torque NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2839 of 2898

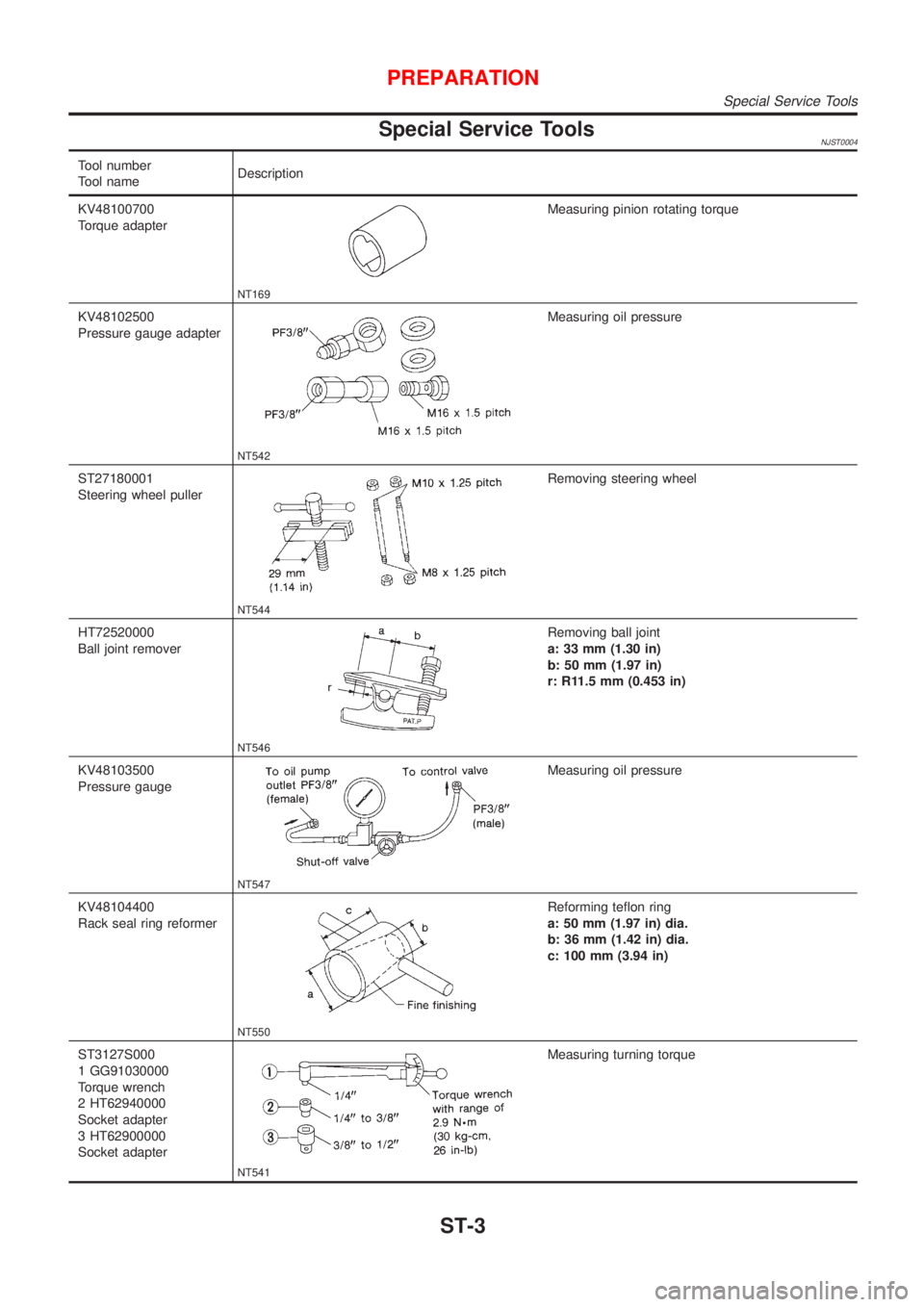

Special Service ToolsNJST0004

Tool number

Tool nameDescription

KV48100700

Torque adapter

NT169

Measuring pinion rotating torque

KV48102500

Pressure gauge adapter

NT542

Measuring oil pressure

ST27180001

Steering wheel puller

NT544

Removing steering wheel

HT72520000

Ball joint remover

NT546

Removing ball joint

a: 33 mm (1.30 in)

b: 50 mm (1.97 in)

r: R11.5 mm (0.453 in)

KV48103500

Pressure gauge

NT547

Measuring oil pressure

KV48104400

Rack seal ring reformer

NT550

Reforming teflon ring

a: 50 mm (1.97 in) dia.

b: 36 mm (1.42 in) dia.

c: 100 mm (3.94 in)

