torque NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2319 of 2898

SMA211A

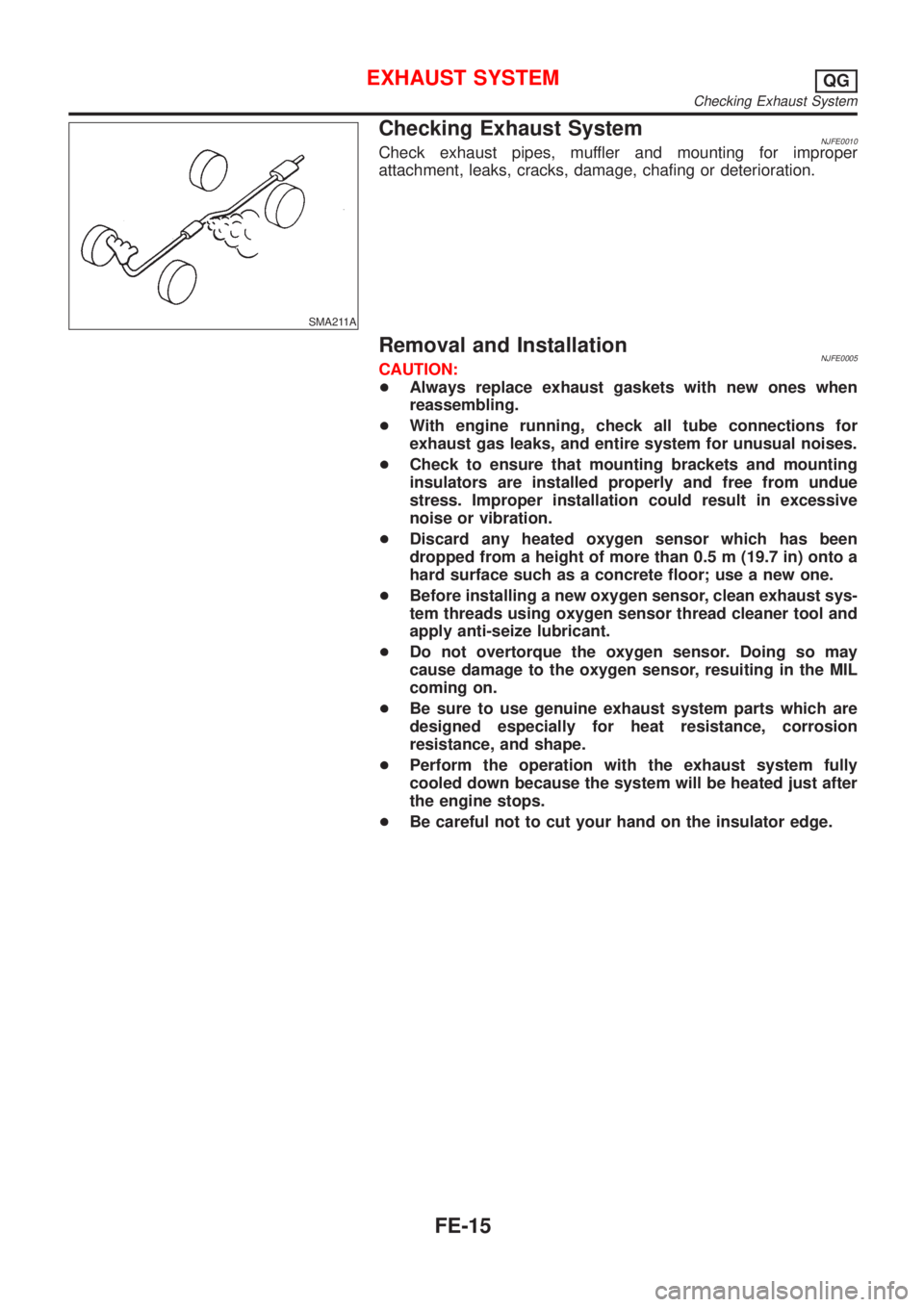

Checking Exhaust SystemNJFE0010Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

Removal and InstallationNJFE0005CAUTION:

+Always replace exhaust gaskets with new ones when

reassembling.

+With engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

+Check to ensure that mounting brackets and mounting

insulators are installed properly and free from undue

stress. Improper installation could result in excessive

noise or vibration.

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing a new oxygen sensor, clean exhaust sys-

tem threads using oxygen sensor thread cleaner tool and

apply anti-seize lubricant.

+Do not overtorque the oxygen sensor. Doing so may

cause damage to the oxygen sensor, resuiting in the MIL

coming on.

+Be sure to use genuine exhaust system parts which are

designed especially for heat resistance, corrosion

resistance, and shape.

+Perform the operation with the exhaust system fully

cooled down because the system will be heated just after

the engine stops.

+Be careful not to cut your hand on the insulator edge.

