torque NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2487 of 2898

RHA143E

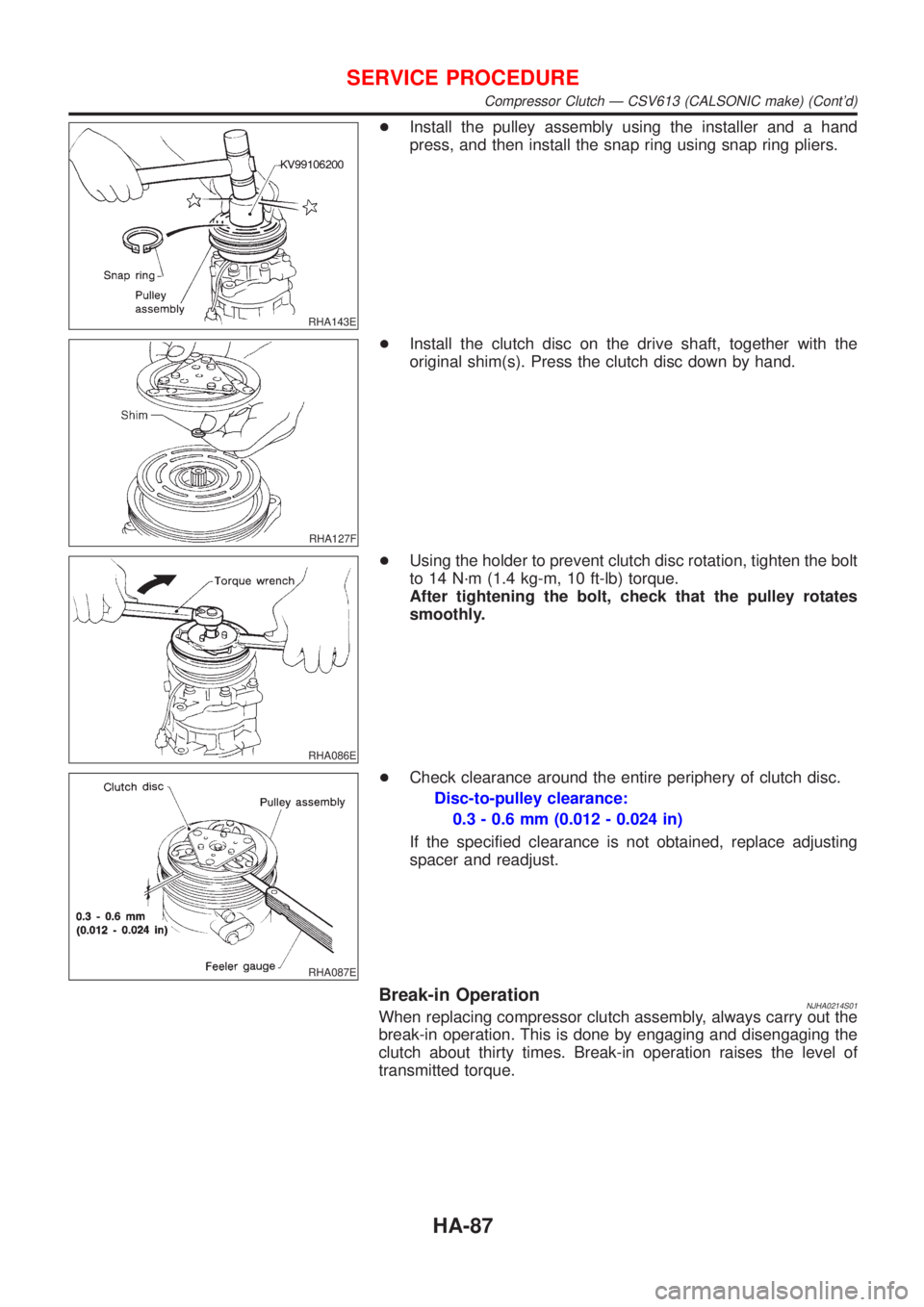

+Install the pulley assembly using the installer and a hand

press, and then install the snap ring using snap ring pliers.

RHA127F

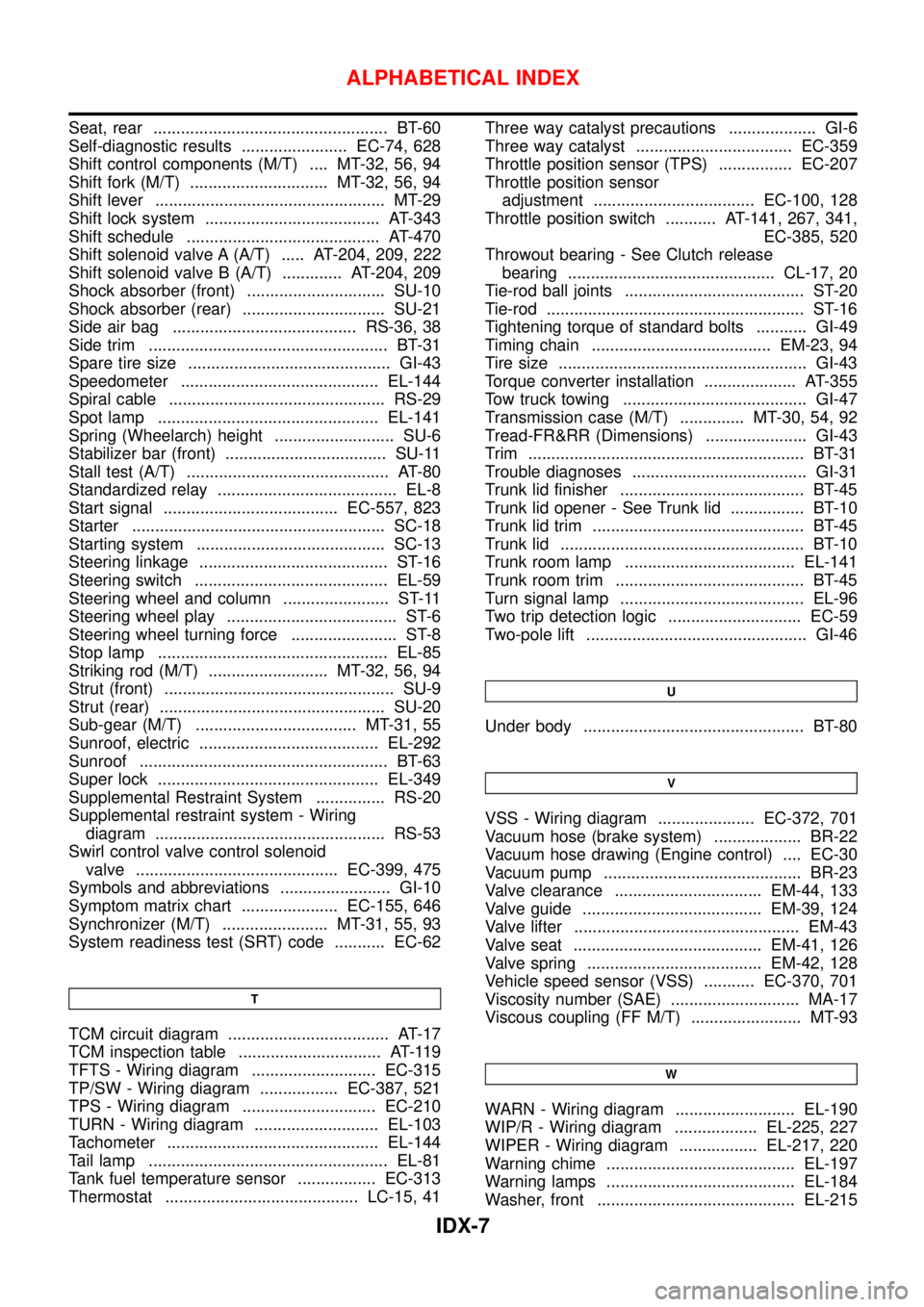

+Install the clutch disc on the drive shaft, together with the

original shim(s). Press the clutch disc down by hand.

