oil temperature NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 37 of 2898

Pilot pressure generated by the operation of shift solenoid valves

A and B is applied to the end face of shift valves A and B.

The drawing above shows the operation of shift valve B. When the

shift solenoid valve is ªONº, pilot pressure applied to the end face

of the shift valve overcomes spring force, moving the valve upward.

LOCK-UP CONTROLNJAT0015S03The torque converter clutch piston in the torque converter is locked

to eliminate torque converter slip to increase power transmission

efficiency. The solenoid valve is controlled by an ON-OFF duty

signal sent from the TCM. The signal is converted to an oil pres-

sure signal which controls the torque converter clutch piston.

Conditions for Lock-up OperationNJAT0015S0301When vehicle is driven in 4th gear position, vehicle speed and

throttle opening are detected. If the detected values fall within the

lock-up zone memorized in the TCM, lock-up is performed.

Overdrive control switch ON OFF

Selector lever ªDº position

Gear position D

4D3

Vehicle speed sensor More than set value

Throttle position sensor Less than set opening

Closed throttle position switch OFF

A/T fluid temperature sensor More than 40ÉC (104ÉF)

SAT010J

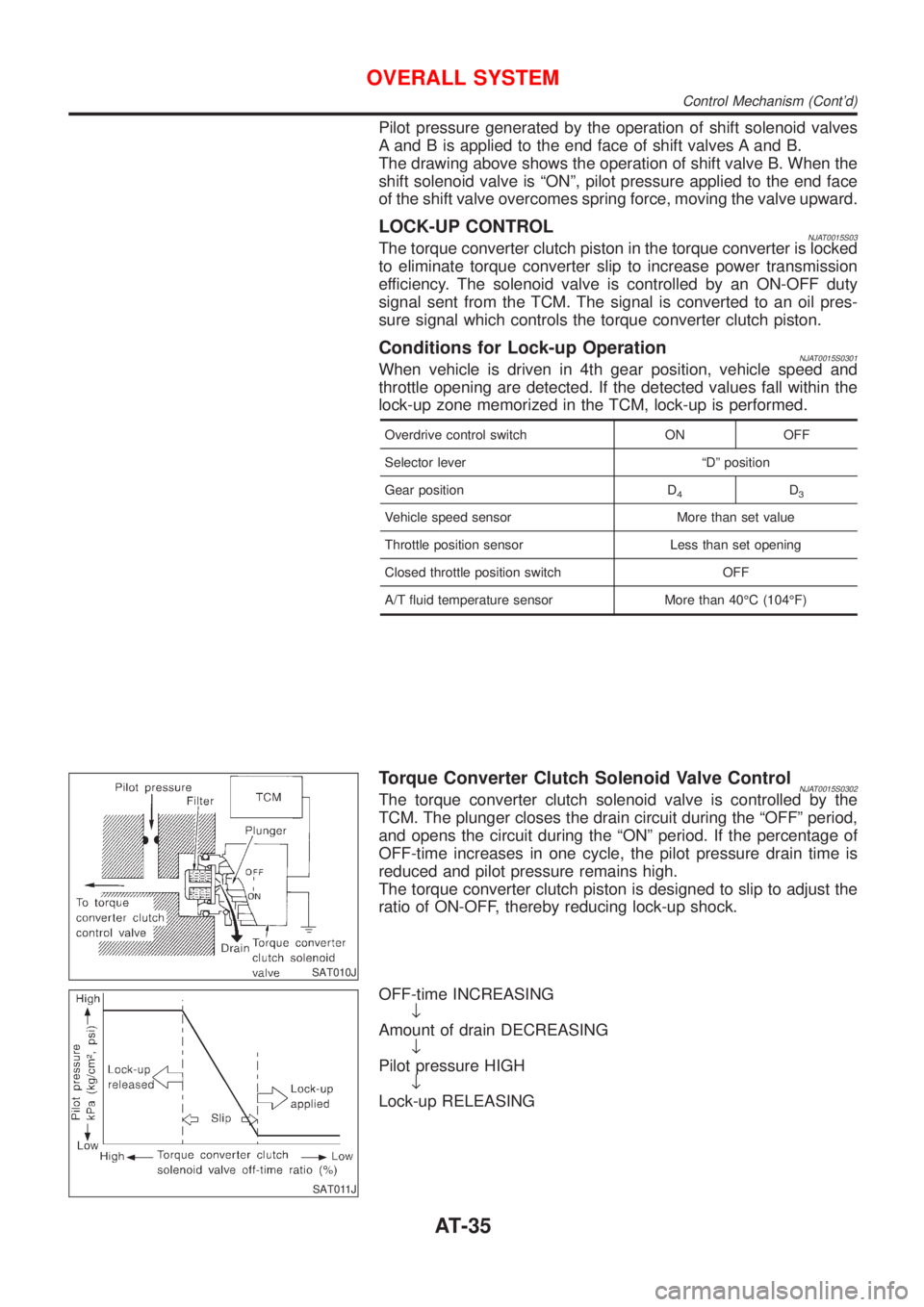

Torque Converter Clutch Solenoid Valve ControlNJAT0015S0302The torque converter clutch solenoid valve is controlled by the

TCM. The plunger closes the drain circuit during the ªOFFº period,

and opens the circuit during the ªONº period. If the percentage of

OFF-time increases in one cycle, the pilot pressure drain time is

reduced and pilot pressure remains high.

The torque converter clutch piston is designed to slip to adjust the

ratio of ON-OFF, thereby reducing lock-up shock.