EXHAUST SYSTEMQG

Checking Exhaust System

FE-15

Page 2324 of 2898

SMA803A

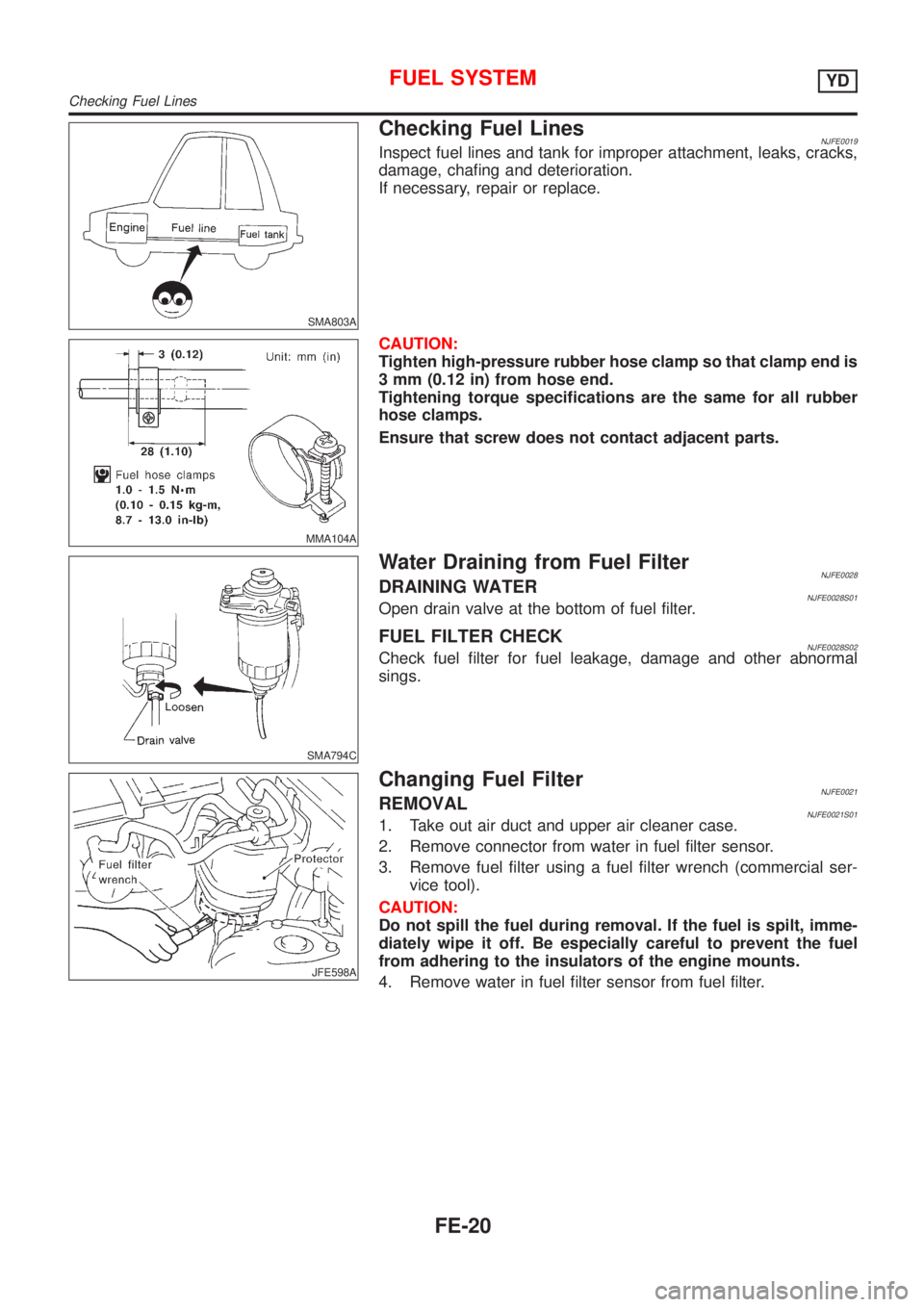

Checking Fuel LinesNJFE0019Inspect fuel lines and tank for improper attachment, leaks, cracks,

damage, chafing and deterioration.

If necessary, repair or replace.

MMA104A

CAUTION:

Tighten high-pressure rubber hose clamp so that clamp end is

3 mm (0.12 in) from hose end.

Tightening torque specifications are the same for all rubber

hose clamps.

Ensure that screw does not contact adjacent parts.

SMA794C

Water Draining from Fuel FilterNJFE0028DRAINING WATERNJFE0028S01Open drain valve at the bottom of fuel filter.

FUEL FILTER CHECKNJFE0028S02Check fuel filter for fuel leakage, damage and other abnormal

sings.

JFE598A

Changing Fuel FilterNJFE0021REMOVALNJFE0021S011. Take out air duct and upper air cleaner case.

2. Remove connector from water in fuel filter sensor.

3. Remove fuel filter using a fuel filter wrench (commercial ser-

vice tool).

CAUTION:

Do not spill the fuel during removal. If the fuel is spilt, imme-

diately wipe it off. Be especially careful to prevent the fuel

from adhering to the insulators of the engine mounts.