RHA086E

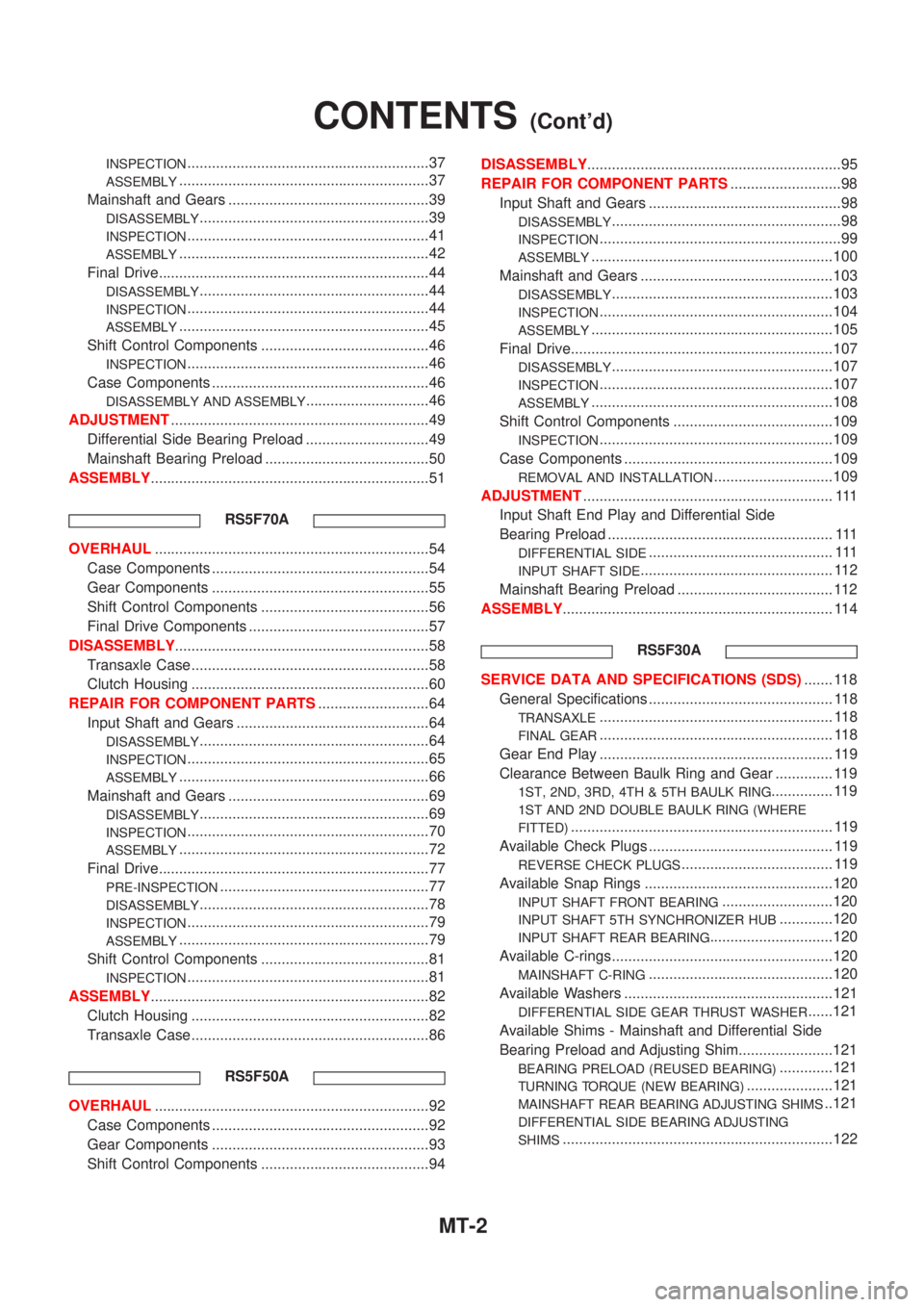

+Using the holder to prevent clutch disc rotation, tighten the bolt

to 14 N´m (1.4 kg-m, 10 ft-lb) torque.

After tightening the bolt, check that the pulley rotates

smoothly.

