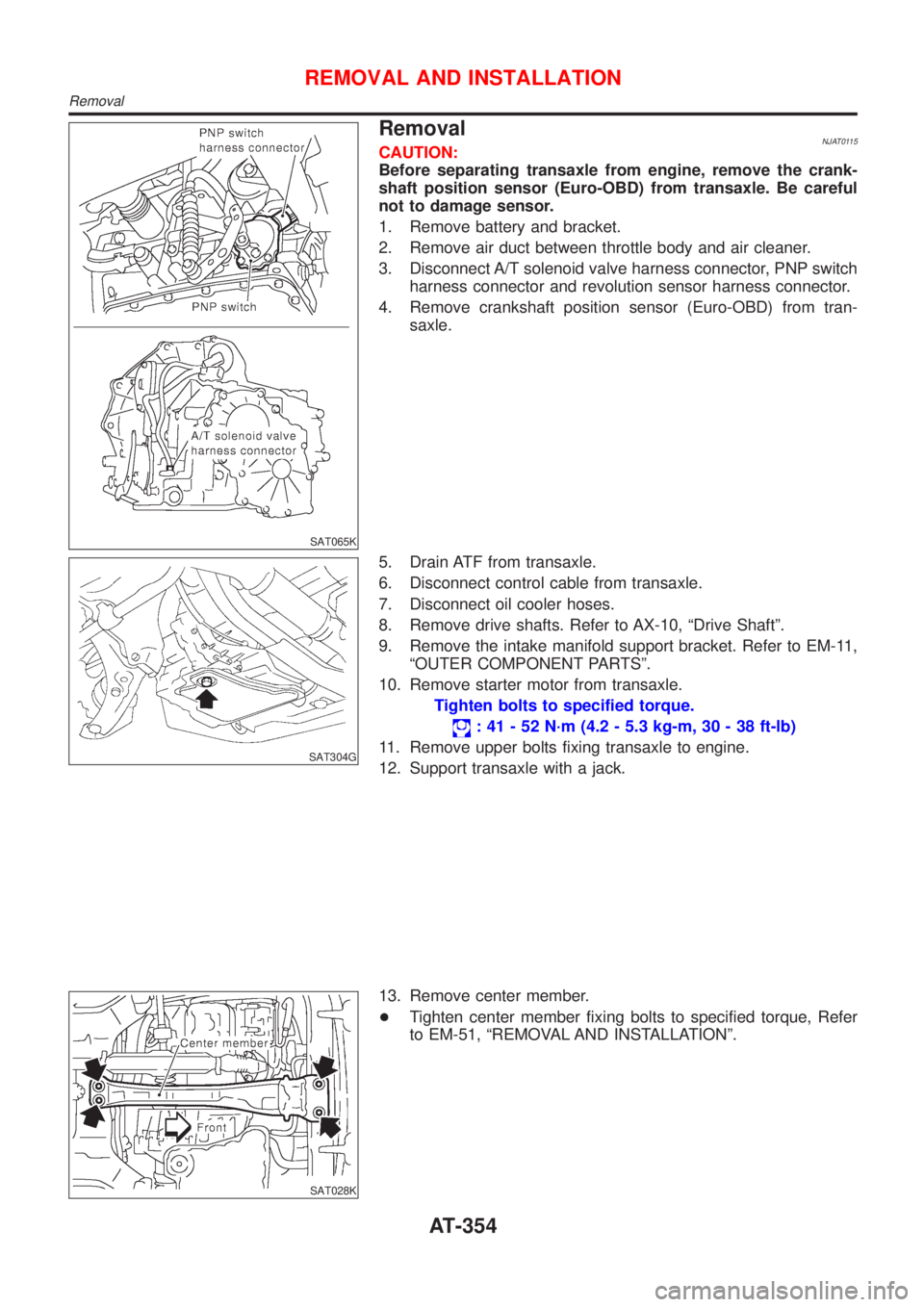

SAT065K

RemovalNJAT0115CAUTION:

Before separating transaxle from engine, remove the crank-

shaft position sensor (Euro-OBD) from transaxle. Be careful

not to damage sensor.

1. Remove battery and bracket.

2. Remove air duct between throttle body and air cleaner.

3. Disconnect A/T solenoid valve harness connector, PNP switch

harness connector and revolution sensor harness connector.

4. Remove crankshaft position sensor (Euro-OBD) from tran-

saxle.