SAT011J

OFF-time INCREASING

¯

Amount of drain DECREASING

¯

Pilot pressure HIGH

¯

Lock-up RELEASING

OVERALL SYSTEM

Control Mechanism (Cont'd)

AT-35

Page 82 of 2898

SAT767B

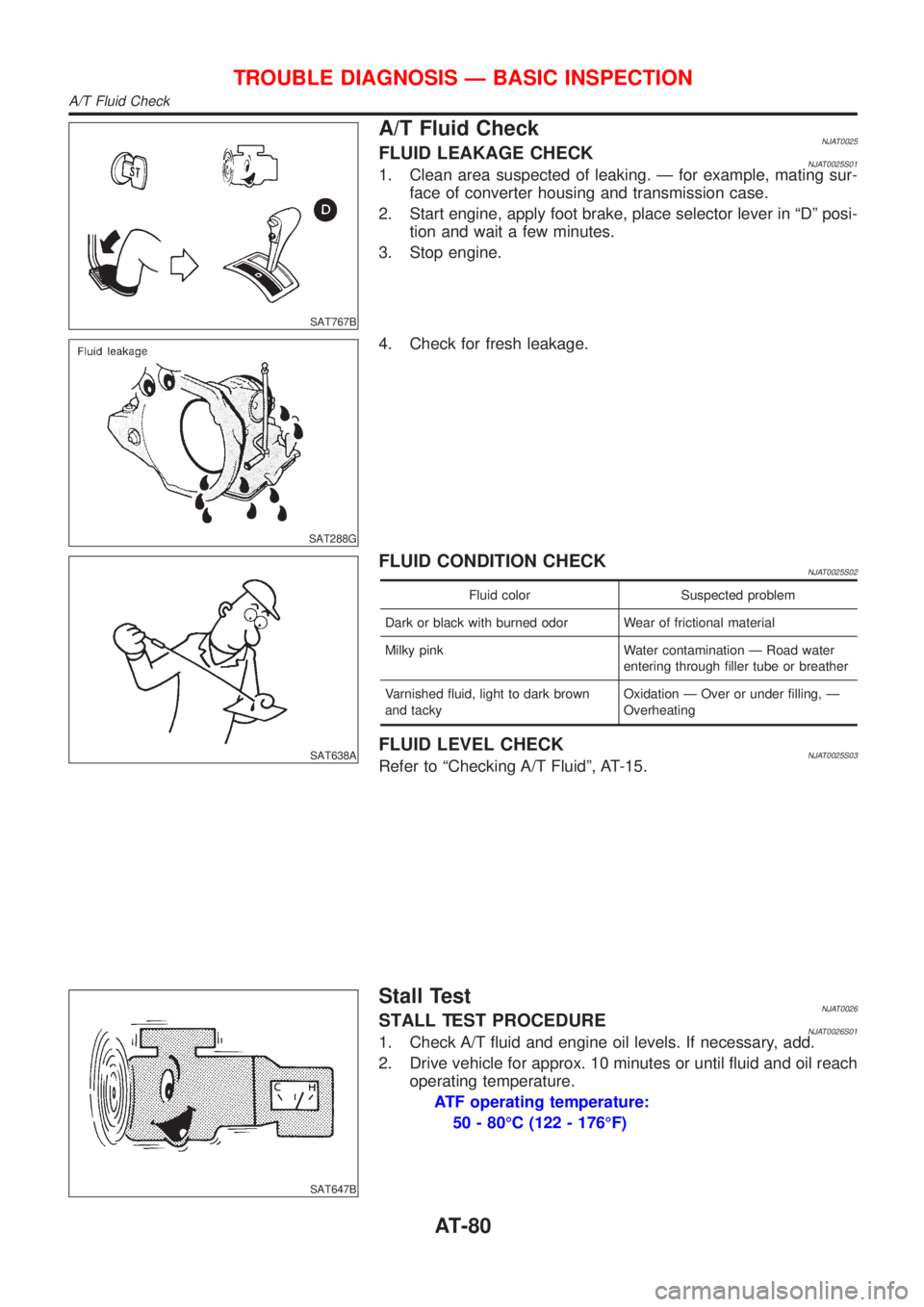

A/T Fluid CheckNJAT0025FLUID LEAKAGE CHECKNJAT0025S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

SAT288G

4. Check for fresh leakage.

SAT638A

FLUID CONDITION CHECKNJAT0025S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNJAT0025S03Refer to ªChecking A/T Fluidº, AT-15.

SAT647B

Stall TestNJAT0026STALL TEST PROCEDURENJAT0026S011. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