RHA087E

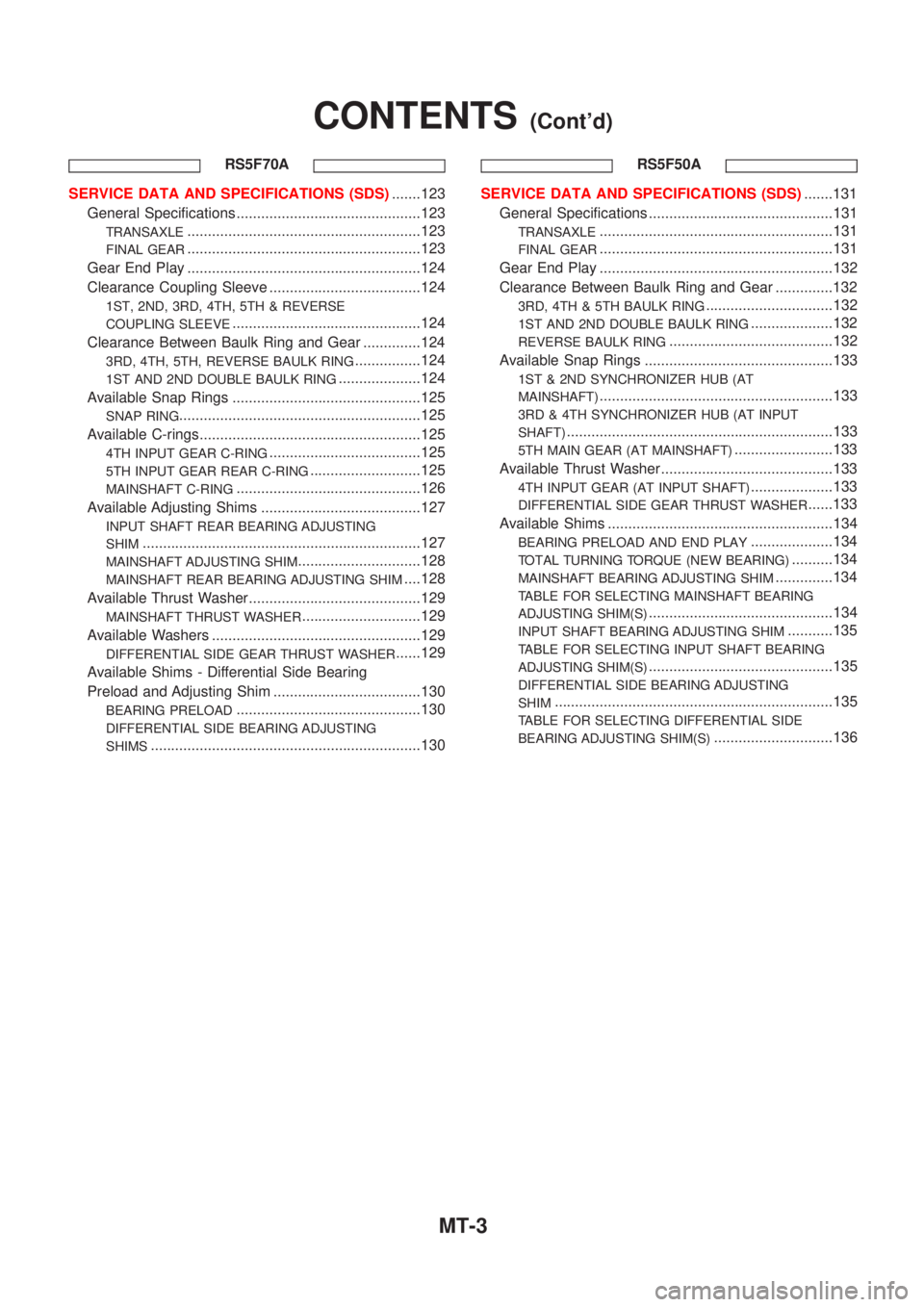

+Check clearance around the entire periphery of clutch disc.

Disc-to-pulley clearance:

0.3 - 0.6 mm (0.012 - 0.024 in)

If the specified clearance is not obtained, replace adjusting

spacer and readjust.

Break-in OperationNJHA0214S01When replacing compressor clutch assembly, always carry out the

break-in operation. This is done by engaging and disengaging the

clutch about thirty times. Break-in operation raises the level of

transmitted torque.

SERVICE PROCEDURE

Compressor Clutch Ð CSV613 (CALSONIC make) (Cont'd)

HA-87

Page 2505 of 2898

Seat, rear ................................................... BT-60

Self-diagnostic results ....................... EC-74, 628

Shift control components (M/T) .... MT-32, 56, 94

Shift fork (M/T) .............................. MT-32, 56, 94

Shift lever .................................................. MT-29

Shift lock system ...................................... AT-343

Shift schedule .......................................... AT-470

Shift solenoid valve A (A/T) ..... AT-204, 209, 222

Shift solenoid valve B (A/T) ............. AT-204, 209

Shock absorber (front) .............................. SU-10

Shock absorber (rear) ............................... SU-21

Side air bag ........................................ RS-36, 38

Side trim .................................................... BT-31

Spare tire size ............................................ GI-43

Speedometer ........................................... EL-144

Spiral cable ............................................... RS-29

Spot lamp ................................................ EL-141

Spring (Wheelarch) height .......................... SU-6

Stabilizer bar (front) ................................... SU-11

Stall test (A/T) ............................................ AT-80

Standardized relay ....................................... EL-8

Start signal ...................................... EC-557, 823

Starter ....................................................... SC-18

Starting system ......................................... SC-13

Steering linkage ......................................... ST-16

Steering switch .......................................... EL-59

Steering wheel and column ....................... ST-11

Steering wheel play ..................................... ST-6

Steering wheel turning force ....................... ST-8

Stop lamp .................................................. EL-85

Striking rod (M/T) .......................... MT-32, 56, 94

Strut (front) .................................................. SU-9

Strut (rear) ................................................. SU-20

Sub-gear (M/T) ................................... MT-31, 55

Sunroof, electric ....................................... EL-292

Sunroof ...................................................... BT-63

Super lock ................................................ EL-349

Supplemental Restraint System ............... RS-20

Supplemental restraint system - Wiring

diagram .................................................. RS-53

Swirl control valve control solenoid

valve ............................................ EC-399, 475

Symbols and abbreviations ........................ GI-10

Symptom matrix chart ..................... EC-155, 646

Synchronizer (M/T) ....................... MT-31, 55, 93

System readiness test (SRT) code ........... EC-62

T

TCM circuit diagram ................................... AT-17

TCM inspection table ............................... AT-119

TFTS - Wiring diagram ........................... EC-315

TP/SW - Wiring diagram ................. EC-387, 521

TPS - Wiring diagram ............................. EC-210

TURN - Wiring diagram ........................... EL-103

Tachometer .............................................. EL-144

Tail lamp .................................................... EL-81

Tank fuel temperature sensor ................. EC-313

Thermostat .......................................... LC-15, 41Three way catalyst precautions ................... GI-6

Three way catalyst .................................. EC-359

Throttle position sensor (TPS) ................ EC-207

Throttle position sensor

adjustment ................................... EC-100, 128

Throttle position switch ........... AT-141, 267, 341,

EC-385, 520

Throwout bearing - See Clutch release

bearing ............................................. CL-17, 20

Tie-rod ball joints ....................................... ST-20

Tie-rod ........................................................ ST-16

Tightening torque of standard bolts ........... GI-49

Timing chain ....................................... EM-23, 94

Tire size ...................................................... GI-43

Torque converter installation .................... AT-355

Tow truck towing ........................................ GI-47

Transmission case (M/T) .............. MT-30, 54, 92

Tread-FR&RR (Dimensions) ...................... GI-43

Trim ............................................................ BT-31

Trouble diagnoses ...................................... GI-31

Trunk lid finisher ........................................ BT-45

Trunk lid opener - See Trunk lid ................ BT-10

Trunk lid trim .............................................. BT-45

Trunk lid ..................................................... BT-10

Trunk room lamp ..................................... EL-141

Trunk room trim ......................................... BT-45

Turn signal lamp ........................................ EL-96

Two trip detection logic ............................. EC-59

Two-pole lift ................................................ GI-46

U

Under body ................................................ BT-80

V

VSS - Wiring diagram ..................... EC-372, 701

Vacuum hose (brake system) ................... BR-22

Vacuum hose drawing (Engine control) .... EC-30

Vacuum pump ........................................... BR-23

Valve clearance ................................ EM-44, 133

Valve guide ....................................... EM-39, 124

Valve lifter ................................................. EM-43

Valve seat ......................................... EM-41, 126

Valve spring ...................................... EM-42, 128

Vehicle speed sensor (VSS) ........... EC-370, 701

Viscosity number (SAE) ............................ MA-17

Viscous coupling (FF M/T) ........................ MT-93

W

WARN - Wiring diagram .......................... EL-190

WIP/R - Wiring diagram .................. EL-225, 227

WIPER - Wiring diagram ................. EL-217, 220

Warning chime ......................................... EL-197

Warning lamps ......................................... EL-184

Washer, front ........................................... EL-215

ALPHABETICAL INDEX

IDX-7

Page 2574 of 2898

INSPECTION...........................................................37

ASSEMBLY.............................................................37

Mainshaft and Gears .................................................39

DISASSEMBLY........................................................39

INSPECTION...........................................................41

ASSEMBLY.............................................................42

Final Drive..................................................................44

DISASSEMBLY........................................................44

INSPECTION...........................................................44

ASSEMBLY.............................................................45

Shift Control Components .........................................46

INSPECTION...........................................................46

Case Components .....................................................46

DISASSEMBLY AND ASSEMBLY..............................46

ADJUSTMENT...............................................................49

Differential Side Bearing Preload ..............................49

Mainshaft Bearing Preload ........................................50

ASSEMBLY....................................................................51

RS5F70A

OVERHAUL...................................................................54

Case Components .....................................................54

Gear Components .....................................................55

Shift Control Components .........................................56

Final Drive Components ............................................57

DISASSEMBLY..............................................................58

Transaxle Case ..........................................................58

Clutch Housing ..........................................................60

REPAIR FOR COMPONENT PARTS...........................64

Input Shaft and Gears ...............................................64

DISASSEMBLY........................................................64

INSPECTION...........................................................65

ASSEMBLY.............................................................66

Mainshaft and Gears .................................................69

DISASSEMBLY........................................................69

INSPECTION...........................................................70

ASSEMBLY.............................................................72

Final Drive..................................................................77

PRE-INSPECTION...................................................77

DISASSEMBLY........................................................78

INSPECTION...........................................................79

ASSEMBLY.............................................................79

Shift Control Components .........................................81

INSPECTION...........................................................81

ASSEMBLY....................................................................82

Clutch Housing ..........................................................82

Transaxle Case ..........................................................86

RS5F50A

OVERHAUL...................................................................92

Case Components .....................................................92

Gear Components .....................................................93

Shift Control Components .........................................94DISASSEMBLY..............................................................95