4. Remove water in fuel filter sensor from fuel filter.

FUEL SYSTEMYD

Checking Fuel Lines

FE-20

Page 2326 of 2898

SEF122U

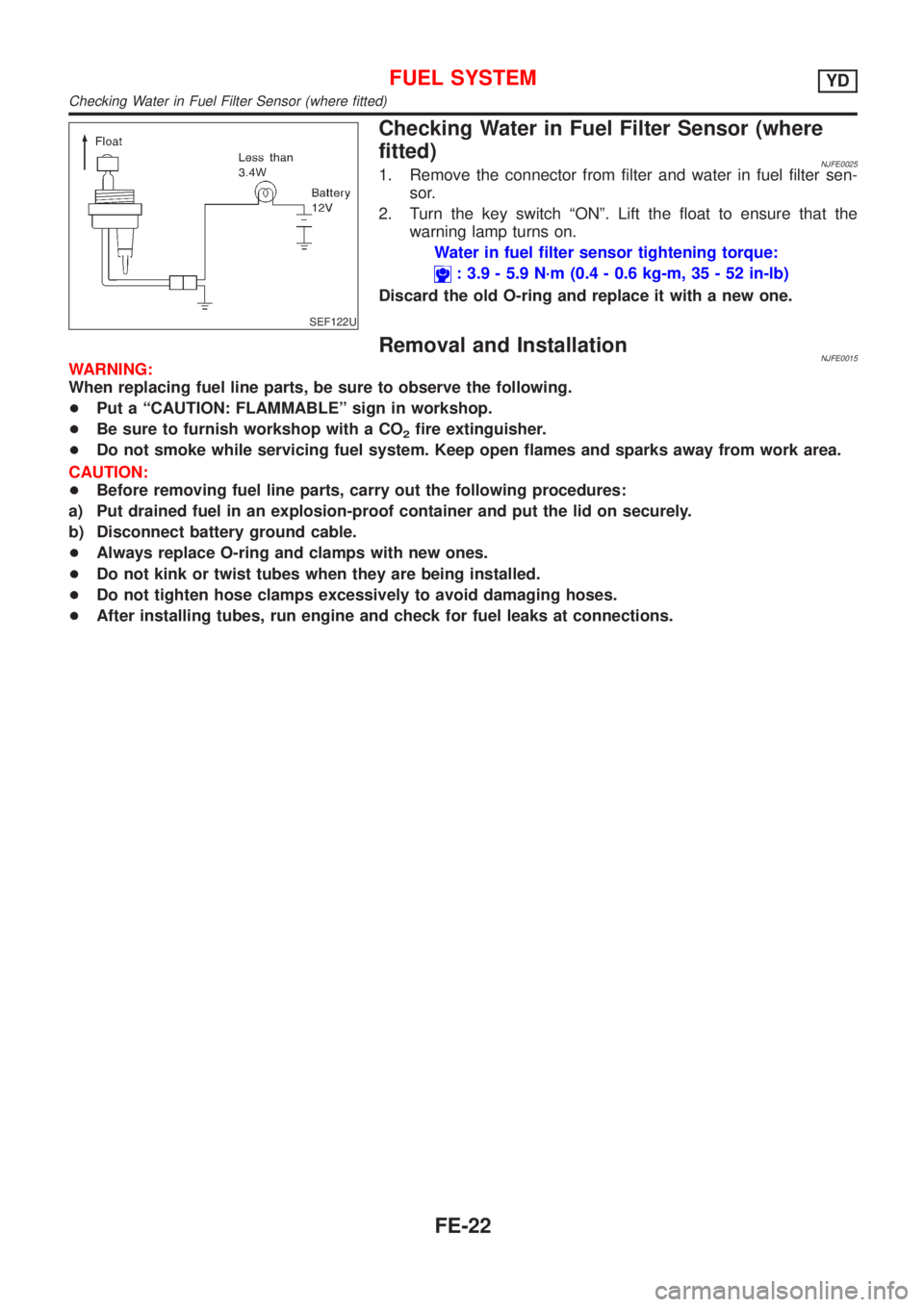

Checking Water in Fuel Filter Sensor (where

fitted)

NJFE00251. Remove the connector from filter and water in fuel filter sen-

sor.

2. Turn the key switch ªONº. Lift the float to ensure that the

warning lamp turns on.

Water in fuel filter sensor tightening torque:

: 3.9 - 5.9 N´m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

Discard the old O-ring and replace it with a new one.

Removal and InstallationNJFE0015WARNING:

When replacing fuel line parts, be sure to observe the following.

+Put a ªCAUTION: FLAMMABLEº sign in workshop.

+Be sure to furnish workshop with a CO

2fire extinguisher.

+Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

CAUTION:

+Before removing fuel line parts, carry out the following procedures:

a) Put drained fuel in an explosion-proof container and put the lid on securely.

b) Disconnect battery ground cable.

+Always replace O-ring and clamps with new ones.

+Do not kink or twist tubes when they are being installed.

+Do not tighten hose clamps excessively to avoid damaging hoses.

+After installing tubes, run engine and check for fuel leaks at connections.

FUEL SYSTEMYD

Checking Water in Fuel Filter Sensor (where fitted)

FE-22

Page 2348 of 2898

TOWING POINT.......................................................48

TIGHTENING TORQUE OF STANDARD BOLTS........49

ISO 15031-2 TERMINOLOGY LIST..............................50ISO 15031-2 Terminology List ...................................50

CONTENTS(Cont'd)

