drain bolt NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 614 of 2898

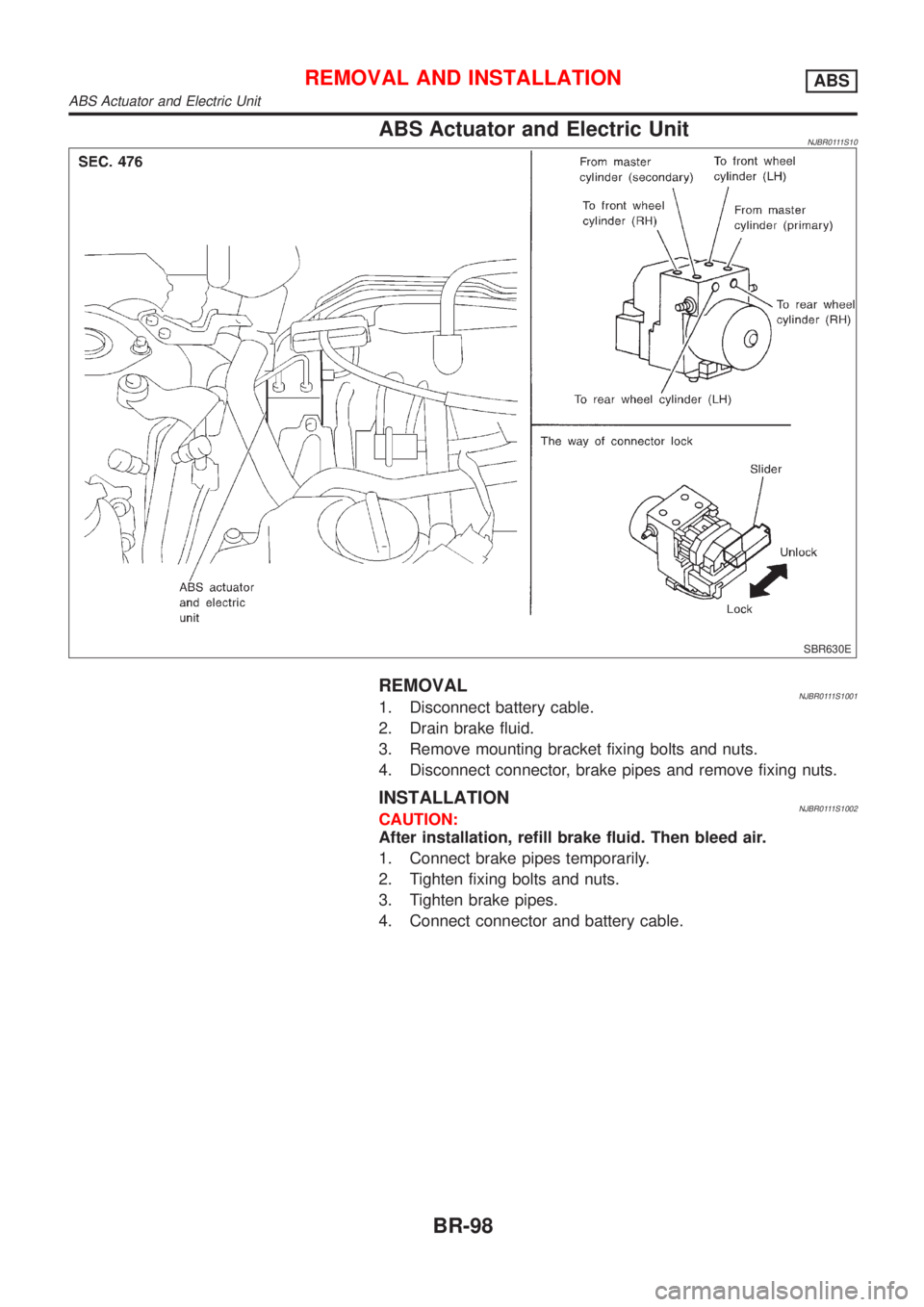

ABS Actuator and Electric UnitNJBR0111S10

SBR630E

REMOVALNJBR0111S10011. Disconnect battery cable.

2. Drain brake fluid.

3. Remove mounting bracket fixing bolts and nuts.

4. Disconnect connector, brake pipes and remove fixing nuts.

INSTALLATIONNJBR0111S1002CAUTION:

After installation, refill brake fluid. Then bleed air.

1. Connect brake pipes temporarily.

2. Tighten fixing bolts and nuts.

3. Tighten brake pipes.

4. Connect connector and battery cable.

REMOVAL AND INSTALLATIONABS

ABS Actuator and Electric Unit

BR-98

Page 714 of 2898

ComponentsNJCL0019

YCL003

RemovalNJCL00201. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

2. Remove union bolt and clutch hose from operating cylinder.

3. Remove operating cylinder mounting bolts, and remove cylin-

der from vehicle.

DisassemblyNJCL0021Remove dust cover, and remove piston assembly from cylinder

body.

InspectionNJCL0022Inspect for following, and replace parts if necessary.