REPAIR FOR COMPONENT PARTS...........................98

Input Shaft and Gears ...............................................98

DISASSEMBLY........................................................98

INSPECTION...........................................................99

ASSEMBLY...........................................................100

Mainshaft and Gears ...............................................103

DISASSEMBLY......................................................103

INSPECTION.........................................................104

ASSEMBLY...........................................................105

Final Drive................................................................107

DISASSEMBLY......................................................107

INSPECTION.........................................................107

ASSEMBLY...........................................................108

Shift Control Components .......................................109

INSPECTION.........................................................109

Case Components ...................................................109

REMOVAL AND INSTALLATION.............................109

ADJUSTMENT............................................................. 111

Input Shaft End Play and Differential Side

Bearing Preload ....................................................... 111

DIFFERENTIAL SIDE............................................. 111

INPUT SHAFT SIDE............................................... 112

Mainshaft Bearing Preload ...................................... 112

ASSEMBLY.................................................................. 114

RS5F30A

SERVICE DATA AND SPECIFICATIONS (SDS)....... 118

General Specifications ............................................. 118

TRANSAXLE......................................................... 118

FINAL GEAR......................................................... 118

Gear End Play ......................................................... 119

Clearance Between Baulk Ring and Gear .............. 119

1ST, 2ND, 3RD, 4TH & 5TH BAULK RING............... 119

1ST AND 2ND DOUBLE BAULK RING (WHERE

FITTED)

................................................................ 119

Available Check Plugs ............................................. 119

REVERSE CHECK PLUGS..................................... 119

Available Snap Rings ..............................................120

INPUT SHAFT FRONT BEARING...........................120

INPUT SHAFT 5TH SYNCHRONIZER HUB.............120

INPUT SHAFT REAR BEARING..............................120

Available C-rings......................................................120

MAINSHAFT C-RING.............................................120

Available Washers ...................................................121

DIFFERENTIAL SIDE GEAR THRUST WASHER......121

Available Shims - Mainshaft and Differential Side

Bearing Preload and Adjusting Shim.......................121

BEARING PRELOAD (REUSED BEARING).............121

TURNING TORQUE (NEW BEARING).....................121

MAINSHAFT REAR BEARING ADJUSTING SHIMS..121

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIMS

..................................................................122

CONTENTS(Cont'd)

MT-2

Page 2575 of 2898

RS5F70A

SERVICE DATA AND SPECIFICATIONS (SDS).......123

General Specifications .............................................123

TRANSAXLE.........................................................123

FINAL GEAR.........................................................123

Gear End Play .........................................................124

Clearance Coupling Sleeve .....................................124

1ST, 2ND, 3RD, 4TH, 5TH & REVERSE

COUPLING SLEEVE

..............................................124

Clearance Between Baulk Ring and Gear ..............124

3RD, 4TH, 5TH, REVERSE BAULK RING................124

1ST AND 2ND DOUBLE BAULK RING....................124

Available Snap Rings ..............................................125

SNAP RING...........................................................125

Available C-rings......................................................125

4TH INPUT GEAR C-RING.....................................125

5TH INPUT GEAR REAR C-RING...........................125

MAINSHAFT C-RING.............................................126

Available Adjusting Shims .......................................127

INPUT SHAFT REAR BEARING ADJUSTING

SHIM

....................................................................127

MAINSHAFT ADJUSTING SHIM..............................128

MAINSHAFT REAR BEARING ADJUSTING SHIM....128

Available Thrust Washer..........................................129

MAINSHAFT THRUST WASHER.............................129

Available Washers ...................................................129

DIFFERENTIAL SIDE GEAR THRUST WASHER......129

Available Shims - Differential Side Bearing

Preload and Adjusting Shim ....................................130

BEARING PRELOAD.............................................130

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIMS

..................................................................130RS5F50A

SERVICE DATA AND SPECIFICATIONS (SDS).......131

General Specifications .............................................131

TRANSAXLE.........................................................131

FINAL GEAR.........................................................131

Gear End Play .........................................................132

Clearance Between Baulk Ring and Gear ..............132

3RD, 4TH & 5TH BAULK RING...............................132

1ST AND 2ND DOUBLE BAULK RING....................132

REVERSE BAULK RING........................................132

Available Snap Rings ..............................................133

1ST & 2ND SYNCHRONIZER HUB (AT

MAINSHAFT)

.........................................................133

3RD & 4TH SYNCHRONIZER HUB (AT INPUT

SHAFT)

.................................................................133

5TH MAIN GEAR (AT MAINSHAFT)........................133

Available Thrust Washer..........................................133

4TH INPUT GEAR (AT INPUT SHAFT)....................133

DIFFERENTIAL SIDE GEAR THRUST WASHER......133

Available Shims .......................................................134

BEARING PRELOAD AND END PLAY....................134

TOTAL TURNING TORQUE (NEW BEARING)..........134

MAINSHAFT BEARING ADJUSTING SHIM..............134

TABLE FOR SELECTING MAINSHAFT BEARING

ADJUSTING SHIM(S)

.............................................134

INPUT SHAFT BEARING ADJUSTING SHIM...........135

TABLE FOR SELECTING INPUT SHAFT BEARING

ADJUSTING SHIM(S)

.............................................135

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIM

....................................................................135

TABLE FOR SELECTING DIFFERENTIAL SIDE

BEARING ADJUSTING SHIM(S)

.............................136

CONTENTS(Cont'd)