GI-2

Page 2355 of 2898

NJGI0002

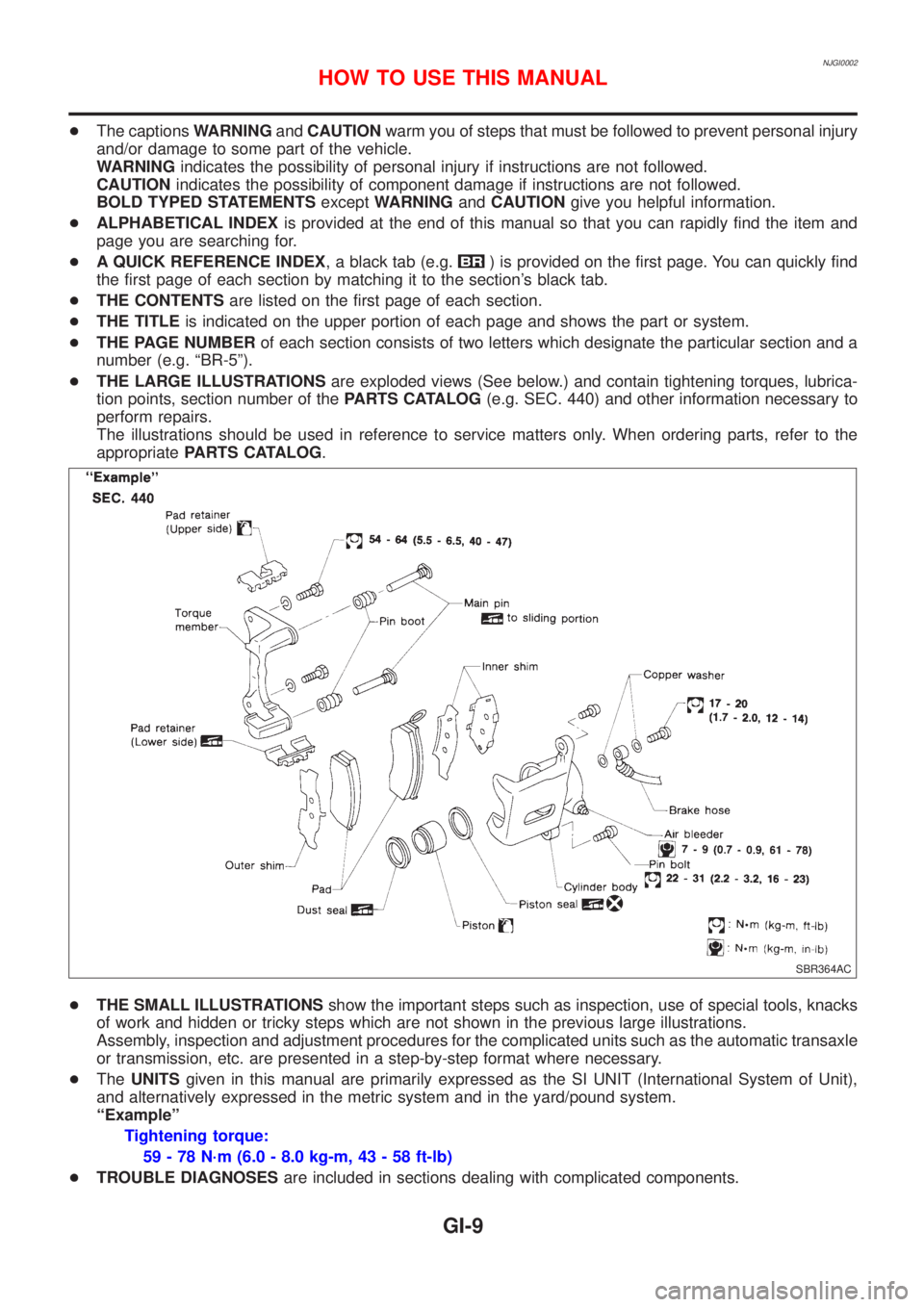

+The captionsWARNINGandCAUTIONwarm you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

+ALPHABETICAL INDEXis provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

+A QUICK REFERENCE INDEX, a black tab (e.g.

) is provided on the first page. You can quickly find

the first page of each section by matching it to the section's black tab.

+THE CONTENTSare listed on the first page of each section.

+THE TITLEis indicated on the upper portion of each page and shows the part or system.

+THE PAGE NUMBERof each section consists of two letters which designate the particular section and a

number (e.g. ªBR-5º).

+THE LARGE ILLUSTRATIONSare exploded views (See below.) and contain tightening torques, lubrica-

tion points, section number of thePARTS CATALOG(e.g. SEC. 440) and other information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriatePARTS CATALOG.

SBR364AC

+THE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

+TheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

ªExampleº

Tightening torque:

59 - 78 N´m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

+TROUBLE DIAGNOSESare included in sections dealing with complicated components.