ST3127S000

1 GG91030000

Torque wrench

2 HT62940000

Socket adapter

3 HT62900000

Socket adapter

NT541

Measuring turning torque

PREPARATION

Special Service Tools

ST-3

Page 2841 of 2898

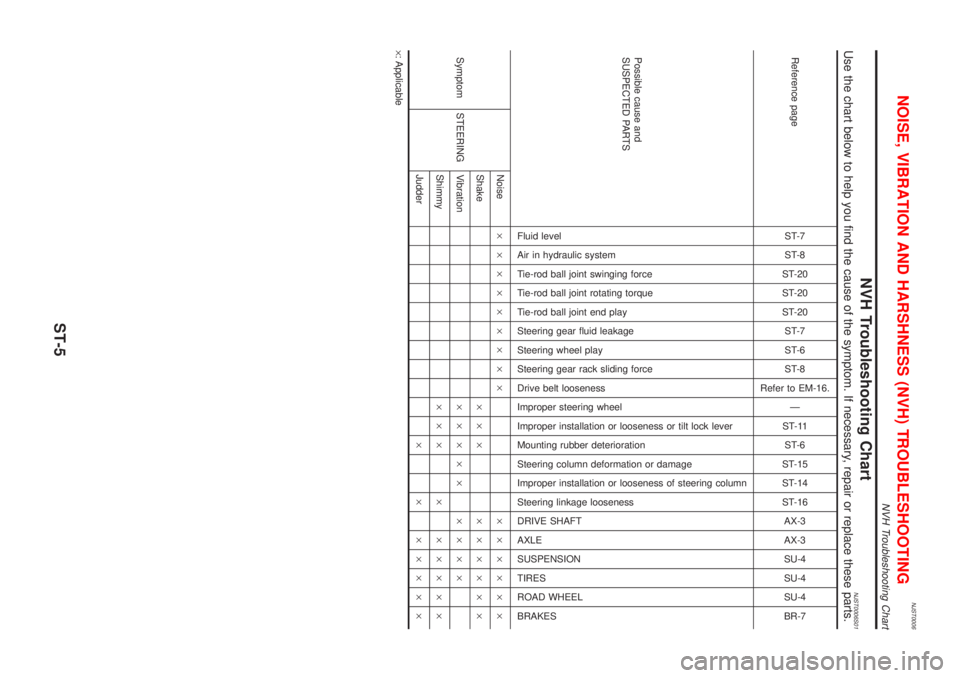

NJST0006

NVH Troubleshooting ChartNJST0006S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-7

ST-8

ST-20

ST-20

ST-20

ST-7

ST-6

ST-8

Refer to EM-16.

Ð

ST-11

ST-6

ST-15

ST-14

ST-16

AX-3

AX-3

SU-4

SU-4

SU-4

BR-7

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symptom STEERINGNoise´´´´´´´´´ ´´´´´´

Shake´´´ ´´´´´´

Vibration´´´´´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-5

Page 2854 of 2898

SST879C

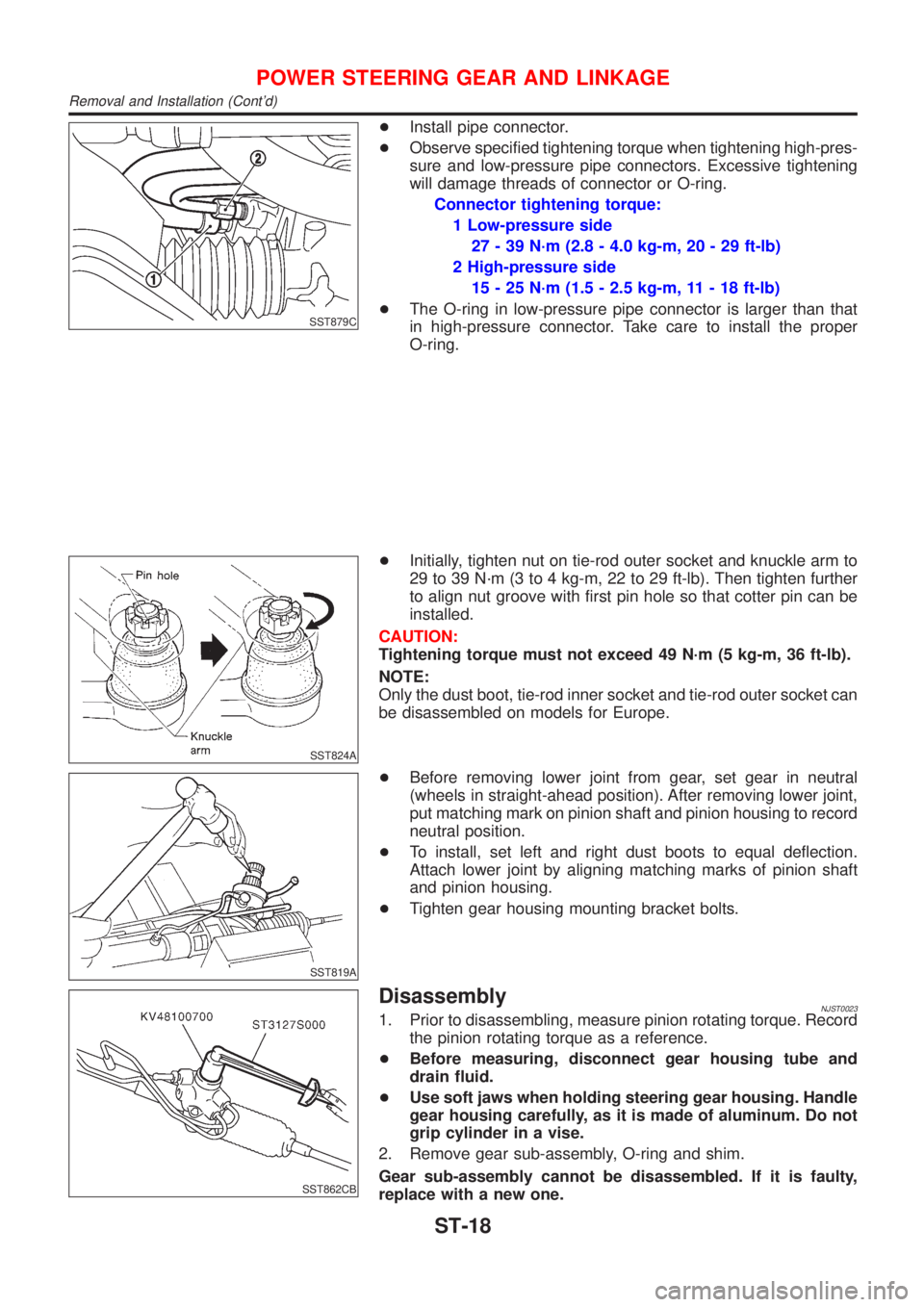

+Install pipe connector.