+Damage, foreign material, wear, rust, and pinholes on the cyl-

inder inner surface, piston, and sliding part of piston cup

+Weak spring

+Crack and deformation of dust cover

OPERATING CYLINDER

Components

CL-14

Page 716 of 2898

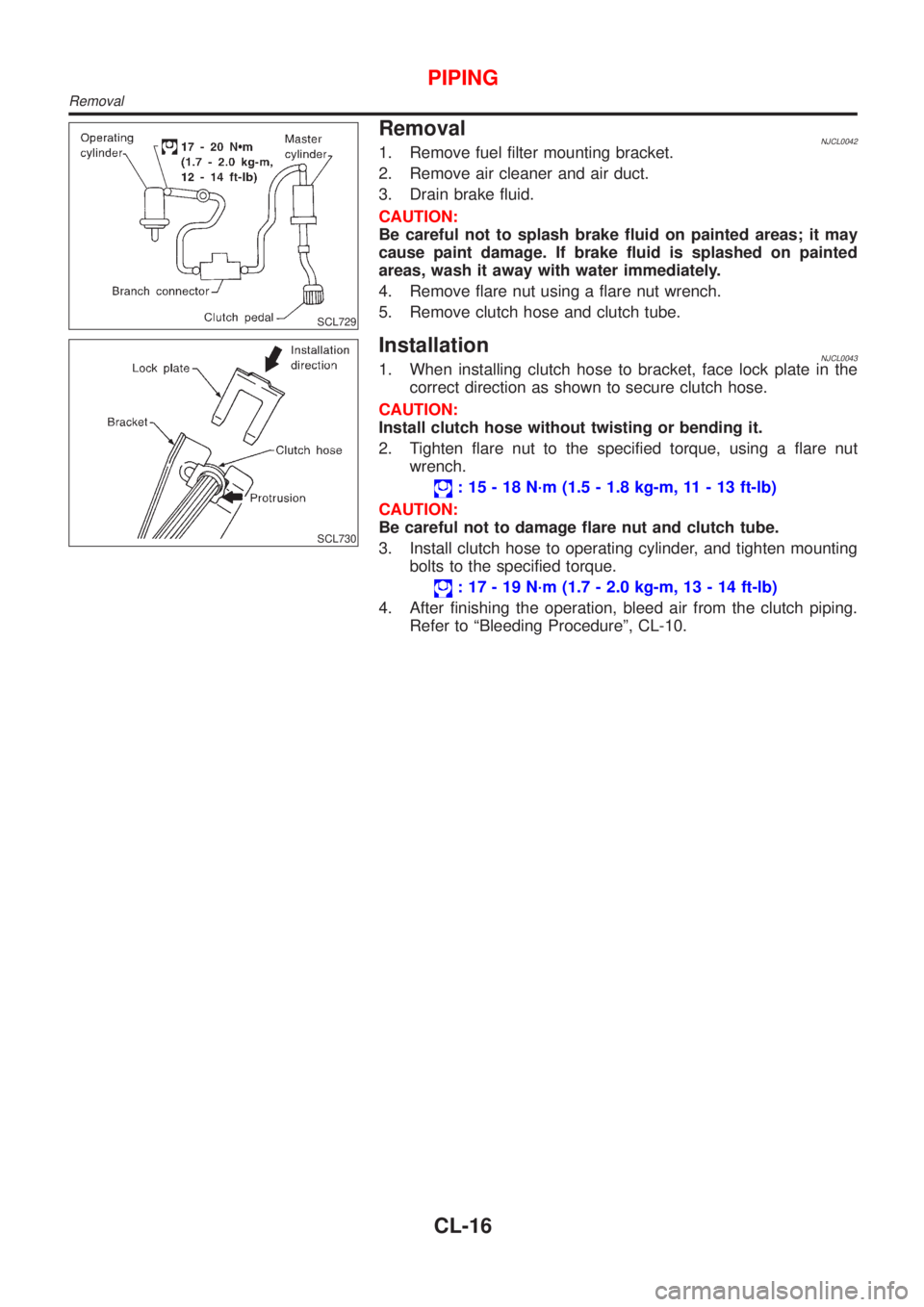

SCL729

RemovalNJCL00421. Remove fuel filter mounting bracket.

2. Remove air cleaner and air duct.

3. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

4. Remove flare nut using a flare nut wrench.

5. Remove clutch hose and clutch tube.

SCL730

InstallationNJCL00431. When installing clutch hose to bracket, face lock plate in the

correct direction as shown to secure clutch hose.

CAUTION:

Install clutch hose without twisting or bending it.

2. Tighten flare nut to the specified torque, using a flare nut

wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

CAUTION:

Be careful not to damage flare nut and clutch tube.

3. Install clutch hose to operating cylinder, and tighten mounting

bolts to the specified torque.

: 17 - 19 N´m (1.7 - 2.0 kg-m, 13 - 14 ft-lb)

4. After finishing the operation, bleed air from the clutch piping.

Refer to ªBleeding Procedureº, CL-10.