HOW TO USE THIS MANUAL

GI-9

Page 2356 of 2898

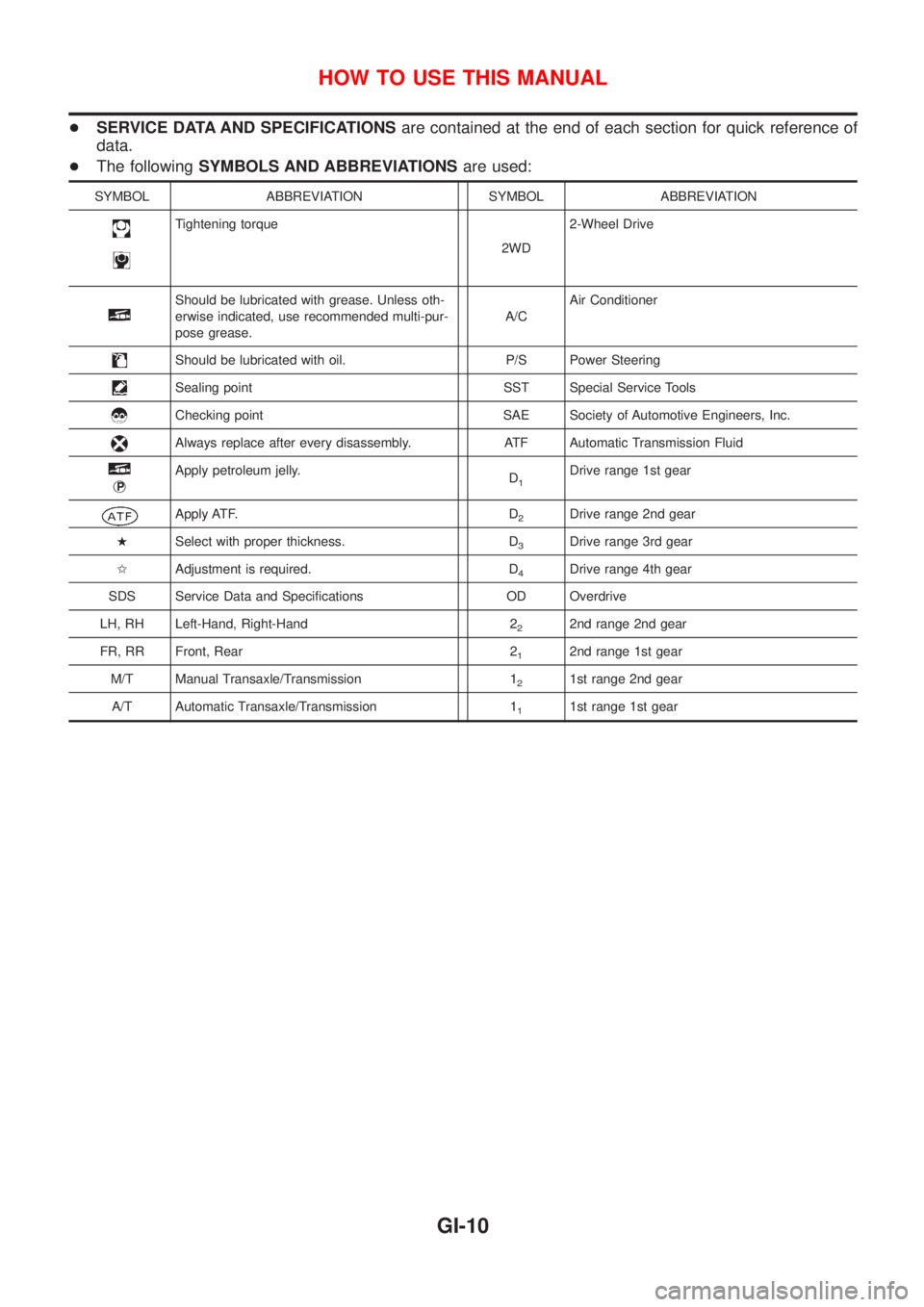

+SERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

+The followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

jP

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

HSelect with proper thickness. D

3Drive range 3rd gear

IAdjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

HOW TO USE THIS MANUAL

GI-10

Page 2395 of 2898

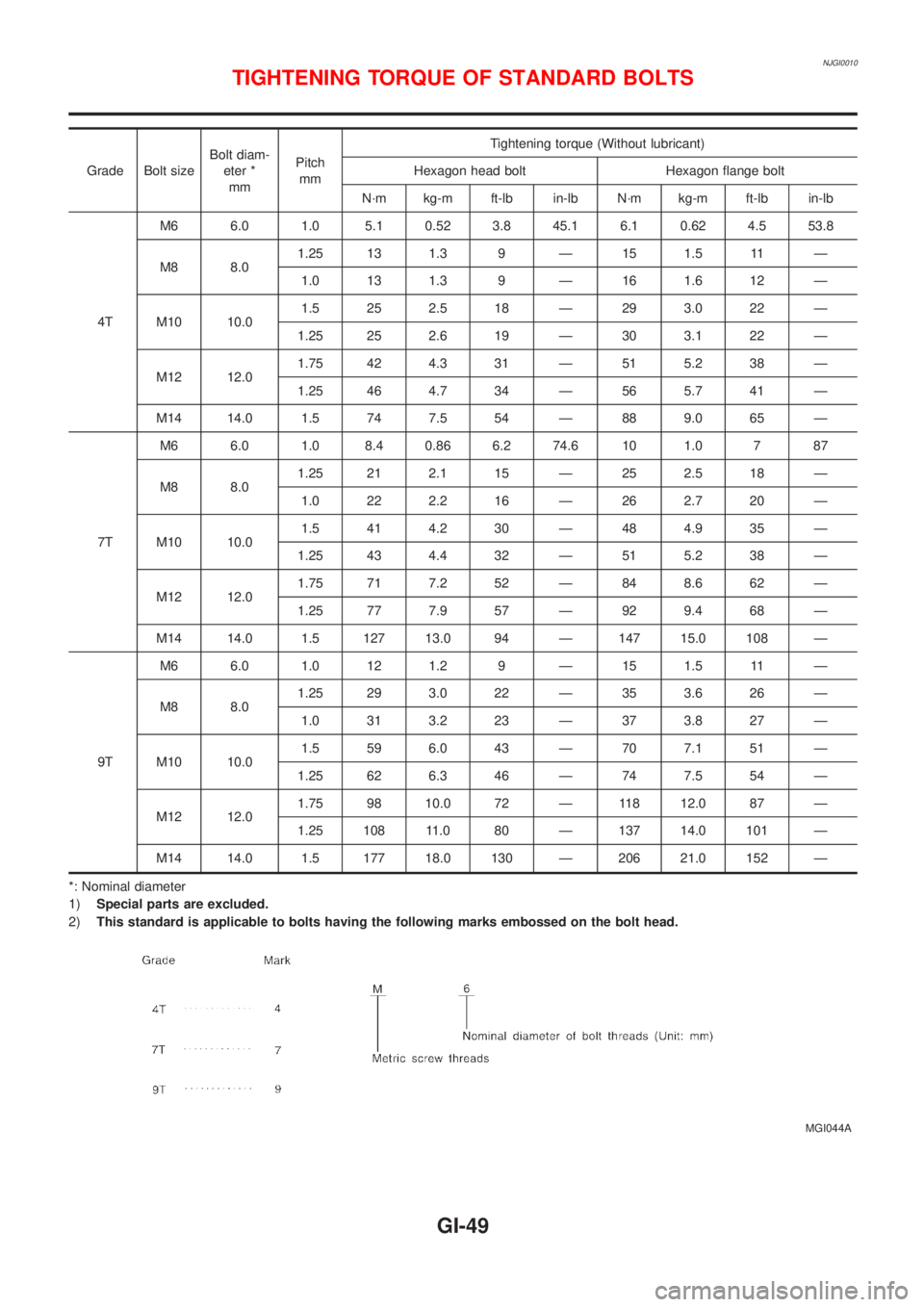

NJGI0010

Grade Bolt sizeBolt diam-

eter *

mmPitch

mmTightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N´m kg-m ft-lb in-lb N´m kg-m ft-lb in-lb

4TM6 6.0 1.0 5.1 0.52 3.8 45.1 6.1 0.62 4.5 53.8

M8 8.01.25 13 1.3 9 Ð 15 1.5 11 Ð

1.0 13 1.3 9 Ð 16 1.6 12 Ð

M10 10.01.5 25 2.5 18 Ð 29 3.0 22 Ð

1.25 25 2.6 19 Ð 30 3.1 22 Ð