+Observe specified tightening torque when tightening high-pres-

sure and low-pressure pipe connectors. Excessive tightening

will damage threads of connector or O-ring.

Connector tightening torque:

1 Low-pressure side

27 - 39 N´m (2.8 - 4.0 kg-m, 20 - 29 ft-lb)

2 High-pressure side

15 - 25 N´m (1.5 - 2.5 kg-m, 11 - 18 ft-lb)

+The O-ring in low-pressure pipe connector is larger than that

in high-pressure connector. Take care to install the proper

O-ring.

SST824A

+Initially, tighten nut on tie-rod outer socket and knuckle arm to

29 to 39 N´m (3 to 4 kg-m, 22 to 29 ft-lb). Then tighten further

to align nut groove with first pin hole so that cotter pin can be

installed.

CAUTION:

Tightening torque must not exceed 49 N´m (5 kg-m, 36 ft-lb).

NOTE:

Only the dust boot, tie-rod inner socket and tie-rod outer socket can

be disassembled on models for Europe.

SST819A

+Before removing lower joint from gear, set gear in neutral

(wheels in straight-ahead position). After removing lower joint,

put matching mark on pinion shaft and pinion housing to record

neutral position.

+To install, set left and right dust boots to equal deflection.

Attach lower joint by aligning matching marks of pinion shaft

and pinion housing.

+Tighten gear housing mounting bracket bolts.

SST862CB

DisassemblyNJST00231. Prior to disassembling, measure pinion rotating torque. Record

the pinion rotating torque as a reference.

+Before measuring, disconnect gear housing tube and

drain fluid.

+Use soft jaws when holding steering gear housing. Handle

gear housing carefully, as it is made of aluminum. Do not

grip cylinder in a vise.

2. Remove gear sub-assembly, O-ring and shim.

Gear sub-assembly cannot be disassembled. If it is faulty,

replace with a new one.

POWER STEERING GEAR AND LINKAGE

Removal and Installation (Cont'd)

ST-18

Page 2855 of 2898

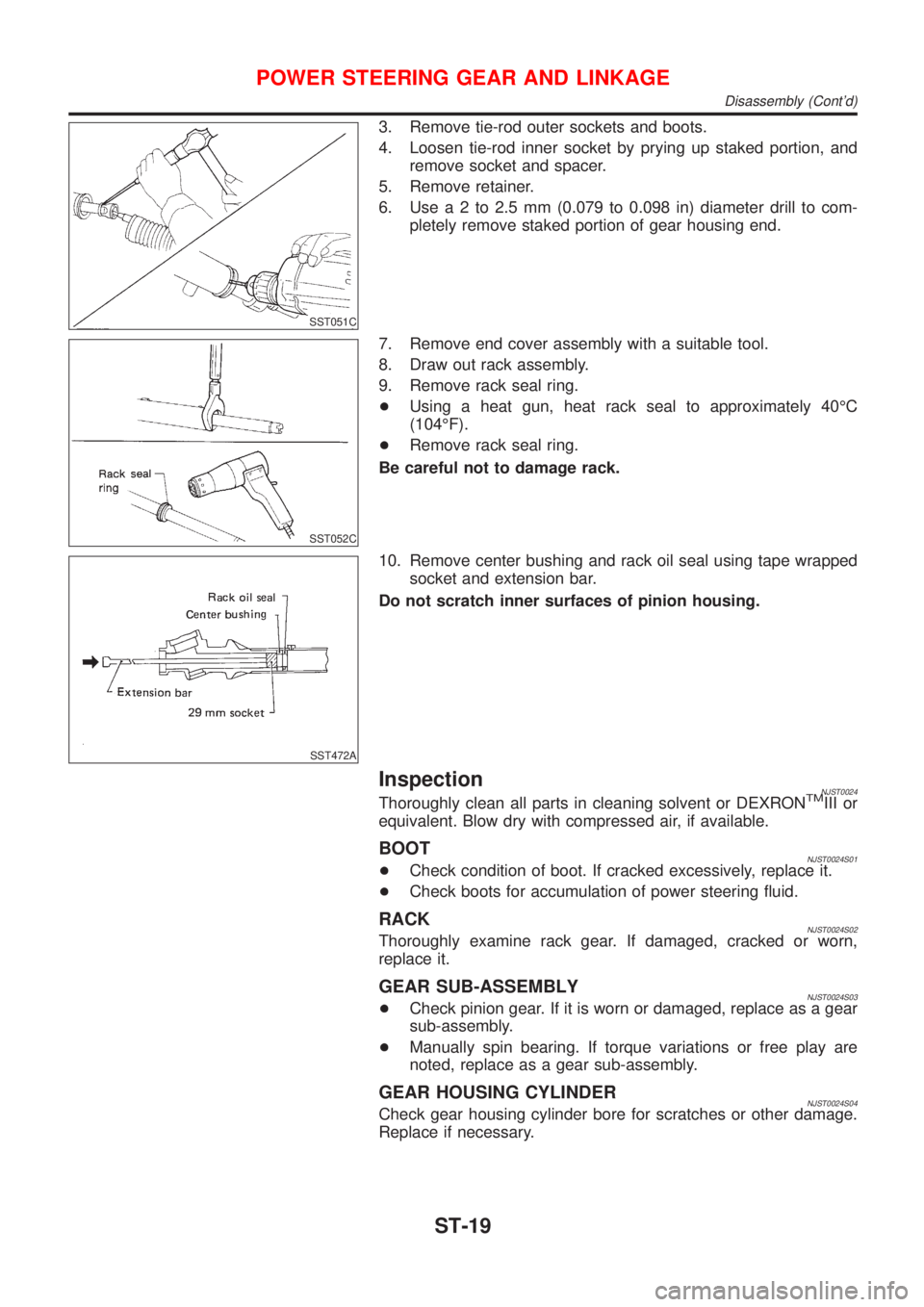

SST051C

3. Remove tie-rod outer sockets and boots.

4. Loosen tie-rod inner socket by prying up staked portion, and

remove socket and spacer.