A/T Fluid Check

AT-80

Page 86 of 2898

SAT561J

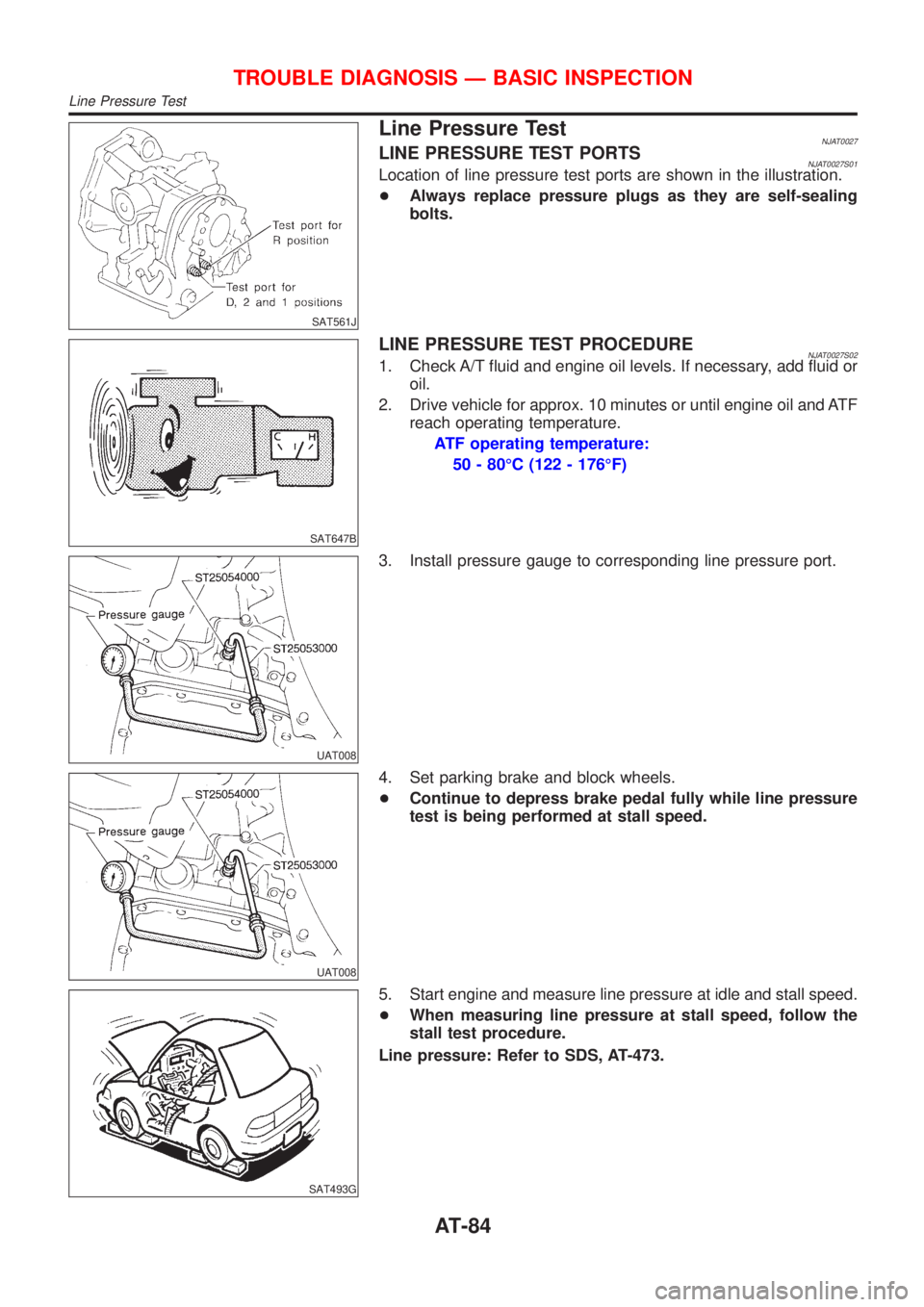

Line Pressure TestNJAT0027LINE PRESSURE TEST PORTSNJAT0027S01Location of line pressure test ports are shown in the illustration.

+Always replace pressure plugs as they are self-sealing

bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENJAT0027S021. Check A/T fluid and engine oil levels. If necessary, add fluid or

oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

UAT008

3. Install pressure gauge to corresponding line pressure port.

UAT008

4. Set parking brake and block wheels.

+Continue to depress brake pedal fully while line pressure

test is being performed at stall speed.

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

+When measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer to SDS, AT-473.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test

AT-84

Page 87 of 2898

JUDGEMENT OF LINE PRESSURE TESTNJAT0027S03

Judgement Suspected parts

At idleLine pressure is low in all positions.+Oil pump wear

+Control piston damage

+Pressure regulator valve or plug sticking

+Spring for pressure regulator valve damaged

+Fluid pressure leakage between oil strainer and pressure regulator valve

+Clogged strainer

Line pressure is low in particular

position.+Fluid pressure leakage between manual valve and particular clutch

+For example, line pressure is:

þ Low in ªRº and ª1º positions, but

þ Normal in ªDº and ª2º positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-23.