PIPING

Removal

CL-16

Page 2158 of 2898

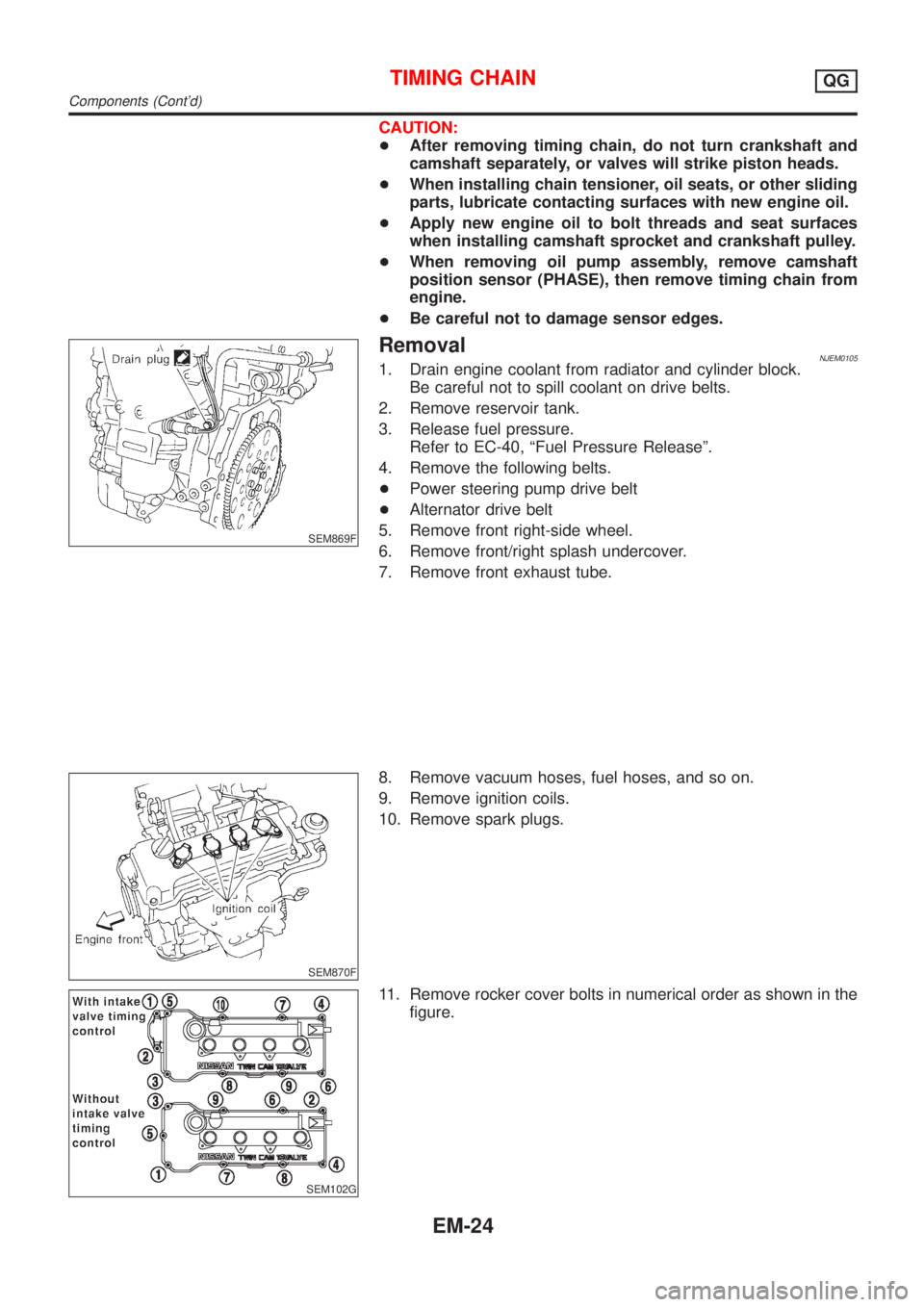

CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing chain tensioner, oil seats, or other sliding

parts, lubricate contacting surfaces with new engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

+When removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

+Be careful not to damage sensor edges.

SEM869F

RemovalNJEM01051. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Remove reservoir tank.

3. Release fuel pressure.

Refer to EC-40, ªFuel Pressure Releaseº.

4. Remove the following belts.

+Power steering pump drive belt

+Alternator drive belt

5. Remove front right-side wheel.

6. Remove front/right splash undercover.

7. Remove front exhaust tube.

SEM870F

8. Remove vacuum hoses, fuel hoses, and so on.

9. Remove ignition coils.

10. Remove spark plugs.

SEM102G

11. Remove rocker cover bolts in numerical order as shown in the

figure.