SAT304G

5. Drain ATF from transaxle.

6. Disconnect control cable from transaxle.

7. Disconnect oil cooler hoses.

8. Remove drive shafts. Refer to AX-10, ªDrive Shaftº.

9. Remove the intake manifold support bracket. Refer to EM-11,

ªOUTER COMPONENT PARTSº.

10. Remove starter motor from transaxle.

Tighten bolts to specified torque.

: 41 - 52 N´m (4.2 - 5.3 kg-m, 30 - 38 ft-lb)

11. Remove upper bolts fixing transaxle to engine.

12. Support transaxle with a jack.

SAT028K

13. Remove center member.

+Tighten center member fixing bolts to specified torque, Refer

to EM-51, ªREMOVAL AND INSTALLATIONº.

REMOVAL AND INSTALLATION

Removal

AT-354

Page 357 of 2898

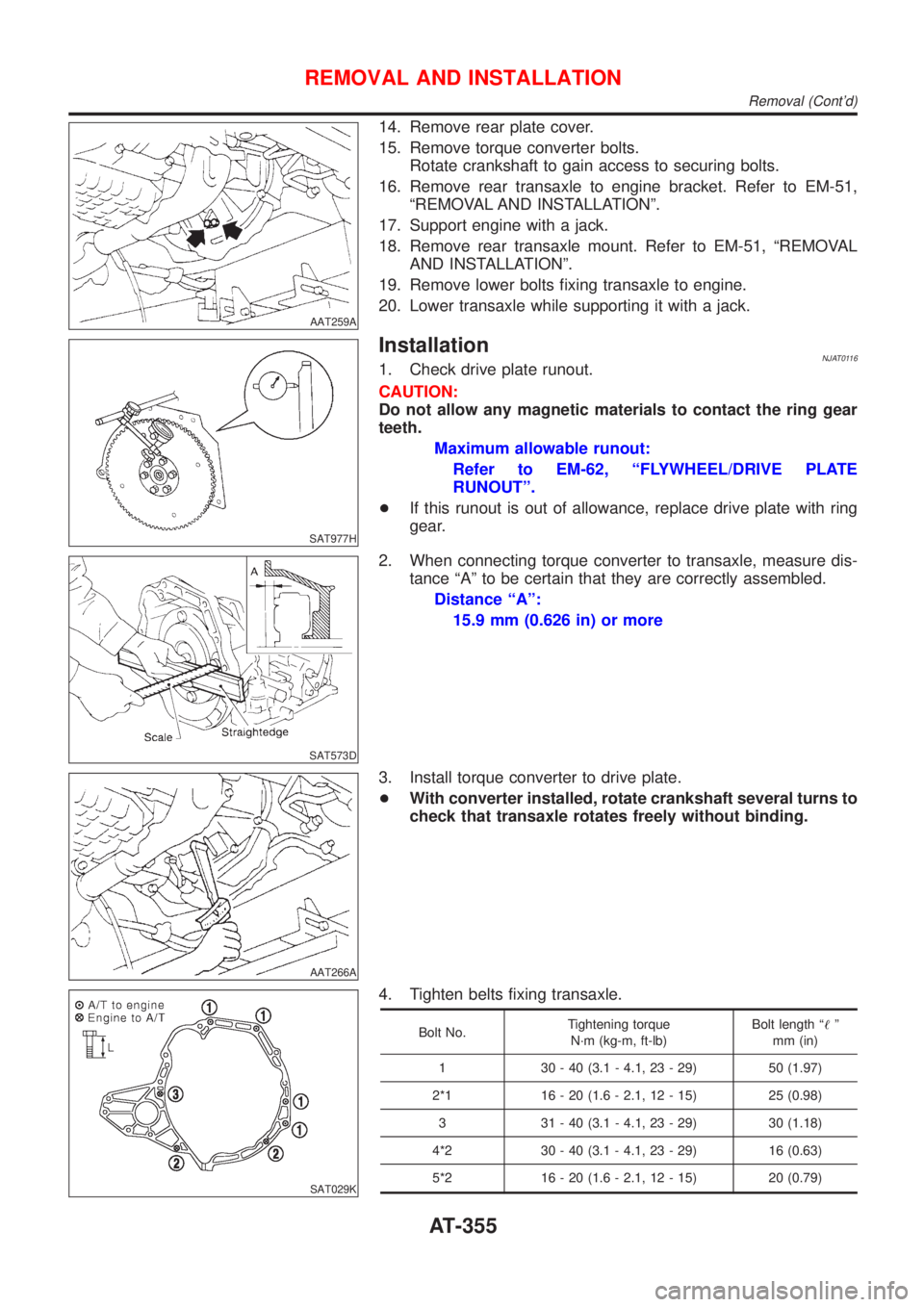

AAT259A

14. Remove rear plate cover.

15. Remove torque converter bolts.

Rotate crankshaft to gain access to securing bolts.