M12 12.01.75 42 4.3 31 Ð 51 5.2 38 Ð

1.25 46 4.7 34 Ð 56 5.7 41 Ð

M14 14.0 1.5 74 7.5 54 Ð 88 9.0 65 Ð

7TM6 6.0 1.0 8.4 0.86 6.2 74.6 10 1.0 7 87

M8 8.01.25 21 2.1 15 Ð 25 2.5 18 Ð

1.0 22 2.2 16 Ð 26 2.7 20 Ð

M10 10.01.5 41 4.2 30 Ð 48 4.9 35 Ð

1.25 43 4.4 32 Ð 51 5.2 38 Ð

M12 12.01.75 71 7.2 52 Ð 84 8.6 62 Ð

1.25 77 7.9 57 Ð 92 9.4 68 Ð

M14 14.0 1.5 127 13.0 94 Ð 147 15.0 108 Ð

9TM6 6.0 1.0 12 1.2 9 Ð 15 1.5 11 Ð

M8 8.01.25 29 3.0 22 Ð 35 3.6 26 Ð

1.0 31 3.2 23 Ð 37 3.8 27 Ð

M10 10.01.5 59 6.0 43 Ð 70 7.1 51 Ð

1.25 62 6.3 46 Ð 74 7.5 54 Ð

M12 12.01.75 98 10.0 72 Ð 118 12.0 87 Ð

1.25 108 11.0 80 Ð 137 14.0 101 Ð

M14 14.0 1.5 177 18.0 130 Ð 206 21.0 152 Ð

*: Nominal diameter

1)Special parts are excluded.

2)This standard is applicable to bolts having the following marks embossed on the bolt head.