Line pressure is high.+Maladjustment of throttle position sensor

+A/T fluid temperature sensor damaged

+Line pressure solenoid valve sticking

+Short circuit of line pressure solenoid valve circuit

+Pressure modifier valve sticking

+Pressure regulator valve or plug sticking

+Open in dropping resistor circuit

At stall

speedLine pressure is low.+Maladjustment of throttle position sensor

+Line pressure solenoid valve sticking

+Short circuit of line pressure solenoid valve circuit

+Pressure regulator valve or plug sticking

+Pressure modifier valve sticking

+Pilot valve sticking

SAT786A

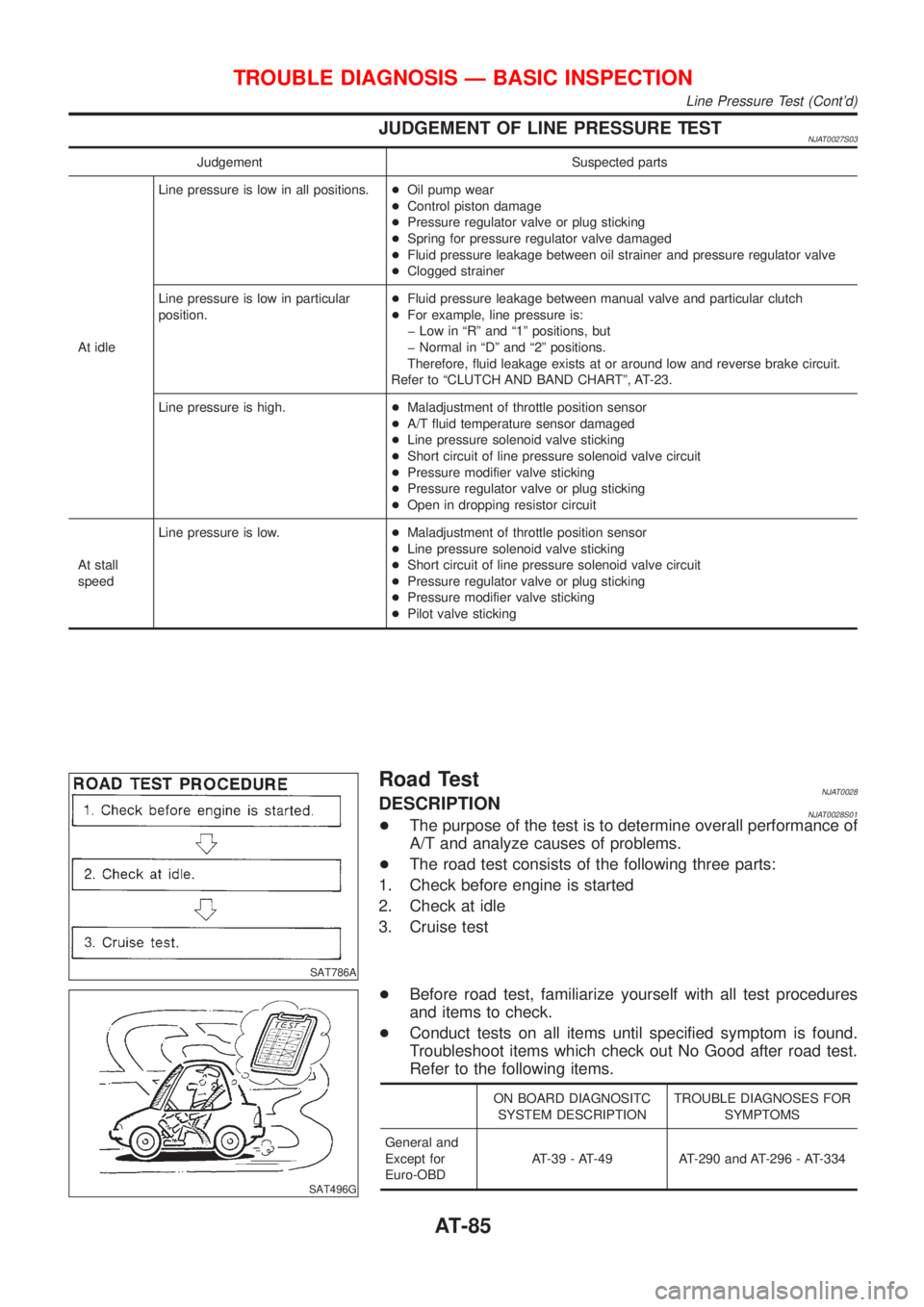

Road TestNJAT0028DESCRIPTIONNJAT0028S01+The purpose of the test is to determine overall performance of

A/T and analyze causes of problems.

+The road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

SAT496G

+Before road test, familiarize yourself with all test procedures

and items to check.

+Conduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to the following items.

ON BOARD DIAGNOSITC

SYSTEM DESCRIPTIONTROUBLE DIAGNOSES FOR

SYMPTOMS

General and

Except for

Euro-OBDAT-39 - AT-49 AT-290 and AT-296 - AT-334

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-85

Page 97 of 2898

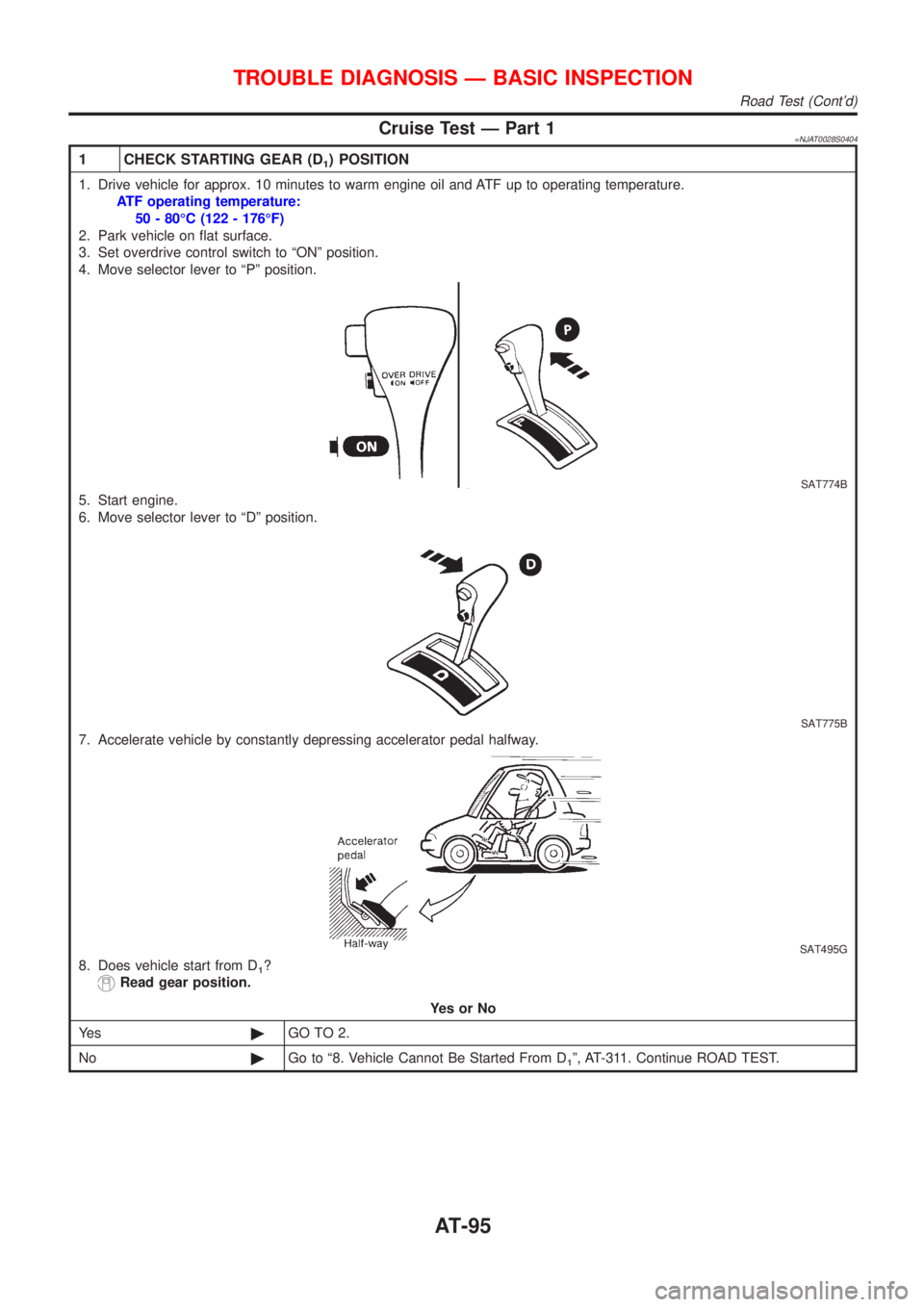

Cruise Test Ð Part 1=NJAT0028S0404

1 CHECK STARTING GEAR (D1) POSITION

1. Drive vehicle for approx. 10 minutes to warm engine oil and ATF up to operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

2. Park vehicle on flat surface.

3. Set overdrive control switch to ªONº position.

4. Move selector lever to ªPº position.

SAT774B

5. Start engine.

6. Move selector lever to ªDº position.

SAT775B

7. Accelerate vehicle by constantly depressing accelerator pedal halfway.

SAT495G

8. Does vehicle start from D1?

Read gear position.