MT-3

Page 2576 of 2898

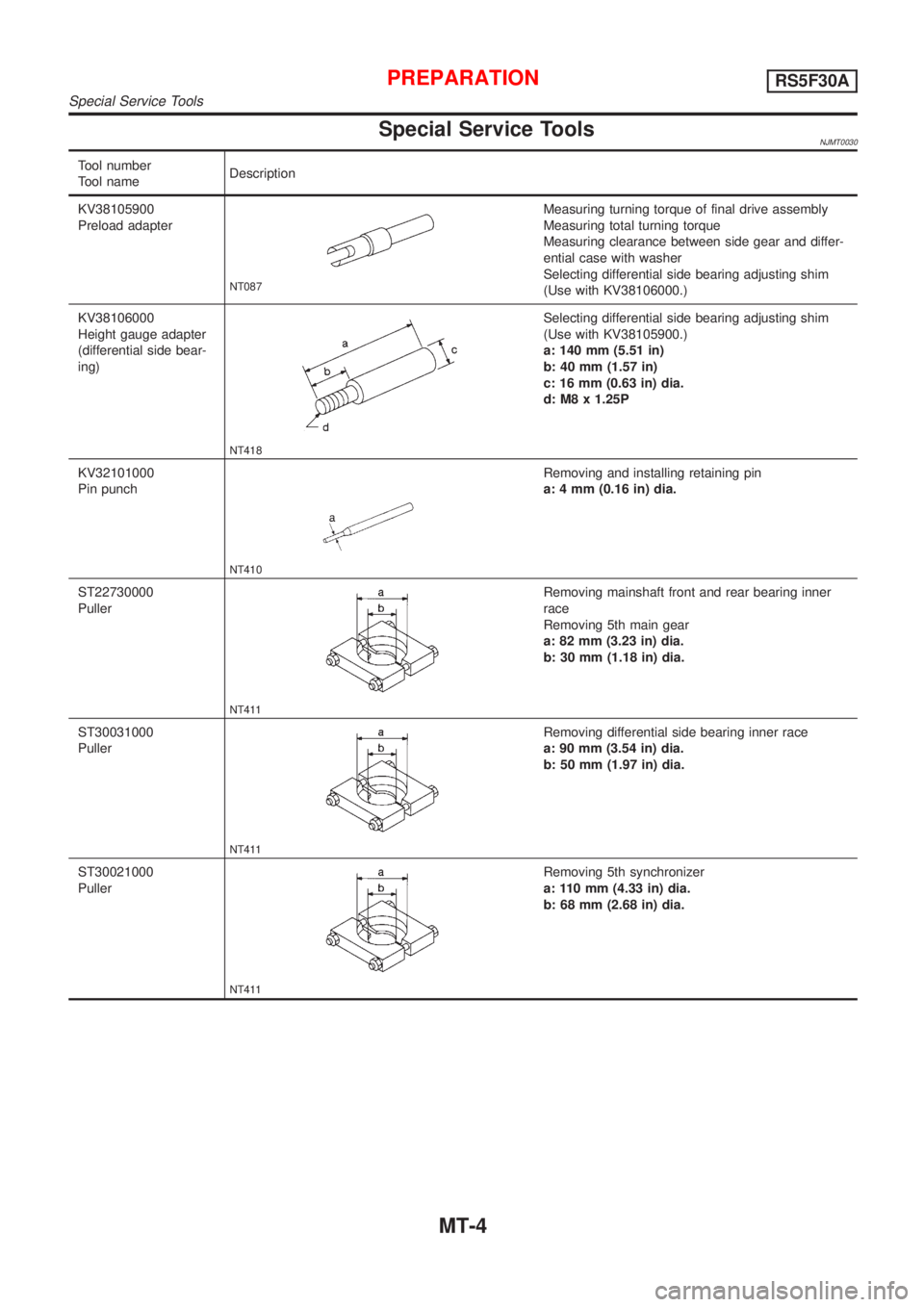

Special Service ToolsNJMT0030

Tool number

Tool nameDescription

KV38105900

Preload adapter

NT087

Measuring turning torque of final drive assembly

Measuring total turning torque

Measuring clearance between side gear and differ-

ential case with washer

Selecting differential side bearing adjusting shim

(Use with KV38106000.)

KV38106000

Height gauge adapter

(differential side bear-

ing)

NT418

Selecting differential side bearing adjusting shim

(Use with KV38105900.)

a: 140 mm (5.51 in)

b: 40 mm (1.57 in)

c: 16 mm (0.63 in) dia.

d: M8 x 1.25P

KV32101000

Pin punch

NT410

Removing and installing retaining pin

a: 4 mm (0.16 in) dia.

ST22730000

Puller

NT411

Removing mainshaft front and rear bearing inner

race

Removing 5th main gear

a: 82 mm (3.23 in) dia.

b: 30 mm (1.18 in) dia.

ST30031000

Puller

NT411

Removing differential side bearing inner race

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST30021000

Puller

NT411

Removing 5th synchronizer

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

PREPARATIONRS5F30A

Special Service Tools

MT-4

Page 2579 of 2898

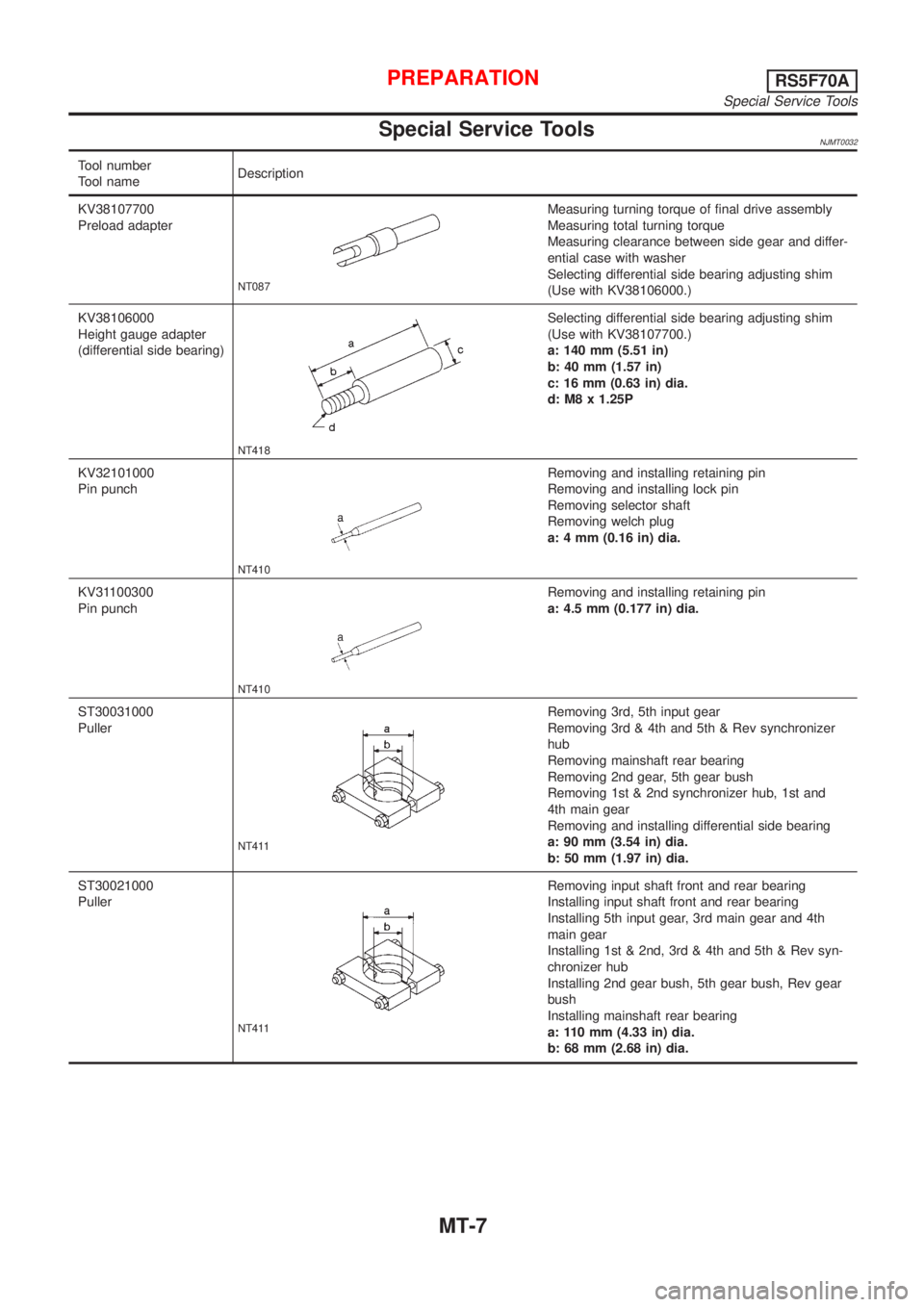

Special Service ToolsNJMT0032

Tool number

Tool nameDescription

KV38107700

Preload adapter

NT087

Measuring turning torque of final drive assembly

Measuring total turning torque

Measuring clearance between side gear and differ-

ential case with washer

Selecting differential side bearing adjusting shim

(Use with KV38106000.)