5. Remove retainer.

6. Usea2to2.5mm(0.079 to 0.098 in) diameter drill to com-

pletely remove staked portion of gear housing end.

SST052C

7. Remove end cover assembly with a suitable tool.

8. Draw out rack assembly.

9. Remove rack seal ring.

+Using a heat gun, heat rack seal to approximately 40ÉC

(104ÉF).

+Remove rack seal ring.

Be careful not to damage rack.

SST472A

10. Remove center bushing and rack oil seal using tape wrapped

socket and extension bar.

Do not scratch inner surfaces of pinion housing.

InspectionNJST0024Thoroughly clean all parts in cleaning solvent or DEXRONTMIII or

equivalent. Blow dry with compressed air, if available.

BOOTNJST0024S01+Check condition of boot. If cracked excessively, replace it.

+Check boots for accumulation of power steering fluid.

RACKNJST0024S02Thoroughly examine rack gear. If damaged, cracked or worn,

replace it.

GEAR SUB-ASSEMBLYNJST0024S03+Check pinion gear. If it is worn or damaged, replace as a gear

sub-assembly.

+Manually spin bearing. If torque variations or free play are

noted, replace as a gear sub-assembly.

GEAR HOUSING CYLINDERNJST0024S04Check gear housing cylinder bore for scratches or other damage.

Replace if necessary.

POWER STEERING GEAR AND LINKAGE

Disassembly (Cont'd)

ST-19

Page 2856 of 2898

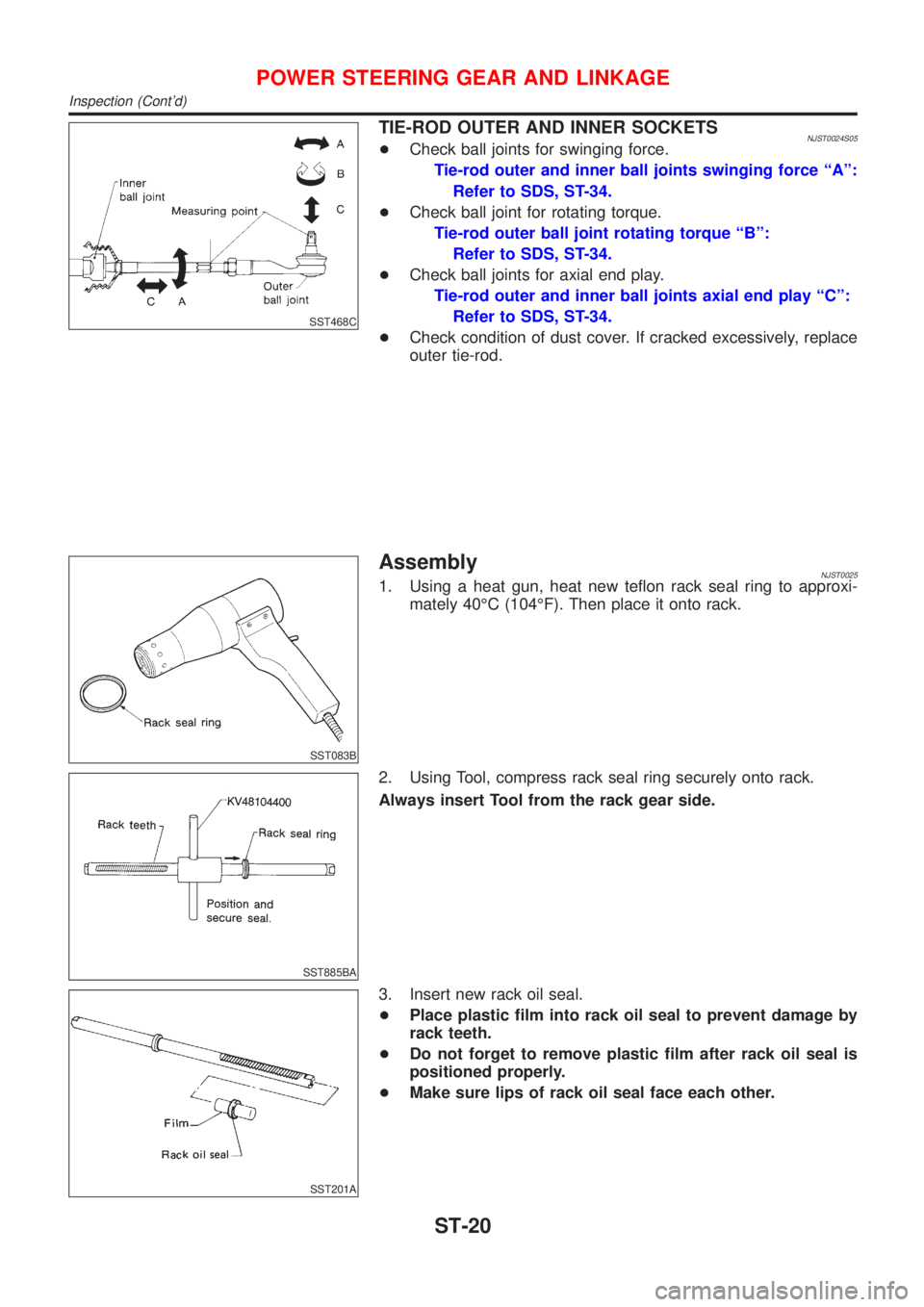

SST468C

TIE-ROD OUTER AND INNER SOCKETSNJST0024S05+Check ball joints for swinging force.