YesorNo

Ye s©GO TO 2.

No©Go to ª8. Vehicle Cannot Be Started From D

1º, AT-311. Continue ROAD TEST.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-95

Page 116 of 2898

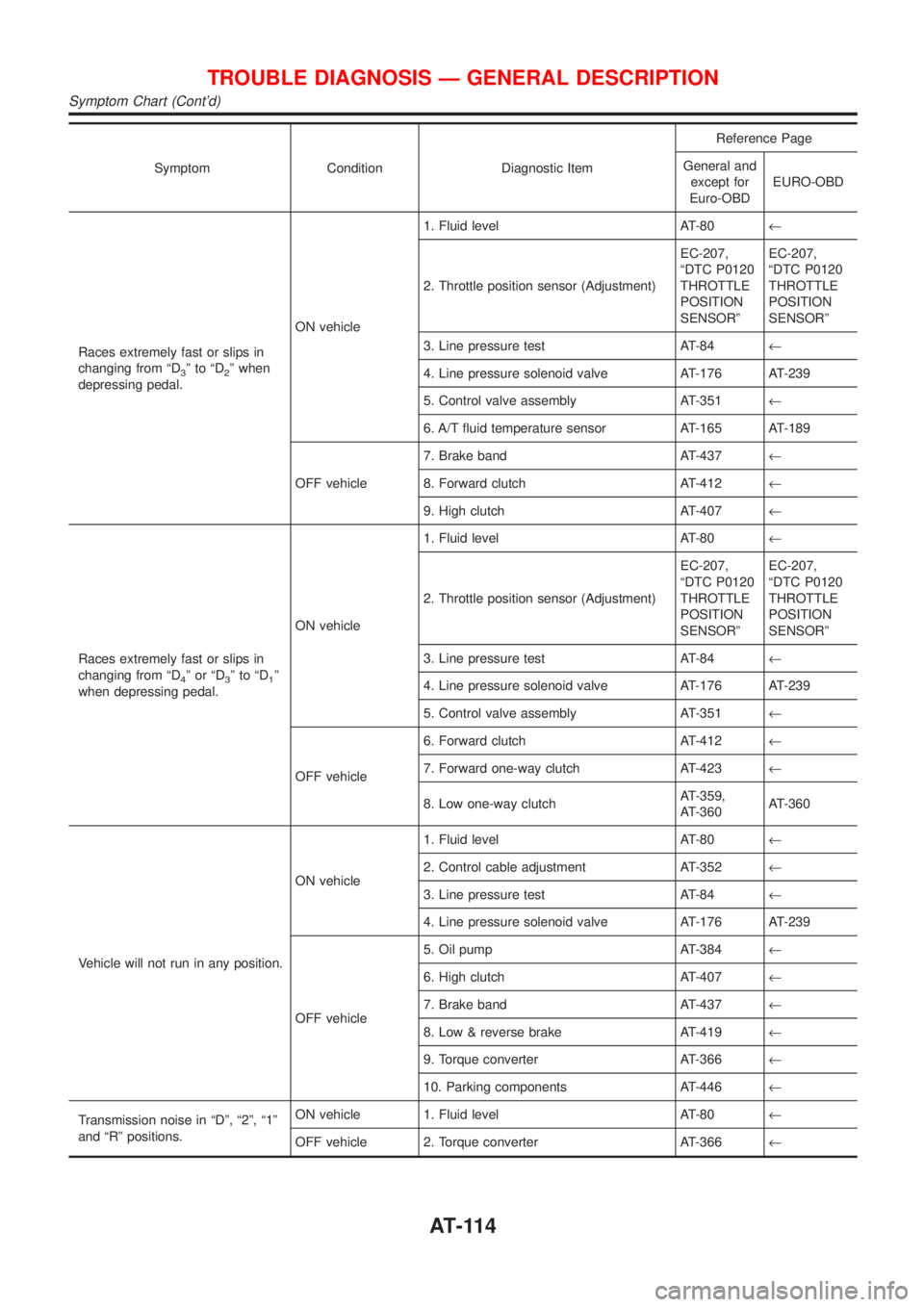

Symptom Condition Diagnostic ItemReference Page

General and

except for

Euro-OBDEURO-OBD

Races extremely fast or slips in

changing from ªD

3ºtoªD2º when

depressing pedal.ON vehicle1. Fluid level AT-80¬

2. Throttle position sensor (Adjustment)EC-207,

ªDTC P0120

THROTTLE

POSITION

SENSORºEC-207,

ªDTC P0120

THROTTLE

POSITION

SENSORº

3. Line pressure test AT-84¬

4. Line pressure solenoid valve AT-176 AT-239

5. Control valve assembly AT-351¬

6. A/T fluid temperature sensor AT-165 AT-189

OFF vehicle7. Brake band AT-437¬

8. Forward clutch AT-412¬

9. High clutch AT-407¬

Races extremely fast or slips in

changing from ªD

4ºorªD3ºtoªD1º

when depressing pedal.ON vehicle1. Fluid level AT-80¬

2. Throttle position sensor (Adjustment)EC-207,

ªDTC P0120

THROTTLE

POSITION

SENSORºEC-207,

ªDTC P0120

THROTTLE

POSITION

SENSORº

3. Line pressure test AT-84¬