KV38106000

Height gauge adapter

(differential side bearing)

NT418

Selecting differential side bearing adjusting shim

(Use with KV38107700.)

a: 140 mm (5.51 in)

b: 40 mm (1.57 in)

c: 16 mm (0.63 in) dia.

d: M8 x 1.25P

KV32101000

Pin punch

NT410

Removing and installing retaining pin

Removing and installing lock pin

Removing selector shaft

Removing welch plug

a: 4 mm (0.16 in) dia.

KV31100300

Pin punch

NT410

Removing and installing retaining pin

a: 4.5 mm (0.177 in) dia.

ST30031000

Puller

NT411

Removing 3rd, 5th input gear

Removing 3rd & 4th and 5th & Rev synchronizer

hub

Removing mainshaft rear bearing

Removing 2nd gear, 5th gear bush

Removing 1st & 2nd synchronizer hub, 1st and

4th main gear

Removing and installing differential side bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST30021000

Puller

NT411

Removing input shaft front and rear bearing

Installing input shaft front and rear bearing

Installing 5th input gear, 3rd main gear and 4th

main gear

Installing 1st & 2nd, 3rd & 4th and 5th & Rev syn-

chronizer hub

Installing 2nd gear bush, 5th gear bush, Rev gear

bush

Installing mainshaft rear bearing

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

PREPARATIONRS5F70A

Special Service Tools

MT-7

Page 2582 of 2898

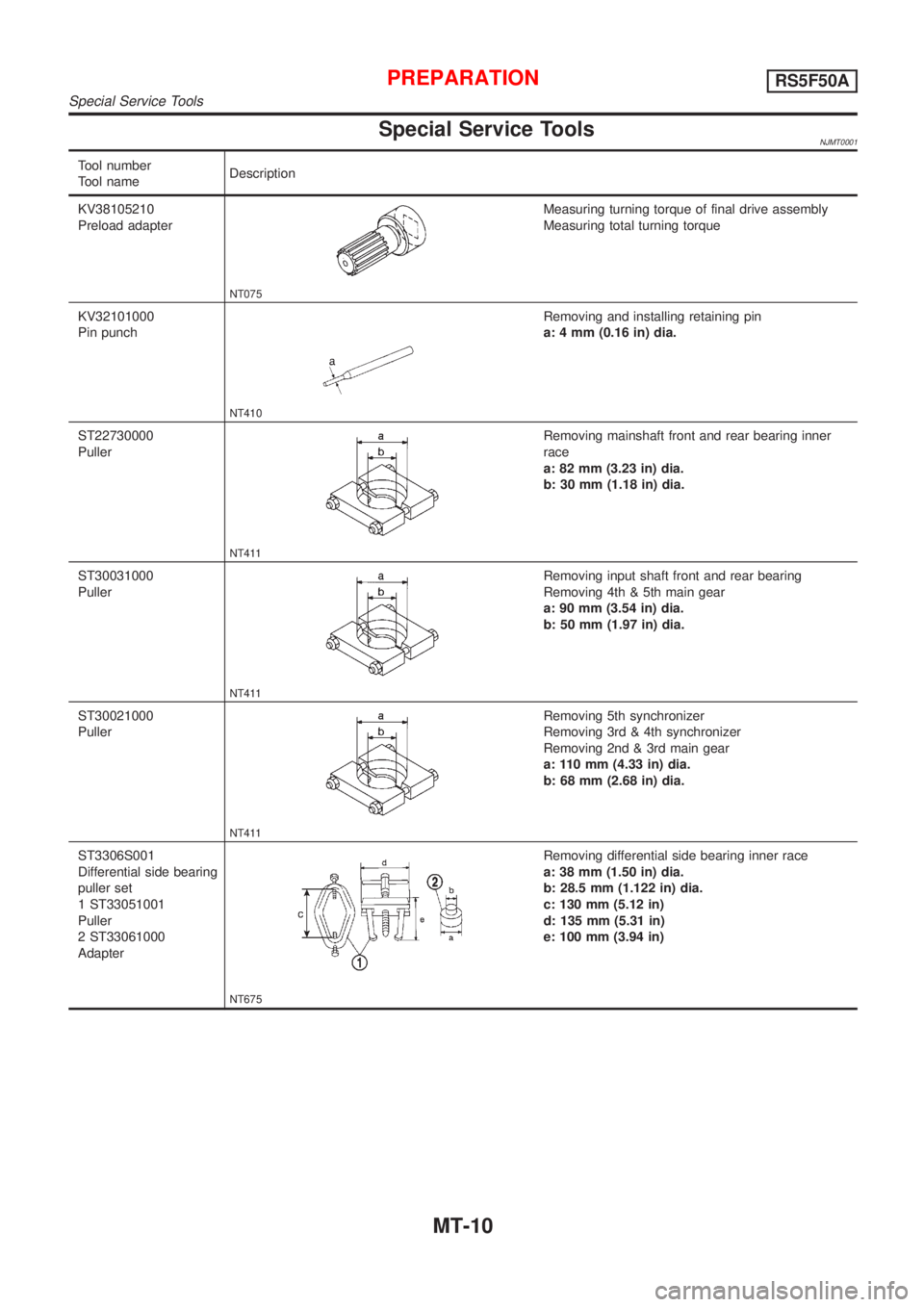

Special Service ToolsNJMT0001

Tool number

Tool nameDescription

KV38105210

Preload adapter

NT075

Measuring turning torque of final drive assembly

Measuring total turning torque

KV32101000

Pin punch

NT410

Removing and installing retaining pin

a: 4 mm (0.16 in) dia.

ST22730000

Puller

NT411

Removing mainshaft front and rear bearing inner

race

a: 82 mm (3.23 in) dia.

b: 30 mm (1.18 in) dia.