Tie-rod outer and inner ball joints swinging force ªAº:

Refer to SDS, ST-34.

+Check ball joint for rotating torque.

Tie-rod outer ball joint rotating torque ªBº:

Refer to SDS, ST-34.

+Check ball joints for axial end play.

Tie-rod outer and inner ball joints axial end play ªCº:

Refer to SDS, ST-34.

+Check condition of dust cover. If cracked excessively, replace

outer tie-rod.

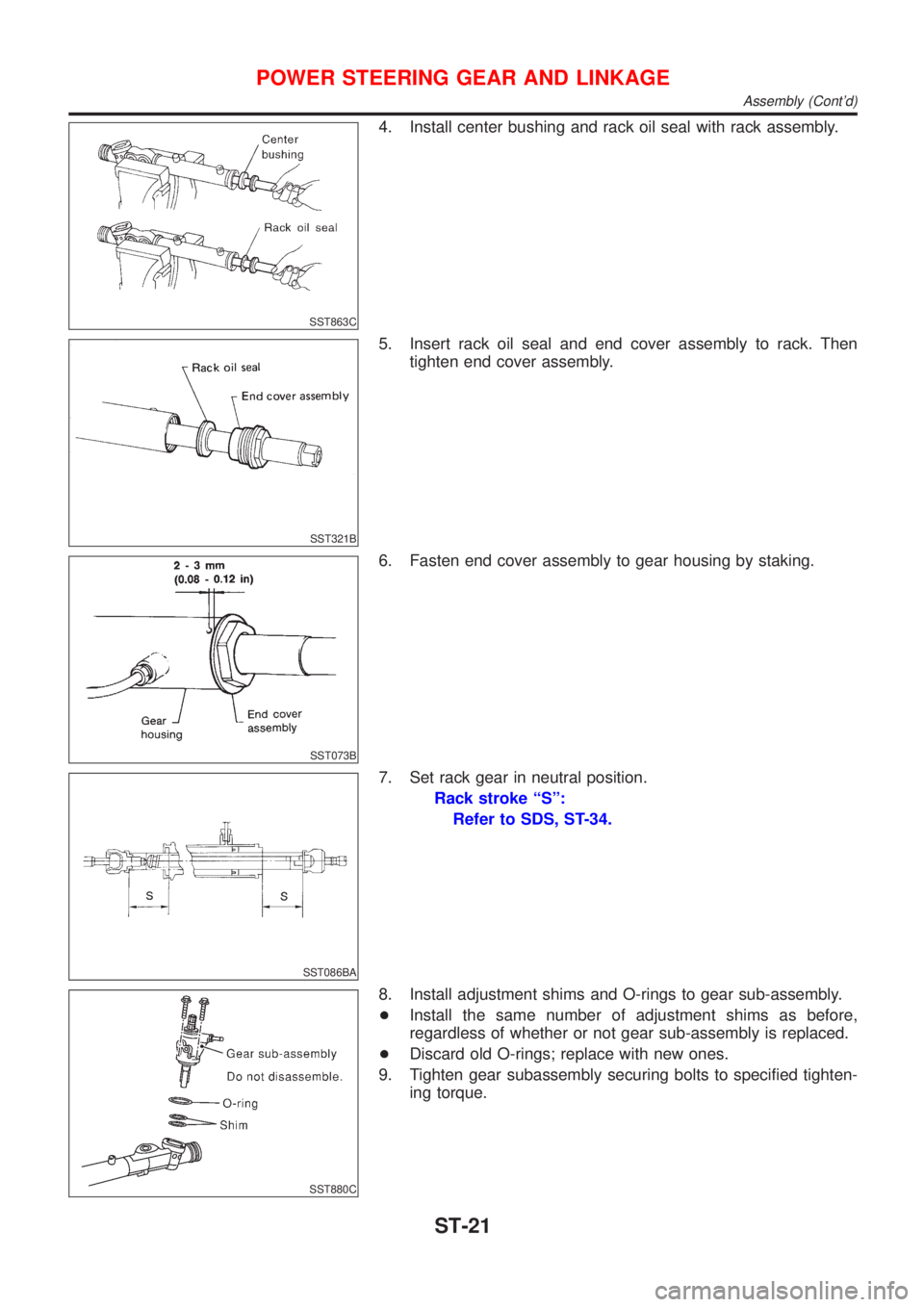

SST083B

AssemblyNJST00251. Using a heat gun, heat new teflon rack seal ring to approxi-

mately 40ÉC (104ÉF). Then place it onto rack.

SST885BA

2. Using Tool, compress rack seal ring securely onto rack.

Always insert Tool from the rack gear side.

SST201A

3. Insert new rack oil seal.

+Place plastic film into rack oil seal to prevent damage by

rack teeth.

+Do not forget to remove plastic film after rack oil seal is

positioned properly.

+Make sure lips of rack oil seal face each other.

POWER STEERING GEAR AND LINKAGE

Inspection (Cont'd)

ST-20

Page 2857 of 2898

SST863C

4. Install center bushing and rack oil seal with rack assembly.

SST321B

5. Insert rack oil seal and end cover assembly to rack. Then

tighten end cover assembly.

SST073B

6. Fasten end cover assembly to gear housing by staking.

SST086BA

7. Set rack gear in neutral position.

Rack stroke ªSº:

Refer to SDS, ST-34.

SST880C

8. Install adjustment shims and O-rings to gear sub-assembly.

+Install the same number of adjustment shims as before,

regardless of whether or not gear sub-assembly is replaced.

+Discard old O-rings; replace with new ones.

9. Tighten gear subassembly securing bolts to specified tighten-

ing torque.