TIMING CHAINQG

Components (Cont'd)

EM-24

Page 2169 of 2898

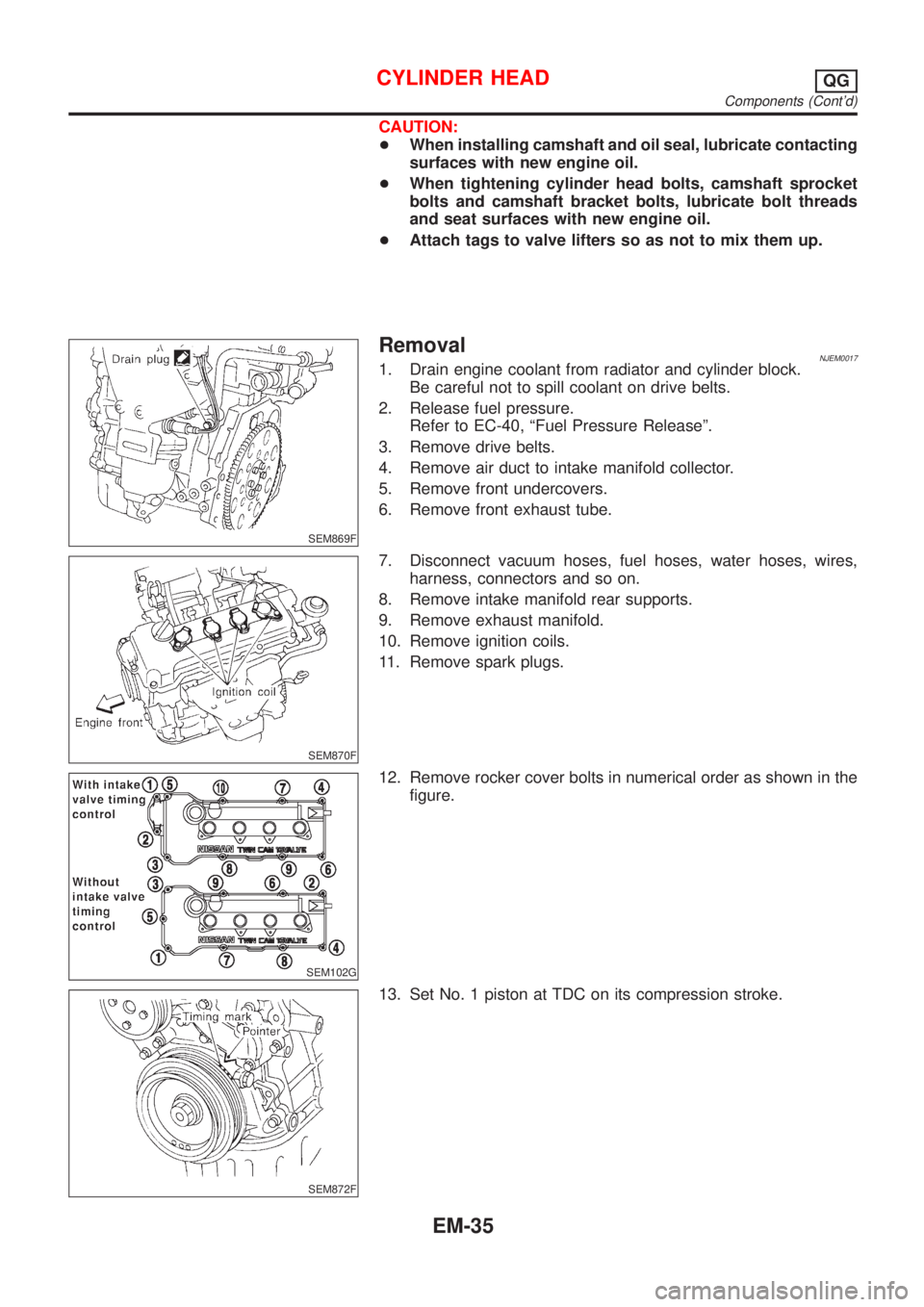

CAUTION:

+When installing camshaft and oil seal, lubricate contacting

surfaces with new engine oil.

+When tightening cylinder head bolts, camshaft sprocket

bolts and camshaft bracket bolts, lubricate bolt threads

and seat surfaces with new engine oil.

+Attach tags to valve lifters so as not to mix them up.

SEM869F

RemovalNJEM00171. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Release fuel pressure.

Refer to EC-40, ªFuel Pressure Releaseº.

3. Remove drive belts.

4. Remove air duct to intake manifold collector.

5. Remove front undercovers.

6. Remove front exhaust tube.

SEM870F

7. Disconnect vacuum hoses, fuel hoses, water hoses, wires,

harness, connectors and so on.

8. Remove intake manifold rear supports.

9. Remove exhaust manifold.

10. Remove ignition coils.

11. Remove spark plugs.

SEM102G

12. Remove rocker cover bolts in numerical order as shown in the

figure.

SEM872F

13. Set No. 1 piston at TDC on its compression stroke.

CYLINDER HEADQG

Components (Cont'd)

EM-35

Page 2186 of 2898

WARNING:

+Position vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

+Before disconnecting fuel hose, release pressure.

Refer to EC-40, ªFuel Pressure Releaseº.

+Be sure to lift engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

+When lifting the engine, always use engine slingers in a

safe manner.

+When removing drive shaft, be careful not to damage

grease seal of transaxle.