16. Remove rear transaxle to engine bracket. Refer to EM-51,

ªREMOVAL AND INSTALLATIONº.

17. Support engine with a jack.

18. Remove rear transaxle mount. Refer to EM-51, ªREMOVAL

AND INSTALLATIONº.

19. Remove lower bolts fixing transaxle to engine.

20. Lower transaxle while supporting it with a jack.

SAT977H

InstallationNJAT01161. Check drive plate runout.

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Maximum allowable runout:

Refer to EM-62, ªFLYWHEEL/DRIVE PLATE

RUNOUTº.

+If this runout is out of allowance, replace drive plate with ring

gear.

SAT573D

2. When connecting torque converter to transaxle, measure dis-

tance ªAº to be certain that they are correctly assembled.

Distance ªAº:

15.9 mm (0.626 in) or more

AAT266A

3. Install torque converter to drive plate.

+With converter installed, rotate crankshaft several turns to

check that transaxle rotates freely without binding.

SAT029K

4. Tighten belts fixing transaxle.

Bolt No.Tightening torque

N´m (kg-m, ft-lb)Bolt length ª!º

mm (in)

1 30 - 40 (3.1 - 4.1, 23 - 29) 50 (1.97)

2*1 16 - 20 (1.6 - 2.1, 12 - 15) 25 (0.98)

3 31 - 40 (3.1 - 4.1, 23 - 29) 30 (1.18)

4*2 30 - 40 (3.1 - 4.1, 23 - 29) 16 (0.63)

5*2 16 - 20 (1.6 - 2.1, 12 - 15) 20 (0.79)

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-355

Page 358 of 2898

SAT058K

*1: With gusset to A/T

*2: With gusset to cylinder block

SAT638A

5. Reinstall any part removed.

6. Adjust control cable. Refer to AT-352.

7. Check continuity of PNP switch. Refer to AT-334.

8. Refill transaxle with ATF and check fluid level.

9. Move selector lever through all positions to be sure that tran-

saxle operates correctly. With parking brake applied, idle

engine. Move selector lever through ªNº to ªDº, to ª2º, to ª1º and

ªRº positions. A slight shock should be felt through the hand

gripping the selector each time the transaxle is shifted.

10. Perform road test. Refer to AT-85.

REMOVAL AND INSTALLATION

Installation (Cont'd)