POWER STEERING GEAR AND LINKAGE

Assembly (Cont'd)

ST-21

Page 2858 of 2898

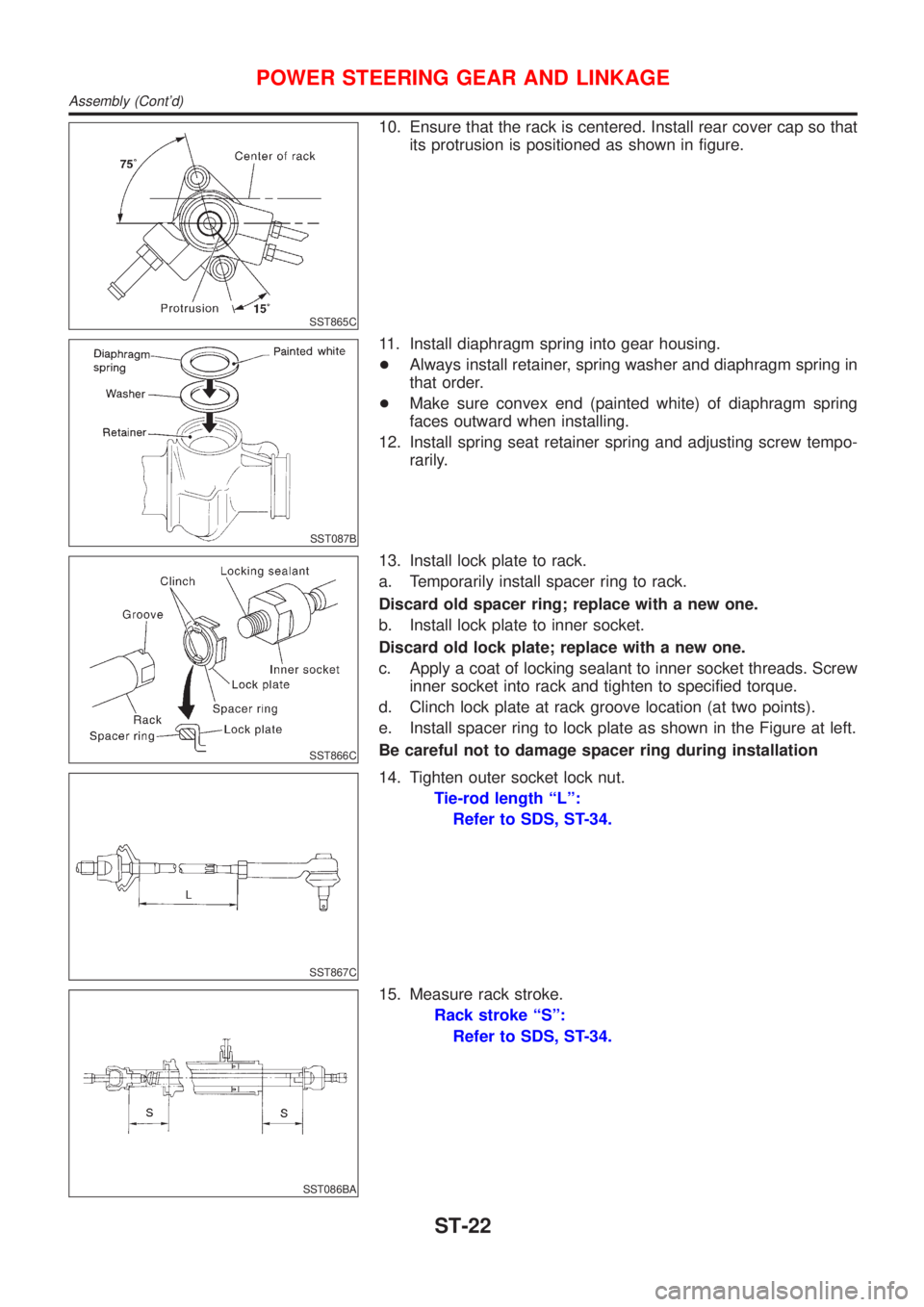

SST865C

10. Ensure that the rack is centered. Install rear cover cap so that

its protrusion is positioned as shown in figure.

SST087B

11. Install diaphragm spring into gear housing.

+Always install retainer, spring washer and diaphragm spring in

that order.

+Make sure convex end (painted white) of diaphragm spring

faces outward when installing.

12. Install spring seat retainer spring and adjusting screw tempo-

rarily.

SST866C

13. Install lock plate to rack.

a. Temporarily install spacer ring to rack.

Discard old spacer ring; replace with a new one.

b. Install lock plate to inner socket.

Discard old lock plate; replace with a new one.

c. Apply a coat of locking sealant to inner socket threads. Screw

inner socket into rack and tighten to specified torque.

d. Clinch lock plate at rack groove location (at two points).

e. Install spacer ring to lock plate as shown in the Figure at left.

Be careful not to damage spacer ring during installation

SST867C

14. Tighten outer socket lock nut.

Tie-rod length ªLº:

Refer to SDS, ST-34.

SST086BA

15. Measure rack stroke.

Rack stroke ªSº:

Refer to SDS, ST-34.