+Before separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNJEM0022S011. Drain coolant from radiator and cylinder block. Refer to LC-18,

ªChanging Engine Coolantº.

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from

engine.

8. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-52

Page 2189 of 2898

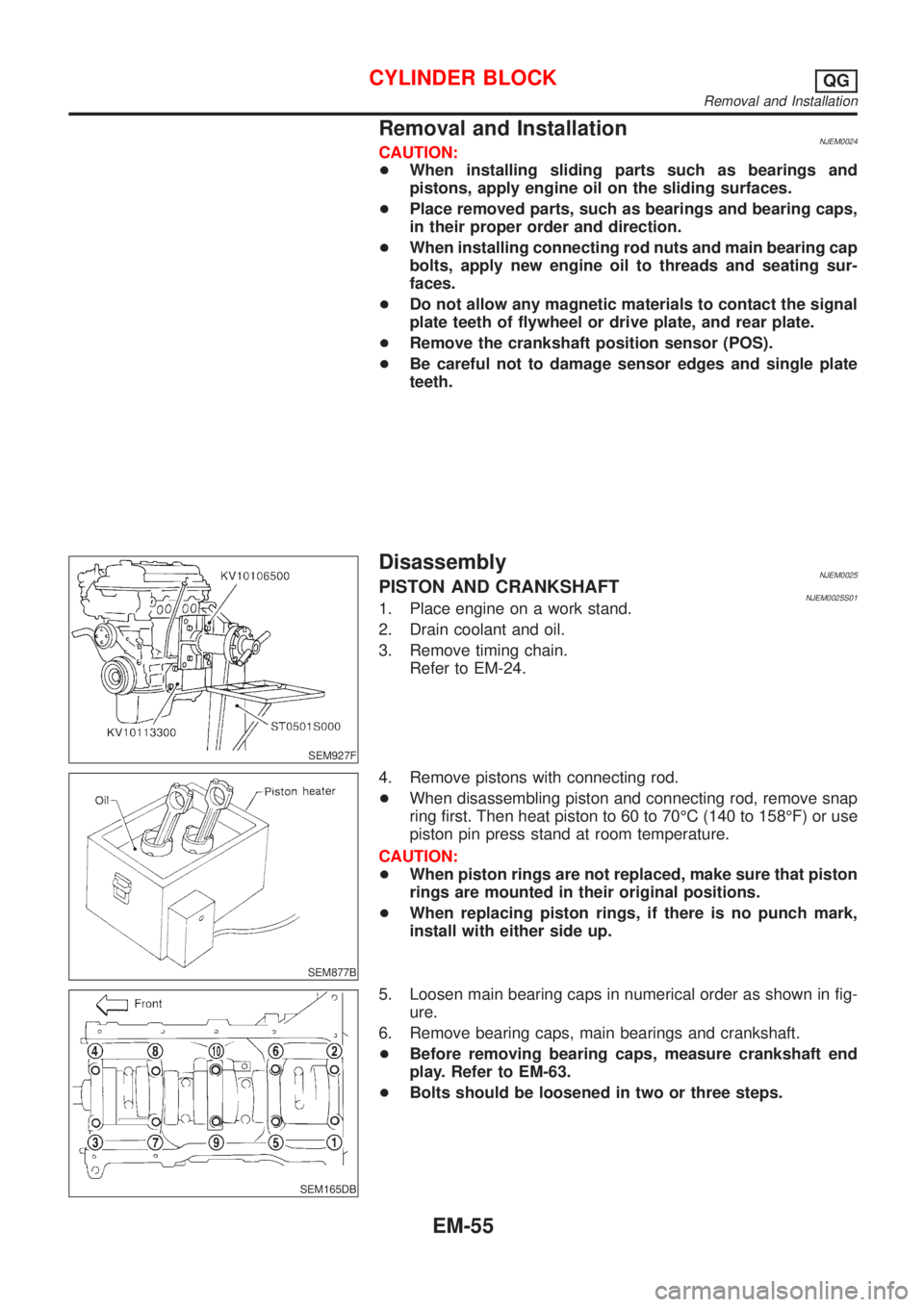

Removal and InstallationNJEM0024CAUTION:

+When installing sliding parts such as bearings and

pistons, apply engine oil on the sliding surfaces.

+Place removed parts, such as bearings and bearing caps,

in their proper order and direction.

+When installing connecting rod nuts and main bearing cap

bolts, apply new engine oil to threads and seating sur-

faces.

+Do not allow any magnetic materials to contact the signal

plate teeth of flywheel or drive plate, and rear plate.

+Remove the crankshaft position sensor (POS).

+Be careful not to damage sensor edges and single plate

teeth.

SEM927F

DisassemblyNJEM0025PISTON AND CRANKSHAFTNJEM0025S011. Place engine on a work stand.

2. Drain coolant and oil.

3. Remove timing chain.

Refer to EM-24.

SEM877B

4. Remove pistons with connecting rod.

+When disassembling piston and connecting rod, remove snap

ring first. Then heat piston to 60 to 70ÉC (140 to 158ÉF) or use

piston pin press stand at room temperature.