MGI044A

TIGHTENING TORQUE OF STANDARD BOLTS

GI-49

Page 2399 of 2898

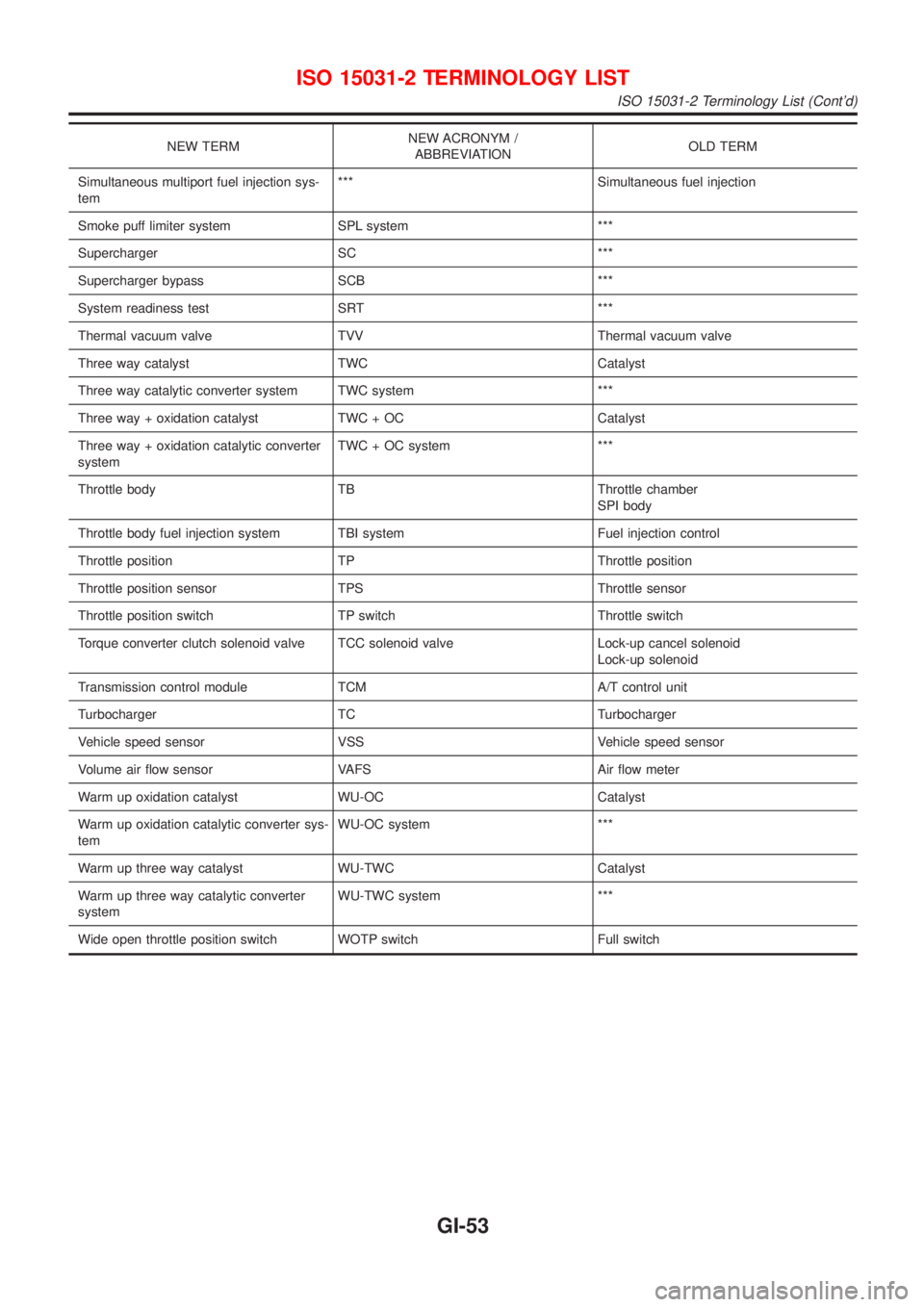

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancel solenoid

Lock-up solenoid

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

temWU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter

systemWU-TWC system ***

Wide open throttle position switch WOTP switch Full switch

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 Terminology List (Cont'd)

GI-53

Page 2404 of 2898

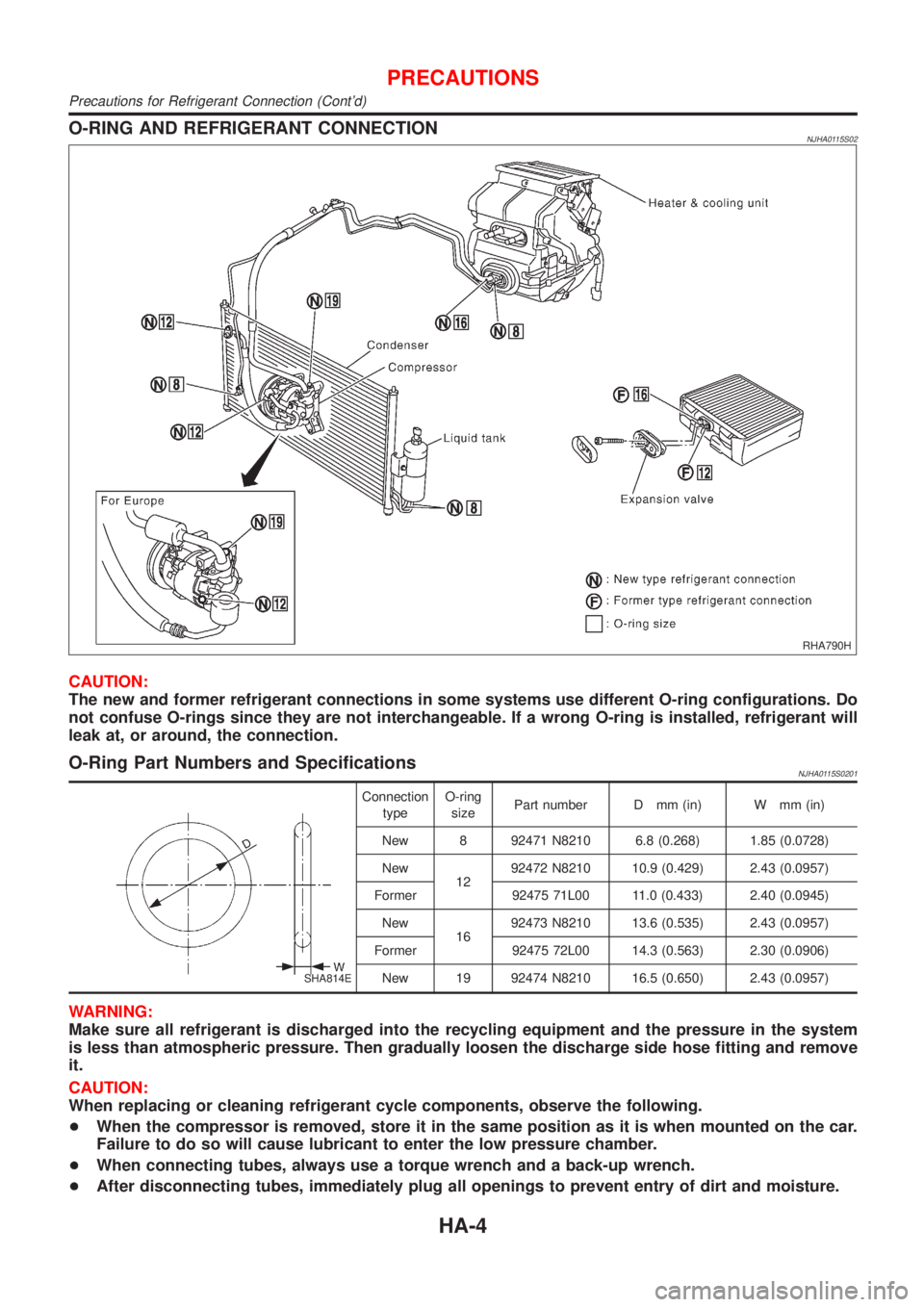

O-RING AND REFRIGERANT CONNECTIONNJHA0115S02

RHA790H

CAUTION:

The new and former refrigerant connections in some systems use different O-ring configurations. Do

not confuse O-rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will

leak at, or around, the connection.