POWER STEERING GEAR AND LINKAGE

Assembly (Cont'd)

ST-22

Page 2859 of 2898

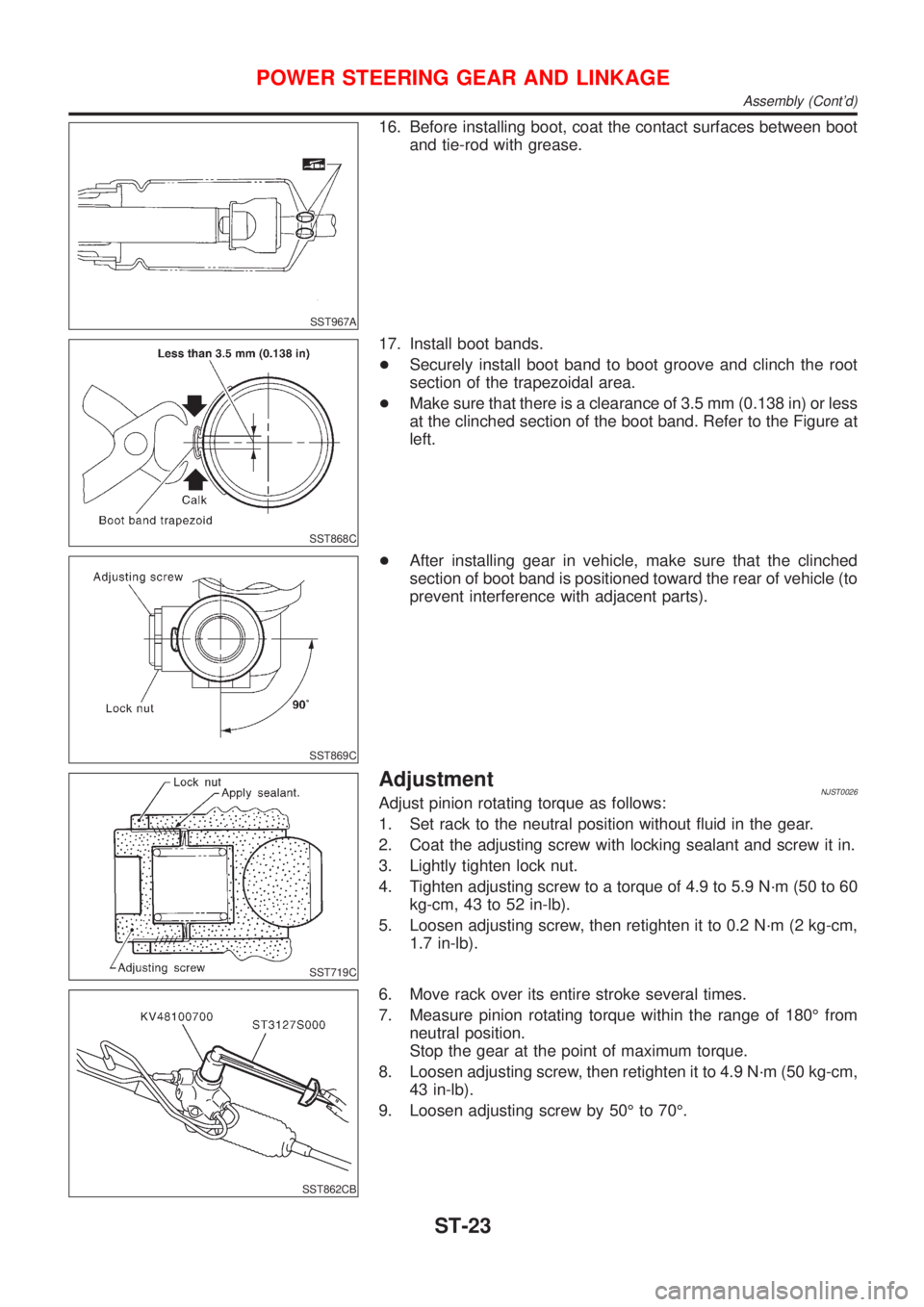

SST967A

16. Before installing boot, coat the contact surfaces between boot

and tie-rod with grease.

SST868C

17. Install boot bands.

+Securely install boot band to boot groove and clinch the root

section of the trapezoidal area.

+Make sure that there is a clearance of 3.5 mm (0.138 in) or less

at the clinched section of the boot band. Refer to the Figure at

left.

SST869C

+After installing gear in vehicle, make sure that the clinched

section of boot band is positioned toward the rear of vehicle (to

prevent interference with adjacent parts).

SST719C

AdjustmentNJST0026Adjust pinion rotating torque as follows:

1. Set rack to the neutral position without fluid in the gear.

2. Coat the adjusting screw with locking sealant and screw it in.

3. Lightly tighten lock nut.

4. Tighten adjusting screw to a torque of 4.9 to 5.9 N´m (50 to 60

kg-cm, 43 to 52 in-lb).

5. Loosen adjusting screw, then retighten it to 0.2 N´m (2 kg-cm,

1.7 in-lb).

SST862CB

6. Move rack over its entire stroke several times.

7. Measure pinion rotating torque within the range of 180É from

neutral position.

Stop the gear at the point of maximum torque.

8. Loosen adjusting screw, then retighten it to 4.9 N´m (50 kg-cm,

43 in-lb).

9. Loosen adjusting screw by 50É to 70É.

POWER STEERING GEAR AND LINKAGE

Assembly (Cont'd)

ST-23

Page 2860 of 2898

SST713C

10. Prevent adjusting screw from turning, and tighten lock nut to

specified torque.

SST090B

11. Check rack sliding force on vehicle as follows:

a. Install steering gear onto vehicle, but do not connect tie-rod to

knuckle arm.

b. Connect all piping and fill with steering fluid.

c. Start engine and bleed air completely.

d. Disconnect steering column lower joint from the gear.

e. Keep engine at idle and make sure steering fluid has reached

normal operating temperature.

f. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Average rack sliding force:

Sedan

152 - 240 N (15.5 - 24.5 kg, 34.2 - 54.0 lb)

Hatchback

132 - 308 N (13.5 - 31.4 kg, 30 - 69 lb)

Maximum force deviation:

Sedan

98 N (10 kg, 22 lb)

Hatchback

176 N (17.9 kg, 39 lb)

g. Check sliding force outside above range at rack speed of 40

mm (1.57 in)/s.

Maximum rack sliding force (Sedan only):

294 N (30 kg, 66 lb)

Maximum force deviation (Sedan only):

147 N (15 kg, 33 lb)

+If rack sliding force is not within specification, readjust by

repeating adjustment procedure from the beginning.