CAUTION:

+When piston rings are not replaced, make sure that piston

rings are mounted in their original positions.

+When replacing piston rings, if there is no punch mark,

install with either side up.

SEM165DB

5. Loosen main bearing caps in numerical order as shown in fig-

ure.

6. Remove bearing caps, main bearings and crankshaft.

+Before removing bearing caps, measure crankshaft end

play. Refer to EM-63.

+Bolts should be loosened in two or three steps.

CYLINDER BLOCKQG

Removal and Installation

EM-55

Page 2228 of 2898

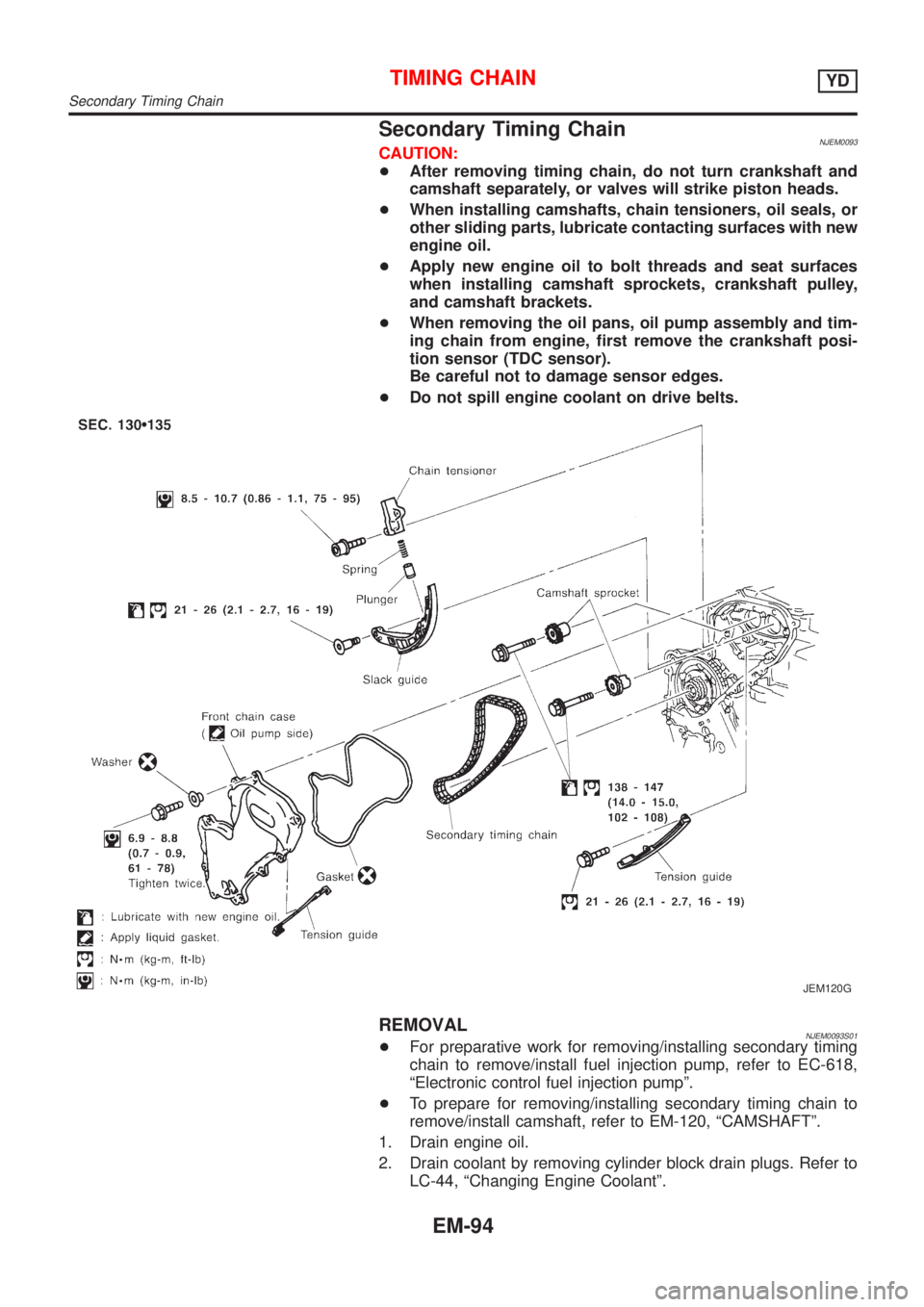

Secondary Timing ChainNJEM0093CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets, crankshaft pulley,

and camshaft brackets.

+When removing the oil pans, oil pump assembly and tim-

ing chain from engine, first remove the crankshaft posi-

tion sensor (TDC sensor).

Be careful not to damage sensor edges.

+Do not spill engine coolant on drive belts.

JEM120G

REMOVALNJEM0093S01+For preparative work for removing/installing secondary timing

chain to remove/install fuel injection pump, refer to EC-618,

ªElectronic control fuel injection pumpº.

+To prepare for removing/installing secondary timing chain to

remove/install camshaft, refer to EM-120, ªCAMSHAFTº.