O-Ring Part Numbers and SpecificationsNJHA0115S0201

SHA814E

Connection

typeO-ring

sizePart number D mm (in) W mm (in)

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

New

1292472 N8210 10.9 (0.429) 2.43 (0.0957)

Former 92475 71L00 11.0 (0.433) 2.40 (0.0945)

New

1692473 N8210 13.6 (0.535) 2.43 (0.0957)

Former 92475 72L00 14.3 (0.563) 2.30 (0.0906)

New 19 92474 N8210 16.5 (0.650) 2.43 (0.0957)

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system

is less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove

it.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

+When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

+When connecting tubes, always use a torque wrench and a back-up wrench.

+After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-4

Page 2405 of 2898

+When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

+Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

+Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

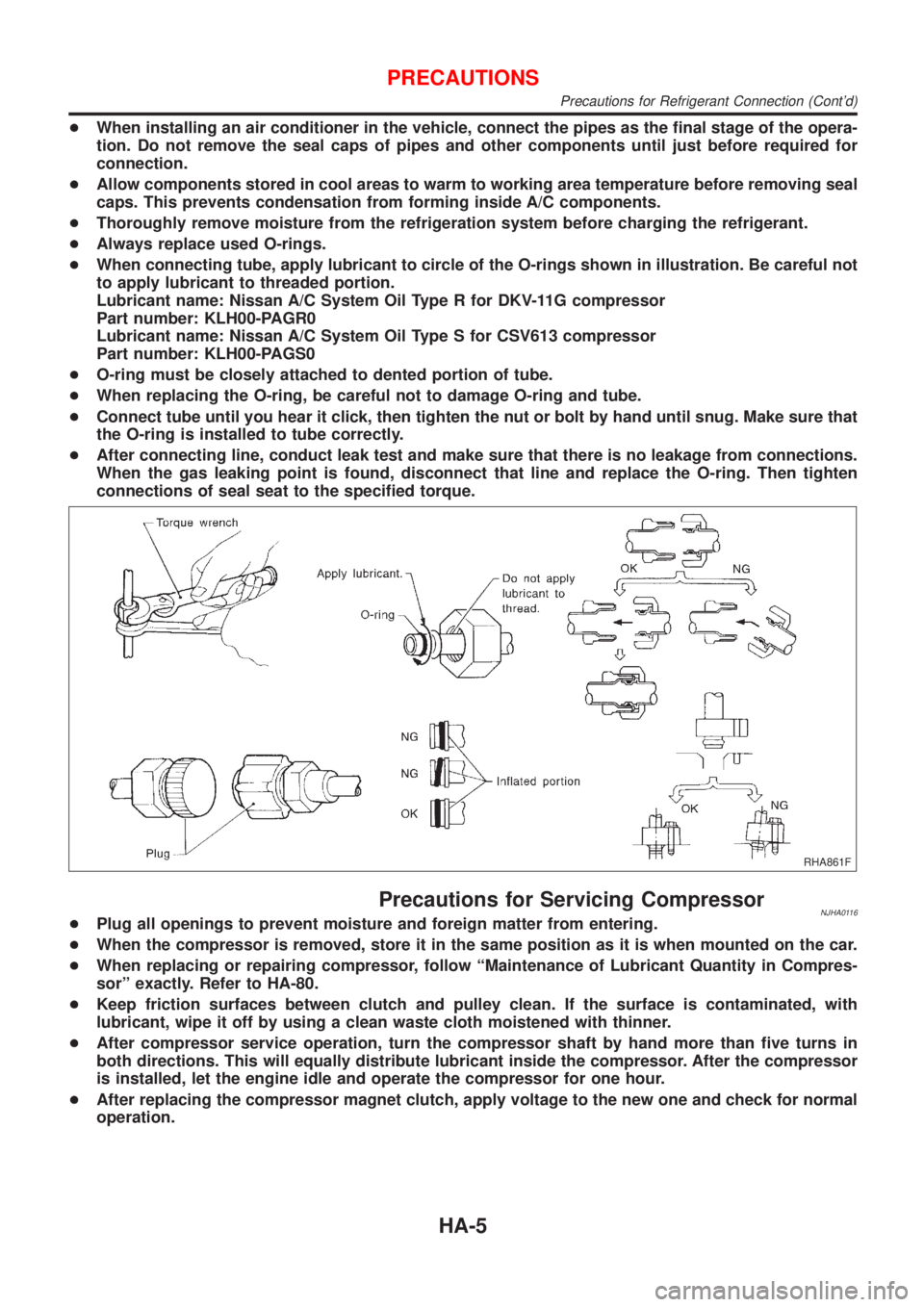

+Always replace used O-rings.

+When connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type R for DKV-11G compressor

Part number: KLH00-PAGR0

Lubricant name: Nissan A/C System Oil Type S for CSV613 compressor

Part number: KLH00-PAGS0

+O-ring must be closely attached to dented portion of tube.

+When replacing the O-ring, be careful not to damage O-ring and tube.

+Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

+After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNJHA0116+Plug all openings to prevent moisture and foreign matter from entering.

+When the compressor is removed, store it in the same position as it is when mounted on the car.

+When replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-80.

+Keep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

+After compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

+After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-5