4. Line pressure solenoid valve AT-176 AT-239

5. Control valve assembly AT-351¬

OFF vehicle6. Forward clutch AT-412¬

7. Forward one-way clutch AT-423¬

8. Low one-way clutchAT-359,

AT-360AT-360

Vehicle will not run in any position.ON vehicle1. Fluid level AT-80¬

2. Control cable adjustment AT-352¬

3. Line pressure test AT-84¬

4. Line pressure solenoid valve AT-176 AT-239

OFF vehicle5. Oil pump AT-384¬

6. High clutch AT-407¬

7. Brake band AT-437¬

8. Low & reverse brake AT-419¬

9. Torque converter AT-366¬

10. Parking components AT-446¬

Transmission noise in ªDº, ª2º, ª1º

and ªRº positions.ON vehicle 1. Fluid level AT-80¬

OFF vehicle 2. Torque converter AT-366¬

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Symptom Chart (Cont'd)

AT-114

Page 171 of 2898

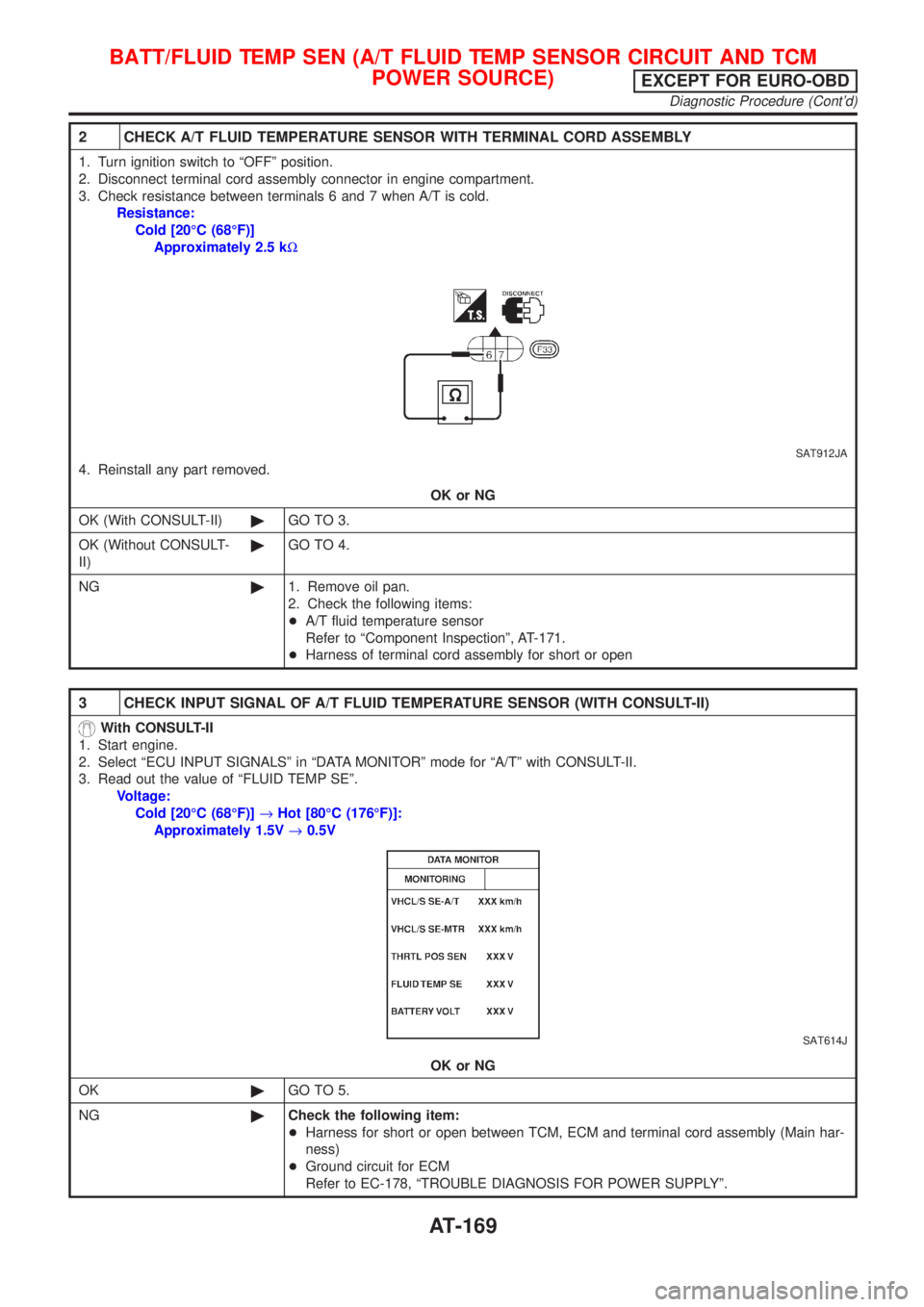

2 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT912JA

4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 3.

OK (Without CONSULT-

II)©GO TO 4.

NG©1. Remove oil pan.

2. Check the following items:

+A/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-171.