ST30031000

Puller

NT411

Removing input shaft front and rear bearing

Removing 4th & 5th main gear

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST30021000

Puller

NT411

Removing 5th synchronizer

Removing 3rd & 4th synchronizer

Removing 2nd & 3rd main gear

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

ST3306S001

Differential side bearing

puller set

1 ST33051001

Puller

2 ST33061000

Adapter

NT675

Removing differential side bearing inner race

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 100 mm (3.94 in)

PREPARATIONRS5F50A

Special Service Tools

MT-10

Page 2583 of 2898

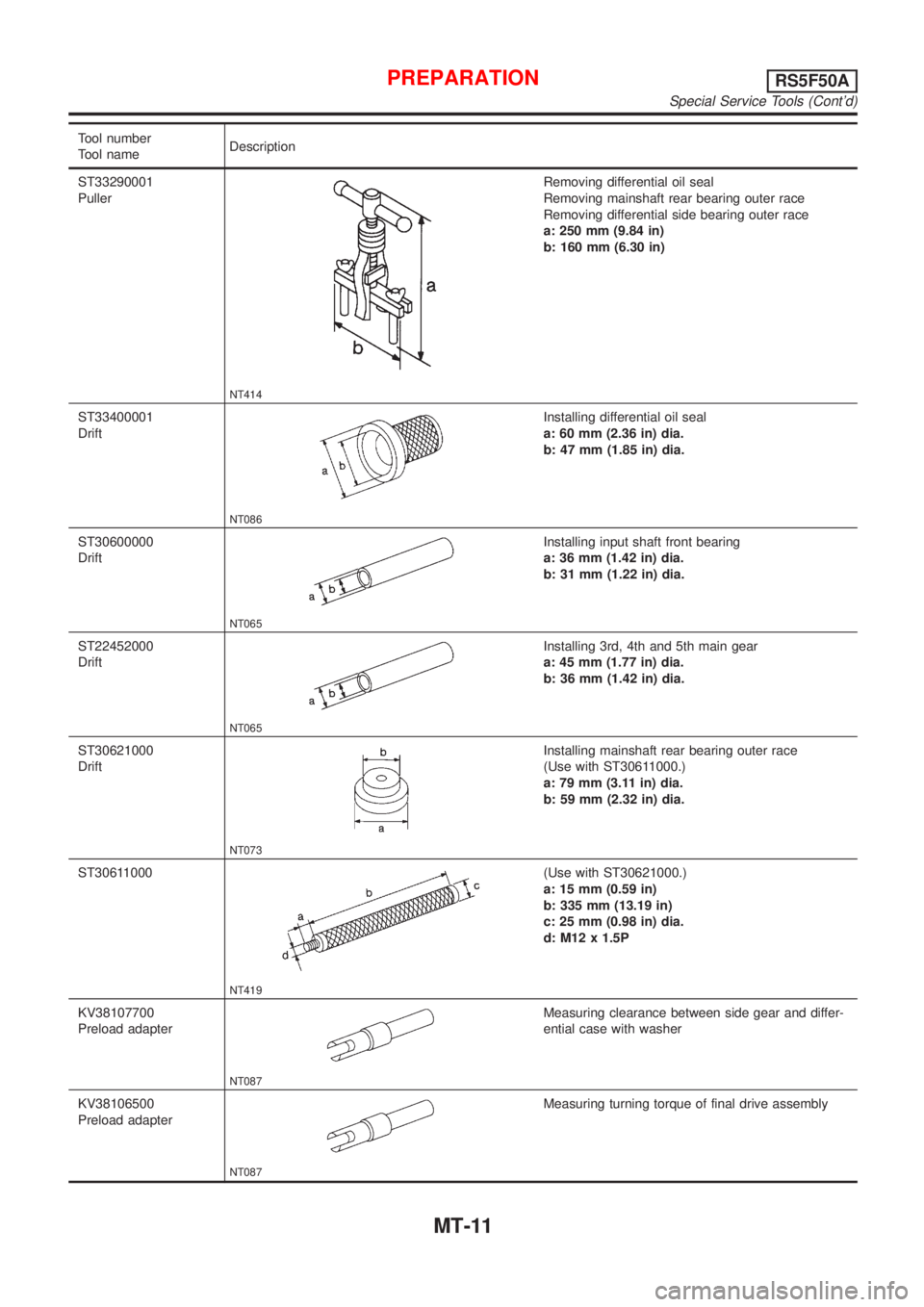

Tool number

Tool nameDescription

ST33290001

Puller

NT414

Removing differential oil seal

Removing mainshaft rear bearing outer race

Removing differential side bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

ST33400001

Drift

NT086

Installing differential oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

ST30600000

Drift

NT065

Installing input shaft front bearing

a: 36 mm (1.42 in) dia.

b: 31 mm (1.22 in) dia.

ST22452000

Drift

NT065

Installing 3rd, 4th and 5th main gear

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

ST30621000

Drift

NT073

Installing mainshaft rear bearing outer race

(Use with ST30611000.)

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

ST30611000

NT419

(Use with ST30621000.)

a: 15 mm (0.59 in)

b: 335 mm (13.19 in)

c: 25 mm (0.98 in) dia.

d: M12 x 1.5P

KV38107700

Preload adapter

NT087

Measuring clearance between side gear and differ-

ential case with washer

KV38106500

Preload adapter

NT087

Measuring turning torque of final drive assembly

PREPARATIONRS5F50A

Special Service Tools (Cont'd)