1. Drain engine oil.

2. Drain coolant by removing cylinder block drain plugs. Refer to

LC-44, ªChanging Engine Coolantº.

TIMING CHAINYD

Secondary Timing Chain

EM-94

Page 2244 of 2898

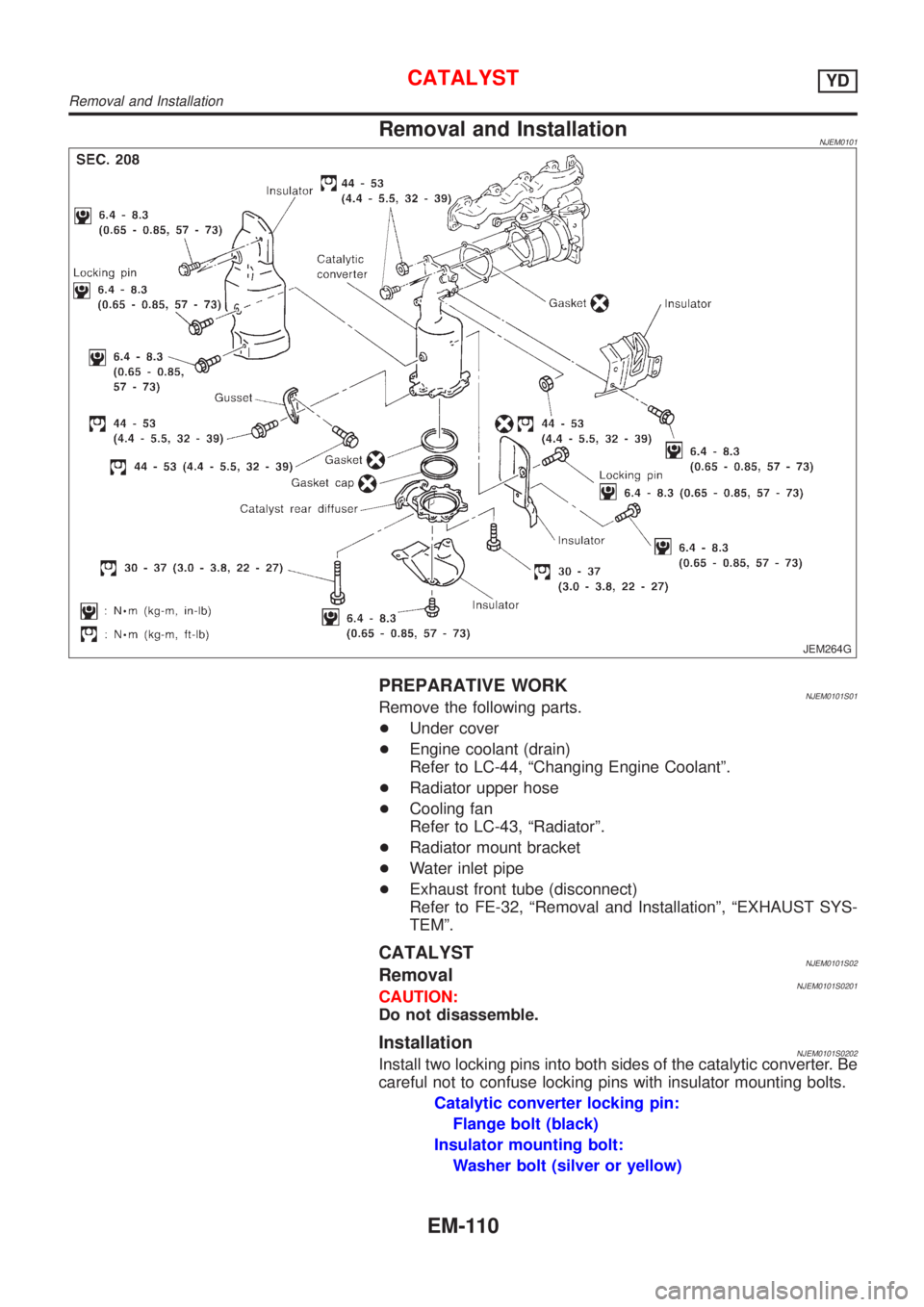

Removal and InstallationNJEM0101

JEM264G

PREPARATIVE WORKNJEM0101S01Remove the following parts.

+Under cover

+Engine coolant (drain)

Refer to LC-44, ªChanging Engine Coolantº.

+Radiator upper hose

+Cooling fan

Refer to LC-43, ªRadiatorº.

+Radiator mount bracket

+Water inlet pipe

+Exhaust front tube (disconnect)

Refer to FE-32, ªRemoval and Installationº, ªEXHAUST SYS-

TEMº.

CATALYSTNJEM0101S02RemovalNJEM0101S0201CAUTION:

Do not disassemble.

InstallationNJEM0101S0202Install two locking pins into both sides of the catalytic converter. Be

careful not to confuse locking pins with insulator mounting bolts.