+Harness of terminal cord assembly for short or open

3 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT614J

OK or NG

OK©GO TO 5.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC-178, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-169

Page 196 of 2898

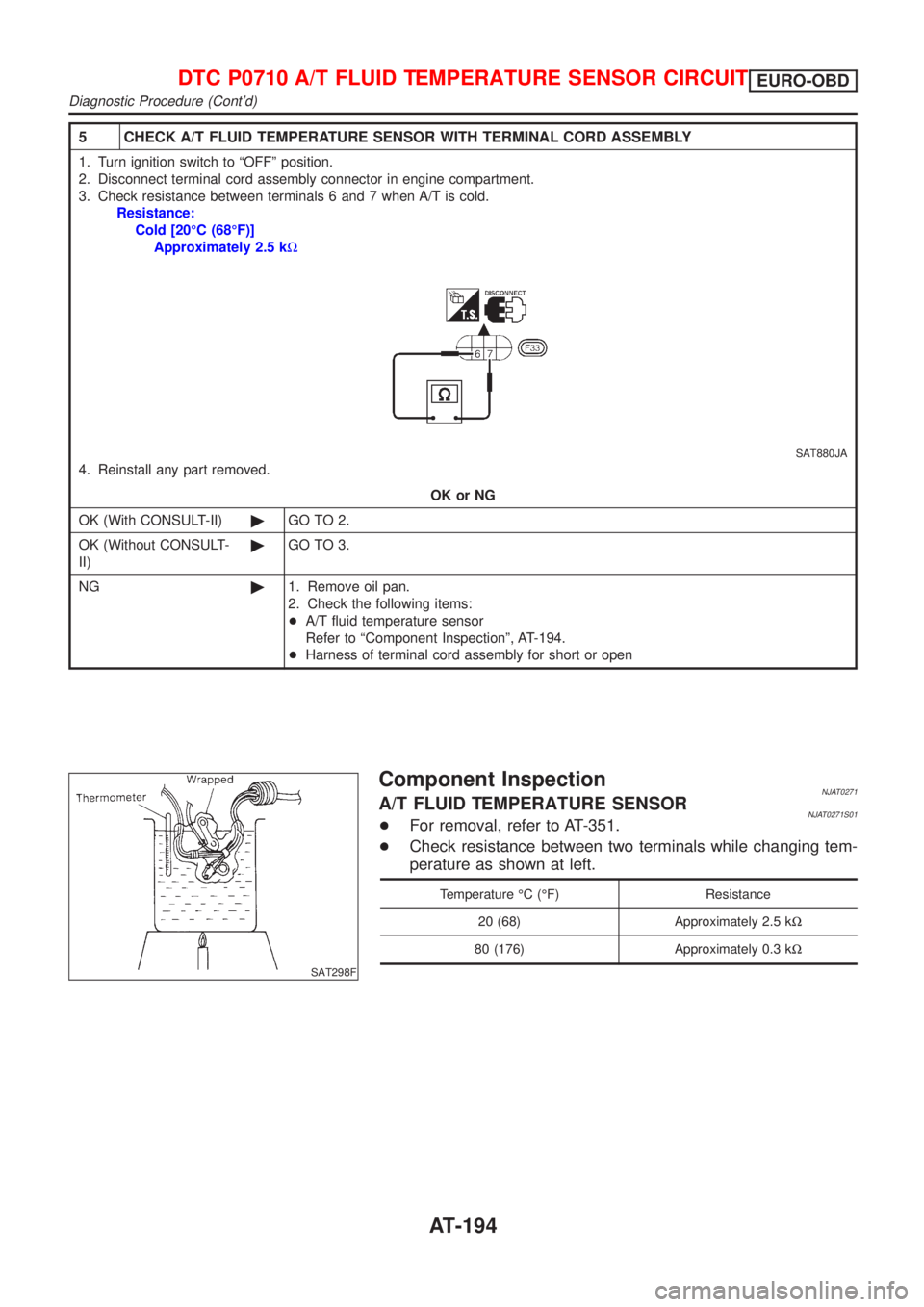

5 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT880JA

4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©1. Remove oil pan.

2. Check the following items:

+A/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-194.

+Harness of terminal cord assembly for short or open

SAT298F

Component InspectionNJAT0271A/T FLUID TEMPERATURE SENSORNJAT0271S01+For removal, refer to AT-351.

+Check resistance between two terminals while changing tem-

perature as shown at left.

Temperature ÉC (ÉF) Resistance

20 (68) Approximately 2.5 kW

80 (176) Approximately 0.3 kW

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUITEURO-OBD

Diagnostic Procedure (Cont'd)