AT-356

Page 475 of 2898

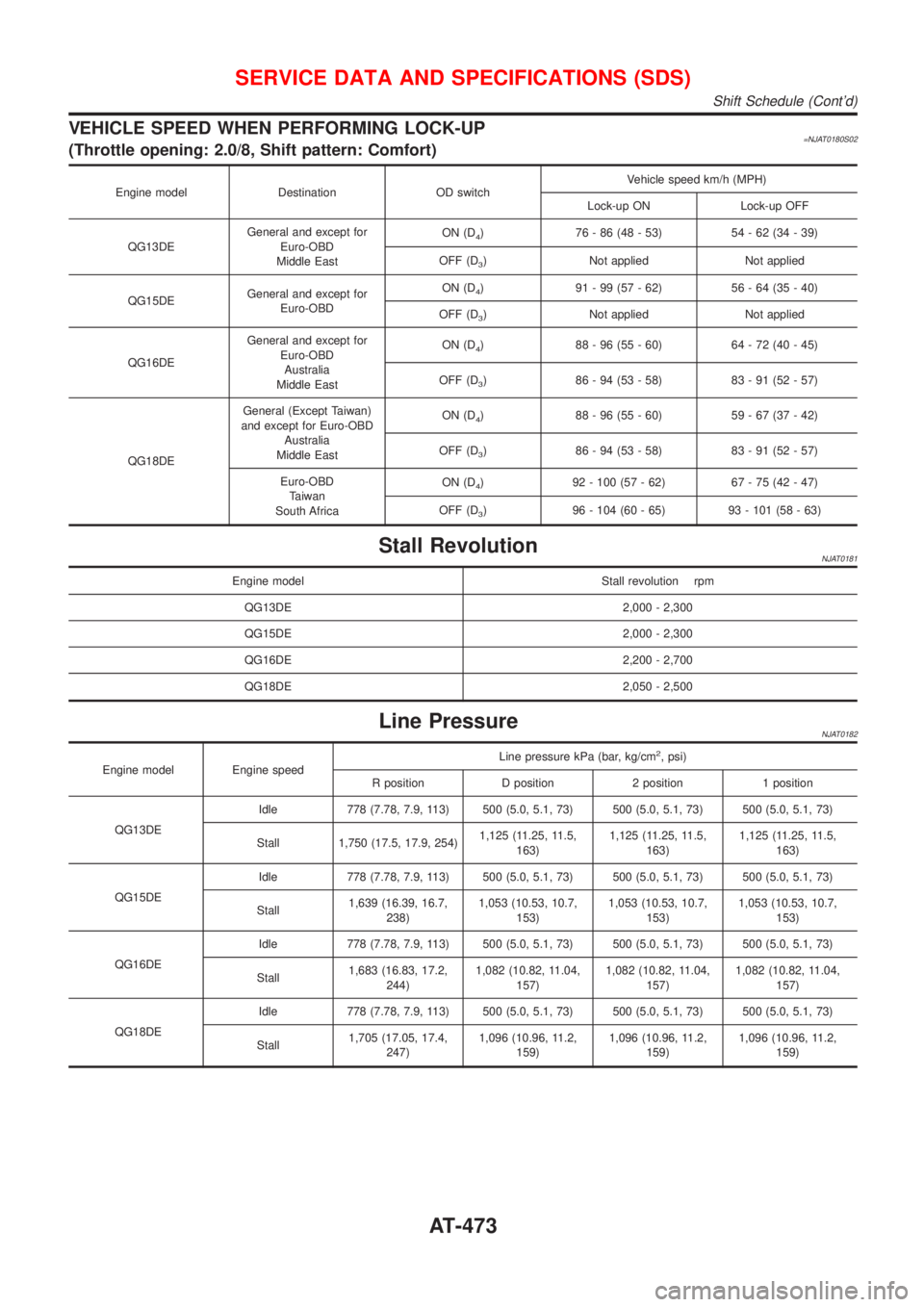

VEHICLE SPEED WHEN PERFORMING LOCK-UP=NJAT0180S02(Throttle opening: 2.0/8, Shift pattern: Comfort)

Engine model Destination OD switchVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

QG13DEGeneral and except for

Euro-OBD

Middle EastON (D

4) 76-86(48-53) 54-62(34-39)

OFF (D

3) Not applied Not applied

QG15DEGeneral and except for

Euro-OBDON (D

4) 91-99(57-62) 56-64(35-40)

OFF (D

3) Not applied Not applied

QG16DEGeneral and except for

Euro-OBD

Australia

Middle EastON (D

4) 88-96(55-60) 64-72(40-45)

OFF (D

3) 86-94(53-58) 83-91(52-57)

QG18DEGeneral (Except Taiwan)

and except for Euro-OBD

Australia

Middle EastON (D

4) 88-96(55-60) 59-67(37-42)

OFF (D

3) 86-94(53-58) 83-91(52-57)

Euro-OBD

Taiwan

South AfricaON (D

4) 92 - 100 (57 - 62) 67 - 75 (42 - 47)

OFF (D

3) 96 - 104 (60 - 65) 93 - 101 (58 - 63)

Stall RevolutionNJAT0181

Engine model Stall revolution rpm

QG13DE 2,000 - 2,300

QG15DE 2,000 - 2,300

QG16DE 2,200 - 2,700

QG18DE 2,050 - 2,500

Line PressureNJAT0182

Engine model Engine speedLine pressure kPa (bar, kg/cm

2, psi)

R position D position 2 position 1 position

QG13DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall 1,750 (17.5, 17.9, 254)1,125 (11.25, 11.5,

163)1,125 (11.25, 11.5,

163)1,125 (11.25, 11.5,

163)

QG15DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall1,639 (16.39, 16.7,

238)1,053 (10.53, 10.7,

153)1,053 (10.53, 10.7,

153)1,053 (10.53, 10.7,

153)

QG16DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall1,683 (16.83, 17.2,

244)1,082 (10.82, 11.04,

157)1,082 (10.82, 11.04,

157)1,082 (10.82, 11.04,

157)

QG18DEIdle 778 (7.78, 7.9, 113) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73) 500 (5.0, 5.1, 73)

Stall1,705 (17.05, 17.4,

247)1,096 (10.96, 11.2,

159)1,096 (10.96, 11.2,

159)1,096 (10.96, 11.2,

159)

SERVICE DATA AND SPECIFICATIONS (SDS)

Shift Schedule (Cont'd)