MT-11

Page 2596 of 2898

SMT652C

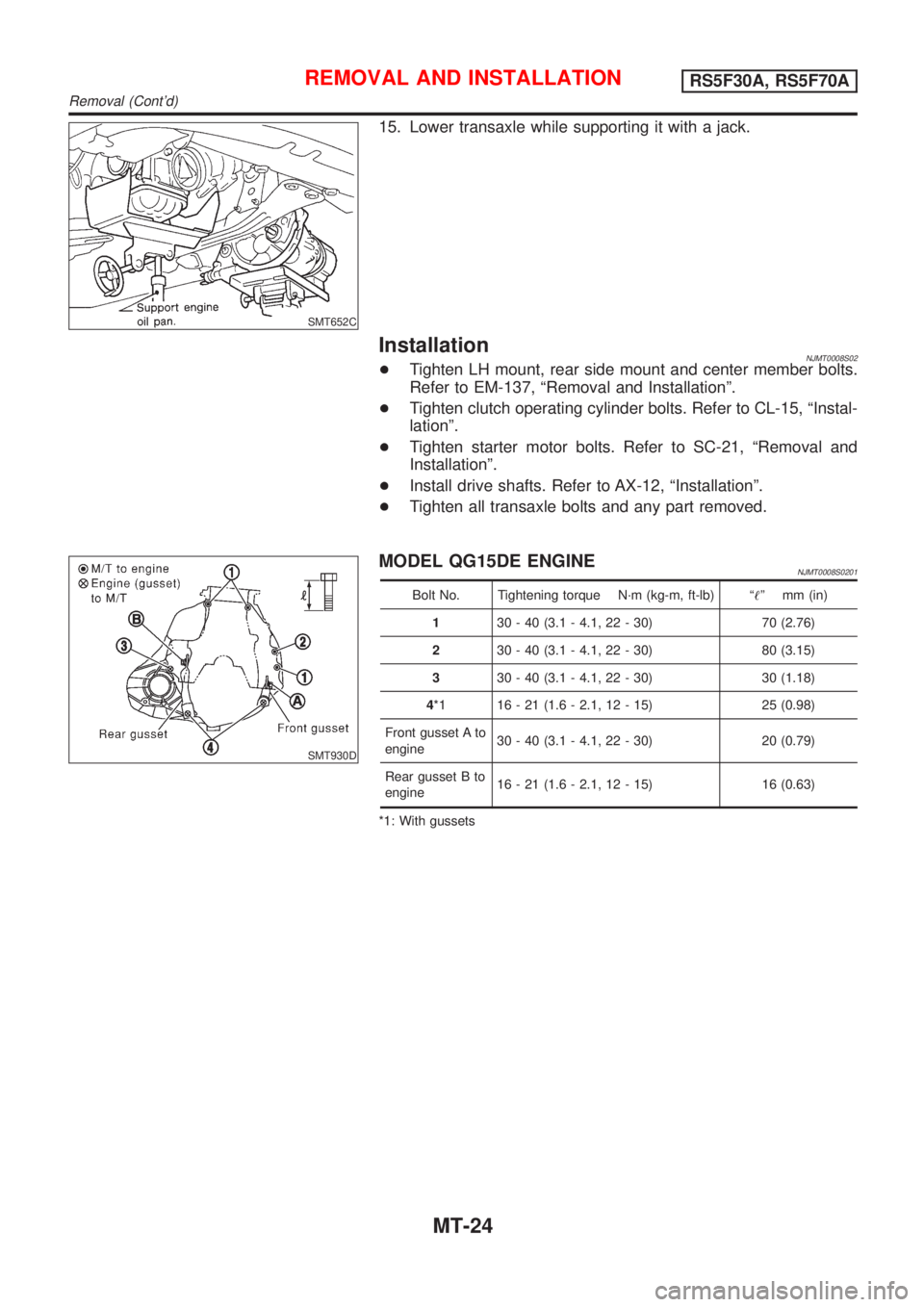

15. Lower transaxle while supporting it with a jack.

InstallationNJMT0008S02+Tighten LH mount, rear side mount and center member bolts.

Refer to EM-137, ªRemoval and Installationº.

+Tighten clutch operating cylinder bolts. Refer to CL-15, ªInstal-

lationº.

+Tighten starter motor bolts. Refer to SC-21, ªRemoval and

Installationº.

+Install drive shafts. Refer to AX-12, ªInstallationº.

+Tighten all transaxle bolts and any part removed.

SMT930D

MODEL QG15DE ENGINENJMT0008S0201

Bolt No. Tightening torque N´m (kg-m, ft-lb) ª!º mm (in)

130 - 40 (3.1 - 4.1, 22 - 30) 70 (2.76)

230 - 40 (3.1 - 4.1, 22 - 30) 80 (3.15)

330 - 40 (3.1 - 4.1, 22 - 30) 30 (1.18)

4*1 16 - 21 (1.6 - 2.1, 12 - 15) 25 (0.98)

Front gusset A to

engine30 - 40 (3.1 - 4.1, 22 - 30) 20 (0.79)

Rear gusset B to

engine16 - 21 (1.6 - 2.1, 12 - 15) 16 (0.63)

*1: With gussets

REMOVAL AND INSTALLATIONRS5F30A, RS5F70A

Removal (Cont'd)

MT-24

Page 2597 of 2898

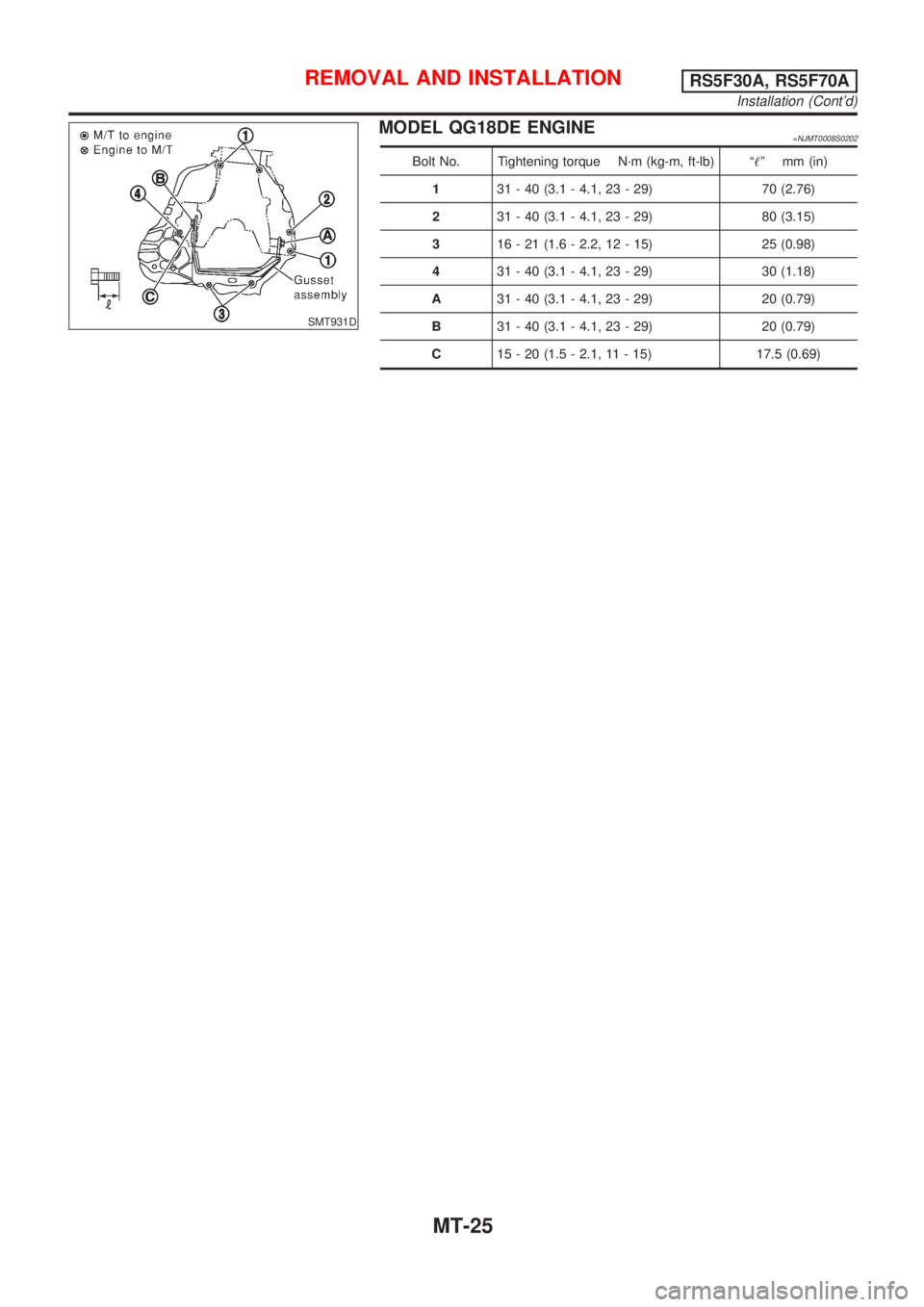

SMT931D

MODEL QG18DE ENGINE=NJMT0008S0202

Bolt No. Tightening torque N´m (kg-m, ft-lb) ª!º mm (in)

131 - 40 (3.1 - 4.1, 23 - 29) 70 (2.76)

231 - 40 (3.1 - 4.1, 23 - 29) 80 (3.15)

316 - 21 (1.6 - 2.2, 12 - 15) 25 (0.98)

431 - 40 (3.1 - 4.1, 23 - 29) 30 (1.18)

A31 - 40 (3.1 - 4.1, 23 - 29) 20 (0.79)

B31 - 40 (3.1 - 4.1, 23 - 29) 20 (0.79)

C15 - 20 (1.5 - 2.1, 11 - 15) 17.5 (0.69)

REMOVAL AND INSTALLATIONRS5F30A, RS5F70A

Installation (Cont'd)

MT-25