AT-194

Page 280 of 2898

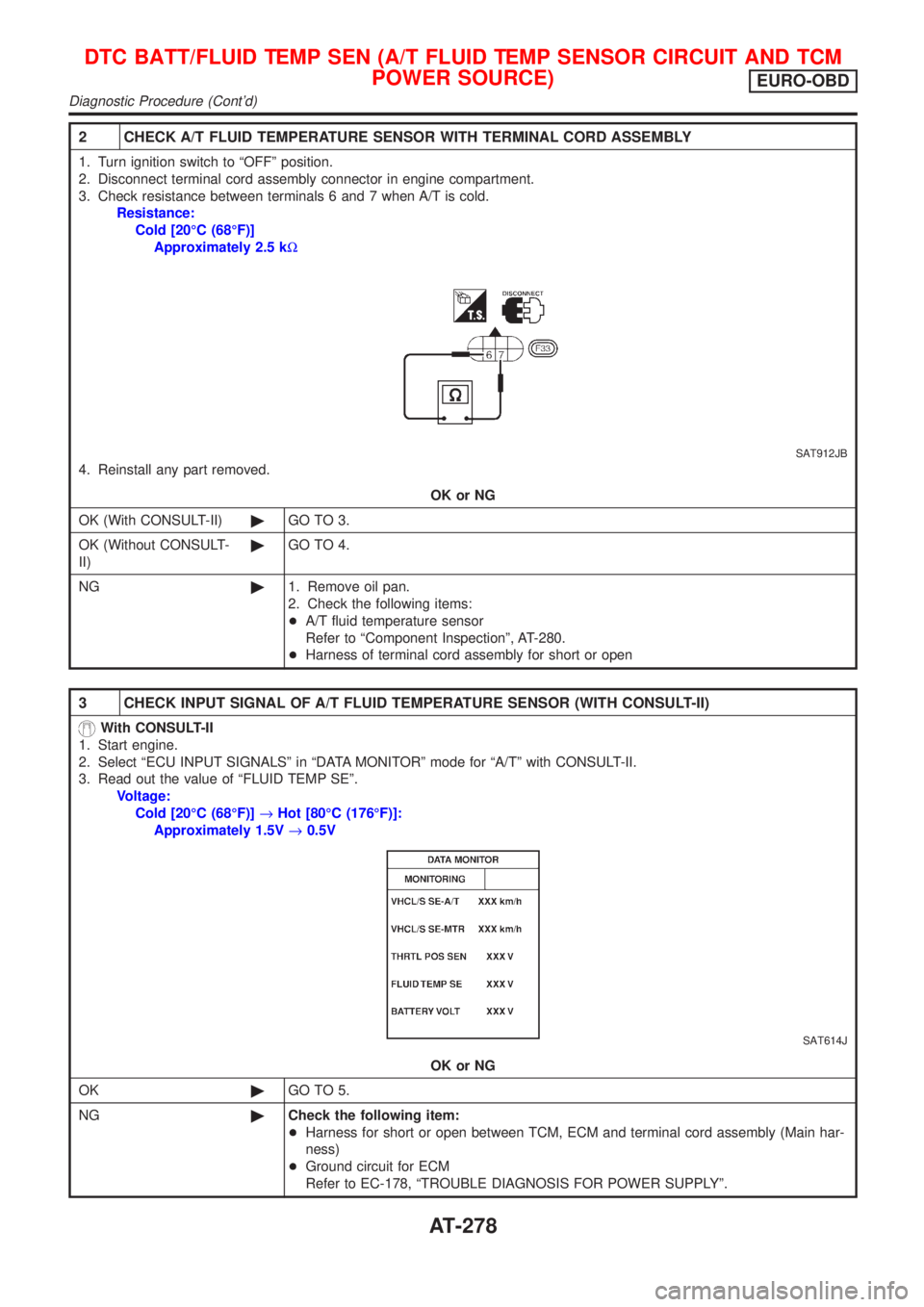

2 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT912JB

4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 3.

OK (Without CONSULT-

II)©GO TO 4.

NG©1. Remove oil pan.

2. Check the following items:

+A/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-280.

+Harness of terminal cord assembly for short or open

3 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT614J

OK or NG

OK©GO TO 5.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC-178, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EURO-OBD

Diagnostic Procedure (Cont'd)

AT-278

Page 731 of 2898

ECM Terminals and Reference Value .....................578

Wiring Diagram ........................................................579

Diagnostic Procedure - Load Signal - .....................583

Diagnostic Procedure - Heater Control Panel

(Fan Switch) - ..........................................................589

Component Inspection .............................................590

MI & DATA LINK CONNECTORS..............................591

Wiring Diagram ........................................................591

SERVICE DATA AND SPECIFICATIONS (SDS).......593

Fuel Pressure Regulator..........................................593

Idle Speed and Ignition Timing ................................593

Mass Air Flow Sensor..............................................593

Intake Air Temperature Sensor ................................593

Engine Coolant Temperature Sensor ......................593

Throttle Position Sensor ..........................................593

Heated Oxygen Sensor 1 Heater (Front) ................593

Heated Oxygen Sensor 2 Heater (Rear).................593

Fuel Tank Temperature Sensor (Where Fitted) .......594

EGR Volume Control Valve (Where Fitted) .............594

EGR Temperature Sensor (Where Fitted) ...............594

EVAP Canister Purge Volume Control Valve ..........594

IACV-AAC Valve ......................................................594

Injector .....................................................................594

Ignition Coil with Power Transistor ..........................594

Condenser ...............................................................594

Fuel Pump ...............................................................594

Crankshaft Position Sensor (POS) ..........................595

Camshaft Position Sensor (PHASE) .......................595

YD

TROUBLE DIAGNOSIS - INDEX................................596

Alphabetical & P No. Index for DTC .......................596

PRECAUTIONS...........................................................598

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...........598

Engine Fuel & Emission Control System ................599

Precautions ..............................................................600

Wiring Diagrams and Trouble Diagnosis .................601

PREPARATION...........................................................602

Special Service Tools ..............................................602

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.......................................................................603

Engine Control Component Parts Location .............603

Circuit Diagram ........................................................606

System Diagram ......................................................608

System Chart ...........................................................609

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION.............................................610

Fuel Injection Control System .................................610

Fuel Injection Timing Control System...................... 611

Air Conditioning Cut Control ....................................612Fuel Cut Control (at no load & high engine

speed) ......................................................................612

Crankcase Ventilation System .................................613

BASIC SERVICE PROCEDURE.................................614

Injection Tube and Injection Nozzle ........................614

Electronic Control Fuel Injection Pump ...................618

Fuel Filter .................................................................625

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION.............................................................627

DTC and MI Detection Logic ...................................627

Diagnostic Trouble Code (DTC) ..............................627

Malfunction Indicator (MI) ........................................628

CONSULT-II .............................................................632

TROUBLE DIAGNOSIS - INTRODUCTION................637

Introduction ..............................................................637

Work Flow ................................................................639

TROUBLE DIAGNOSIS - BASIC INSPECTION.........641

Basic Inspection.......................................................641

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................646

Symptom Matrix Chart .............................................646

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................656

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................658

ECM Terminals and Reference Value .....................659

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................665

Description ...............................................................665

Diagnostic Procedure ..............................................665

TROUBLE DIAGNOSIS FOR POWER SUPPLY........666

Main Power Supply and Ground Circuit ..................666

DTC P0100 MASS AIR FLOW SEN...........................673

Component Description ...........................................673

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................673

ECM Terminals and Reference Value .....................673

On Board Diagnosis Logic.......................................673

DTC Confirmation Procedure ..................................673

Wiring Diagram ........................................................675

Diagnostic Procedure ..............................................677

DTC P0115 COOLANT TEMP SEN............................680

Description ...............................................................680

On Board Diagnosis Logic.......................................680

DTC Confirmation Procedure ..................................680

Wiring Diagram ........................................................682

Diagnostic Procedure ..............................................683

DTC P0120 ACCEL POS SENSOR............................685

Description ...............................................................685

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................685

ECM Terminals and Reference Value .....................685

CONTENTS(Cont'd)

EC-7