+If rack sliding force is still out of specification after

readjustment, gear assembly needs to be replaced.

POWER STEERING GEAR AND LINKAGE

Adjustment (Cont'd)

ST-24

Page 2870 of 2898

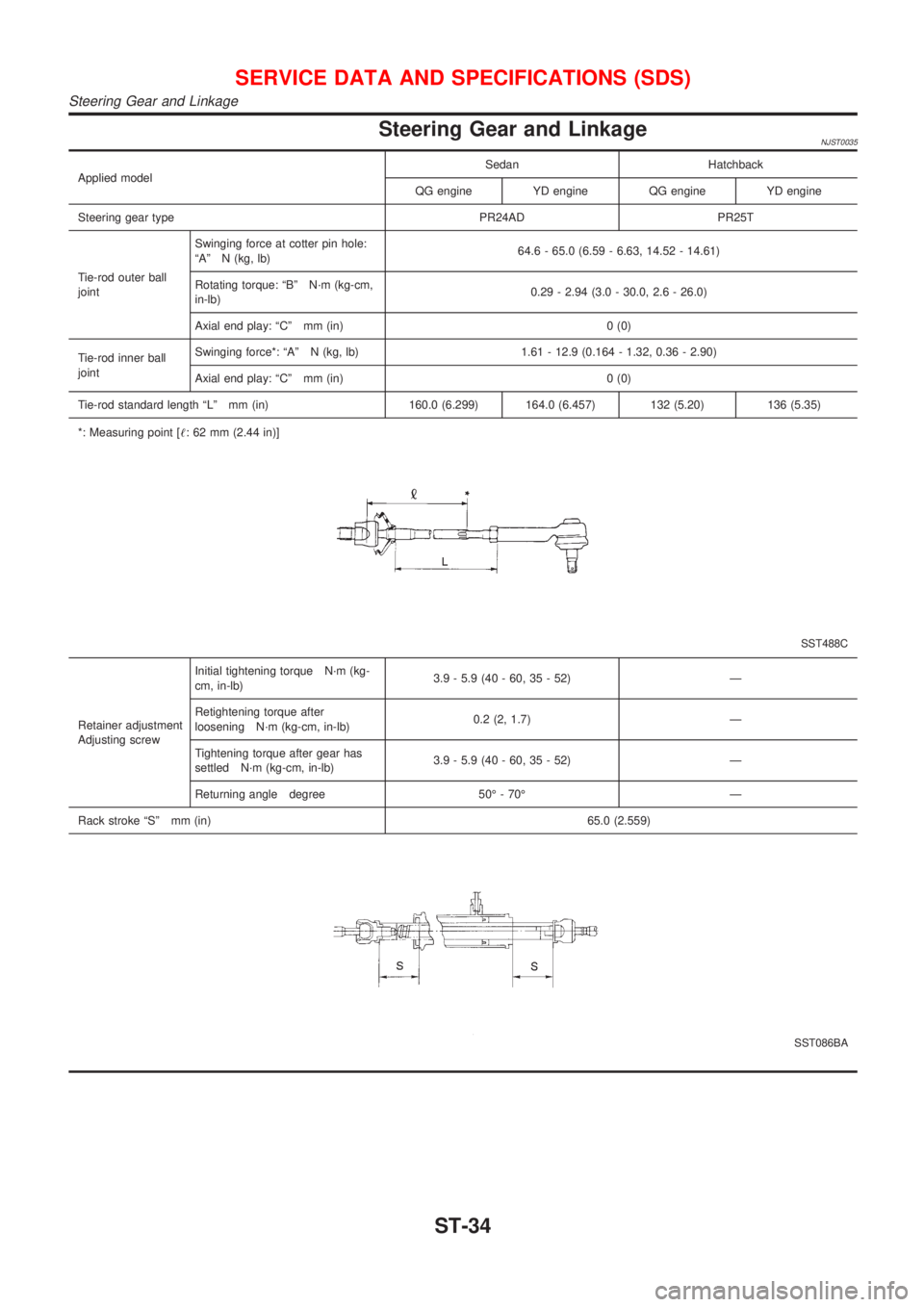

Steering Gear and LinkageNJST0035

Applied modelSedan Hatchback

QG engine YD engine QG engine YD engine

Steering gear type PR24AD PR25T

Tie-rod outer ball

jointSwinging force at cotter pin hole:

ªAº N (kg, lb)64.6 - 65.0 (6.59 - 6.63, 14.52 - 14.61)

Rotating torque: ªBº N´m (kg-cm,

in-lb)0.29 - 2.94 (3.0 - 30.0, 2.6 - 26.0)

Axial end play: ªCº mm (in) 0 (0)

Tie-rod inner ball

jointSwinging force*: ªAº N (kg, lb) 1.61 - 12.9 (0.164 - 1.32, 0.36 - 2.90)

Axial end play: ªCº mm (in) 0 (0)

Tie-rod standard length ªLº mm (in) 160.0 (6.299) 164.0 (6.457) 132 (5.20) 136 (5.35)

*: Measuring point [!: 62 mm (2.44 in)]

SST488C

Retainer adjustment

Adjusting screwInitial tightening torque N´m (kg-

cm, in-lb)3.9 - 5.9 (40 - 60, 35 - 52) Ð

Retightening torque after

loosening N´m (kg-cm, in-lb)0.2 (2, 1.7) Ð

Tightening torque after gear has

settled N´m (kg-cm, in-lb)3.9 - 5.9 (40 - 60, 35 - 52) Ð

Returning angle degree 50É - 70É Ð

Rack stroke ªSº mm (in)65.0 (2.559)

SST086BA

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering Gear and Linkage

ST-34