AT-473

Page 490 of 2898

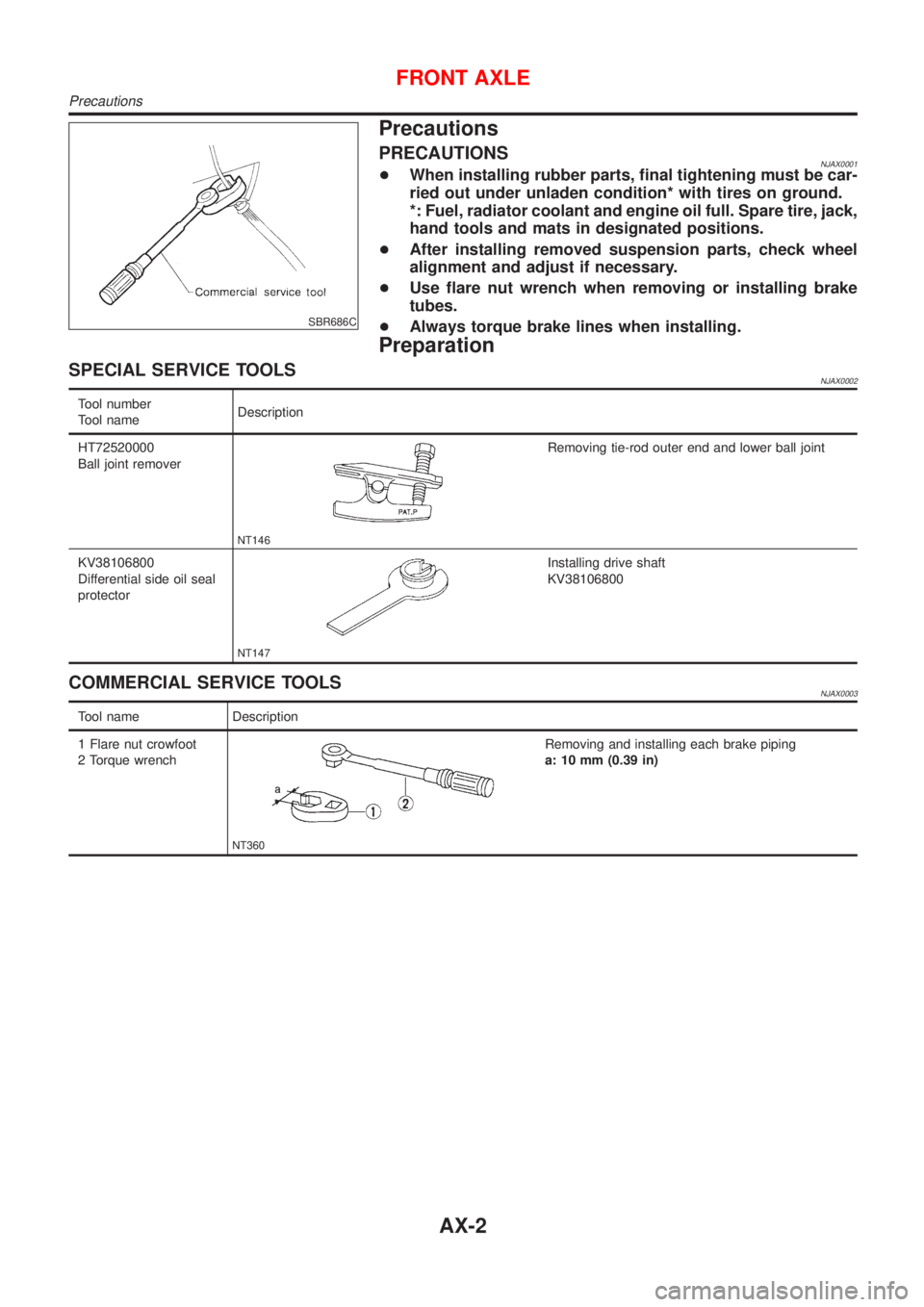

SBR686C

Precautions

PRECAUTIONSNJAX0001+When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

+After installing removed suspension parts, check wheel

alignment and adjust if necessary.

+Use flare nut wrench when removing or installing brake

tubes.

+Always torque brake lines when installing.

Preparation

SPECIAL SERVICE TOOLSNJAX0002

Tool number

Tool nameDescription

HT72520000

Ball joint remover

NT146

Removing tie-rod outer end and lower ball joint

KV38106800

Differential side oil seal

protector

NT147

Installing drive shaft

KV38106800

COMMERCIAL SERVICE TOOLSNJAX0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

FRONT AXLE

Precautions

AX-2