Catalytic converter locking pin:

Flange bolt (black)

Insulator mounting bolt:

Washer bolt (silver or yellow)

CATALYSTYD

Removal and Installation

EM-110

Page 2246 of 2898

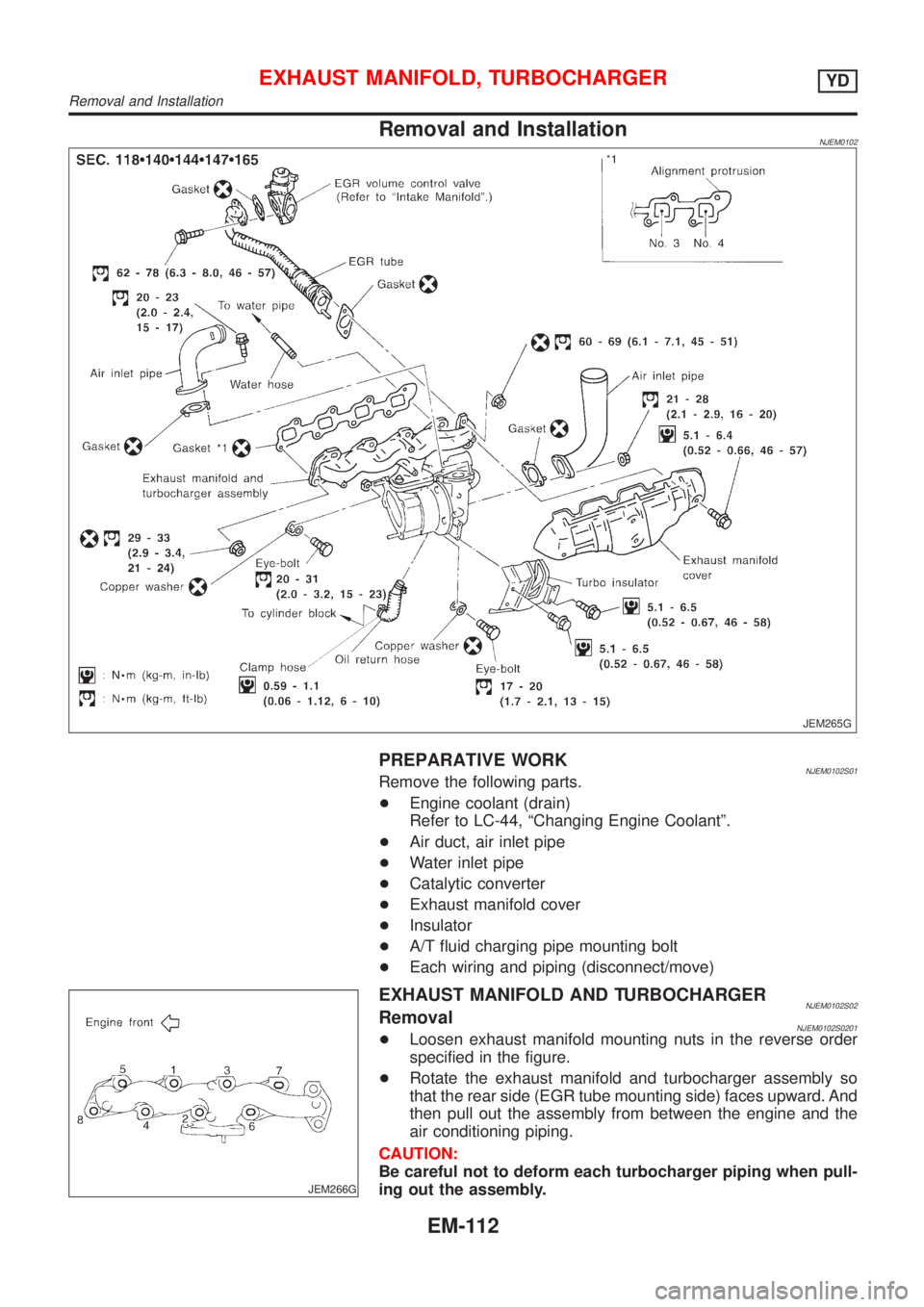

Removal and InstallationNJEM0102

JEM265G

PREPARATIVE WORKNJEM0102S01Remove the following parts.

+Engine coolant (drain)

Refer to LC-44, ªChanging Engine Coolantº.

+Air duct, air inlet pipe

+Water inlet pipe

+Catalytic converter

+Exhaust manifold cover

+Insulator

+A/T fluid charging pipe mounting bolt

+Each wiring and piping (disconnect/move)

JEM266G

EXHAUST MANIFOLD AND TURBOCHARGERNJEM0102S02RemovalNJEM0102S0201+Loosen exhaust manifold mounting nuts in the reverse order

specified in the figure.

+Rotate the exhaust manifold and turbocharger assembly so

that the rear side (EGR tube mounting side) faces upward. And

then pull out the assembly from between the engine and the

air conditioning piping.

CAUTION:

Be careful not to deform each turbocharger piping when pull-

ing out the assembly.

EXHAUST MANIFOLD, TURBOCHARGERYD

Removal and Installation

EM-112